Page 1

1.0 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.0 Safety Symbol Definitions . . . . . . . . . . . . . . . . . .2

3.0 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4.0 Product Components . . . . . . . . . . . . . . . . . . . . . .3

5.0 Puller Specifications . . . . . . . . . . . . . . . . . . . . . .3

6.0 Introduction to Cable Pulling . . . . . . . . . . . . . . . .3

7.0 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

8.0 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

8.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . .5

8.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

RPS-0148 07/02

Instruction Sheet

CP2000: 2000 lb Cable Puller

IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. If shipping damage is found, notify carrier at once. Shipping damage is NOT

covered by warranty. The carrier is responsible for all repair and replacement costs resulting from damage in shipment.

SAFETY ISSUES

IMPORTANT – USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to select the

proper components and design to insure that all safety measures have been taken to avoid the risk of personal injury and property

damage from your application or system.

GARDNER BENDER IS NOT RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE, MAINTENANCE OR THE

APPLICATION OF ITS PRODUCTS. Please contact Gardner Bender for guidance when you are in doubt as to the proper safety

precautions to be taken in designing and setting up your particular application. Technical Support # 1-800-624-4320.

8.3 Pulling Cable . . . . . . . . . . . . . . . . . . . . . . . . .6

9.0 Repair and Maintenance . . . . . . . . . . . . . . . . . . .7

9.1 Shear Pin Placement . . . . . . . . . . . . . . . . . . .7

9.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . .7

10.0 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Page 2

2

1.0 DESCRIPTION

This cable puller is designed to be used together with the

power drive from a portable power threader. The product has

been tested with the Mini-Collins®and Rigid™ pipe threader.

Other brands you may already have can also be used.

Each cable puller application will depend upon your particular

need. In this manual we will cover general procedures as they

apply to our equipment.

Please read and understand this manual before attempting to

use this equipment. Most important is the safety of

the operator.

2.0 SAFETY SYMBOL DEFINITIONS

The symbol below is used to call your attention to instructions

concerning your personal safety. Watch for these symbols.

They point out important safety precautions. They mean

“ATTENTION! Become alert. Your personal safety is

involved.” Read the message that follows and be alert to the

possibility of personal injury or death.

DANGER: Indicates a high probability that death,

severe bodily injury or major property damage could result.

WARNING: Is serious but less inevitable. There is

some probability that death, severe bodily injury or

major property damage could result.

CAUTION: Is less serious but still demands

attention. Indicates a hazard which may result in minor

injury or property damage.

3.0 WARNINGS

This section contains information for your protection,

safety and quick reference. When using an electrical

appliance basic precautions should always be followed,

including the following.

Read all Instructions before using the CP2000.

Always have this manual available for reference at the

job site.

DANGER: Do not allow anyone to operate this

equipment until they have read and understood all

operating and safety instructions.

WARNING: This cable puller is not to be used as a

hoist for lifting, supporting, or transporting people or

loads. Failure to observe these precautions could result

in serious injury.

WARNING: Never stand directly behind the path of a

pulling rope. Keep exposed part of pulling rope as short

as possible. A broken pulling rope can whip with

extreme force.

WARNING: Only operate in well lighted areas.

DANGER: Do not operate in an area that contains

hazardous or combustible material. A fire or explosion

can result.

WARNING: All pulling system components must be

rated to withstand the maximum pull forces.

DANGER: Never stand directly under a vertical pull.

WARNING: Keep the work area clear of

all bystanders.

CAUTION: Check all pulling system parts before

use. Never use worn or defective components.

DANGER: Pulling system components can break

during use. Always protect yourself by wearing gloves,

protective glasses and hard hat.

DANGER: Do not allow anyone to operate this

equipment until they have read and understood all

operating and safety instructions.

WARNING: Only use rope that is rated for the

pulling force required. Check the rope often for damage.

Damaged rope can break and cause eye or other

bodily injury.

DANGER: Electrical equipment must be grounded

while in use to protect the operator from electric shock.

DANGER: Only use extension cords that are rated

and marked for outdoor use.

DANGER: Never use this equipment in rain or

damp locations.

DANGER: Disconnect power before service

or repair.

WARNING: The rope on the capstan can crush your

hand during operation. Do not allow the rope to wrap

around any part of your body. Keep loose clothing,

hands and body away from moving parts.

WARNING: This cable puller is not to be used as a

hoist for lifting, supporting, or transporting people or

loads. Failure to observe these precautions could result

in serious injury.

WARNING: Keep hands and loose objects away

from moving parts during operation. Serious injury

may occur.

CAUTION: This unit contains a pin designed to

shear if maximum recommended load is exceeded. This

sudden shearing action may send a shock to the rope,

possibly causing injury. Avoid such hazards by wearing

leather gloves and never wrap the rope around yourself.

Page 3

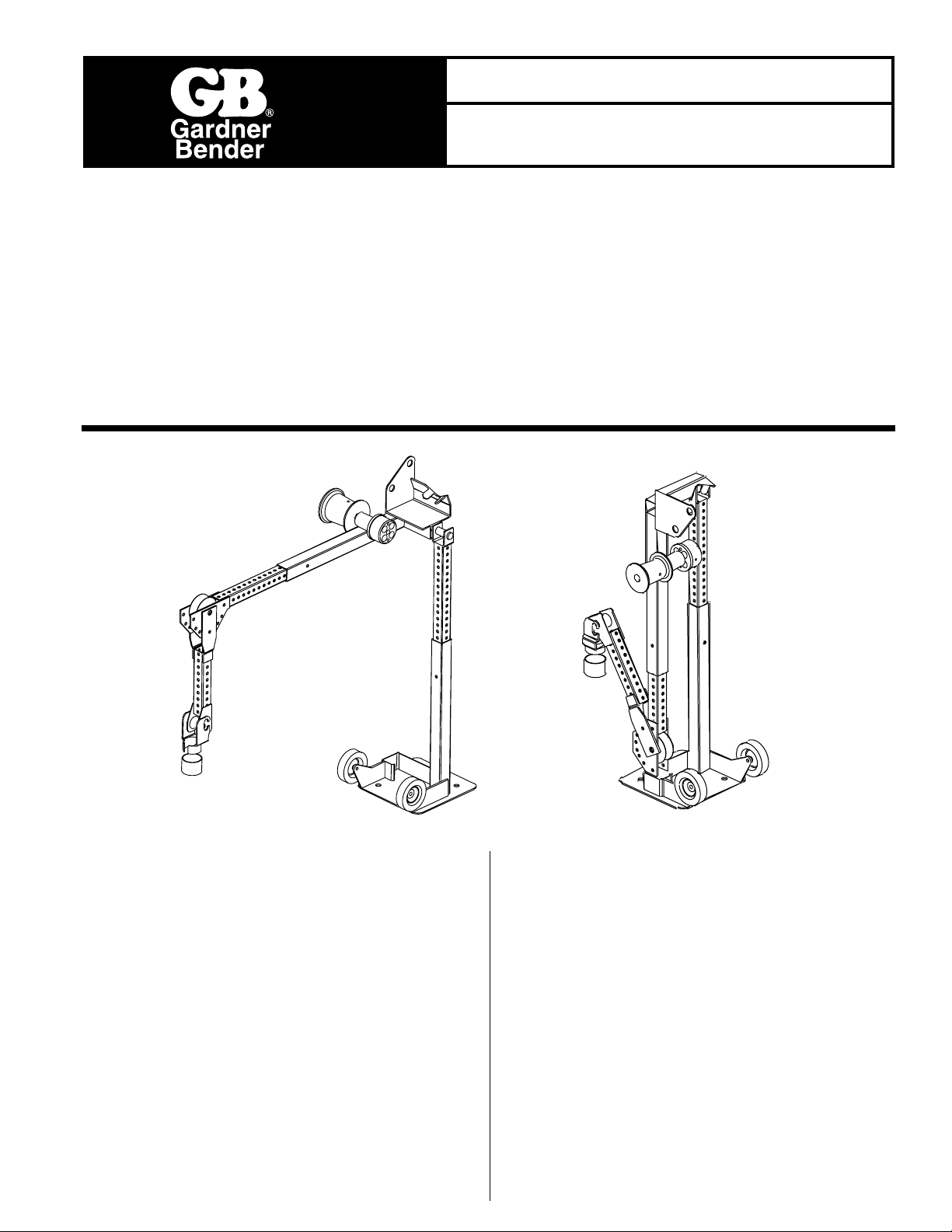

4.0. PRODUCT COMPONENTS

1. 2000 Pound Puller: Adjustable for pulling from all

directions. Includes capstan and guide pulley.

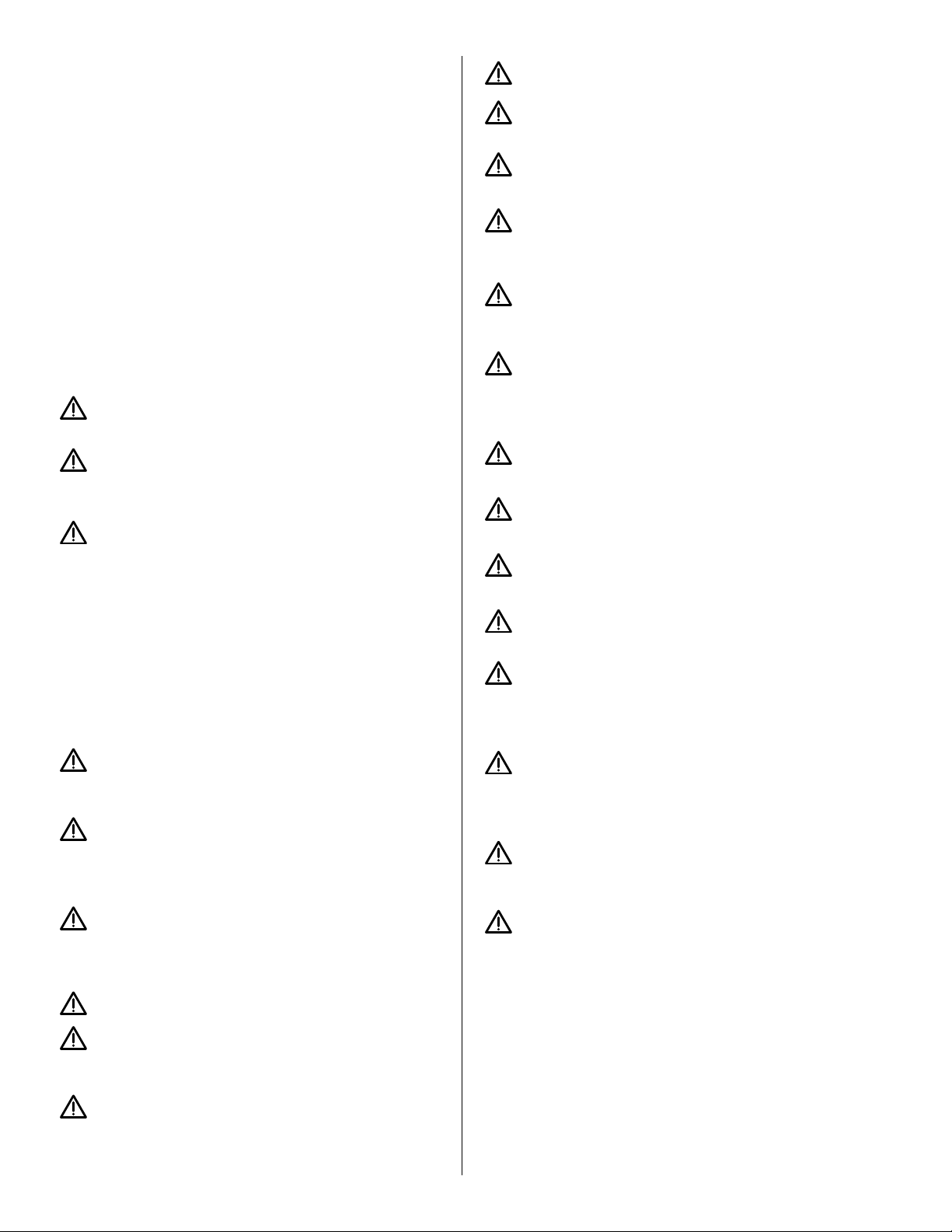

2. Switch Clamp: Attaches over the switch on the power drive.

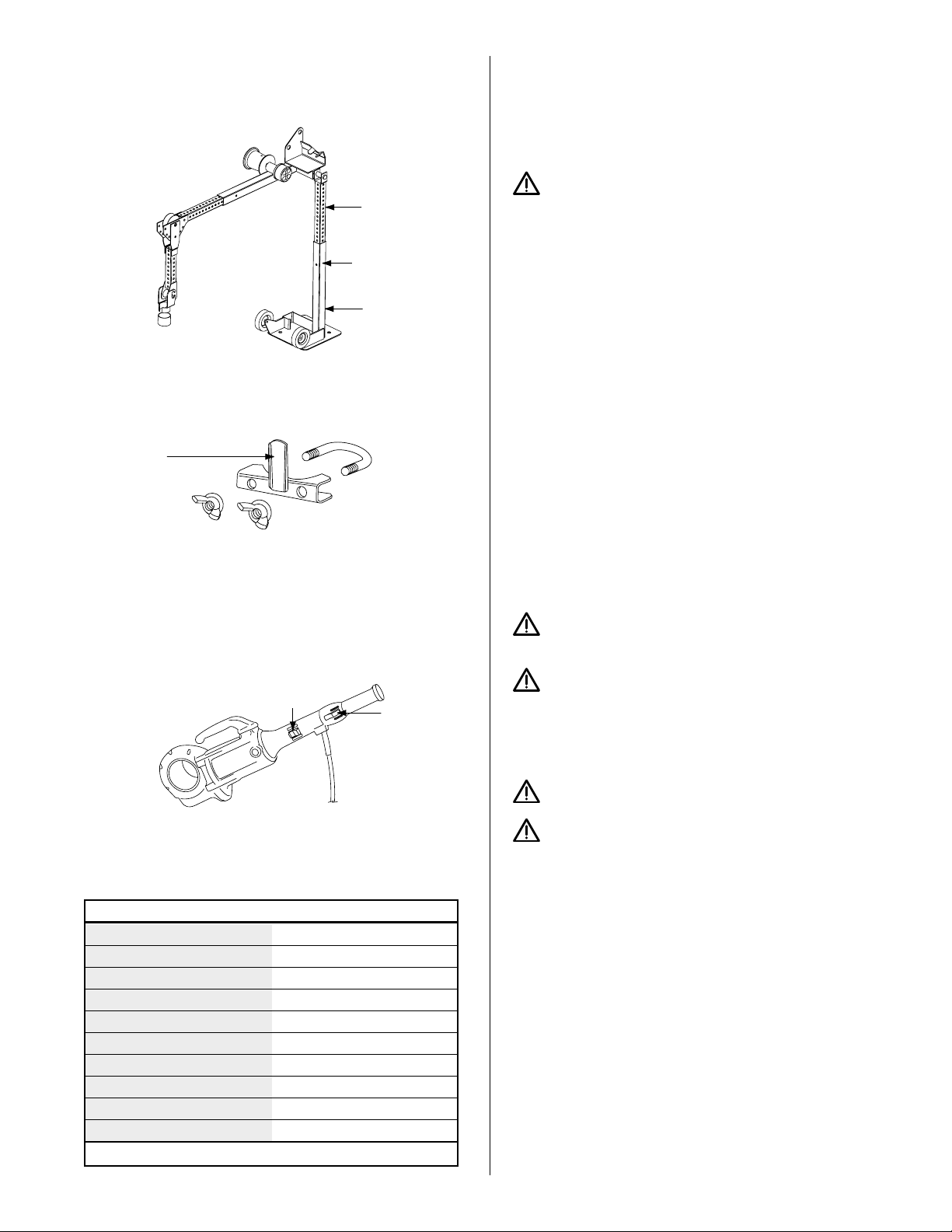

3. Pipe Threader‚ Power Drive (not included): Provides

the power for puller operations. It attaches to the drive

adaptor on the puller body. See it's manual for additional

operating information.

5.0 PULLER SPECIFICATIONS

6.0 INTRODUCTION TO CABLE PULLING

Each cable pulling operation can be different. Only

experienced personnel should be responsible for setup and

operation of this equipment. During a cable pull, very high

forces can be developed. Any failure of the components of

the system can be dangerous.

WARNING: All pulling system components must be

rated to withstand the maximum pull forces.

Safe and efficient cable pulling will require knowledge of the

following subjects.

1. Planning

Each operation will need its own special set up. Selection of

the proper sheaves, ropes and puller is critical.

Planning the length of the pull is another important

consideration. Cable weight and internal conduit bends will

create resistance to the pull. Size of conduit and cables

already present must be considered. To keep the pulling

force within equipment specifications, shorter pulls may

be required.

2. Installation

Make sure the puller is secured in place. Fastening the puller

to the floor can be accomplished by using the four through

holes on the puller base. Position the puller so the force is

parallel to the conduit. When securing components to other

objects, make sure they can support the pulling force.

3. Safe Operation

Know what the limits of your puller are. Always check

equipment for damage prior to operation.

WARNING: All pulling system components must be

rated to withstand the maximum pull forces.

CAUTION: Check all pulling system parts before

use. Never use worn or defective components.

Thoroughly inspect the work area. Make sure ample space is

available for equipment and personnel. Check for secure

footing and ventilation of any combustible gasses.

WARNING: Only operate in well lighted areas.

DANGER: Do not operate in an area that contains

hazardous or combustible material. A fire or explosion

can result.

Capstan Theory

The capstan uses the friction of the pulling rope to multiply

force. The total pulling force is determined by:

1. Number of wraps of rope on the capstan.

2. Tailing force the operator applies to the rope.

With the full 5 wraps of rope on the capstan, the operator can

easily generate sufficient pulling force for most applications.

For the best operator control during cable pulling, use the

fewest rope wraps needed to maintain an even pull. Only add

more rope wraps to the capstan if the operator needs

additional leverage. Never add or remove wraps from a

moving capstan.

3

Puller Specifications

Weight* 65 lb

Maximum Extended Height 116"

Maximum Arm Reach 70"

Continuous Pull Force 2000 lbs

Breakout Pull Force 2500 lbs

Power Source Portable Pipe Threader

Drive Speed 25 rpm

Pulling Speed 18 fpm

Required Rope Diameter

1

⁄2"

Required Rope Type Double Braided Polyester

*Without power drive or foot switch.

Figure 1. 2000 Pound Puller

Figure 3. Mini-Collins®Power Drive (not included)

Figure 2. Switch Clamp

Tab

Power Switch

Forward/Reverse

Switch

Leg Extension

Clevis Pin

Foot

Page 4

WARNING: The rope on the capstan can crush your

hand during operation. Do not allow the rope to wrap

around any part of your body. Keep loose clothing,

hands and body away from moving parts.

During normal pulling operations, the cable resistance will

constantly change. This will require the operator to change

his tailing force in response. The operator can relax this force

completely and stop the pull at any time. The capstan

requires some tailing force before it will pull. This assures

complete operator control. Do not continue to hold the rope

on the capstan if it starts to slip. Rope wear from friction and

heat will result. This could cause the rope to break. Turn off the

motor and secure the rope.

On a vertical pull, resistance to the force of gravity will tend to

reverse the pull. The weight of the cable will increase as the

vertical height of the pull increases due to the added cable

length. Resistance created by friction will require more pulling

force, but will not reverse the pull.

DANGER: Never stand directly under a vertical pull.

Using Sheaves

Sheaves are used to change the direction of pull and reduce

the friction load. When you install a sheave, make sure the

sheave support can withstand the total force. The force on

the sheave can be as high as double the pulling force. See

Figure 5.

WARNING: All pulling system components must be

rated to withstand the maximum pull forces.

Pulling Rope

WARNING: Only use rope that is rated for the

pulling force required. Check the rope often for damage.

Damaged rope can break and cause eye or other

bodily injury.

The pulling rope is a very important part of the cable pulling

system. Use a rope with a low stretch factor that has a load

rating greater than the total estimated pulling forces expected.

WARNING: Never stand directly behind the path of a

pulling rope. Keep exposed part of pulling rope as short

as possible. A broken pulling rope can whip with

extreme force.

7.0 ASSEMBLY

1. Extend the CP2000:

Remove the clevis pin from the foot. Raise the leg

extension to release the puller arm from the base. See

Figure 7. Reinstall the clevis pin in the foot to secure the

foot to the leg extension. Rotate the puller arm to a parallel

position. Set the arm extension on an available support.

The arm length can be adjusted by removing the clevis pin.

Slide the arm extension in or out as needed and reinstall

the clevis pin.

2. Install the power drive.

The CP2000 requires a power drive (Figure 8) to supply

the pulling force. The CP2000 puller is designed to use a

portable pipe threader power drive such as the MiniCollins

®

or Rigid™. Other power drives that you may

already have may also be used. Before you install the

power drive on the CP2000 you must depress and secure

the power switch with the clamp provided (Figure 9).

4

Figure 4. Pull

Rope Wrap

Capstan

Operator Tailing Force

Pulling Force

5000 lbs.

Support Load

3535 lbs.

Support Load

2500 lbs. Pull

2500 lbs. Load

2500 lbs. Pull

Figure 5. Pull vs. Load

Cleavis Pin

Figure 7. CP2000 Extended

Figure 9. Switch Clamp

Tab

Figure 8. Mini-Collins®Power Drive

Puller Arm

Power Switch

Forward/Reverse

Switch

Page 5

Install the switch clamp on the power drive handle so the

tab depresses the power switch to the “ON” position. See

Figure 10.

Remove the side handle from the power drive. Slide the

power drive head onto the drive coupler on the puller.

Rotate the power drive to ease installation and clear the

drive cradle. When installed correctly, the power drive will

set into the cradle. See Figure 11.

Put the side handle through the hole in the cradle and

install into the pipe threader. See Figure 12. This will

secure the power drive to the puller. Other power drive

units will require a similar procedure.

3. Install the foot switch (optional - model CP15).

Use of a foot switch with this puller is recommended to

insure optimal operator control. Connect the power drive

cord to the foot switch. Connect the foot switch to a

suitable receptacle or extension cord. Always use

extension cords rated for outdoor use.

DANGER: Electrical equipment must be grounded

while in use to protect the operator from electric shock.

DANGER: Only use extension cords that are rated

and marked for outdoor use.

DANGER: Never use this equipment in rain or

damp locations.

DANGER: Disconnect power before service

or repair.

8.0 OPERATION

8.1 Preparation

Preparing for the pull is a very important part of the operation.

This can affect the safety of all the personnel and prevent

damage to the equipment.

1. Check the conduit and raceway system. Is it secure and

able to withstand the total pulling forces? Is it the proper

size for the cables?

2. Check all the pulling system components. Make sure they

are in good operating condition and have the proper

load rating.

3. Determine the length and direction of each pull segment.

Consider the puller load rating.

4.Inspect the operation area. Is there ample room for all

personnel and equipment? Is the area safe?

WARNING: Only operate in well lighted areas.

DANGER: Do not operate in an area that contains

hazardous or combustible material. A fire or explosion

can result.

5. Make sure there are enough personnel to operate the pull

safely. Clear the area of all other people.

WARNING: Keep the work area clear of

all bystanders.

8.2 Setup

The CP2000 can be adjusted to reach and pull from many

positions. This can reduce the need to install additional

Figure 10. Power Drive Handle

Clamp

Figure 11. Power Drive and Puller Drive

Power Drive Head

Drive Cradle

Puller Drive Coupler

Side Handle

Figure 12. Power Drive Side Handle

5

Side Handle

Power Drive

Figure 13. Foot Switch

Foot Switch

Page 6

sheaves and extensions. Remove the clevis pin from the foot

and raise or lower the puller arm to the needed height.

Reinstall the clevis pin. Remove the clevis pin from the puller

arm and extend or retract the arm extension as needed.

Reinstall the clevis pin. The puller arm also pivots up and

down to provide additional adjustment. See Figure 14.

Pull Direction

The puller arm sheave can be positioned for either RIGHT,

LEFT, UP or DOWN pulling operations. It is important that the

sheave is in the correct position.

To position the puller arm sheave:

Remove the clevis pin from the puller arm. Remove the arm

extension from the puller arm. Rotate the arm extension to

the needed position and reinsert the arm extension into the

puller arm. Adjust the length of the arm and install the

clevis pin.

To Pull UP:

The puller sheave must be on the upper side of the puller

arm. See Figure 15.

To Pull DOWN:

Puller sheave must be on the upper side of the puller arm.

Rotate the entire puller arm upside down to position the puller

sheave to the bottom. The power drive will be held in the

cradle by its handle. See Figure 16.

DANGER: Never stand directly under a vertical pull.

To pull to the RIGHT:

Rotate the puller arm to the right.

To pull to the LEFT:

Rotate the puller arm to the right as you would for a right pull.

Rotate the entire puller arm upside down to position the puller

sheave to the left. The power drive will be held in the cradle

by its handle.

Puller Position

To position the puller sheave, adjust the puller arm according

to the previous instructions in the “HEIGHT AND REACH

ADJUSTMENT” section in this manual. Set the puller sheave

for the direction of the pull. Align the puller sheave with the

conduit opening. Rest the puller arm securely on the conduit

in the access box.

NOTE: Additional adapters may be needed if the puller arm

cannot contact the conduit. The puller foot may be fastened

to the floor for added stability if needed.

WARNING: All pulling system components must be

rated to withstand the maximum pull forces.

8.3 Pulling Cable

This section of this manual will only cover the cable pulling

operation of the CP2000 unit. We will assume that the conduit

has been cleaned and tested for obstructions and the rope is

fed and connected securely to the cable. Position observers

at critical points of the pull and have clear communication

with them.

To Start the Pull:

Position the rope over the sheave on the puller. Wrap the

tailing end of the rope once (1) around the capstan. Grasp the

tailing rope firmly and well behind the capstan.

WARNING: Never stand directly behind the path of a

pulling rope. Keep exposed part of pulling rope as short

as possible. A broken pulling rope can whip with

extreme force.

Depress and hold the foot switch. Apply a medium pulling

force to the tailing rope. If the pull will not begin, release the

foot switch. Apply an additional wrap of tailing rope to the

capstan and repeat. Only add one (1) wrap at a time up to a

total of five (5). For the best operator control during cable

pulling, use the fewest rope wraps needed to maintain an

even pull. Only add more rope wraps to the capstan if the

operator needs additional leverage. Never add or remove

wraps from a moving capstan.

Completing the Pull:

Allow the tailing rope to coil on the floor between you and the

puller as the pull continues. Never allow the rope to

Figure 14. Height and Reach Adjustment

Figure 15. Set Up for Upward Pulls

Figure 16. Set Up for Downward Pull

Clevis Pin

Clevis Pin

Base

6

Puller Sheave

Page 7

accumulate behind or around your legs. If you loose control of

the pull, the rope can be pulled back violently toward

the capstan.

WARNING: The rope on the capstan can crush your

hand during operation. Do not allow the rope to wrap

around any part of your body. Keep loose clothing,

hands and body away from moving parts.

During normal pulling operations, the cable resistance will

constantly change. This will require the operator to change

his tailing force in response. The operator can relax this force

completely and stop the pull at any time. The capstan

requires some tailing force before it will pull. This assures

complete operator control. Do not continue to hold the rope

on the capstan if it starts to slip. Rope wear from friction and

heat will result. This could cause the rope to break. Turn off the

motor and secure the rope.

CAUTION: This unit contains a pin designed to

shear if maximum recommended load is exceeded. This

sudden shearing action may send a shock to the rope

possibly causing injury. Avoid such hazards by wearing

leather gloves and never wrap the rope around yourself.

The CP2000 is equipped with a shear pin that will shear at

2500 lbs (1134kg) pulling force. This is for added protection

for the operator and equipment. Do not attempt a pulling

operation that exceeds this limit. If this should occur, secure

the rope and repair the unit. See Section 9.0 Repair and

Maintenance section in this manual.

On a vertical pull, resistance to the force of gravity will tend to

reverse the pull. The weight of the cable will increase as the

vertical height of the pull increases due to the added cable

length. If your equipment fails during a vertical pull the entire

cable and rope can fall. Resistance created by friction will

require more pulling force, but will not reverse the pull.

Always securely tie the rope when the pull is complete.

DANGER: Never stand directly under a vertical pull.

9.0 REPAIR AND MAINTENANCE

9.1 Shear Pin Placement

1. Remove the power drive from the CP2000 arm:

• Unthread the side handle from the power drive.

• Rotate the power drive up and slide it off from the

drive coupler.

2. Remove the drive coupler from the puller arm.

3. Remove the two (2) setscrews from the drive coupler.

4. Insert a small size punch into the setscrew hole and push

the shear pin completely out. Be careful. Do not damage

the internal threads.

NOTE: Use a wheel puller to remove the drive coupler from

the shaft, if it needs replacement. Use only mild steel .25 dia.

2

1

⁄2" long as shear pin replacement. Use the punch to install a

new shear pin and reassemble the unit.

9.2 Lubrication

Monthly:

• Apply EP 80/90 gear lube to the arm pivot thru the hole in

the shaft.

• Apply EP 80/90 gear lube to the puller sheave thru the hole

in the sheave.

• Apply high temperature bearing grease to the grease fitting

in the end of the capstan.

• Use a dry silicone spray as needed to lubricate the arm

extension and leg extension. This will also protect

against rust.

NOTE: Lubricate the power drive as per specifications of

drive manufacturer.

10.0 PARTS LIST

Figure 17. CP2000 Right View

Capstan

Rope Wrap

Tailing Rope

7

Figure 18. Power Drive

Side Handle

Drive Coupler

Set Screw

Shear Pin

Drive Coupler

Figure 19. Shear Pin Replacement

CP2000 Repair Parts Listing

Part # Description

CP2000-1 Wheel Kit

CP2000-2 Capstan

*see note Key - Idler Shaft

*see note Set Screw,

5

⁄16" - 18 x 3⁄8"

CP2000-3 Conduit Adapter Arm

CP2000-4 11⁄2" Conduit Coupling

CP2000-5 2" Conduit Coupling

CP2000-6 Shear Pin, 1⁄4"

CP2000-7 Warning Label Kit

CP2000-8 Frame Adjustment Pin

CP2000-9 Switch Clamp Assembly

*

Note: Comes with replacement capstan, #CP2000-2.

Page 8

Gardner

Bender

RPS-0148 07/02

PO Box 3241 • Milwaukee, WI 53201-3241 • 414-352-4160 • Fax 414-352-2377

6615 Ordan Drive • Mississauga, Ontario L5T 1X2 • 905-564-5749 • Fax 905-564-0305

WARRANTY: Gardner Bender warrants its product

against defects in workmanship and materials for 1

year from date of delivery to user. Chain is not

warranted. Warranty does not cover ordinary wear

and tear, abuse, misuse, overloading, altered products

or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest GB

Authorized Service Center for inspection, transportation

prepaid. Furnish evidence of purchase date. If the claim

comes under the terms of our warranty the Authorized

Service Center will REPAIR OR REPLACE PARTS

AFFECTED and return the unit prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine Gardner Bender parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact Gardner Bender

(414)352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest Gardner Bender

Service Center. The Gardner Bender Service Center will provide complete and prompt service on all Gardner

Bender products. For closest service center please visit our website @ www.gardnerbender.com.

CP2000-1 Wheel Kit

CP2000-2 Capstan

CP2000-3 Conduit Adapter Arm

CP2000-4 1

1

⁄

2" Conduit Coupling

CP2000-6 Shear Pin, 1⁄

4"

CP2000-7 Warning Label Kit

CP2000-8 Frame Adjustment Pin

CP2000-9 Switch Clamp Assembly

CP2000-5 2" Conduit Coupling

WARNING

THIS CABLE PULLER IS NOT TO BE USED AS A HOIST

FOR LIFTING, SUPPORTING, OR TRANSPORTING PEOPLE

OR LOADS. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN SERIOUS INJURY.

WARNING

KEEP HANDS AND LOOSE

OBJECTS AWAY FROM MOVING

PARTS DURING OPERATION.

SERIOUS INJURY MAY OCCUR.

CAUTION

THIS UNIT CONTAINS A PIN DESIGNED TO SHEAR IF MAXIMUM

RECOMMENDED LOAD IS EXCEEDED. THIS SUDDEN SHEARING

ACTION MAY SEND A SHOCK TO THE ROPE POSSIBLY CAUSING

INJURY. AVOID SUCH HAZARDS BY WEARING LEATHER GLOVES

AND NEVER WRAP THE ROPE AROUND YOURSELF.

WARNING

MAKE SURE ALL PINS ARE IN PLACE AND SECURE

DURING OPERATION. SERIOUS INJURY MAY OCCUR.

5-459

5-460

5-461

Loading...

Loading...