GB 1 1-8 HP User Manual

Instruction

Genesis Series

®

Sheet

IMPORTANT RECEIVING INSTRUCTIONS: Visually inspect all components for shipping damage.If any

shipping damage is found, notify carrier at once.Shipping damage is NOT covered by warranty.The carrier

is responsible for all repair or replacement cost resulting from damage in shipment.

Carefully plan your system by selecting components designed to perform the intended operation and which

will adequately perform with existing equipment.Always check the product limitations regarding pressure

ranges, load capacities and set-up requirements.The system operating pressure must not exceed the

pressure rating of the lowest rated component in the system.Read all CAUTIONS, WARNINGS, and

INSTRUCTIONS included with, or attached to, each product. Follow all safety precautions to avoid personal

injury or property damage during the system operation.GB ELECTRICAL CANNOT BE RESPONSIBLE

FOR DAMAGE OR INJURY RESULTING FROM UNSAFE USE OF PRODUCT, LACK OF

MAINTENANCE, OR INCORRECT PRODUCT AND SYSTEM APPLICATION. Contact GB ELECTRICAL

when in doubt as to safety precautions or applications.

Titan Pumps

1

⁄8 HP

1

■

SPECIFICATIONS

Specification “B”Version “E”Version

Operating

Electrical Power Source

Motor Rating

Flow Rate

Unloading (or Bypass)

Pressure

Operating Oil

Temperature

Reservoir Capacity

Shipping Weight

■

SAFETY INFORMATION

25 Amp @10,000 psi (700 Bar) and 12,000 RPM 12.5 Amp @ 10,000 psi (700 Bar) and 12,000 RPM

30 Amp/115 Volt Grounded 15 Amp/230 Volt

single-phase, 50-60 Hz single-phase, 50-60 Hz

1

⁄8 HP Universal Motor, 0.84 kW Universal Motor,

1

operates at 60-125 Volts, 82-89 dbA operates at 115-240 Volts, 82-89 dbA

for operation below 32° (0° C), change oil to MIL-H-5606 (see page 8 for procedure)

53 lbs to 165 lbs (116,6 kg to 363 kg) depending on valve and reservoir configuration

0-10,000 psi (700 bar) maximum

3

640 in

/min (10,51/min) @ 0 psi (0 bar)

3

60 in

/min (1,01/min) @ 10,000 psi (700 bar)

1600 psi

150° F (65.5° C) maximum

1.3, 2.4, 10.4 gallon (5, 9, 20, 40 liter)

FAILURE TO COMPLY WITH WARNINGS AND CAUTIONS MAY CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

Do not use electric pumps in an explosive

atmosphere. Adhere to all local and

national electrical codes.

Do not use hoses, fittings, or couplers with

pressure ratings below 10,000 psi (700 bar).

Install pressure gauges in the system to

monitor operating pressure.

Titan pumps have an internal relief valve

installed under the pump cover.This relief

valve is factory adjusted and must not be

repaired or adjusted except by qualified

hydraulic technicians.

To help prevent pump failure, check

hydraulic reservoir fluid level prior to

pump operation.When gauge reads low,

add oil. Always be sure cylinders are fully

retracted before adding fluid to the

reservoir. Use only GB Electrical hydraulic

oil. Use of any other oils or fluids may void

your pump warranty.

To prevent damage to pump electric motor,

check specifications. Using incorrect

power source will damage the motor.

2

■

INSTALLATION

■

Attach Hydraulic Hoses

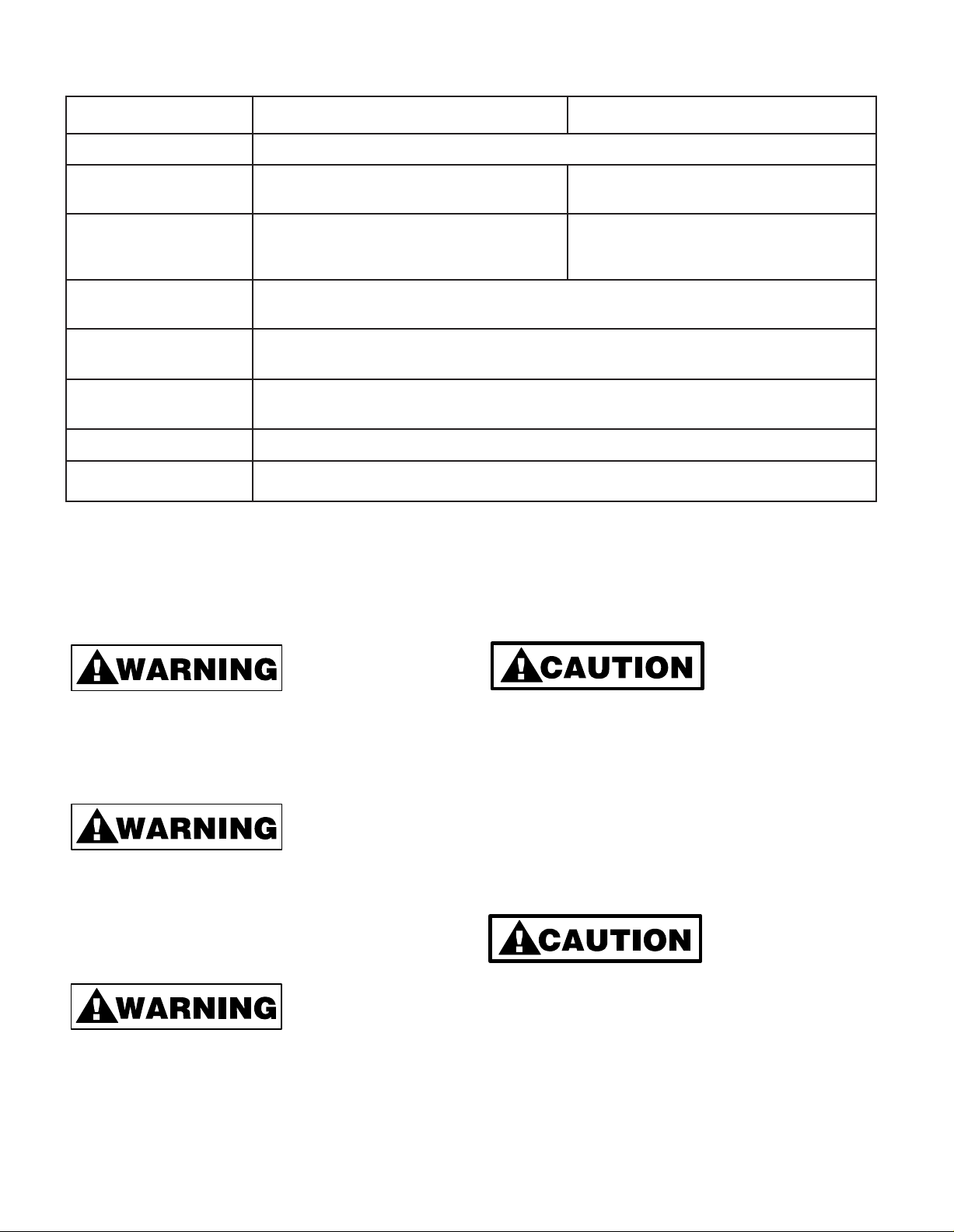

Thread hose(s) or coupler(s) into outlet port(s) of the valve (A).Use 11⁄2 wraps of teflon tape on the hose

fittings, leaving the first complete thread free of tape (B).Pumps with 3-way valves have 1 outlet port;

pumps with 4-way valves have 2 outlet ports.All hoses and components used with this pump must have a

working pressure rating higher than, or equal to, the maximum pressure rating of the pump.

■

Install Oil Level Gauge

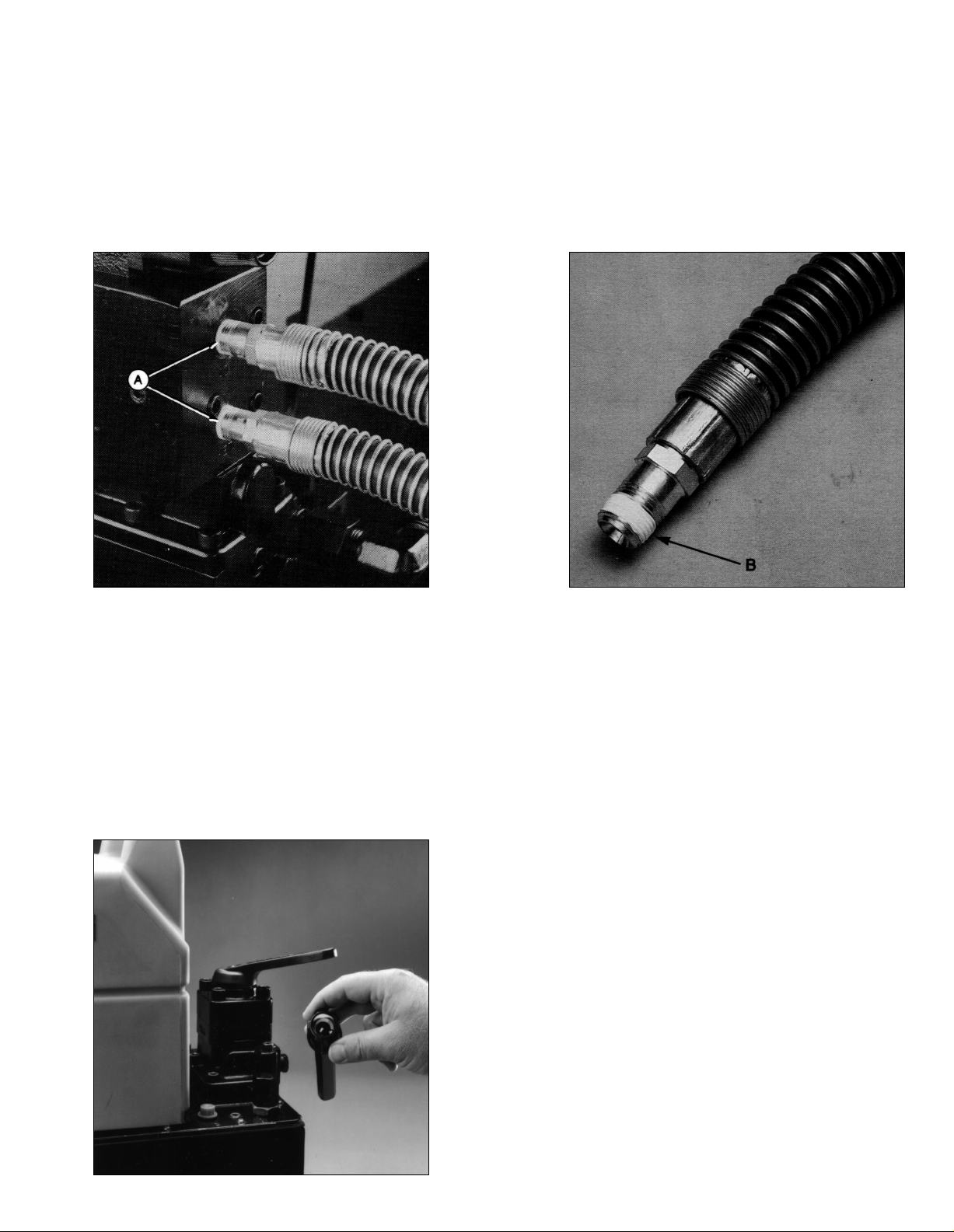

For shipping purposes, a plug is installed in the

fill hole on the top of the reservoir.Remove this

plug and install the oil level gauge that was

shipped with the pump.NEVER RUN THE

PUMP WITH THE SHIPPING PLUG

INSTALLED.THIS WILL CAUSE DAMAGE TO

THE PUMPING MECHANISM.

...“Installation” continued on next page

3

Loading...

Loading...