Page 1

IMPORTANT: RECEIVING INSTRUCTIONS: Visually inspect

all components for shipping damage. If any shipping damage is

found, notify carrier at once.

Shipping damage is NOT covered by warranty. The carrier is

responsible for all repair or replacement costs resulting from

damage in shipment.

Instruction

Sheet

CO2 CONDUIT

FISHING

SYSTEMS

IMPORTANT—USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to select the

proper components and design to insure appropriate integration with your operations and existing equipment and that all safety

measures have been taken to avoid the risk of personal injury and property damage from your application or system.

GB ELECTRICAL CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE, MAINTENANCE OR

APPLICATION OF ITS PRODUCTS. Please contact GB ELECTRICAL for guidance when you are in doubt as to the proper safety

precautions to be taken in designing and setting up your particular application. To protect your warranty use only GB/Enerpac

hydraulic oil.

Model JO25C Power Pak II™ (5 lb. CO

2

System with Caddy)

Model JO25 Power Pak I™

Model JO250 Powr House™ (5 lb. CO

2

System)

(50 lb. CO

2

System)

Model JO220 Powr House™ (20 lb. CO2System) not shown.

INTRODUCTION

The GB/Jet Line Carbon Dioxide (CO

2

) Conduit Fishing Systems are high pressure tools which are used to place a pull line

in most conduit runs from

1

/2” through 6” diameter.

These systems are completely self-contained and no other

energy source is required. They are convenient to use in

remote locations and in new construction where there is no

temporary electrical power available or where only one or two

conduit runs are required.

Each system consists of five basic components:

• A high pressure gas (CO

2

) driving media.

• A control valve to start and stop the gas flow.

• Hose and seal-off to conduct the gas to the conduit and form

a seal at the conduit entrance.

• A line carrier to serve as a movable piston that supplies the

pulling force.

• Pull line for pulling wire through the conduit or to pull in a

rope or cable for large difficult runs.

A thorough understanding of all components and their function

and operating precautions is essential for safe and efficient use

of the system.

Read all of the instructions before attempting to use the system

or blow line in the Conduit.

IMPORTANT SAFETY INSTRUCTIONS

Wear a hard hat, eye

protection, and gloves.

When using a carbon dioxide

conduit fishing system basic

precautions should always

be followed. FAILURE TO OBSERVE THESE INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH.

Do not discharge a cylinder

containing carbon dioxide

(CO

2

) in a non-ventilated

manhole or other non-ventilated areas. Carbon dioxide is relatively inert, but is heavier than air and will displace it and accumulate in depressions and along the floor. Concentrations of

Page 2

10% (100,000 ppm) can produce unconsciousness and death

from oxygen deficiency. Concentrations of 5% may produce

shortness of breath and headaches. Provide adequate

ventilation.

When operating a CO

2

System,

do not direct the high pressure

CO

2

stream towards any part of

the body; serious injury or possible death could occur.

All GB/Jet Line Systems are

designed to force loose debris

of all types out of the conduit by

means of a pressurized force. Serious or critical injury could

occur to anyone struck by high velocity exiting debris or the line

carrier. Warn all personnel to stand clear of the conduit exit prior

to commencing pressurization, flush-out procedures, or blowing

line into the conduit.

Do not hold the seal-off by therubber cone when discharging

CO

2

. Maintain a firm grip on

the seal-off hose and operating valve at all times while discharging CO

2

. The high velocity jet of CO2causes a recoil force, and

the free end of the hose could whip around possibly causing

injury or damage to equipment.

During use, portions of the

cylinder, valve, hose and seal-

off will become very cold as

may be noted by frost forming on these parts. Do not touch these

areas with bare hands. If bare hands become frozen to the frosted parts, do not pull away–run water over hand and metal part to

free it.

When transporting a GB/Jet

Line 5 Ib. CO

2

System, remove

the seal-off and hose assembly, install the safety pin in the valve handle, and screw down the

handle regulating screw to hold the safety pin in place.

Always make sure the 20 Ib.

and 50 Ib. CO

2

cylinders are

securely strapped to the cart to

prevent overturning and damage to the cylinder and valve.

When not in use or while being transported, close the cylinder

valve on 20 Ib. and 50 Ib. cylinders, depressurize operating hose

assembly and remove it from the cylinder to prevent accidental

discharge. Replace the screw on valve cover on 50 Ib. cylinders.

With excessive or constant use,

the liquid CO

2

in the cylinder

may freeze solid into dry ice,

the pressure in the cylinder may drop to zero, and the gas may

not flow. If this occurs, allow the cylinder to thaw out at room temperature; the pressure will return to normal. Do not apply heat to

the cylinder to speed up thawing. This could raise the cylinder

pressure to an excessively high level, causing the cylinder valve

safety disc to rupture and discharge the cylinder contents.

If the safety disc ruptures, have it replaced at an authorized fire

extinguisher service center, or replace it with a single GB/Jet Line

safety disc.

IMPORTANT: Use commercial grade CO

2

only when refilling the

CO

2

cylinder. Never, under any circumstances, substitute any

gas other than carbon dioxide (CO

2

). The cylinder is pressure

rated for CO

2

only.

Use only a GB/Jet Line System. GB has incorporated safety features into the CO

2

system; orifice flow restrictions, adjustable flow

regulation, low temperature pressure rated hose, and a rupture

disc pressure relief system.

Do not substitute any parts or accessories not manufactured by

GB/Jet Line on your CO

2

system.

Have the cylinders hydrostatically pressure tested by a qualified

local fire extinguisher service center at two year intervals. Under

no circumstances should the hydrostatic test intervals exceed

five years.

Observe all federal, state and local codes concerning handling,

transporting and storing of compressed gas cylinders.

CARBON DIOXIDE (CO2)

Carbon dioxide may exist in three physical states; solid (dry ice at

-109° F), liquid (under pressure) or gaseous CO

2

. Only the liquid

and gaseous states are useful in conduit fishing.

Carbon dioxide is normally stored in cylinders in liquid form under

pressure (838 P.S.I. at 70°F). It will rapidly turn into a high pressure, high velocity gas when the cylinder or operating hose valve

is opened. It is this high pressure, high velocity gas that is used

to drive the line carrier through the conduit. During the expansion

process, portions of the cylinder, valve, hose, and seal-off will

become very cold as may be visibly noted by frost forming on

these components.

Wear gloves, do not touch

these areas with bare hands.

Bare hands may become

frozen to the metal parts.

GB/JET LINE CO2 CYLINDERS

GB/Jet Line supplies three sizes of CO

2

Cylinders, 5, 20, and 50

Ibs., meeting U.S. Department of Transportation (DOT) requirements for compressed gas. Each cylinder bears a neck stamp

showing a DOT number indicating the maximum allowable working pressure, serial number, manufacturers identification code,

and date of manufacture.

The 5, 20, and 50 Ib. sizes indicate the weight in pounds of liquid

CO

2

that the cylinder will hold. CO2cylinders are supplied filled

and ready for use. When a cylinder becomes empty, it may be

refilled by most authorized fire extinguisher service centers. The

5 Ib. CO

2

cylinders may be refilled from the 50 Ib. CO2cylinder.

A refill connector Model RV5 is required for this operation. See

the refilling instructions on page 6.

Do not refill the CO

2

cylinders

with air, nitrogen or other

gasses. The cylinder is pressure rated for CO

2

use only.

Hydrostatic Pressure Testing –CO2cylinders returned to GB/

Jet Line for service or repair will be hydrostatically pressure tested for safety if the latest date stamp is more than two years old.

When a cylinder passes the hydrostatic pressure test, the month

and year shall be stamped on the cylinder by the approved testing center. Cylinders failing the pressure test must be destroyed.

2

Page 3

CO2 Cylinder Specifications

Model No. 1103N 1208 950

Cyl. Size 5 Ib. 20 Ib. 50 Ib.

Weight (full) * 14 Ibs. 55 Ibs. 154 Ibs.

Weight (empty) * 9 Ibs. 35 Ibs. 104 Ibs.

Weight (CO

2

) 5 Ibs. 20 Ibs. 50 Ibs.

Diameter * 5” 8” 9”

Height* 17

1

/2” 27” 51”

Valve Type Squeeze Rotary Rotary

Valve Coupling Ball Lock Threaded Threaded

Pressure (70°F) 838 P.S.I. 838 P.S.I. 838 P.S.I.

Maximum Cylinder See DOT 3 AA rating

Working Pressure stamped on cylinder neck

* Dimensions and empty weight of the cylinder may vary slightly,

depending on cylinder manufacturer.

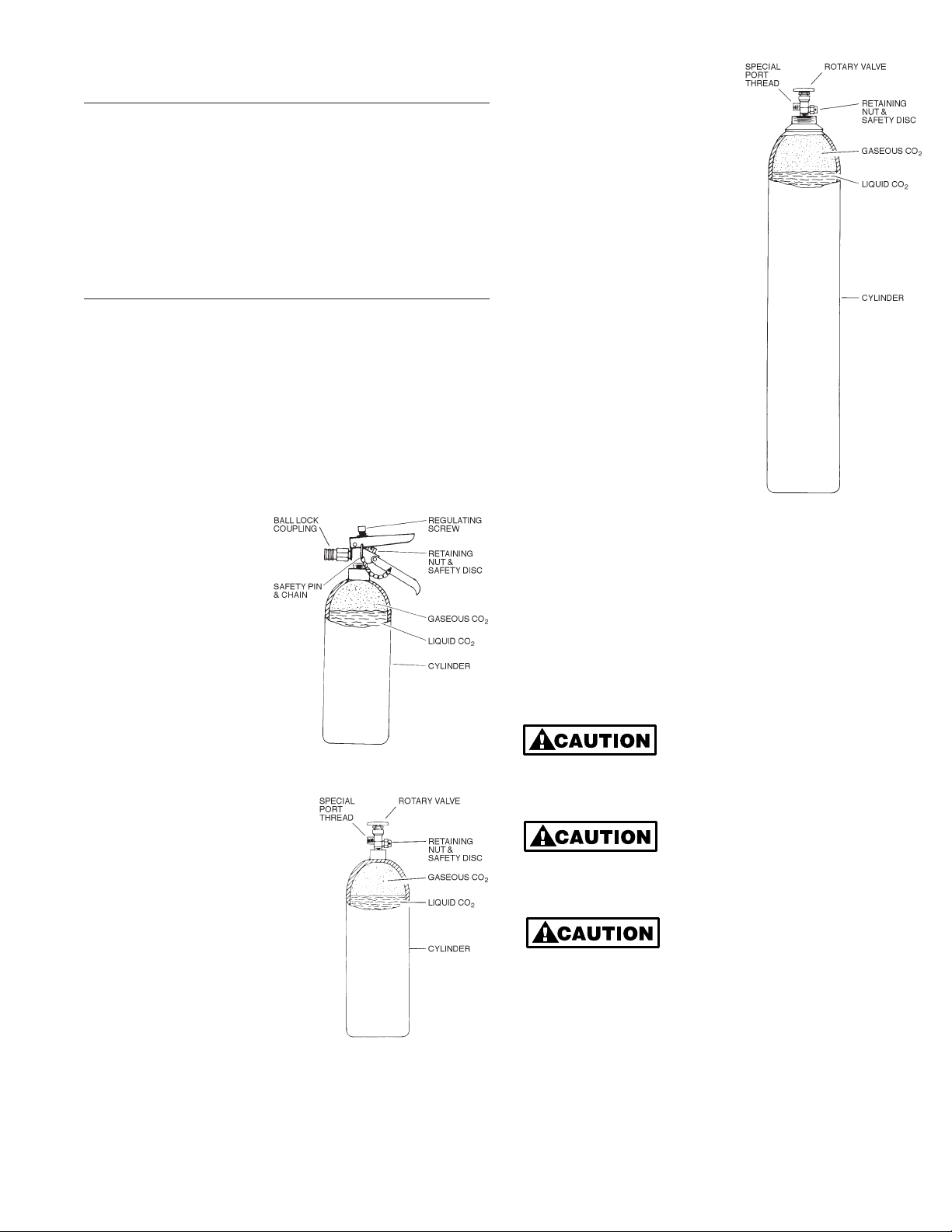

Model 1103N 5 Ib. CO2 Cylinder – The 1103N, 5 Ib. CO

2

cylinder, is used in both Power Pak I and Power Pak ll conduit fishing

kits.

The cylinder is equipped with a "squeeze to operate" hand valve.

A thumb screw is used to limit the operating handle movement

and regulate the amount of CO

2

dispensed. Adjusting the screw

will permit a mere trickle of CO

2

and backing out further will permit full handle travel and

a full flow of CO

2

(Refer

to Figure 1).

A safety pin inserted

through the handle and

valve body prevents the

handle from being

depressed accidentally. The

pin should always

be in place when the cylinder is not in use or when

the cylinder is being

transported.

A ball lock quick coupling is

provided for attaching sealoff Model 1215 or 1216.

Model 1208 20 Ib. CO2 Cylinder –

The model 1208, 20 Ib. cylinder, is

a cart-transported cylinder weighing approximately 55 Ibs. when

fully charged with 20 Ibs. of CO

2

.

This cylinder should always remain

strapped in the cart to prevent

overturning and damage to the

cylinder or valve.

The cylinder has a rotary hand

valve with a special port thread.

The valve requires a matching coupling nut and stem with an O-ring

face seal as supplied on Model

1105 CO

2

Operating Valve and

Hose Assembly (Refer to Figure 2

and 9).

Model 950 50 Ib. CO2 Cylinder– The model 950, 50 Ib. CO

2

cylinder, is a cart transported

cylinder weighing approximately

154 Ibs. when fully charged with

50 Ibs. of liquid CO

2

(Refer to

Figures 3 and 9).

The cylinder is equipped with a

rotary hand valve with a special

port thread. The valve requires

a matching coupling nut and

stem with an O-ring face seal

as supplied on the Model 1105

CO

2

Operating Valve and Hose

Assembly.

A screw on valve safety cover is

supplied with the cylinder and

should always be in place when

the cylinder is not in use or while

the cylinder is being transported.

The 50 Ib. cylinder may be used

as a field refilling supply tank for

the 5 Ib. cylinder if desired. See

refilling instructions on page 6.

USE AND OPERATION

With the GB/Jet Line CO

2

system, gas generated from the liquid

CO

2

stored in the cylinder is used to propel the line carrier

and pull line through the conduit.

When using the CO

2

system, adjust the flow regulating screw on

the “squeeze to operate” valve handle on the 5 Ib. cylinder or on

the 1105 valve and hose assembly. Regulate the flow to a moderate amount sufficient to keep the line carrier moving and the

line flowing into the conduit. Develop a light touch and conserve

CO

2

(Refer to Figure 4).

The valve handle is very easy to

operate when the regulating

screw is backed out. Do not

attempt to force the handle or damage to the screw and handle

could occur.

There is substantial force when

the valve is operated and CO

2

is

discharged in open air. Point the

nozzle in a safe direction and maintain a firm grip on the seal-off

frost guard and valve.

Where conduit is run under

ground; it may contain water or

be subjected to flooding. It may

be desirable to blow the water out before blowing a line in the

conduit. Because the water will be blown out ahead of the line

carrier, take precautions to protect nearby equipment that could

be damaged by moisture and sludge (Refer to Figure 16).

3

Figure 1

1103N 5 Lb. CO

2

Cylinder

Figure 2

1208 20 Lb. CO

2

Cylinder

Figure 3

950 50 Lb. CO

2

Cylinder

Page 4

BLOWING LINE IN THE CONDUIT

The GB/Jet Line CO2system is designed to blow a line in

“sealed” conduit such as EMT with compression type couplings,

rigid conduit, and plastic conduit with adhesive bonded joints.

These types of conduit generally require very little effort to install

a pull line with the CO

2

system.

There are some conduit runs that will be difficult or impossible to

blow a line in with the CO

2

system, such as:

• Conduit containing hard packed sand, silt, debris, or concrete.

• Conduit with separated joints.

• Conduit with two sizes of duct connected by a reducer coupling.

• Conduit with unsealed set screw couplings.

• Small diameter conduit of several hundred feet with multiple

bends.

PREPARATION

It is helpful to know the purpose for which a line is to be used

once it has been blown into the conduit. This will aid the user in

selecting the appropriate line for the job.

Knowing the approximate length of the conduit will prevent

selecting a line that is too short for the run; i.e., if the user wishes

to place a light line in a

3

/4” conduit with an estimated length of

195 to 200 feet, a 300 ft. power saver line package should be

selected for the run. An alternate solution would be to use a

3

/4”

foam line carrier pulling bulk nylon line. Either selection would

insure an adequate length of line.

Selecting the Pull Line – The following list is presented as a

guide in selecting a pull line. Users must determine for themselves which best fits their needs.

1. Identification of a conduit run termination where multiple con-

duit runs originate at a single location.

Recommended Line: Power Saver Line Packages or Bulk

Nylon Line.

2. Placing a line in the conduit for use at a later date.

Recommended Line: Small conduit

1

/2”, 3/4”, and 1” Power

Saver Line Packages, Bulk Nylon Line or PL232. Larger conduit 1

1

/4” through 6” Tag-Along Line Packages, PL Series

Line PL232, PL235, and PL2310.

3. Pulling in a larger line, rope or steel winch cable.

Recommended Line: Small conduit

1

/2”, 3/4” and 1”. Same as

2 above. Larger conduit PL232 or PL235.

4. Pulling wire in conduit.

Recommended Line: PL232, PL235, and PL2310.

SEAL-OFFS

Seal-offs provide a means of making the final connection

between the CO

2

operating valve and the conduit, as well as providing a means of feeding pull line into the conduit. The tapered

rubber cone that forms the seal at the conduit entrance must be

held firmly in the conduit when flushing out water and debris or

blowing line in the conduit. Be sure to keep a firm hold on the

seal-off hose frost guard while operating unit.

All CO

2

seal-offs are equipped with a male quick disconnect plug

that plugs into the operating valve ball lock coupling on the 5 Ib.

CO

2

cylinder valve or the 1105 operating valve and hose assem-

bly used with the 20 Ib. and 50 Ib. CO

2

cylinders (Refer to

Figure 4).

Connect the seal-off to the 5 Ib. CO

2

cylinder valve or the 1105

operating valve as follows:

1. Rotate the valve ball

lock coupling sleeve

to align notch with

embedded ball

(Refer to Figure 4).

2. Retract the ball lock

sleeve.

3. Plug in seal-off connector.

4. Release the sleeve to lock coupling.

5. Rotate sleeve notch away from embedded ball to prevent acci-

dental disconnection.

Disconnect the seal-off from the CO

2

operating valve when

threading pull line through the feed port and attaching a line carrier. This step will make the preparation job easier and eliminate

the possibility of accidental discharge of CO

2

.

Always maintain a firm grip on

the seal-off hose frost guard

when the seal-off is connected

to the operating valve (See Figure 5). This will prevent the free

end from whipping around while discharging CO

2

.

Model 1215 Seal-Off – The 1215 Seal-Off with two foot hose is

designed for use with the 5 Ib. CO

2

cylinder for blowing line in

3

/4”, 1/2”, 1”, and 11/4” conduit. This seal-off is required for blowing

power saver line packages in

1

/2”, 3/4”, and 1” conduit. The 1215

seal-off works equally well with the larger GB/Jet Line 20 and 50

Ib. systems when connected to the 1105 CO

2

operating valve

and hose assembly.

The feed through port will accept bulk nylon line and pull line up

to

1

/8” diameter.

Model 1216 Seal-Off – The 1216 Seal-Off with two foot hose is

similar to the 1215 except for a larger sealing cone. It may be

used in conduit sizes 1

1

/2” through 2 1/2” diameter and with pull

line up to

1

/8” diameter.

Model 1206 Seal-Off – The 1206 Seal-Off is designed for use

with the larger GB/Jet Line 20 and 50 Ib. CO

2

systems. It must be

used with the 1105 operating valve and hose assembly. The

large rubber cone will fit conduit sizes 1

1

/2” through 6”. The feed

through port will accept all GB/Jet Line PL Series pull lines

PL232, PL235, and PL2310.

OPERATING ACCESSORIES

GB/Jet Line provides specially designed easy-to-use operating

accessories for the CO

2

systems that meet most conduit fishing

needs.

Model 1105 Operating Valve and Hose Assembly – The 1105

operating valve and 12 ft. hose assembly connects to the 20 or

50 Ib. CO

2

cylinder and allows the operator a wide range of

movement to reach hard-to-get-to conduit runs.

4

RETAINING NUT

& SAFETY DISC

OPERATING

HANDLE

REGULATING SCREW

BALL LOCK

COUPLING

SEAL-OFF FITTING

MALE PLUG

SLEEVE NOTCH &

EMBEDDED BALL

CARRY HANDLE

Figure 4

Operating Valve and Seal-Off Coupling

Page 5

Connection to the 20 Ib. or 50 Ib. CO2cylinder rotary valve is

made with the special thread coupling nut and O-ring face seal

on the hose stem. The coupling nut screwed hand tight on the

valve port is all that is required for a good seal. When the cylinder

rotary valve is opened (opening one or two turns is sufficient) the

hose is pressurized up to the operator held hand valve.

Any of the GB/Jet Line CO

2

seal-offs may be threaded up with

pull line and line carrier and then connected to the operating

valve quick coupling. An adjusting screw is provided on the operating valve handle to limit the valve travel and regulate the flow of

CO

2

gas as required by the user.

When not in use, disconnect the seal-off from the operating

valve, close the cylinder rotary valve, operate the operating valve

to depressurize the hose and remove it from the cylinder valve.

Store the hose on the cylinder cart hose hanger hooks or in the

cart tool box.

Model 1142 Angle Adapter (See Figure 11) – The 1142 Angle

Adapter is provided for use with the 1215 seal-off for installing

line in small junction boxes and hard-to-get-to conduit.

To use, remove the rubber cone on the 1215 seal-off and screw

the angle adapter on the threaded end of the brass feed through

fitting.

Always maintain a firm grip on the seal-off hose behind the feed

through fitting to counteract the recoil force of the high velocity

CO

2

gas.

Blowing Line Packages through

Conduit – This is the easiest

method of placing a light weight pull

line in the conduit. The line package

or seal-off requires no thread up for

this operation. However, it is recommended that the seal-off be connected to the operating valve and a preliminary CO

2

flow adjustment be

made by alternately operating the

valve and adjusting the regulating

screw. If more CO

2

flow is required,

back out the regulating screw one

or two more turns (Refer to Figure 4

and 5).

Always maintain a firm grip on the

frost guard of the seal-off hose to

prevent it from whipping around.

Power Saver Line Package –

Select the Power Saver line package for size and length of line to fit

up to 1” diameter conduit. It is

recommended that you flex the

package back and forth two or

three times to loosen it prior to its

use. This will make the line easier to dispense.

Proceed as follows:

1. Pull out approximately two

feet of line. Hold on to this trailing end to prevent its loss in the

conduit.

2. Insert the line package in the conduit-foam tip first.

3. Hold the seal-off hose frost

guard, force rubber cone firmly in

the conduit entrance and give the

line package two or three quick

spurts of CO

2

. The package

should be blown through the conduit trailing a line as it goes

(Refer to Figure 6 and Table 1).

4. It is recommended that

the ends of the line be

tied off until ready for use

to prevent the end from

being accidentally pulled

back into the conduit.

Tag-Along Line Package -

Tag-Along Line Packages

perform the same function

as Power Saver line packages except they are used

in 1

1

/4” diameter and larger

conduit. Tag-Along packages must be used with a

line carrier to supply the

pulling force.

Select the Tag-Along Line

Package and a line carrier

either foam or inflatable that fits the conduit diameter and proceed as follows:

1. If a foam line carrier is selected, attach the Tag-Along pack-

age plastic eye to the foam line carrier hook. Pull out approximately two feet of line and hold on to the trailing end (Refer to

Figure 7).

2. Insert the foam line carrier and Tag-Along package in the

conduit.

3. Hold the seal-off hose frost guard, force rubber cone firmly in

the conduit entrance and squeeze the CO

2

operating valve

handle. Continue to apply a flow of CO

2

until line carrier

comes out the other end of the conduit. The run time will be

longer than for the Power Saver line package because of the

larger conduit and greater volume of CO

2

required. However,

the run time in 3” and 4” conduit 200 and 300 feet long should

be completed in a matter of seconds (Refer to Figure 7).

4. Tie off the ends of the

line to prevent it from

being accidentally

pulled into the conduit.

Inflatable Line Carrier

1. Select an Inflatable line

carrier within its conduit

diameter range and

attach the Tag-Along

Line Package to the

wire bail. Pull out

approximately two feet

of line and hold on to

the trailing end.

5

Figure 6

Blowing a Power Saver Line

Package In Conduit

Conduit Length

Model Dia. Ft.

LP2150

1

/2” 150’

LP3200

3

/4” 200’

LP3300

3

/4” 300’

LP3450

3

/4” 450’

LP4200 1” 200’

LP4300 1” 300’

LP4450 1” 450’

Table 1

Power Saver Line Packages

CONDUIT

1215

SEAL-OFF

POWER SAVER

LINE PACKAGE

TRAILING END

OF LINE

Figure 7

Blowing a Foam Line Carrier and

Tag-Along in Conduit

FOAM

LINE

CARRIER

1216

SEAL-OFF

TRAILING

END OF LINE

CONDUIT

Length Strength

Model Ft. Lbs.

LP2206T 400 22

LP2208T 600 22

LP2207T 800 22

LP1704T 1200 22

LP1705T 600 50

Table 2

Tag-Along Line Packages

Figure 8

Blowing an Inflatable Line Carrier and

Tag-Along in Conduit

THE

INFLATABLE®

LINE CARRIER

1216 SEAL-OFF

CONDUIT

TAG-A-LONG

LINE PACKAGE

TRAILING

END OF LINE

LOCK BALL

COUPLING

REG ULATING

SCREW

1215 SEAL-OFF

FROST GUARD

GRIP HERE

Figure 5

1103N Cylinder with 1215

Seal-Off Connected

Page 6

2.

Unfurl the Inflatable line carrier and place it in the conduit-bag

portion first (Refer to Figure 8).

3. In large conduit (4, 5, and 6” diameter), it may be necessary to

point the seal-off nozzle at the plastic sleeve of the Inflatable

to achieve initial inflation. This is accomplished by tilting the

seal-off in the conduit entrance. Otherwise the collapsed

Inflatable may allow the small diameter stream of CO2 to blow

past it.

BLOWING PULL LINE IN THE CONDUIT

All CO

2

systems may be used to blow pull line or nylon line in the

Conduit. Position cart

transported cylinder

and pull line in a location that will allow good

access to the conduit

entrance (Refer to Figure 9).

Set up as follows:

1. Connect the 1105

Operating Valve and

hose assembly coupling nut to the CO

2

cylinder valve.

Hand tight is sufficient for a good

seal.

2. Open the CO

2

cylinder rotary valve one or two turns is suffi-

cient to pressurize the hose up to the operating valve.

3. Connect the seal-off to the operating valve and make a prelim-

inary operating valve adjustment for moderate flow of CO

2

.

This is accomplished by backing out the operating valve handle regulating screw and operating the valve until the desired

flow of CO

2

gas is obtained (Refer to Figure 9).

Always maintain a firm grip

on the seal-off hose frost

guard to prevent it from whip-

ping around while making this adjustment and discharging CO

2

.

4. Disconnect the seal-off from the operating valve while threading pull line through the feed port and attaching the line

carrier.

5. Thread the pull line through the seal-off feed

port (Refer to Figures 10, 11, 12 and 13).

6. Tie the pull line securely to the line carrier to prevent loss in

the conduit (Refer to Figures 14 and 15).

7. Re-connect the seal-off to the operating valve and insert the

line carrier in the conduit.

8. Hold the seal-off hose frost guard, force seal-off firmly into the

conduit entrance and squeeze the operating valve to start the

flow of CO

2

. Continue the flow of CO2until the line carrier

comes out the other end of the conduit. This should take

approximately 20 to 30 seconds in a clear 3” or 4” duct that is

300 ft. long. If the duct contains water as shown in Figure 16,

the run time will be longer.

REFILLING THE 5 LB CYLINDER

To refill a 5 Ib. cylinder from a 50 Ib. cylinder, invert the 50 Ib.

cylinder sufficiently to

allow the CO

2

liquid to

flow to the top of the

valve end of the cylinder. The liquid in the 50

Ib. cylinder must cover

the valve so that it will

drain to the 5 Ib. cylinder, otherwise the 5 Ib.

cylinder will be filled

only with CO

2

gas.

Weigh the empty 5 Ib.

cylinder before beginning the refill operation. Refer to step 9.

1. Invert the 50 Ib. cylinder to an angle of approximately 30°

with the valve end down. Make sure the 50 Ib. cylinder is

held securely to prevent rolling or sliding and damage to the

cylinder valve.

2. Attach the threaded hex nut on the RV5 Refill Connector to

the 50 Ib. cylinder valve. Finger tight is sufficient.

6

1105 OPERATING VALVE

AND HOSE ASSEMBLY

CYLINDER

ROTARY VALVE

Figure 9

Blowing Pull Lines in Conduit

Figure 10

1215 Seal-Off for

1

/2", 3/4", 1", and 1 1/4"

Conduit

Figure 11

1215 Seal-Off with 1142 Angle

Adapter

Figure 12

1216 Seal-Off for 1

1

/4" to 2 1/2" Conduit

Figure 13

1206 Seal-Off for 1

1

/2" to 6" Conduit

Install on port

when flushing out

conduit or when blowing

Tag-Along line packages

Figure 14

Pull Line Attached to Foam Line

Carrier

Figure 15

Pull Line Attached to the Inflatable

Line Carrier

FOAM LINE CARRIER

1105 OPERATING VALVE AND HOSE

ASSEMBLY WITH 1206 SEAL-OFF

Figure 16

Water Being Pushed Ahead of Foam Line Carrier

Figure 17

Refilling the 5 Lb. CO

2

from the 50 Lb. Cylinder

SEAL-OFF

Page 7

3. Attach the other end of the RV5 to the 5 Ib. cylinder valve by

plugging it into the quick coupling (Refer to Figure 17).

4. Chill the 5 Ib. cylinder as follows:

(a) With the valve on the 5 Ib. cylinder in the open position

(handle depressed), open the 50 Ib. cylinder rotary valve

for a full six seconds.

(b) Close both valves.

(c) Release trapped pressure in the RV5 by loosening the

coupling nut at the 50 Ib. cylinder valve.

(d) Remove the RV5 from the 50 Ib. cylinder valve.

(e) With the RV5 still attached to the 5 Ib. cylinder, hold the

hose and point it in a safe direction. Operate the 5 Ib.

cylinder valve and release a short burst (3 to 4 seconds)

of CO

2

. Expelling CO2from the 5 Ib. cylinder will cause it

to become chilled.

5. Re-attach the RV5 to the 50 Ib. cylinder.

6. Open both cylinder valves and fill the 5 Ib. cylinder.

7. Close both valves when the audible sound of CO

2

flow stops

(about 15-30 seconds).

8. Disconnect the RV5 coupling nut from the 50 Ib. cylinder

valve first. This will bleed the trapped pressure in the hose

and prevent damage to the O-ring in the 5 Ib. cylinder operating valve.

9. Weigh the 5 Ib. cylinder. A full cylinder should weigh the total

obtained by adding 5 Ibs. to the empty weight.

10. If the 5 Ib. cylinder is underweight, operate the valve as in

step 4 and re-chill the cylinder. Re-attach the RV5 to both

50 Ib. and 5 Ib. cylinders and repeat steps 5, 6, 7, and 8.

11. If overweight, leave cylinder on the scales and bleed CO

2

until the correct weight is obtained.

NOTE: After the 5 Ib. cylinder has been filled, it may be very cold,

and the pressure may be low. It is recommended that the

cylinder be stored overnight at room temperature (70°F.).

This will insure full working capability of the cylinder.

MAXIMUM NUMBER OF CONDUIT RUNS

The following tables are presented as a guide to the maximum

number of conduit runs that can be achieved in “sealed” conduit

before refilling of the CO

2

cylinder is required.

“Sealed” conduit for this purpose is considered as EMT with compression type couplings, rigid conduit with threaded couplings

and plastic conduit with adhesive bonded joints.

Conditions of the conduit, operating valve adjustment and operator experience will cause the number of runs to vary.

Conduit Conduit Run Length (feet)

Diameter 100’ 200’ 300’ 400’

1

/2” 170 80 55 40

3

/4”75352017

1” 42 20 13 10

1

1

/4”281286

1

1

/2”18864

2” 14 5 3 2

2 1/2”7320

Table 3

5 Ib. CO

2

Cylinder Maximum Number of Conduit Runs Before Refilling

Conduit Conduit Run Length (feet)

Diameter 100’ 200’ 300’ 400’

1

/2” 700 345 225 170

3

/4” 315 155 103 79

1” 175 86 58 42

1

1

/4” 115 57 38 28

1

1

/2”78382518

2” 44 21 14 10

2

1

/2”281497

3” 19 9 6 4

3

1

/2”14743

4” 11 5 3 2

5” 7 3 2

6” 4 2

Table 4

20 Ib. CO

2

Cylinder Maximum Number of Conduit Runs Before Refilling

Conduit Conduit Run Length (feet)

Diameter 100’ 200’ 300’ 400’

1

/2” 1750 876 582 439

3

/4” 796 396 260 196

1 ” 443 220 145 107

1

1

/4” 290 142 95 70

1

1

/2” 195 96 64 47

2” 108 52 35 26

2

1

/2”64322116

3” 44 22 14 11

3

1

/2”3316108

4” 25 12 8 6

5” 16 8 5 4

6” 11 5 3 2

Table 5

50 Ib. CO2 Cylinder Maximum Number of Conduit Runs Before Refilling.

7

Page 8

WARRANTY: GB ELECTRICAL, INC. warrants its

products against defects in workmanship and materials for 1 year from date of delivery to user. Chain is

not warranted. Warranty does not cover ordinary wear

and tear, abuse, misuse, overloading, altered products

or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question of warranty claim arises, send the unit to the nearest GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our warranty the Authorized Service Center will REPAIR OR

REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact GB Electrical

(414) 352-4160 for the name of the nearest GB Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL Service Center. The Service Center will provide complete and prompt service on all GB ELECTRICAL products.

GB Electrical, Inc.

An Applied Power Company

6101 N. Baker Road, Milwaukee, WI 53209

Phone: (414) 352-4160 FAX (414) 352-2377

RPS-0095 Rev. A 03/07

Loading...

Loading...