Page 1

Gardner

Bender

Instruction

Sheet

IMPORTANT RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage. If any shipping

damage is found, notify carrier at once. Shipping damage is NOT covered by warranty. The carrier is responsible for

all repair or replacement costs resulting from damage in shipment.

IMPORTANT USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken

to select the proper components and design to insure appropriate integration with your operations and existing

equipment and that all safety measures have been taken to avoid the risk of personal injury and property damage

from your application or system.

GB ELECTRICAL CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE,

MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact GB Electrical for guidance when you are

in doubt as to the proper safety precautions to be taken in designing and setting up your particular application.

Cyclone

Serial Numbers Begining With “E”

B2000

®

Bender

Description

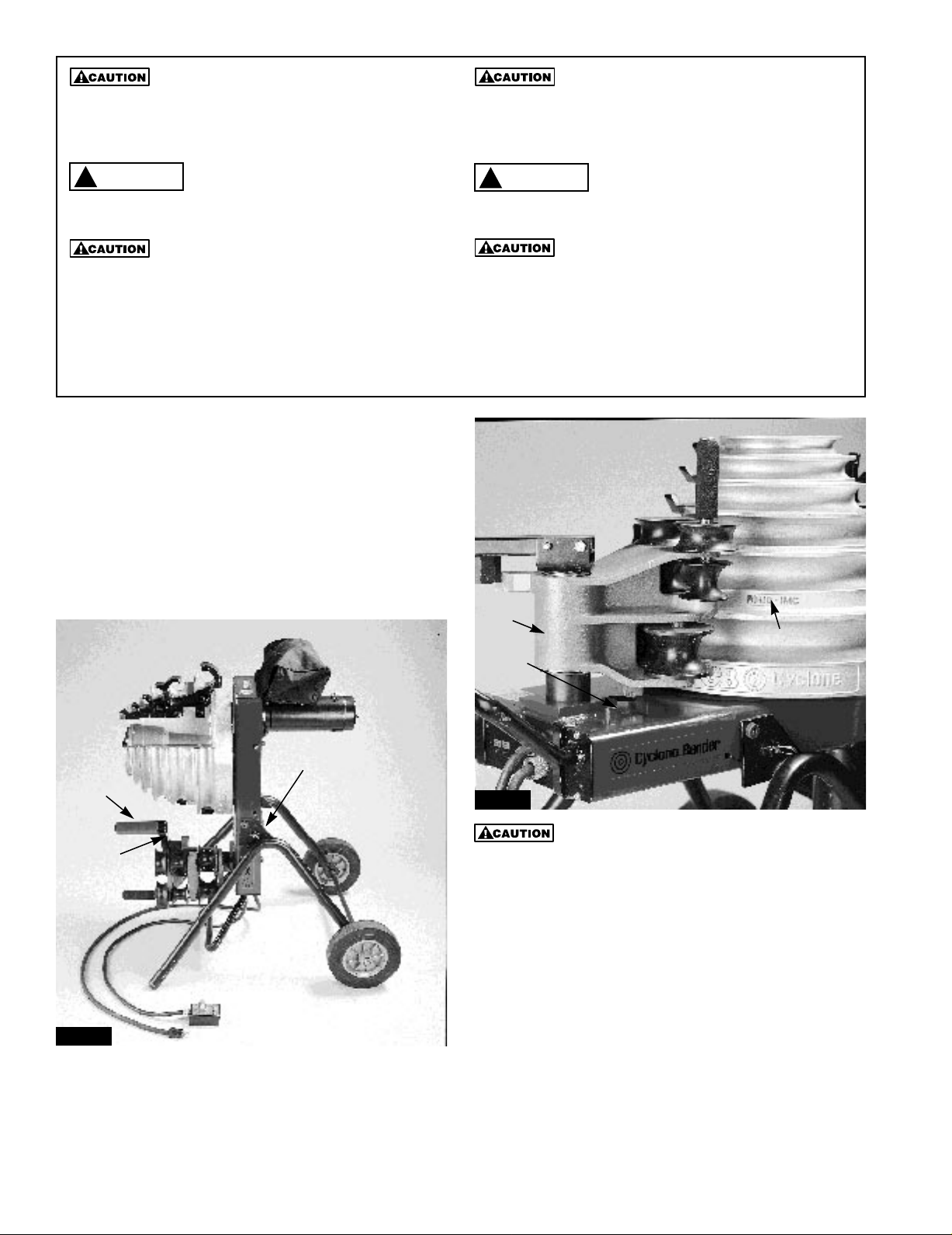

The Cyclone®, GB model B2000 production bender is

used to bend EMT, IMC, rigid steel or rigid aluminum

conduit. A single bending shoe accommodates sizes

1

⁄2", 3⁄4", 1", 11⁄4", 11⁄2" and 2" conduit. The shoe is

driven by a 115 volt, 15 amp motor. The roller housing

consists of a single urethane roller and support arm,

also three sets of nylon rollers.

The bender control pendant consists of a zero light, an

override push button and a two-position toggle switch

for “Bend and Return”.

An 8-ft electrical cord connects the pendant to the

bender frame.

The bender can be used in a horizontal or

vertical position.

To avoid damaging the bender control circuit, an input

voltage sensing system is built into the control circuit. If

input voltage is less than 92V AC or higher than

132V AC the bender will shut off. One of the two lights

located on the end plate will light to indicate whether

high or low voltage exists.

Re-set the bender by unplugging the power cord, and

plugging it in again. If the incoming current voltage has

not been corrected, the bender will continue to shut off.

The voltage range must be within 92V AC to 132V AC.

Any situation which causes a voltage drop or increase

must be corrected before using the B2000 Bender.

Voltage drops may be caused by:

• Extension cords that are too long.

• Extension cords made of light (16-18 gauge) wire.

• Multiple power tools on a single circuit.

• Other devices which require high amperes to operate.

Bending

Shoe

Specifications

Power Source.............................120V 60 cycle AC

Pendant Control Circuit..............12V DC

Motor..........................................1 h.p. 100V 60 cycle

Weight........................................345 lbs.

Height.........................................38 inches

Width..........................................31 inches

Length ........................................45 inches

Fuses, Time Delay .....................15 Amp

Bend Capability..........................1⁄2" - 2" IMC, EMT

Upper Roller

Frame

Stop

High/Low

Voltage

Indicator

Pendant Control

Rigid Steel or Rigid

Aluminum

DC

Page 2

During pipe bending, stand behind the frame handle.

Keep hands, clothing and control cord away from the

bending shoe and rollers.

Select an operating area large enough to permit

loading pipe section and bending without striking

objects or personnel.

WARNING

!

Do not locate the bender on damp or wet surfaces. Do

not stand on wet surfaces while operating the bender.

To prevent damage to the bending shoe, do not allow

the clamping jaws to strike the upper roller support arm

when the shoe is rotating. Position the roller housing

against the frame stop. See Figure 1.

WARNING

!

To avoid possible injury, do not place fingers under the

bottom edge of the bending shoe. See Figure 2.

Do not attempt to bend conduit or pipe other than 1⁄2"

through 2" IMC, EMT, rigid steel or aluminum. Bending

other materials will damage the bender and void the

warranty.

NOTE: All operations referring to “toward the operator” are viewed from the lifting handle end of the

bender frame.

Operation

Bending 1⁄2", 3⁄4" and 1" IMC, EMT and

rigid conduit.

1. Position the bender in a level dry area large enough

to permit loading and unloading various lengths of

conduit. Plug power cord into a 115 volt outlet.

Position the frame, either horizontally or vertically,

by pulling the spring loaded pin on the side of the

bender frame. See Figure 1.

Vertical Position

Roller

Housing

Material Idetifier

Frame

Stop

Positioning Pin

Upper Roller

Support Arm

Figure 1

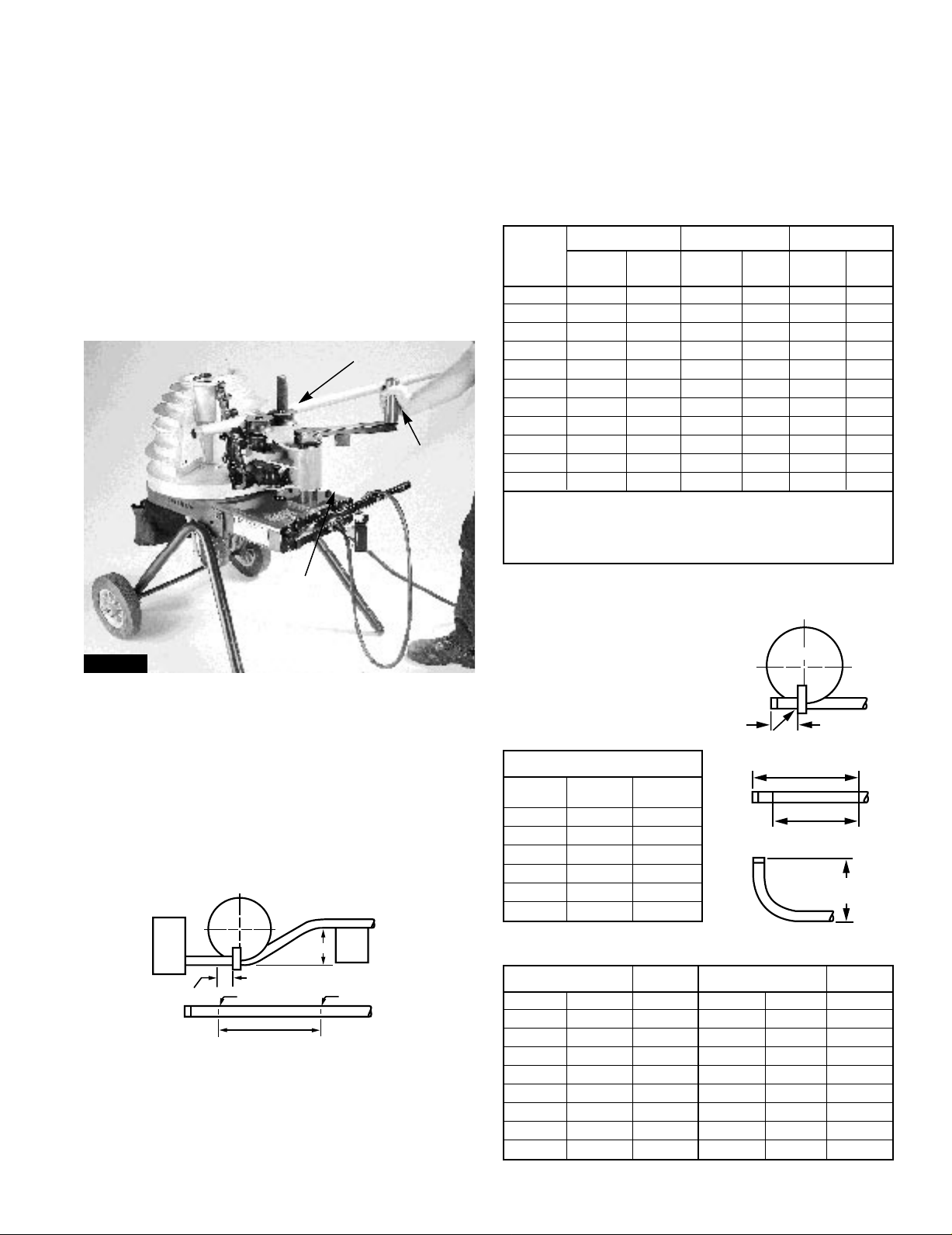

2. Identify the type (IMC, EMT or Rigid) and size

conduit to be bent.

3. Locate the markings that indicate which grooves are

used for specific materials, and which grooves are

used for specific size conduit. See Figure 2.

Figure 2

To avoid damaging the rollers and roller housing, always

place the roller housing against the frame stop prior to

rotating the shoe.

4. Push the roller housing against the frame stop.

See Figure 2. Rotate the shoe to bring the required

grooves (EMT, IMC or Rigid) facing toward the

operator. To activate the shoe, hold the pendant

toggle switch in “Return” and press the override

button until the zero light goes out. The shoe will

rotate and stop in the load position. The zero light

will come on.

5. The upper urethane roller and support arm (figure 3)

is used for bending 1⁄2" through 1" conduit . One of

the top three shoe grooves will be used, depending

on conduit size.

2

Page 3

Jaw

Figure 3

Bend Groove

Frame Stop

6. When bending 1⁄2" - 1" conduit the upper roller and

support arm must be positioned between the shoe

and the roller housing. Position the urethane roller

by moving the roller housing against the frame stop

and removing the pin.

7. Lift the roller support arm to clear the nylon rollers

and swing the arm (toward shoe) over the roller

housing. Lower the arm into the support bracket and

insert the ring pin. See Figure 4.

9. Each time a different size and type of conduit is

being bent, three facts must be determined and set

into the bender shoe control system. The required

settings are: conduit size, material and desired bend

angle. Prior to setting, be sure the desired size

indicator scale is toward the operator and the

correct shoe grooves are also toward the operator.

a. Lift the angle knob locking handle (figure 5).

Use the two small knobs to rotate the angle

disc, clockwise, until the red zero line is directly

in line with the zero line on the size scale.

b. Set the bender for specific conduit size by

turning the angle disc until the red line is on the

size indicator mark which matches the size

conduit being bent. Be sure the correct size

indicator is being used (EMT, lMC, or Rigid).

c. Move the bend angle knob (figure 5) until the

flat edge of the pointer is on a line indicating the

exact degree of bend desired. Lower the center

handle to lock the pointer and scale and to

prevent inadvertent movement during bending.

Locking Handle

Angle Set Knob

Rotating

Knob

Roller

Support Arm

Figure 4

8. Insert the conduit in the shoe groove marked with

the number matching the size conduit being bent.

The conduit must set in the shoe and in the jaw. The

end of the conduit must extend a minimum of 2"

beyond the jaw. See Figure 3. Refer to table A or B

on page 5 for bending data.

Angle

Indicator

Disk

Figure 5

Size Indicator

10. Activate the bending shoe by holding the pendant

control toggle switch in the “Bend” position. The

shoe will rotate until the angle set on the indicator

is reached.

11. To remove the conduit, hold the toggle switch in

“Return”. The shoe will return to the start position

and stop automatically. The zero set light will come

on. Bending more conduit of the same type and size

is accomplished by loading conduit and pressing the

toggle switch.

3

Page 4

Bending 11⁄4”, 11⁄2” and 2” Conduit

NOTE: All operations referring to “toward the operator”

are viewed from the lifting handle end of the bender

frame.

1. Bending 11⁄4" through 2" requires using one of the

three sets of nylon rollers and one of the grooves on

the lower half of the bending shoe.

2. Move the roller housing against the frame stop

(figure 10). The upper urethane roller must be on the

outside (toward frame handle) of the roller housing

(figure 6). If it’s not, pull the ring pin. Lift

the roller support arm, swing it over the roller

housing, lower the handle into the bracket and insert

the ring pin.

Nylon Rollers

Upper

Urethane Roller

Upper Urethane Roller

Nylon Rollers

Figure 6

Frame Handle

To avoid damage to the bending shoe, always place

the roller housing against the frame stop, prior to

activating the bending shoe.

3. Check the bending shoe to be sure the correct

grooves for the conduit being bent are facing toward

the operator. If the shoe must be rotated, hold the

pendant control toggle switch in “Return” and press

the override button until the zero light goes out. The

shoe will rotate 180° then stop in the load position

(figure 7).

4. When bending 11⁄4" - 2"

conduit, position roller

Zero Light

Override Button

housing and upper arm.

Then push the conduit

between the shoe groove

and the 2" nylon rollers

until the bend mark on the

conduit is in line with the

outside edge of the

clamp jaw.

5. Grasp the upper urethane

roller and move the support

Figure 7

Toggle

Switch

arm counterclockwise until

it contacts the roller housing. The two nylon rollers

should have moved against the conduit and should

firmly hold the conduit in the shoe (figure 8).

Figure 8

6. Each time a different size and type of conduit is

being bent, three facts must be determined and set

into the bender shoe control system. The required

settings are: conduit size, material and desired bend

angle. Prior to setting, be sure the desired size

indicator scale is toward the operator and the

correct shoe grooves are also toward the operator.

a. Lift the angle knob locking handle to release the

angle set knob and angle indicating disc. Use

the two small knobs to rotate the angle disc,

clockwise (figure 9).

b. Set the bender for specific conduit size by

turning the angle disc until the red line and

pointer are on an outer size indicator mark

which matches the size conduit being bent

(figure 9). Be sure the correct size indicator is

being used (EMT, lMC, or Rigid).

c. Move the bend angle knob (figure 9) until the

flat edge of the pointer is on the line indicating

the exact degree of bend desired. Lower the

center handle to lock the pointer and scale

and to prevent inadvertent movement

during bending.

Size Indicator

Set Knob

Zero Point

Figure 9

4

IMC/Rigid

Angle

Protractor

EMT Size

Indicator

Page 5

7. Use the control pendant. The zero light should be

Offset

Beam

Box

M

Front Edge of Clamp

See T able A

Min. 2"

Mark #2Mark #1

Shoe

Min. 2˝

Stub Length

Set Back

Mark #2

Mark #1

Front Edge of

Clamp Mark #2

Stub to Bottom

of Pipe

on. Hold the toggle switch in the “Bend” position.

The shoe will rotate until the desired bend is

achieved, then stop automatically.

NOTE: If the zero light is not on, press the toggle

switch to return until the shoe stops and the zero

light comes on.

8. To unload conduit, hold the toggle switch in the

“Return” position. The shoe will return to the start

position and stop automatically.

9. Grasp the upper urethane roller and move the

support arm clockwise until the rollers move away

from the conduit (figure 10). Push the roller housing

against the frame stop. Remove bent conduit.

Roller Housing Handle

Upper

Urethane Roller

3. Next rotate conduit 180˚ level, place mark #2 in

line with front edge of shoe clamp and make

second bend.

NOTE: When bending rigid aluminum, set bend

angle indicator approximately 4˚ short of

desired angle, since aluminum does not

have spring-back of steel.

Table A

15˚ Bend 30˚ Bend 45˚ Bend

Offset Conduit Conduit Conduit

Required Max. Size M Max. Size M Max. Size M

3

2”

4” 1

6” 2” 23

8” 30

10” 38

12” 46

14” 54

16” 61

18” 67

20” 77

22” 85” 44” 31

To locate distance between centers of offset bending marks other than listed in

table A use the following multipliers:

⁄4”7

1

⁄2”157⁄16”

3

⁄4”

3

⁄4”8”

3

⁄16” 1” 12”

5

⁄8”11⁄2” 16” 1” 115⁄16”

5

⁄8” 2” 20” 11⁄4”141⁄8”

3

⁄8” 24” 11⁄2”1615⁄16”

1

⁄16” 28” 2” 1913⁄16”

13

⁄16” 32” 225⁄8”

7

⁄16” 36” 257⁄16”

1

⁄4” 40” 281⁄4”

15˚ bend - 3.9

30˚ bend - 2.0

45˚ bend - 1.4

1

⁄2”81⁄2”

1

⁄8”

Frame Stop

Figure 10

10. To bend more conduit of the same material and at

the same angle, load and secure as described in

steps 3 through 6. To bend the same type conduit

but at a different angle, load and secure; turn angle

indicator to the desired angle, then press toggle

to bend.

11. Bending different type and size conduit requires

repeating steps 2 through 10.

Offset Bending

1. Obtain distance “M" from table A, and measure this

distance from mark #1 and place mark #2.

2. Now place mark #1 in line with front edge of shoe

clamp and make first bend.

Stub-up Bending

1. Table C shows

minimum length (inches).

2. Mark #1 is stub length,

deduct from this as per

table C and obtain mark #2.

Table B

BEND RADIUS

Conduit Radius Radius

Size Rigid / IMC EMT

1

⁄2”331⁄32”3

Table C

5

3

⁄4”4

1” 5

1

⁄4”6

1

1

⁄2”7

1

2” 8

1

⁄2” Rigid 73⁄4”1

1

⁄2” IMC 73⁄4”1

1

⁄2” EMT 75⁄8”1

3

⁄4” Rigid 9” 11⁄2” Rigid 131⁄2”

3

⁄4” IMC 9” 11⁄2” IMC 131⁄2”

3

⁄4” EMT 81⁄2”1

1” Rigid 10

1” IMC 10

1” EMT 10

25

⁄32”429⁄32”

9

⁄16”529⁄32”

7

⁄8”7

9

⁄16”7

9

⁄32”8

Conduit Stub-up Conduit Stub-up

Size Set-back Size Set-back

7

⁄8”

3

⁄32”

1

⁄2”

9

⁄16”

1

⁄4” Rigid 123⁄4”

1

⁄4” IMC 121⁄2”

1

⁄4” EMT 13”

1

⁄2” EMT 131⁄2”

1

⁄8” 2” Rigid 153⁄4”

1

⁄8” 2” IMC 151⁄2”

3

⁄8” 2” EMT 151⁄2”

Page 6

Maintenance

Gardner

Bender

A unit of Tools and Supplies

If motor will not run: Motor could become overheated

due to long repeated usage or severe strain. Allow

motor to cool. If motor still does not run check the fuse.

To avoid possible injury, always unplug the bender

power cord before attempting maintenance work.

Fuse Replacement: The fuse is located behind the

handle mounting plate. Remove the two brackets and

the mounting screws around the plate. Use caution to

avoid dropping the handle. Remove the handle

assembly and circuit control. Set the handle assembly

aside.

The fuse is located in a white bracket in the left corner

of the control panel (figure 11). Remove and replace

with a new 15 amp, 125 volt fuse, part number

E1601000. Connect the power cord and pendant

connectors, install the end plate. Check bender

operation.

For any repair other than above, contact an authorized

GB Technical Service Center.

Angle Adjustment

Two different size indicator scales are mounted on the

shoe outer rim. One for 1⁄2" thru 2" IMC and Rigid, the

other for EMT 1⁄2" thru 2" (figure 12).

Each size indicator is adjustable to compensate for over

long or short bends which may be due to differences in

conduit characteristics or other variations.

Bends which are too long: Loosen the indicator scale

(for type material being bent) mounting screws. Slide

the indicator clockwise as many degrees as the

overbend (if bend is 5˚ over, move indicator 5˚

clockwise). The degree of movement is observed by

watching one of the size marks as it moves past the

angle disc scale. Tighten the mounting screws.

Bends which are too short: Loosen the indicator (for

type material being bent) mounting screws. Slide the

indicator counterclockwise as many degrees as the

bend is short (if bend is 5˚ short move counterclockwise

5˚ ). The degree movement is observed by watching

one of the size marks as it moves past the angle disc

scale. Tighten the mounting screws.

Size Indicator Scale

Fuse

Figure 11

Handle Mounting Plate

Figure 12

Note: Two scales

one for rigid and

one for IMC

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL

Service Center. The GB ELECTRICAL Service Center will provide complete and prompt service on all GB

ELECTRICAL products.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact GB Electrical

(414)352-4160 for the name of the nearest GB

Authorized Service Center.

WARRANTY: GB ELECTRICAL, INC. warrants its

product against defects in workmanship and materials

for 1 year from date of delivery to user. Chain is not

warranted. Warranty does not cover ordinary wear

and tear, abuse, misuse, overloading, altered products

or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest GB

Authorized Service Center for inspection, transportation

prepaid. Furnish evidence of purchase date. If the claim

comes under the terms of our warranty the Authorized

Service Center will REPAIR OR REPLACE PARTS

AFFECTED and return the unit prepaid.

6101 N. Baker Road • Milwaukee, WI 53209 • 414-352-4160 • Fax 414-352-2377

6

RPS-0097 1/98

Loading...

Loading...