Page 1

IMPORTANT: RECEIVING INSTRUCTIONS: Visually inspect

all components for shipping damage. If any shipping damage is

found, notify carrier at once.

Shipping damage is NOT covered by warranty. The carrier is

responsible for all repair or replacement costs resulting from

damage in shipment.

Instruction

Sheet

1105A

Operating Valve

and Hose Assembly

IMPORTANT—USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to select the

proper components and design to insure appropriate integration with your operations and existing equipment and that all safety

measures have been taken to avoid the risk of personal injury and property damage from your application or system.

GARDNER BENDER CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE, MAINTENANCE

OR APPLICATION OF ITS PRODUCTS. Please contact GARDNER BENDER for guidance when you are in doubt as to the

proper safety precautions to be taken in designing and setting up your particular application.

Prior to attaching the1105A hose fitting to a

CO

2 tank valve, be certain the tank valve is

closed. CO

2 escaping under pressure will

cause injury.

INSTALLATION

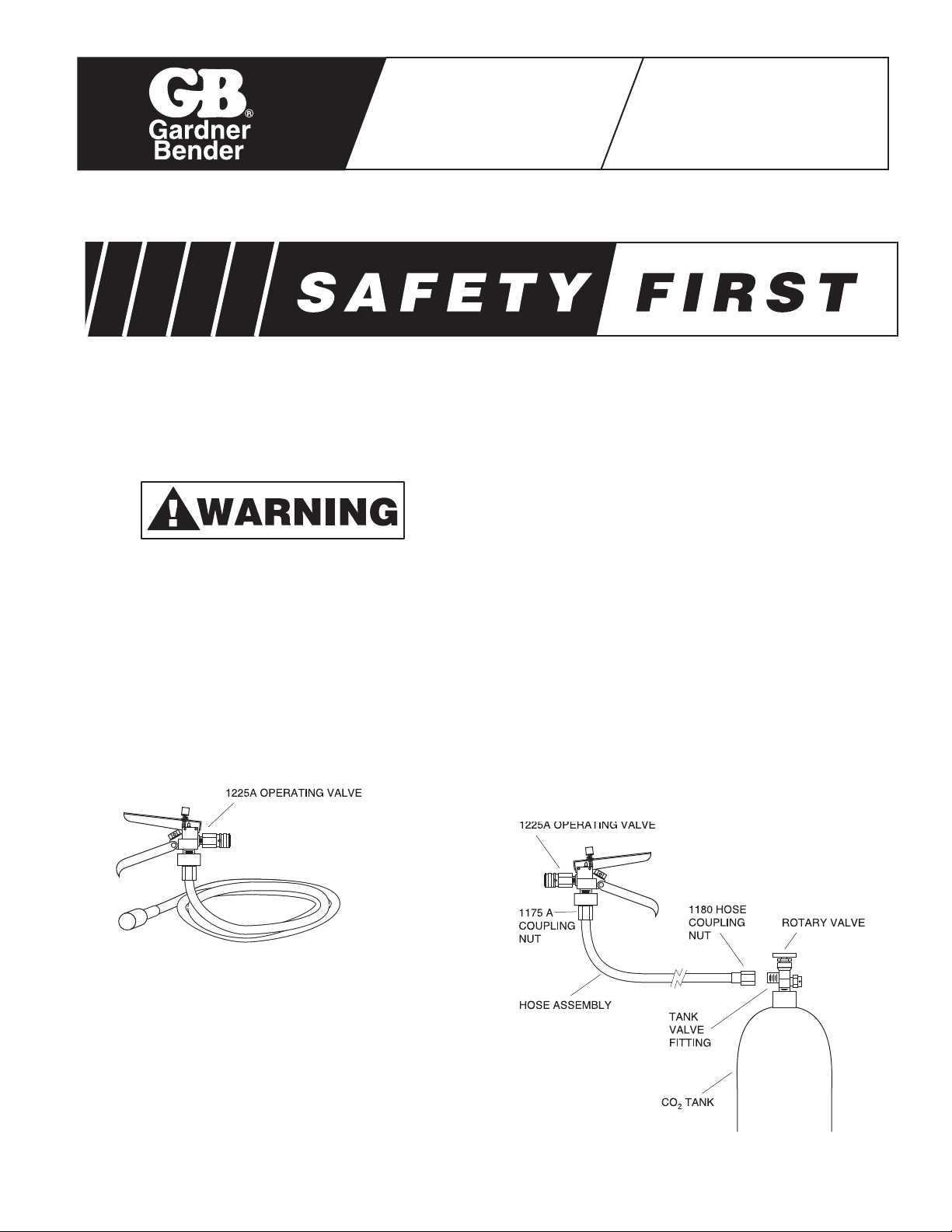

The 1105A operating valve and hose assembly

consists of a 1225A operating valve and a 12

foot hose assembly. See Figure 1.

Figure 1

1105A Operating Valve and Hose Assembly

Swaged fittings on the hose assembly are

“factory installed” and are not replaceable. If

hose or fittings are damaged, discard the hose

assembly (UG12). The 1175A and 1180 coupling

can be replaced.

For hoses longer than 12 feet remove 1180

coupling and connect UG12 to existing hose and

replace 1180 coupling.

NOTE: The 1105A hose assembly is specifically

designed for use on GB Model 950 and

GB Model 1208 CO

2

tanks. Do not

attempt to modify the 1105A valve and

hose assembly to fit any other type of

gas or compressed air tanks such as

oxygen, acetylene, etc.

ATTACH THE 1105A OPERATING VALVE AND

HOSE ASSEMBLY to a 20 or 50 pound CO

2

tank. Thread the hose coupling nut “hand tight”

onto the tank valve. See Figure 2.

Figure 2

CO2Tank and 1105A Operating Valve & Hose Assembly

Page 2

6101 N. Baker Road, Milwaukee, WI 53209

Phone: (414) 352-4160 FAX (414) 352-2377

WARRANTY: GARDNER BENDER warrants its

products against defects in workmanship and

materials for 1 year from date of delivery to user.

Chain is not warranted. Warranty does not cover

ordinary wear and tear, abuse, misuse, overloading,

altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When

question of warranty claim arises, send the unit to the

nearest GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GARDNER BENDER parts, select an

Authorized GB Service Center for your repair needs.

Only repairs performed by an Authorized Service

Center displaying the official GB Authorized sign are

backed with full factory warranty. Contact GARDNER

BENDER (414) 352-4160 for the name of the nearest

GB Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GARDNER BENDER

Service Center. The Service Center will provide complete and prompt service on all GARDNER BENDER products.

RPS-0093 0110

OPERATION

The 1105A operating valve and hose assembly

controls the flow of gas from the CO

2

tank. Gas

will remain under pressure in the 1105A hose

assembly.

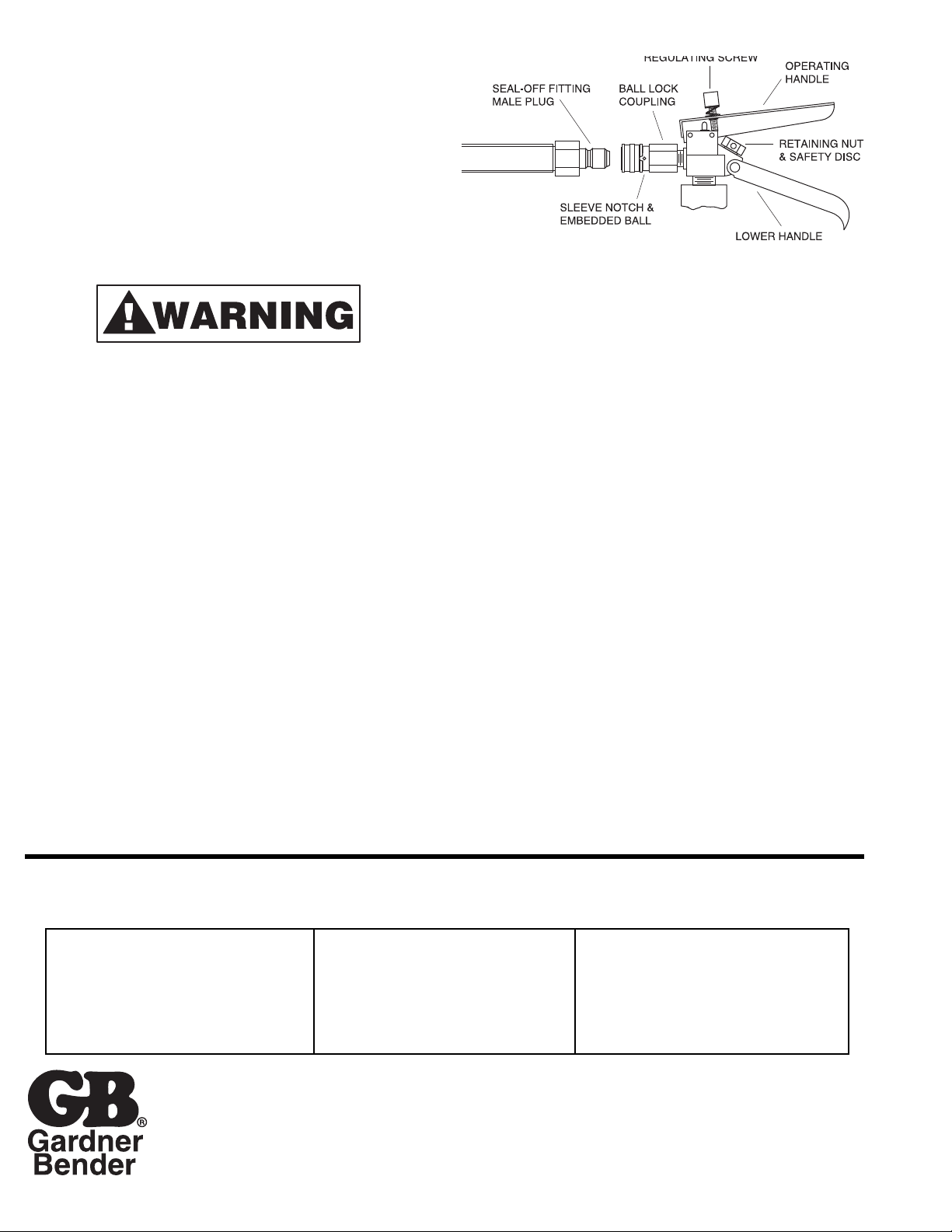

The 1105A operating valve accepts seal-off

assemblies from 1/2 to 6 inch capacity. See

Figure 3.

To prevent injury, always keep a firm grip on

seal-offs and operating valves. An unrestrained

hose will be uncontrollable when the operating

valve is opened to release CO

2

.

11..

Connect the seal-off assembly to the

operating valve.(Refer to Figure 3).

22..

Turn the ball lock coupling sleeve to align the

sleeve notch with the ball embedded in the

ball lock coupling.

33..

Pull the sleeve toward the valve and hold it

while inserting the fitting from the seal-off.

44..

Release the sleeve, turn the notch away from

the embedded ball to prevent releasing the

seal-off.

55..

Check the coupling connection by pulling the

seal-off to be certain it is seated in the valve

ball lock coupling.

Figure 3

Operating Valve and Seal-Off Coupling

66..

To release CO2gas into the hose and 1105A

operating valve, open the tank rotary valve.

77..

To release CO

2

depress the operating handle

on the 1105A hose assembly.

88..

When not using the seal-off, disconnect it

from the 1105A operating valve. Turn off the

rotary valve on the CO

2

tank and squeeze

the valve handle to release any remaining

CO

2

in the hose assembly.

STORING THE 1105A VALVE AND HOSE

ASSEMBLY

11..

Loosen the hose coupling nut and remove the

hose assembly.

22..

Place the valve and hose assembly in the

tank cart storage box.

33..

Install the CO

2

tank protective cap by placing

it over the rotary valve and threading it onto

the tank.

Loading...

Loading...