Gaylord C-6000-D Service Manual

THE

GAYLORD

EFFECTIVE DATE 05-10

TECHNICAL MANUAL

FOR THE C-6000-D CONTROL CABINET

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • TUALATIN, OREGON 97062 U.S.A.

800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

GAYLORD INDUSTRIES

World Headquarters: 10900 SW Avery Street • Tualatin, Oregon 97062 U.S.A.

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. We are proud to be able

to provide you with a quality product that incorporates

the latest engineering concepts and is a result of over 60

years of experience in the foodservice kitchen exhaust

industry.

If you have other Gaylord equipment such as a Gaylord

Ventilator, Utility Distribution System, Quencher Fire

Protection System, or Roof Top Air Handling Equipment,

etc., please refer to the corresponding supplementary

equipment manuals.

If you have further questions, please call us toll free at

1-800-547-9696 or email:info@gaylordusa.com. We are

more than happy to help.

Sincerely,

Gaylord Industries

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: info@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062 U.S.A.

II

TABLE OF CONTENTS

GENERAL DESCRIPTION _________________________________________________________ 5

MODEL NUMBER DESCRIPTION ___________________________________________________ 6

STARTING THE C-6000-D COMMAND CENTER________________________________________ 7

MANUAL START _________________________________________________________________ 8

AUTOSTART ____________________________________________________________________ 9

REMOTE START ________________________________________________________________ 11

STOPPING THE EXHAUST/SUPPLY FAN(S) / STARTING WASH __________________________ 12

WASH MODES _________________________________________________________________ 13

EXTERNAL FIRE MODE __________________________________________________________ 17

INTERNAL FIRE MODE __________________________________________________________ 18

UV SAFETY ____________________________________________________________________ 20

UV COMPONENTS ______________________________________________________________ 21

UV SYSTEM ON ________________________________________________________________ 22

UV SAFETY INTERLOCKS ________________________________________________________ 23

UV LAMP FAILURE ______________________________________________________________ 24

FAN ON - UV SYSTEM OFF _______________________________________________________ 25

UV LAMP LIFE _________________________________________________________________ 26

PROGRAMMING INSTRUCTIONS (MENU) ___________________________________________ 27

PROGRAMMING INSTRUCTIONS (MENU) - CYCLE TYPE ______________________________ 28

PROGRAMMING INSTRUCTIONS (MENU) - DETERGENT ______________________________ 29

PROGRAMMING INSTRUCTIONS (MENU) - WASH LENGTH ____________________________ 30

PROGRAMMING INSTRUCTIONS (MENU) - DELAY TIME _______________________________ 31

PROGRAMMING INSTRUCTIONS (MENU) - SET CLOCK _______________________________ 32

PROGRAMMING INSTRUCTIONS (MENU) - AUTOMODE _______________________________ 33

PROGRAMMING INSTRUCTIONS (MENU) - SET WASH TIMES __________________________ 34

PROGRAMMING INSTRUCTIONS (MENU) - WASH TEST _______________________________ 35

PROGRAMMING INSTRUCTIONS (MENU) - # OF WASHES _____________________________ 36

GPC-6000 CABINET PARTS LIST __________________________________________________ 38

GPC-6000 PLUMBING PARTS LIST _________________________________________________ 39

C-6000-D PARTS LIST ___________________________________________________________ 40

C-6000-D PLC STATUS LIGHTS ____________________________________________________ 44

C-6000-D INTERNAL WIRING _____________________________________________________ 46

C-6000-D.1 INTERNAL WIRING ____________________________________________________ 48

C-6000-D EXTERNAL WIRING _____________________________________________________ 50

C-6000-D WASH CONTROL WIRING ________________________________________________ 52

C-6000-D TERMINAL VOLTAGES ___________________________________________________ 53

C-6000-D-UV PARTS LIST ________________________________________________________ 55

C-6000-D-UV PLC STATUS LIGHTS ________________________________________________ 60

C-6000-D-UV INTERNAL WIRING __________________________________________________ 62

C-6000-D-UV.1 INTERNAL WIRING _________________________________________________ 64

C-6000-D-UV EXTERNAL WIRING__________________________________________________ 66

C-6000-D-UV TERMINAL VOLTAGES ________________________________________________ 68

C-6000-D-UV WASH CONTROL WIRING_____________________________________________ 70

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED

IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR OTHERWISE WITHOUT PRIOR

WRITTEN PERMISSION OF GAYLORD INDUSTRIES COPYRIGHT 2009.

© Copyright 2010, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specications resulting from a continuing program of product

improvement or the availability of new materials.

ADDITIONAL COPIES $15.00

III

This page intentionally left blank.

IV

GENERAL DESCRIPTION

The C-6000-D Control Cabinet is designed to control one or more of the following Gaylord products;

• CG3 Ventilators

• CG3-UV Ventilators

• CG3-UV-SPC Ventilators

• RSPC-ESP Pollution Control Units

• Gaylord Duct Sumps (GDS)

The C-6000-D Command Center will:

• Start/Stop Exhaust and Supply Fan(s)

• Control Wash system in Ventilators, Pollution Control Units, and/or Gaylord Duct Sumps

• Start/Stop Ultraviolet Lamps (UV)

• Start/Stop Electrostatic Cells (ESP or SPC)

• Interface with the Fire Protection (FP) system

• Interface with a Building Management System (BMS)

• Connect to an Autostart device, Gaylord model “TST”, if applicable

C-6000-D

COMMAND

CENTER

5

MODEL NUMBER DESCRIPTION

The C-6000-D Command Center is typically installed in a Gaylord Plumbing Cabinet (GPC). The model

number for the Gaylord Plumbing Cabinet is made up of an alphabetic prex followed by a series of

alphabetic and/or numeric sufxes to designate the type of control and various options. Sequence of

model numbers is as follows.

1._____ 2._____ 3._____ 4._____ 5._____ 6._____ 7._____ 8._____ 9._____ 10.____ 11.____

Prex Control # UV #

Sequences

Low

Detergent

Cold

Water

Mist

Light

Switch

Security

Access

Trim

Ring

Pipe

Size

220 Volts

Explanation of Pre-Fixes and Suffixes

1. GPC

GPC ...........................Gaylord Plumbing Cabinet

2. Control #

6000-D .......................Utilizes C-6000-D Control

3. UV (If Applicable)

UV ..............................Has inputs and outputs for Ultraviolet light control (UV)

4. # Sequences (# Wash Solenoids)

__ ...............................Leave BLANK for 1 plumbing sequence

S# ..............................Has # of plumbing sequences indicated to wash at different times

Ex) S2 – Has 2 plumbing sequences

S#/S# .........................On Main Cabinet that has a Sub Panel. The rst part (S#), indicates

the Total number of plumbing sequences controlled by the control.

The second part (S#), indicates the number of plumbing sequences

in the Main Cabinet. Ex) S5/S2: Controls a total of 5 plumbing sequences.

2 plumbing sequences in the main cabinet, and 3 plumbing sequences in

the Sub Panel.

5. Low Detergent

LD ..............................If cabinet has a Low Detergent Flow switch installed

6. Cold Water Mist

CM .............................If cabinet has a Cold Water Mist plumbing loop installed

7. Light Switch

LS ..............................If cabinet has a Light Switch installed

8. Trim Ring

TR ..............................If cabinet has a Trim Ring installed

9. Security Access

SA ..............................If cabinet has Security Access (Keyed Lift and Turn latch)

10. Plumbing Loop Size

1.00 ............................Indicates Plumbing Loop Size (diameter of pipe) in inches

11. 220 Volts

220V ..........................Indicates Control is designed to be connected to 220VAC Supply Voltage

Model Number Example:

GPC-6000-D-UV-S3-LD-CM-LS-TR-SA-1.25-220V

Sub Panel Model Number Example:

GPC-SUB-S3-LD-1.25

6

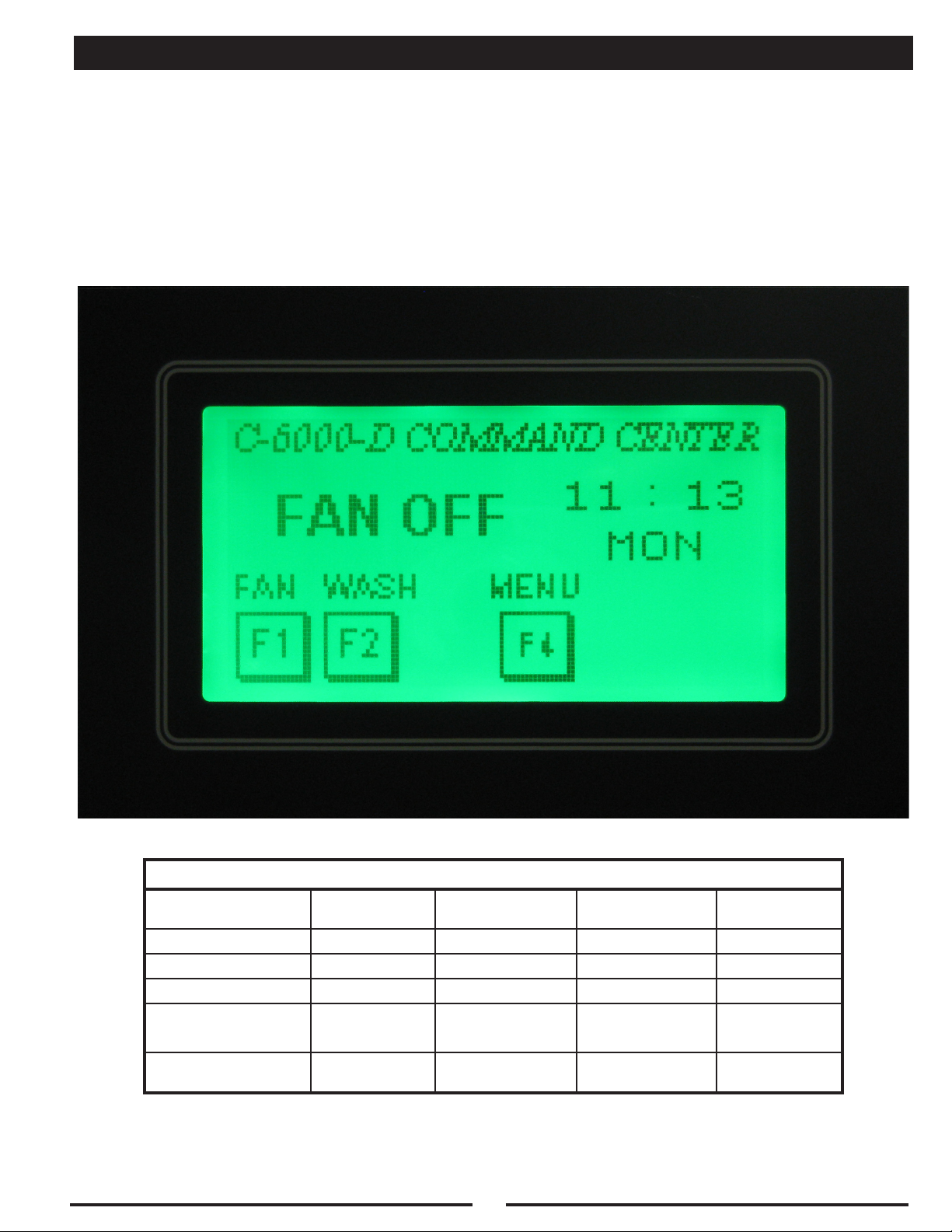

STARTING THE C-6000-D COMMAND CENTER

The C-6000-D can be started through one of three options:

1. Manually - - Press the “F1” (FAN) button

2. Autostart - - Autostart thermostats in the ventilator activate the C-6000-D

3. Remotely - - Remotely start the C-6000-D from a switch or BMS

* See the following pages for more details on each of these options

Typical Sequence of Operations for C-6000-D

Mode

Fan Off (Stand by) Closed Off Off Off

Fan On Open On On Off

Wash On Closed Off Off On

External Fire (Ansul)

Activated

Internal Fire

Thermostat Activated

Electric

Damper

Open On Off

Closed Off Off On

Exhaust Fan Supply Fan Wash

On

(After 60 Sec.)

7

MANUAL START

To Start the Fan(s) press the “F1” (FAN) button.

Pressing the “F1” (FAN) button will result in:

1. Supply Fan On Starts immediately

2. The Electric Damper opens (after

approximately 45 seconds)

After a 45 second delay:

1. Exhaust Fan Starts

2. UV Lamps On (if applicable)

3. ESP or SPC Cells On (if applicable)

8

AUTOSTART

Description:

The C-6000-D is designed to start the Exhaust and Supply Fan(s) automatically when cooking starts,

if the ventilator it is connected to is equipped with Autostart thermostats, Gaylord model “TST”. The

Autostart thermostats (TST’s) are preset at the factory to 90°F, and may be adjusted in the eld, if

necessary.

Code Requirements:

Some municipalities require the exhaust fan to start automatically whenever cooking operations occur,

to comply with IMC 507.2.1.1. This code requires the exhaust fan to be interlocked with the cooking

equipment such that it will start whenever cooking operations occur. This can be accomplished with

Temperature Sensing Thermostat(s) in the ventilator, Gaylord model “TST”.

Operation:

Whenever the temperature in the ventilator canopy is above 90°F, and the C-6000-D is OFF, the Exhaust

and Supply Fan(s), UV Lamps (if applicable), ESP or SPC Cells (if applicable) will start automatically

in “Autostart” mode, and display the text shown below.

9

AUTOSTART

Automatic Shutdown:

After the temperature in the ventilator canopy drops below 90°F, the C-6000-D will start to countdown from

60 minutes. After 60 minutes the Exhaust and Supply Fan(s), and UV Lamps will shut off automatically.

Once the countdown has started:

1. The Fan(s), UV, and ESP or SPC cells can be started by pressing the “F1” (FAN) button and

cancel the countdown.

2. The Fan(s), UV, and ESP or SPC cells can be stopped by pressing the “F2” (WASH) button and

cancel the countdown, and Start the Wash.

Note:

The Fans and UV should be started

manually normally, by pressing the “F1”

(FAN) button. The Autostart is provided

as a back-up when the user forgets to

start the Fans before starting cooking.

While in “Autostart” mode, pressing

the “F1” (FAN ON) button will put the

C-6000-D back into a normal “FAN ON”

mode.

10

REMOTE START

Description:

The C-6000-D can be started remotely, from a Fan On/Off Switch located elsewhere, or from a Building

Management System (BMS). This is accomplished by connecting terminals “21” and “27” to a “Remote”

switch. Please note that terminal “21” has 24VDC on it. Refer to the C-6000-D Internal Wiring diagram

for more details.

Operation:

When the C-6000-D is Remotely Started, the Exhaust and Supply Fan(s), UV Lamps and ESP/SPC

Cells will start.

Note:

If the C-6000-D has been started “Remotely”, the Fan(s), UV, and ESP/SPC Cells cannot be shut off

at the C-6000-D. The C-6000-D must be shut off “Remotely” by removing power from terminal “27”.

When power is removed from terminal “27”, the C-6000-D will start to Wash.

11

STOPPING THE EXHAUST/SUPPLY FAN(S) / STARTING WASH

To Stop the Fan(s) and Start the Wash press the “F2” (WASH) button. The C-6000-D can also be set

to start the Wash Automatically. To do this set the C-6000-D to run in “AutoMode” and setting the times

to Wash in the Menu. See “Programming Instructions” for information on setting up the “AutoMode”.

CAUTION: The cooking equipment must be shut off prior to shutting off the exhaust fan. Failure to do

this will cause excessive heat buildup and could cause the surface fire protection system to discharge.

Pressing the “F2” (WASH) button will result in:

1. Exhaust Fan Off

2. Supply Fan Off

3. Electric Dampers Close (if applicable)

4. UV Lamps Off (if applicable)

5. ESP or SPC Cells Off (if applicable)

After a 45 second delay:

1. Wash Starts

12

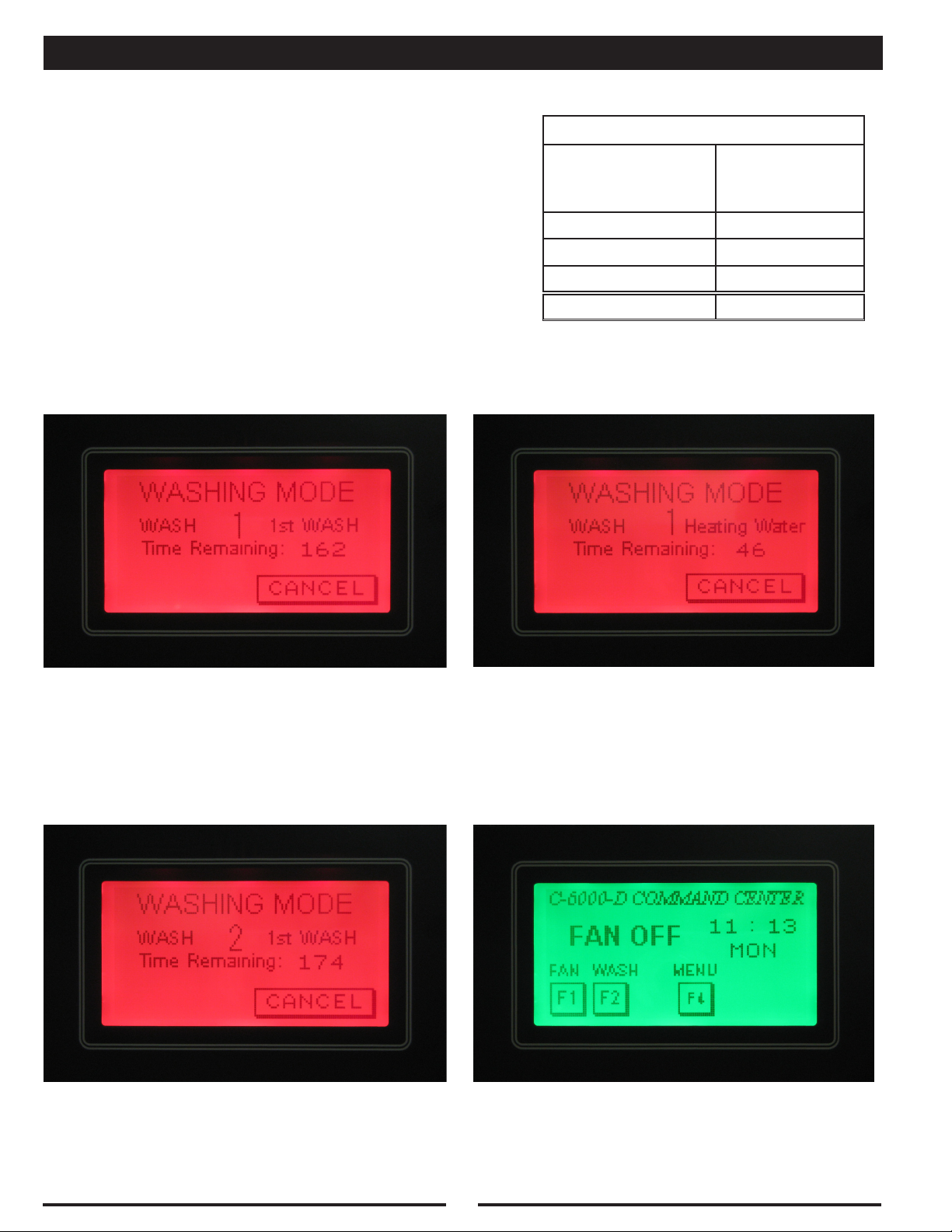

WASH MODES

The C-6000-D can be programmed to control up to 13

Wash Sequences (solenoids). The C-6000-D can control

“HOOD” wash cycles and “ESP” cycles, or a combination

of both. The length of each wash cycle can be set from 3 to

9 minutes. The delay between wash sequences can be set

from 1 to 99 minutes. The delay is designed to allow time for

the Hot Water to reheat if necessary and allow time for the

ESP or SPC cells to soak between wash cycles. To Start the

Wash, press the “F2” (WASH) button. The Fan(s) cannot

be restarted until the entire wash cycle has completed, or

the wash cycle has been canceled. To Stop the Wash before the wash cycle has completed, press the

“CANCEL” button. Refer to the “Programming Instructions” on how to adjust the times.

NOTE: The ventilator wash system is designed

to remove daily accumulations of grease within

the extraction chamber. If the ventilator is not

washed a minimum of once during a cooking

day, a grease buildup could accumulate which

the wash system cannot remove. If this occurs,

it is recommended that the ventilator be put

through several wash cycles by pushing the

“F2” (WASH) button on the Command Center.

If this does not remove the grease, it will be

necessary to remove the grease manually by

using a scraping tool, such as a putty knife,

or retain the services of a commercial hood

cleaning service to steam clean or pressure

wash the system.

Recommended Wash

Cycle Lengths

Type of Cooking

Light-Duty 3

Medium-Duty 5

Heavy-Duty 9

Length of

Wash Cycle

HOT WATER REQUIREMENTS

For proper operation of the wash system

there must be adequate water pressure and

temperature. There is a pressure/temperature

gauge inside the control cabinet.

Water Pressure: 40 psi min. - 80 psi max.

Water Temperature: 140°F min. - 180°F max.

13

WASH MODES

“HOOD” Wash Description:

A “HOOD” Wash cycle is used for any water wash ventilator.

It will wash using Hot Water and detergent. If there is more

than one Sequence (solenoid), the C-6000-D will delay

between each Sequence, then the 2nd Wash Sequence

will start and run. After all of the washes are complete the

C-6000-D will display a “FAN OFF” message. Refer to the

table for a typical “HOOD” Wash.

WASH SEQUENCE #1

“HOOD” Wash Cycle (Typical)

Length of

Description

Wash #1 3

Delay 1

Wash #2 5

Total Time 9

DELAY

Wash Cycle

(Minutes)

WASH SEQUENCE #2

FAN OFF

14

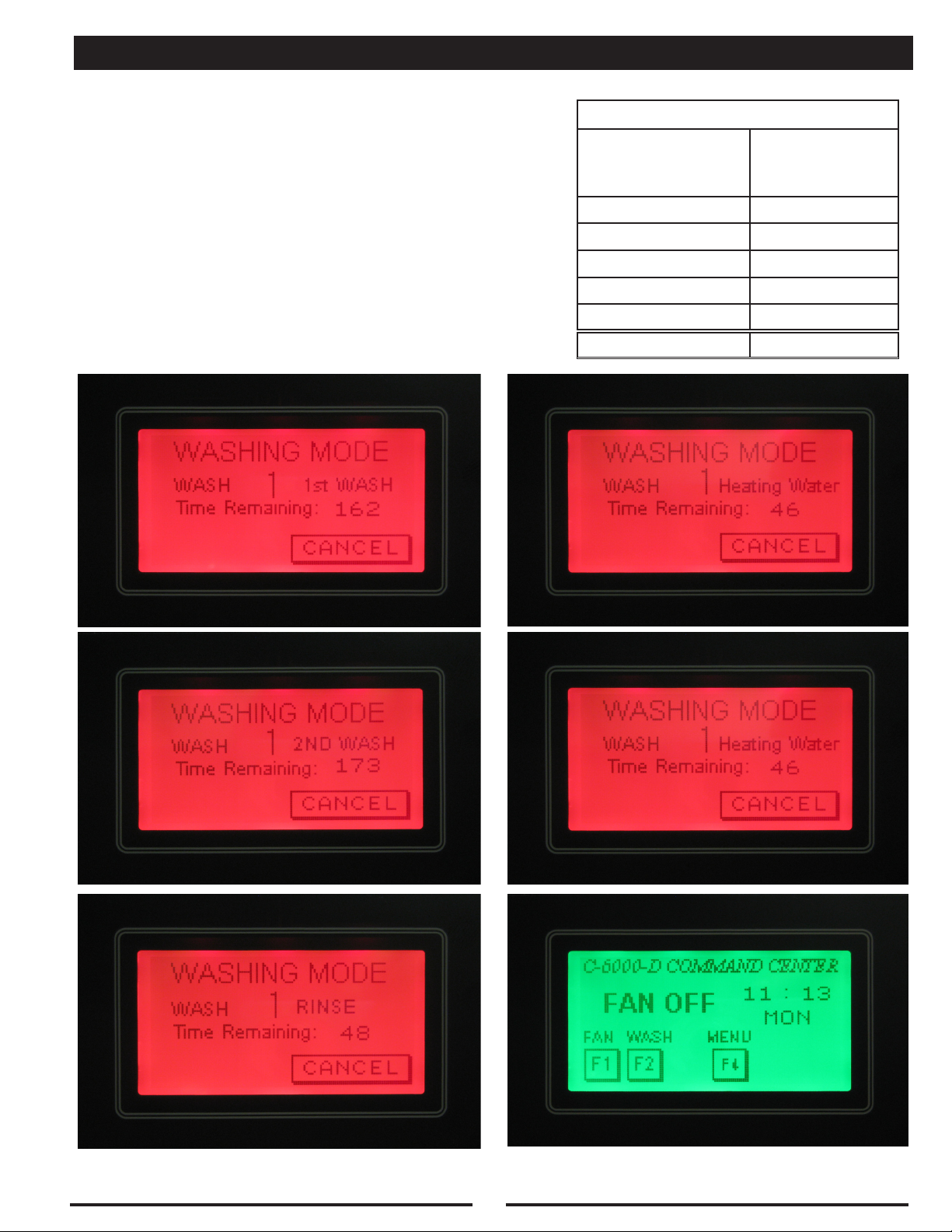

WASH MODES

“ESP” Wash Description:

An “ESP” Wash cycle is used for CG3-UV-SPC ventilators or

RSPC-ESP Pollution Control Units. An “ESP” Wash uses a

“Wash-Delay-Wash-Delay-Rinse” cycle. This is designed to

Wash the ESP or SPC cells with Hot Water and Detergent,

allow to soak, then Wash again, allow to soak, then Rinse

with Hot Water only. The length of the Wash cycles and the

Delay are adjustable. The length of the Rinse is xed at 3

minutes. After all of the washes are complete the C-6000-D

will display a “FAN OFF” message. Refer to the table for a

typical “ESP” Wash.

WASH #1

“ESP” Wash Cycle (Typical)

Length of

Description

Wash - 1st Wash 3

Delay 1

Wash - 2nd Wash 3

Delay 1

Rinse 3

Total Time 11

DELAY

Wash Cycle

(Minutes)

WASH #2

RINSE

DELAY

FAN OFF

15

WASH MODES

Low Detergent (Option)

Some control cabinets are equipped with a low detergent ow switch. The control cabinet model number

would have the letters “LD” in the model number, if the it includes a low detergent ow switch

When the detergent is low:

A message will ash indicating “LOW DETGNT”

during the wash cycle. This indicates that the

detergent is low and/or the detergent pump is

not pumping

When the detergent is low:

A message will ash indicating “LOW DETGNT”

after the end of all of the wash cycles. This

indicates that the detergent is low and/or the

detergent pump is not pumping. To clear the

“LOW DETGNT” message, ll the detergent,

and run the C-6000-D through a Wash cycle.

It may be necessary to prime the pump, refer

to the “Detergent Pump Operation”.

Note:

If the detergent tank is lled with water or

detergents other than Formula G-510, the

detergent ow switch will act as if there is no

detergent. The viscosity of water and other

detergents is too low to be detected by the low

detergent ow switch

16

EXTERNAL FIRE MODE

Fire Protection System - Activated

Description:

The C-6000-D should be wired to the Fire Protection System for the Ventilator(s) and/or Pollution Control

Unit(s) it is controlling. A set of normally open contacts in the Fire Protection System needs to be wired

to terminals “4” and “FS” in the C-6000-D, refer to the C-6000-D Internal Wiring Diagram for more

details. Please note that terminal “4” has 120VAC on it. If the Surface Fire Protection System for the

Ventilator(s) is activated the C-6000-D will be placed in an “External Fire” mode.

Operation:

In an “External Fire” mode, the C-6000-D will:

1. Start Exhaust Fan

2. Shut off Supply Fan

3. Run water in ventilator(s) and/or Pollution Control Unit(s) after a 60-second delay

4. Close Alarm Contacts “A1” & “A2” - refer to C-6000-D Terminals for more details

5. Open Alarm Contacts “Q1” & “Q2” - refer to C-6000-D Terminals for more details

Note:

The Fan(s) cannot be restarted until the microswitch in the Fire Protection System for the Ventilator(s)

and/or Pollution Control Unit has been reset. After the microswitch has been reset, the Fan(s) can be

restarted by pressing the “F1” (FAN) button.

17

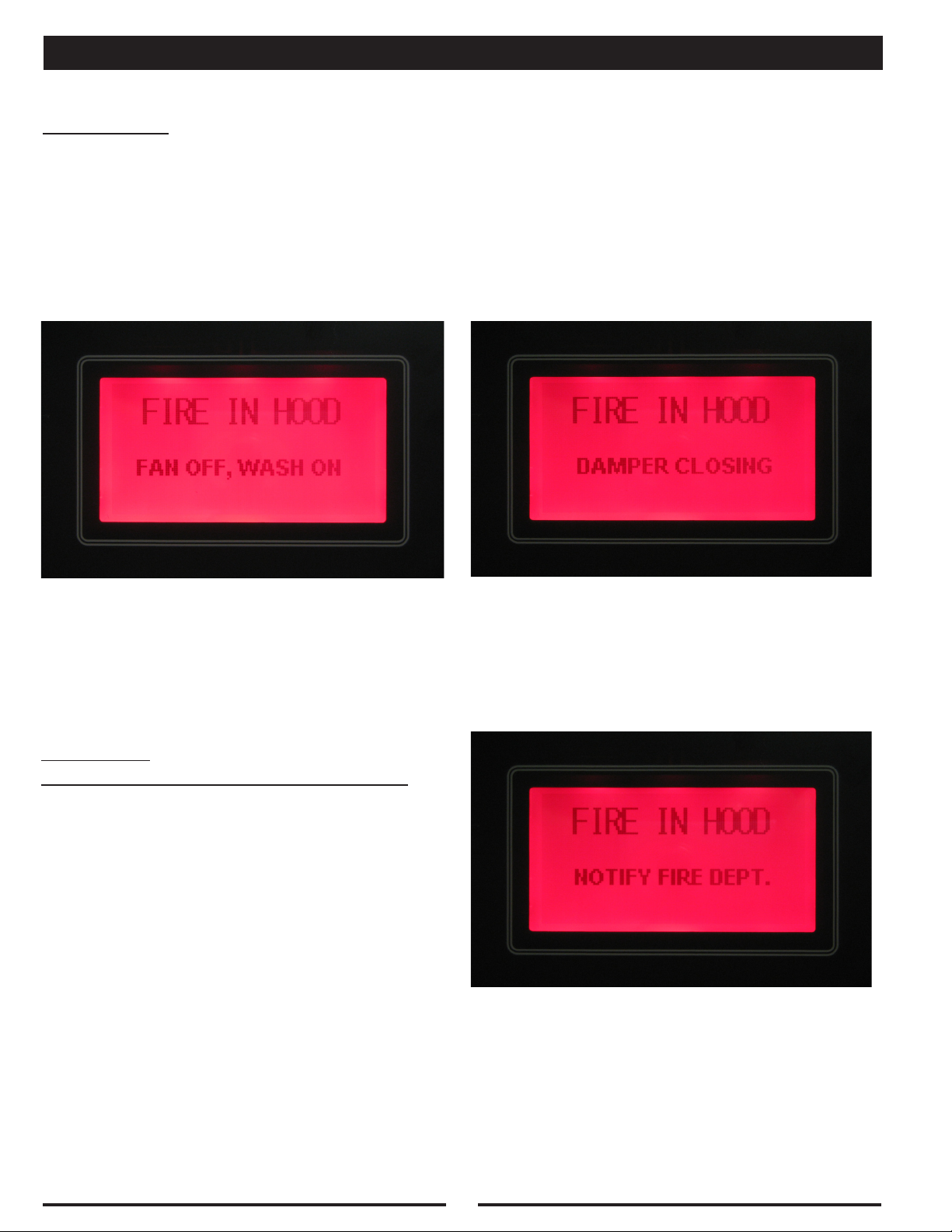

INTERNAL FIRE MODE

Thermostat - Activated

Description:

If the ventilator(s) connected to the C-6000-D are equipped with thermostat(s) at the duct/plenum to

detect re, and a re is detected at the Exhaust Duct collar, or if the thermostat in the Pollution Control

Unit detects a re, the C-6000-D will go into an “Internal Fire” mode. Refer to the appropriate Gaylord

Ventilator Technical Manual, or Gaylord Pollution Control Unit Technical Manual for thermostat location

and temperature setting.

1st Screen 2nd Screen

Operation:

In an “Internal Fire” mode, the C-6000-D will:

1. Shut off Exhaust Fan

2. Shut off Supply Fan

3. Run water in ventilator(s) and/or Pollution

Control Unit(s) immediately

4. Close Alarm Contacts “A1” & “A2” - refer to

C-6000-D Terminals for more details

5. Open Alarm Contacts “Q1” & “Q2” - refer to

C-6000-D Terminals for more details

3rd Screen

18

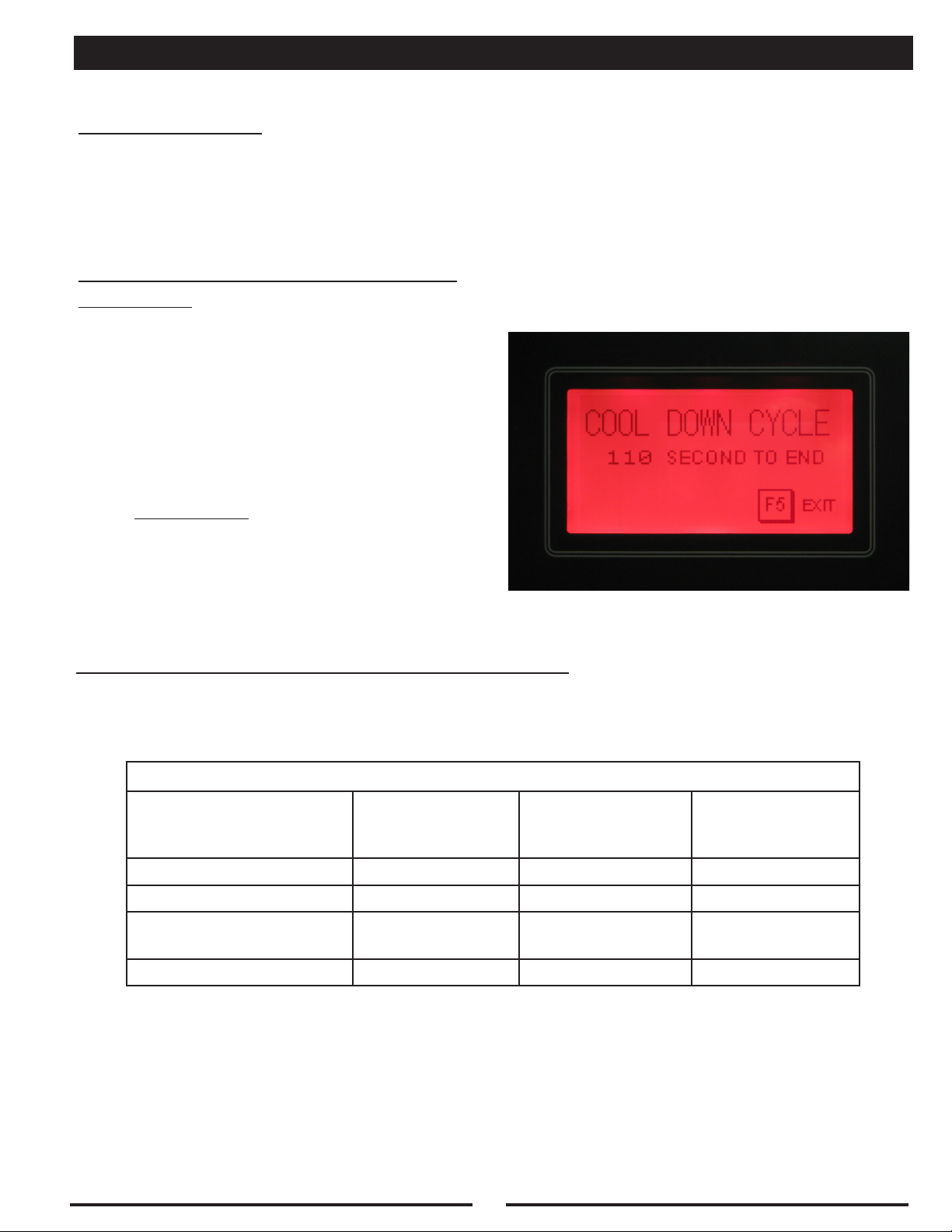

INTERNAL FIRE MODE

Thermostat - Activated

Cool Down Cycle:

After the temperature at the thermostat(s) cools below its’ activation temperature, the C-6000-D will

enter a “Cool Down Cycle” for 2 minutes. The C-6000-D will count down from 120 seconds. The water

will continue to run until the end of the “Cool Down Cycle”, or until the “F5” (EXIT) button is pressed.

After the “Cool Down Cycle is complete, the Fan(s) can be restarted by pressing the “F1” (FAN) button.

Internal & External fire modes at the

same time:

It is possible that both the Internal and External

Fire modes can be activated at the same time. If

this occurs, the Internal Fire Mode will override the

External Fire mode until the thermostat(s) cool below

the set point, refer to the appropriate Ventilator or

Pollution Control Technical Manual for the set point.

At this point the Cool Down Cycle will start counting

down for 2 minutes. After the Cool Down Cycle, the

External Fire mode will start.

Special Note: If the control is in the Cool

Down Cycle when the External Fire mode

is activated, the Cool Down Cycle will nish

counting down for 2 minutes, before switching

to the External Fire Mode.

Summary of Both Fire Modes at the Same Time:

1. Internal Fire Mode (until thermostat temperature drops below the set point)

2. Cool Down Cycle (for 2 minutes)

3. External Fire Mode (until the External Fire Switch is reset)

FIRE MODE SUMMARY

Cool Down Cycle

Exhaust Fan

Supply Fan

Electric Damper

Position (if applicable)

INTERNAL Fire

OFF OFF ON

OFF OFF OFF

FIRE EXHAUST EXHAUST

(for Internal Fire

Mode Only!)

EXTERNAL Fire

Water Spray

ON ON ON

19

UV SAFETY

Warning:

DO NOT defeat the purpose of the UV Safety Interlocks during Cleaning or Maintenance!

As with many types of technology if it is not used properly and/or proper precautions are not taken there

is the potential for injury or harm. This is especially true with UVC light due to the fact that it does not

physically hurt at the time of exposure. While UVC is very effective at breaking down grease molecules,

direct exposure to large amounts is harmful to skin and eyes. The amount of UVC generated in these

ventilators is greater than that what results from direct exposure to the sun. Under no circumstances is

it acceptable to view the lighted lamps without proper eye protection or expose bare skin directly to the

light. All interlocks and safety precautions called for in this manual must be followed to avoid the potential

for harm to service personnel and/or operators. In addition, only trained and authorized personnel may

perform some maintenance.

Personal Protective Equipment

Personal Protective equipment must be used at all times when working on any Gaylord “UV” ventilators,

this includes:

1. Eye protection that prevents 100% of UVC being transmitted through the lens must be worn at all

times when performing service work on any Gaylord “UV” ventilator that is energized and/or has the

potential to be energized and expose personnel to UVC light.

2. Whenever service work is performed it is recommended that long sleeve shirts and long pants be

worn to minimize the potential for inadvertent exposure of the skin to UVC.

20

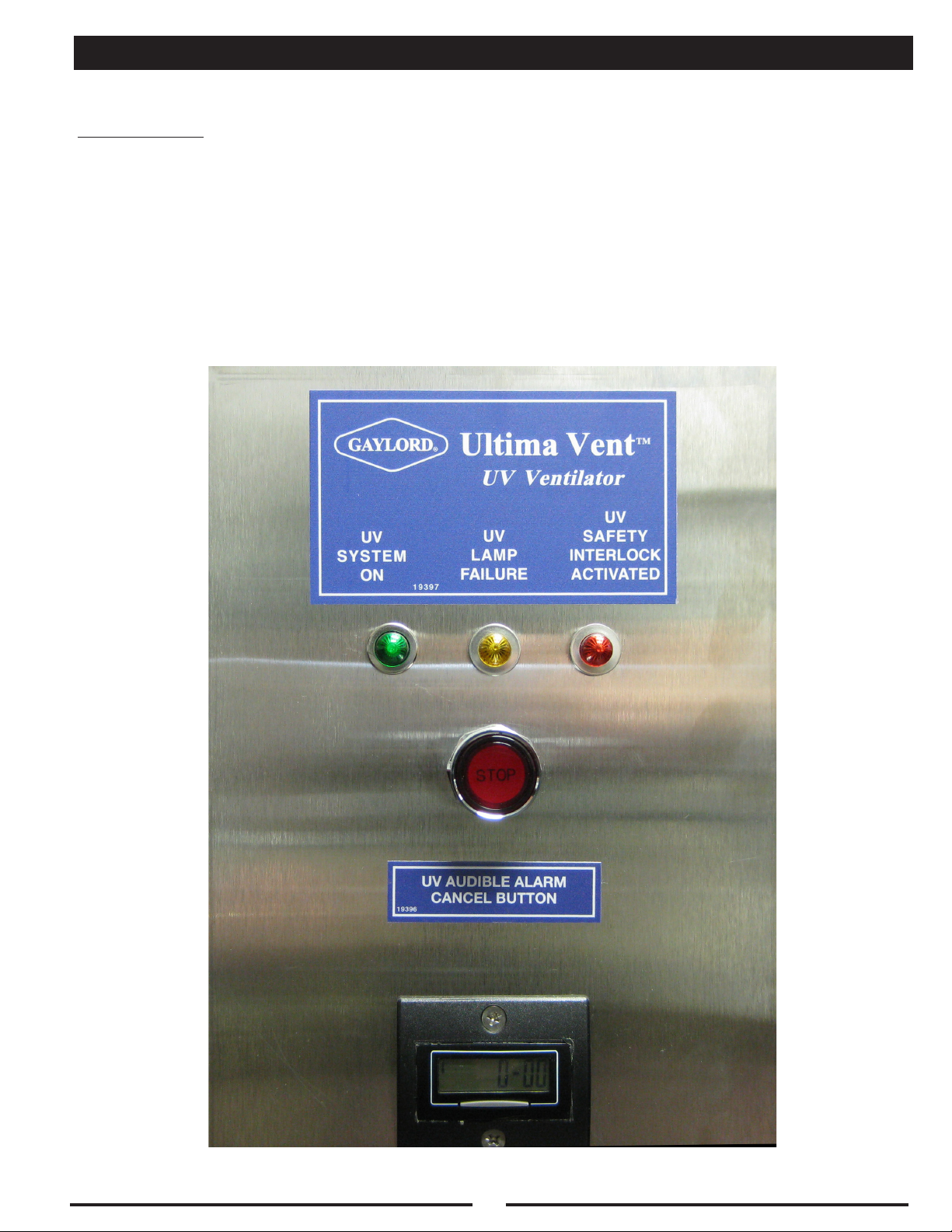

UV COMPONENTS

Description:

If the C-6000-D is controlling Gaylord “UV” ventilators, the model number will include “UV” in the model

number. The C-6000-D-UV will include the following components:

1. UV Status Lights

• Green - “UV System On”

• Yellow - “UV Lamp Failure”

• Red - “UV Safety Interlock Activated”

2. UV Audible Alarm Cancel button

3. UV Hour Meter

21

UV SYSTEM ON

Description:

When the C-6000-D-UV is running in the “Fan On”, “Autostart”, or “Remote Start” mode, the UV Lamps

will turn on. Under Normal conditions, when the UV Lamps are running normally the “UV System On”

Green light will illuminate. If either the Yellow or Red UV Lights are illuminated, refer to the following

pages.

22

Loading...

Loading...