Gaylord CG3-UV, C-6000-UV Service Manual

THE

GAYLORD VENTILATOR

EFFECTIVE DATE 10-2007

TECHNICAL MANUAL

FOR THE Ultima Vent

WATER-WASH VENTILATORS

WITH POLLUTION CONTROL AND THE

MODEL C-6000-UV ESP COMMAND CENTER

TM

“CG3-UV SPC” SERIES

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • TUALATIN, OREGON 97062 U ..S.A.

1-800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

1

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES

World Headquarters: 10900 S.W. Avery Street • Tualatin, Oregon 97062-1149 U.S.A.

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. We are proud to be able

to provide you with a quality product that incorporates

the latest engineering concepts and is a result of over

50 years of experience in the foodservice kitchen

exhaust industry.

If you have other Gaylord equipment such as a Gaylord

Utility Distribution System, Quencher Fire Protection

System, or Roof Top Air Handling Equipment, etc.,

please refer to the corresponding supplementary

equipment manuals.

If you have further questions, please visit our web site

at: www.gaylordusa.com, or call us toll-free at 1-800-

547-9696. We are more than happy to help.

Sincerely,

Gaylord Industries

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: gaylord@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SY STEMS • FIRE PROTE CTION • UTILITY DI STRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062 U.S.A.

2

TABLE OF CONTENTS

"CG3-UV" VENTILATOR DESCRIPTIONS .............................................................................................. 4–-5

"CG3-UV" SERIES PRINCIPLE OF OPERATION ..................................................................................... 6–9

DAILY OPERATION .................................................................................................................................. 10

PREVENTIVE MAINTENANCE ............................................................................................................. 11-12

SAFETY CONCERNS WITH UVC ............................................................................................................. 13

DETERGENT PUMP OPERATION ............................................................................................................ 14

DETERGENT FOR THE WASH SYSTEM ................................................................................................. 15

MODEL C-6000 SERIES COMMAND CENTER - INSTRUCTIONS........................................................16–19

ENGINEERING DATA ...........................................................................................................................20-21

START-UP PROCEDURES ....................................................................................................................... 22

RP DEVICE–INITIAL START-UP ................................................................................................... 23

MEASURING INLET SLOT VELOCITY .....................................................................................24-26

OPTIONAL CONTINUOUS COLD WATER MIST ....................................................................................... 27

TROUBLESHOOTING:

SMOKE LOSS ............................................................................................................................. 28

GREASE EXTRACTION ............................................................................................................... 28

EXHAUST FAN.................................................................................................................. .. 29

WASH SYSTEM ..................................................................................................................... 29–30

FIRE CYCLE ................................................................................................................................ 31

BACKFLOW PREVENTERS .................................................................................................... 31-32

VACUUM BREAKER ................................................................................................................... 31

RP DEVICE .................................................................................................................................. 32

DRAINS........................................................................................................................................ 32

MISCELLANEOUS ....................................................................................................................... 32

UV SYSTEM ............................................................................................................................33-34

PLC STATUS LIGHT CHART ....................................................................................................... 35

C-6000-UV TERMINAL VOLTAGES .............................................................................................. 36

UV STATUS LIGHTS .................................................................................................................... 37

PARTS LISTS:

MODEL GPC-6000-UV-VB SERIES CONTROL CABINET ............................................................ 38

MODEL GPC-6000-UV SERIES CONTROL CABINET .................................................................. 39

MODEL GPC-6000-UV-S SERIES CONTROL CABINET .............................................................. 40

OPTIONAL CONTINUOUS COLD WATER MIST .......................................................................... 41

MODEL C-6000-UV SERIES CONTROL ....................................................................................... 42

DAMPER CONTROL MOTOR AND CG3-UV-FDL WIRING ........................................................... 43

DETERGENT PUMP .................................................................................................................... 44

MISCELLANEOUS VENTILATOR PARTS .................................................................................... 45

UV MODULE ................................................................................................................................ 46

WIRING DIAGRAMS ............................................................................................................................47–51

STANDARD VENTILATOR MODELS ........................................................................................................ 52

METRIC CONVERSION CHART................................................................................................................ 53

START-UP INSPECTION REPORT ........................................................................................................... 54

LIMITED WARRANTY ........................................................................................................ Inside back cover

Patent Pending

© Copyright 2004, Gaylord Industries

ALL RIGHT RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED,

STORED IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM

BY AN ELECTRONIC, MECHANICAL, PHOTOCOPYING, RECORDING

MEANS OR OTHERWISE WITHOUT THE WRITTEN PERMISSION OF

GAYLORD INDUSTRIES COPYRIGHT 2004.

The manufacturer reserves the right to modify the materials and specifications resulting from a continuing

program of product improvement or the availability of new materials.

Additional Copies $15.00

3

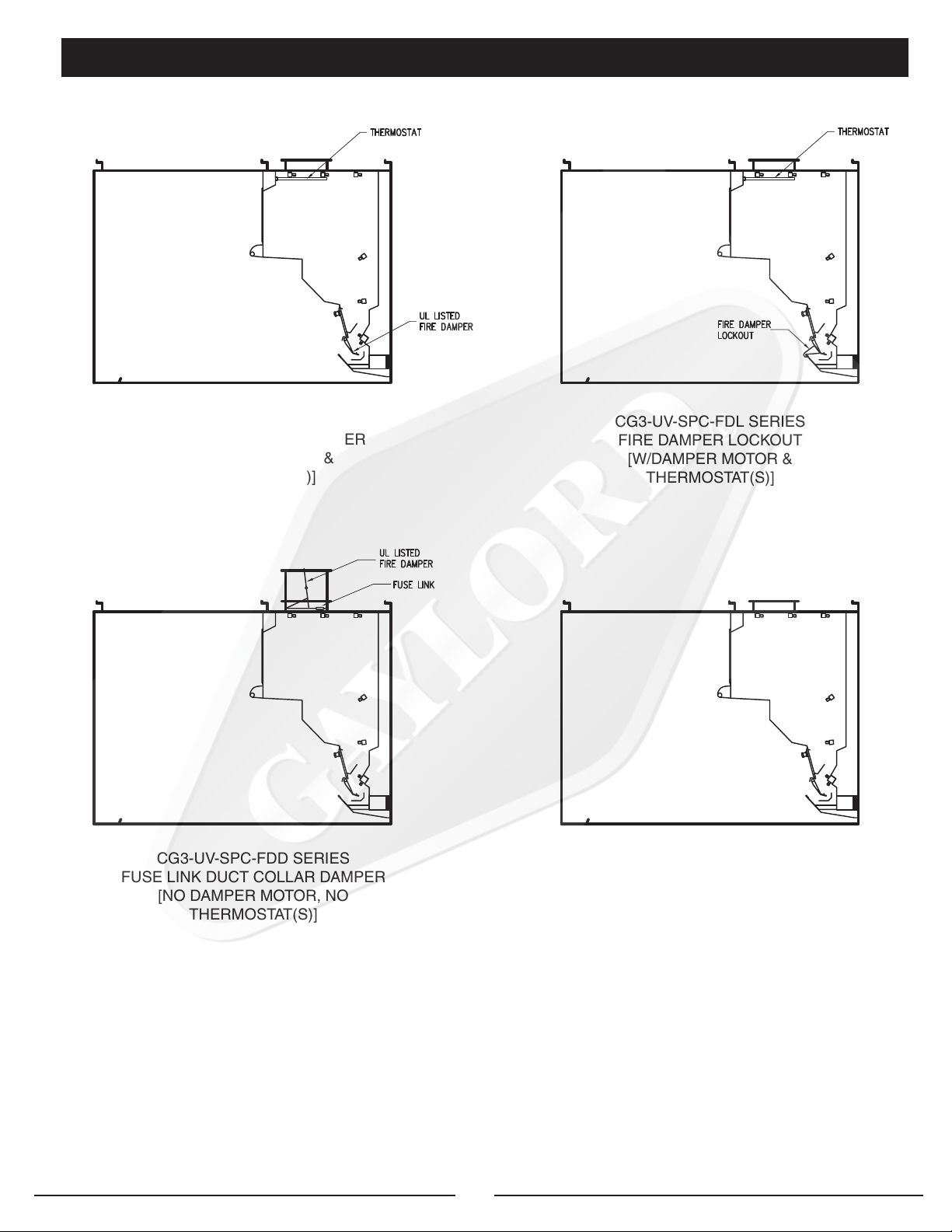

"CG3-UV" VENTILATOR DESCRIPTIONS

There are 4 different types of "CG3-UV SPC” Gaylord

water-wash ventilators. The differences involve the type and

location of fire damper, whether it has an ultraviolet radiation

system, and whether the ventilator has a fire damper. The

first part of the model number indicates the type of ventilator,

see below:

Explanation of Prefixes:

CG3-UV Water-wash ventilator with three-position, ther-

mostatically activated (electric) damper at air

inlet slot.[With Damper motor and 1 or

more Thermostat(s)]

CG3-UV-FDL Water-wash ventilator with three-position, ther-

mostatically activated (electric) damper at air

inlet slot. A bracket (Fire Damper Lockout) has

been added to prevent the damper from closing

to the fire position.[With Damper motor and

1 or more Thermostat(s)]

CG3-UV-FDD Inlet damper is fixed, and there is a weighted

fuse link activated fire damper located at

the duct collar. [No Damper motor, No

Thermostats]

CG3-UV-ND Inlet damper is fixed. No Fire Damper at duct

collar. A bracket (Fire Damper Lockout) has

been added to show that the damper will not

close to the fire position. [No Damper motor,

No Thermostats]

Summary of "CG3-UV" Ventilators:

The CG3-UV and CG3-UV-FDL are very similar. Both have a

damper motor that closes the inlet damper during the wash

mode and stays closed until the exhaust fan is started. Both

have thermostats that can detect an “Internal Fire”. The main

difference is the CG3-UV-FDL has a Fire Damper Lockout

(FDL) bracket added that prevents the inlet damper from

closing to the fire position, so it does NOT have a fire damper.

The CG3-UV-FDD and CG3-UV-FDT are similar to each other.

Both have fixed inlet dampers and do not have damper motors.

They both have fuse link activated fire dampers in the duct

collar that will close when the temperature reaches 280°F.

The CG3-UV-FDT has an added thermostat that will detect an

“Internal Fire” and activate the “Internal Fire Mode”. The CG3UV-FDD does NOT have any thermostats.

The CG3-UV-ND has a fixed inlet damper and does NOT have

a fire damper.

4

"CG3-UV" SERIES VENTILATOR DESCRIPTIONS

CG3-UV SPC SERIES

ELECTRIC INTERNAL DAMPER

[W/DAMPER MOTOR &

THERMOSTAT(S)]

CG3-UV-SPC-FDD SERIES

FUSE LINK DUCT COLLAR DAMPER

[NO DAMPER MOTOR, NO

THERMOSTAT(S)]

CG3-UV-SPC-FDL SERIES

FIRE DAMPER LOCKOUT

[W/DAMPER MOTOR &

THERMOSTAT(S)]

CG3-UV-SPC-ND SERIES

NO DAMPERS

[NO DAMPER MOTOR, NO

THERMOSTAT(S)]

5

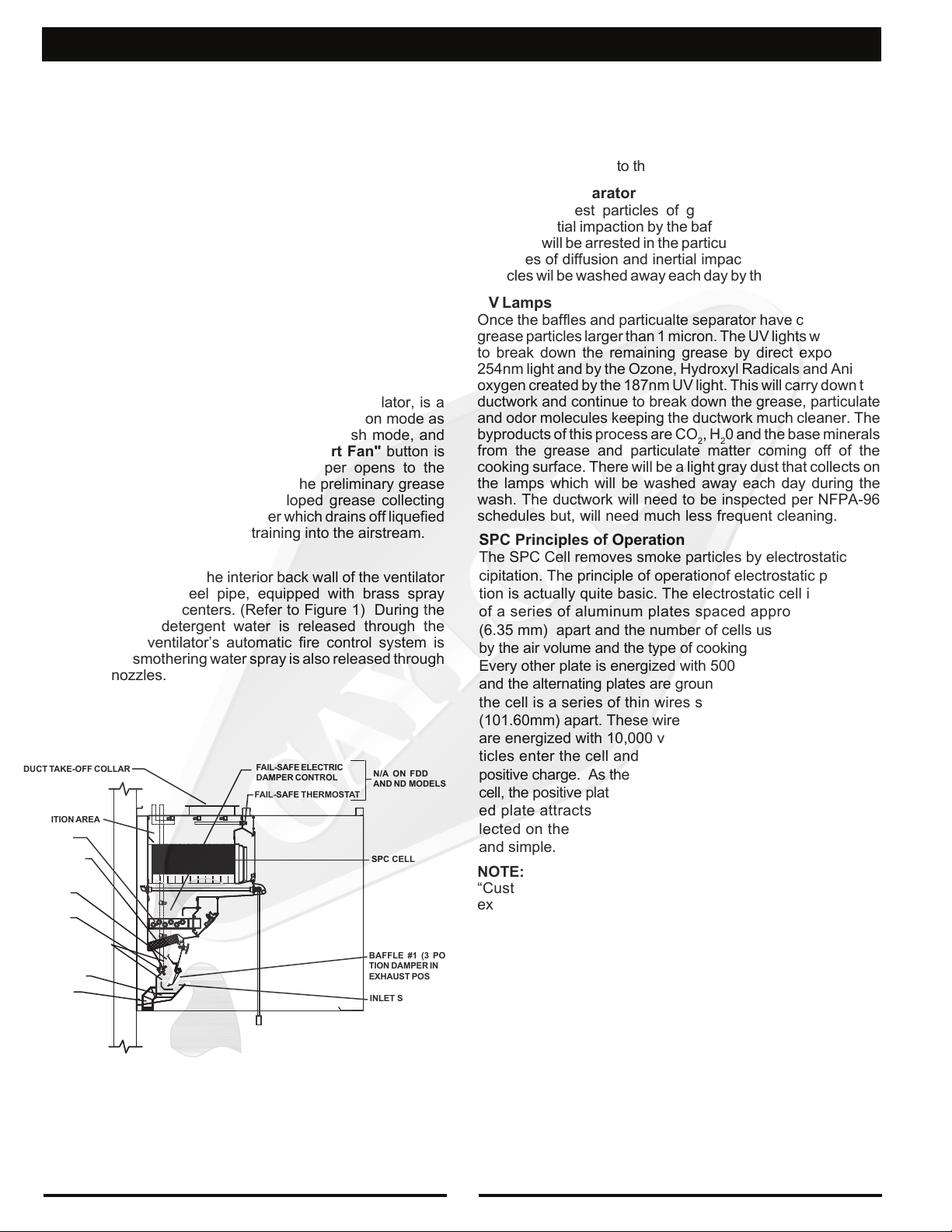

"CG3-UV" SERIES VENTILATOR PRINCIPLE OF OPERATION

GREASE EXTRACTION

The Gaylord “CG3-UV” SPC Series Ventilator extracts up to

99% of the grease, dust and lint particles from the airstream

passing through it, when operated and maintained in accordance with design specifications.

The hot, contaminant-laden air rising from the cooking

surface merges with the higher velocity air that wipes the front

of the cooking equipment and extends, like an air blanket, from

the front edge of the cooking equipment to the air inlet of the

ventilator. As the air moves through the ventilator at a high

speed, it is forced to make a series of turns around three

baffles. As the high velocity air turns around each baffle, the

heavier-than-air particles of grease, dust and lint are thrown out

of the airstream by centrifugal force. The extracted grease,

dust and lint are collected in the interior of the ventilator,

remaining out of the airstream until removed daily by the wash

cycle.

Baffle #1

This baffle, located at the air entrance of the ventilator, is a

three position damper. Position 1 is the exhaust on mode as

shown in Figure 1 below, position 2 is the wash mode, and

position 3 is the fire mode. When the "Start Fan" button is

pushed on the control cabinet, the damper opens to the

exhaust mode (position 1) to become the preliminary grease

extraction baffle. There is a small sloped grease collecting

gutter on the back side of the damper which drains off liquefied

grease, preventing it from re-entraining into the airstream.

Baffle #2

This baffle is located on the interior back wall of the ventilator

and is a stainless steel pipe, equipped with brass spray

nozzles on 8" to 10" centers. (Refer to Figure 1) During the

wash cycle, hot detergent water is released through the

nozzles. If the ventilator’s automatic fire control system is

activated, fire smothering water spray is also released through

the spray nozzles.

DUCT TAKE-OFF COLLAR

TRANSITION AREA

UV LAMPS

PARTICULATE

SEPARATOR

BAFFLE #3

BAFFLE #2

OPTIONAL "CUSTOM

AIR" BAFFLES

MAIN GUTTER

DRAIN LINE

FAIL-SAFE ELECTRIC

DAMPER CONTROL

FAIL-SAFE THERMOSTAT

N/A ON FDD

AND ND MODELS

SPC CELL

BAFFLE #1 ( 3 POS ITION DAMPER IN THE

EXHAUST POSITION)

INLET SLOT

Baffle #3

This baffle is located on the back of the inspection doors. This

baffle is also a grease collecting gutter, collecting grease, dust

and lint extracted by the ventilator - preventing the contaminants

from dropping back into the high velocity airstream.

Particulate Separator

Once the largest particles of grease have been captured

through inertial impaction by the baffles. The smaller particles

of grease will be arrested in the particulate separator using the

principles of diffusion and inertial impaction. These collected

particles wil be washed away each day by the automatic wash.

UV Lamps

Once the baffles and particualte separator have collected the

grease particles larger than 1 micron. The UV lights will be able

to break down the remaining grease by direct exposure to

254nm light and by the Ozone, Hydroxyl Radicals and Anionic

oxygen created by the 187nm UV light. This will carry down the

ductwork and continue to break down the grease, particulate

and odor molecules keeping the ductwork much cleaner. The

byproducts of this process are CO

from the grease and particulate matter coming off of the

, H20 and the base minerals

2

cooking surface. There will be a light gray dust that collects on

the lamps which will be washed away each day during the

wash. The ductwork will need to be inspected per NFPA-96

schedules but, will need much less frequent cleaning.

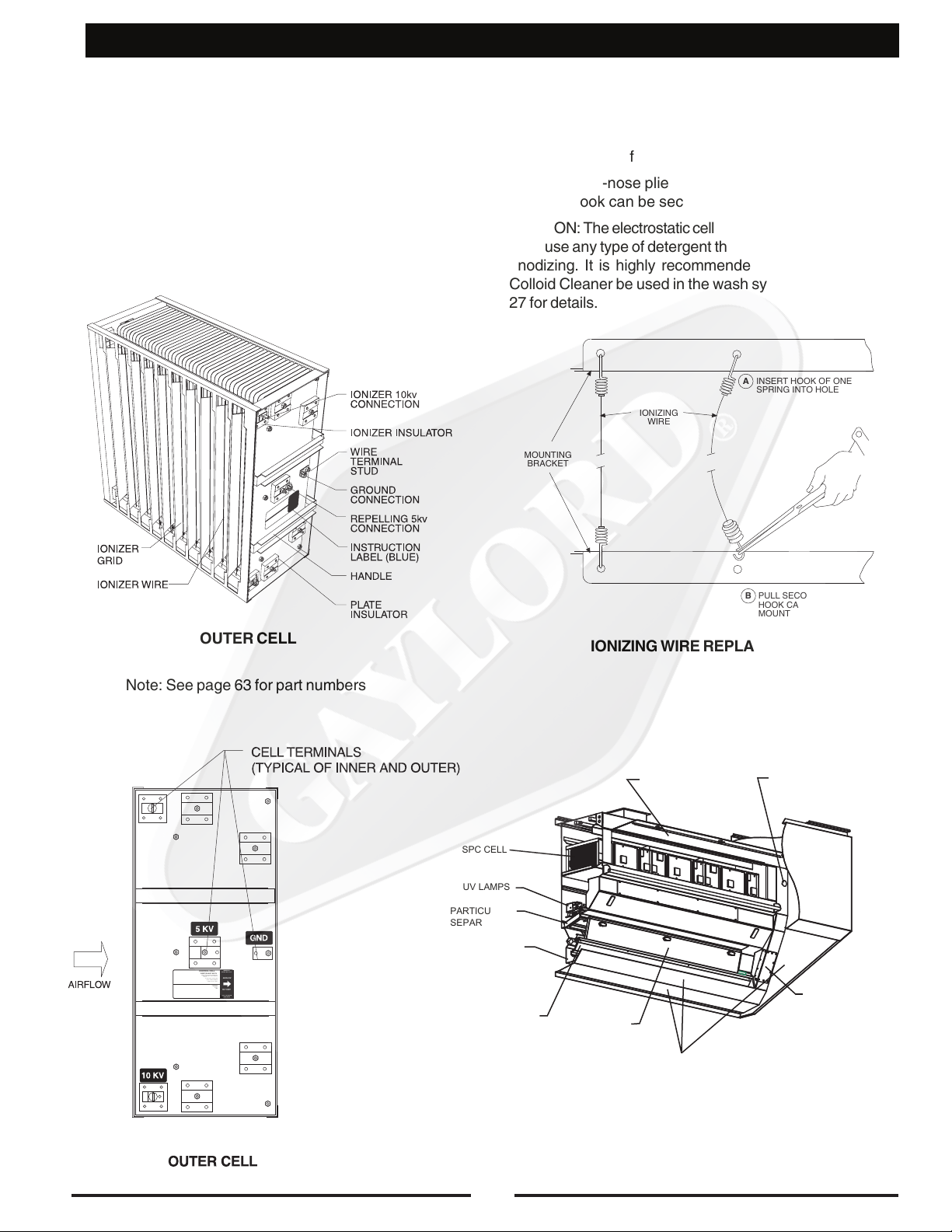

SPC Principles of Operation

The SPC Cell removes smoke particles by electrostatic precipitation. The principle of operationof electrostatic precipitation is actually quite basic. The electrostatic cell is made up

of a series of aluminum plates spaced approximately 1/4”

(6.35 mm) apart and the number of cells used is determined

by the air volume and the type of cooking equipment involved.

Every other plate is energized with 5000 volts of D.C. power

and the alternating plates are grounded. At the entry point of

the cell is a series of thin wires spaced at approximately 4”

(101.60mm) apart. These wires, referred to as ionizing wires,

are energized with 10,000 volts D.C. and as the smoke particles enter the cell and pass over the wires they receive a

positive charge. As the charged particles continue through the

cell, the positive plate repels them and the negative or grounded plate attracts them. Thus, the smoke particles are collected on the negative plates. The action isefficient, safe

and simple.

NOTE: Some ventilators may be equipped with optional

“Custom Air” baffles (shown dotted) which reduces the

exhaust volume where the baffle occurs.

NOTE: Some ventilators may be equipped with optional

continuous cold water mist. Refer to Page 27 for details.

FIG. 1

GREASE EXTRACTION

6

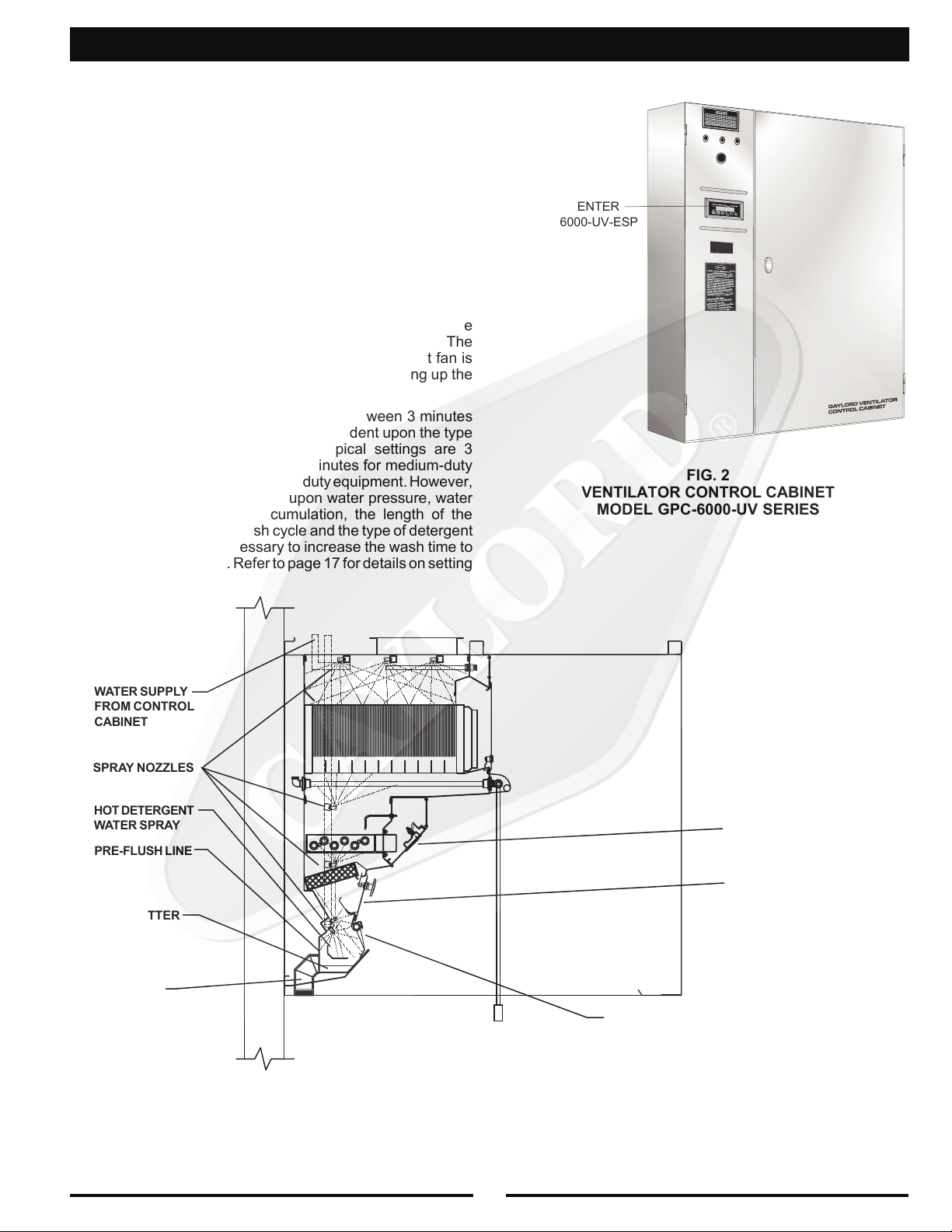

"CG3-UV" SERIES VENTILATOR PRINCIPLE OF OPERATION

WASH CYCLE

The wash cycle is activated each time the exhaust fan is shut

off by pushing the “Start Wash” button on the Command

Center or as programmed on the clock. When activated the UV

lamps shut off, the exhaust and supply fans shut off, the

damper control is energized and the damper begins closing

forward to the wash position, and once closed the hot water

wash sprays come on.

This hot detergent water washes the day’s grease, dust and

lint accumulation from the interior of the ventilator flushing it

down to the main gutter which slopes to a pre-flushed drain

which leads to the building drain system. Spray nozzles are

located on 8" to 10" centers on the wash manifold mounted on

the interior back wall of the ventilator. At the end of the wash

cycle, the water automatically shuts off, and the interior of the

ventilator is clean - ready for the next day’s operations. The

damper remains in the wash position until the exhaust fan is

restarted. This is to prevent conditioned air from going up the

exhaust system during off hours.

The length of the wash cycle may be set between 3 minutes

and 9 minutes. The length of time is dependent upon the type

of cooking equipment being used. Typical settings are 3

minutes for light-duty equipment, 5 minutes for medium-duty

equipment, and 9 minutes for heavy-duty equipment. However,

adequate cleaning is dependent upon water pressure, water

temperature, daily grease accumulation, the length of the

wash cycle, frequency of wash cycle and the type of detergent

being used. It may be necessary to increase the wash time to

achieve proper cleaning. Refer to page 17 for details on setting

the wash time.

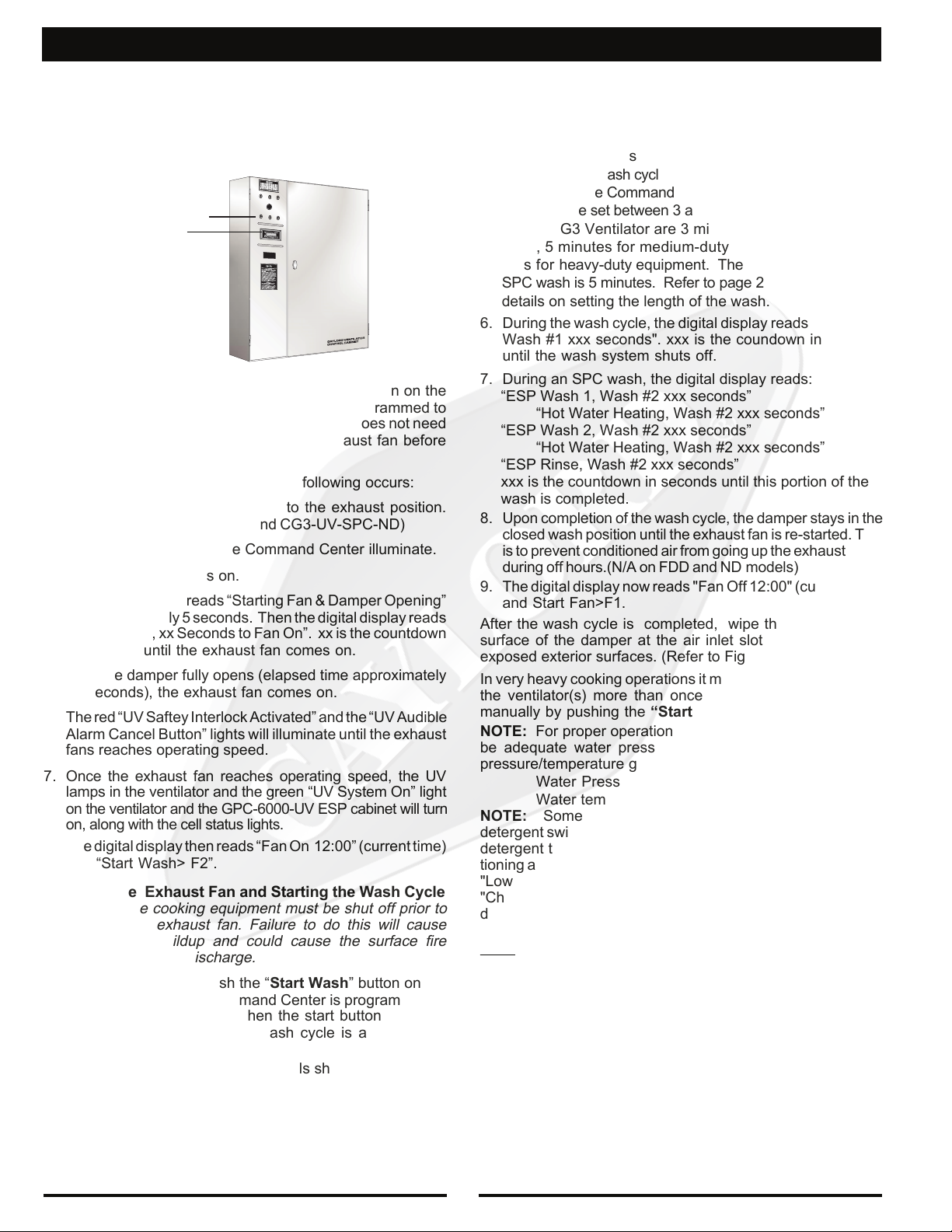

COMMAND CENTER

MODEL C-6000-UV-ESP

SERIES

FIG. 2

VENTILATOR CONTROL CABINET

MODEL GPC-6000-UV SERIES

WATER SUPPLY

FROM CONTROL

CABINET

SPRAY NOZZLES

HOT DETERGENT

WATER SPRAY

PRE-FLUSH LINE

MAIN GUTTER

DRAIN LINE

HINGED UV

ACCESS DOORS

FULL-LENGTH HINGED

INSPECTION DOORS

DAMPER CLOSED FORWARD TO

THE WASH POSITION (N/A ON

FDD AND ND MODEL CG3-UV SPC)

FIG. 3

WASH CYCLE

7

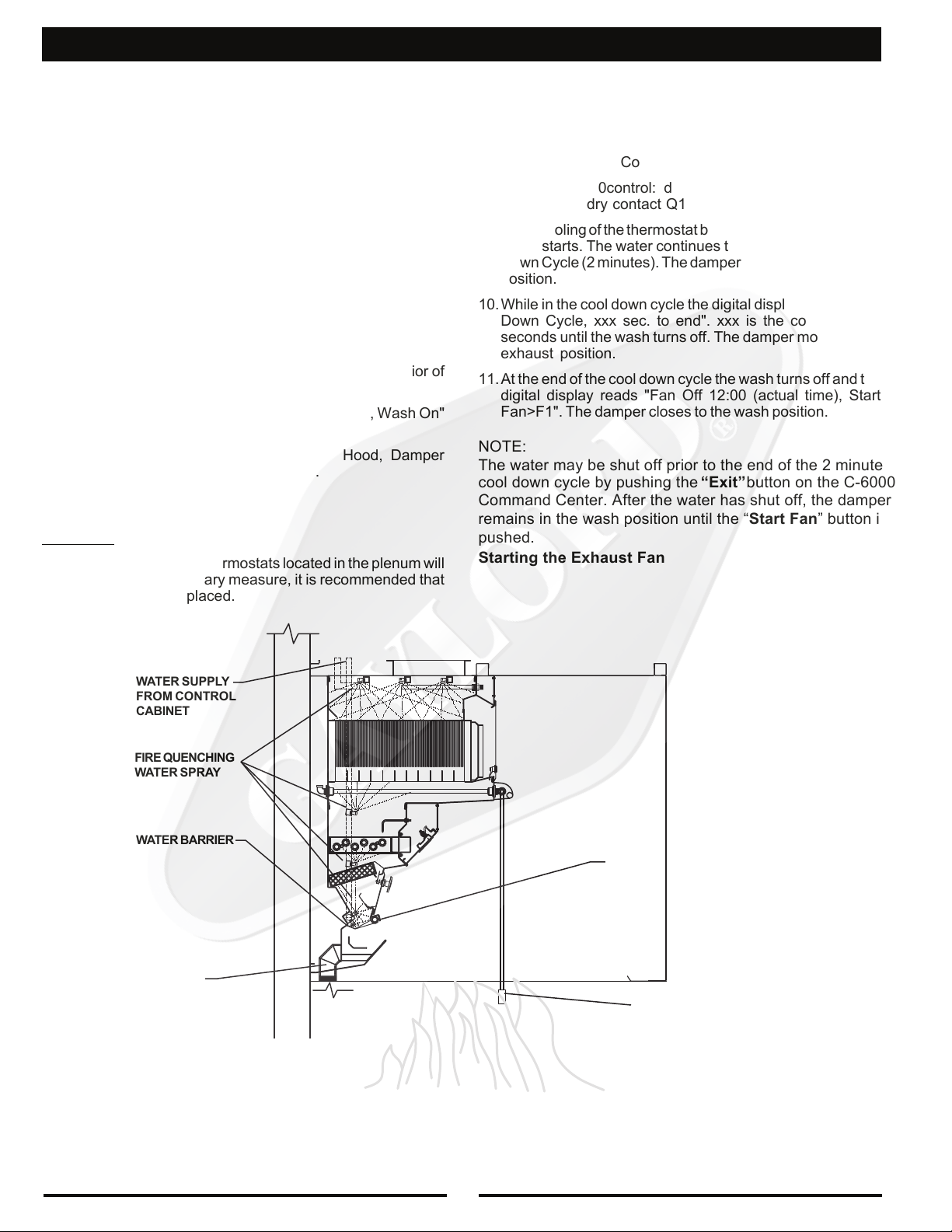

"CG3-UV" SERIES VENTILATOR PRINCIPLE OF OPERATION

INTERNAL FIRE MODE—For CG3-UV SPC

Automatic internal fire protection is accomplished by the

action of the thermostat(s), which are located at the point

where the ductwork joins the ventilator. When the temperature

of the conveying airstream, which must pass over the thermostats, reaches 250°F, the system is activated, and the

following occurs:

1. The damper begins closing back to the fire position,

position 3 as shown in Fig.4—stopping the combustionsupporting, natural draft through the ventilator and creating

a fire barrier to contain the fire in the kitchen.

2. The UV lamps are shut off.

3. The exhaust fan serving the ventilator is shut off. The supply

fan is also shut off.

4. Fire-smothering water spray is released into the interior of

the ventilator through the spray nozzles.

5. The digital display reads "Fire In Hood, Fan Off, Wash On"

for approximately 5 seconds.

6. Then the digital display reads "Fire In Hood, Damper

Closing" for approximately 5 seconds.

CAUTION:

In case of severe fire the thermostats located in the plenum will

activate. As a precautionary measure, it is recommended that

the thermostats be replaced.

7. Then the digital display reads "Fire In Hood, Notify Fire

Department". This display stays on until the thermostat

cools down below 250°F.

7. A red light on the Command Center illuminates.

8. On the C-6000control: dry contacts A1 & A2 will

CLOSE and dry contact Q1 & Q2 will OPEN.

9. Upon cooling of the thermostat below 250

o

F, the Cool Down

Cycle starts. The water continues to spray during the Cool

Down Cycle (2 minutes). The damper moves to the exhaust

position.

10.While in the cool down cycle the digital display reads "Cool

Down Cycle, xxx sec. to end". xxx is the countdown in

seconds until the wash turns off. The damper moves to the

exhaust position.

11.At the end of the cool down cycle the wash turns off and the

digital display reads "Fan Off 12:00 (actual time), Start

Fan>F1". The damper closes to the wash position.

NOTE:

The water may be shut off prior to the end of the 2 minute

cool down cycle by pushing the “Exit” button on the C-6000

Command Center. After the water has shut off, the damper

remains in the wash position until the “Start Fan” button is

pushed.

Starting the Exhaust Fan

WATER SUPPLY

FROM CONTROL

CABINET

FIRE QUENCHING

WATER SPRAY

WATER BARRIER

DRAIN LINE

DAMPER CLOSED BACK TO

THE FIRE POSITION

SURFACE FIRE

PROTECTION NOZZLE

(OPTIONAL)

FIG. 4

FIRE CYCLE

8

"CG3-UV" SERIES VENTILATOR PRINCIPLE OF OPERATION

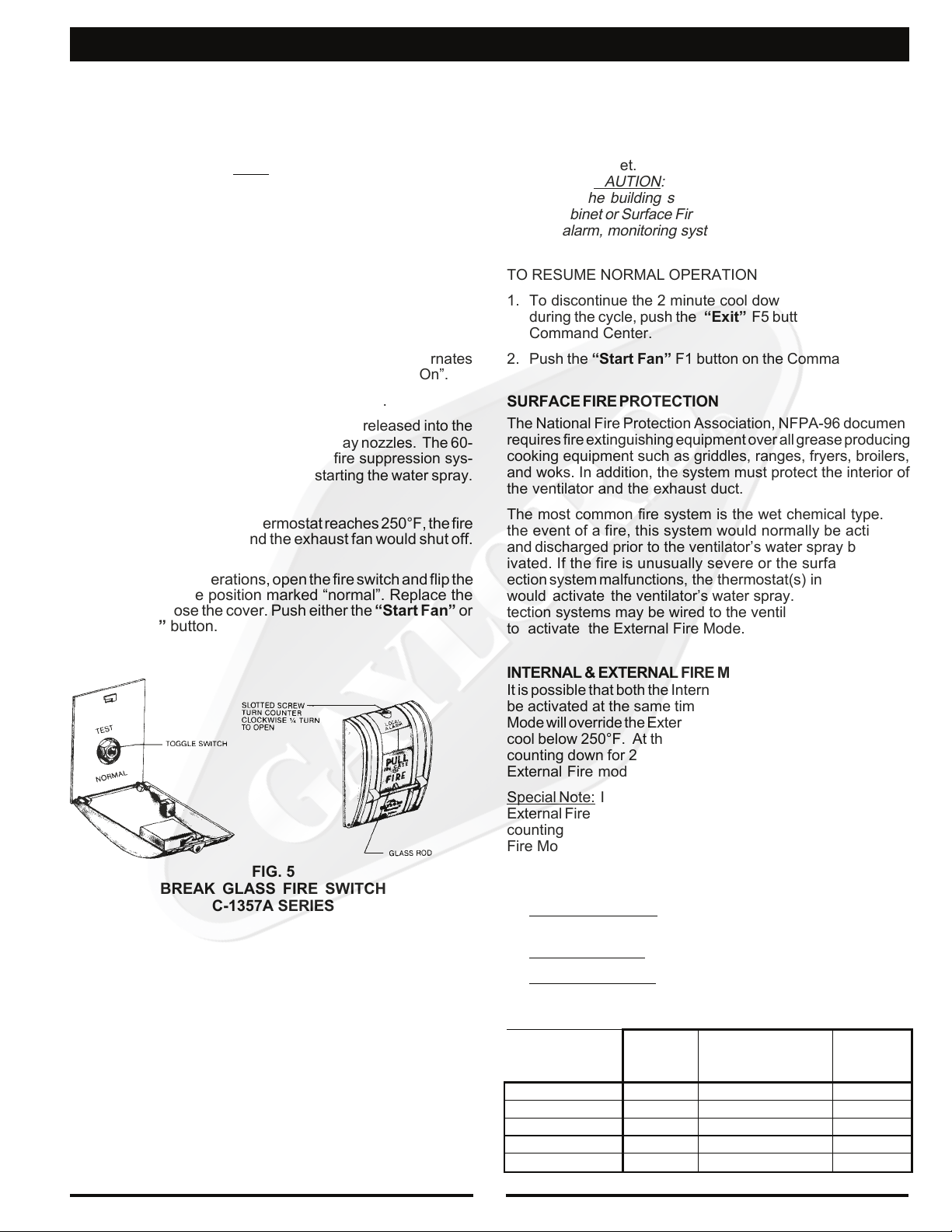

EXTERNAL FIRE MODE

An External Fire Mode is activated by the Ventilator’s Surface

Fire Protection (Duct, Plenum, Surface/Appliance) system’s

microswitch or contacts and/or an optional break glass fire

switch (see Figure 5).

Note: The Surface Fire Protection

system must be UL listed for such application and is separate

from the ventilator’s water-wash system. Terminals 4 & FS are

used for the External Fire Mode, refer to the wiring diagram for

details. The break glass fire switch, if used, would normally be

located at the exit of the kitchen. When the External Fire Mode

is activated the following occurs:

1. The Exhaust Fan comes on immediately if it was off to help

remove smoke, heat, etc.

2. The Supply Fan shuts off immediately.

3. The digital display reads “Ext.FireActive” and alternates

between “Reset FireSwitch” and “Fan On, Wash On”.

4. A red light on the Command Center flashes.

5. After a 60-second delay, a water spray is released into the

interior of the ventilator through the spray nozzles. The 60-

second delay allows the ventilator’s fire suppression sys-

tem time to put out the fire, before starting the water spray.

If the fire intensifies and the thermostat reaches 250°F, the fire

damper would then close and the exhaust fan would shut off.

See Internal Fire Mode.

To resume normal operations, open the fire switch and flip the

toggle switch to the position marked “normal”. Replace the

glass rod and close the cover. Push either the “Start Fan” or

“Start Wash” button.

TESTING INTERNAL FIRE MODE

To test the Internal Fire Mode, a fire detected by the ventilator’s

thermostat(s), push and hold the “Fire Test Switch” button for

20 seconds. It is located inside the electrical compartment of

the control cabinet. Pushing this switch duplicates thermostatic action.

CAUTION: Before any Fire Tests are performed,

check with the building superintendent to see if the Gaylord

control cabinet or Surface Fire Protection system is wired to the

building alarm, monitoring system, and/or the fire department

TO RESUME NORMAL OPERATION

1. To discontinue the 2 minute cool down cycle at any point

during the cycle, push the “Exit” F5 button on the C-6000

Command Center.

2. Push the “Start Fan” F1 button on the Command Center.

SURFACE FIRE PROTECTION

The National Fire Protection Association, NFPA-96 document

requires fire extinguishing equipment over all grease producing

cooking equipment such as griddles, ranges, fryers, broilers,

and woks. In addition, the system must protect the interior of

the ventilator and the exhaust duct.

The most common fire system is the wet chemical type. In

the event of a fire, this system would normally be activated

and discharged prior to the ventilator’s water spray being activated. If the fire is unusually severe or the surface fire protection system malfunctions, the thermostat(s) in the ventilator

would activate the ventilator’s water spray. Surface fire protection systems may be wired to the ventilator control cabinet

to activate the External Fire Mode.

.

FIG. 5

BREAK GLASS FIRE SWITCH

C-1357A SERIES

INTERNAL & EXTERNAL FIRE MODES AT THE SAME TIME

It is possible that both the Internal and External Fire modes can

be activated at the same time. If this occurs the Internal Fire

Mode will override the External Fire mode until the thermostat(s)

cool below 250°F. At this point the Cool Down Cycle will start

counting down for 2 minutes. After the Cool Down Cycle, the

External Fire mode will start.

Special Note: If the control is in the Cool Down Cycle when the

External Fire mode is activated, the Cool Down Cycle will finish

counting down for 2 minutes, before switching to the External

Fire Mode.

Summary of Both Fire Modes at the Same Time

1. Internal Fire Mode (until thermostat temperature drops

below 250°F)

Cool Down Cycle (for 2 minutes)

2.

3.

External Fire Mode (until the External Fire Switch is reset)

FIRE MODE SUMMARY:

Note: The Damper Position does not apply to

CG3-U V-FDL SP C

CG3-U V-

FDD SPC

or CG3-UV-ND SPC

Exhaust Fan

Supply Fan

Damper Position

Water Spray

UV Lamps

INTERNAL

FIRE

OFF OFF ON

OFF OFF OFF

FIRE EXHAUST EXHAUST

ON ON ON

OFF OFF ON

COOL DOWN

CYCLE (for Internal

Fire Mode only!)

EXTERNAL

FIRE

9

DAILY OPERATION

DAILY OPERATION

All functions of the ventilator, such as starting the exhaust fan,

starting the wash cycle, etc., are controlled by the Command

Center located on the control cabinet. Refer to Pages 16

through 19 for detailed instructions on the operation of the

Command Center.

ESP CELL STATUS LIGHTS

COMMAND CENTER

MODEL C-6000-UV SPC SERIES

VENTILATOR CONTROL

MODEL GPC-6000-UV-ESP

FIG. 6

CABINET

SERIES

To start the exhaust fan push the “Start Fan” button on the

Command Center. If the Command Center is programmed to

start the fan automatically, then the start button does not need

to be pushed. It is important to start the exhaust fan before

turning on the cooking equipment.

When the exhaust fan is activated the following occurs:

1. The damper begins opening on to the exhaust position.

(N/A on CG3-UV-SPC-FDD and CG3-UV-SPC-ND)

2. Green status lights on the Command Center illuminate.

3. The supply fan comes on.

4. The digital display reads “Starting Fan & Damper Opening”

for approximately 5 seconds. Then the digital display reads

“Starting Fan, xx Seconds to Fan On”. xx is the countdown

in seconds until the exhaust fan comes on.

5. After the damper fully opens (elapsed time approximately

45 seconds), the exhaust fan comes on.

6. The red “UV Saftey Interlock Activated” and the “UV Audible

Alarm Cancel Button” lights will illuminate until the exhaust

fans reaches operating speed.

7. Once the exhaust fan reaches operating speed, the UV

lamps in the ventilator and the green “UV System On” light

on the ventilator and the GPC-6000-UV ESP cabinet will turn

on, along with the cell status lights.

8. The digital display then reads “Fan On 12:00” (current time)

and “Start Wash> F2”.

Stopping the Exhaust Fan and Starting the Wash Cycle

CAUTION: The cooking equipment must be shut off prior to

shutting off the exhaust fan. Failure to do this will cause

excessive heat buildup and could cause the surface fire

protection system to discharge.

To start the wash cycle push the “Start Wash” button on the

Command Center. If the Command Center is programmed to

start the wash automatically, then the start button does not

need to be pushed. When the wash cycle is activated the

following occurs:

1. The UV lamps and electrostatic cells shut off.

2. The exhaust and supply fans shut off.

3. The damper begins closing forward to the wash position.

(See Figure 3, page 7). This action takes approximately 45

seconds. (N/A on FDD and ND models)

4. The digital display reads "Starting Wash, Damper Closing"

for approximately 5 seconds, then the digital display reads

"Starting Wash, Wash On in xx seconds". xx is the

countdown in seconds to until the wash starts.

After the damper in the ventilator closes to the wash pos-

5.

ition, the hot detergent injected water sprays come on to

wash away the grease and smoke collected during the day’s

operation. The wash cycle stays on for the length of time programmed in the Command Center. The length of the wash

cycle may be set between 3 and 9 minutes. Typical settings

for the CG3 Ventilator are 3 minutes for light-duty equipment, 5 minutes for medium-duty equipment and 9 minutes for heavy-duty equipment. The typical setting for the

SPC wash is 5 minutes. Refer to page 20 for

details on setting the length of the wash.

6. During the wash cycle, the digital display reads "Wash On,

Wash #1 xxx seconds". xxx is the coundown in seconds

until the wash system shuts off.

7. During an SPC wash, the digital display reads:

“ESP Wash 1, Wash #2 xxx seconds”

“Hot Water Heating, Wash #2 xxx seconds”

“ESP Wash 2, Wash #2 xxx seconds”

“Hot Water Heating, Wash #2 xxx seconds”

“ESP Rinse, Wash #2 xxx seconds”

xxx is the countdown in seconds until this portion of the

wash is completed.

8. Upon completion of the wash cycle, the damper stays in the

closed wash position until the exhaust fan is re-started. This

is to prevent conditioned air from going up the exhaust stack

during off hours.(N/A on FDD and ND models)

9. The digital display now reads "Fan Off 12:00" (current time)

and Start Fan>F1.

After the wash cycle is completed, wipe the exposed front

surface of the damper at the air inlet slot, as well as other

exposed exterior surfaces. (Refer to Figure 7, Page 11).

In very heavy cooking operations it may be necessary to wash

the ventilator(s) more than once a day. This can be done

manually by pushing the “Start Wash” button.

NOTE: For proper operation of the wash system there must

be adequate water pressure and temperature. There is a

pressure/temperature gauge inside the control cabinet.

Water Pressure 40 psi min. - 80 psi max.

Water temperature 140°F min. - 180°F max.

NOTE: Some control cabinets are equipped with a low

detergent switch. If so equipped, the green light will flash if the

detergent tank is empty or if the detergent pump is malfunctioning and detergent is not pumping. The digital display reads

"Low Detergent" and the text alternates from "Fill Tank" and

"Check Pump". If the detergent tank is filled with water the

detergent switch will activate as if there is no detergent.

NOTE: The ventilator wash system is designed to remove

daily accumulations of grease within the extraction

chamber. If the ventilator is not washed a minimum of once

during a cooking day, a grease buildup could accumulate which

the wash system cannot remove. If this occurs, it is

recommended that the ventilator be put through several wash

cycles by pushing the “Start Wash” button on the Command

Center. If this does not remove the grease, it will be necessary

to remove the grease manually by using a scraping tool, such

as a putty knife, or retain the services of a commercial hood

cleaning service to steam clean or pressure wash the system.

WARNING: Some commercial hood cleaning services blow

a fire retardant chemical into hood and duct systems. Fire

retardant chemicals should never be applied to any portion of

The Gaylord Ventilator. If retardant is applied to the ventilator,

it must be removed.

10

PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

Some of the required maintenance can be performed by the

operator. However, direct exposure to UV light is hazardous to

your Skin and Eyes and contact with live electrical components poses a significant risk up to and including death.

Therefore, a trained, qualified and certified technician must

perform most of the maintenance.

The following should be checked periodically in order to keep

the Gaylord Ventilator and UV System operating at design

efficiency:

Daily

1. Make sure the green "UV System On" and “Cell Satus”

lamps on the hood and control cabinet are on when the

fan is on. If not, follow the UV SPC Troubleshooting proc-

edures on pages 33-34.

Weekly

1. The detergent tank should be checked at least weekly and

kept full with a recommended detergent. (Refer to Page 15)

Monthly

1. The detergent system fittings should be checked at least

monthly. This is an airtight system and fittings should be

tight. (For complete details refer to the Detergent Pump

section on Page 14.)

2. At least monthly, at the conclusion of a wash cycle, open

the inspection doors of the ventilator and check to ensure

that the interior has been cleaned of grease, dust, and lint.

(Refer to Figure 7) If overall cleaning appears to be

inadequate, refer to “Troubleshooting of the Wash Sys-

tem”, Page 29.

3. The main grease gutter of the ventilator should be checked

at least monthly to remove any foreign material such as

paper towels, order chits, etc.

4. Check the Particulate Separators, UV Lamps, and SPC

Cells to ensure they are being cleaned of grease, lint and

dust. If the cleaning is inadequate:

1. Remove the particulate separators, and/or SPC cell,

through the inspection (wash access) doors and run

them through a dishwasher or soak tank and replace.

2. The wash system needs adjustment. Refer to "Trouble

shooting the Wash System", page 29.

Every Six Months

1. Exhaust fan(s) should be checked every six months for belt

tightness, belt alignment, and lubrication of necessary

moving parts.

NOTE: A blue lithium based grease is best suited for high

heat and speed bearing lubrication.

2. Check for proper velocity at air inlet slot. Refer to Pages 24

through 26 for method of checking velocity.

3. Test the "Internal Fire Mode" to check for proper damper

closure. Refer to Page 9 for instructions.

4. Detergent tank and foot valve should be cleaned every six

months.

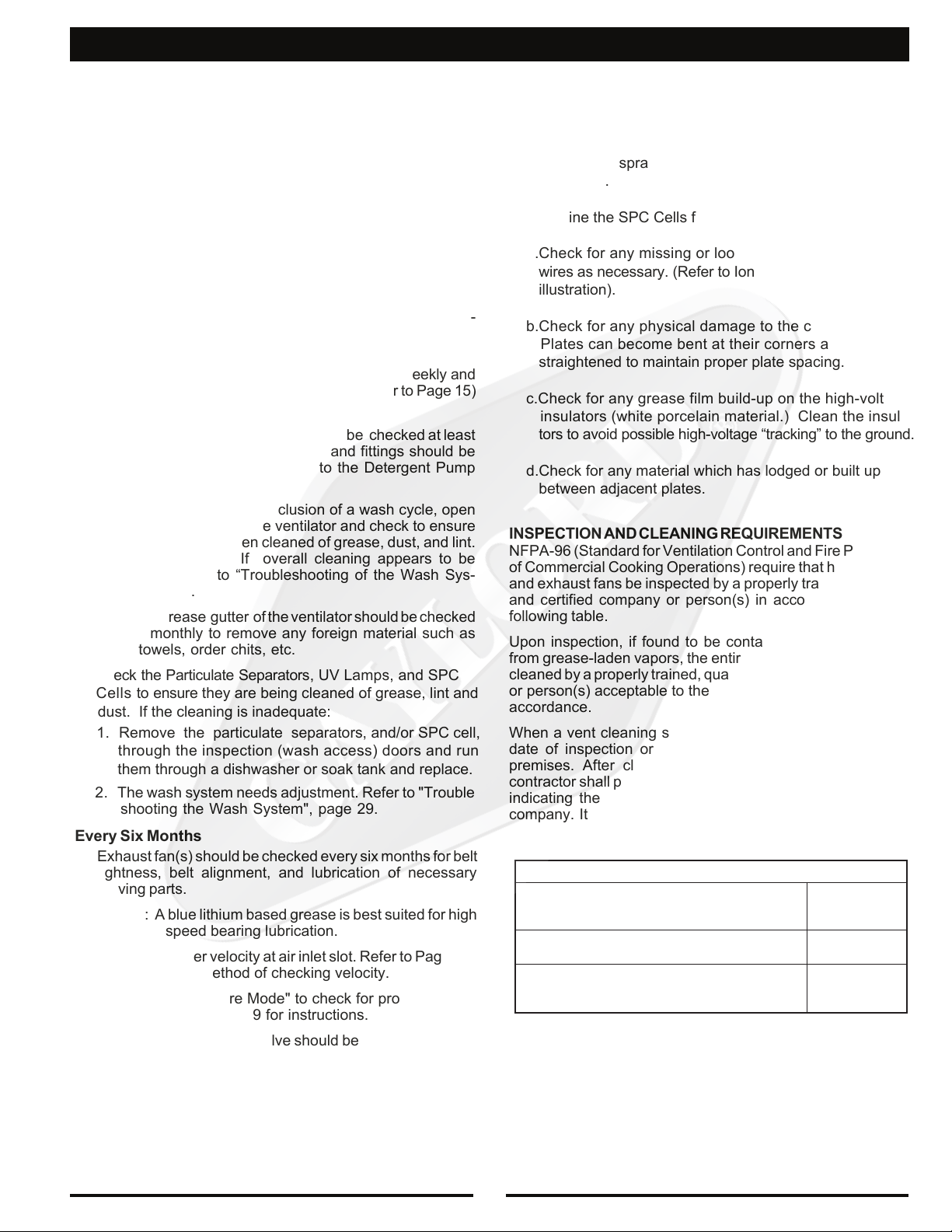

Every Six Months (SPC)

Every 6 months remove and inspect the SPC cells and

check the following:

1. Check all the spray nozzles to ensure that they are spray ing properly.

2. Examine the SPC Cells for the following:

a.Check for any missing or loose ionizer wires. Replace

wires as necessary. (Refer to Ionizing Wire Replacement

illustration).

b.Check for any physical damage to the collector plates.

Plates can become bent at their corners and must be

straightened to maintain proper plate spacing.

c.Check for any grease film build-up on the high-voltage

insulators (white porcelain material.) Clean the insula tors to avoid possible high-voltage “tracking” to the ground.

d.Check for any material which has lodged or built up

between adjacent plates.

INSPECTION AND CLEANING REQUIREMENTS

NFPA-96 (Standard for Ventilation Control and Fire Protection

of Commercial Cooking Operations) require that hoods, ducts

and exhaust fans be inspected by a properly trained, qualified

and certified company or person(s) in accordance with the

following table.

Upon inspection, if found to be contaminated with deposits

from grease-laden vapors, the entire exhaust system shall be

cleaned by a properly trained, qualified, and certified company

or person(s) acceptable to the authority having jurisdiction in

accordance.

When a vent cleaning service is used, a certificate showing

date of inspection or cleaning shall be maintained on the

premises. After cleaning is completed, the vent cleaning

contractor shall place or display within the kitchen area a label

indicating the date cleaned and the name of the servicing

company. It shall also indicate areas not cleaned.

ELUDEHCSNOITCEPSNIMETSYSTSUAHXE

snoitarepognikoocemulov-hgihgnivressmetsyS

gnikooc

kowrogniliorbrahc,gnikoocruoh-42sahcus

gnikoocemulov-etaredomgnivressmetsyS

snoitarepo

,snoitarepognikoocemulov-wolgnivressmetsyS

lanosaes,spmacyad,sehcruhcsahcus

sretnecroinesro,sessenisub

ylretrauQ

yllaunna-imeS

yllaunnA

Factory trained service agencies are certified by Gaylord

Industries, Inc. to perform these inspections. For the name and

phone number of your nearest agent visit our web site at

www.gaylordusa.com, email at info@gaylordusa.com, or call

1-800-547-9696.

11

ESP SECTION - PREVENTIVE MAINTENANCE

MOUNTING

BRACKET

IONIZING

WIRE

INSERT HOOK OF ONE

SPRING INTO HOLE

A

PULL SECOND SPRING UNTIL

HOOK CAN BE SECURED IN

MOUNTING BRACKET HOLE

B

SMOKE POLLUTION CONTROL CELL

AIRFLOW

HighVoltage - Be sure power is off and high voltage circuit is grounded before

touching the wire terminals. Refer to the Gaylord“ClearAire”Technical Manual

for complete operation & maintenance instructions.

Cell Removal - This cell weighs more than 52lbs. Handle with care when removing for cleaning and

servicing.When handling cell, hold framework only. Do not touch the plates as they could be damaged.

Cleaning Cell -The smoke pollution control cells in this system are made of aluminum. Use of a deter-

gent harmful to aluminum will void the warranty and may cause permanent damage.

WARNING: CELL AND UNIT AIRFLOW DIRECTION MUST MATCH

AIRFLOW

INNER CELL

MODELNO.: C-24-I

CAUTION

INNER CELL

MODELNO.: C-24-I

SMOKE POLLUTION CONTROL CELL

HighVoltage - Be sure power is off and high voltage circuit is grounded before

touching the wire terminals. Refer to the Gaylord“ClearAire”Technical Manual

for complete operation & maintenance instructions.

Cell Removal - This cell weighs more than 52lbs. Handle with care when removing for cleaning and

servicing.When handling cell, hold framework only. Do not touch the plates as they could be damaged.

Cleaning Cell - The smoke pollution control cells in this system are made of aluminum. Use of a deter-

gent harmful to aluminum will void the warranty and may cause permanent damage.

WARNING: CELL AND UNIT AIRFLOW DIRECTION MUST MATCH

CAUTION

b. Check for any physical damage to the collector plates.

Plates can become bent at their corners and must be

straightened to maintain proper plate spacing.

c.Check for any grease film build-up on the high voltage

insulators (white porcelain material.) Clean the insulators to avoid possible high voltage “tracking” to the ground.

d.Check for any material which has lodged or built up

between adjacent plates.

Replacing the Ionizing Wire

1.Remove all of the broken wire from the cell mounting brackets.

2.Install the new wire:

A. Insert hook of one spring into hole.

B. Use long-nose pliers and carefully pull second spring

until hook can be secured in mounting bracket hole.

CAUTION: The electrostatic cells are made of aluminum. DO

NOT use any type of detergent that may attack aluminum or

anodizing. It is highly recommended that Formula G-510

Colloid Cleaner be used in the wash system. Refer to Page

27 for details.

OUTER CELL

Note: See page 63 for part numbers

SPC CELL

UV LAMPS

PARTICULATE

SEPARATOR

MAIN GREASE

GUTTER

DURING CLEAN-UP

PROCEDURES AT

THE END OF THE

COOKING PERIOD

SPECIAL ATTENTION

SHOULD BE GIVEN

TO WIPING CLEAN

THE DAMPER AT

THE AIR INLET OF

THE VENTILATOR

IONIZING WIRE REPLACEMENT

SPC ACCESS DOOR(S)

INSPECTION

(WASH ACCESS

DOO RS)

DURING CLEAN-UP PROCEDURES

AT THE END OF THE COOKING

PERIOD THESE AREAS SHOULD

BE WIPED DOWN.

FIG. 7

PLUNGER SAFETY SWITCH

"DAMPER ACTUATOR

ACCESS” PANEL

DAMPER ACTUATOR

LOCATED BEHIND

THIS PANEL

12

UV PREVENTIVE MAINTENANCE

CERTIFIED SERVICE AGENT MAINTENACE WARNING!

Warning: Do NOT defeat the purpose of the interlocks during cleaning and maintenance!

These items will need to be performed by a trained and qualified Certified Service Agency (CSA) on the same schedule as

the exhaust system inspection schedule described in NFPA96 and on the previous page in this tech manual. These tasks

involve potential exposure to high doses of UV light and live

electrical components. There is risk of injury to skin and eyes

and in the case of electrical shock, injury or death! For a list of

CSAs go to www.gaylordusa.com and go to "Service Agencies" for a list of companies nearest you.

1. Inspection of the Lamps and Ballasts

a. Check the lamps for proper operation

1. Turn on the fan and look for the green "UV System

On" light on each hood section

a. If it is not on refer to "UV Troubleshooting",

pages 34-35.

2. Open the UV Access door with the key

3. Turn on fan

4. Close inspection (wash access) doors

5. Depress the UV Access door safety switch

6. Check all indicator LEDs, 6 green and 3 red, to

ensure that they are all on. If they are not all on go to

"UV Troubleshooting", pages 34-35.

2. Inspect the Upper Wash chamber (around the UV

lamps)

a. Disconnect the UV module power cord

b. Remove the nuts holding the UV module to the ventila-

tor with a nut driver

c. Remove the UV module from the ventilator

d. Check for build-up of deposits of grease, dust and/or lint.

e. Clean as necessary with a mild dteregent, water and a rag

f. If the area is not clean refer to "Troubleshooting the

Wash System", on page 29.

g. Reinstall the UV module.

3. Test the Safety Interlock switches

a. Open the inspection (wash access) door with the fan on

• The UV lamps should shut off

• An audible alarm on the C-6000 should come on

• The Red “UV Safety Interlock Activated” light on the

ventilator and C-6000 control should come on

b. Open the UV Access door with the fan on

• The UV lamps should shut off

• An audible alarm on the C-6000 should come on

• The Red “UV Safety Interlock Activated” light on the

ventilator and C-6000 control should come on

c. Turn off the breaker to the Exhaust Fan. Press the

“Start Fan” button on the C-6000 control

• The UV lamps should shut off (stay off)

• An audible alarm on the C-6000 should come on

• The Red “UV Safety Interlock Activated” light on the

ventilator and C-6000 control should come on

4. Check all gaskets for damage

a. Replace any gaskets that are worn or damaged

5. Check the Hour Meter

a. Record the hours.

b. Determine the approximate hours between inspection

intervals.

c. Determine when the 8000-hour life of the lamps will

occur and inform the operator of the approximate date

when the lamps will need to be replaced

Replacing UV Lamps

Danger!

These items will need to be performed by a trained and qualified

Certified Service Agency (CSA). These tasks involve potential

exposure to high doses of UV light and live electrical components. There is a risk of serious injury to skin and eyes from

UV light. There is risk of shock, injury, and/or death from

electrical. For a list of CSA’s go to www.gaylordusa.com and

go to the “Service Agencies” for a list of certified companies

nearest you.

1. Secure all power to the C-6000 control

2. Secure all circuits that provide power to the UV lamps

3. Open the UV Access door with the key

4. Disconnect the UV module power cord

5. Remove the nuts holding the UV module to the ventilator

with a nut driver

6. Remove the UV module from the ventilator

7. Remove the bolts on each end of the UV module (2 on each

end) that hold the end caps on

8. Disconnect the lamp connector(s) on the UV lamp(s) to be

replaced

• Each lamp connector should be labeled from 1 to 6 on

both ends

• Lamp #1 is at the Front of the ventilator when the UV

module is installed

• Lamp #6 is at the Back of the ventilator when the UV

module is installed

• Be sure to re-label the lamp connectors if necessary

9. Lubricate the lamps around the grommets on each end of

the UV lamp with a small amount of G-510 or similar

detergent

10.Slide the UV lamp out one end, CAREFULLY!

11.Inspect the grommets around the lamps

• Replace any grommets that show cracks, checking, or

any other damage

12.Check all wires for damage

• Replace any wires showing damage

13.Lubricate each of the new UV lamp(s) before installing with

a small amount of G-510 or similar detergent

14.Re-connect the lamp connectors on both ends of the UV

lamps

• Each lamp connector should be labeled from 1 to 6) on

both ends

• Lamp #1 is at the Front of the ventilator when the UV

module is installed

• Lamp #6 is at the Back of the ventilator when the UV

module is installed

15.Re-install the UV module end caps and torque the bolts to

7-10 in-lbs.

16.Re-install the UV module in the ventilator

17.Tighten all nuts holding the UV module to the ventilator

18.Re-connect the UV module power cord

19.Check for proper operation of UV lamps

13

SAFETY CONCERNS WITH UVC

As with many types of technology if it is not used properly and/

or proper precautions are not taken there is the potential for

injury or harm. This is especially true with UVC light due to the

fact that it does not physically hurt at the time of exposure.

While UVC is very effective at breaking down grease molecules, direct exposure to large amounts is harmful to skin and

eyes. The amount of UVC generated in these hoods is greater

than that what results from direct exposure to the sun. Under

no circumstances is it acceptable to view the lighted lamps

without proper eye protection or expose bare skin directly to

the light. All interlocks and safety precautions called for in this

manual must be followed to avoid the potential for harm to

service personnel and/or operators. In addition, only trained

and authorized personnel may perform some maintenance

See previous page for details.

Personal Protective Equipment

1. Eye protection that prevents 100% of UVC being transmit-

ted through the lens must be worn at all times when

performing service work on any Ultima Vent that is ener-

gized and/or has the potential to be energized and expose

personnel to UVC light.

2. Whenever service work is performed it is recommended

that long sleeve pants and shirts be worn to minimize the

potential for inadvertent exposure of the skin to UVC.

Safety Interlocks

This product comes equipped with the following sensors to

verify that all access doors are in place and that the exhaust

fan is running:

1. Mechanical door switch on the UV Access door to ensure

that the door is closed

2. Proximity Switch on the Inspection (wash access door) to

ensure that the door is closed.

3. Air Pressure switch to verify air flow and exhaust fan

operation

All of these devices must be working and/or adjusted properly

in order for the system to operate properly.

14

DETERGENT PUMP OPERATION

The Gaylord Ventilator detergent pump is an integral part of the

wash-down system of The Gaylord Ventilator. The pump is

located within the control cabinet unless otherwise specified.

(Refer to schematics on Pages 38 through 40.)

OPERATION

The detergent pump is started when the wash cycle begins.

The pump draws detergent up from the detergent tank, pushing

it through the copper tubing and into the hot water line serving

the ventilator.

NOTE: Some control cabinets are equipped with a low

detergent switch. If so equipped, the green light will flash if the

detergent tank is empty or if the detergent pump is malfunctioning and detergent is not pumping. The digital display reads

"Low Detergent" and the text alternates from "Fill Tank" and

"Check Pump". If the detergent tank is filled with water the

detergent switch will activate as if there is no detergent.

Initial Operation

To prime and operate the pump for the first time, it is recom-

mended that water be used instead of detergent to prevent

detergent from spilling in case of leaks at the system’s fittings.

Priming The Pump

The detergent pump is self-priming. Push the pump test

switch, located on the junction box of the motor, and hold down

until liquid climbs up the vinyl tubing and fills the pump head.

The pump will be operating properly when both upper and lower

poppet checks can be seen moving up and down slightly. If the

pump does not self-prime, an air lock may have developed

within the pump head and the following action should be taken:

1. Hold down pump test switch and loosen top cap slightly to

allow air to be pushed out. Repeat as necessary until liquid

climbs up tube and fills pump head.

Note: Do not overly tighten cap or damage to the pump

head will occur.

2. If the pump still does not work properly, check the following:

A. Foot valve should be clean and immersed in the liquid.

B. Check all fittings to ensure an airtight system.

C. Poppet checks within the foot valve, pump head and

brass check valve should be clean and operating

freely.

D. Detergent lines should be free and clear.

PREVENTIVE MAINTENANCE

As with any piece of fine equipment, a reasonable amount of

care must be taken to keep it in good working order:

1. Caution should be taken not to spill detergent on the

exterior of the pump.

2. A periodic check should be made of all fittings

to guarantee their tightness.

NOTE: The detergent pump motor has sealed bearings and

will not require lubrication.

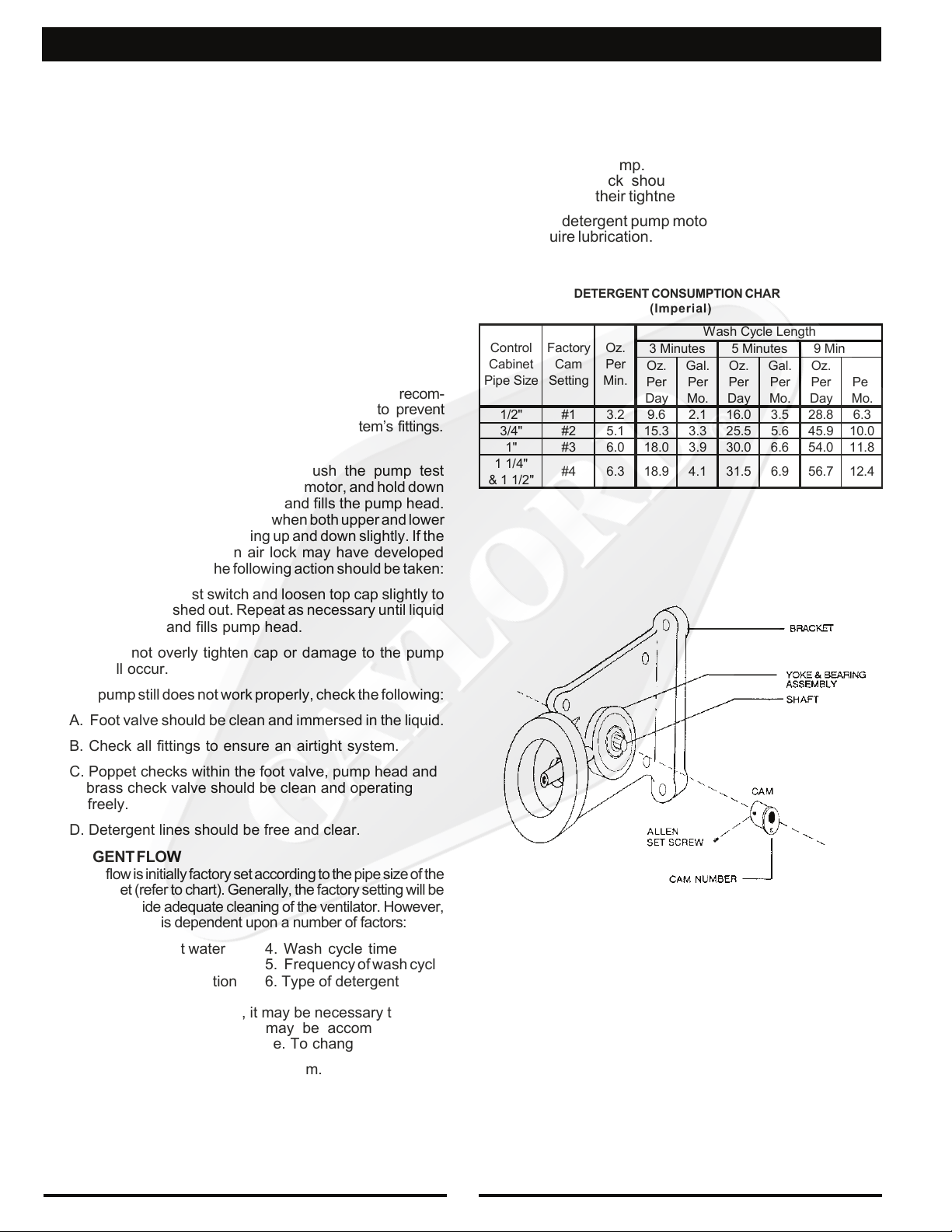

DETERGENT CONSUMPTION CHART

Control

Cabinet

Pipe Size

1 1/4"

& 1 1/2"

Factory

Cam

Setting

1/2" #1 3.2 9.6 2.1 16.0 3.5 28.8 6.3

3/4" #2 5.1 15.3 3.3 25.5 5.6 45.9 10.0

1" #3 6.0 18.0 3.9 30.0 6.6 54.0 11.8

Min.

#4 6.3 18.9 4.1 31.5 6.9 56.7 12.4

Oz.

Per

(Impe ria l)

3 Minutes

Oz.

Gal.

Per

Per

Day

Mo.

Wash Cycle Length

5 Minutes 9 Minutes

Oz.

Gal.

Per

Per

Day

Mo.

Oz.

Per

Day

Gal.

Per

Mo.

DETERGENT FLOW

Detergent flow is initially factory set according to the pipe size of the

control cabinet (refer to chart). Generally, the factory setting will be

sufficient to provide adequate cleaning of the ventilator. However,

adequate cleaning is dependent upon a number of factors:

1. Temperature of hot water 4. Wash cycle time

2. Water pressure 5. Frequency of wash cycle

3. Daily grease accumulation 6. Type of detergent

Depending upon these factors, it may be necessary to adjust

the detergent flow. Adjustment may be accomplished by

changing the cam to a different size. To change the cam:

1. Loosen Allen set screw on brass cam.

2. Remove cam and replace with next size as required.

3. Cam #1 minimum setting. Cam #4 maximum setting.

NOTE: Cams are available from Gaylord Industries or your

Gaylord Certified Service Agency.

FIG. 8

15

DETERGENT FOR THE WASH SYSTEM

FORMULA G-510 is the only cleaner recommended by Gaylord Industries for use in the washdown system of The Gaylord

Ventilator. FORMULA G-510 is a concentrated colloid cleaner

specially formulated to remove the daily accumulation of

grease inside The Gaylord Ventilator without damaging the

rubber and synthetic parts of the detergent pumping system.

FORMULA G-510 is biodegradable, safe for kitchen personnel, and has a variety of uses.

DILUTION OF FORMULA G-510 FOR

VENTILATOR CLEANING

Normal Cleaning

For ventilators covering cooking equipment such as broilers,

griddles, fryers, or any other heavy grease producing equipment, fill the detergent tank with full strength FORMULA

G-510.

Light-Duty Cleaning

For ventilators covering light grease producing equipment such

as ovens, kettles, steamers and ranges, fill the detergent tank

with a mixture of one part FORMULA G-510 to one part water.

Cleaning the Ventilator Exterior

Mix one part FORMULA G-510 to twenty parts water in hand

spray bottle. Spray on and wipe off. NOTE: Once a day, this

same solution should be used to clean the front of the fire

damper and main grease extracting baffle.

FOR OTHER CLEANING JOBS

The colloidal action of FORMULA G-510 makes it a cleaner

especially well-suited for use in kitchens. The colloids break

up dirt and grease into millions of tiny particles that constantly

repel each other. These particles cannot recombine or rede-

posit on a surface and are, therefore, easily washed away.

FORMULA G-510 is biodegradable and contains no harsh

chemicals, yet offers outstanding performance on the tough-

est cleaning jobs.

Use a mixture of one part FORMULA G-510 to twenty parts

water for:

VINYL/PLASTIC/WALLS...Removes dirt, grease, food de-

posits and fingerprints.

REFRIGERATORS...Removes dirt, spilled milk, blood,

mildew and objectionable odors.

RESTROOMS...Add a disinfectant to clean all fixtures,

walls, floors, etc.

Use a mixture of one part FORMULA G-510 to five parts water

for extremely heavy grease build-up, such as on the floor and

on equipment around deep-fryers. Spray on and rinse or wipe

off. For extremely soiled areas, gentle agitation, followed by a

soaking period, will result in more thorough cleaning.

DON’T be afraid to experiment with FORMULA G-510 because

it contains no phosphates, nitrates, enzymes, sulfates, sulfonates or silicates.

LIMITED WARRANTY

G-510 CHEMICAL DIVISION warrants that FORMULA G-510 will not cause cleansing agent damage

to the rubber and synthetic parts of the injection pump

(“O” rings, diaphragms, washers, tubing, and other

such parts) used with The Gaylord Ventilator, Heat

Reclaim Unit, or Pollution Control Equipment. G-510

CHEMICAL DIVISION’S obligation under this warranty and any warranties implied by law shall be

limited to repairing or replacing, at its option, any of

said parts which G-510 CHEMICAL DIVISION'S

examination shall disclose to its satisfaction to have

been damaged by the use of FORMULA G-510 for the

life of the detergent pumping system. This warranty

shall not cover damages caused by any other detergent. The use of any other detergent shall void this

warranty.

All repairs and replacement parts under this warranty

shall be F.O.B. G-510 CHEMICAL DIVISION’S fac-

tory. The owner shall pay the necessary freight and

delivery charges; also removal and installation

costs. Any federal, state or local taxes are also extra.

Requests for repairs or replacement parts should be

made to 20/10 Products Inc., PO Box 7609, Salem,

OR 97303.

This is the sole warranty with respect to FORMULA G-

510. G-510 CHEMICAL DIVISION MAKES NO OTHER

WARRANTY OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE WHICH EXCEED

THE AFORESAID OBLIGATION ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS AGREEMENT. G-510 CHEMICAL DIVISION SHALL NOT BE

RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM A

BREACH OF THIS WARRANTY.

IMPORTANT

If a cleansing agent other than FORMULA G-510 is used with

The Gaylord Ventilator injection pump, it is recommended that

a warranty similar to the above be obtained from the manufacturer of said product.

For name and address of the nearest FORMULA G-510

distributor contact:

20/10 Products Inc.

P.O. Box 7609

Salem, OR 97303

Phone: 800-286-2010

FAX: 503-363-4296

E-Mail: twentyten@juno.com

16

MODEL C-6000 SERIES COMMAND CENTER - INSTRUCTIONS

General Description:

The C-6000 Command Center is designed to start and stop the

exhaust fan and wash up to 5 groups of ventilators in sequence

with a delay period between each group. A sequence wash may

be necessary if the building’s hot water system is not capable

of supplying the required volume of water at one given time.

The exhaust fan and wash sequence may be started Manu-

ally by pushing the “Start Fan” or “Start Wash” buttons, or

may be programmed for Automatic operation.

3. Programming the length of the wash cycles and delay

periods between the wash and rinse cycles. The maximum

length of a wash cycle is 9 minutes. The maximum length

of the delay period is 99 minutes.

4. Skipping a day so the exhaust fan and wash cycle do not

operate for holidays or specific days within a 7-day week

when the kitchen is not operating.

Programmed operations may include:

1. Starting the exhaust fan once within a 24-hour period.

2. Stopping the exhaust fan and starting the wash cycle

sequence once within a 24-hour period

START

WASH

SPANI SH

MEN U EXI T EN TER

ESPAN OL

START

FAN

Part # 1 9764

The C-6000 Command Center provides information and programming for various functions by accessing nine different menu

catagories. An overview of the nine menu items are as follows:

1. Service - Di splay s Gaylo rd's web site add ress:

gaylordusa.com

2. Detergent - Displays Toll-Free Number to order detergent:

800-286-2010

3. Wash Length - Sets length of each wash cycle from 3 to

9 minutes

4. Delay Time (for sequence wash units only) - Sets delay

between washes from 1 minute to 99 minutes

5. Set Clock - Day, hour and minutes

6. AutoMode [M or A] - Sets the C-6000 to Manual or

Automatic modes. In Automatic mode, the C-6000 will start

the Fan and Wash at the preset times that were set using

the Set Wash Times option.

A = Automatic / M = Manual

Also allows individual days (Mon, Tues., etc.) to be set ON

or OFF when Automatic mode is selected.

7. Set Wash Times - Sets Start Times for Automatic start of

Fan and wash when C-6000 is set to Automatic mode.

8. Wash Test - Runs through a complete Wash Cycle with

decresed times

Damper Closing Time = 10 sec.

Wash Times = 10 sec.

Water Heating Time = 10 sec.

Exits menu when finished.

9. Number of Washes - Preset at factory and protected with

a password. Allows the number of washes to be changed

from 1 to 5 (S1 to S5).

FIGURE 9

C-6000 COMMAND CENTER

Using the Menu:

To Enter the Menu, press the MENU button [F4].

To navigate the Menu:

• Press [F1] to go to the Next menu item

• Press [F2] to go to the Previous menu item

• Press [F5], the EXIT button to exit the Menu

• Press [F6], the ENTER button to select a Menu item

17

MODEL C-6000 SERIES COMMAND CENTER - INSTRUCTIONS

1. Service

• Press [F6] [ENTER] to display Gaylord’s web site

address: gaylordusa.com

• Press [F5] [EXIT] to return to the menu

2. Detergent

• Press [F6] [ENTER] to display the Phone Number to

order Detergent: 800-286-2010

• Press [F5] [EXIT] to return to the menu

3. Wash Length

• Press [F6] [ENTER] to display the Length of Wash #1

• Press [F3] to Increase the Wash Time up to 9 Minutes

(Maximum)

• Press [F4] to Decrease the Wash Time down to 3

Minutes (Minimum)

• Press [F1] to adjust the Length of Wash #2 (if applicable)

• Press [F5] [EXIT] to return to the menu

• Note: Press [F1] to advance through all washes (ex.)

“-S2” has 2 washes)

4. Delay Time

• Press [F6] [ENTER] to display the Delay Time between

washes (Not used if there is only one wash)

• Press [F3] to Increase the Delay Time up to 99 Minutes

(Maximum)

• Press [F4] to Decrease the Delay Time down to 1 Minute

(Minimum)

• Press [F5] [EXIT] to return to the menu

5. Set Clock

• Press [F6] [ENTER] to display the current Day of the

Week (1=Sunday)

• Press [F3] to change to the next Day of the Week

(1=Sun, 2=Mon, 3=Tues, etc.), keep pressing [F3] to

cycle around if necessary

• Press [F1] to go to the current Hour

• Press [F3] to increase the Hour, keep pressing [F3] to

cycle around if necessary

• Press [F1] to go to the current Minute

• Press [F3] to increase the Minute, keep pressing [F3]

to cycle around if necessary

• Press [F5] [EXIT] to return to the menu

6. AutoMode [A or M]

• Used to select [M]anual or [A]utomatic mode. If [A] is

displayed, the C-6000 is set to operate in Automatic

mode. If [M] is displayed, the C-6000 is set to operate in

Manual mode.

• Press [F6] [ENTER] to display the “Set Mode” screen

• Press [F6] [ENTER] again to toggle between [M]anual

or [A]utomatic mode

Setting Which Days of the Week to Run:

• Press [F1] to select which days to run the C-6000 in

Automatic mode

• “Sun ON” or “Sun OFF” will display

• Press [F3] to set a day to “ON”. Set a day to “ON” in order

for the C-6000 to run on that day

• Press [F4] to set a day to “OFF”. Set a day to “OFF” in

order for the C-6000 NOT to run on that day

• Press [F1] to cycle through each day of the week [Sun

– Sat.]

• Press [F5] [EXIT] to return to the menu

7. Set WashTimes

• Only used when C-6000 is set to Automatic mode

• Press [F6] [ENTER] to display the Start time for the Fan

on Sunday (Sun. Fan)

• Press [F3] to increase the Hour

• Press [F4] to increase the Minutes

• Press [F1] to go to the Start time for the Wash on

Sunday (Sun.Wash)

• Set the time, using the same method described above

• Press [F1] to cycle through for each day of the week, for

the Start Times for the Fan and Wash

• Press [F5] [EXIT] to return to the menu

8. Wash Test

• Press [F6] [ENTER] to run the C-6000 through a

complete Wash cycle with decreased times

• After the Wash Test is complete, the C-6000 will return

to the Fan Off mode

9. Number of Washes

• Pressing [F6] [ENTER] will prompt for a password

It is not necessary to change this value. It is preset at

the Factory.

TIME CLOCK OPERATION

AutoMode is used to have C-6000 start the exhaust/supply

fans automatically, once per day. The AutoMode also stops

the fans and starts the wash cycle, once per day.

To use the AutoMode:

1. Set Wash Length(s) (Menu item #3)

Set length of each wash cycle, from 3 minutes to 9

minutes

2. Set Delay Time between washes, if control has more

than one wash solenoid (Menu item #4)

Set amount of time to wait between washes, from 1

minute to 99 minutes

3. Set Clock (Menu item #5)

Please note that the clock is a 24-hour clock.

Example: 1:00 PM = 13:00

Set the current day of the week.

Example: 1 = Sun. 2 = Mon. 3 = Tues, etc.

4. Turn AutoMode ON (Menu item #6)

Pressing (F6) Enter will toggle between [A]utomatic and

[M]anual modes

After it is set to [A]utomatic mode, set which days of the

week the Exhaust/Supply Fan will run - setting a day to

"ON" means the Exhaust/Supply Fan will start on that

day, and the Wash will run.

Example: Sun ON

Mon OFF

Tues ON

5. Set Wash Times, set start times for Fans & Wash

(Menu item #7).

Set the time for the Fans to Start for each day of the week.

Example: Sun. Fan 5:00

Mon.Fan 5:00

Set the time for the Wash to Start for each day of the week.

Example: Sun.Wash 22:00

Mon.Wash 22:00

18

Loading...

Loading...