Page 1

Gardner

Bender

Instruction

!

IMPORTANT

BOS57 / BOSA57

No-Dog

Sheet

IMPORTANT: RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage. If any shipping

damage is found, notify carrier at once. Shipping damage is NOT covered by warranty.The carrier is responsible for

all repair or replacement costs resulting from damage in shipment.

IMPORTANT USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to

select the proper components and design to insure appropriate integration with your operations and existing

equipment and that all safety measures have been taken to avoid the risk of personal injury and property damage

from your application or system.

GB ELECTRICAL, INC. CANNOT BE HELD RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE

USE, MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact GB's technical service depar tment

for assistance if you are in doubt as to the proper safety precautions essential to designing and setting up your

particular application.

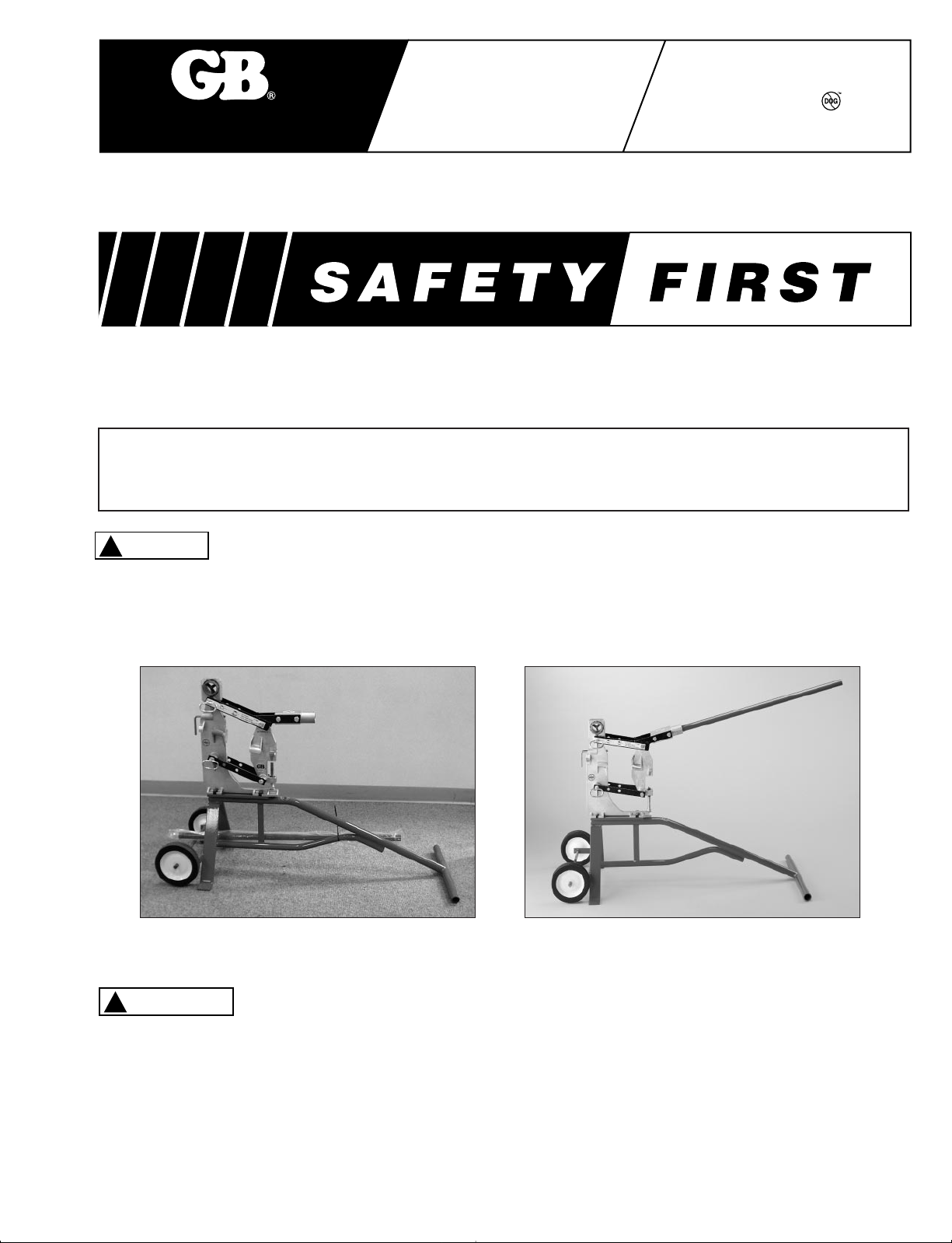

Offset Bender

CAUTION

!

Model BOS57 and BOSA57 are designed for bending 1⁄2" EMT, IMC, Rigid and 3⁄4" EMT Conduit.

ATTEMPTS TO BEND ANY OTHER SIZES OR TYPES OF CONDUIT WILL DAMAGE THE BENDER

AND VOID ALL WARRANTY.

Upon initial receipt

Fully assembled

TO AVOID POOR QUALITY BENDS, BE SURE BRACKET TO FRAME MOUNTING HARDWARE IS

TIGHTENED SNUGLY TO PREVENT SIDE-TO-SIDE MOVEMENT. CHECK HARDWARE PERIODICALLY

OR IF EXCESS BRACKET MOVEMENT IS ENCOUNTERED.

1

Page 2

!

CAUTION

Initial Set-up Procedures

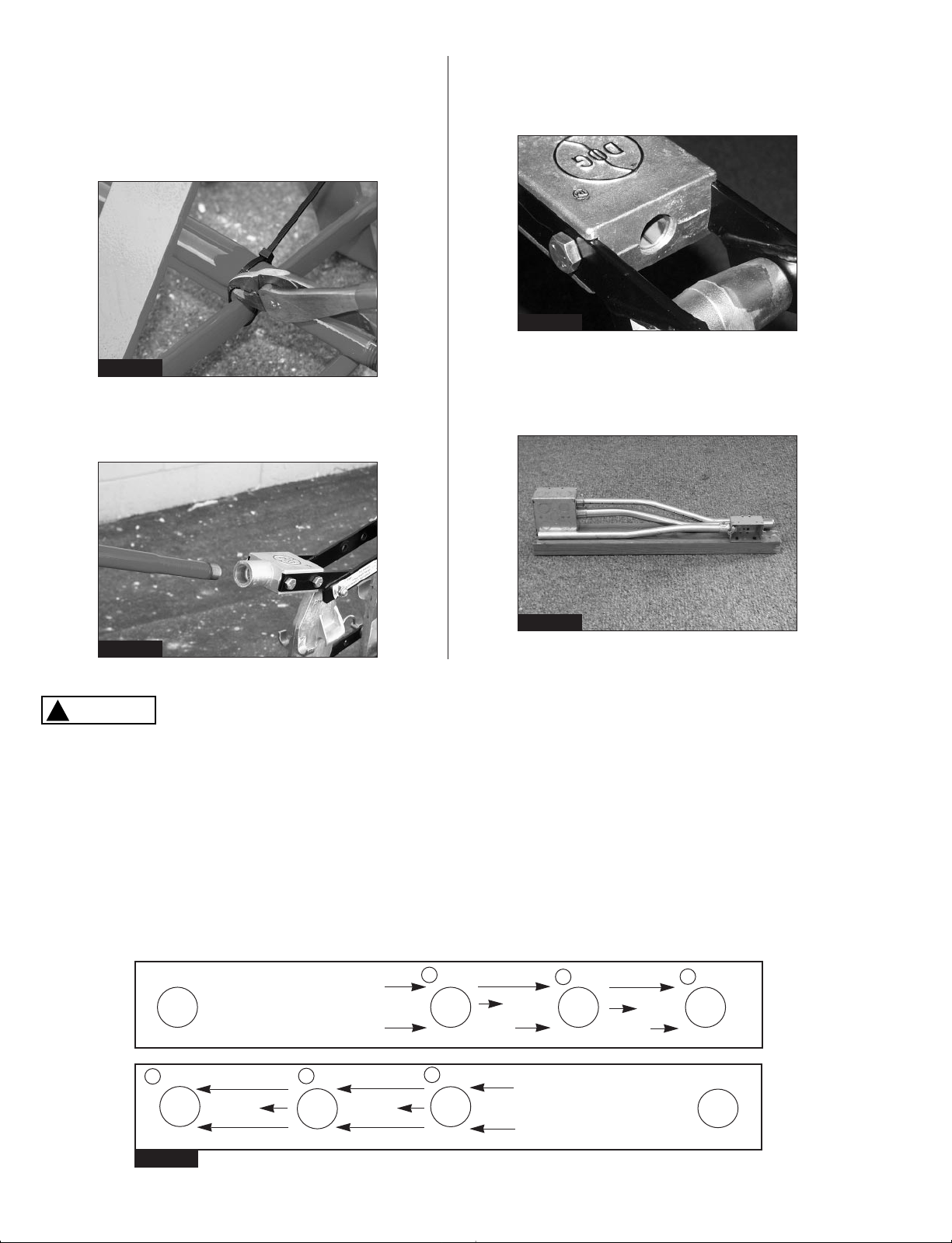

1. Remove all packing materials. Remove the

bender handle from the lower frame by cutting

the cable ties securing the handle to the frame.

See Figure 1.

The threads should pass all the way through and

be flush with the back side of the yoke.

See Figure 3.

Figure 3

Figure 1

3. Once the initial set-up is complete, the bender

will require specific steps to accomplish various

2. Install the bender handle by threading it

conduit bends. See Figure 4.

completely into the yoke.See figure 2.

Figure 4

Figure 2

DO NOT ATTEMPT TO BEND CONDUIT OTHER THAN 1⁄2" EMT (THINWALL), IMC AND RIGID OR 3⁄4"

EMT CONDUIT. USE OF ANY OTHER SIZES OR TYPES OF CONDUIT WILL DAMAGE THE BENDER

AND COULD CAUSE INJURIES.

Operating Procedures

1. Bending conduit is accomplished using jaws on the frame to stabilize the conduit. The jaws are

designed to accomidate specific types and sizes of conduit.

2. Determine the size and type of conduit, and the offset height required. Review the bracket decals to

locate the correct side of the frame to use. See Figure 5.

Patent pending

3

1

+

⁄2"

Figure 5

1

⁄2" EMT

Offset Height Range

Add to Height for Springback

Pin Position

2

0"-21⁄2"

3

+

⁄8"

0"-11⁄2"

0"-3⁄4"

1

1

+

⁄8"

1

0"-3⁄4"

1

+

⁄4"

2

0"-2"

Pin Position

Offset Height Range

Add to Height for Springback

3

+

0"-3"

⁄16"

3

⁄4" EMT

3

5

+

⁄16"

Patent pending

2

Page 3

3. Each bracket decal contains three vital pieces

of information.

a. Pin Position: Three locations to insert

retaining pin, which will produce different

heights of offset bends.

b.Offset Height Range: The range of offset

height that this pin hole position will

3

produce. (ie.0-

⁄4", 0-2" and 0-3")

c. Add to Height for Springback:The fraction

with a plus sign indicates the amount to

add to the offset height to correct for

conduit springback.

4. Select the correct hole location on the bracket,

pull the retaining pin and move the bracket until

the selected hole lines up with the frame hole.

Insert the retaining pin. See Figure 6.

Example: Offset height required = 2 inches

Conduit is

1

⁄2" EMT.

Hole Location is #2

Fraction added is +

1

⁄8", therefore

2"+1⁄8" = 21⁄8"

1

2

⁄8" is stop screw measurement for

step 6.

Figure 8

7. Lower the bender handle and complete the

bend by pushing down until the handle stops

moving. See Figure 9A. Raise the handle and

remove the conduit.See Figure 9B.

Figure 6

5. Raise the bender handle and insert the conduit

into the correct size bending jaws (check bend

bracket decals).See Figure 7. Be sure the

conduit extends a minimum of 2" beyond the jaw.

Figure 7

6. Set the bend stop screw adjustment by turning

the screw until the distance between the bottom

of hex head and the bottom of the frame is the

offset height plus the fractional number on the

decal. See Figure 8.

Figure 9A

Figure 9B

3

Page 4

Gardner

Bender

A unit of Tools and Supplies

Forming a Saddle Bend

1. Repeat steps listed in Operating Procedures

and complete the first offset bend.

2. Do not remove conduit.Keep all adjustments

and settings the same. Raise the bender handle

until the conduit can be slid forward.Slide the

conduit forward until the end of the first offset

bend is positioned past the second jaw. See

Figure 10. Level the conduit and hold it steady.

Figure 10

3. Push the handle down to complete the second

offset bend. See Figure 11. Raise the handle

and remove the conduit.

Conduit Reamer

1.The conduit reaming tool has a blade for the

inside and outside surface of the conduit.

Complies with article 348-11 of NEC.

2. Press the open end of the conduit against the

reamer blade.Hold the conduit fir mly and rotate

it 2 or 3 times to remove burrs and shar p edges.

See Figure 12.

Figure 12

Repeat Bending Feature

1. An adjustable length indicator is located on the

front edge of the bend frame.The indicator has

a maximum travel of 4 inches. See Figure 13.

2. Position the conduit into the bending jaws.

Loosen the thumb screw and move the indicator

until it contacts the end of the conduit.Tighten

the thumb screw. See Figure 13.

Adjustable

Length

Indicator

Figure 11

Figure 13

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest Gardner Bender Service Center. The GB

Service Center will provide complete and prompt service on all Gardner Bender products.

PARTS AND SERVICE: For quality workmanship and

genuine Gardner Bender parts, select an Authorized

Gardner Bender Service Center for your repair needs.

Only repairs performed by an Authorized Service

Center displaying the official Gardner Bender

Authorized sign are backed with full factory warranty.

Contact Gardner Bender (414)352-4160 for the name

of the nearest GB Authorized Service Center.

WARRANTY:Gardner Bender warrants its product

against defects in workmanship and materials for 1

year from date of delivery to user.Chain is not

warranted.Warranty does not cover ordinary wear

and tear, abuse, misuse, overloading, altered

products or use of improper fluid.

WARRANTY RETURN PROCEDURE:When question

of warranty claim arises, send the unit to the nearest

Gardner Bender Authorized Service Center for

inspection, transportation prepaid. Fur nish evidence of

purchase date. If the claim comes under the terms of

our warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

6101 N. Baker Road, Milwaukee, WI 53209 • Phone:(414)352-4160 • FAX (414)352-2377

ZRPS-0135 4/99

Loading...

Loading...