Page 1

Master Series Heavy Duty

M/MS/MST Series Gas Ranges and Char Broilers

Installation, Operation and Maintenance Manual

Original instructions

Part Number 1382680 Rev 4 (1/15/16)

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers is

known to the state of California to cause cancer. Operation of this product could expose you to carbon

monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of California

to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Part # 1382680 Rev 4 (1/15/16)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . 4

Clearance from Combustible Construction . . . . 4

Clearance from Non-Combustible Construction

4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Gas Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Of Ovens Equipped With Casters . . 5

Installing Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation and Air Supply . . . . . . . . . . . . . . . . . . . . 6

Installation of Oven Flue Riser . . . . . . . . . . . . . . . . 6

Installation Instructions for

Low Pro le Backguard . . . . . . . . . . . . . . . . . . . . . . . 6

Valve Controlled Griddles (M Models) . . . . . . . . 13

Valve controlled Griddles (MS/MST Models) . .13

Oven (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

“RC” Convection Ovens . . . . . . . . . . . . . . . . . . . . . . 13

Char-Broiler (M,MS Models) . . . . . . . . . . . . . . . . . . 14

Char-Broiler (MST Models) . . . . . . . . . . . . . . . . . . .14

Assembly of Char-Broiler . . . . . . . . . . . . . . . . . . . . 15

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . 15

Painted Finishes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Stainless Steel Finishes . . . . . . . . . . . . . . . . . . . . . . 15

Oven Interior (Porcelain Enamel) . . . . . . . . . . . . . 16

Oven Interior – Optional continuous Clean . . .16

Automatic Pilot Valve . . . . . . . . . . . . . . . . . . . . . . .16

Griddle Seasoning . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Griddle Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation Instructions for

High Pro le Backguards and Shelves . . . . . . . . . . 7

Installation Instructions for

Salamander or Cheesmelter . . . . . . . . . . . . . . . . . . 7

Assembly of Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Optional Common Rail Installation . . . . . . . . . . . . 8

Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . . . 11

Testing and Adjustments . . . . . . . . . . . . . . . . . . . . 11

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Open Top Burners (M/MS Models) . . . . . . . . . . .12

Open Top Burners (MST Models) . . . . . . . . . . . . . 12

Hot Top Sections And Spectro-Top Sections

(M Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Hot Top Sections And Spectro-Top Sections

(MS/MST Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Thermostatically Controlled Griddles

(M Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Open Top Burners . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Top Grates

Seasoning Cast Iron Top Grates . . . . . . . . . . . . . . 17

ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . 18

Pilot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Burner Gas/Air Adjustments . . . . . . . . . . . . . . . . . 18

Cast Iron Hot tops and Spectro-Heat Tops . . . . 18

FDO Heavy Duty Oven Control . . . . . . . . . . . . . .19

BJWA Griddle Thermostat . . . . . . . . . . . . . . . . . . .20

CONVECTION OVEN USER TIPS – SUFFIX

“RC”. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TROUBLE SHOOTING

CONVECTION OVEN . . . . . . . . . . . . . . . . . . . 21

Part # 1382680 Rev 4 (1/15/16) Page 3

Page 4

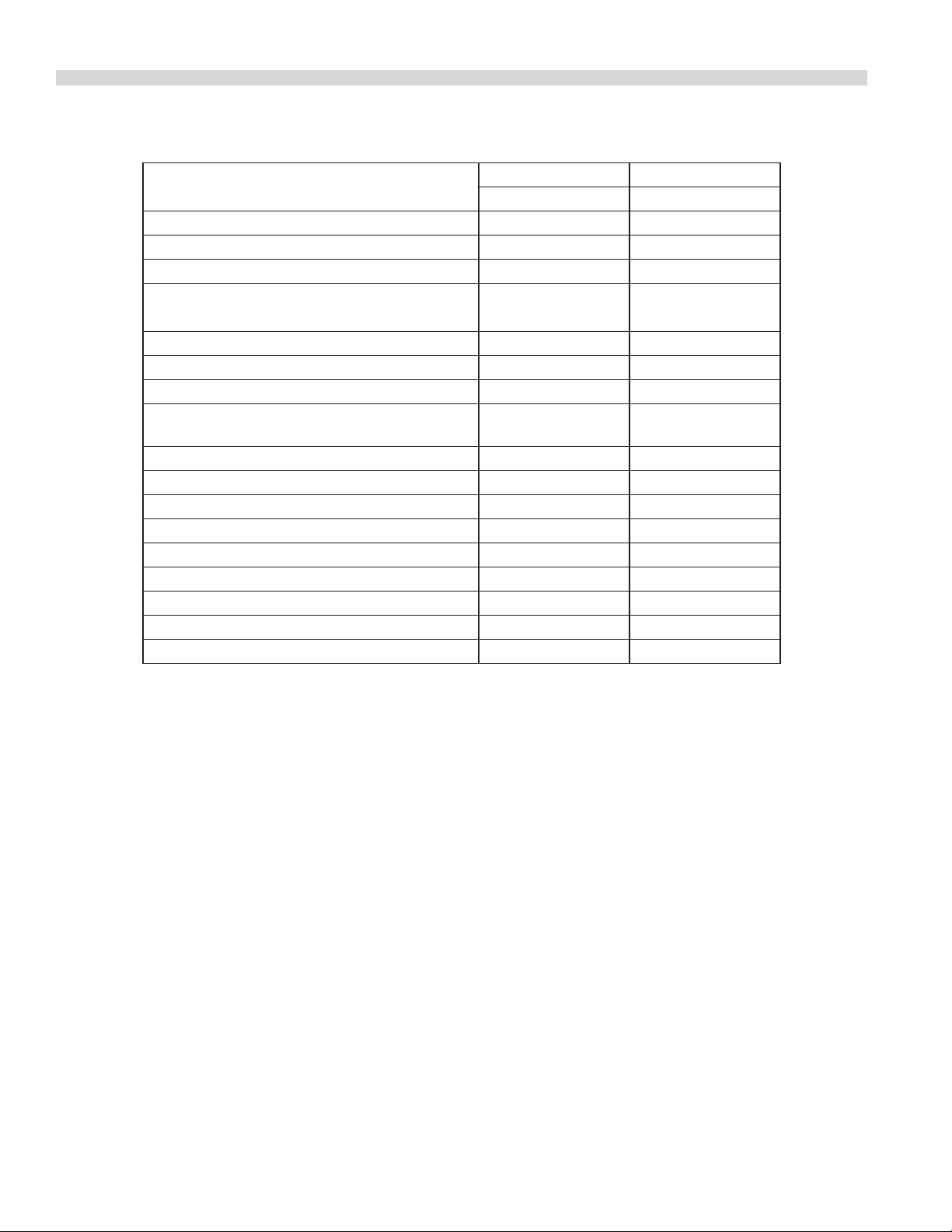

SPECIFICATIONS

MODEL NUMBER

(M,MS)(12,43) Open Burner 24,000 20,000

MST43 Open Burner 24,000 20,000

M(M43-1,2,3),12S-6 Hot top burner 22,000 22,000

M43 FTR Front Open Burner 18,000 16,000

Rear French top 15,000 16,000

(M, MS)(4,42,44,54) Open Burner 35,000 35,000

MST(42,44,54) Open burner 35,000 35,000

(M,MS)(45,54,5) Spectro Heat Burner 15,000 11,000

MST45 Spctro Heat Burner

M(42-6,46,6) Even Heat Hot Top Burner. 30,000 30,000

MST(42-6,46,6) Even Heat Hot Top Burner 27,000 27,000

(M,MS)47 Griddle burner 33,000 33,000

MST 47 Griddle Burner 30,000 30,000

M48 Griddle Burner 33,000 33,000

(M,MS,MST) Oven Burner 40,000 35,000

(M,MS,MST)(17,24,34) Char-Broiler 15,000 15,000

(M1R) Single deck oven section 40,000 40,000

(M2R) Double stacked ovens 80,000 80,000

GAS TYPE NATURAL GAS TYPE-PROPANE

INPUT (BTU/H) INPUT (BTU/H)

Total of 3 burners

40,000

Total of 3 burners

40,000

Natural Gas Operating Pressure=6.0” Water Column, measured at manifold tap.

Propane Gas Operating Pressure=10.0” Water Column, measured at manifold tap.

Clearance from Combustible Construction

Models (M,MST)5(S,T) & (M,MST)45(R,RC,S,T) must be

installed with no less than six inch (6”) clearance from

combustible construction at sides and rear.

Models (M,MS,MST)42(R,RC,S,T), (M,MS,MST)

44(R,RC,S,T), (M,MS,MST)54(R,RC,S,T), (M,MS,

MST)4(S,T), (M,MST)46(R,RC,S,T), (M,MST)47

(R,RC,S,T), M47-23(R,RCS,T), M47-45(R,RC,S,T), M48(R,RCS,T),

M48-23(R,RC,S,T), M48-45(R,RC,S,T) (M,MST)(6,7,8)(S,T) must

be installed with no less than fourteen inches (14”) on the

side, and six inch (6”) rear clearance from combustible

construction.

Models (M,MS,MST)43(R,RC,S,T ) must be installed with no less

than eleven inch (11”) side and six inch (6”) rear clearance

from combustible construction.

Clearance from Non-Combustible Construction

Models (M,MS,MST)(17,24,34)B(E) are for INSTALLATION IN

NON-COMBUSTIBLE LOCATIONS ONLY with zero (0”) sides

and rear clearance. Models with su x “RC” must be installed

with zero inches (0”) side and no less than one inch (1”) rear

clearance from non-combustible construction. All other

models may be installed with zero inches (0”) sides and rear

clearance from non-combustible construction.

Part # 1382680 Rev 4 (1/15/16)Page 4

Page 5

INSTALLATION

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the pre x and su x

letters and numbers) and the warranty serial number. The

rating plate a xed to the unit contains this information.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

speci ed. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

Installation Notices

Legs must be tted to the oven where it is installed on a

combustible oor.

When installed without legs on a non-combustible curb or

platform, the front of the unit should extend at least 3 inches

or 76 mm such that the ventilation gap will not be blocked.

Gas Installation

Before assembly and connection check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located behind the lower front panel.

Connect a unit stamped on the data plate located behind

the lower front panel. Connect a unit stamped “NAT”

only to natural gas; connect those stamped “PRO” only to

propane gas.

B. If it is a new installation have the gas authorities check

meter size and piping to assure that the unit is supplied

with su cient amount of gas pressure required to

operate the UNIT.

C. If it is additional or replacement equipment have gas

authorities check pressure to make certain that existing

meter and piping will supply fuel to the unit with not

more than 1/2” water column pressure drop.

NOTE: When checking gas pressure be sure that all other

equipment on the same gas line is on. A pressure regulator is

not supplied as standard equipment with GARLAND Heavy

Duty equipment, however a 1-1.4” pressure regulator is

sold as an option with the original purchase. If you would

like to purchase a regulator after original purchase contact

your equipment dealer. Installation must conform with the

National fuel Gas code ANSI Z223-1-1988 or latest edition,

NFPA No. 54 – Latest Edition and National electrical code

ANSI/NFPA 70-1990 or latest edition and/or local code to

assure safe and e cient operation.

In Canada, the installation must comply with

CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE, or

CAN/CGA-B149.2 PROPANE GAS INSTALLATION CODE, and

local codes where applicable.

In Canada, electrical connection must comply with

applicable sections of the Canadian Electrical Codes, C22.1

– 1990 (or latest edition), “Safety Standard for Installation,

Part 1” and C22.2 – No O-M 1982 (or latest edition), “General

Requirements, Part 2”.

NOTE: The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-o (not

supplied by manufacturer) during any testing of the gas

supply piping system at test pressures equal to or less than

1/2 PSIG (3.45 KPA).

NOTE: Adequate clearance must be provided for servicing

and proper operation.

NOTE: This appliance is not recommended for residential

installation.

Installation Of Ovens Equipped With Casters

A. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69/CSA 6.16, Addenda

Z21.69B-2006/CSA 6.16B-2006 (or latest edition), and a

quick-disconnect device that complies with the Standard

for Quick Disconnects for Use with Gas Fuel, ANSI Z21.41/

CSA 6.9, Addenda Z21.41A-2005/CSA 6.16A-2005 (or

latest edition).

B. The front casters of the unit are equipped with brakes

to limit the movement of the range without depending

on the connector and any quick-disconnect device or its

associated piping to limit the appliance movement.

C. Please be aware, required restraint is attached to a

bracket (which is located on the left rear caster), and if

disconnection of the restraint is necessary, be sure to

reconnect the restraint after the oven has been returned

to its originally installed position.

Part # 1382680 Rev 4 (1/15/16) Page 5

Page 6

INSTALLATION Continued

Installing Legs

Raise the front of the unit and block. DO NOT lay unit on its

back. Position leg insert into leg retainer opening and tap up

until it seats at collar ange. Repeat at rear of unit and ensure

all four legs are adjusted to the same height. When oor is

uneven, adjust legs to level the unit.

Ventilation and Air Supply

Proper ventilation is highly important for good operation.

The ideal method of ventilating a range is the use of

a properly designed canopy which should extend

approximately six inches (6”) beyond all sides of the

appliance and six feet (6’) six inches (6”) from the oor.

A strong exhaust fan will create a vacuum in the room, for an

exhaust system vent to work properly, replacement air must

enter the room in which the vent is located.

All gas burners and pilots need su cient air to operate and

large objects should not be placed in front of this oven which

would obstruct the air ow through the front.

Installation of Oven Flue Riser

The oven ue is packed inside the oven for shipping

purposes. Before installing the back guard, high shelf or

range mount salamander you must install the oven ue riser.

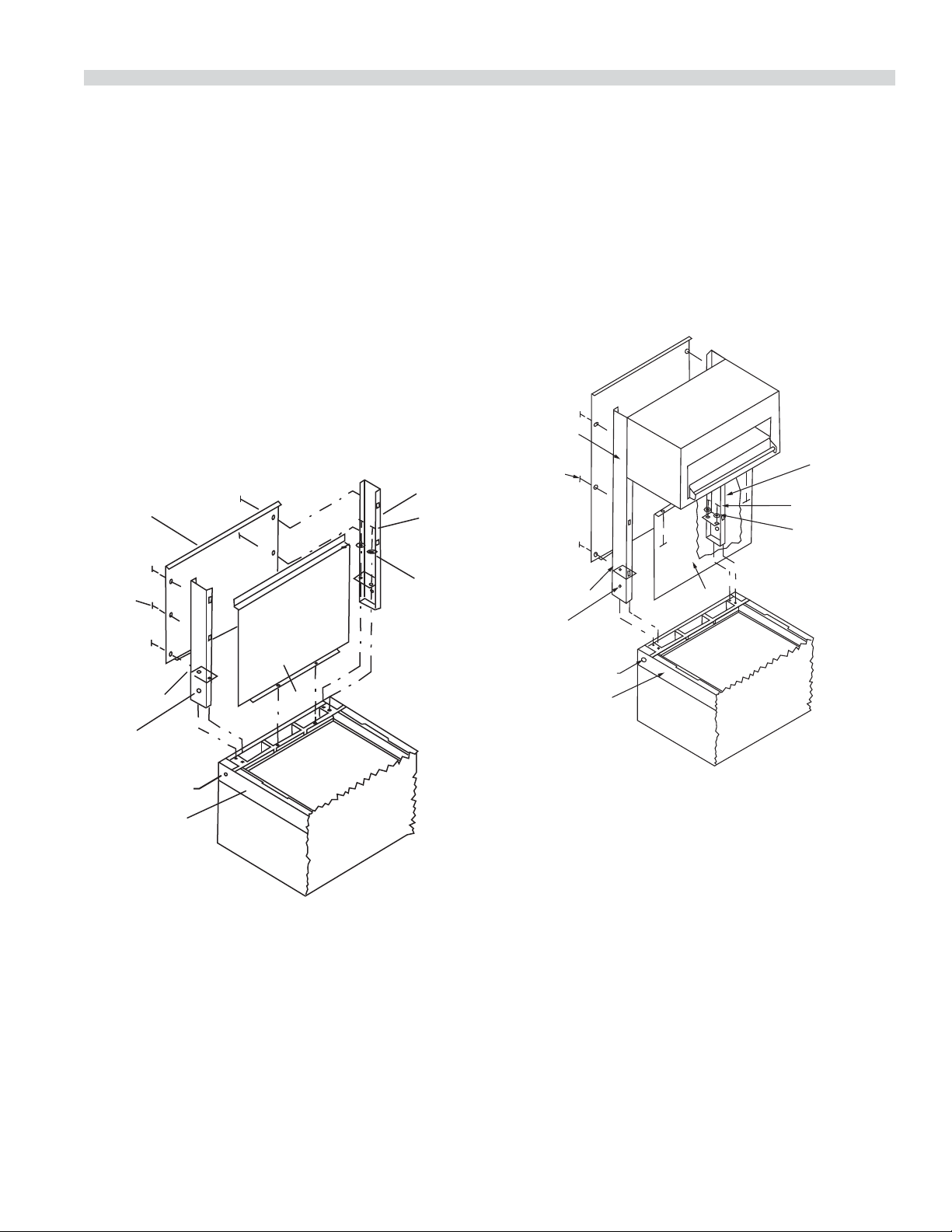

Installation Instructions for

Low Pro le Backguard

1. Remove ue cap, (6), by removing six, (6), #10 sheet metal

screws.

2. Remove front panel, (5), by lifting upward.

3. With back panel, (4), still attached to the uprights, (2 & 3),

drop the uprights into the rectangular openings at the

rear of the range. (1).

4. Fasten the uprights, (2 & 3), to the range with four (4),

5/16” x 18 and at washers, (7 & 8).

5. If the range is in a battery line-up, fasten units together at

hole marked “X” with ¼” x 20 bolts, nuts and washers.

6. Reattach the front panel, (5) to the backguard with sheet

metal screws previously removed.

7. Reinstall ue cap, (6), to top of backguard.

6

9

4

3

7

8

Remove the two #10 sheet metal screws from the rear center

of the main top. Position the oven ue riser over the center

square hold with the at surface to the rear of the range.

Reinstall the two #10 sheet metal screws, securing the oven

ue riser to the rear main top.

2

"X"

"X"

~

5

~

1

Part # 1382680 Rev 4 (1/15/16)Page 6

Page 7

INSTALLATION Continued

Installation Instructions for

High Pro le Backguards and Shelves

1. Remove front panel, (5), by lifting upward.

2. With back panel, (4), still attached to the uprights, (2 &3),

drop the uprights into the rectangular openings at the

rear of the range, (1).

3. Fasten the uprights, (2 & 3), to the range with four, (4),

5/16” x 18 and at washers, (6 & 7).

4. If the range is in a battery line-up, fasten units together at

hole marked “X” with 1/4” x 20 bolts, nuts and washers.

5. Reattach the front panel, (5) to the backguard with sheet

metal screws previously removed.

3

4

8

6

7

3. Fasten the uprights, (2 & 3), to the range with four, (4),

5/16” x 18 and at washers, (6 & 7).

4. If the range is in a battery line-up, fasten units together at

hole marked “X” with 1/4” x 20 bolts, nuts and washers.

5. Reattach the front panel, (5) to the salamander or

cheesemelter with sheet metal screws previously

removed.

4

"X"

Garland

8

2

5

3

6

7

2

"X"

"X"

1

5

Installation Instructions for

Salamander or Cheesmelter

1. Remove front panel, (5), by removing two, (2), sheet

metal screws from the underside of the salamander or

cheesemelter.

2. With back panel, (4), still attached to the uprights, (2 & 3),

drop the uprights into the rectangular openings at the

rear of the range, (1).

"X"

1

~

Assembly of Battery

All heavy duty batteried equipment is aligned and tted at

the factory, from left to right and must be installed in this

order. There is a diagram provided with every heavy duty

battery.

All models described, except model M110XMmay be

installed to battery with GARLAND M/MS/MST40 Series

Ranges, sharing common manifold connections.

A. All such units should be placed in their respective battery

position. Detach valve panels to prevent damage,

remove them from the area where the battery is being

assembled.

Part # 1382680 Rev 4 (1/15/16) Page 7

Page 8

INSTALLATION Continued

B. Level each unit (to the oven rack) by adjusting the six inch

(6”) legs (refer back to Item 1 for limitations), or where

legs are not used, adjust level with shims. Readjust legs, if

required.

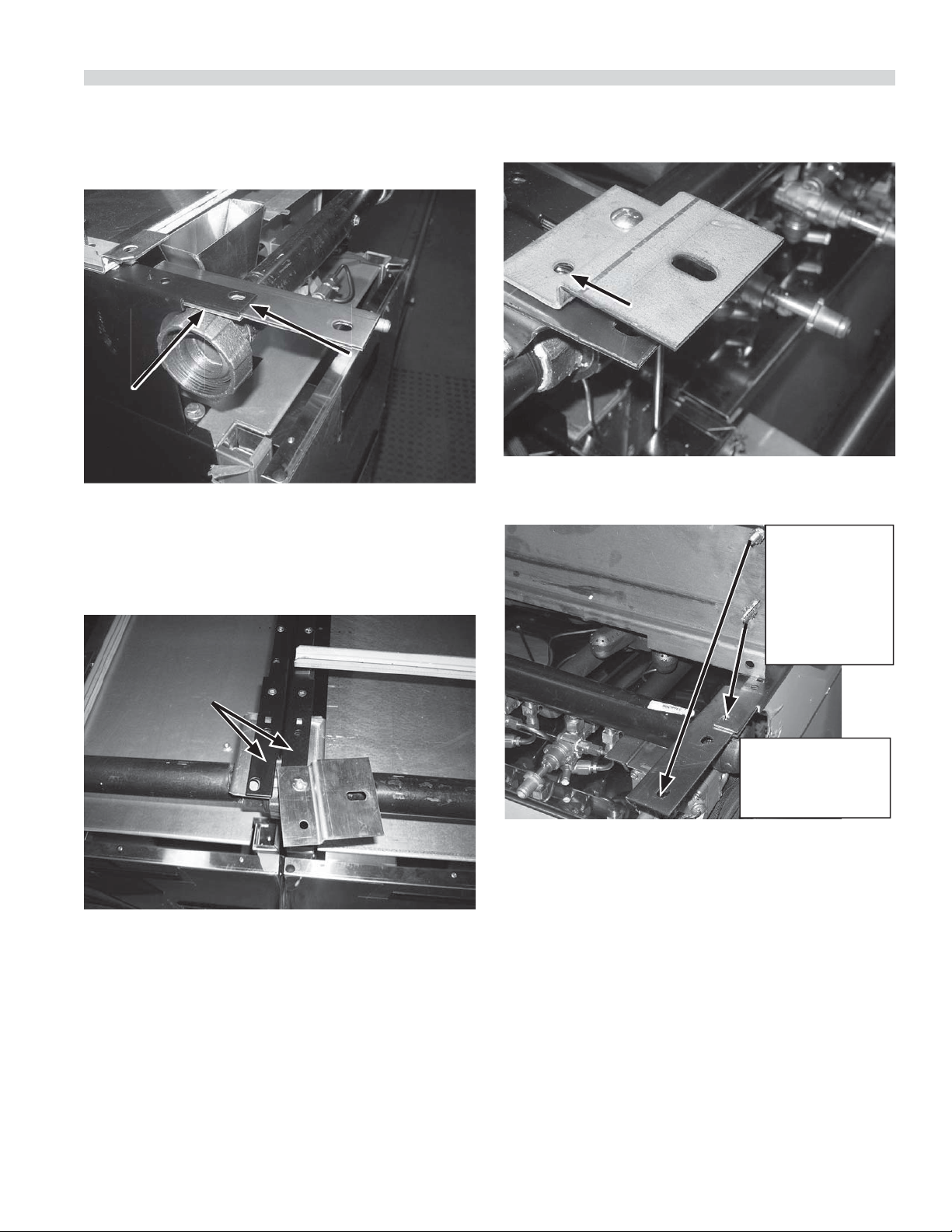

C. Connect units together by mating the unions at each

end of the manifold. (Adjoining units must have

matching unions, unless the union parts are of the

same speci cations, a leak proof connection cannot be

assured.) Hand tighten unions at this point.

D. The units should be fastened at the rear by inserting 5/16”

bolts through the holes provided at the rear of the burner

box sides. Install washer and nut and hand tighten. Be

sure of proper unit alignment in the battery before nal

tightening of these bolts or unions. Improper tightening

will cause “fanning” or “bowing” of batteried units.

The nal tightening of the union should be accomplished

by using a suitable spanner wrench. If such a wrench

is not available, the GARLAND union collar has special

ridges, and a cold chisel can be driven against these

ridges to properly seat and seal the union.

E. The manifold of this unit or the manifold of which is

a part of must be equipped with a certi ed pressure

regulator suitable for battery application and adjustable

for an outlet pressure at the manifold as speci ed on the

rating plate.

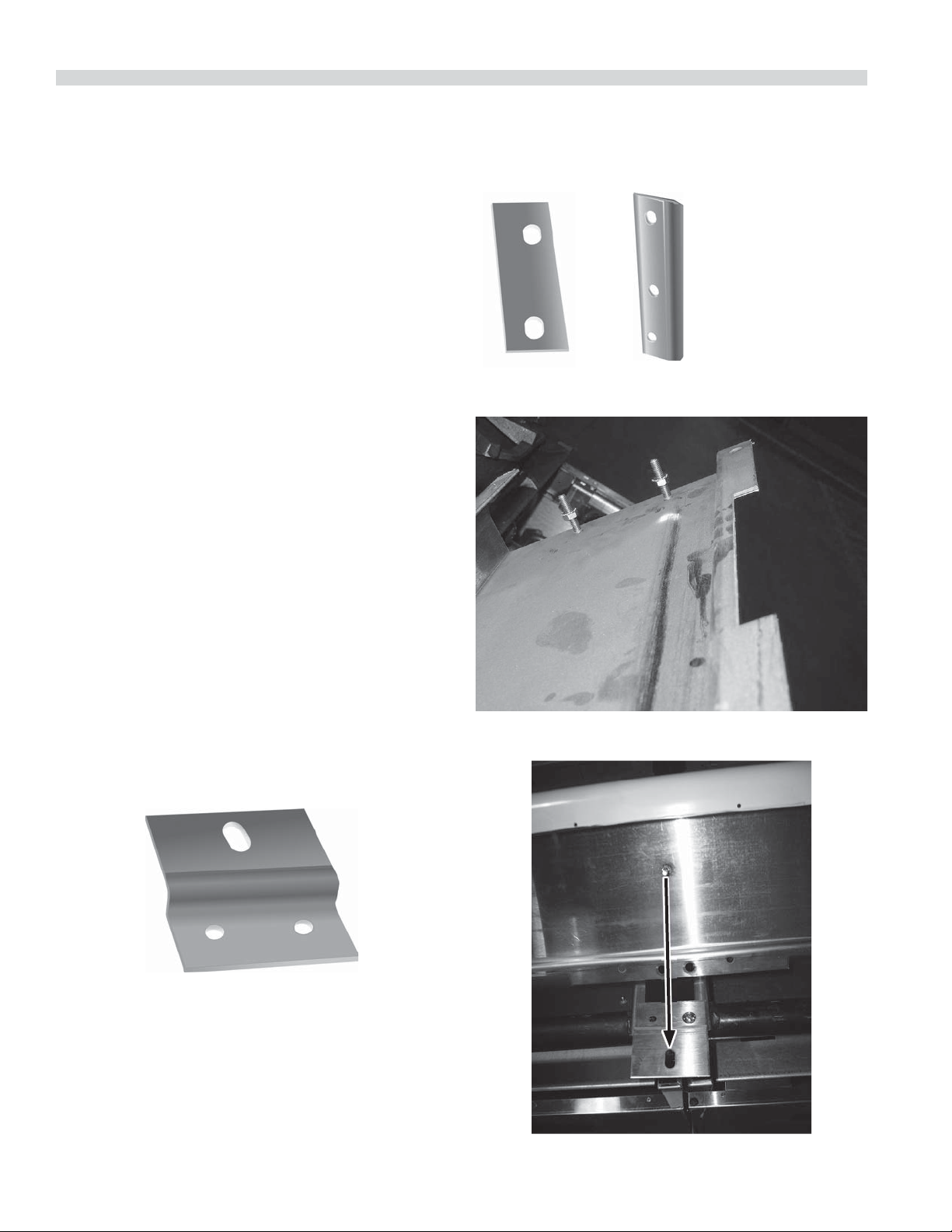

Spacers X2 End rail support

(Right & Left) brackets

mounted at each end

of the rail.

Rail with studs for end rail bracket.

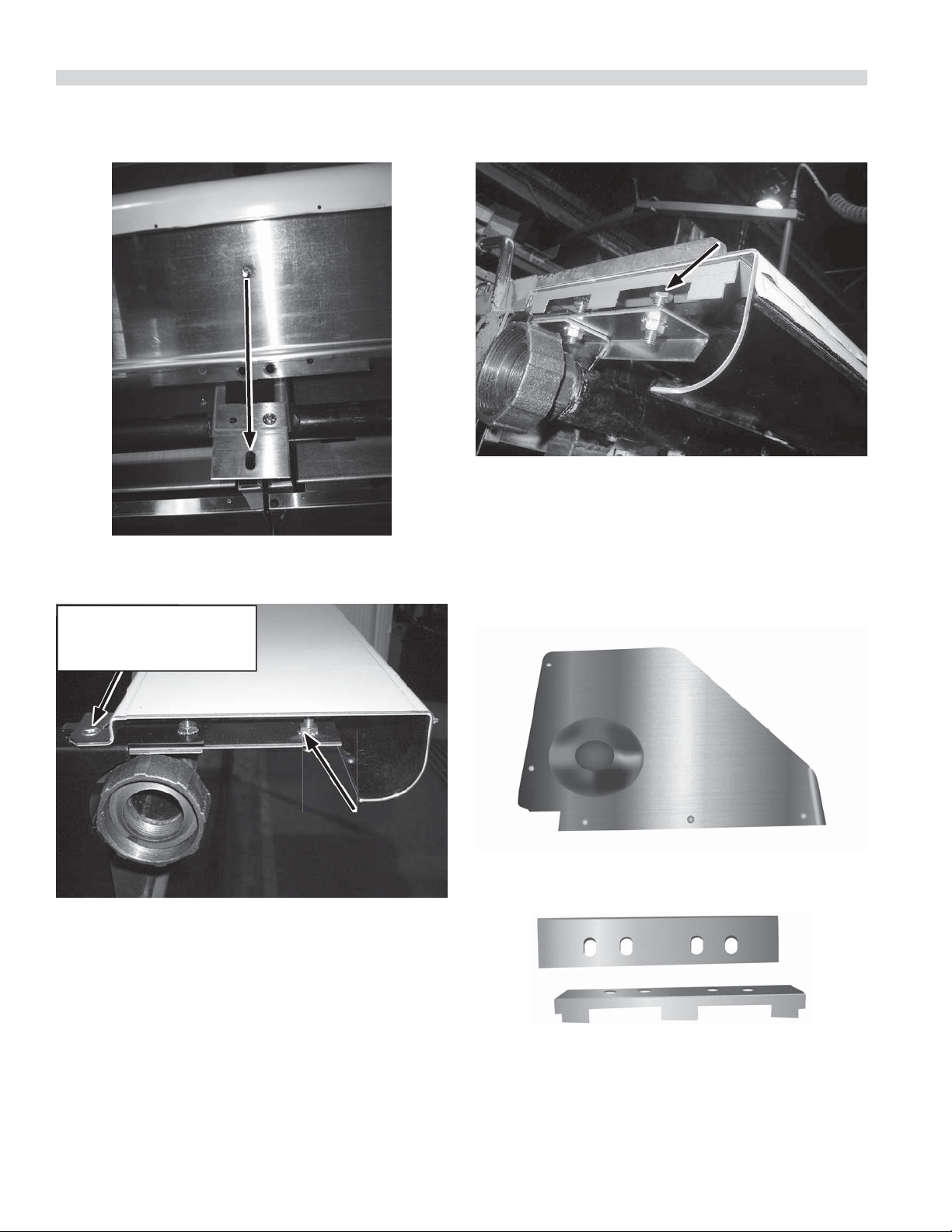

Optional Common Rail Installation

Rail Accessories

Rail Support Bracket

Rail with stud to align with rail center support bracket.

Part # 1382680 Rev 4 (1/15/16)Page 8

Page 9

INSTALLATION Continued

A

B

A

A

Installation

B

A

1. Install end rail support bracket.

A. Install end rail support bracket between manifold

bracket and top ange.

B. Align back holes on bracket with holes in the top of

the burner box side.

A

3. Align rail support bracket with holes (A) on top of 2

adjacent ranges and insert 2 screws and nuts to fasten.

Align studs with

holes in bracket

and range top.

Ensure nuts are

on studs prior to

being assembled

onto the range

A

2. Install spacers between manifold bracket and top ange

before connecting center rail support bracket across

ranges. Be sure holes line up.

A. Spacer ts between ange and manifold bracket.

Align holes in bracket

with hole in range

top. Assemble nuts

onto studs

4. End rail support bracket should align as per step 1. Studs

at each end of rail align with holes in end rail support

brackets. Assemble 1 nut onto stud before and after rail

assembly.

Note: End enclosure bracket should be installed at this point

between rail and end bracket if required. See nal assembly

option step 7.

Part # 1382680 Rev 4 (1/15/16) Page 9

Page 10

A

A

A

INSTALLATION Continued

5. Align and insert stud into rail center support bracket.

Assemble nut and washer to stud after alignment.

Insert counter sink screw

and nut into top of ange of

A

range. 2 sides per range

A

7. Final assembly Option: If an end enclosure is required

the end enclosure bracket should be installed during rail

assembly, step #4. Mount bracket over studs and tighten

against underside of rail (A).

End Enclosure Parts

End Enclosure Rt/Lt

A

6. Final Assembly:

After rail has been assembled insert athead screw and

nut to attach rail to top side of range.

A. Adjust rail level and position with nuts between rail

and bracket and secure adjustment with nuts below

the bracket. When adjustment is complete tighten

countersunk screw and nut.

End Enclosure Bracket

Part # 1382680 Rev 4 (1/15/16)Page 10

Page 11

INSTALLATION Continued

Pressure Regulators

1. Must have a maximum regulation capacity for the total

connected load.

2. The pressure regulator(s) installed must be listed by a

nationally recognized agency.

3. The pressure regulator(s) must have a pressure

adjustment range to allow adjustment to the manifold

pressure on the appliance rating plate.

4. Unless the manifold pressure on all connected appliances

is the same, a separate pressure regulator must be

supplied for each appliance(s) having di ering manifold

pressures.

5. Gas supply lines may be connected at right, left or both

ends of a battery or at the TEE connections on spreader

plates. If ve (5) or more units are placed in a battery,

more that one (1) supply line should be used. A readily

accessible, approved type of hand shut-o valve should

be installed on each supply line.

WARNING: Local codes may require that the pressure

regulator be externally vented. This will be supplied by

others.

Testing and Adjustments

All ttings and pipe connections must be tested for

leaks. Use approved gas leak detectors, soap solutions or

equivalent, checking over and around the ttings and pipe

connections. DO NOT USE A FLAME! Accessibility to all gas

lines and ttings require that valve panel(s) lower front

panel(s), oven rack(s) be removed. It may be necessary to

remove or at least raise and securely prop griddles, hot

tops and top grates. All parts removed (including fasteners)

should be stored safely for re-use.

Testing

1. Be sure that all valves and thermostats are in the “OFF”

position.

2. Turn on the main gas supply valve. Light all top section

pilots.

3. Leak test all valves and ttings as described in the

procedure above. Correct any leaks as required and

recheck.

4. Light oven pilot.

5. If the range is provided with an oven shut-o valve

separate from the thermostat, turn this valve on and

set the thermostat at 500 degrees. If the range oven

thermostat has an “OFF” position on the dial the

thermostat is equipped with an internal, integral oven

shut-o valve. Set this thermostat dial to 500 degrees. In

both cases, gas will now ow to the oven burner.

6. Leak test all valves, ttings, etc. As above. Correct any

leaks and retest.

7. Shut o all range valves and set thermostat dials to “O ’

or low position.

All units are tested and adjusted at the factory. However,

burners and pilots should be checked at installation and

adjusted if necessary.

Part # 1382680 Rev 4 (1/15/16) Page 11

Page 12

OPERATION

Open Top Burners (M/MS Models)

Lighting

1. Remove top grates and ring grates.

2. Check ash tubes to see they are properly positioned on

burner charge ports.

3. Light pilots.

4. Replace top grates and ring grates.

5. Turn valve completely on by rotating the knob counterclockwise 1/4 turn. Burner ame should be 1/2” stable

blue ame and should impinge on the underside of pot

placed on ring grate.

Shut Down

1. Turn all valves to the “O ” position by rotating the knob

clockwise 1/4 turn.

2. If the unit is to be shut down for an extended period of

time, close the inline gas valve.

Open Top Burners (MST Models)

Lighting

1. Push in the gas valve and turn it anti-clockwise to the

ignition position.

2. Holding the valve fully in, light pilot burner with a match

or taper.

3. Turn burner valve on by rotating the knob counterclockwise 1/4 turn. A sharp blue ame should be

approximately 1/4” high.

4. Replace hot top sections.

Shut Down

1. Turn all valves to the “OFF” position by rotating the knob

clockwise 1/4 turn.

2. If the unit is to be shut down for an extended period of

time, close the inline gas valve.

Hot Top Sections And Spectro-Top Sections (MS/

MST Models)

Lighting

1. Push in the valve and turn it anti-clockwise to the ignition

position.

2. Holding the valve fully in, light pilot burner with a match

or taper.

3. When the pilot is lit, continue to hold the valve fully in for

20 seconds, then release it. If the pilot goes out, wait for (5)

minutes, then repeat from step 1.

4. When pilot is established, push the valve in again and

turn it anti-clockwise to the desired ame setting.

5. To shut the burner o , turn the dial to the “O” position

and the safety device will disengage within (60) seconds.

3. When the pilot is lit, continue to hold the valve fully in for

20 seconds, then release it. If the pilot goes out, wait for (5)

minutes, then repeat from step 1.

4. When pilot is established, push the valve in again and

turn it anti-clockwise to the desired ame setting.

5. To shut the burner o , turn the dial to the “O” position

and the safety device will disengage within (60) seconds.

Hot Top Sections And Spectro-Top Sections

(M Models)

Lighting

1. Raise or remove hot top sections. Every burner has one

pilot located at the front right side of the burner.

2. Light pilots. The pilot burner should be adjusted to

provide for rapid ignition on the burner.

Thermostatically Controlled Griddles

(M Models)

Lighting

1. Raise griddle at front and block.

2. Light Pilots located at the front right side of each burner.

3. Sensing bulbs must be fully inserted into their individual

holders which are located on the underside of the

griddle.

4. Set thermostat to maximum, one at a time. Burner

should have 5/16” stable blue ame. DO NOT ALLOW

THE GRIDDLE TO HEAT LONGER THAN 1 MINUTE! WHEN

READY TO USE THE GRIDDLE, IT MUST BE SEASONED

BEFORE ACTUAL USE, SEE “SEASONING INSTRUCTION” IN

THE MAINTENANCE SECTION.

Part # 1382680 Rev 4 (1/15/16)Page 12

Page 13

OPERATION Continued

5. Lower griddle carefully into position taking extreme

caution not to leave any part of the capillary tube in the

burner compartment.

Shut Down

1. Turn all valves to the “OFF” position by rotating the knob

clockwise 1/4 turn.

2. If the unit is to shut down for an extended period of time,

close the inline gas valve.

Valve Controlled Griddles (M Models)

Lighting

1. Raise griddle at front and block.

2. Light pilots located at the front right side of each burner.

3. Turn burner valves on to full position. Burners should

have 1/2” to a 5/8” stable blue ame.

DO NOT ALLOW THE GRIDDLE TO HEAT LONGER THAN

1 MINUTE! WHEN READY TO USE THE GRIDDLE, IT MUST

BE SEASONED BEFORE ACTUAL USE, SEE “SEASONING

INSTRUCTION” IN THE MAINTENANCE SECTION.

4. Lower griddle into position.

Shut Down

1. Turn all valves to the “OFF” position by rotating the knob

clockwise 1/4 turn.

2. If the unit is to be shut down for an extended period of

time, close the inline gas valve.

Valve controlled Griddles (MS/MST Models)

1. Push in the valve and turn it anti-clockwise to the ignition

position.

Oven (Standard)

Lighting

1. Push in the main/pilot gas valve and turn it anti-clockwise

to the ignition position.

2. Holding the oven gas valve fully in, depress the red piezo

ignitor button located behind the lower drop down

panel.

3. When the pilot is lit, continue to hold the oven gas valve

fully in for 20 seconds, then release it,. If the pilot goes

out, wait for 5 minutes then repeat from step 1.

4. When pilot is established, push that gas valve in again

and turn it anti-clockwise to the full on position, then set

the thermostat to the desired temperature.

Shut Down

1. Turn the oven valve dial to the “O” position and the safety

device will disengage within 60 seconds.

2. If the range is to be shut down for an extended period of

time, close the in line gas valve.

“RC” Convection Ovens

For 115v usage, a cord and plug is provided but connection

to the electrical service must comply with local codes; or in

the absence of local codes, with the National electrical Code,

ANSI/NFPA No. 70 - (current edition).

WARNING: Electrical Grounding Instructions.

This appliance is equipped with a three pronged (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly grounded three pronged

receptacle. Do not cut or remove the grounding prong from

this plug.

2. Holding the valve fully in, light pilot burner with a match

or taper.

3. When the pilot is lit, continue to hold the valve fully in for

20 seconds, then release it. If the pilot goes out, wait for (5)

minutes, then repeat from step 1.

4. When pilot is established, push the valve in again and turn

it anti-clockwise to the desired ame setting.

5. To shut the burner o , turn the dial to the “O” position

and the safety device will disengage within (60) seconds.

Part # 1382680 Rev 4 (1/15/16) Page 13

POWER FAILURE NOTE: In the event of a power failure, no

attempt should be made to operate this oven. This oven is

gas operated but has electrical features, motor and door

switches.

A wiring diagram is attached to the rear of this unit.

Lighting Instructions

1. Push in the main/pilot gas valve and turn it anti-clockwise

to the ignition position.

Page 14

OPERATION Continued

2. Holding the oven gas valve fully in, depress the red piezo

ignitor button located behind the lower drop down

panel.

3. When the pilot is lit, continue to hold the oven gas valve

fully in for 20 seconds, then release it. If the pilot goes out,

wait for 5 minutes then repeat from step 1.

4. When the pilot is established, push the gas valve in again

and turn it anti-clockwise to the full on position, then set

the thermostat to the desired temperature.

Start Up

1. Activate the power switch to “cook” position.

2. Turn oven gas valve to the on.

3. Turn the thermostat to desired setting.

Cool Down

1. Turn thermostat and oven valve o .

2. Open door.

3. Activate power to the cool down position.

Shut Down

C. We recommend, at the end of the bake or roasting

period, when the oven will be idle for any period of time

or before shutting down completely, that the doors

be left open, and by use of the cool-down position on

the fan switch, the fan continues to run for at least 20

minutes.

Note: The convection oven motor should never be turned

“OFF” during cooking or when the oven is “HOT”

Char-Broiler (M,MS Models)

Lighting

1. Raise or remove the cooking grates. Every group of two

(2) burners has one pilot located centrally between them.

2. Depress the piezo ignitor button to light pilots. The pilot

burner should be adjusted to provide for rapid ignition

on the burner.

3. Turn burner valve on by rotating the know anti-clockwise.

A sharp blue ame should be approximately 1/4” high.

Shut Down

1. Turn all valves to the “OFF” position “ by rotating the knob

clockwise 1/4 turn.

1. Turn thermostat o .

2. Return power switch to “OFF” position.

3. Turn oven valve o .

The motor on your range convection oven is maintenance

free since it is constructed with self lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions to

follow on the care of your motor.

A. When the motor is operating, it cools itself internally by

air entering the rear of the motor case, provided proper

clearance has been allowed.

B. Since the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, the heat from the blower wheel is

conducted down the shaft and into the armature of the

motor. This action could shorten motor life.

2. If the unit is to be shut down for an extended period of

time, close the inline gas valve.

Char-Broiler (MST Models)

Lighting

1. Raise or remove the cooking grates. Every group of two

(2) burners has one pilot located centrally between them.

2. Push in the gas valve and turn it anti-clockwise to the

ignition position.

3. Holding the gas valve fully in, depress the red piezo

ignitor button located behind the lower door panel.

4. When the pilot is lit, continue to hold the gas valve fully in

for 20 seconds, then release it. If the pilot goes out, wait for

(5) minutes then repeat from step 1.

5. When pilot is established, push the gas valve in again and

turn it anti-clockwise to the full on position, then set the

thermostat to the desired temperature.

Part # 1382680 Rev 4 (1/15/16)Page 14

Page 15

OPERATION Continued

Shut Down

1. Turn all valves to the “OFF” position by rotating the knob

clockwise 1/4 turn.

2. If the unit is to be shut down for an extended period of

time, close the inline gas valve.

NOTE: MODELS WITH SUFFIX “E” ARE EQUIPPED WITH

AN ELECTRIC SPARK IGNITION MODULE FOR PILOT

BURNER IGNITION. PUSHING THE SPARK BUTTON WILL

SIMULTANEOUSLY IGNITE ALL PILOTS.

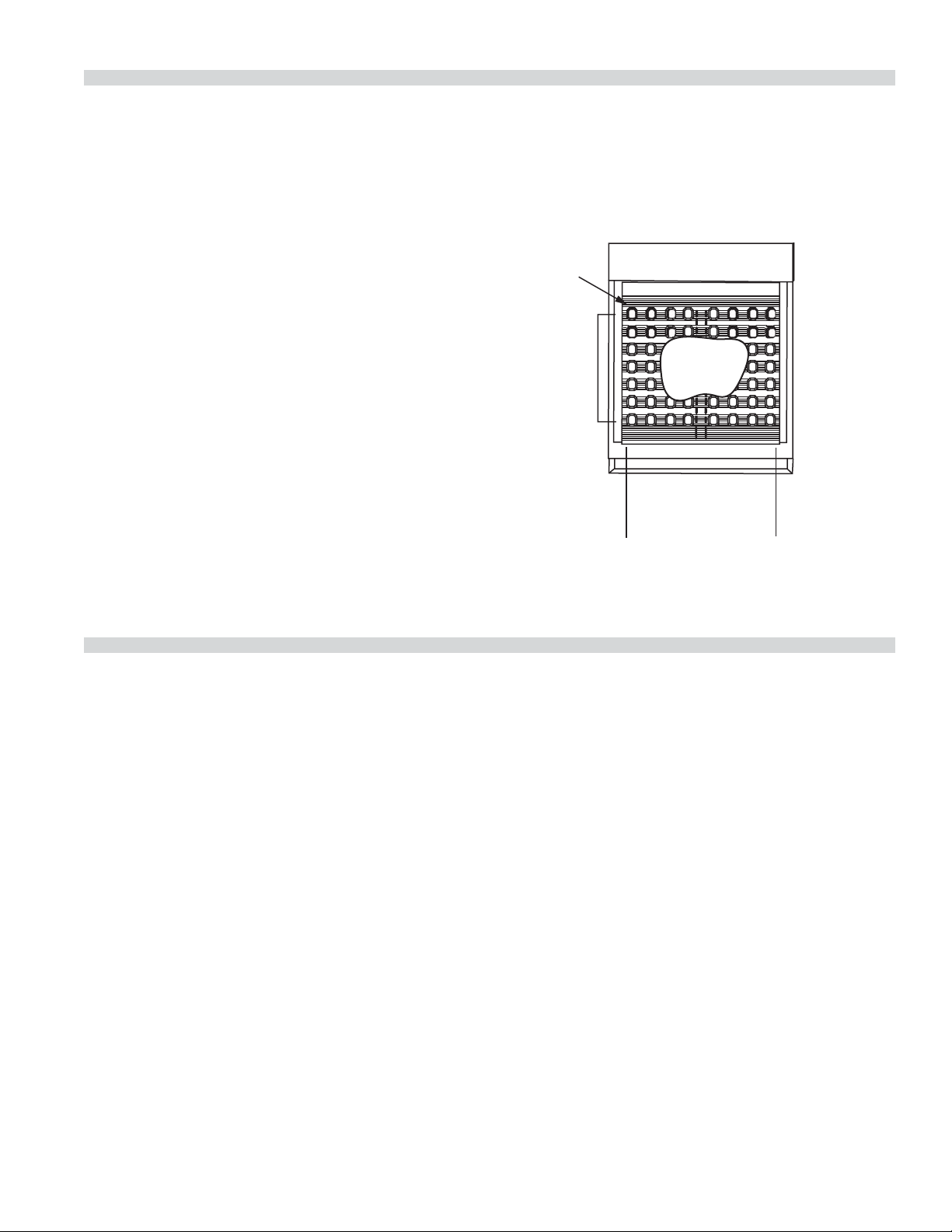

Assembly of Char-Broiler

Steel Rock Support Rods

Each broiler is supplied with 5/8” diameter steel rods to

support the briquettes. These rods are to be installed in the

grooves in the support bracket which are atop the main

burners.

Briquettes

REFER TO THE DIAGRAM BELOW FOR THE PROPER

BRIQUETTE ARRANGEMENT.

Steel bars

7 Rows

Top view (less main top)

Arrangement

of briquettes

as illustrated

Front

MS34B (17 Rows)

MS24B (11 Rows)

MS17B ( 7 Rows)

MAINTENANCE

We suggest maintenance and repairs to be performed by

GARLAND authorized service agent. You will nd a listing of

agencies in your information manual.

Painted Finishes

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

The oven should be permitted to cool down before cleaning

exterior surfaces. Wipe exposed cleanable surface when cool

with a mild detergent and hot water. Stubborn residue spots

may be removed with a light weight non metallic scouring

pad. Dry thoroughly with a clean cloth.

NOTE: Many parts of the commercial range are raw steel, (i.e.

hot tops, griddles, springs, door hooks, etc.) and can react

to moisture, forming rust. This occurrence is normal and not

considered a factory defect. Clean with a stainless steel or

ber pad. A coating of salt free oil may be applied.

Stainless Steel Finishes

For routine cleaning just wash with a hot water and

detergent solution. Wash just a small area at a time or the

water will evaporate leaving the chemicals behind causing

streaking. Rinse the washed area with a clean sponge dipped

in a sanitizing solution and wipe dry with a soft cloth before

it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel

has been polished in one direction. Rub with the polished

lines to preserve the original nish. Then thoroughly rinse as

before.

Part # 1382680 Rev 4 (1/15/16) Page 15

Page 16

MAINTENANCE Continued

To prevent nger prints there are several stainless steel

polishes on the market that leave an oil or waxy lm. Do not

use on surfaces that will be in contact with food. Stainless

steel may discolor if overheated. These stains can usually be

removed by vigorous rubbing with a scouring powder paste.

Use only stainless steel, wooded or plastic tools if necessary

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers of knives as particles of the iron may

become imbedded and rust. STEEL WOOL SHOULD NEVER

BE USED. Either a typical bleach solution or hot water can be

used to sanitize stainless steel without harm.

Oven Interior (Porcelain Enamel)

NOTE: Disconnect line cord (if applicable) from power

supply before cleaning or servicing.

1. Before cleaning oven interior, remove all oven racks

and guides (if “RC” base). Oven racks and guides can be

cleaned with a mild soap and warm water or run through

dish washer.

2. The porcelain interior can be cleaned with oven cleaners

such as “Easy-O ”, or “Dow Oven cleaner”. Apply only

when oven is cold.

3. Heavy Staining – When the oven appears soiled, due to

heavy staining, we suggest preheating the empty oven

each day for 1 or 2 hours (depending on the condition of

the oven) for e ective results. Also ordinary household

ammonia has proven to be e ective in removing bakedon “soil” build-up, and has the bene cial e ect of keeping

the microscopic “pores” of the coating open and free to

perform its cleaning action. An occasional light swabbing

with household ammonia while the oven is at room

temperature will prove extremely bene cial.

Abrasives should not be used – in order to maintain

continuous cleaning action, it is very important to avoid

the use of abrasive materials such as steel wool scouring

pads, abrasives or sharp implements which can cause

permanent damage to the surface coating. In addition,

oven cleaners such as “Easy-O ” or “Dow Oven Cleaner”

will clog the “PORES” of the special coating and will retard

the cleaning action.

4. Period “Tune-Up” – although the oven appears clean, we

recommend operating the oven at high heat for 2 hours

approximately once each moth. This will insure against

build-up of solids in hard to see places and in the pores of

the coating.

Oven Interior – Optional continuous Clean

NOTE: Disconnect line cord (if applicable) from power

supply before cleaning or servicing.

1. “Break-In Period” – When the oven is new, operate the

oven for at least two hours at high heat, with the oven

empty, before normal cooking operating. Continue

preheating the oven for two hours prior to use during

the rst two weeks. During this break-in period, it is

important that the oven surfaces be kept clean of

excessive soiling due to spillage.

2. How to put “continuous cleaning” action to work: Each

day, after baking and roasting operations have ceased,

empty the oven, turn the temperature control up to

high heat (500 degrees). This high heat will accelerate

the cleaning action and reduce the time required to

e ectively clean the oven. Usually the cleaning operation

will take about 45 to 60 minutes.

Automatic Pilot Valve

The automatic pilot valve is a protective device which allows

gas to ow to the burner only when the pilot burner is

burning.

A too loose or too tight connection of the thermocouple nut

to the automatic pilot valve can prevent the thermocouple

from activating the valve. It should be drawn up nger tight

and then TIGHTENED ONLY 1/4 TURN WITH A WRENCH.

Griddle Seasoning

A. Remove all factory applied protective material by

washing with hot water, mild detergent or soap solution.

B. Apply a thin coat of cooking oil to the griddle surface,

about one ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

C. Light all burners, set at lowest possible setting. Some

discoloring will occur when heat is applied to steel.

D. Heat the griddle slowly for 15 to 20 minutes. Then wipe

away oil. Repeat the procedure 2 to 3 times until the

griddle has a slick, mirror like nish. Do this until you have

reached the desired cooking temperature.

Part # 1382680 Rev 4 (1/15/16)Page 16

Page 17

MAINTENANCE Continued

IMPORTANT: Do not attain high (on valve control) or 450

degrees (on thermostat control) during “SEASONING” period.

The griddle will not require reseasoning if it is used properly.

If the griddle is over heated and produce begins to stick

to the surface it may be necessary to repeat the seasoning

process again. If the griddle is cleaned with soap and water it

will be necessary to reseason the griddle surface again.

Griddle Cleaning

DO NOT use water on griddle tops while still hot or DO

NOT COOL BY USING ICE! THIS WILL CAUSE GRIDDLE PLATE

TO WARP AND POSSIBLE CRACK. THIS IS NOT A FACTORY

DEFECT.

To produce evenly cooked, perfectly browned griddle

products, keep griddle free from carbonized grease.

Carbonized grease on the surface hinders the transfer of

heat from the griddle surface to food product. This results

in uneven browning and loss of cooking e ciency, and

worst of all, carbonized grease tends to cling to the griddle

foods, giving them a highly unsatisfactory and unappetizing

appearance. To keep the griddle clean and operating at peak

performance, follow these simple instructions:

A. AFTER EACH USE clean griddle thoroughly with a grill

scraper or spatula. Wipe o any excess debris left from

cooking process.

B. ONCE A DAY clean griddle surface with a grill brick and

grill pad. Remove grease container and clean thoroughly,

in same manner as any ordinary cooking utensil.

C. ONCE A WEEK clean griddle surface thoroughly. If

necessary, use a grill stone or grill pad over the griddle

surface. Rub with grain of the metal while still warm A

detergent may be used on the plate surface to help clean

it, but care must be taken to be sure it is thoroughly

removed. After removal of detergent, the surface of the

plate should be covered with a thin lm of oil to prevent

rusting.

To remove discoloration, use a non-abrasive cleaner.

Before re-using the griddle must be reseasoned. Keep

griddle drain tube to grease container clear at all times on

those models without side grease container.

Open Top Burners

Periodically burners should be removed and cleaned with

soap and hot water. You may soak the burner in a bucket of

hot soapy water and brush o any burnt on grease or debris.

Allow the cast iron burner to dry thoroughly before installing

into the range. If the burner ports are blocked or plugged

with grease, it will be necessary to clear the ports with a wire

or blunt instrument. Cast iron top grates and ring grates –

clean thoroughly with hot water and a mild detergent. You

may also clean with a wire brush to remove baked-on food

particles.

Top Grates

Seasoning Cast Iron Top Grates

1. Remove the cast iron top grates from the range.

2. Wash the cast iron top grates thoroughly with a mild soap

and warm water.

3. Dry the cast-iron top grates thoroughly with a clean cloth.

4. Immediately after drying, season the top grates lightly

with a non-toxic oil, (Liquid vegetable oil or Pam spray oil).

WARNING: DO NOT SEASON THE TOP GRATES WHILE ON THE

RANGE TOP! Seasoning grates on the range top over an open

ame could cause a ash re.

5. After seasoning, replace the top grates onto the range.

Turn all the range top sections “ON LOW”. Allow the top

sections to burn in this manner for at least 20 minutes

before using pots or pans on the top grates.

SEASONING OF THE TOP GRATES WILL BE REQUIRED

WHENEVER THEY HAVE BEEN CLEANED. FAILURE TO SEASON

GRATES WILL CAUSE RUSTING.

CAST IRON TOP and RING GRATE(s) can be cleaned with mild

soap and warm water for baked on material, a wire brush can

be used. Dry thoroughly, Lightly coat with vegetable oil to

help prevent rust from forming. At the rear of the cast iron

top grate there are spill shields. These should be removed

and cleaned. Replace after cleaning to prevent grease and

spillovers dripping down the back of range.

CAUTION: This griddle plate is steel, but the surface is

relatively soft and can be scored or dented by careless use

of spatula. Be careful not to dent, scratch, or gouge the plate

surface. This will cause food to stick in those areas. Also, note

since this is a steel griddle if a light coating of oil is not always

present rust will develop on unexposed areas.

Part # 1382680 Rev 4 (1/15/16) Page 17

Page 18

MAINTENANCE Continued

Cast Iron Hot tops and Spectro-Heat Tops

DO NOT use water on tops while still hot or DO NOT COOL BY

USING ICE!

While the surface is still slightly warm, wipe down with a

clean burlap cloth. Burnt on spillage should be scraped o . If

necessary, remove the plate and wash in a sink with soap and

hot water. Dry thoroughly. In damp climates, wipe down with

a light coating of oil to prevent rusting. Avoid excessive use

of water as this could damage the surface and the controls

below.

ADJUSTMENTS

Pilot Adjustment

All pilot adjustment valves are mounted on the range top

manifold.

If required the open burner pilot should be adjusted so that

the tip of the pilot ame reached the middle of the ash tube

opening. This ame may show a slight yellow tip.

The pilot burner for the griddle or hot top burner should

provide for rapid ignition of the burner but should not

impinge on any part of the burner. When properly adjusted it

should neither lift o the burner nor should it show a yellow

tip.

NOTE: Cast Iron Hot tops & Spectro-Heat Tops surface will

“tone” (blue/brown discoloration) from heat. This toning will

not diminish function or operating and is not a defect.

Burner Gas/Air Adjustments

Variations in eld conditions, rough handling of the

equipment in transit may indicate the need for adjustment

of primary air to the burners. Check operation and adjust

as below to provide a sharp blue ame at full rate (open

valve fully so that the thermostat is calling for maximum gas

ow). On the burner (star, “H” griddle, knuckle, broiler, oven

burners) locate the air shutter. Loosen the lock-nut so that

the air shutter turns freely. Reinstall burner. Turn on gas low

and ignite burner. Rotate air shutter to obtain the following:

1. Open (Star) Burner: 1/2” stable, sharp inner blue cones.

2. Hot tops, griddles: 5/16” stable, sharp inner blue cones.

3 Knuckle burners: 4” to 6” stable, blue ame, slight yellow

tips.

4. Broiler burners: 3 1/2” to 4” stable, blue ame, slight

yellow tips.

If the burner ames are sharp but lift o the burner ports,

reduce the amount of primary air by closing the air shutter.

NOTE: The rates shown in the chart in the speci cation

section are maximum rates and must not be exceeded

Part # 1382680 Rev 4 (1/15/16)Page 18

Page 19

ADJUSTMENTS Continued

FDO Heavy Duty Oven Control

The model FDO oven thermostat is a precision-made

instrument, carefully set at the factory to accurately control

oven temperatures from 150° to 500°F, (66° to 260°C). All

adjustments are accessible from the front of the appliance

after moving the dial. To remove the dial, grasp the outer

edges and pull straight out.

By-Pass Adjustment

The Robertshaw FDO snap/throttle thermostat requires that

the by-pass ame be properly adjusted. To adjust proceed as

follows:

Calibration

Plate

Dial

Stop

MODEL

FDO

Indicator Mark

0

5

4

0

0

4

0

5

3

0

0

3

0

5

2

By-pass Flame

Adjuster

Calibration

Lock Screws

5

0

0

5

5

0

1

5

0

3

0

0

Calibration Instructions

Field calibration is seldom necessary and should not

be resorted to unless experience with cooking results

undoubtedly indicate that the control is not maintaining

the temperature for which the dial is set. To check oven

temperatures when calibrating, use only a reliable mercury

thermometer, or preferably an oven pyrometer. To check

calibration, proceed as follows:

1. Place the thermocouple of the test instrument or reliable

mercury thermometer in the center of the oven.

2. Turn the oven temperature control knob to 400°F, (204°C),

and allow the oven to cycle at least three times.

3. Continue to monitor the oven temperature, recording

the readings at 5 minute intervals until three successive

readings are within 5°F, (2°C), of each other.

If the temperature does not read within 15°F, (8°C), of the dial

setting, recalibrate as follows.

1. Remove the oven temperature control dial, making sure

the setting is not disturbed.

2. Hold the calibration plate, (located directly behind the

control dial), and loosen the two calibration lock screws

until the plate can be rotated independently of the

control.

1. Ensure pilot ame is lit and adjusted.

2. Turn oven temperature control to 200°F, (93°C), and allow

the oven to heat for three minutes.

3. Turn, the oven temperature control to the lowest

position, then turn slowly counter-clockwise until the

audible “click” is heard.

4. Making sure the oven temperature control dial is not

disturbed, turn the by-pass ame adjusting screw

clockwise to decrease, or counter-clockwise to increase

the ame on the burner to the lowest possible stable

ame. When properly adjusted, the by-pass ames will

cover the entire length of the burner.

3. Turn the calibration plate until the temperature indicated

on the plate corresponds with the reading on the test

instrument. Hold the plate in place and tighten the

screws rmly.

4. Repeat step 3 in the previous section, checking the

temperature to ensure the adjustment has been made

properly.

5. Replace the temperature control dial.

NOTE: If adjustment of the calibration plate is prevented by

the position of the lock screws, the screws can be moved to

other holes that have been tapped for them.

Part # 1382680 Rev 4 (1/15/16) Page 19

Page 20

ADJUSTMENTS Continued

BJWA Griddle Thermostat

When the griddle surface reaches the temperature for which

the dial is set the control cuts down the ow of gas to the

amount required to keep the griddle at that temperature.

The control must be adjusted to pass enough gas to keep the

entire burner ignited. To properly adjust the by-pass setting,

proceed as follows:

1. Light the burner by turning the dial fully “ON.”

2. After 5 minutes, turn the dial clockwise to a point slightly

past, (to the right of), the rst mark on the dial.

3. Remove the dial by pulling it straight o .

4. With a screwdriver, turn the by-pass adjustment screw

counter-clockwise to decrease the ame, or clockwise to

increase the ame, until there is a minimum ame along

the entire burner.

CALIBRATION

SCREW

BY-PASS

ADJUSTMENT

SCREW

3. Check the temperature reading when the control cuts

down to by-pass, by placing the sensor rmly on the

griddle surface directly above the sensing bulb of the

control. Test instrument should read from 350° to 410°F,

(196° to 213°C). If the dial setting does not agree with

the test instrument reading within the above limits,

recalibrate.

NOTE: NO ATTEMPT SHOULD BE MADE TO RECALIBRATE

THE GRIDDLE CONTROL WITHIN THE WARRANTY PERIOD IF

THE TEMPERATURE IS WITHIN ±20°F OF THE DIAL SETTING.

RECALIBRATION SHOULD BE PERFORMED IF THE CONTROL IS

FOUND TO BE INACCURATE BY MORE THAN ±20°F, AND LESS

THAN ±50°F. IF THE CONTROL IS FOUND TO BE INACCURATE

BY MORE THAN ±50°F DURING THE WARRANTY PERIOD, THE

CONTROL WILL BE REPLACED UNDER WARRANTY.

To recalibrate:

1. Remove the dial and push out the center metal insert.

2. Replace the dial without the insert.

3. Holding the dial rmly in place, insert a screwdriver

through the center of the dial and seat it in the slot in

the calibration screw. DO NOT TURN THIS SCREW! Exert

pressure on the screwdriver to push the calibration stem

inward.

4. While holding the calibration stem pushed inward with

the screwdriver, turn the control DIAL to the temperature

indicated on the test instrument. Release pressure on the

calibration stem.

ROBERTSHAW BJWA

THERMOSTAT

Calibration

1. Use a Robertshaw test instrument with a disc-type

thermocouple, or a reliable “surface” type thermometer.

(NOTE: A drop of oil on the face of the disc will provide for

better contact.)

2. Turn ALL griddle control dials to 400°F, (240°C). allow the

temperature to stabilize by waiting for the thermostat(s)

to cycle three times before taking a temperature reading.

5. Remove the dial from the control, replace the dial insert,

and reinstall the dial on the control.

6. Set the dial to 450° F, (232° C). Check temperature

as before. If the temperature is not now within the

acceptable ±20°F, (4°C), range, the sensing element is

inoperative and the control should be replaced.

Part # 1382680 Rev 4 (1/15/16)Page 20

Page 21

CONVECTION OVEN USER TIPS – SUFFIX “RC”

• As a guide, set oven temperatures 25° to 50° lower than

called for in recipes or directions using standard or

conventional ovens. Cooking time may be less depending

upon the product you are preparing. 2% to 5% is a

general rule. Product should be watched the rst time it is

prepared.

• Cooking time and oven temperature will vary depending

upon such factors as size of load, temperature of product,

and mixture of recipe, particular moisture.

• When you have established satisfactory time and

temperature for your products, record them on a chart

and keep as a reference guide.

• Preheat oven thoroughly before use. To reach 350° takes

approximately 15 minutes. The burner “ON” light will go

o when temperature is reached. For optimum results

oven should be preheated for 30 minutes to allow for

thorough heat saturation.

• The load should be centered on the racks to allow for

proper heat circulation around the sides.

• Load size. The oven will hold three (3) 18” x 26” sheet

pans, six (6) 12” x 20” x 2.5” steam table pans or one (1)

21” x 17 x 7” roast pan with cover.

• Never place pans directly on the oven bottom. Always

use the lowest rack position which will allow the air to

circulate within the oven cavity.

• Load and unload food as quickly as possible to prevent

an excessive drop in temperature.

• Avoid using wrapped pans since level pans bake more

evenly.

• Do not use a deep pan for shallow cakes, cookies, etc. as

circulation across the surface is essential for even cooking

and browning.

• To prevent excessive shrinkage, roast meats at a low

temperature, 250º to 325º.

• When rethermalizing frozen products, preheat the oven

50º higher than cooking temperature to compensate for

heat loss during and after loading. Thermostat must be

returned to cooking temperature after loading.

• To conserve energy, turn the oven o and cool down

when not in use.

TROUBLE SHOOTING CONVECTION OVEN

Cakes are dark on the sides and not done in the center Lower oven temperature

Cake edges are too brown Reduce number of pans or lower temperature

Cakes have light outer color Raise temperature

Cake settles slightly in the center Bake longer or raise oven temperature slightly Do not open

doors to oven for long periods

Cake ripples Overloading pans or batter is too thin

Cakes are too coarse Lower oven temperature

Pies have uneven color Reduce number of pies per rack or eliminate use of bake pans

Cupcakes crack on top Lower oven temperature

Meats are browned and not done in the center Lower oven temperature and roast longer

Meats are well done and not browned Raise temperature Limit amount of moisture

Meats develop hard crust Reduce temperature or place pan of water in oven

Part # 1382680 Rev 4 (1/15/16) Page 21

Page 22

Notes

Part # 1382680 Rev 4 (1/15/16)Page 22

Page 23

Notes

Part # 1382680 Rev 4 (1/15/16) Page 23

Page 24

GARLAND

1177 KAMATO ROAD, MISSISSAUGA, ONTARIO, CANADA. L4W 1X4

8884427526

WWW.GARLANDGROUP.COM

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

your operational needs from one restaurant to multiple locations.

StarCare – Warranty & lifetime service, certi ed OEM parts, global parts inventory, performance audited

ExtraCare — CareCode, 24/7 Support, online/mobile product information

LifeCare – Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

Talk with KitchenCare™ • 1-844-724-CARE • www.mtwkitchencare.com

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

©2014 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved.

Page 25

©2014 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved.

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

Talk with KitchenCare™ • 1-844-724-CARE • www.mtwkitchencare.com

LifeCare – Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

ExtraCare — CareCode, 24/7 Support, online/mobile product information

StarCare – Warranty & lifetime service, certi ed OEM parts, global parts inventory, performance audited

your operational needs from one restaurant to multiple locations.

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

WWW.GARLANDGROUP.COM

8884427526

1177 KAMATO ROAD, MISSISSAUGA, ONTARIO, CANADA, L4W1X4

GARLAND

Page 26

placer un bac rempli d’eau dans le four

Augmenter la température. Limiter la quantité d’humidité

Abaisser la température et prolonger le rôtissage

moule de cuisson

de longues périodes

température du four. Ne pas ouvrir les portes du four pendant

Diminuer la température du four

Pièce nº 1382680 Rev 4 (01/15/16) Page 23

Si les viandes présentent une croûte dure Réduire la température ou

ne sont pas brunies

Si les viandes sont bien cuites, mais

cuites au centre

Si les viandes sont brunies, mais ne sont pas

Les petits gâteaux sont fendus sur le dessus Diminuer la température du four

Les tartes ne sont pas de couleur égale Réduire le nombre de tartes par plaque ou ne pas utiliser de

Les gâteaux sont trop lourds Diminuer la température du four

Formation de rides sur le gâteau Surcharge des plaques ou pâte trop ne

Le gâteau est légèrement a aissé au milieur Augmenter la durée de la cuisson ou augmenter légèrement la

Les gâteaux ont une couleur extérieure claire Augmenter la température

Les bords des gâteaux sont trop bruns Réduire le nombre de plaques ou diminuer la température

cuits au centre

Les gâteaux sont foncés sur les côtés, mais ne sont pas

refroidir s’il n’est pas utilisé.

• Pour économiser l’énergie, arrêter le four et le laisser

la température de cuisson.

chargement. Après le chargement, régler le thermostat à

compenser la perte thermique pendant et après le

four 50º au-dessus de la température de cuisson pour

• Pour réchau er des produits congelés, préchau er le

viandes à basse température, soit de 250 à 325 º.

• Pour empêcher une perte de poids excessive, rôtir les

produit bien cuit et bien doré.

circulation de surface est essentielle pour obtenir un

gâteaux minces, de biscuits, etc. étant donné que la

• Ne pas utiliser de plats profonds pour la cuisson de

régulière si les plats sont bien de niveau.

• Éviter d’utiliser des plats déformés car la cuisson est plus

possible a n d’éviter les chutes brutales de température.

• Charger et décharger les aliments aussi rapidement que

permettant la circulation d’air dans la cavité du four.

four. Toujours utiliser la position la plus basse de la grille

• Ne jamais placer les plats directement sur le fond du

x 7 avec couvercle.

vapeur de 12 x 20 x 2,5 po ou une (1) rôtissoire de 21 x 18

à pâtisserie de 18 x 26 po, six (6) récipients de table à

• Poids de la charge. Le four peut contenir trois (3) plaques

DÉPANNAGE DU FOUR À CONVECTION

côtés.

permettre une bonne circulation de la chaleur sur les

• Les charges doivent être centrées sur les grilles pour

30 minutes pour permettre la saturation de la chaleur.

un résultat optimal, le four doit être préchau é pendant

s’éteint lorsque la température est atteinte. Pour obtenir

15 minutes. L’indicateur lumineux du brûleur «ON»

atteindre la température de 350º, il faut compter environ

• Bien préchau er le four avant son utilisation. Pour

référence.

sur un tableau et de les conserver comme guide de

cuisson satisfaisants par produit, il est bon de les noter

• Une fois que l’on a établi des temps et températures de

pourcentage d’eau en particulier.

température du produit et le mélange de la recette, du

en fonction de facteurs tels que le poids de la charge, la

• Le temps de cuisson et la température du four varient

lors de la première préparation.

préparé, entre 2 et 5 % en général. Surveiller le produit

Le temps de cuisson peut être inférieur selon le produit

les recettes pour les fours standards ou conventionnels.

25 à 50º en dessous de la température indiquée dans

• D’une façon générale, régler les températures du four

CONVECTION - SUFFIXE «RC»

CONSEILS POUR L’UTILISATEUR DU FOUR À

Page 27

Pièce nº 1382680 Rev 4 (01/15/16)Page 22

être remplacée.

thermostatique ne fonctionne pas et la commande doit

toujours pas un écart acceptable de ±20°F (4°C), le bulbe

comme précédemment. Si la température ne présente

6. Régler le cadran à 450° F (232° C). Véri er la température

l’insert du cadran et remonter le cadran sur la commande.

5. Retirer le cadran de la commande; remettre en place

pression sur la tige d’étalonnage.

température indiquée sur l’instrument d’essai. Relâcher la

le tournevis, tourner le CADRAN de commande à la

4. Tout en maintenant la tige d’étalonnage enfoncée avec

pousser la tige d’étalonnage vers l’intérieur.

CETTE VIS! Exercer une pression sur le tournevis pour

dans la fente de la vis d’étalonnage. NE PAS TOURNER

insérer un tournevis dans le centre du cadran et le placer

3. Tout en maintenant fermement le cadran en place,

2. Remettre en place le cadran sans s’insert.

pour le faire sortir.

1. Retirer le cadran et pousser l’insert métallique central

Pour Étalonner :

COMMANDE SERA REMPLACÉE AU TITRE DE LA GARANTIE.

SUPÉRIEUR À ±50°F PENDANT LA PÉRIODE DE GARANTIE, LA

SUPÉRIEURE À ±20°F ET INFÉRIEURE À ±50°F. SI L’ÉCART EST

DIFFÉRENCE DE TEMPÉRATURE DE LA COMMANDE EST

UN NOUVEL ÉTALONNAGE DOIT ÊTRE EFFECTUÉ SI LA

TEMPÉRATURE EST À ±20°F DU RÉGLAGE DU CADRAN

DE GRIL PENDANT LA PÉRIODE DE GARANTIE SI LA

NOTA : NE PAS ESSAYER D’ÉTALONNER LA COMMANDE

les limites ci-dessus, procéder à un nouvel étalonnage.

correspond pas à la mesure de l’instrument d’essai dans

350° et 410°F (196° et 213°C). Si le réglage du cadran ne

d’essai devrait indiquer une température comprise entre

du bulbe thermostatique de la commande. L’instrument

le capteur sur la surface du gril, directement au-dessus

l’alimentation vers la dérivation en appuyant fermement

3. Véri er la température quand la commande coupe

s’éteignent trois fois avant de mesurer la température.

stabiliser en attendant que les thermostats s’allument et

du gril à 400°F (240°C). Laisser la température se

2. Tourner TOUS les cadrans de commande de température

RÉGLAGES suite

Page 28

Pièce nº 1382680 Rev 4 (01/15/16) Page 21

dans d’autres trous qui ont été letés.

de la plaque d’étalonnage, les vis peuvent être déplacées

du disque assurera un meilleur contact.)

de type «surface». (NOTA : Une goutte d’huile à la surface

thermocouple de type à disque ou un pyromètre able

1. Utiliser un instrument d’essai Robertshaw avec un

Étalonnage

ROBERSHAW

THERMOSTAT BJWA

NOTA : Si la position des vis de blocage empêche le réglage

température.

5. Remettre en place le cadran de commande de

correctement.

température pour s’assurer que le réglage a été e ectué

4. Répéter l’étape 3 de la section précédente, en véri ant la

plaque en place et bien serrer les vis.

mesure e ectuée avec l’instrument d’essai. Maintenir la

température indiquée sur la plaque corresponde à la

3. Tourner la plaque d’étalonnage jusqu’à ce que la

DE DÉRIVATIONW

VIS DE RÉGLAGE

VIS D'ÉTALONNAGE

amme minimum sur la totalité du brûleur.

montre pour l’augmenter, jusqu’à ce qu’il y ait une

diminuer la amme ou dans le sens des aiguilles d’une

dans le sens inverse des aiguilles d’une montre pour

4. Avec un tournevis, tourner la vis de réglage de dérivation

3. Retirer le cadran en tirant droit dessus

après (à droite de) la première marque sur le cadran.

aiguilles d’une montre jusqu’à un point situé légèrement

2. Au bout de 5 minutes, tourner le cadran dans le sens des

1. Allumer le brûleur en ouvrant complètement le cadran.

procéder comme suit :

Pour régler correctement la commande de dérivation,

passer assez de gaz pour maintenir tout le brûleur allumé.

température. La commande doit être réglée pour laisser

gaz à la quantité nécessaire pour maintenir le gril à cette

le cadran est réglé, la commande limite l’alimentation en

Quand la surface du gril atteint la température pour laquelle

puisse tourner indépendamment de la commande.

vis de verrouillage d’étalonnage jusqu’à ce que la plaque

derrière le cadran de commande) et desserrer les deux

2. Immobiliser la plaque d’étalonnage (située directement

en s’assurant que le réglage n’est pas modi é.

1. Retirer le cadran de commande de température du four

température du cadran, réétalonner comme suit.

Si la température di ère de plus de 15°F (8°C) de la

entre elles.

mesures successives aient un écart maximal de 5°F (2°C)

les résultats à intervalles de 5 minutes jusqu’à ce que trois

3. Continuer de surveiller la température du four en notant

au mois trois fois.

sur 400°F (204°C) et laisser le four s’allumer et s’éteindre

2. Tourner le bouton de commande de température du four

thermomètre à mercure able au centre du four.

1. Placer le thermocouple de l’instrument d’essai ou un

pour four. Pour véri er l’étalonnage, procéder comme suit :

thermomètre à mercure ou, de préférence, un pyromètre

du four lors de l’étalonnage, utiliser uniquement un

réglées les commandes. Pour véri er les températures

maintiennent pas les températures sur lesquelles sont

démontrent sans aucun doute que les commandes ne

devra pas essayer de le faire sauf si les résultats de cuisson

L’étalonnage sur place est rarement nécessaire et on ne

Thermostat De Gril BJWA

Instructions D’étalonnage

RÉGLAGES suite

Page 29

Pièce nº 1382680 Rev 4 (01/15/16)Page 20

couvriront toute la longueur du brûleur.

fois correctement réglées, les ammes de dérivation

d’obtenir la amme basse la plus stable possible. Une

sens inverse pour diminuer la amme du brûleur a n

aiguilles d’une montre pour augmenter ou dans le

de réglage de amme de dérivation dans le sens des

température du four n’est pas déréglé, tourner la vis

valeurs maximales à ne pas dépasser.

REMARQUE : les valeurs indiquées dans le tableau sont des

4. En s’assurant que le cadran de commande de

l’obturateur d’air.

entende un «clic».

sens inverse des aiguilles d’une montre jusqu’à ce qu’on

du brûleur, réduire la quantité d’air primaire en fermant

Si la amme du brûleur est bleue, mais décollée des ori ces

position la plus basse, puis la tourner lentement dans le

3. Tourner la commande de température du four à la

4 po avec les pointes légèrement jaunes.

4. Brûleurs de la rôtissoire - amme stable, bleue de 3 1/2 à

minutes.

à 200°F (93°C) et laisser le four chau er pendant trois

2. Tourner le bouton de commande de température du four

bleue avec les pointes légèrement jaunes.

3. Brûleurs articulés - amme stable de 4 à 6 po, amme

2

0

5

0

0

3

0

5

1

0

5

5

0

0

5

4

5

0

D'étalonnage

Vis De Verrouillage

De Dérivation

De Flamme

Dispositif De Réglage

1. Véri er que la amme de veilleuse est allumée et réglée.

cônes internes bleus.

2. Plaques de cuisson - grils - amme stable de 5/16 po,

bleus.

1. Brûleur ouvert amme stable de 1/2 po, cônes internes

3

0

0

3

5

0

4

0

0

FDO

MODÈLE

allumer le brûleur. Faire tourner l’obturateur pour obtenir :

librement. Remettre le brûleur en place. Ouvrir le gaz et

l’écrou de blocage pour permettre à l’obturateur de tourner

«H», rôtissoire, brûleurs articulés, brûleurs ouverts). Desserrer

l’obturateur d’air du brûleur (grilloir à plaque ouverte, gril en

thermostat provoque le débit maximal de gaz). Localiser

(ouvrir le robinet complètement de manière à ce que le

dessous de façon à obtenir une amme bleue à plein régime

De Cadran

Butée

Véri er le fonctionnement et régler comme indiqué cinécessaire le réglage de l’arrivée d’air primaire aux brûleurs.

brutale durant le transport du matériel peuvent rendre

D'étalonnage

Plaque

Repère Indicatif

réglage, procéder comme suit :

dérivation soit correctement réglée. Pour e ectuer ce

Le thermostat FDO Robertshaw exige que la amme de

Réglage De Dérivation

cadran, saisir les bords extérieurs et tirer tout droit.

de l’appareil après avoir déposé le cadran. Pour déposer le

et 260°C). Tous les réglages sont accessibles depuis l’avant

précision les températures du four entre 150° et 500°F (66°

précision, réglé soigneusement en usine pour contrôler avec

Le modèle FDO de thermostat de four est un instrument de

Les variations des conditions sur place ou une manutention

Réglage Du Mélange Gaz/Air Du Brûleur

devrait pas décoller du brûleur ni avoir une pointe jaune.

empiéter sur le brûleur. Une fois correctement réglée, elle ne

cuisson doit allumer rapidement le brûleur, mais ne doit pas

La veilleuse pour le brûleur du gril ou de la plaque de

amme peut avoir une extrémité légèrement jaune.

atteigne le milieu de l’ouverture du tube à décharge. Cette

réglée de façon à ce que l’extrémité de la amme de veilleuse

Si nécessaire, la veilleuse des brûleurs ouverts doit être

collecteur supérieur de la cuisinière.

Tous les robinets de réglage des veilleuses sont situés sur le

Commande De Four Robuste FDO

Réglage Des Veilleuses

RÉGLAGES

Page 30

comme un défaut.

sur l’e cacité et le fonctionnement et n’est pas considéré

bleue/brune) à cause de la chaleur. Ceci n’a aucun e et

en fonte et des plaques Spectro-Heat «vire» (décoloration

REMARQUE : La couleur de la surface des plaques chau ante

surfaces et commandes en dessous.

Éviter d’utiliser trop d’eau car cela pourrait endommager les

couche d’huile pour empêcher la formation de rouille.

Bien sécher. Dans les climats humides, passer une légère

la laver dans un évier avec de l’eau chaude et du savon.

déversements recuits. Si nécessaire, retirer la plaque et

à l’aide d’un torchon propre en toile à sac. Gratter les

Lorsque la surface est encore légèrement tiède, essuyer

PAS LES REFROIDIR EN UTILISANT DE LA GLACE!

NE PAS UTILISER D’EAU sur les plaques encore chaudes et NE

Et Plaques Chau antes Spectro

Plaques Chau ante En Fonte

graisse et les déversements ne tombent derrière la cuisinière.

remettre en place après les avoir nettoyés pour éviter que la

antidéversement. Ils doivent être retirés et nettoyés. Les

l’arrière de la grille supérieure en fonte se trouvent les écrans

d’huile végétale pour empêcher les grilles de rouiller. À

métallique. Bien sécher et appliquer une légère couche

aliments recuits dessus, on peut utiliser une brosse

avec de l’eau tiède et du savon doux. Pour déloger les

LES GRILLES SUPÉRIEURES EN FONTE peuvent être nettoyées

APPARITION.

PROCÉDURE N’EST PAS RESPECTÉE, LA ROUILLE FERA SON

APRÈS CHAQUE NETTOYAGE DE CES GRILLES. SI CETTE

L’APPRÊTAGE DES GRILLES SUPÉRIEURES SERA NÉCESSAIRE

Pièce nº 1382680 Rev 4 (01/15/16) Page 19