Garland MP-ED-20-S Installation Manual

INSTALLATION AND

OPERATION MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1936601 Rev 6 (01/08) © 2005 Garland Commercial Industries, Inc.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Congratulations! You have just purchased the latest in cooking technology, the new moisture+™ from Garland.

Garland is an established leader in innovative oven technology, and has manufactured this multifunction oven with the

operator in mind. The moisture+

™

provides function not previously available in a convection oven. Your moisture+™ will operate

as three pieces of equipment: a convection oven, a humidi ed baking oven, and a humidi ed cook & hold oven. Additionally,

the optional wet-clean water spray attachment allows you to easily spray down the oven interior during cleaning. Garland,

long known for o ering the “best baking” convection ovens available, adds the moisture+ to its model line to provide you, the

user with, a workhorse oven that will provide years of useful service.

Like any other ne, precision built appliance, your moisture+

™

oven should be given regular care and maintenance. Periodic

inspection by your dealer or a quali ed service agency is recommended. When corresponding with the factory or your local

authorized factory service center regarding service problems or replacement parts, be sure to refer to the particular oven by

the correct model number, (including the pre x/su x letters and numbers), and the warranty serial number. The rating plate

a xed to the oven contains this information.

Part # 1936601 Rev. 6 (01/08)Page 2

TABLE OF CONTENTS

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . .4

PREPARING THE OVEN FOR INSTALLATION . . . . . . . . 5

Legs and Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Open Base Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Stacking Two Ovens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wall Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

GAS CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . .9

WATER CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . .10

Water Quality Requirements. . . . . . . . . . . . . . . . . . . . . . . . 10

Spray/Flex Hose W/Quick Disconnect . . . . . . . . . . . . . . . 10

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

VENTILATION AND AIR SUPPLY . . . . . . . . . . . . . . . . . .11

INSTALLATION OF A DIRECT VENT . . . . . . . . . . . . . . .11

GAS MODEL TESTING & LIGHTING INSTRUCTIONS 12

To Conserve Energy: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

High Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Low Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pulse Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cool Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cook/Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Start/Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Numeric Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

“N”/Scroll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

“Y”/Enter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

OPERATING INSTRUCTIONS, (Deluxe Models) . . . . .17

Programmable Control (Deluxe Models) . . . . . . . . . . . . 17

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Auto Cool Down And Cool Down . . . . . . . . . . . . . . . . . . . 17

Start/Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Changing the Temperature Scale, (°F or °C). . . . . . . . . . 17

Basic Cook Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Using Cook & Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cooking With a Core Probe . . . . . . . . . . . . . . . . . . . . . . . . . 19

Programming Recipe Keys. . . . . . . . . . . . . . . . . . . . . . . . . . 20

System Program Options. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cooking With a Recipe Key . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using the Shelf Timer Feature . . . . . . . . . . . . . . . . . . . . . . 21

Display Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EXPLANATION OF CONTROLS (Standard Models) .13

Moisture Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Moisture Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fan Speed Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Light Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OPERATING INSTRUCTIONS, (Standard Models). . .14

In O Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Interior Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cool Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Moisture Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Moisture Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

EXPLANATION OF CONTROLS, (Deluxe Models) . . .15

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

On/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Moisture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

COOKING WITH MOISTURE . . . . . . . . . . . . . . . . . . . . . .26

Mechanical Control, (Standard Models) . . . . . . . . . . . . . 26

Programmable Control, (Deluxe Models). . . . . . . . . . . . 26

User Moisture Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Tips For Cooking With Moisture. . . . . . . . . . . . . . . . . . . . . 26

MOISTURE + COOKING GUIDE . . . . . . . . . . . . . . . . . . .27

PERFORMANCE RECOMMENDATIONS . . . . . . . . . . . .29

About Moisture Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

TEMPERATURE CALIBRATION . . . . . . . . . . . . . . . . . . . .30

PROBLEMS / SOLUTIONS . . . . . . . . . . . . . . . . . . . . . . . .31

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Fan Area Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

MOTOR CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

WATER SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Part # 1936601 Rev. 6 (01/08) Page 3

DIMENSIONS AND SPECIFICATIONS

38"

[965mm]

2-1/4"

[57mm]

2-1/4"

[57mm]

32-3/4"

[832mm]

DOOR OPENING

REQUIRED

32"

[813mm]

58.5"

[1486mm]

26-1/2"

[673mm]

FLOOR

LINE

40" [1015mm]

ADD 4" [102mm]

FOR DEEP OVENS

32-3/4"

[832mm]

DOOR OPENING

REQUIRED

32"

[813mm]

32"

[813mm]

70-1/4"

[1784mm]

5-1/2"

[140mm]

6-1/4"

[159mm]

SINGLE DECK

GAS SUPPLY

3/4" NPT

1/8" NPT

WATER SUPPLY

DOUBLE STACK

GAS SUPPLY

1" NPT

15"

[381mm]

8-1/4"

[210mm]

10-1/2"

[267mm]

1-1/2" NPT

DRAIN CONNECTION

Notes:

1. Standard electrical

specications include motor

requirements.

2. All ovens have a ¾ HP, two

speed motor; 1140 and 1725

RPM, 60 Hz.

3. Garland recommends that a

separate 15 Amp circuit be

provided for each 120V oven

4. A 6 foot line cord is provided for

each 120V oven with a NEMA

5-15P plug.

5. Double stack installations

require an individual power

supply connection to each

oven.

Gas input ratings are for

installations up to 2000 feet

(610 m) above sea level. Specify

altitudes above 2000 feet.

Models

Natural ¾” NPT 80,000 23.5

Propane ¾” NPT 60,000 17.6

Electric

Models

MP-ES/GS-10-S

MP-ES/GS-20-S

MP-ED/GD-10-S

MP-ED/GD-20-S

Gas

Input Ratings

Gas

Inlet

BTU

Hour

Input Ratings Nominal Amperes

Total KW/Line

kW

208/240/460

X-Y Y-Z X-Z X/Y/Z X/Y/Z X/Y/Z

11 3.33 3.33 4.33 N/A 53 46 24 31.8/27.7/31.8 27.6/24.0/27.6 10.5/9.5/10.5

Model Description

Std Depth,

Sgl Deck

Std Depth,

Dbl Deck

Deep Depth,

Sgl Deck

Deep Depth,

Dbl Deck

kW

120V

208V

1Ph

1 Ph

Interior Dimensions: in [mm] Exterior Dimensions: in [mm]

W H D W H D

29 [736] 24 [610]

240 V

1 Ph

460V

1 ph

208V 3 Ph 240V 3 Ph 460V 3 Ph

24 [610]

38 [965]

28 [711]

60-3/4 [1543]

72-1/2 [1842] 1024/464 84

60-3/4 [1543]

72-1/2 [1842] 1024/464 84

Commercial cooking equipment

requires an adequate ventilation

system. For additional information

refer to the National Fire Protection

Associations standard NFPA96,

“Vapors Removal from Cooking

Equipment” (Note: For North

America only)

Weight

(lbs/kg)

510/232 42

40 [1016]

510/232 42

44 [1118]

Size

(Cu ft)

Part # 1936601 Rev. 6 (01/08)Page 4

PREPARING THE OVEN FOR INSTALLATION

Figure 1.

CASTER INSERT (4)

CASTER (4)

SCREW (2 PER CASTER INSERT)

FLAT WASHER (4 EACH LEG)

BOLT (4 EACH LEG)

FOOT INSERT (4)

LEG ASSEMBLY (4)

BOLT (4 EACH CASTER)

FLAT WASHER (4 EACH CASTER)

DOUBLE DECK CASTER (4)

Legs and Casters

NOTE: If you will be installing an open base kit, please skip to

the next page and proceed with the steps listed under “Open

Base Assembly.”

1. (See Figure 1.). At the bottom end of each leg, install the

bullet foot insert or caster insert. The t of the insert to the

leg is intended to be snug, tap them lightly into place with

a mallet or rubber hammer.

Install two #5 x 1/4” self-drilling, thread forming screws

into each caster insert.

2. Screw a caster into the insert on each of the four legs.

The caster must be inserted at least three full threads to

properly support the oven. A 1” (25mm) open-end wrench

may be needed to properly install the casters.

OR

Using your ngers, screw the ends of the bullet feet into

the leg clockwise until they are at their shortest length.

3. Carefully tip and lower the oven onto its left side so you

can easily reach the bolt mounting locations in the base.

4. The four holes in the top of each leg or in the top plate of

double stack casters will match the bolt locations at each

corner of the oven base.

You will need four 3/8-16 x 1” hex head bolts and four 3/8”

at washers to mount each leg. Align the leg to one of the

matching bolt holes on the base and insert a bolt with

washer.

Install the remaining three bolts and nger-tighten all

four before using an 11/16” wrench to fully tighten them

all. Be sure to tighten all four bolts for each leg or caster.

When installing casters, make sure the two casters with

brakes are installed at the front of the oven.

5. Carefully return the oven to an upright position. Ensure

the two legs/casters that touch the oor rst when you

raise the oven are blocked and chocked so they do not slip

away.

6. It is very important to use the adjustable bullet foot

inserts in leveling the unit.

7. If you have installed casters, be sure to install the restraint

bracket on the lower left corner of the rear of the oven

using two #10 x 3/4” sheet metal screws.

Part # 1936601 Rev. 6 (01/08) Page 5

PREPARING THE OVEN FOR INSTALLATION

Figure 2.

RACK GUIDE UPPER SUPPORT

RACK GUIDE (2)

INNER GUIDE POSITION

FOR TRAYS

OUTER GUIDE POSITION

FOR RACKS

OPEN BASE PANEL

SCREW (6x)

LEG ASSEMBLY (4)

W/FOOT INSERT

OPEN BASE UPPORT CLIP (4)

SCREW (1 EACH CLIP)

SCRREW (2 EACH CLIP)

INNER

OU

T

ER

Open Base Assembly

Use the following sequence of steps to assemble and install

the open base accessory.

1. (See Figure 2.). Align the rack guide upper support to the

corresponding holes in the oven base. Fasten using three

#10 x 3/4” machine screws on each side of the oven.

2. At the lower end of each leg install an “L” shaped support

clip using a #10 x 3/4” sheet metal screw. Do this before

fastening the leg to the base.

3. Install legs to the bolt holes at the front and rear of the

base on the oven’s left side, (side lying on the oor). If

installing casters, be sure to install a locking caster on the

front leg. Refer to the section, “Legs and Casters,” on the

previous page for installation details.

4. Fasten the open base panel in place on the brackets of

the two legs already installed, using one #10 x 3/4” sheet

metal screw in each corner.

5. While supporting the open base panel, install the rightside legs as in step 2. Ensure the caster with a brake is at

the front of the oven. Fasten the remaining two corners of

the open base panel to the other two legs just installed.

6. Carefully return the oven to an upright position. Ensure

the two legs/casters that touch the oor rst when you

raise the oven are blocked and chocked so they do not slip

away.

7. Install the rack guides in one of the two available

positions. The inner position sets the guides at a width

to accommodate oven pans. The outer position sets the

guides at a width to accommodate wire oven racks. To

attach, insert the longer straight end at the top of the rack

guide all the way into the mounting hole, then align the

bottom holes and lower the rack guide into position.

8. It is very important to use the adjustable bullet foot

inserts in leveling the unit.

9. If you have installed casters, be sure to install the restraint

bracket on the lower left corner of the rear of the oven

using two #10 x 3/4” sheet metal screws.

Part # 1936601 Rev. 6 (01/08)Page 6

PREPARING THE OVEN FOR INSTALLATION

7

9

3

2

1

14

13

11

8

12

5

12

4

9

13

Stacking Two Ovens

1. Follow the instructions in the section entitled, “Legs and

Casters,” on page 5. Then resume at step 2 on this page to

complete the stacking process.

2. Move the lower oven as close to the nal installation point

as possible, leaving enough space around the oven to

allow access for the remaining installation steps. If casters

have been installed, apply the brakes on the two front

wheels.

3. Carefully raise the upper oven and place it on top of the

lower oven, aligning the four lower corners of the upper

even to the four upper corners of the lower oven.

4. At the rear of the stacked ovens, install the stacking

bracket using six 1/4-20 x 1” hex head bolts with lock

washers and nuts. Firmly tighten all six nuts/bolts to

secure the ovens together.

5. Remove the outer ue vent from the right top corner of

the rear of each oven, saving the screws.

6. If they are not already fastened together, assemble the

two parts of the interconnecting ue channel included in

the stacking kit, using six #10 x 3/4” sheet metal screws.

7. Fit the channel assembly over the ue vent area of each

oven and fasten using the screws removed in step 5.

8. If you have installed casters, be sure to install the restraint

bracket on the lower left corner of the rear of the upper

oven using two #10 x 3/4” sheet metal screws.

9. If your installation requires one common gas inlet for both

ovens, use the piping included with your stacking kit to

assemble the interconnecting gas pipe. Refer to Figure 3.

NOTE: It is recommended, when stacking a Moisture + Oven

with a Master Convention Oven, that the Moisture + be

located on the bottom.

Item Reference Key For Figure 3

Item

No.

Item Description

1 MSCR-HH STL 1/4-20x3/4

2 LKSHR-SPL 1/4x1/2x1/6

3 Nut - Hex 1/4-20 STL ZP

4 Bell Reducer 1” x 3/4”

5 3/4 Tee NPT

7 Flue Assembly – Double Stack

8 Pipe Union 3/4 NPT

10 Close Nipple 3/4 x 1

11 Pipe 3/4 x 20-1/2”

12 3/4 x 3-1/2 Nipple

13 Bell Reducer

14 Stacking Bracket Rear

Figure 3.

Part # 1936601 Rev. 6 (01/08) Page 7

INSTALLATION

It is the responsibility of the purchaser to ensure the oven is

installed in a manner to meet all local codes. In the absence

of local codes, applicable national codes are referenced in this

booklet. In the case of discrepancy between the information

in this booklet and local codes, it is recommended you

consult your local inspector(s). This appliance meets or

exceeds all applicable regulations and standards in eect on

its date of manufacture.

Location

The importance of the proper installation of Commercial

Gas Cooking Equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

specications. Installation must conform to local codes or, in

the absence of local codes, with the National Fuel Code, ANSI

Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the

Propane Installation Code, CAN/CGA-B149.2, as applicable.

GAS CONNECTIONS

The type of gas for which the oven is equipped is stamped on

the data rating plate. It is located inside the lower front trim

cover. Connect an oven stamped “NAT” to natural gas only.

Connect an oven stamped “PRO” to propane gas only.

If the oven is being installed into a new location, have gas

authorities check the meter size and piping to assure the supply

line has a sucient amount of gas pressure to operate the oven.

If the oven is a replacement or additional appliance to an

existing installation have gas authorities check the pressure

to ensure the existing meter and pressure will supply the

oven with no more than a 1/2” water column pressure drop.

Note: When checking the gas pressure make sure all other

appliances on the same gas line are turned on.

A pressure regulator is supplied with Garland convection

ovens. The regulator pressure is preset to deliver the gas

at the pressure shown on the rating plate. Do not install

an additional regulator where the unit connects to the

gas supply unless the gas pressure exceeds the maximum

recommended pressure.

The oven and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 PSI (3.45 kPa).

The oven must be isolated from the gas supply piping system

by closing its individual manual shut-o valve during any

pressure testing of the supply system at test pressures equal

to or less than 1/2 PSI (3.45 kPa).

Wall Clearance

This oven, single or stacked, must be installed with adequate

clearance to combustible and non-combustible walls.

Sides: 1 inch [25 mm]

Back: 3 inches [76 mm] for gas ovens, and

6 inches [152 mm] for electric ovens.

Garland recommends that a one inch clearance be

maintained between this oven and any other cooking

appliance.

Garland recommends that this oven not be installed with a

broiler or open burner appliance immediately adjacent to the

right side.

Each appliance shall be located with respect to building

construction and other equipment so as to permit access to

the appliance. Such access and clearance may be necessary

for servicing and cleaning.

Prior to connecting to the building gas supply the lines

should be purged of all metal lings, pipe thread compound

or other debris.

The gas connection piping (3/4” for single ovens, 1” for

stacked ovens), must be considered when planning the

supply line. Undersized gas supply lines may restrict the

gas ow and aect performance. If other gas appliances are

supplied by the same supply line, it must be sized to carry

the combined volume required for all the appliances without

causing a more than 1/2” pressure drop at the manifold of

each appliance on line at full rate.

Recommended supply pressures are 7” ± 5% WC for natural

gas (NAT) and 11” ± 5% WC for propane (PRO). The inlet

pressure for the supply line must not exceed 13.8” WC natural

and 15”WC for propane.

Two ovens stacked may be supplied by a single gas line. The

minimum recommended size of a single supply line for two

stacked ovens is 1 inch.

Assemble the gas pipes and ttings provided in the stacking

kit as shown in the Figure 3 on page 7. Use a pipe thread

compound that is intended for use on propane gas piping.

Be sure to check for leaks before nalizing the installation. Use

appropriate solutions or detection devices.

Installations in which a exible gas connection hose is

used, require the supplied strain relief to be installed at the

lower left rear corner of the base. Install the strain relief in

accordance with applicable codes. The strain relief must limit

the movement of the oven to prevent unnecessary stress on

the exible connector.

Part # 1936601 Rev. 6 (01/08)Page 8

ELECTRICAL CONNECTIONS

ELECTRIC OVENS - SHIPPED WITH KNOCKOUT

PLATE FOR POWER SUPPLY

REMOVE THIS SCREW TO ALLOW

ACCESS TO THE TERMINAL BLOCK (ELECTRIC OVENS)

OR CORD CONNECTIONS (GAS OVENS)

A separate electrical connection must be supplied for each

oven. Connection to the electrical service must be grounded

in accordance with local codes, or in the absence of local

codes with the National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.2, as applicable.

A strain relief for the power supply cord is required. The

installer must supply a cord bushing that meets local and

national codes.

For 120VAC usage a cord and NEMA 5-15P plug is provided.

Garland recommends a separate 15 Amp service for each

oven. Ovens for 120V service are supplied with a three

pronged plug for your protection against shock hazard and

should be plugged directly into a properly grounded threeprong receptacle.

DO NOT CUT OR REMOVE THE GROUNDING PRONG FROM

THE PLUG.

A wiring diagram is axed to the rear of the oven and

included in this booklet.

CAUTION:

DISCONNECT ALL OVENS FROM ELECTRI-

CAL SUPPLY BEFORE

SERVICING.

POWER FAILURE:

IN THE EVENT OF A POWER

FAILURE, NO ATTEMPT SHOULD BE MADE

TO OPERATE THIS OVEN.

Figure 4.

Part # 1936601 Rev. 6 (01/08) Page 9

WATER CONNECTIONS

B

A

A

B

1/8" NPT WATER

SUPPLY CONNECTION

DETAIL A

1-1/2" NPT MALE

TRAP ADAPTER

DETAIL B

It is the responsibility of the purchaser to install and maintain

the water supply to the moisture+ oven. Failure to provide

satisfactory water quality to operate the oven properly

can cause damage to integral components and void your

warranty.

This oven must be installed to comply with the applicable

federal, state, or local plumbing codes.

Water supply connection to the moisture+ is made via a

1/8” NPTF tting at the rear of the oven. The ability to move

the oven for service and cleaning may be a consideration

when choosing the type of connection and supply line to be

attached at this tting.

The moisture+ water delivery system includes a water

pressure regulator that has been pre-set to operate at 20 psi.

The water supply must maintain at least 20 psi and a ow rate

of three gallons per minute for proper operation of the oven’s

moisture injection system.

Water Quality Requirements

Garland recommends that the supply water be ltered before

it enters the oven’s water delivery system. This will extend the

life of the oven and its water delivery system components by

minimizing particles in typical tap water sources that cause

scaling and build-up of mineral deposits.

The recommended minimum water quality standards,

whether treated or pre-treated, and based on 10 hours of use

per day, and daily cleaning./descaleing are as follows:

Total dissolved solids – less than 60 parts per million, total

alkalinity – less than 20 parts per million, silica – less than 13

parts per million, chlorine – less than 30 parts per million and

a pH Factor greater than 7.5.

Consult a local water treatment specialist for an on-site

water analysis for recommendations concerning feed water

treatment (if required), in order to remove or reduce harmful

concentrations of minerals. The use of highly mineralized

water will cause more frequent cleaning and reduce

operating eciency. The fact that a water supply is potable is

not proof that it will be suitable for moisture mode operation.

Component failure/service related to poor water quality will

not be covered under warranty.

Spray/Flex Hose W/Quick Disconnect

Your moisture+ oven may be equipped with the optional

spray/ex hose assembly. The spray/ex hose assembly is

intended to assist in cleaning the oven. The water pressure

and velocity may vary, depending on the pressure and

velocity of the water supply connected to the oven.

Drain

Your moisture+ oven has a gravity drain in the right rear

corner of the oven cavity. The drain pipe that exits the rear

of the oven must be directed downward toward the oor,

and should run directly to an open oor drain. Garland

provides an 1-1/2” male pipe adapter for connecting your

drain lines. Avoid using exible hose that could sag or kink,

allowing water to accumulate. The drain must be vented. This

connection must be at least 1-1/2” (38.1 mm) in diameter and

congured in accordance with local codes.

Figure 5.

Part # 1936601 Rev. 6 (01/08)Page 10

VENTILATION AND AIR SUPPLY

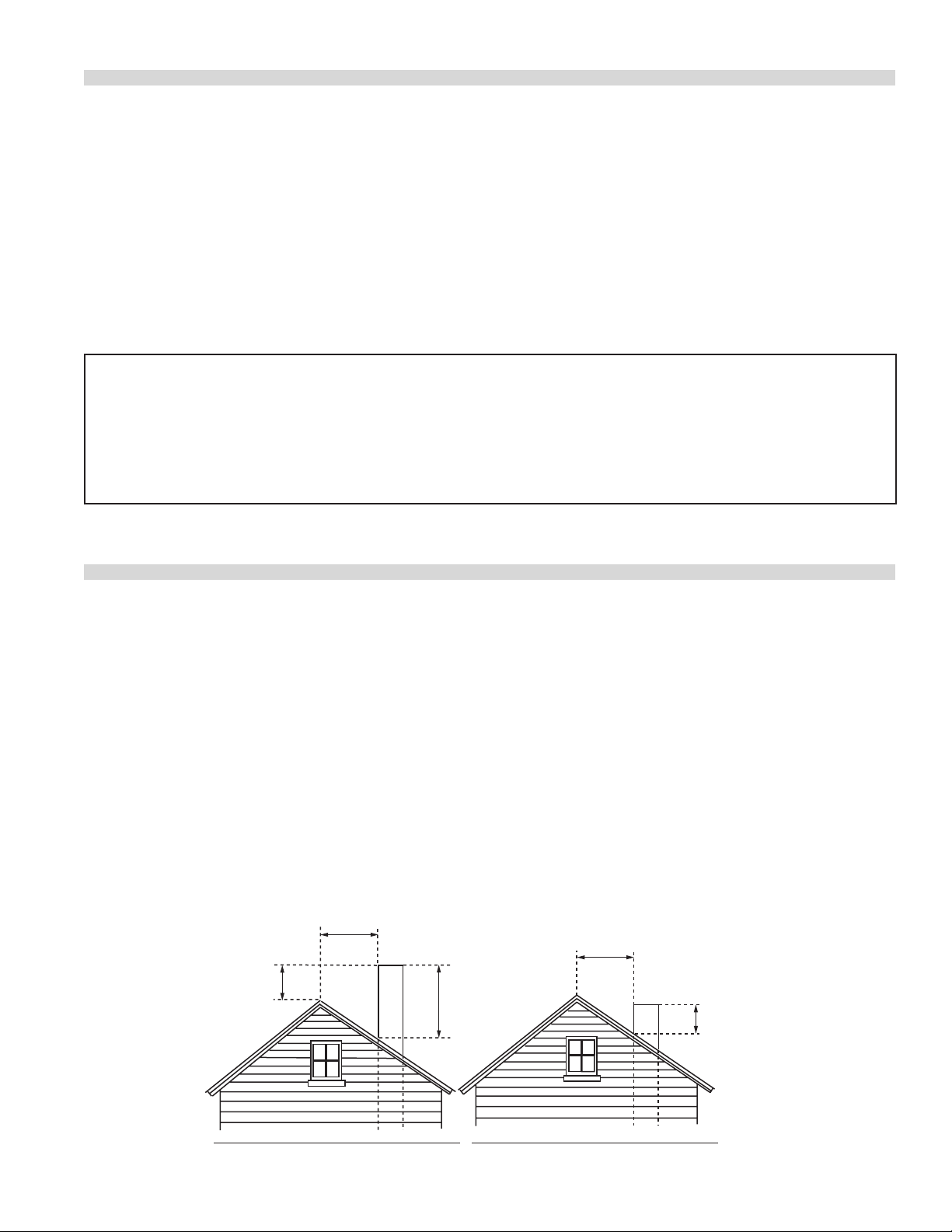

Termination Less than 10 feet (3 meters) from ridge Termination More than 10 feet (3 meters) from ridge

Less than 10 feet (3 meters)

More than 10' (3 meters)

2' (60cm) Min.

3' (90cm) Min.

3' (90cm) Min.

Figure 6.

Proper ventilation is highly important for eective operation.

There are only two choices for properly venting an oven:

1) canopy hood, or, 2) direct venting. The ideal method of

venting a gas oven is through the use of a properly designed

canopy hood. The hood should extend beyond all sides of the

oven 6 inches, (150 mm), and be installed at least 78 inches,

(1950mm), from the oor.

A strong exhaust fan will create a vacuum in the room. For

exhaust system vents to work properly, exhaust and make-up

air must be balanced. For proper air balance, contact your

local H.V.A.C. contractor.

IMPORTANT

ALL GAS BURNERS AND PILOTS NEED SUFFICIENT AIR TO OPERATE AND LARGE

OBJECTS SHOULD NOT BE PLACED IN FRONT OF THIS OVEN, WHICH COULD

OBSTRUCT THE AIRFLOW THROUGH THE FRONT. OBJECTS SHOULD NOT BE PLACED

ON MAIN TOP REAR OF THE OVEN WHILE IN USE. THIS COULD OBSTRUCT THE

VENTING SYSTEM OF THE OVEN’S FLUE PRODUCTS.

INSTALLATION OF A DIRECT VENT

All gas burners and pilots need sucient air to operate

and large objects should not be placed in the rear or at

the bottom of this oven which would obstruct the airow

through the front covers. Do not place objects over the oven

vent exit.

Some localities require an electric oven to be installed under

an exhaust hood. Be sure to consult your local code inspector

prior to operating any gas or electric oven.

When the installation of a canopy hood is impossible, the

oven may be direct vented. Before direct venting check you

local codes on ventilation, in the absence of local codes

refer to the National Fuel Code NFPA 54, ANSI Z223.1 (latest

revision).

If the oven is to be connected to a direct ue vent, it is

necessary that a draft diverter be installed to ensure proper

ventilation.

The draft diverter should be positioned on the main top of

the oven and fastened with sheet metal screws provided. All

parts described above are available from the manufacturer.

Note: Each oven has been factory tested and adjusted

prior to shipment. It may be necessary to further adjust the

oven as part of a proper installation. Such adjustments are

the responsibility of the installer. Adjustments cannot be

considered defects in material or workmanship and they are

not covered under the original equipment warranty.

DO NOT UNDERSIZE THE VENT PIPE! This can cause resistance

to ow and impede good venting. We suggest that if a

horizontal run must be used it should rise no less than 1/4”

(6.25mm) for each linear foot of run, and after a total of 180°

of bends you should increase the size of stove pipe by 2”. The

ue should rise 2’ (60 cm) to 3’ (90 cm) above the rooine or

2’ (60cm) to 3’ (90cm) above any portion of a building within a

horizontal distance of 10’ (3 m).

Part # 1936601 Rev. 6 (01/08) Page 11

Loading...

Loading...