Page 1

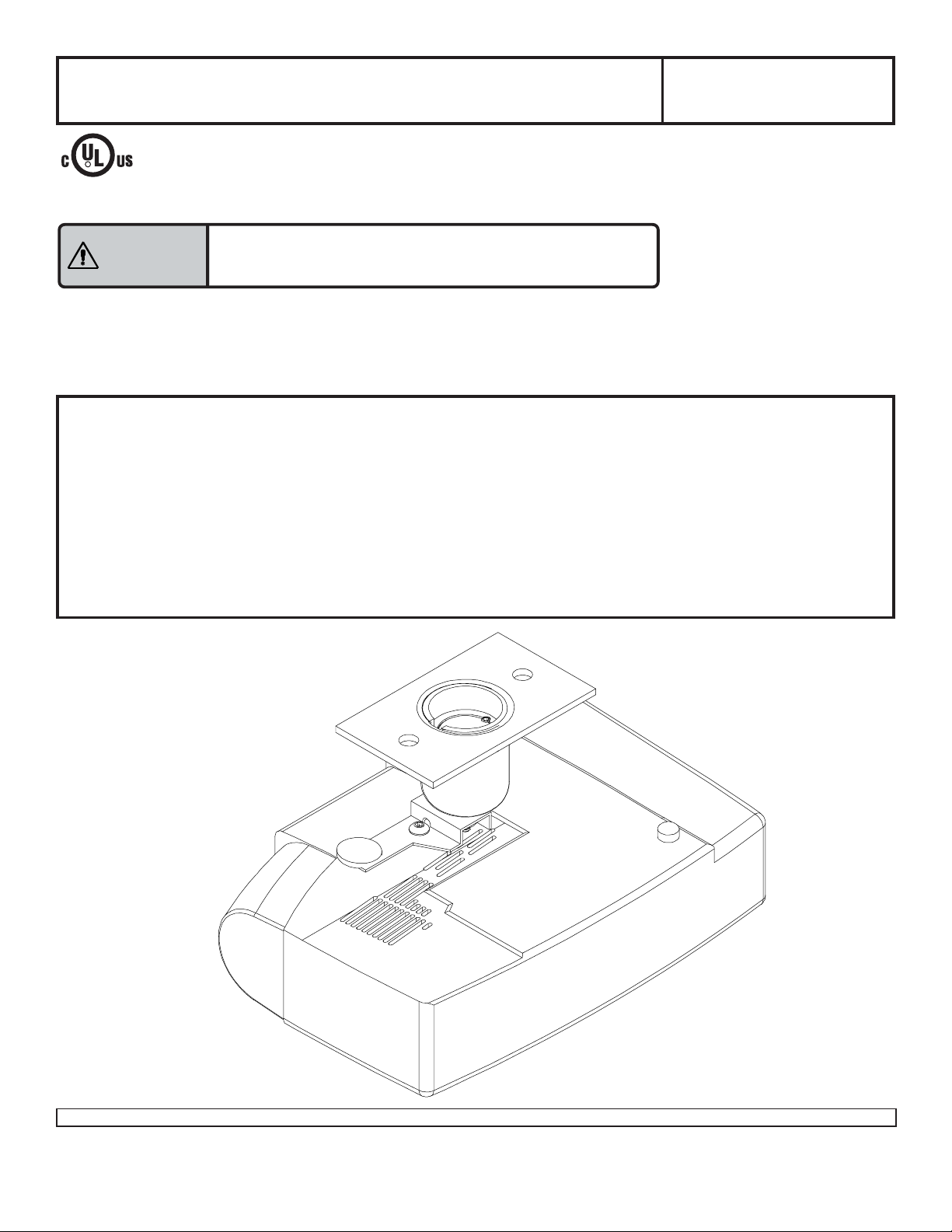

Installation and Assembly - Security Projector Mount

for Gateway™ 210 Projector

This product is intended for use with UL

R

Listed products and must be installed

by a qualified professional installer.

Maximum Load Capacity: 20 lb (9.1 kg)

Model: PJ-G210

Reference Gateway 8007000

Read instruction sheet before you start installation and assembly .

Installer must verify that the ceiling will safely support

W ARNING

the combined weight of projector mount and projector.

IMPORTANT! Be sure not to touch the projector while tightening the set screw on the

ball and socket mount. This may cause the image to be unaligned when you let go.

IMPORTANT! Turn to the appropriate page for your application and ceiling condition.

Three Different Applications:

Flush Mount..................................................................................................................................... step 3, page 5

Threaded Rod ..................................................................................................................................step 4, page 5

Extension Column........................................................................................................................................ page 6

Installation Conditions:

To Wood Joist Finished Ceilings,

Exposed Wood Joists, or Wood Beam Ceilings........................................................................................ page 3

T o Concrete Ceilings.................................................................................................................................... page 4

1 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 04-21-03 SHEET #: 055-9158-1

Page 2

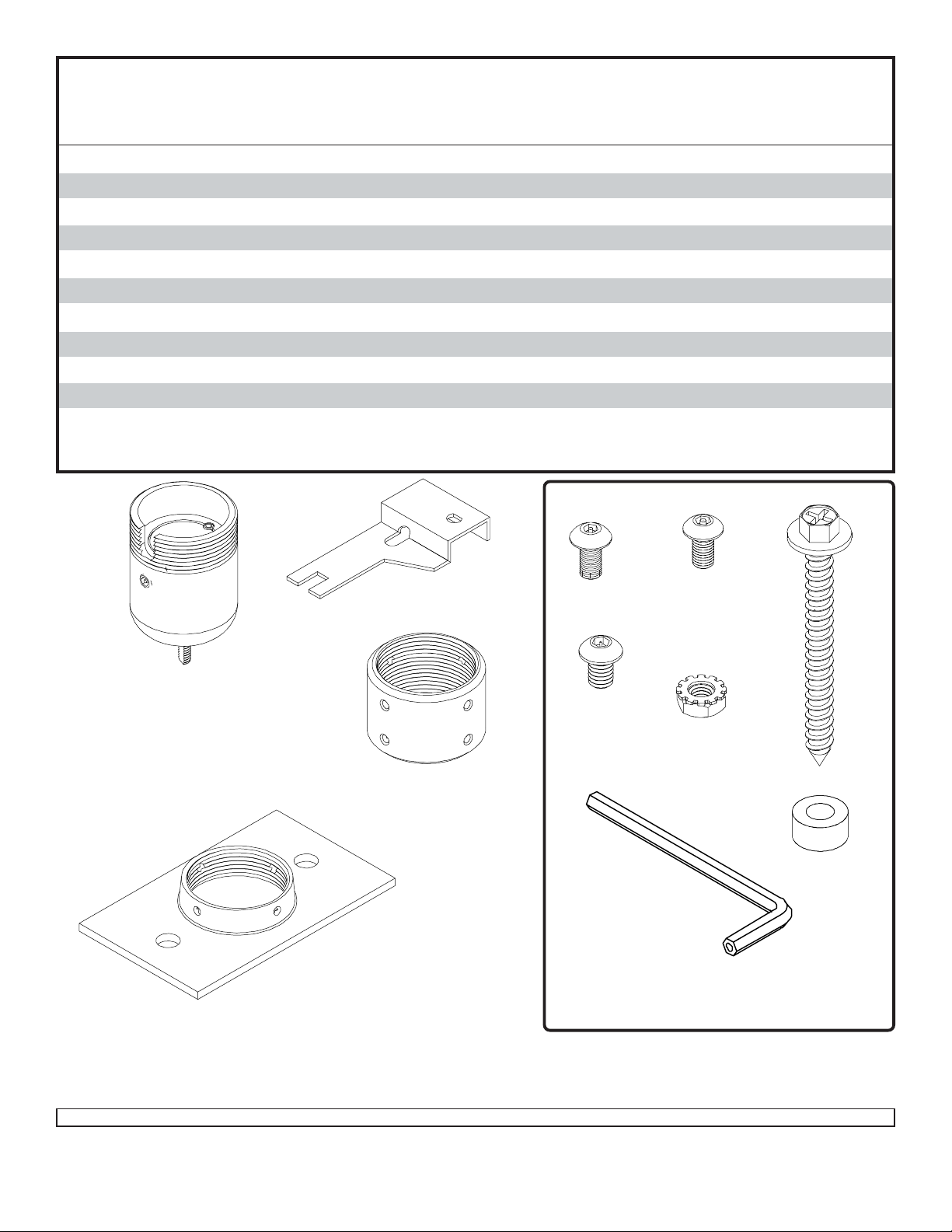

Before you start check the parts list to insure all of the parts shown are included.

Parts List

Description Qty . Part Number

A ball and socket assembly 1 055-0365

B 4 mm security allen wrench 1 560-9646

C M5 x .8 x 10 mm socket pin type F screw 1 520-1 16 4

1

D

/4 - 20 x 3/8 socket pin screw 1 520-1 10 9

E1/4 - 20 x 3/8 nut 1 530-9303

F #14 x 2.5 phillips hex head wood screw 2 5S1-015-C03

G ceiling plate 1 142-1006

H .25" ID x .56" OD x .26 spacer 2 590-1050

I extension column connector 1 580-1013

J 10-32 x 3/8 socket pin screw 2 520-1084

K bracket 1 055-1366

For Missing Parts, contact customer service at 1-800-729-0307.

K

G

A

C

J

D

E

F

I

H

B

Note: Actual parts may appear slightly different than illustrated.

2 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

FASTENERS

ISSUED: 04-21-03 SHEET #: 055-9158-1

Page 3

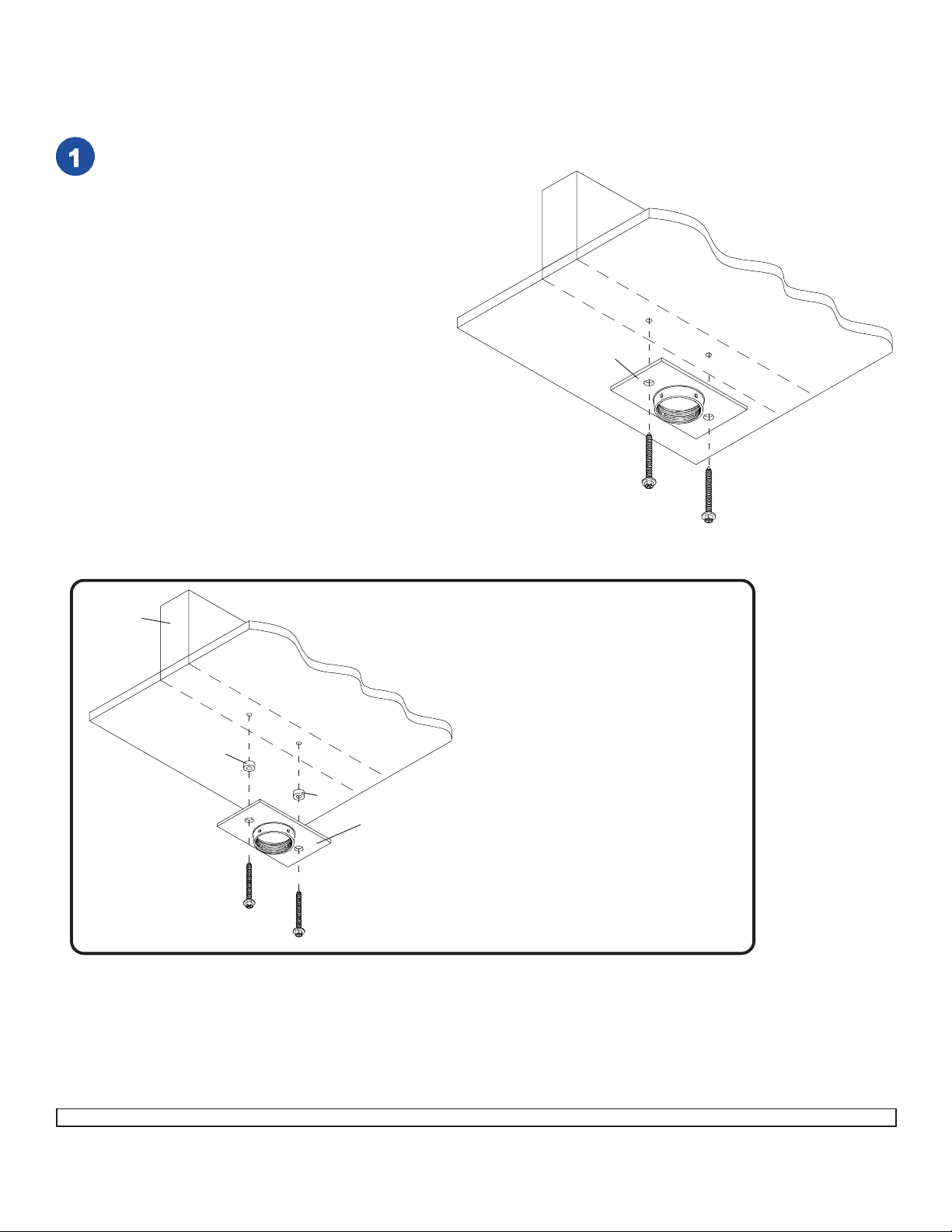

Installation To Wood Joist Finished Ceilings,

Exposed Wood Joists, or Wood Beam Ceilings

Drill two 5/32" (4 mm) dia. holes to a minimum

depth of 2.5" (64 mm). Attach ceiling plate (G)

with two #14 x 2.5" (6 mm x 65 mm) wood

screws (F) as shown using 3/8" (10 mm) socket

wrench. Tighten wood screws (F) so ceiling

plate (G) is firmly attached.

DO NOT TIGHTEN WITH EXCESSIVE FORCE!

Overtightening can cause stress damage to

wood screws (F) greatly reducing their holding

power! Tighten to 80 in • lb (9 N.M.) maximum

torque.

WOOD

JOIST

CEILING

G

WARNING: It is the responsibility of the

installer to verify that the ceiling will safely

support the combined load of all attached

hardware and components.

IMPORTANT: Be sure to drill holes into the

joist CENTER!

F

F

WOOD

JOIST

H

F

CEILING

For optional Cord Management,

install two spacers (H) between ceiling

plate (G) and ceiling.

H

G

F

3 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 04-21-03 SHEET #: 055-9158-1

Page 4

Installation to Concrete Ceilings

ACC 203 (Alligator® concrete anchors) are recommended.

Drill two 1/4" (6 mm) dia. holes to a minimum

depth of 2.5" (64 mm). Attach ceiling plate (G)

using two concrete anchors and #14 x 2.5" wood

screws (F) as shown in Illustration A and 1, 2,

and 3 (below). Tighten all fasteners.

IMPORTANT: It is the responsibility of the

installer to verify that the ceiling will safely

support the combined load of all attached

hardware and components.

CAUTION: Tighten wood screws so ceiling plate

(G) is firmly attached. But DO NOT TIGHTEN

WITH EXCESSIVE FORCE! Overtightening can

cause stress damage to wood screws, greatly

reducing their holding power! Tighten to 80 in •

lb (9 N.M.) maximum torque.

concrete

anchor

CONCRETE CEILING

G

1

Drill hole and insert anchor

2

G

F

Place ceiling plate over anchor and secure with screw

concrete

ceiling

concrete

anchor

concrete

anchor

3

concrete

F

After repeating step one tighten all fasteners

anchor

F

Illustration A

FOR DIRECT A TT ACHMENT TO LOAD BEARING CONCRETE

ONLY! Concrete expansion anchors are not intended for

attachment to concrete ceilings covered with a layer of plaster ,

drywall, or other finishing material. If mounting to concrete

ceiling covered with plaster / drywall is unavoidable, plaster /

drywall must be counterbored as shown below.

metal

bracket

INCORRECT

concrete

metal

bracket

CORRECT

concrete

plaster/

CUT AW A Y VIEW

4 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

dry wall

ISSUED: 04-21-03 SHEET #: 055-9158-1

plaster/

dry wall

Page 5

Flush Mount Application

Screw ball and socket assembly (A) into ceiling plate (G). Align the

notch with one of the four holes of the ceiling plate (G) and secure

ball and socket assembly (A) with a M5 x 10 mm socket pin

screw (C) using security allen wrench (B) as shown in detail 1.

Skip to step 6.

WOOD

JOIST

CEILING

G

A

B

C

A

DETAIL 1

1/2 -13 THREADED ROD

NOTCH

G

THREADED

ROD

ACC 810

Installation to

Threaded Rod

Accessory ACC 810, threaded rod adapter, is

required. (Sold Separately)

Screw ACC 810 into extension column

connector (I). Align slot in ACC 810 with one of

the top holes in extension column connector (I).

Insert and tighten one 10-32 x 3/8 socket pin

screw (J) through extension column connector

(I) into slot on ACC 810 using 4 mm security

allen wrench (B). See detail 2.

Align slot in ball and socket mount (A) to one of

the bottom holes in extension column connector

(I). Insert and tighten one 10-32 x 3/8 socket pin

screw (J) through extension column connector

(I) into slot in ball and socket mount (A).

See detail 3.

Skip to step 6.

A

SLOT

SLOT

ACC 810

I

I

DETAIL 2

SLOT

J

SLOT

J

THREADED

ROD

ACC 810

I

A

DETAIL 3

5 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 04-21-03 SHEET #: 055-9158-1

Page 6

Installation to

Extension Column

G

C

Screw extension column to ceiling plate (G).

Align the notch with one of the four holes in

the ceiling plate (G) and secure extension

column with a M5 x 10 mm socket pin

screw (C) using security allen wrench (B).

See detail 4.

Screw extension column connector (I) to

extension column. Align slot in extension

column with one of the top holes in

extension column connector (I). Insert and

tighten one 10-32 x 3/8 socket pin screw (J)

through extension column connector (I) into

slot on extension column using security

allen wrench (B). See detail 5.

Screw ball and socket mount (A) to

extension column connector (I). Align slot in

ball and socket mount (A) to one of the

bottom holes in extension column connector

(I). Insert and tighten one 10-32 x 3/8 socket

pin screw (J) through extension column

connector into slot in ball and socket mount

(A) using security allen wrench (B).

See detail 6.

EXTENSION

COLUMN (SOLD

SEPARA TELY)

SLOT

I

G

EXTENSION

COLUMN

DETAIL 4

EXTENSION

COLUMN

SLOT

ACC 850 - EXTENSION COLUMN CONNECTOR

WITH CORD MANAGEMENT - MA Y BE USED IN

PLACE OF EXTENSION COLUMN CONNECTOR (I).

THIS ALLOWS INST ALLER TO ROUTE CORDS UP

THROUGH THE EXTENSION COLUMN.

(SOLD SEPARA TEL Y)

A

SLOT

I

DETAIL 5

I

A

J

EXTENSION

COLUMN

SLOT

J

DETAIL 6

6 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 04-21-03 SHEET #: 055-9158-1

Page 7

Attach bracket (K) to ball and socket assembly (A)

using 1/4 - 20 nut (E).

A

To adjust roll, pitch, and yaw loosen the set screw

(shown below) using security allen wrench (B) or

standard 4 mm allen wrench. You should be able to

just slightly loosen the screw so that your adjustments

can be set without having to hold the projector. Move

projector to desired position and slowly tighten set

screw.

Note: Be sure not to touch the projector while

tightening the set screw. This may cause the image

to be unaligned when you let go.

K

E

Press button on side of projector to lift projector foot.

Slide bracket (K) under projector foot. Push foot

down. Secure bracket (K) with 1/4 - 20 socket pin

screw (D).

CEILING

CUTA W A Y VIEW OF

CEILING PLA TE (G)

WOOD

JOIST

D

IMPORTANT: Security allen wrench (B) is your key for

projector removal. Store it in a safe place.

WOOD

JOIST

CEILING

SET SCREW

PROJECTOR

A

PROJECTOR

K

PROJECTOR

FOOT

7 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

© 2003 Peerless Industries, Inc. All rights reserved.

ISSUED: 04-21-03 SHEET #: 055-9158-1

Page 8

PEERLESS LIMITED W ARRANTY

Peerless warrants its products, under normal use, to be free from defects in material and workmanship for a period of five years

from the date of purchase. Peerless, at its sole discretion, will repair or replace such defective equipment free of charge provided

the products are returned prepaid to Peerless. Thereafter, repairs will be made at established factory prices. Unauthorized service

or repairs by anyone other than authorized Peerless personnel renders this W arranty void and releases Peerless from any further

responsibility or obligation. Any damage caused by failure to observe proper packing or to observe instructions for installation, by

accident or in transit or elsewhere will not be covered by the W arranty. This W arranty is in lieu of all other W arranties expressed

or implied, and no one is authorized to assume any liability on behalf of Peerless or impose any obligation on it in connection with

the sale of any product other than as outlined above. In no event will responsibility be assumed or implied for consequential

damages arising from the theft of any product secured by a Peerless security device, by delay of installation, interrupted operation

or other causes.

8 of 8

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 04-21-03 SHEET #: 055-9158-1

Loading...

Loading...