Page 1

Gardner

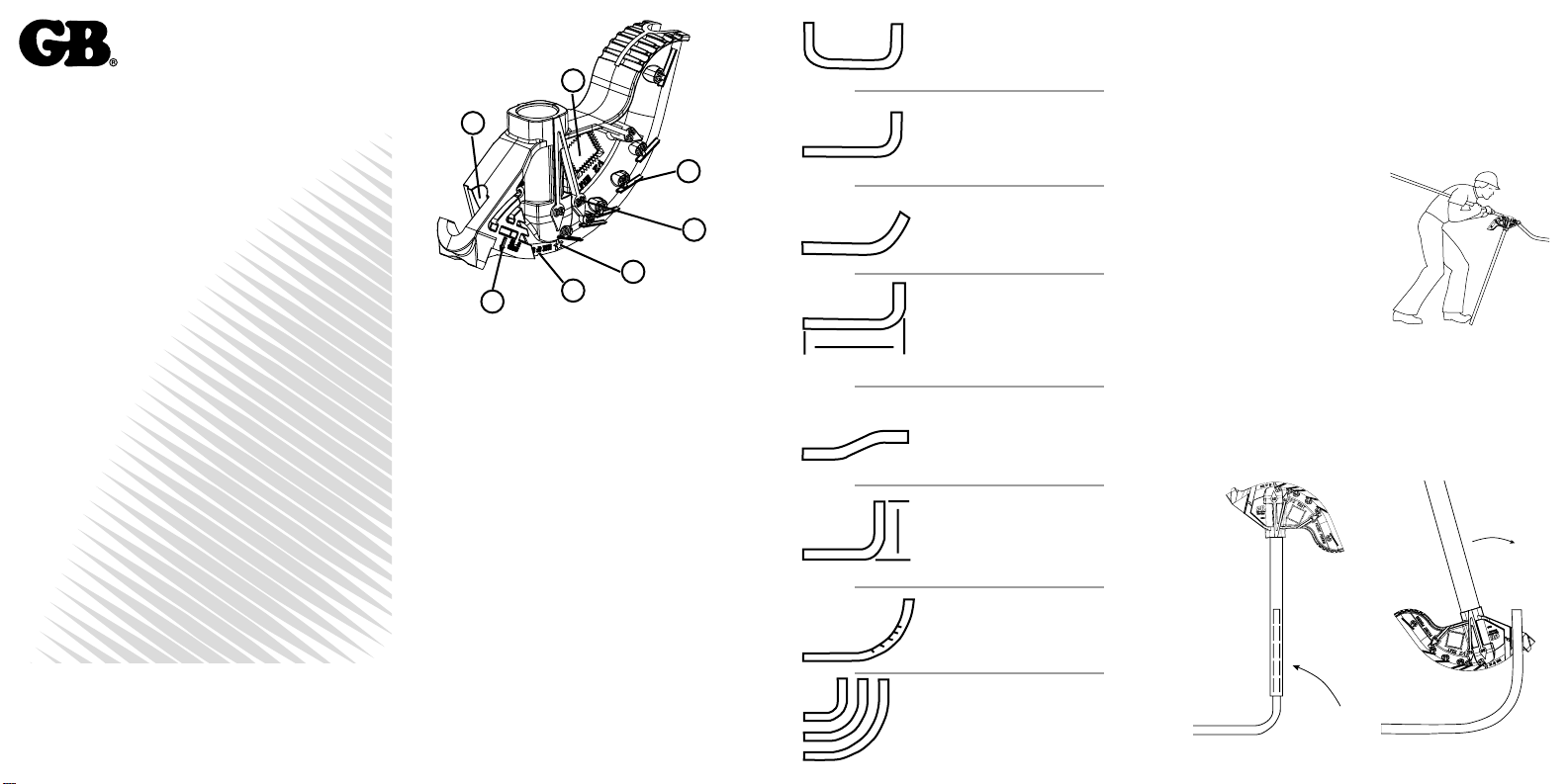

Back-to-Back Bend

90˚ Bend

“Dog Leg” Bend or “Kick”

Leg Length

Offsets

Rise or “Stub-ups”

Segment Bend

Concentric Bends

6

1. ARROW

Indicates start of bend. Use for stubs and

saddle bends.

2. RIM NOTCH

Locates center of saddle bend.

3. STAR

Indicates the back of a 90° bend.

4. ANGLE ARROWS

Indicates the angle when bending on the

floor.(sighting down the bender)

5. DEGREE SCALES

Indicates the angle when bending in the

air.(sighting in-line with the conduit)

6. BEND BACK

Special channel designed for

correcting overbends.

7. CONDUIT VISE

Clamps conduit during cutting.

5

3

2

4

7

BENDING NOTES:

Thread handles into bender head as far as

they will go.

BENDING ON THE FLOOR:

For best results keep the conduit pinned to

the floor by applying constant pressure on

the foot pedal throughout the entire bend.

BENDING IN THE AIR:

Tuck the conduit under your

arm and use your foot to

keep the handle from

sliding on the floor.Keep

your hands and body

close to the bender

throughout the bend.

CORRECTING OVER BENDS:

There are two options for correcting

over-bends.One option uses the open

end of the handle as a “cheater” bar and

the second uses the hook area.

OPTION 1

OPTION 2

1

Benfield®Style Hand Bender

How to Bend Guide

960 Series Benders

For instructions in Spanish and French please visit

Por favor, para instrucciones en Español y Francés visite

Pour des instructions en espagnol et français, veuillez visiter

www.gardnerbender.com

Bender

Page 2

Deduct

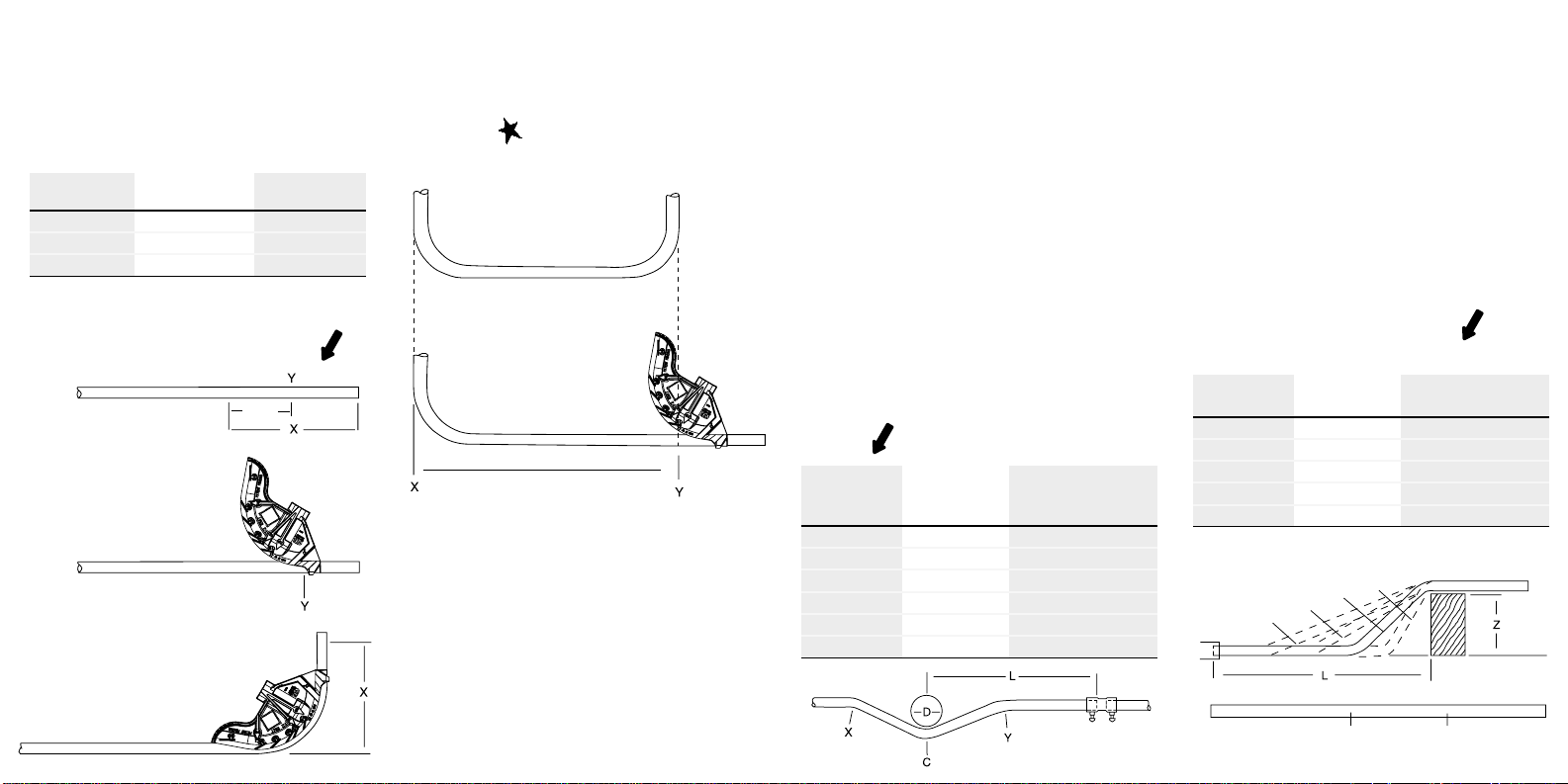

90° OR STUB BENDS:

BENDING ON THE FLOOR:

1. Measure stub height (x)

2. Subtract amount shown in chart from

stub height. Deduct amount is also

noted on bender (example: subtract 5"

for a

1

⁄2" bender)

3. Mark conduit at final deduct location.

4. Line up mark on conduit with arrow

on bender.Make the bend.

BACK T O BACK BENDS:

1. Measure and mark distance on the

conduit from a fixed point (x) to the

back of the 90° bend (Y).

2. Align the mark (Y) on the conduit with

the star on the bender and make

the bend.

SADDLE BENDS:

This bend is used to avoid an obstruction,

such as a pipe.The most common bend is a

45° center bend and two 22

1

⁄2° outer bends.

Another method of making a saddle bend is

a 60° center bend and two 30°.

1. Measure the height/diameter (D) of the

object to be crossed over.

2. Measure the distance (L) to the object to

be crossed over and add

3

⁄16" to the

length for each inch of the object height.

3. Mark this distance (C) on the conduit.

It is the center point.

4. Make the outer bend marks (X and Y) at a

distance of 2

1

⁄2" x the object size. Mark

each from the center mark.

5. Align the center mark (C) with the “notch”

on the bender and make a 45° bend.

6. Align the outer marks (X and Y) with the

arrow and make a 22

1

⁄2° bend.

Move Center Make Outside Mark

Obstruction Mark Ahead From Center Mark

Height Distance Distance

1"

3

⁄16"2

1

⁄2"

2"

3

⁄8"5"

3"

9

⁄16"7

1

⁄2"

4"

3

⁄4" 10"

5"

15

⁄16"12

1

⁄2"

6" 11⁄8" 15"

Conduit EMT RIGID/IMC

Size Deduct Amt. Deduct

1

⁄2"5"3

3

⁄4"

3

⁄4"6" 7"

1" 8" 381⁄2"

OFFSET BENDS:

Offset bends are most commonly used to

feed into a panel box or to go around an

obstruction.The most common offset angle

is 30° due to the angle multiplier = 2.

1. Measure the height of offset (Z).

2. Measure the distance to obstruction (L)

and add shrink amount (chart below) for

each inch of offset. Mark the distance on

the conduit (X).

3. Using the offset height (Z) times angle

multiplier (chart below) subtract this

amount from the 1st mark and mark this

on the conduit (X).

4. Align the marks with the arrow and

make your bends.

Angle Constant Shrinkage / Inch

of Bend Multiplier of Offset Depth

10" 6.0"

1

⁄16"

211⁄2" 2.6"

3

⁄16"

30" 2.0"

1

⁄4"

45" 1.4"

3

⁄8"

60" 1.2"

1

⁄2"

L + Shrinkage

221⁄2°

30°

45°

60°

X

Y

Loading...

Loading...