Page 1

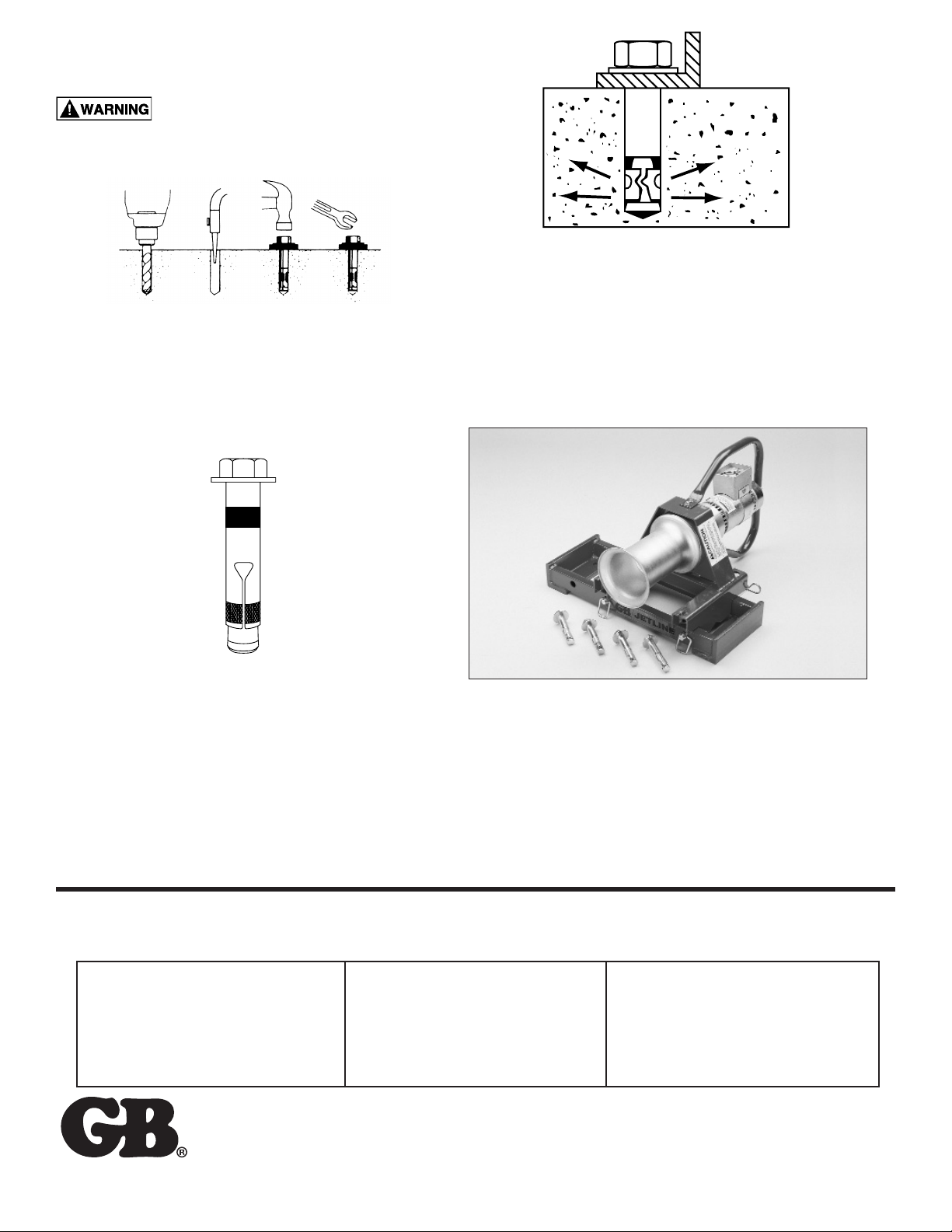

Prior to installing the CP80 Floor Mount, be sure to

establish what concrete pad specifications are required.

Contact a qualified structural or civil engineer. Concrete

mounting pad must be a minimum of 3,000 psi rated.

Concrete wedge anchors are provided with the CP80

Floor Mount. To avoid injury, follow the anchor

manufacturers instructions. The four (4) wedge-style

anchors are

3

⁄4” x 6”.

Do not exceed the Puller maximum pulling capacity of

8,000 lbs. Watch the Puller force gauge to be constantly

aware of the level of force being generated during the

cable pull process.

During pulling operations, no one is permitted to stand

directly in line of pulling rope which is under tension.

Floor Mount Installation

Drilling Holes

1. Position the CP80 Floor Mount in the location desired.

Be sure the narrow end of the frame is facing toward

the conduit. See figure 2.

2. Once the frame is in position, use the four mounting

holes as a template to mark the location for

drilling holes.

3. Anchor bolts are wedge-style (

3

⁄4” x 6”). Drill 4 holes.

a. Drill four holes perpendicular to the work surface

using a bit with a diameter equal to the anchor

diameter. Drill the hole to a depth exceeding

minimum embedment, but not closer than two

anchor diameters to the bottom or opposite concrete

surface. Through drilling may be allowed when using

sleeve anchors in hollow concrete block. TO

ENSURE FULL HOLDING POWER, DO NOT

REAM THE HOLE OR ALLOW THE DRILL TO

WOBBLE. See figure 3(a).

IMPORTANT: RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage. If any shipping

damage is found, notify carrier at once. Shipping damage is NOT covered by warranty. The carrier is responsible for

all repair or replacement costs resulting from damage in shipment.

Gardner

Bender

Instruction

Sheet

CP80

Floor Mount

Assembly

IMPORTANT USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to

select the proper components and design to insure appropriate integration with your operations and existing

equipment and that all safety measures have been taken to avoid the risk of personal injury and property damage

from your application or system.

GB ELECTRICAL, INC. CANNOT BE HELD RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE

USE, MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact GB's technical service department

for assistance if you are in doubt as to the proper safety precautions essential to designing and setting up your

particular application.

JETLINE

Figure 1

Figure 2

Toward

Conduit

Page 2

WARRANTY: GB ELECTRICAL, INC. warrants its

products against defects in workmanship and

materials for 1 year from date of delivery to user.

Chain is not warranted. Warranty does not cover

ordinary wear and tear, abuse, misuse, overloading,

altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest

GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact GB Electrical

(414) 352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL

Service Center.The Service Center will provide complete and prompt service on all GB ELECTRICAL products.

GB Electrical, Inc.

An Applied Power Company

6101 N. Baker Road, Milwaukee, WI 53209

Phone: (414) 352-4160 FAX (414) 352-2377

RPS-0132 Rev. A 03/07

b. Clean holes using compressed air and a wire brush.

Check the hole depth and adjust as necessary.

See figure 3(b).

Wear Safety Goggles

4. Position the mounting base over the drilled holes.

Assemble anchor with nut and washer so that the top

of the nut is flush with the top of the anchor.

See figure 4.

5. Insert the anchors through the four holes in

the mounting base and into the drilled holes in

the concrete. Drive the anchors into the holes

until the washer is flush with the mounting base.

See figure 5.

6. Tighten the anchor nuts 3-5 turns past the hand tight

position or until all four anchors securely hold the

mounting base to the concrete.

7. Position the CP800 Power Head on the mounting

base. See figure 6. Insert the two long pins through the

outside of the base into the Power Head frame and

exiting the other side of the mounting base. Insert an

“R” clip into the hole of each pin.

Figure 3

Figure 5

Figure 6

Figure 4

(a) (b) (c) (d)

Loading...

Loading...