Page 1

Model B400, B400D,

B400L & B400DL

Eegor® Hydraulic Benders

Gardner

Bender

Instruction

Sheet

IMPORTANT RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage. If any

shipping damage is found, notify carrier at once. Shipping damage is NOT covered by warranty. The carrier is

responsible for all repair or replacement costs resulting from damage in shipment.

GARDNER BENDER CANNOT BE HELD RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY

UNSAFE USE, MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact Gardner

Bender’s technical service department for assistance if you are in doubt as to the proper safety

precautions essential to designing and setting up your particular application.

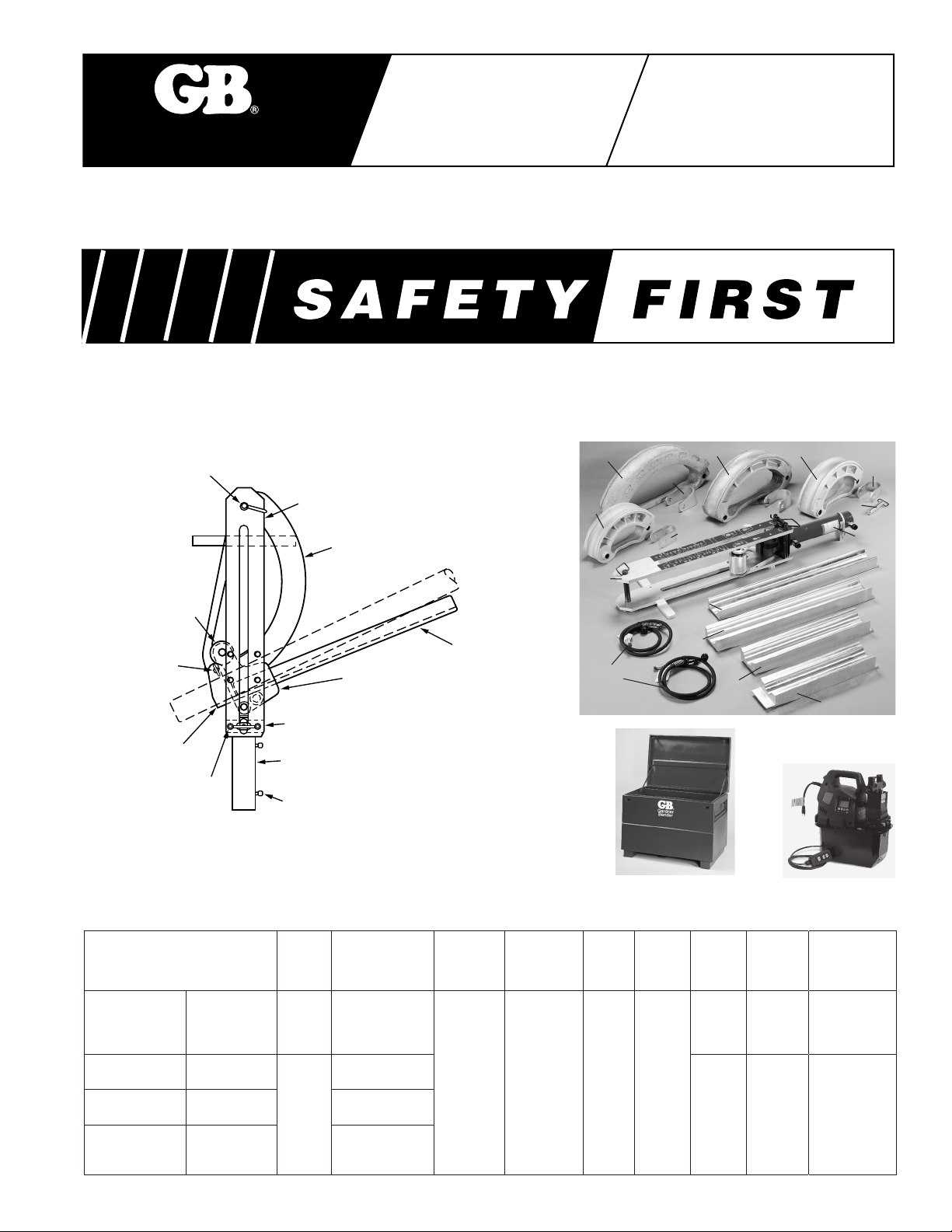

Shoe Pivot Pin

Frame Plate

Bending Shoe

4" dia. Roller

U-strap

Lock Pin

U-strap

Double Anchor Pin

Compression Roller Assembly

(Roller Ass'y/Cylinder Clevis/

Roller Ass'y)

Cylinder Support Block

Cylinder

Coupler

Note:

Position couplers in direction

shown so as to prevent damage

to hoses when making full

90˚ bend.

Follower Bar

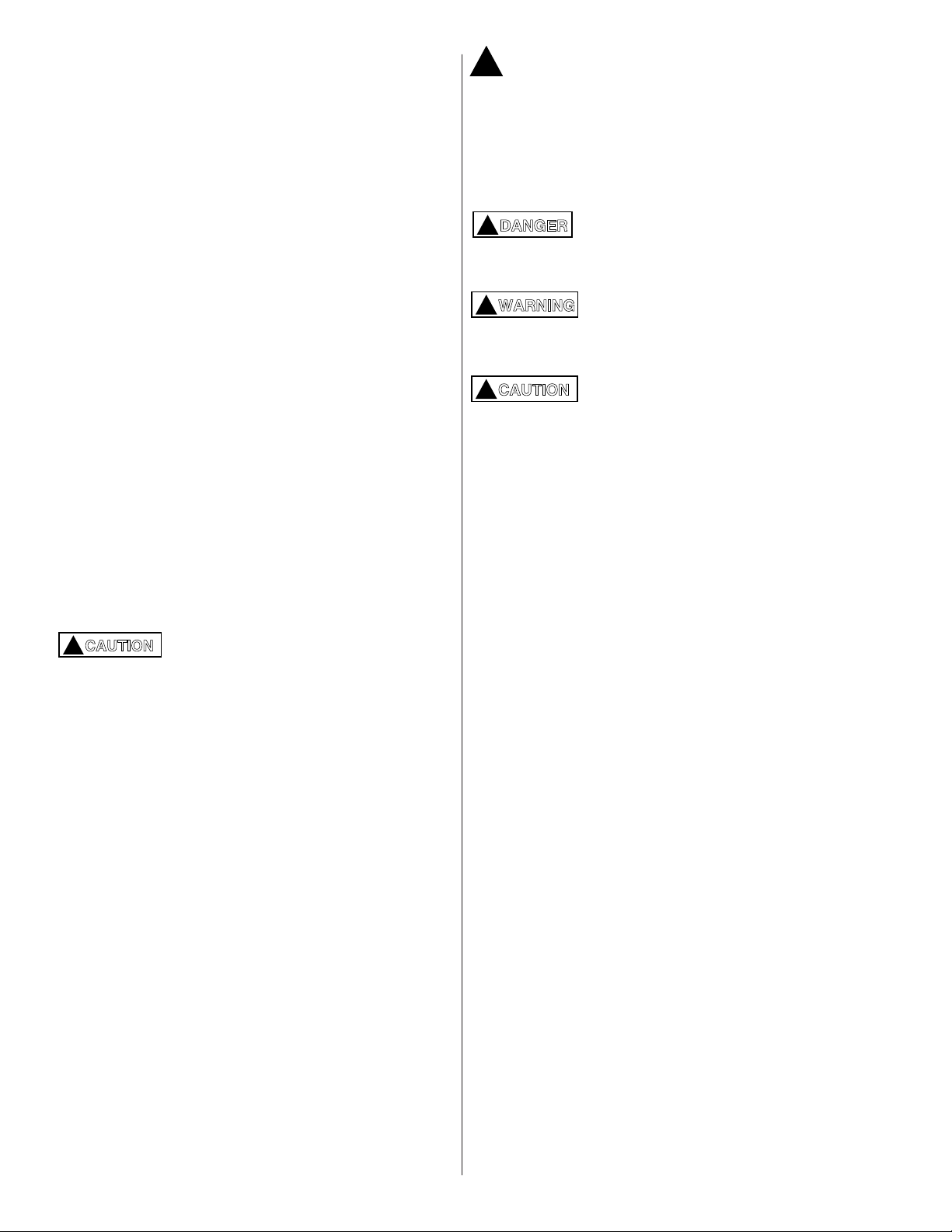

Eegor® & Ultra EegorTM Bender Component Chart

BS4000 4"

BZ44 4"

BS2500 21⁄2"

BZ728

HC-913

B400

Eegor® Benders are shipped in metal

storage cases.

BS3500 31⁄2"

BZ28 21⁄2"

BFB4000 4"

BFB3500 31⁄2"

BFB3000 3"

BZ39 31⁄2"

BS3000 3"

BZ34 3"

BZ76

CD3014

BFB2500 21⁄2"

P408S Electric Hydraulic Pump

Order Eegor® Set Model Number Size Set Pump and Hoses

®

Deluxe Eegor

ULTRA Eegor™

Standard Eegor

Bender Set

Standard Eegor

ULTRA Eegor™

Standard Eegor

ULTRA Eegor™

Bender Set

B400LP408S

®

B400DLP408S

®

B400DL

®

B400DLP408S

2-1/2",

3",

3-1/2",

4" sets

2-1/2",

3", 4"

sets

P408S Pump

(2) HC913 Hoses

P408S Pump

(2) HC913 Hoses

Pump and Hose

Not Included

P408S Pump

(2) HC913 Hoses

Bender

Frame

BZ70

includes

cylinder

block, top

and bottom

frame

plates and

frame pivot

assembly

with clevis

eye

1

Adjustable

Compression

Roller

Assembly Pins Cylinder

BZ74

BZ72

includes

all rollers,

top roller

plate

assembly,

and bottom

plate

assembly

double

anchor

frame

pin

BZ76

U-strap

pin

BZ78

bend

shoe

pin

CD3028

Bending

Shoes

BS4000

BS3500

BS3000

BS2500

BS4000

BS3000

BS2500

Follow

Bar U-strap

BFB4000

BFB3500

BFB3000

BFB2500

BFB4000

BFB3000

BFB2500

BZ44 (4")

BZ39 (3-1/2")

BZ34 (3")

BZ28 (2-1/2")

BZ44 (4")

BZ34 (3")

BZ28 (2-1/2")

Page 2

Unpacking

!

Remove all bender shoes, follow bars, U-straps and

pins. Inspect for damage and compare these

components to the complete set shown on page one

for possible missing parts. Depending on which set

you purchased - the basic difference in component

content will be whether you purchased a set having

the 31⁄2" size shoe, follow bar and U-strap included.

Maintenance of your Eegor® Bender

Aside from conventional care of the hydraulic

components, very little maintenance of the Eegor®

bender is required. Removing sand or dirt from

grooves and moving parts will extend bender life and

facilitate ease of operation.

!

Safety Alert Symbol

The symbol above is used in conjunction with a

danger, warning or caution statement. It alerts

operators, supervisors and all personnel that safety

precautions are required during specific operations

and specific conditions. Failure to comply with safety

data could result in serious injury or death.

DANGER

!

Indicates a high probability of death or severe injury or

major property damage could result.

WARNING

!

Indicates serious but less probability of death, sever

bodily injury or major property damage could result.

Lubricate rollers, when needed, with molybdenum

disulfide paste only (such as Dow Corning’s

Molykote #G-n paste, or equivalent). For heavy

use, lubricate rollers weekly. Note: Graphite

formulations are not equivalent lubrication.

Bender Frame Assembly -

Removal, Transporting & Storage

To remove or carry the bender frame assembly—do

so by placing hand on the bottom frame plate. You

should have assistance so that the lifting points are

at the front end and back end of the bottom plate.

CAUTION

!

Avoid pinched fingers by keeping

hands away from the BZ72 roller assembly, which

pivots freely on a pin through the cylinder rod eye and

may swing suddenly aside during handling.

The hydraulic cylinder, cylinder mounting block and

compression roller assembly slide back and forth

between the two frame plates.

This sliding action is a function of the bender design

for locating the cylinder to meet the need of your

particular conduit size; up to a full 90˚ without the need

of another set-up or reposition of the conduit.

The slide action permits the bender assembly to be

collapsed to a shorter length for handling and storage.

When storing, be sure to remove the hydraulic hoses

from the cylinder and install dust caps on the coupler

ports. See the back page for details of storing the

B400DL and B400L models.

CAUTION

!

A less serious alert, but still demands attention to

detail. It indicates a hazardous condition that may

cause minor injuries or property damage.

Introduction

Gardner Bender™ produces twelve versions of the

Eegor® hydraulic conduit bender. Each version uses a

hydraulic cylinder and electrically operated pump to

produce the force necessary to bend conduit sizes

21⁄2" to 4". Differences between model numbers are

based on the accessories included with each model

and the length of the cylinder used to bend the

conduit. Since the process of bending is the same for

all models, the instructions and safety precautions

apply to all application and uses of Gardner Bender™

hydraulic conduit benders.

Bending conduit encounters a wide range of situations

and a variety of conduit materials. Because of the

multiple job specifications, it is not possible to provide

instructions covering every situation. Principal bending

formulas apply to use of the model B400 series

benders. Assembly instructions are specific. Follow

them precisely to ensure safe, reliable and effective

conduit bending.

All instructions are important, but safety alert

symbols are located throughout this manual, and a

separate section is included to address specific

safety concepts.

Before operating Gardner Bender™ conduit benders,

read and understand this entire manual. If any

subjects are not understood, contact Gardner Bender

at 414-352-4160; ask for technical services.

2

Page 3

IMPORTANT—USER SAFETY AND PROTECTION: In setting up systems, take care to select the proper

components and design to ensure appropriate integration with your existing operations and equipment. Observe all

safety measures to avoid the risk of personal injury and damage to property and equipment through improper usage.

CAUTION

!

The Eegor® bender develops 30 tons of force at 9,250

psi. Greater forces will be generated between the

rollers, follow bars and bending shoe. Operators must

follow instructions for assembly and bending conduit

to avoid pinch points and applying forces to incorrect

bender components.

CAUTION

!

Do not use damaged parts to assemble the

Eegor® bender. Items that are damaged or broken

due to extensive wear must be replaced to avoid

potential hazards to the operator.

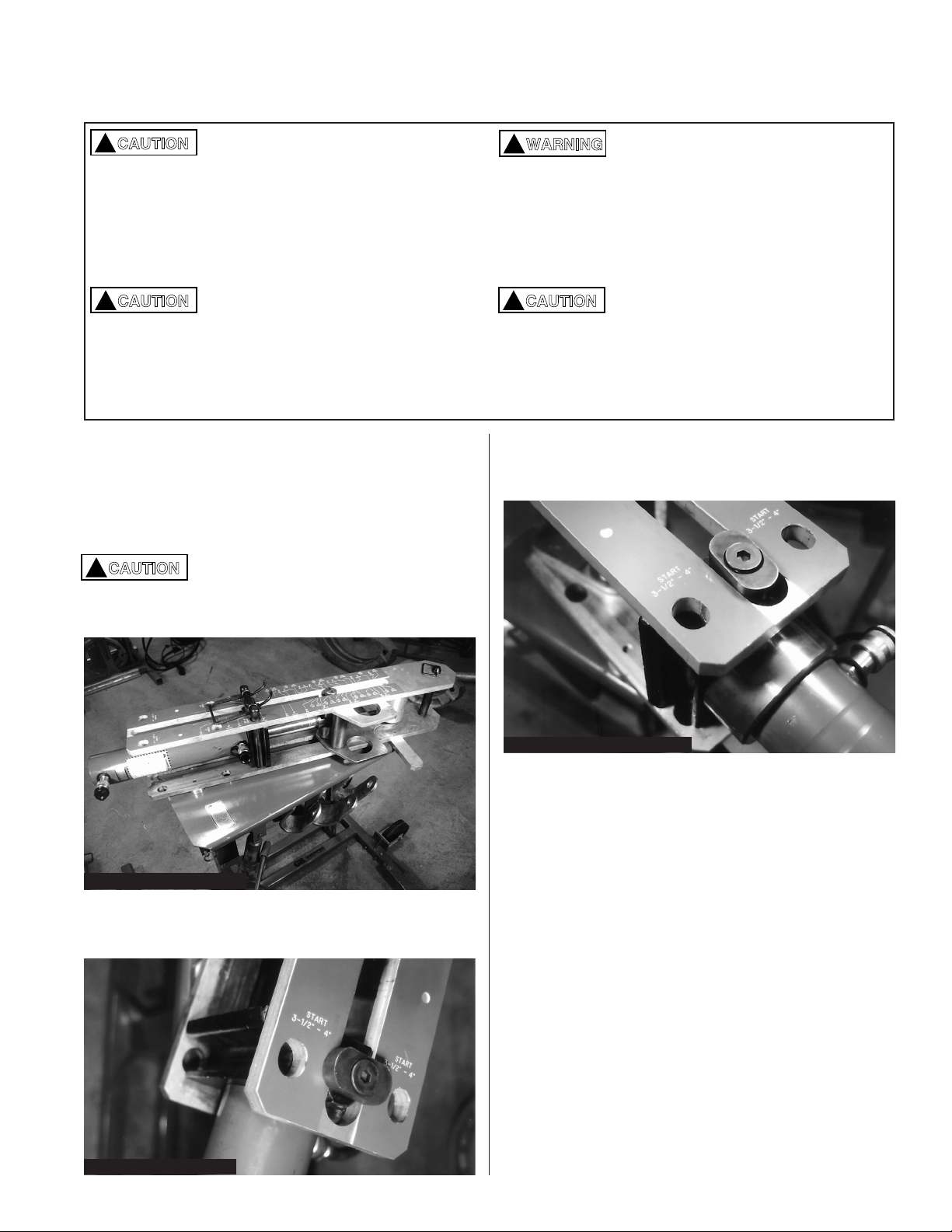

Bender Assembly

A. Frame Assembly

1. Remove the frame assembly and hydraulic

cylinder from the metal case. Place the assembly

on a flat surface. Figure 1.

The cylinder slides within the frame

CAUTION

!

assembly. When lifting or moving,

keep the frames as level as possible

to prevent injury from moving parts.

WARNING

!

Keep hands and loose clothing away from all moving

parts. Frames and rollers move under high pressure.

Do not place hands on conduit or between conduit

and follow bar during operation. Severe injuries could

result.

CAUTION

!

Do not connect or disconnect hydraulic hose fittings

with pressure in the system. A rigid hose indicates the

presence of internal pressure. Prior to electrical or

hydraulic repairs, retract the hydraulic cylinder and

turn off the hydraulic pump.

3. Turn the pivot lock to align it with the slot in the

frame. Lift the top frame off the roller assembly.

Figure 3.

Figure 1: Frame Assembly

2. A pivoting lock holds the top frame in place.

Figure 2.

Figure 2: Lock-on Frame

Figure 3: Removing Top Frame

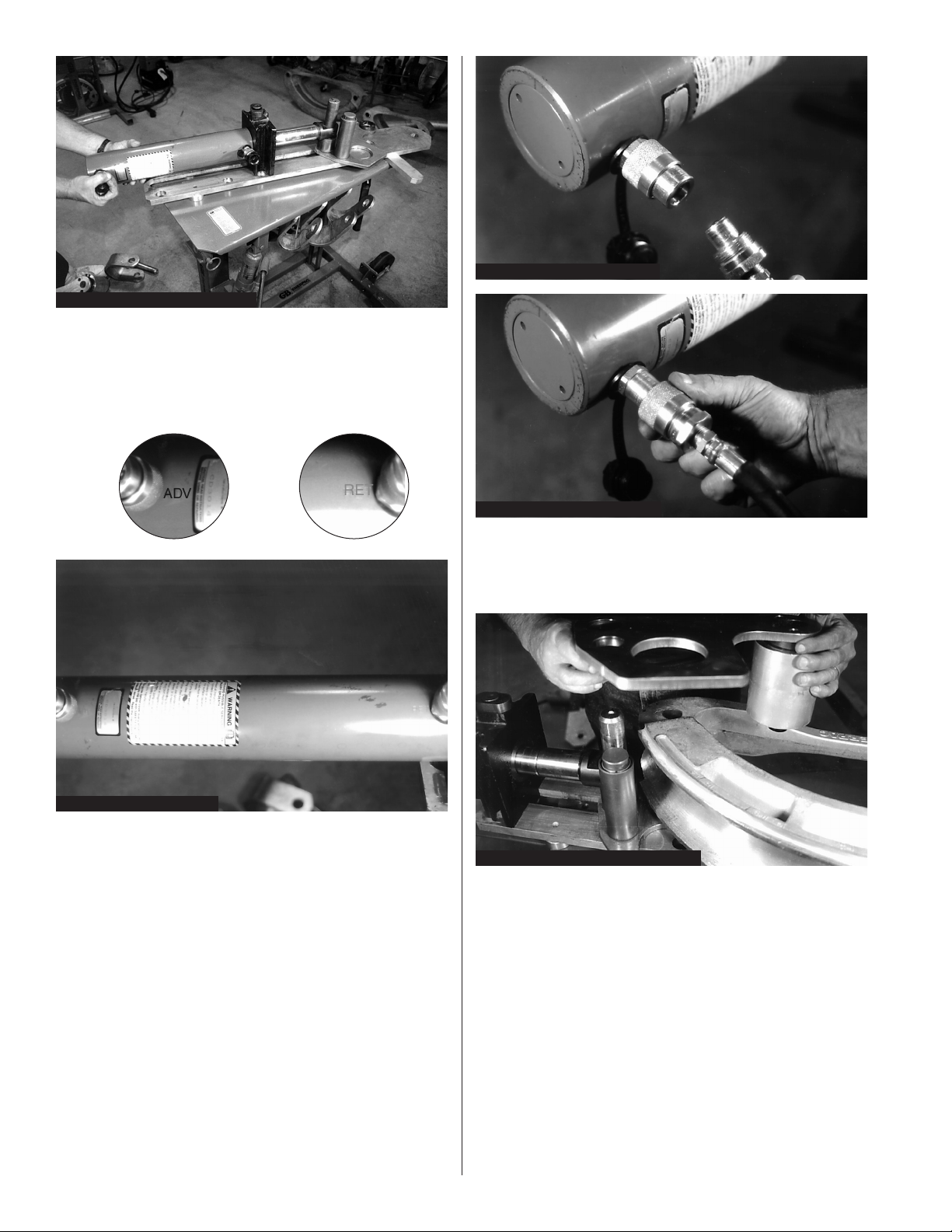

4. Place your foot on the lower frame, grasp the end

of the hydraulic cylinder and pull it toward you.

Align the slots of the cylinder mounting block with

holes in the lower frame that correspond with

conduit size being bent. Figure 4.

NOTE: For model B400L and B400DL align the

cylinder block with the holes for 31⁄2" & 4"

conduit size (last holes in frame). The

cylinder will remain in this position for all

bending sizes and angles to 90˚.

3

Page 4

Figure 4: Moving Cylinder Frame

5. Install the two hydraulic hoses. Apply one wrap of

teflon tape to the threads on the end of the hose.

Remove the pipe plugs from the pump valve, one

port is marked “ADV” the other is marked “RET”.

Install a hose in each port. Figure 5.

Figure 6A: Installing Couplers

Figure 6B: Installing Couplers

7. Remove the upper roller and plate assembly by

pulling straight up. The upper plate and large

aluminum roller are a single assembly. Figure 7.

Figure 5: Hose Installation

6. Connect the hose from the “ADV” port to the

hydraulic cylinder coupler located near the base

of the cylinder. Make sure there is no dirt or

debris in either half prior to assembly. Push the

hose coupler firmly into the cylinder coupler, then

tighten coupler collar. Connect the hose from the

“RET” port to the remaining cylinder coupler.

Figure 6A & 6B.

IMPORTANT: The hose coupler must be firmly

seated in the cylinder coupler and held

tightly while turning the coupler collar.

Hand tighten the collar. Do not use

tools to tighten. Failure to properly

assemble couplers will inhibit oil flow.

Figure 7: Upper Roller Plate Removal

8. The lower plate and roller assembly remain

in position during normal shoe and follow

bar installation.

Bending Shoe and

Follow Bar Installation

A. Model B400L and Model B400DL Ultra Eegor™

1. The B400L and B400DL use a 28" hydraulic

cylinder. As a result, the upper and lower plate

assemblies use the 31⁄2"–4" frame holes for

mounting all sizes of conduit bending shoes. See

figure 8. For smaller sizes of conduit, the cylinder

plunger must be advanced to position the roller

assembly against the follow bar.

4

Page 5

Figure 8: Locating B400L Hydraulic Cylinder

Figure 11: Top Plate Installation

2. Position the desired size shoe on top of the lower

roller and plate assembly. Be sure the bend angle

numbers are facing up. Figure 9.

Figure 9: Positioning Bend Shoes on B400L

3. The top plate and roller assembly is installed over

the shoe. Prior to installation, move the indicator

knob to the “C” position for rigid or IMC conduit;

the “T” position for EMT (thinwall). Figure 10.

NOTE: The roller assembly axle may not engage the

collar initially. To ensure proper engagement,

move the indicator knob slightly until the axle

seats properly. Figure 12.

Figure 12: Correct Upper Plate Position

5. Move the bend shoe to align the pivot hole with

the hole in the bottom frame. If the shoe is too far

away, start the hydraulic pump. Advance the

cylinder until the pivot hole is located under the

frame hole. Install the pivot pin (BZ78). Figure 13.

Figure 10: Position Indicator Knob to “C” or “T”

4. The large roller axle has two flats which engage

the retaining collar on the lower plate. Press the

upper plate down until the lower roller axles are

flush with the top plate holes and the flats of

the upper roller shaft are firmly seated in the

retaining collar.

Figure 13: Hole Alignment Pivot Pin BZ78

6. Install the “U” strap. Be sure the U-strap size

matches the bend shoe size. The stamped

numbers must face up. Position the “U” strap and

secure with pin BZ76. Figure 14.

5

Page 6

Figure 14: Installing “U” Strap & Pin

B. Model B400 and B400D

1. The B400 and B400D use a hydraulic cylinder with

a 14" stroke. As a result, the cylinder mounting

block must be moved to the holes in the frame that

match the size conduit being bent. Figure 15.

Figure 15: Model B400 & B400D Cylinder Block Locations

2. Slide the cylinder along the bottom frame until the

cylinder mounting block grooves are aligned with

the desired holes in the lower frame.

3. Position the bend shoe on top of the lower roller

plate. Be sure the bend angle numbers are

facing up. Figure 16.

Figure 17: Position of Indicator Knob

5. The axle for the large roller (upper plate

assembly) has two flats which engage the retainer

of the lower plate assembly. Press the upper roller

down until the lower roller axles are flush with the

top plate. The flats on the upper roller axle must

fully seat into the retainer collar. Figure 18.

NOTE: The roller assembly may not fully seat on the

first attempt. To ensure proper engagement,

move the indicator knob (slightly) until the

axles of the lower rollers are through the top

plate and flush with the top of it.

Figure 18: Top Plate Installation

6. Move the bend shoe to align the pivot hole with

the hole at the end of the lower frame. Figure 19.

Figure 16: Installing Bend Shoe

4. The top plate and roller assembly are installed

over the bend shoe. Prior to installation, be sure

to move the indicator knob to either “C” for Rigid/

IMC or “T” for EMT (thinwall) conduit. Figure 17.

Figure 19: Bend Shoe Pivot Hole

bend shoe. Install the retaining pin (BZ78) through

the upper frame, bend shoe, and lower frame.

Secure with hairpin cotter. Figure 20.

6

Page 7

7. Position the upper frame over the shoe assembly.

Align the single pivot hole with the pivot hole in the

Figure 20: Install Frame & Pin

8. Turn locking pivot on cylinder block until it is

positioned across the slot in the frame.

9. Place the “U” strap on the end of the bend shoe.

Be sure the number, stamped in the strap, is

facing up. Secure with “U” strap pin BZ76.

Figure 21.

The “U” strap pin (BZ76) must be

CAUTION

!

through the top hole, bend shoe and

bottom hole of “U” strap. If the bottom

hole is not engaged, the “U” strap will

be damaged during bending.

2. Install the double anchor pin (BZ74) by inserting it

in the holes of the upper frame, through the block

grooves and through the holes of the lower frame.

Figure 23.

Figure 23: Double Anchor Pin Installation

3. Slide conduit into the shoe groove and through the

“U” strap. At least 2-3 inches of conduit must

extend beyond the “U” strap to avoid deforming

the end of the conduit. Figure 24.

Figure 21: “U” Strap & Pin Installed

Bending Conduit

A. B400 and B400D

1. The cylinder mounting block has a groove along

each side to accept the double anchor pin. Move

the hydraulic cylinder until the grooves in the

mounting block are aligned with holes in the

frame. The numbers next to the holes must agree

with the conduit size being bent. Figure 22.

Figure 22: Start Holes for Conduit Sizes

Figure 24: Installing Conduit in Shoe & “U” Strap

4. Insert the correct follow bar, tapered end first,

between the rollers and conduit. The follow bar

must be firmly seated against the “U” strap. A

follow bar is used for all types of conduit.

Figure 25.

Figure 25: Follow Bar Installed

7

Page 8

To prevent damage to the follow bar,

CAUTION

!

be sure the follow bar is inserted

tapered end first and rests against

the “U” strap. When installing the follow

bar, the numbers engraved into the

bar must face up.

5. If the follow bar will not fit between the roller

assembly and the conduit, the rollers will have to

be moved. Turn the pump on. Press the “Retract”

button momentarily to move the rollers back.Turn

pump off. Push follow bar into position against the

“U” strap.

6. Prior to pressing the advance button, hold the end

of the follow bar in place by pushing it forward.

Do not place fingers between follow

CAUTION

!

bar and conduit. Severe injury

will result.

7. Press “Advance” button to begin bending. Once

follow bar engages all rollers and bend begins, let

go of the follow bar. Continue holding the

“Advance” button until the bend is complete or the

cylinder reaches maximum length.

8. Large 3", 31⁄2", and 4" conduit require two cycles

of the hydraulic cylinder. When the first stage is

complete the cylinder will stop and the pump

motor will begin to stall. Release the “Advance”

button. Press return (momentarily) to release

pressure on the anchor pin. Do not remove the

conduit shoe or follow bar from the bender.

Reading Bend Angles

1. Bend angles are printed on the upper frame decal.

Locations exist for Rigid, IMC and EMT conduit.

Locate the mark indicating the type of conduit and

the angle desired. Figure 27.

Figure 27: Angle Indicator

2. During the bend the bronze roller shaft travels

through the slot in the upper frame. A line is

scribed on the shaft. When the line on the shaft

reaches the bend angle you have selected, the

bend is complete.

B. B400L and B400DL

1. The cylinder mounting block must be positioned

at the 3

Figure 28.

1

⁄

"–4" holes of the upper frame.

2

9. Lift and remove the anchor pin. Press “Retract”

button until cylinder mounting block grooves are

aligned with holes marked 21⁄2". Replace the

anchor pin through the top frame, cylinder block

and lower frame. Figure 26.

Figure 26: Final Bend Angle Procedure

To avoid damaging the anchor pin, be

CAUTION

!

sure both pin shafts protrude through

the holes in the lower frame.

10. Press “Advance” button until bend is complete.

Figure 28: Cylinder Position B400L & B400DL

2. Position the bending shoe (numbers facing up) on

the lower roller plate. Install the upper roller plate

assembly. Be sure the lower roller axles are flush

with the top of the upper roller plate.

3. Place the upper frame on the cylinder block so the

lock tab and the roller axle are located in the

center groove of the frame. Position the hole (in

the far end) over the pin hole in the bending shoe.

4. Insert the bend shoe pin (BZ78) through the upper

frame, bend shoe and lower frame. Insert the

retaining pin into the hole at the bottom of the

bend shoe pin. Figure 29.

8

Page 9

Figure 29: Upper Frame Shoe & Lower Frame Pinned Together

5. Install the double anchor pin (BZ74) through the

two holes marked “Start” 31⁄2"–4". Both legs of the

pin must extend through the top frame, the

cylinder block and through the lower frame.

Figure 30.

To avoid damaging the follow bar, rest

CAUTION

!

it against the “U” strap. Do not attempt

to bend conduit if a gap exists

between the follow bar and “U” strap.

Figure 32: Follow Bar Installation

8. Turn pump on. Press the pendant button to

“Advance”. Push on the rear of the follow bar until the

conduit and follow bar begin traveling through the

rollers. Figure 33.

NOTE: Consult older instructions for Eegor® models

without bend angle decal on frame.

Figure 30: BZ74 Installation

6. The “U” strap attaches to the bending shoe by

first placing the strap over the shoe, then inserting

the strap retaining pin (BZ76). Be sure the conduit

size number is facing up and the retaining pin is

protruding through the bottom of the “U” strap.

Figure 31.

Figure 31: “U” Strap & Pin Installation

7. Slide conduit into the shoe groove until it enters

the “U” strap and protrudes a minimum of 2"

beyond the “U” strap. The mark placed on the

conduit must be visible at the outer edge of the “U”

strap. Slide the follow bar (tapered end first)

between the conduit and roller assembly.

Figure 33: Begin Bending

9. To determine bend angles, watch the scribed

marks on the roller shaft as it travels past the white

numbers on the red decal. The decal is marked for

all angles and for IMC, Rigid, and EMT conduit.

Locate your specific angle and conduit type on the

decal. When the roller shaft reaches the angle you

desire, release the pendant button.

Figure 34: Angle Indicator

9

Page 10

10. To remove bent conduit, press the “Retract” button

and hold it until the conduit returns to the starting

position.

When the conduit returns to the

CAUTION

!

starting position, the conduit and

follow bar become loose enough to fall

out of the bender. Grab the follow bar

to prevent it from falling out of the

roller assembly.

11. Remove the follow bar, then remove the bent

conduit from the roller assembly. Turn pump off.

Figure 35: Removing Conduit

2. Once close to the follow bar, remove the U-strap by

pulling the pin. Figure 37.

3. Assist follow bar out by retracting the bend shoe

further while pulling out the follow bar with your

free hand. Figure 38.

4. For standard Eegor® models, the double pin will

always end in the same frame holes it started in.

Figure 37

Follow Bar

Synchronization - Removal

Occasionally your follow bar may become out of

synchronization with the movement of the bend shoe

on the return cycle.

If this happens, care should be taken by visual

inspection as you are retracting the cylinder. Figure 36

illustrates what to look for in an out-of-phase

condition. You will note the follow bar slipped forward

over the strap, rather than the front end of follow bar

remaining behind the strap.

Figure 36

Procedure for Removal

1. After completing desired bend, retract the bend

shoe until the strap is close to the follow bar as

shown in figure 36. Do not retract further or make

contact with the U-strap against the follow bar or

breakage could occur.

Figure 38

90° Stub-up and Kick Bend Instructions

Bend Angle

Rise

(H) 15° 30° 45° 60° 90°

2 73⁄ 4 4 213⁄ 16 25⁄ 16 2

4 157⁄ 16 8 511⁄ 16 45⁄ 8 4

6 233⁄ 16 12 81⁄ 2 615⁄ 16 6

8 3015⁄ 16 16 115⁄ 16 91⁄ 4 8

10 385⁄ 8 20 141⁄ 8 119⁄ 16 10

12 463⁄ 8 24 17 137⁄ 8 12

14 541⁄ 16 28 1913⁄ 16 163⁄ 16 14

16 6113⁄ 16 32 225⁄ 8 181⁄ 2 16

18 699⁄ 16 36 257⁄ 16 2013⁄ 16 18

20 771⁄ 4 40 285⁄ 16 231⁄ 8 20

22 85 44 311⁄ 8 253⁄ 8 22

24 923⁄ 4 48 3315⁄ 16 2711⁄ 16 24

26 1007⁄ 16 52 363⁄ 4 30 26

28 1083⁄ 16 56 395⁄ 8 325⁄ 16 28

30 11515⁄ 16 60 427⁄ 16 345⁄ 8 30

Set-back Chart

Nominal “S” Set-back Dimension (inches)

Conduit Stub-ups

Siz e

21⁄ 2 155⁄ 8 91⁄ 8 6 33⁄ 8 15⁄ 8

3 183⁄ 4 11 71⁄ 8 4 13⁄ 4

31⁄ 2 24 133⁄ 4 87⁄ 8 47⁄ 8 17⁄ 8

4 28 161⁄ 4 103⁄ 8 51⁄ 2 17⁄ 8

90° 60° 45° 30° 15°

Diagonal Distance (D) Chart

Kick Bends

10

Page 11

To Make a Stub-up or Kick Bend

1. Determine “H” dimension by measuring rise

or height needed. From “Diagonal Distance

Chart” at right, determine straight length of

pipe (D) needed to reach to desired turn-up

height (H) at desired bend angle.

Turn-up

or

Rise (H)

D

Angle

D

S

2. Lay off this distance (D) from end of conduit

and make first mark.

3. From “Set-back Chart”, select proper

2nd Mark (Position leading edge of U-Strap at this mark.)

1st Mark

set-back dimension (S) corresponding to

conduit size and bend angle desired.

4. Measure distance (S) back from the first mark and make second mark (see figure above).

5. Place conduit in bender with second mark aligned with leading edge of U-strap (see figure above) and bend

conduit to desired angle.

Additional Bending Data for Eegor® Benders

A

B

C

“Developed Length” of Bends Chart

Nominal

Conduit

Size

21⁄ 2 163⁄ 8 1015⁄ 16 83⁄ 16 57⁄ 16 23⁄ 4

3 201⁄ 4 131⁄ 2 10

1

3

4 313⁄ 8 2015⁄ 16 1511⁄ 16 107⁄ 16 51⁄ 4

90° 60° 45° 30° 15°

⁄2 24

7

⁄ 16 185⁄ 16 133⁄ 4 91⁄ 8 49⁄ 16

“Developed Length" of Bends

(inches)

1

⁄8 63⁄4 33⁄8

“Gain” of Bends Chart

Developed Length of Bend:

When conduit is bent, the length along the bend at the neutral

axis (i.e., approximately the centerline of the pipe) is commonly

called “developed length” of the bend.

Nominal

Conduit

Size

21⁄ 2 53⁄ 16 11⁄ 2

3 63⁄ 8 17⁄ 8

31⁄ 2 87⁄ 16 27⁄ 16 11⁄ 8

4 911⁄ 16 23⁄ 4 15⁄ 16

90° 60° 45° 30° 15°

“Gain” of Bends

Measured at Centerline (inches)

3

⁄ 4

7

⁄ 8

5

⁄ 16

3

⁄ 8

1

⁄ 2

9

⁄ 16

1

⁄ 8

1

⁄ 8

1

⁄ 8

3

⁄ 16

Gain of Bend:

The difference between the “squared off” distance (AB + BC) around a corner and the “developed length” (AC)

along a bend is commonly called “gain” of the bend. (Measurements should be made at the pipe centerline.)

Offset Bend Instructions

for the Eegor® Bender

Bending Offsets

Offset bending is easy with the added

benefit of bending good close offsets.

A. To bend the offsets, proceed to bend

in the normal manner covered above

Figure 39

until the desired bend is reached.

See Figure 39.

Figure 40

B. Retract and strip out conduit. Rotate the conduit and locate as shown for the second bend. Complete the

second bend, retract and strip out conduit for a good offset bend.

When making offset bends, caution should be taken not to attempt too tight an offset. The follow bar will

lift off the conduit when starting the second bend if it is too tight. Stop bending immediately or damage

could occur to the bender. Correction is achieved by shifting the conduit so the U-strap engages the

conduit more closely to the unbent portion of the conduit.

11

Page 12

Bender

21⁄ 2" Conduit Offset Chart

B

Offset

or

Rise (H)

Angle

B

2nd Mark

1st Mark (on other side of conduit)

To Make an Offset Bend:

1. Make first mark at location determined either by edge of obstacle or

by following “Kick Bend Instruction for Eegor® Benders” (page 11).

Desired

Offset (H)

(inches) 15° 30° 45° 60°

2 75⁄ 8 – – –

4 153⁄ 8 – – –

6 231⁄ 16 1111⁄ 16 – –

8 3013⁄ 16 1511⁄ 16 – –

10 381⁄ 2 1911⁄ 16 137⁄ 16 –

12 461⁄ 4 2311⁄ 16 161⁄ 4 –

14 54 2711⁄ 16 191⁄ 16 145⁄ 8

16 6111⁄ 16 3111⁄ 16 217⁄ 8 1615⁄ 16

18 697⁄ 16 3511⁄ 16 243⁄ 4 191⁄ 4

20 773⁄ 16 3911⁄ 16 279⁄ 16 219⁄ 16

22 847⁄ 8 4311⁄ 16 303⁄ 8 237⁄ 8

24 925⁄ 8 4711⁄ 16 333⁄ 16 263⁄ 16

26 1003⁄ 8 5111⁄ 16 361⁄ 16 281⁄ 2

28 1081⁄ 16 5511⁄ 16 387⁄ 8 3013⁄ 16

30 11513⁄ 16 5911⁄ 16 4111⁄ 16 331⁄ 8

Measurement (B)

(inches)

2. From the “Offset Chart” for the size of conduit to be bent, obtain

measurement (B) for offset height (H) and bend angle desired.

3. Make second mark at distance (B) beyond first mark and on opposite side of conduit as

illustrated above.

4. Place conduit in Eegor® bender with first mark aligned with leading edge of U-strap (see figure above) and

make first bend to the desired angle.

5. Advance the bent conduit through the frame assembly of the Eegor® bender and rotate the conduit 180°, so

the second mark aligns with the leading edge of the U-strap.

6. Complete offset by making second bend to the exact same angle as the first bend.

3" Conduit Offset Chart 31⁄ 2" Conduit Offset Chart 4" Conduit Offset Chart

Desired

Offset (H)

(inches) 15° 30° 45° 60°

2 75⁄ 8 – – –

4 155⁄ 16 – – –

6 231⁄ 16 115⁄ 8 – –

8 303⁄ 4 155⁄ 8 – –

10 381⁄ 2 195⁄ 8 131⁄ 4 –

12 461⁄ 4 235⁄ 8 161⁄ 16 –

14 5315⁄ 16 275⁄ 8 187⁄ 8 –

16 6111⁄ 16 315⁄ 8 213⁄ 4 165⁄ 8

18 697⁄ 16 355⁄ 8 249⁄ 16 1815⁄ 16

20 771⁄ 8 395⁄ 8 273⁄ 8 211⁄ 4

22 847⁄ 8 435⁄ 8 303⁄ 16 231⁄ 2

24 925⁄ 8 475⁄ 8 331⁄ 16 2513⁄ 16

26 1005⁄ 16 515⁄ 8 357⁄ 8 281⁄ 8

28 1081⁄ 16 555⁄ 8 3811⁄ 16 307⁄ 16

30 1153⁄ 4 595⁄ 8 411⁄ 2 323⁄ 4

Measurement (B)

(inches)

Desired

Offset (H)

(inches) 15° 30° 45° 60°

2 79⁄ 16 – – –

4 155⁄ 16 – – –

6 23 – – –

8 303⁄ 4 151⁄ 2 – –

10 381⁄ 2 191⁄ 2 – –

12 463⁄ 16 231⁄ 2 – –

14 5315⁄ 16 271⁄ 2 185⁄ 8 –

16 6111⁄ 16 311⁄ 2 211⁄ 2 –

18 693⁄ 8 351⁄ 2 245⁄ 16 –

20 771⁄ 8 391⁄ 2 271⁄ 8 –

22 847⁄ 8 431⁄ 2 2815⁄ 16 –

24 929⁄ 16 471⁄ 2 3213⁄ 16 251⁄ 4

26 1005⁄ 16 511⁄ 2 355⁄ 8 279⁄ 16

28 108 551⁄ 2 387⁄ 16 297⁄ 8

30 1153⁄ 4 591⁄ 2 411⁄ 4 323⁄ 16

Measurement (B)

(inches)

Desired

Offset (H)

(inches) 15° 30° 45° 60°

4 155⁄ 16 – – –

6 23 – – –

8 303⁄ 4 – – –

10 387⁄ 16 197⁄ 16 – –

12 463⁄ 16 237⁄ 16 – –

14 5315⁄ 16 277⁄ 16 – –

16 615⁄ 8 317⁄ 16 215⁄ 16 –

18 693⁄ 8 357⁄ 16 241⁄ 8 –

20 771⁄ 8 397⁄ 16 27 –

22 8413⁄ 16 437⁄ 16 2913⁄ 16 –

24 929⁄ 16 477⁄ 16 325⁄ 8 2415⁄ 16

26 1005⁄ 16 517⁄ 16 357⁄ 16 271⁄ 4

28 108 557⁄ 16 385⁄ 16 299⁄ 16

30 1153⁄ 4 597⁄ 16 411⁄ 8 317⁄ 8

Measurement (B)

(inches)

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest Gardner Bender Service Center. The

Gardner Bender Service Center will provide complete and prompt service on all Gardner Bender products.

PARTS AND SERVICE: For quality workmanship and

genuine Gardner Bender parts, select an Authorized

GB Service Center for your repair needs. Only repairs

performed by an Authorized Service Center displaying

the official GB Authorized sign are backed with full

factory warranty. Contact GB Electrical (414)352-4160

for the name of the nearest GB Authorized Service

Center.

WARRANTY: Gardner Bender warrants its product

against defects in workmanship and materials for 1

year from date of delivery to user. Chain is not

warranted. Warranty does not cover ordinary wear and

tear, abuse, misuse, overloading, altered products or

use of improper fluid.

WARRANTY RETURN PROCEDURE: When

question of warranty claim arises, send the unit to the

nearest GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

Gardner

P.O. Box 3241 • Milwaukee, WI 53201-3241 • Phone: (414) 352-4160 • FAX (414) 352-2377

12

RPS-0023 0510

Loading...

Loading...