Page 1

IMPORTANT: RECEIVING INSTRUCTIONS: Visually

inspect all components for shipping damage. If any

shipping damage is found, notify carrier at once.

Shipping damage is NOT covered by warranty. The

carrier is responsible for all repair or replacement costs

resulting from damage in shipment.

Instruction

Sheet

BV208D

IMPORTANT—USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken

to select the proper components and design to insure appropriate integration with your operations and existing

equipment. All safety measures must taken to avoid the risk of personal injury and property damage from your

application or system.

Gardner Bender CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE,

MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact Gardner Bender for guidance when you

are in doubt as to the proper safety precautions to be taken in designing and setting up your particular application.

Special Features

• Heavy Duty 8 ft hose. Optional 15 ft. hose available.

• Complete set of tools for injecting pull line into 1/2" to

6" conduit.

• Four gallon recovery compartment. Expandable to

nine gallons on BV208DA.

• Heavy duty welded steel cart with casters and wheels.

Description

Blo-Vac™ power fishing systems, BV208DA. Each

model is designed for blowing or vacuuming pull line into

electrical conduit. In addition, each Blo-Vac also

operates as a standard shop type wet and dry vacuum

cleaner.

The Blo-Vac unit has three compartments which are

easily separated. The top section contains the power

unit, the center

section(recovery

compartment) collects refuse

and the bottom section (tool

storage) is storage for

accessories (see Fig. 1).

Model BV208D is expandable

to 9 gallons. The BV208D is

constructed from high impact

polypropylene.

Blo-Vac Power finishing

system is capable of injecting

cable pull line into 1/2" to 6"

conduit. Accessories and

materials vary depending on

job requirements. Specifications for length of conduit

runs are guidelines and are not applicable 100% of the

time. (See Technical Specifications on page 4).

Conditions such as debris in conduit and fitting leakage

will reduce the effectiveness of the Blo-Vac system.

Power

Unit

Recovery

Compartment

Tool Storage

Compartment

Fig 1

Blo-Vac Compartments

Page 2

Operation

Blo-Vac motors are not explosion

proof. Do not operate Blo-Vacs in

underground locations or where flammable vapors

exist.

IMPORTANT: Read all operating instructions prior to

using Blo-Vac System.

1. Connect power cord to 115 VAC outlet on a 20 amp

circuit.

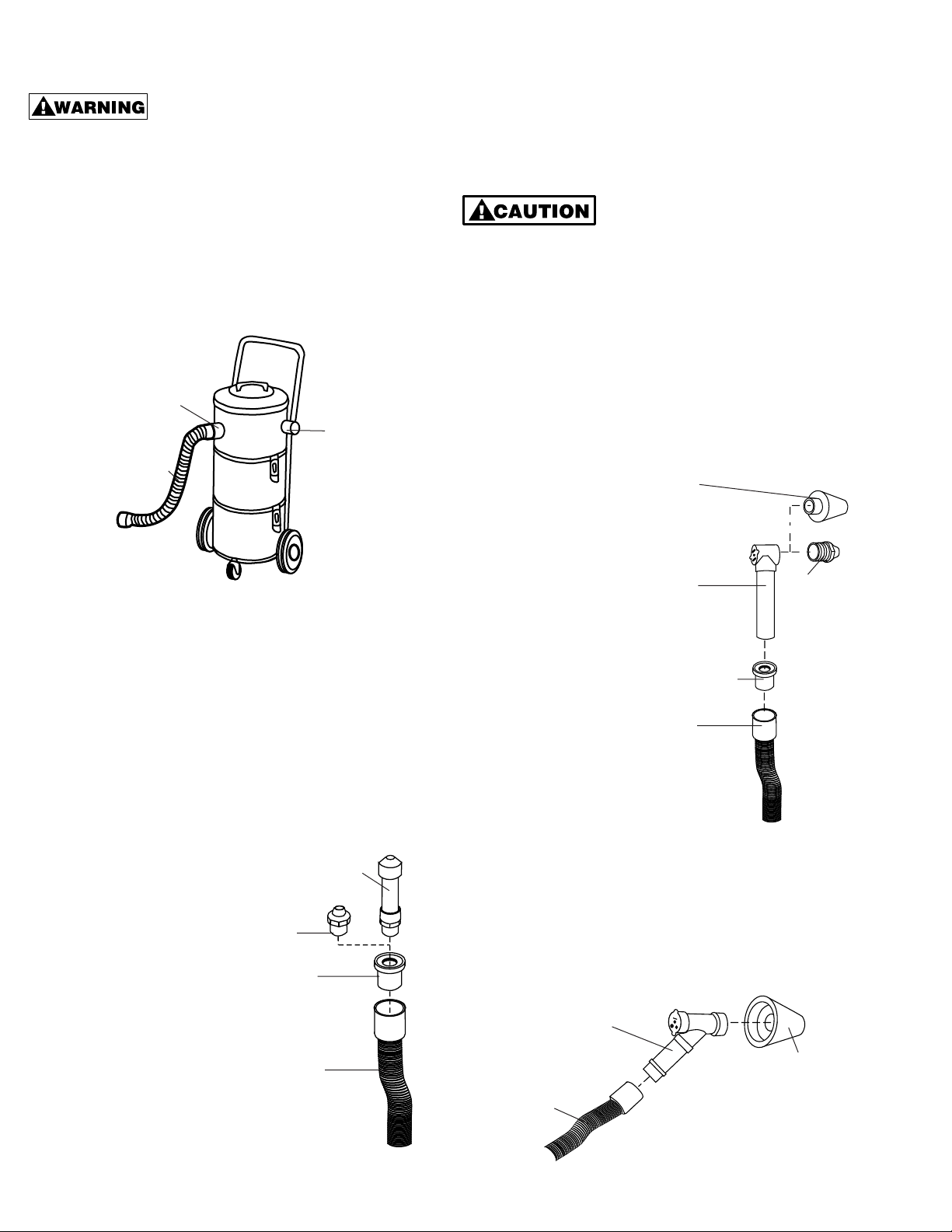

2. Connect the 8 foot hose to either the inlet or outlet

fitting on the Blo-Vac (see Figure 2). The outlet is for

blowing and the inlet is for vacuuming.

3. Select a seal-off, seal-off body and line carrier to

match the size conduit on the job (see “Line Carriers”

and “Pull Line ” for more information). The same items

are required for vacuuming or blowing into conduit.

4. Using the vacuuming method requires two people. The

Blo-Vac and the operator are at one end of the

conduit, another person is required to feed the line

carrier and pull line into the opposite end of the

conduit. Blowing pull line can be accomplished by one

person.

a. Conduit sizes 1/2" to 1-1/4"

i. Use the BV12 hose adapter, JV08 seal-off or the

long JV09 Seal-off. The

JV07 can also be used

(see Figure 3).

ii. Thread the JV08 into the

BV12 adapter. Insert the

adapter into the hose

assembly.

iii. Inject pull line into the

conduit by selecting a

line carrier and attaching

the pull line to it. If a

Power Saver Line

Package is used, a

separate line carrier is

not needed.

iv. Power Savers and Tag-a-Longs are center

dispensing. Unwind about 12 inches of pull line

prior to placing the line carrier into the conduit.

Wrap the loose end around the blower hose or a

stationary object.

v. Place the line carrier into the conduit.

Be sure the pull line is not tangled

around feet or hands of the

operator. Fast moving pull can cause severe burns to

exposed skin.

vi. Position the seal-off in the end of the conduit. The

loose end of the pull line should be between the

seal-off and the conduit.

vii. Turn the Blo-Vac "ON" and continue operating

until the line carrier exits the opposite end of the

conduit.

b. Conduit Sizes 1/2" to 2-1/2"

i. Injecting bulk line into 1/2 to 2-1/2" conduit

requires the JV07

Dial-A-Line

body, BV12

adapter and

either the JV08

or BV23 seal-off

(see Figure 4).

ii. Thread the end

of bulk line into

the round hole in

the metal disk

on back of the

JV07. Pull the

end through the

body and into

the seal-off.

iii. Tie the pull line

to the line

carrier. Insert

the line carrier into

the conduit and operate the Blo-Vac by placing the

seal-off against the conduit opening and turning

the Vac system "ON". Operate the Blo-Vac until

the line carrier exits the opposite end of the

conduit.

Figure 3

Accessories for

1/2" to 1-1/4" Conduit

JV09

Long Seal-Off

JV08

Short

Seal-Off

12568

8 ft Hose

BV12

Hose Adaptor

Figure 4

Accessories for

1/2" to 2-1/2" Conduit

BV23

Seal-Off for

1-1/4" to 2-1/2" Conduit

JV08

Short SealOff

for

1/2" to 1-1/4"

Conduit

JV07

Dial-A-Line™

Seal-Off Body

BV12

Hose Adaptor

12568

8 ft. Hose

Figure 5

Accessories for

2-1/2" to 6" Conduit

BV24

Seal-Off for

2-1/2" to 6" Conduit

B26

Large Dial-A-Line™

Seal-Off Body

12568

8 ft. Hose

12568

8 ft Heavy Duty Hose

Vacuum Inlet

Blower Outlet

Page 3

c. Conduit Sizes 2-1/2" to 6"

i. Items required are the BV26 seal-off body and the

BV24 seal-off (see Figure 5).

ii. Tag-A-Long or bulk nylon pull line and poly-pull

rope are the types of material suitable for 2-1/2" to

6" conduit. A line carrier is required for each type

pull line or poly rope. Maximum pull line size is

PL232 bulk line (see Figure 6).

Maintenance After Vacuuming Dirt and

Water

1. Release the latches securing the top and center

sections together.

2. Remove the filter bag from the bottom tool storage

section. Slide the filter bag onto the intake canister

located on the bottom of the motor. The filter bag

prevents dust from entering the motor. Dust and dirt

will damage the motor and cause premature failure.

3. Clean the filter bag by shaking off the excess dirt.

Store the clean bag in the lower storage compartment.

4. The Blo-Vac is equipped with a ball float to prevent

water from entering the motor. If the ball float seals the

motor inlet, the motor will sound different from usual.

Immediately shut the unit off. Empty the recovery

section and check the inlet screen for dirt and lint.

Clean the screen and reassemble the Blo-Vac

sections.

Line Carriers

Foam Line Carriers

These are the original line carriers

made of high density poly-foam. As

the line carrier travels through the

conduit it provides a swabbing action

cleaning out water and loose debris.

These carriers have a hook on one end for convenient

attachment of a TAG-A-LONG line package and an eye on

the other end for attachment of pull line. Foam line carriers

are available for 1/2" - 6" conduit sizes (See Figure 7).

The Inflatables® Line Carriers

This patented device has less

friction in the conduit and runs faster

than the foam line carrier. The

flexible nature of the inflatable

carrier allows it to conform to the

conduit diameter. It can pass over

local obstructions that would stop a

foam line carrier. This device can be

vacuumed or blown through conduit. They are

manufactured of tough durable nylon material and are

available in four models covering 3/4"-6" conduit sizes

(see Figure 8).

Missile Line Carriers

Molded of polyethylene plastic,

these low friction carriers offer the

highest speed of the three types of

carriers. These carriers were

developed for the CO2Electric

Blowers and Blo-Vac systems for

use in long and large conduit runs.

If the line carrier encounters a

blockage, the slotted skirt allows the carrier to be pulled

out past joints or steps in the conduit. A hard tug on the

pull line will cause the petals to turn inside out allowing for

easy withdrawal. They are available in 2"-6" conduit sizes

(see Figure 9).

Pull Line

Power Saver™ Line Package

A combination carrier and pull line,

this is the easiest and most

versatile line that can be installed in

conduit. The self contained nylon

line package comes in different

sizes for 1/2", 3/4", and 1" conduit.

It dispenses a line as the package

is blown through the conduit (see Figure 10).

Tag-A-Long™ Line Package

This package is designed for longer

runs and must be used with a line

carrier. The increased package

diameter and length prevents the

package from passing freely through

or around bends in conduit less than

1-1/2". Once attached to the line carrier,

the Tag-A-Long line package

function and operation is similar to that of the

Power Saver (see Figure 11).

Figure 7

Foam Line Carrier

Figure 8

The Inflatables®

Figure 9

Missile Line Carrier

Figure 10

Power Saver

Line Package

Figure 6

Blo-Vac System

for 2-1/2" to 6" Conduit

Figure 11

Tag-A-Long

Line Package

Line

Carrier

Seal-Off

Seal-Off Body

Bulk Pull Line

Page 4

RPS-0098 Rev. B 7/07

PO Box 3241 • Milwaukee, WI 53201-3241 • (800) 624-4320 • Fax 414-352-2377

6615 Ordan Drive • Mississauga, Ontario L5T 1X2 • 905-564-5749 • Fax 905-564-0305

WARRANTY: Gardner Bender, INC. warrants its

products against defects in workmanship and

materials for 1 year from date of delivery to user.

Chain is not warranted. Warranty does not cover

ordinary wear and tear, abuse, misuse, overloading,

altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When

question of warranty claim arises, send the unit to the

nearest GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine Gardner Bender parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact Gardner Bender

(414) 352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest Gardner Bender

Service Center. The Service Center will provide complete and prompt service on all Gardner Bender products.

Specifications

BV208DA

Super

Blo-Vac

Vacuum (Inches of Waterlift)

Sealed Vacuum*

110"

Maximum Air Pressure

(Pounds per square inch)*

4

Electrical Rating (Volts-Amps)

120 VAC

13.5A

Type of Motor

By-Pass

Number of Impeller Stages

2

Recovery Capacity Gallons)

9**

Net Weight (Pounds)

44

Height with Cart (Inches)

39-3/4

Motor Brush Life (Hours)

750

Bulk Nylon Line

Unlike the Power Saver and Tag-ALong packages which dispense a

line as it moves through the conduit

the bulk line package remains at

the conduit entrance and the line is

pulled into the conduit by a line

carrier. The bulk line allows for

longer conduit runs (up to 2200 ft.) and tensile strengths

from 22 to 100 lbs (see Figure 12).

Pull Line

Jet Line stranded PL-series pull

lines are designed specifically for

conduit fishing. These lines are

made of strong polyolefin plastic

that will not rust, rot or mildew.

The patented color coded binder

strand spirals around a bundle of

linear, monofilament that give

almost friction free blowing and

vacuuming. This line, considered

the cadillac of pull line, is

guaranteed to be free of knots

or splices. It is available in

lengths to 6500 ft and tensile

strengths from 100 to 1000

lbs (see Figure 13).

Conduit Measuring Tape

Marked in one foot increments,

this tape is designed to be blown into conduit or duct runs

to determine exact run length for accurate cable cutting

without waste. Available in 3000 ft. rolls (see Figure 14).

Figure 13

PL-Series Pull Line

Figure 12

Bulk Pull Line

Figure 14

Conduit Measuring Tape

Technical Specifications

* Will vary with voltage and atmospheric conditions.

** When using recovery compartment and tool storage compartment

together.

CONDUIT RUN LENGTH (ft.)

Conduit

Size

200150 300 400 500 600 700 800 900 1000 1100

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

3"

3-1/2"

4"

5"

6"

2-1/2"

1100 ft. +

BV308D Ultra Blo-Vac

Typical Run with four 90° bends and no obstructions or leaks, using Jet Line

PL232 Pull Line and Foam Line Carrier.

Loading...

Loading...