Garmin TR-1 Gold Marine Autopilot User Manual

TR-1 Gold

Owner’s Manual

906-2000-00

RevH 101507

Thank You

Your purchase of this TR-1 Gold outboard management system enters you in the

prestigious fraternity of anglers who count on TR-1 to control their outboard kickers.

TR-1 Autopilots is dedicated to creating the nest controls and guidance systems for the

best in boating and shing.

TR-1 Gold represents that effort. Enjoy your best shing partner ever. We’re sure you will

agree it is worth its weight in GOLD.

Table of Contents

Safety & Cautions Page 3

Parts List Page 4 & 5

Specications Page 6

Preparation Page 6 & 7

System Layout Page 8

Tools Page 9

Installation of E-H Unit (Pump) Page 9 & 10

Installation of Sensor Ball (Compass) Page 11 &12

Installation of Deckmount/ Tach Page 13

Installation of Handheld/Remote Page 14

Verify Connections Page 14

Battery Connections Page 14

Connect & Fill Hydraulic System Page 15

GPS Connections Page 18

System Functions and Features Page 19

Operating the System Page 20

Power On/Off (Deckmount) Page 21

Engaging Heading Hold Page 21

Change Heading with Remote Steer Page 21

Change Heading with RCAH (Changing Heading while in Autopilot) Page 22

GPS Steering Page 23

Setting North Page 23

Course overground Page 23

Steer to Waypoint Page 24

Orbit Waypoint Page 24

Cloverleaf Pattern Page 24

Search Pattern Page 25

Step Turns, Change Heading with Page 26

Circles, Change heading with Page 26

Reverse Page 26

MOB, change heading with Page 26

Idle/Resume Page 27

Throttle Up & Down Page 27

Zig-Zags, change heading with Page 27

Selecting Special Functions Page 28

Setup, How to make changes with Page 29

Setup Codes, Table of Page 30 & 31

Explanation of Codes Page 31 & 32

Adjusting Your Autopilot (Tuning and Setup) Pages 33-35

Rudder and Counter Rudder Gain Pages 35-37

Trouble Shooting Guide Page 39

2

Rev.H 101507

Safety

You are responsible for the safe and prudent operation of your vessel.

Your TR-1 Gold Autopilot is a tool that will enhance your capability to

operate your boat and catch fish. It does not relieve you from the

responsibility for safe operation of your vessel. You must avoid hazards

to navigation and never leave the helm unattended.

You must always be prepared to promptly regain manual control of your kicker. The

autopilot and the throttle actuators can fail hard over. Learn to operate your autopilot on

calm and hazard free open water.

In case the autopilot becomes inoperable, remove the in line fuse from the battery power

cable.

The steering cylinder can be removed from its mounting bracket on the outboard in case

of hydraulic jamming.

Removing the actuating link between the stepper motor and the carburetor butterfly

crank can disable the electric throttle.

Caution:

Before drilling holes in your boat, be sure you know what you are drilling into.

Watch out for fuel tanks, electrical cables, and hydraulic hoses.

Do not run your pilot with the outboard hard on the steering stops for any

extended time or you will burn out the pump motor.

Be sure to leave the system in Standby mode when Autopilot is not

in use, or if

the kicker motor is not running.

We recommend you use only BioSOY hydraulic fluid in your autopilot hydraulics.

Keep your hands out of the outboard steering hinge area, the autopilot may steer the

motor and smash (or worse) your fingers.

3

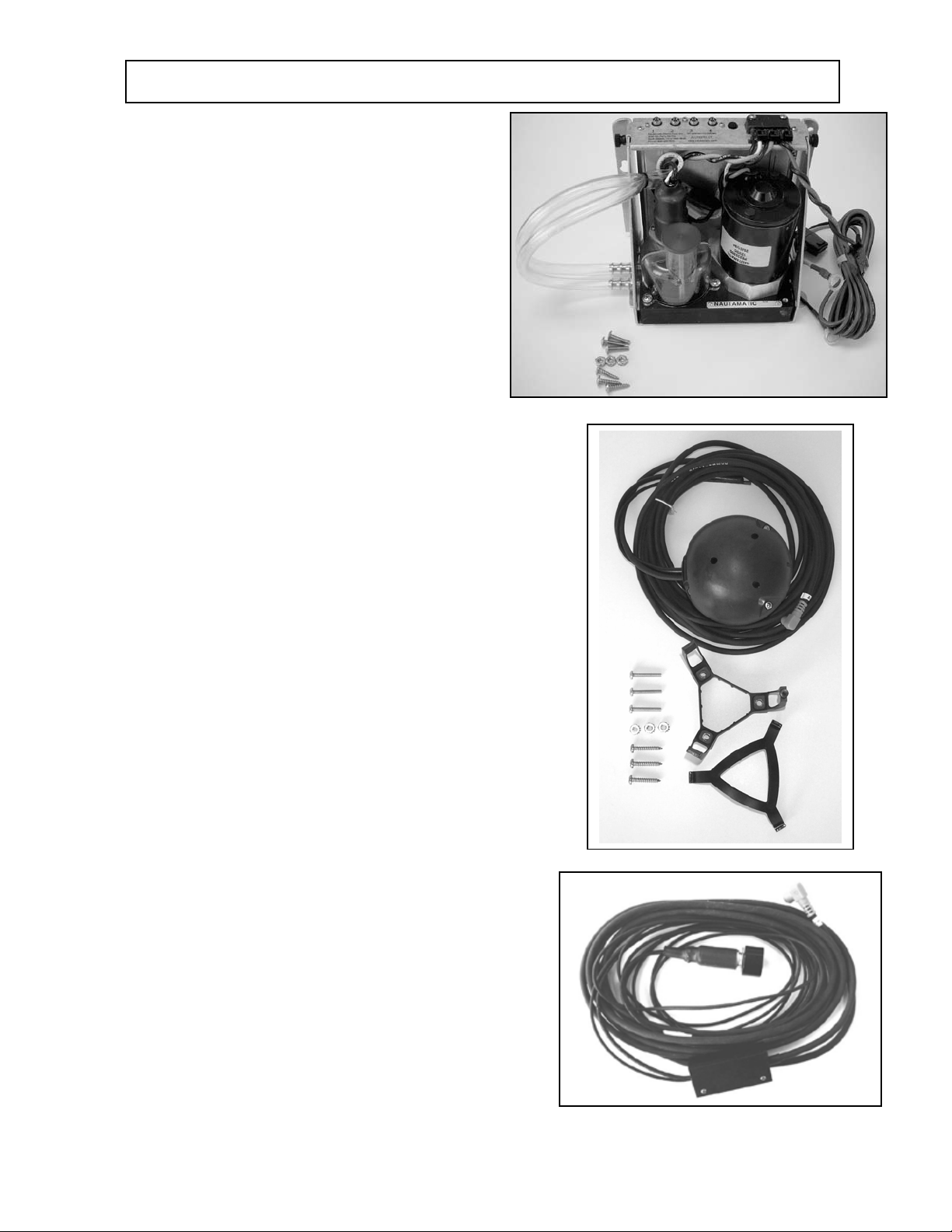

TR-1 Gold Autopilot System Parts List

Electro-Hydraulic unit……………….…….

120-2100-00

Kinked tubing with tie wrap……………….

3 ea. Truss head machine screws #8-32x 3/4

3 ea. Lock washer nuts #8-32………………

3 ea. Truss head sheet metal screws #8 x 3/4

Sensor Ball Unit……………………………….……..

120-2200-00

Sensor Ball Bracket ………………………………….

3 ea. Pan head machine screws #8-32 x 1”…………

3 ea. Lock washer nuts #8-32…………………………

3 ea. Pan head sheet metal screws #8 x 1”…………

Sensor Ball Capture Cage...………………………….

Deck Mount Switch/Tach …………………………

120-2215-00

4

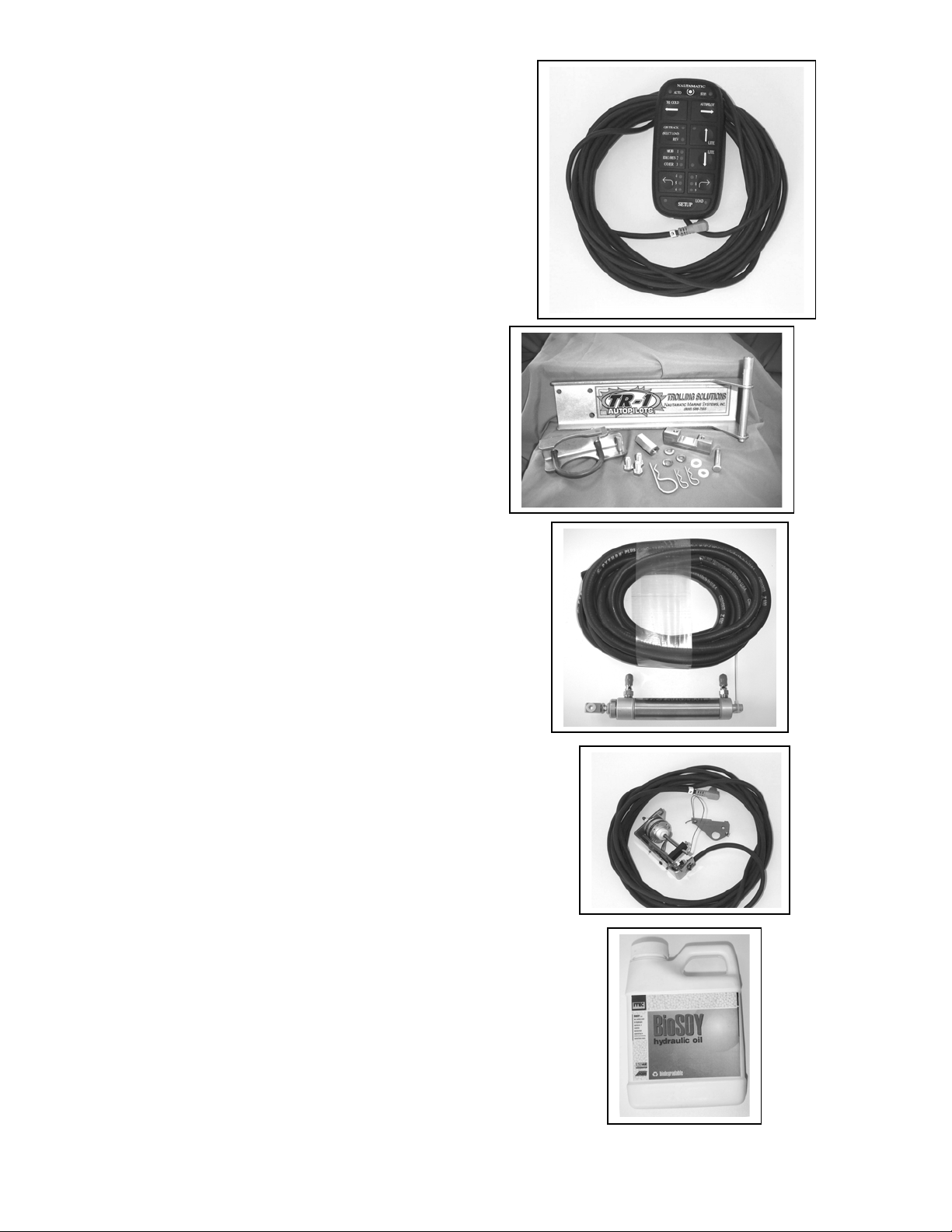

Handheld/Remote Unit...………………………….

120-2020-00

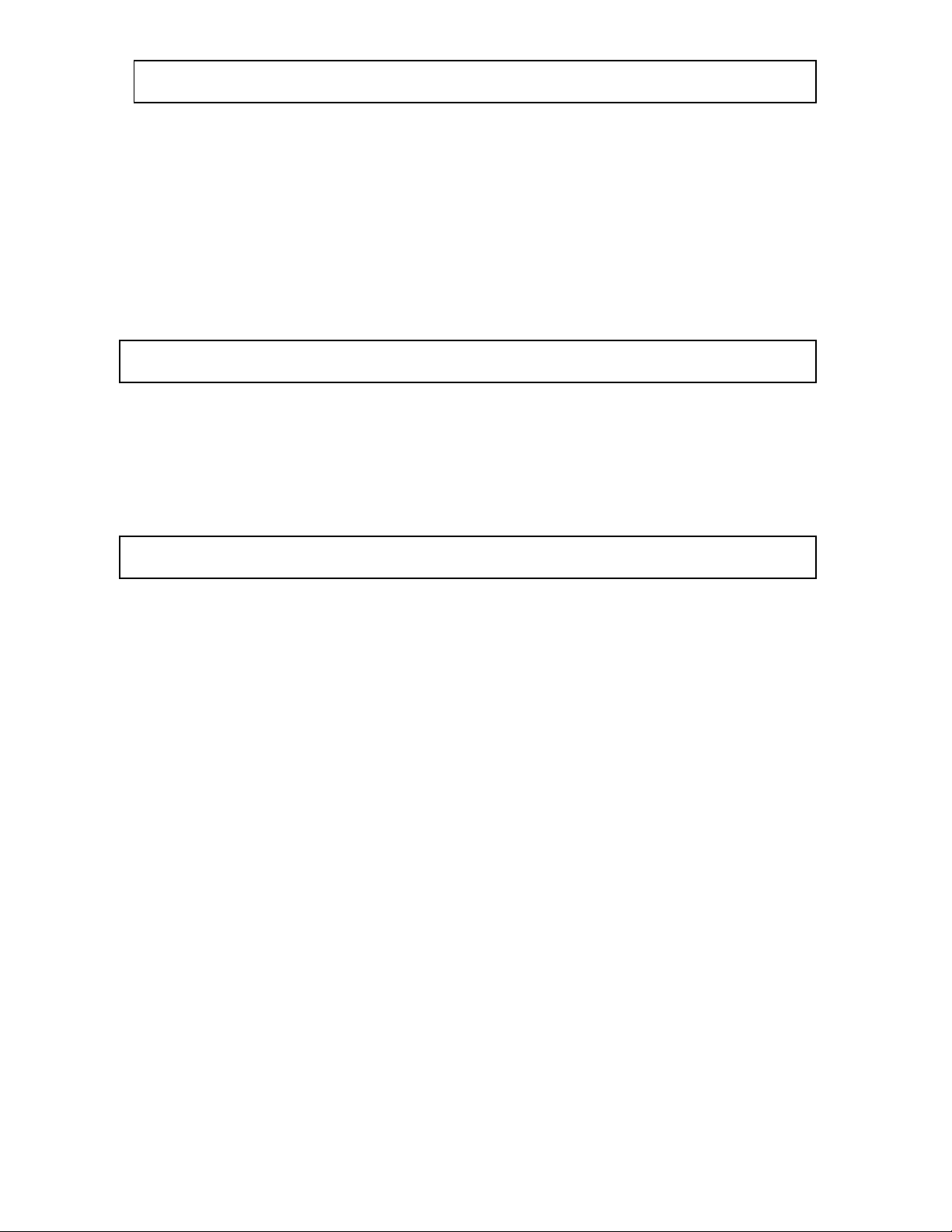

Cylinder Mounting Kit…………………

(Motor Specific)

18 feet Hydraulic Hose…………………………………

120-0013-01

Steering Cylinder………………………………………...

120-0900-00

Throttle Actuator ( Motor Specific)……………………….

1 pt. Hydraulic Fluid

120-0001-01(Bio-Soy)………………………………

5

E-H unit 6.5”H x 7” W x 5” D 8 lb

Sensor Ball 3.6” Dia. Cable length 18’ 2 lb

Remote 5”x 2.5”x 1” Cable length 18’ 1 lb

Deckmount/Tach 5/8”x 2” Cable length 6’

Battery Cable Cable length 9’

Fluid 1 pt. BioSOY Oil 1 lb

Supply Voltage 11.5 – 14.0 VDC

Maximum Current 12 Amperes

Inline Fuse ATO 20 Amp

O

p

erating Ambient Temperature 20 – 120 deg F

TR-1 Gold Specifications

Introduction

This manual comprises two major sections. The first section is a guide to installation of

the “onboard” components of the autopilot system on your boat. The second section is a

guide to adjusting and operating your system. Installation instructions for the throttle

actuator and steering cylinder are motor specific and are provided in separate manuals.

Preparation

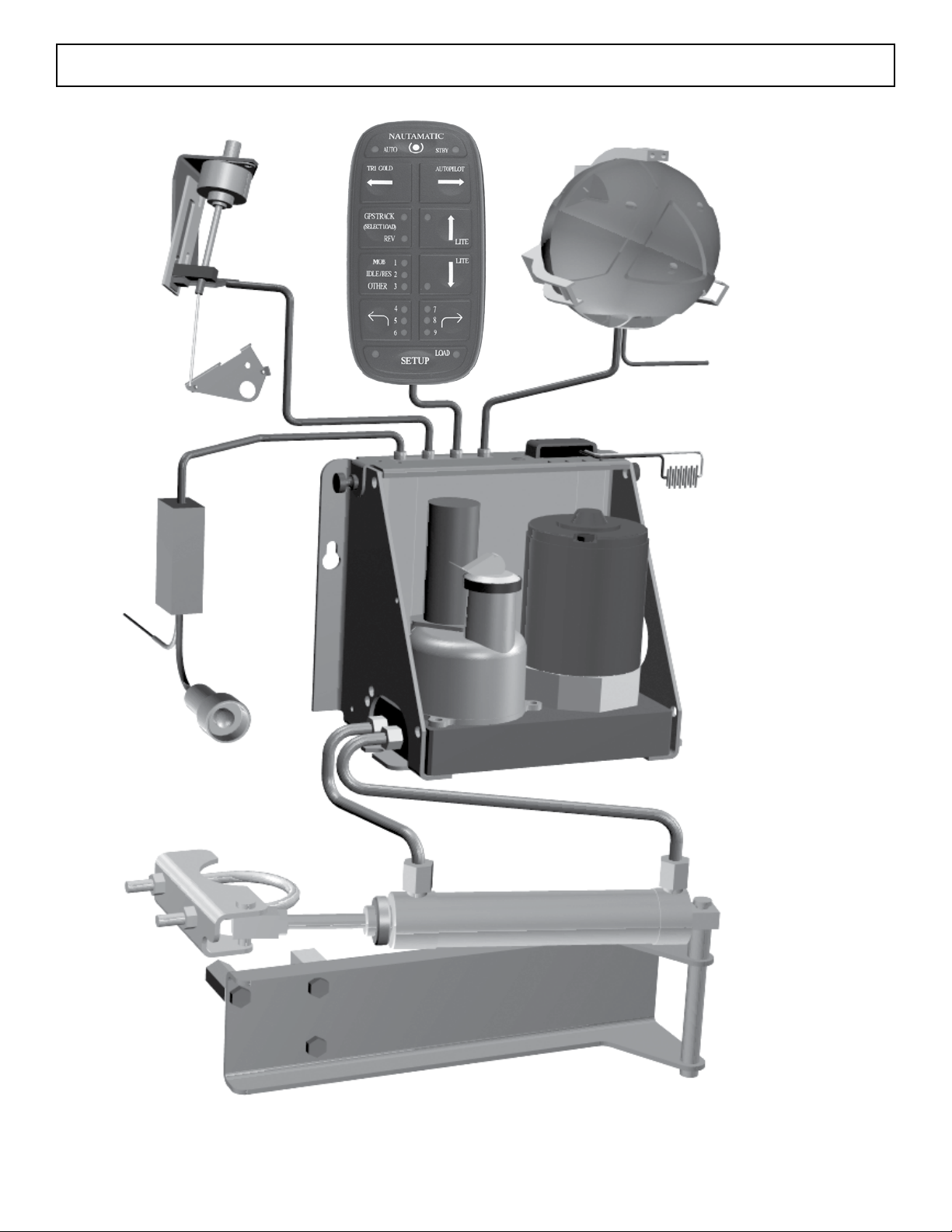

You will be hard mounting three autopilot components in your boat: 1) The Electrohydraulic

Unit. 2) The Deckmount switch. 3) The Sensor ball. These components are shown in relation

to each other and to the engine mounted components in the System Layout diagram on page 8.

As indicated by this diagram, the Electrohydraulic unit and the Deckmount switch are to be

located near the kicker and the Sensor ball is to be located FORWARD OF THE CENTER

OF YOUR BOAT

Spend some time to figure out where you are going to mount all of the components before you

mount any of them. Place the components where you expect to mount them and verify you

have access to and routes for the cables and hoses that connect the components.

x Mounting Screws

Mounting screws are provided for through and blind hole applications. You may choose

to drill and tap the mounting surface.

SCREW TAP DRILL TAP CLEARANCE PILOT

#8 – 32 machine #29 .136 dia #8 –32

#8 – 32 machine 3/16

#8 sheet meta

l 1

/8

6

x Access

The Electrohydraulic Unit is the place where all the components connect together and the place where

fluid is added and fluid level is checked. Leave room for service loops in the cables and hoses.

The Deckmount switch should be easy to reach with your free hand when your other hand is on the

kicker tiller. This can be done after the initial turn on blinking setup is complete. In case of an

emergency, quick access to the deckmount switch is a good idea, by pressing the button once it will

take the autopilot to standby, allowing you to take control of the tiller handle. Pressing the button

again will return it to autopilot mode.

If you intend to hook up to GPS, the connection between the GPS and the autopilot is made at the

Sensor ball and the NMEA 0183 output on your GPS.

x Protection

Locate the Electrohydraulic unit and Sensor ball in places where they will not get submerged or

exposed to wash down.

Use a quality electrical insuating grease compound on all electrical connections (Dow Corning

#4) except the orange connectors # 1,2,3, & 4.

x Moving Parts

Hoses and cables that connect the Electrohydraulic unit to the engine mounted components

need to be free from binding and kinking. Be sure to remember your kicker moves up and down

on the lift bracket, tilts up and down, and steers lock to lock.

x Hose Length

Try to keep the hose length between the steering cylinder and the Electrohydraulic unit short. But

leave enough length for movement of Kicker (See note above on moving Parts).

x Magnetic Environment

The Sensor ball has a compass in it. Do not mount the ball near magnetic materials, magnets

(speakers and electric motors), or high current carrying wires. Small, vehicle fixed, magnetic

disturbances can be calibrated out, but moveable or changing magnetic disturbances such as anchors,

anchor chain, and wiper motors should be kept at least 24” away. A common problem is to have

mounted the ball near a glove box, and then someone puts tools in the glove box. Keep the Sensor

ball away from Air Ride seats.

x Strain Relief and Cable Protection

Do not let the connectors on the Electrohydraulic unit be the sole support for the cables connected to

them. Use the tie wraps to tie the cables down to the Electrohydraulic frame. There are several holes

in the sheet metal frame provided for this purpose.

Don’t run cables and hoses over sharp edges. Use grommets in through holes to protect the cables.

7

Mounts on carburetor

on motor.

System Layout

Handheld/Remote

Sensor Ball: Mount

in front 1/2 of boat.

Throttle

Actuator

GPS connection

NMEA 0183

Tach sensor

wire:Attaches

to spark plug

wire on kicker.

Deckmount On/Off switch:

Mounts near kicker motor, near

transom.

1 2 3 4

Battery

12V

Electrohydraulic Unit: Mount near

transom.

Cylinder

Cylinder Mounting Bracket: Mounts on Motor

lower end.

8

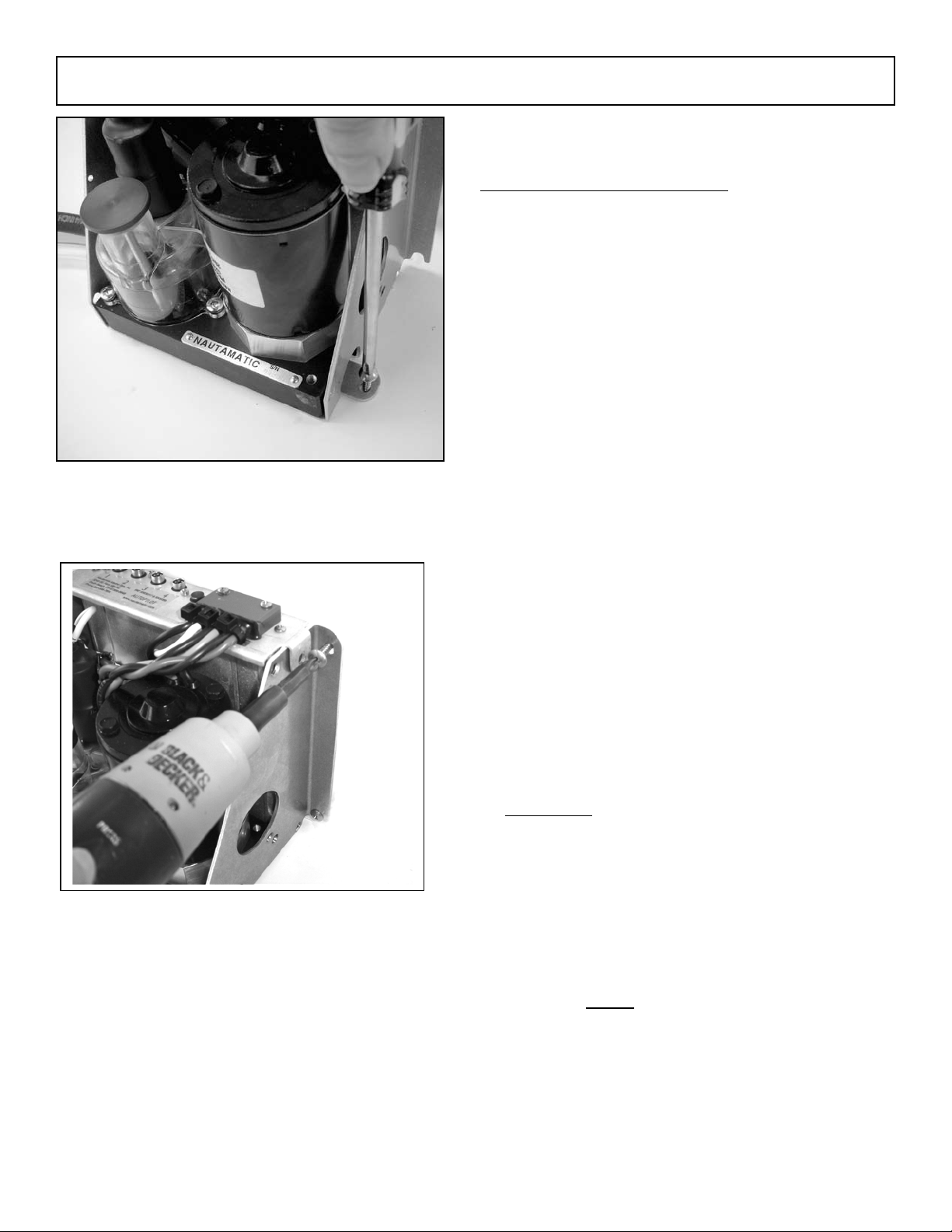

Locate the Electro-Hydraulic unit where it

it will not be subjected to water submersion

or spray from wash down.

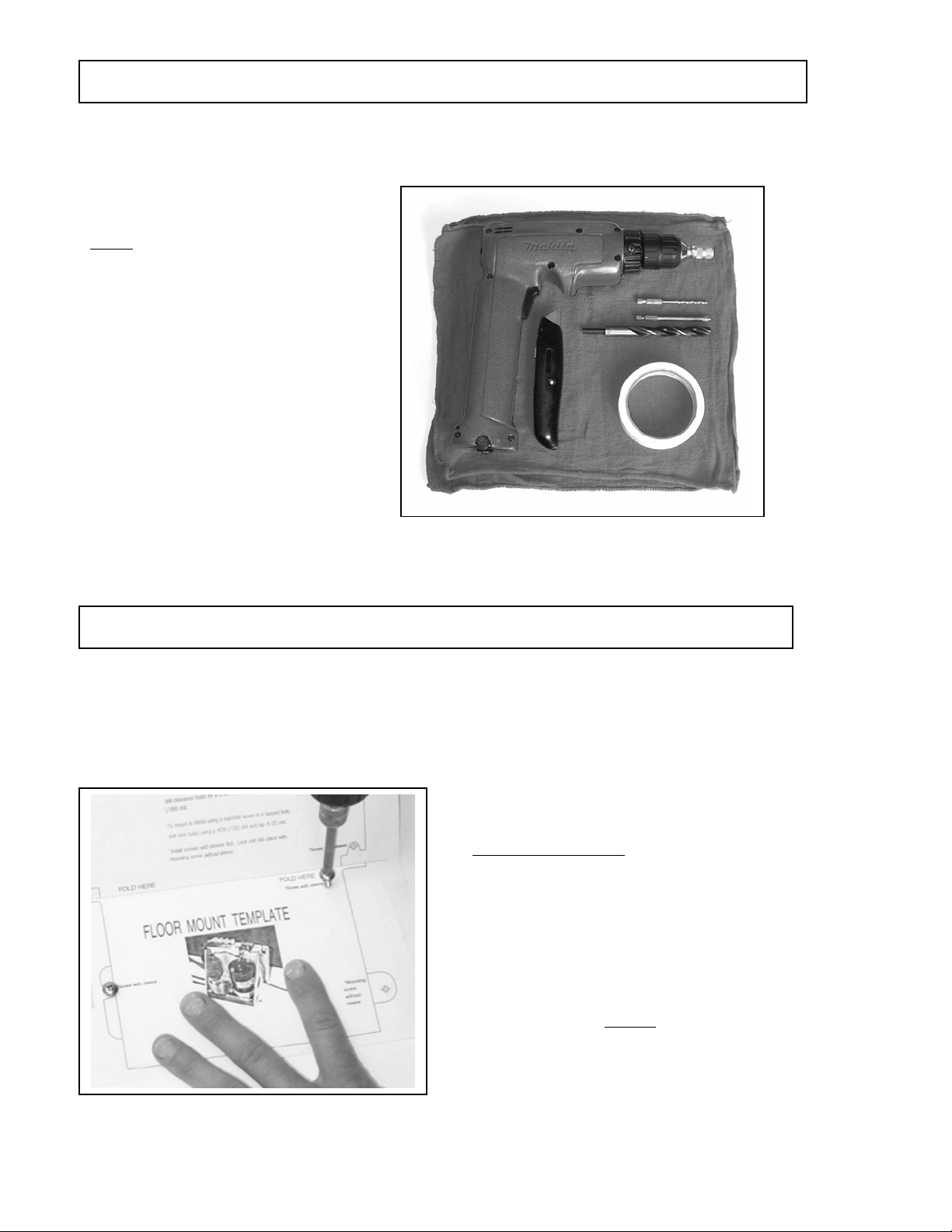

Tools

You should gather the following tools before beginning installation. See throttle and cylinder

supplements for any additional tools that may be needed for your application.

Tools

Power Drill

#1 Phillips screw driver

.125 (1/8) or 3.17 mm dia. drill

.469 (15/32) or 11.90 mm dia. drill

Roll of masking tape

Rags

Knife

Pliers

Silicone RTV

Loctite or similar product

Electrical grease compound

(Dow Corning #4)

Installation of The Electro-Hydraulic Unit

Step one (Template)

Find the mounting template in your autopilot

documentation package. Use the wall or floor

section of the template as needed. Decide which

screw type you need. Hold the template in the

place with tape and drill right through it in the

three indicated locations. See fig.5. Remove

template and install screws in the indicated

locations on template. Tighten these 2 screws

down to 3/32” from the surface to allow enough

space for the bracket on the pump to slide behind

the screw.

Fig .4

Fig. 5

Please read the complete instructions thoroughly before starting your installation. If

you have any questions call our Tech Support line. 1-800-588-7655

9

Mounting Hydraulic Unit

Step Two (Locking unit in place)

Floor Mount: Set the unit on the

floor in front of screws. Slide the left

side back and engage the notch

between the hose fittings around the

left hand screw. Pivot the unit on the

left hand screw counter clockwise

until the notch under the electronics

box on the right hand side is engaged

and the remaining hole you drilled

lines up with the hole in the bottom

tab of the right hand bracket. When

the holes line up, put the last screw in

and the E-H unit is locked in place, as

shown in fig.6.

Wall Mount: Set in place by

hanging the unit on the screws.

One is the keyhole shape on the

upper left backside of E-H unit; the

other is the notched area on the

lower right side of E-H unit. Lock

E-H unit in place by lining up the

last hole on upper right hand corner.

Please note

: You will need to

remove the black plastic

thumbscrew to place the last screw,

as shown in fig.7

You may run the red and black wires to the battery box now, but do not connect to

the battery yet.

Fig. 6

Fig. 7

10

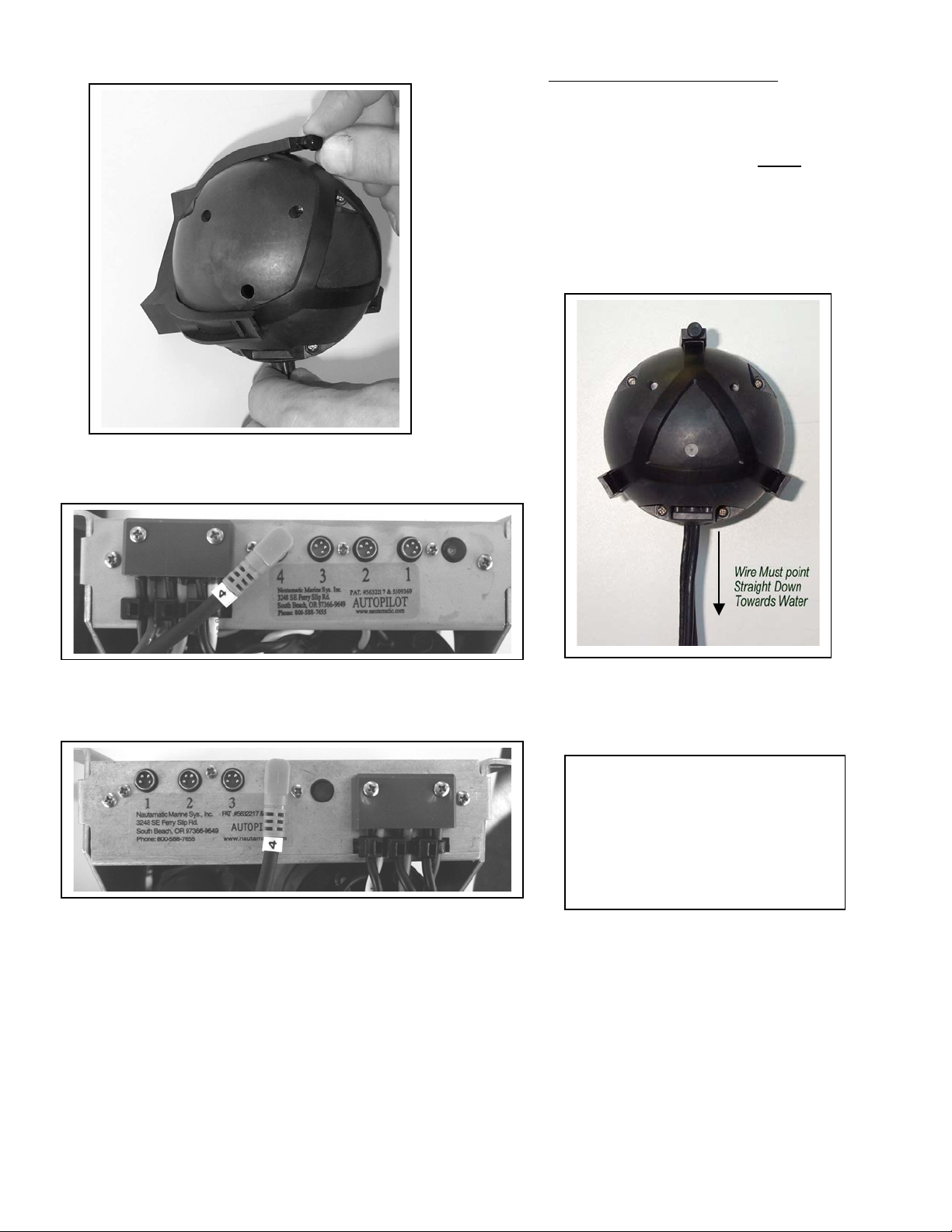

Installation of the Sensor Ball

Hold the mounting bracket in the desired

position and drill through the holes into the

mounting surface. (Be sure that the wire

coming out of the ball can exit the ball

straight down.) Tap if necessary. Install and

tighten the three mounting screws as shown

in fig.8-a

If you need to make a paper template for a

drill pattern: The mounting holes are equally

s

p

aced on a 1.224 inch radius circle.

Fig. 8-a

Fig. 8-b

Place the ball, wires down, into the

bracket and capture it by snapping the

cage over the ball, sliding the tips of the

cage between the ball and the legs of the

bracket. Do the two legs without the

thumbscrew first. Rotate cage upwards to

catch the bracket with the thumbscrew.

See fig. 8-b

Step one (Mounting the Sensor Ball)

Step two (Placing ball in bracket)

The Sensor (Compass) Ball needs to be mounted forward of the center of your boat. Make sure

you mount it away from magnetic disturbances (stereo speakers, wiper motors, anchors). You

will need to calibrate your compass on the water after installation of system and before you use

the autopilot.

11

Step 3 (Adjusting Sensor Ball)

Readjust the ball if necessary and fix

it in position by tightening the

thumbscrew. See Fig 9-A. Make

sure that the wires from the Sensor

Ball are pointing straight down out

the bottom; otherwise the sensor ball

will not work properly. See Fig. 9-B

Fig. 9-A

Fig. 9-B Fig. 10-a

Note: It is important to match

your ECU wiring configuration

to the picture. Just remember

to always plug into matching

numbers from the wire to the

ECU.

Fig. 10-b

Run the wire back to the E-H unit. The wire connector from the Sensor Ball is labeled number

4. It connects to the E-H unit at connector 4, as shown in fig.10-a or 10-b. (this will depend on

your ECU wiring configuration). When you plug in the connectors, the wires go at about a 45q-

angle left of the numbers on the E-H unit (fig. 10-a) or at a 90° angle for fig 10-b. Feel the

connectors start before pushing it down.

12

Loading...

Loading...