Garland MCO-GS-10ESS Installation Manual

INSTALLATION AND

OPERATION MANUAL

"THE MASTER"

GAS CONVECTION OVEN

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G3-1009-146

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

Cleveland Range, LLC.

1333 East 179th Street,

Cleveland, Ohio 44110

Phone: (800) 424-2411

Fax: (800) 624-0218

Part # 260BGS Rev A (06/01/11) © 2011 Garland Commercial Ranges, LTD.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Page 2

Part # 260BGS Rev.A (06/01/11)

CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . 2

DIMENSIONS & SPECIFICATIONS . . . . . . . . 4

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Of Ovens Equipped With Casters . . 5

Installation Of Double Deck Models . . . . . . . . . . . 6

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . 7

Ventilation & Air Supply . . . . . . . . . . . . . . . . . . . . . . 7

Testing & Lighting Instructions . . . . . . . . . . . . . . .8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Master 200 Solid State Control With

Electromechanical Timer . . . . . . . . . . . . . . . . . . . . . 9

PERFORMANCE RECOMMENDATIONS . . 10

COOKING GUIDE . . . . . . . . . . . . . . . . . . . . . . 11

PROBLEMS / SOLUTIONS . . . . . . . . . . . . . . 12

CLEANING & MAINTENANCE . . . . . . . . . . . 13

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Exterior Cleaning. . . . . . . . . . . . . . . . . . . . . . . . 13

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . 13

Fan Area Maintenance . . . . . . . . . . . . . . . . . . . 13

MOTOR CARE . . . . . . . . . . . . . . . . . . . . . . . . . 14

In O Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cool Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part # 260BGS Rev.A (06/01/11) Page 3

DIMENSIONS & SPECIFICATIONS

Single-Deck

Models

Int. Dimensions :In (mm) Ext. Dimensions: In (mm) Ship Wt Ship Dim.

W H D W H * D Lbs/kg Cubic Ft.

Standard Depth 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 41-1/4(1048) 515/230 64

Double-Deck

Models

Int. Dimensions: In (mm) Ext. Dimensions: In (mm) Ship Wt. Ship Dim.

W H D W H * D 2@Lbs/kg Cubic Ft.

Standard Depth 29 (736) 24 (610) 24 (610) 38 (965) 70-1/2 (1791) 41-1/4(1048) 1030/465 128

*Height with or without standard casters. Height with low prole casters (double deck) is 68-1/2" (1740mm).

Input Ratings, Natural Gas Electrical Specications

Models

BTU/hr kW Equiv. Gas Inlet 120V/1Ph. 240V/1Ph.

Single Deck 60,000 17. 6 (1 )@ 3/4" NPT (1)@9.8A (1)@ 5.2A

Double Deck 120,000 35.2 (1 )@1" NPT (2)@9.8A (2)@ 5.2A

1" REAR

GAS INLET

32-1/8"

[816mm]

14-3/4"

[375mm]

D

(includes

fan motor)

17-3/4"

[451mm]

1-1/4"

[32mm]

[816mm]

H

[645mm]

7-3/4"

[197mm]

3/4"

[19mm]

32-1/8"

25-3/8"

3/4" N.PT.

GAS INLET

FLUE: 2-3/8" x 5"

[60mm x 127mm]

TOP VIEW

38"

[965mm]

SINGLE DECK

FR ONT VIEW

2"

[51mm]

38-1/4"

[972mm]

11-1/2"

[292mm]

3/4" REAR

GAS INLET

[1386mm]

34"

[864mm]

54-9/16"

1-1/4"

[32mm]

32-1/8"

[816mm]

H

32-1/8"

[816mm]

6-1/4"

[159mm]

Installation Notes:

Combustable Wall Clear-

DOUBLE DECK

FR ONT VIEW

Manifold Pressure:

Natural: 4.1" WC

ances:

Sides: 1" (25mm)

Back: 3" (76mm)

NOTE: Data applies only to

North America

Entry Clearance:

Crated: 47" (1194mm)

Uncrated: 32-1/2" (826mm)

Notes:

1. Standard electrical specications include motor requirements.

2. (120V units) 115V 3/4 HP, 2-speed motor; 1140 and 1725 rpm 60Hz

3. (240V units) 200-240V, 3/4 HP, 2-speed motor; 1140 and 1725 rpm, 60Hz

4. A 6 ft. line cord is provided for each 120V deck with a (NEMA #5-15P) plug.

5. Garland recommends a separate 15 AMP circuit for each 120V unit.

32-1/8"

[816mm]

35-7/16”

[900mm]

Gas Input ratings shown here are for installations up to 2,000-ft. (610m) above sea level.

Page 4

Part # 260BGS Rev.A (06/01/11)

INTRODUCTION

CONGRATULATIONS! You have just purchased the nest

commercial cooking equipment available anywhere.

Like any other ne, precision built appliance, it should be

given regular care and maintenance. Periodic inspections by

your dealer or a qualied service agency is recommended.

When corresponding with the factory or your local authorized

INSTALLATION

Installation Notes:

Combustible and Non-Combustible Wall Clearance:

Side: 1.0" (25 mm)

Rear: 3.0" (76 mm).

NOTE: Adequate clearance must be provided for servicing

and proper operation.

The importance of the proper installation of Commercial

Gas Cooking Equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer's

specications. Installation must conform to local codes or, in

the absence of local codes, with the National Fuel Code, ANSI

Z223.1, or Natural Gas Installation Code, CAN/CGA-B149.1, as

applicable.

Before assembly and connection, check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located at the rear of the left side panel.

Connect a unit stamped "NATURAL" only to natural gas.

B. If it is a new installation, have gas authorities check meter

size and piping to assure that the unit is supplied with

sucient amount of gas pressure required to operate the

unit.

C. If it is additional or replacement equipment, have gas

authorities check pressure to make certain that existing

meter and piping will supply fuel at the unit with not more

that 1/2" water column pressure drop.

NOTE: When checking pressure be sure that all other

equipment on the same gas line is on. An internal pressure

regulator is supplied with GARLAND Convection Ovens.

Regulator is preset to deliver gas at pressure shown on the

rating plate.

factory service center regarding service problems or

replacement parts, be sure to refer to the particular unit by

the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate, located at the rear of the left side panel, contains

this information.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 PSI (3.45 kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-o

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 PSI

(3.45 kPa).

Installation Of Ovens Equipped With Casters

A. For an appliance equipped with casters, the installation

shall be made with a connector that complies with the

Standard for Connectors for Movable Gas Appliances,

ANSI Z21.69 /CSA 6.16, and a quick-disconnect device that

complies with the Standard for Quick-Disconnect Devices

for Use With Gas Fuel, ANSI Z21.41 / CSA 6.9, and adequate

means must be provided to limit the movement of the

appliance without depending on the connector and the

quick-disconnect device or its associated piping to limit

the appliance movement and the location(s) where the

restraining means may be attached to the appliance shall

be specied.

B. The front casters of the unit are equipped with brakes

to limit the movement of the oven without depending

on the connector and any quick-disconnect device or its

associated piping to limit the appliance movement.

C. The restraint can be attached to the unit near the gas inlet.

If the restraint is disconnected, be sure to reconnect the

restraint after the oven has been returned to its originally

installed position.

Part # 260BGS Rev.A (06/01/11) Page 5

INSTALLATION Continued

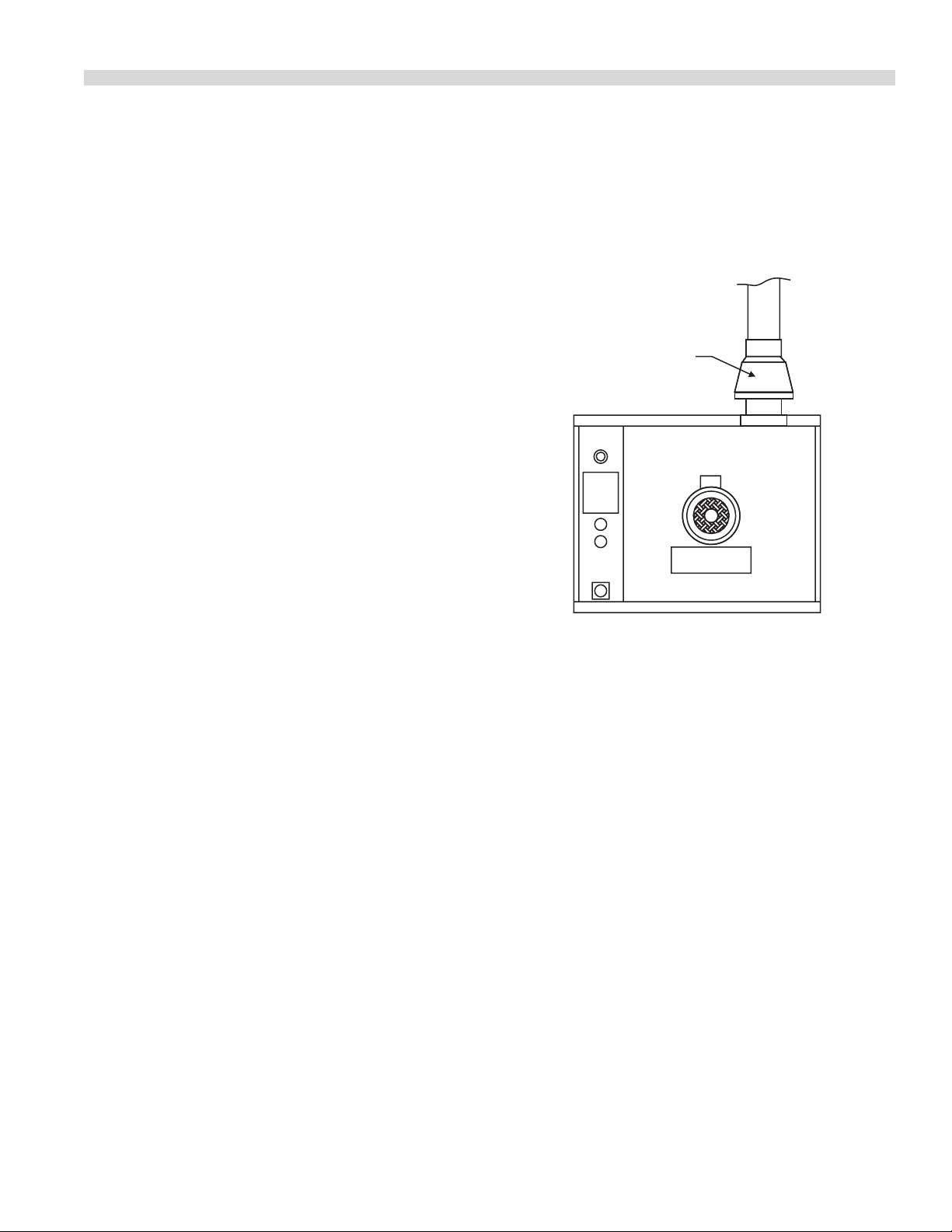

90 Degrees Street Elbow

90 Degrees Street Elbow

20 1/2" Nipple

3/4" to 1"

Bell Reducer

3" Nipple

3" Nipple

3/4" Union

Installation Of Double Deck Models

A. Position insert in bottom leg opening and tap insert up

into leg till it seats at collar. Attach six inch (6") legs to

lower oven section. Raise unit or lay on its left side. Place

the front legs on the oven so as to line up with four (4)

attaching bolt holes. Secure leg to oven frame using (4)

3/8-16 x 3/4 bolts and washers provided. Repeat at rear of

unit.

B. Remove lower front cover of top deck (located under oven

doors). Raise top deck into place and line up body sides

and back of the unit. Fasten the rear of the units together,

with the stacking bracket, using (6) 1/4-20 machine

screws, lock washers and nuts, (provided).

C. Install the interconnecting ue parts, carefully following

the instructions contained in the stacking kit. Pay

particular attention to the type of ovens you are stacking

and be sure to follow the corresponding instructions.

D. Assemble the stacking pipes provided in the stacking

kit as shown in the diagram at the top of this page. This

allows both ovens to be supplied by a single gas line. The

minimum recommended size of a single supply line for

two stacked ovens is 1 inch. Use a pipe thread compound

that is intended for use on propane gas piping and be sure

to check for leaks before nalizing the installation.

E. Check leveling of unit four (4) ways (using a common

carpenter's level on the rack inside the oven).

F. Plug the cord set of each unit into a separate 115-Volt

power supply outlet.

G. Maintain clearance from combustibles.

Each gas appliance shall be located with respect to building

construction and other equipment so as to permit access to

the appliance. Such access and clearance may be necessary

for servicing and cleaning.

CAUTION:

DISCONNECT BOTH UNITS FROM

ELECTRICAL SUPPLY BEFORE SERVICING.

POWER FAILURE

In the event of a power failure, no attempt

should be made to operate this oven.

IMPORTANT

All gas burners need sufficient air to operate

and large objects should not be placed in

front of this oven, which would obstruct the

airflow through the front. Objects should not

be placed on main top rear of oven while in use.

This could obstruct the venting system of the

unit's flue products.

Page 6

Part # 260BGS Rev.A (06/01/11)

INSTALLATION Continued

Gas Connection

The 1" NPT inlet at the rear must be considered in piping the

gas supply for double stack units or ¾" NPT for individual (or

single deck) connections. Undersized gas supply line(s) may

restrict the gas supply and aect performance. If other gas

appliances are supplied by the same supply line, the supply

line must be sized to carry the combined volume without

causing more than 1/2" pressure drop at the manifold of each

appliance on the line at full rate.

Recommended supply pressures are 7" WC, (NAT) (Must not

exceed 13.8" WC [NAT]).

Electrical Connection

A 15 AMP service must be provided for each oven. For 115

VAC usage, a cord and plug (NEMA #5-15P) is provided but

connection to the electrical service must be electrically

grounded in accordance with local codes, or in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70,

or the Canadian Electrical Code, CSA C22.2, as applicable.

This appliance is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle.

of local codes, refer to the National Fuel Code NFPA 54, ANSI

Z223.1 (latest revision).

If the unit is to be connected directly to a direct ue, it is

necessary that draft diverter be installed to insure proper

ventilation.

DRAFT DIVERTER

DO NOT CUT OR REMOVE THE

GROUNDING PRONG FROM THIS PLUG.

A wire diagram is axed to the rear of the unit.

Ventilation & Air Supply

Proper ventilation is highly important for good operation.

There are only two choices for properly venting an oven: 1)

canopy hood style or 2) direct venting. The ideal method

of venting a GAS Convection Oven is through the use of a

properly designed canopy, which should extend 6" (150 mm),

beyond all sides of the appliance and 6'6" (1950 mm) from the

oor.

A strong exhaust fan will create a vacuum in the room. For an

exhaust system vent to work properly, exhaust and make-up

air must be balanced properly. For proper air balance contact

your local H.V.A.C. contractor.

All gas burners and pilots need sucient air to operate and

large objects should not be placed in front of this oven, which

would obstruct the airow through the front. Installation Of A

Direct Flue

When the installation of a canopy type exhaust hood is

impossible the oven may be direct vented. Before direct

venting check your local codes on ventilation, in the absence

Direct venting, should be positioned on the main top and

fastened with sheet metal screws provided.

NOTE: Each oven has been factory tested and adjusted prior

to shipment. It may be necessary to further adjust the oven

as part of a proper installation. Such adjustments are the

responsibility of the installer. Adjustments are not considered

defects in material and workmanship, and they are not

covered under the original equipment warranty.

DO NOT UNDER SIZE VENT PIPE!

This can cause resistance to ow and impede good venting.

We suggest that if a horizontal run must be used it should

rise no less than 1/4" (6.25mm) for each linear foot of run, and

after a total of 180° of bends you should increase the size of

stove pipe by two (2") inches. The ue should rise 2' (60cm) to

3' (90cm) above the rooine or 2' (60cm) to 3' (90cm) above

any portion of a building within a horizontal distance of 10

(3 meters) feet.

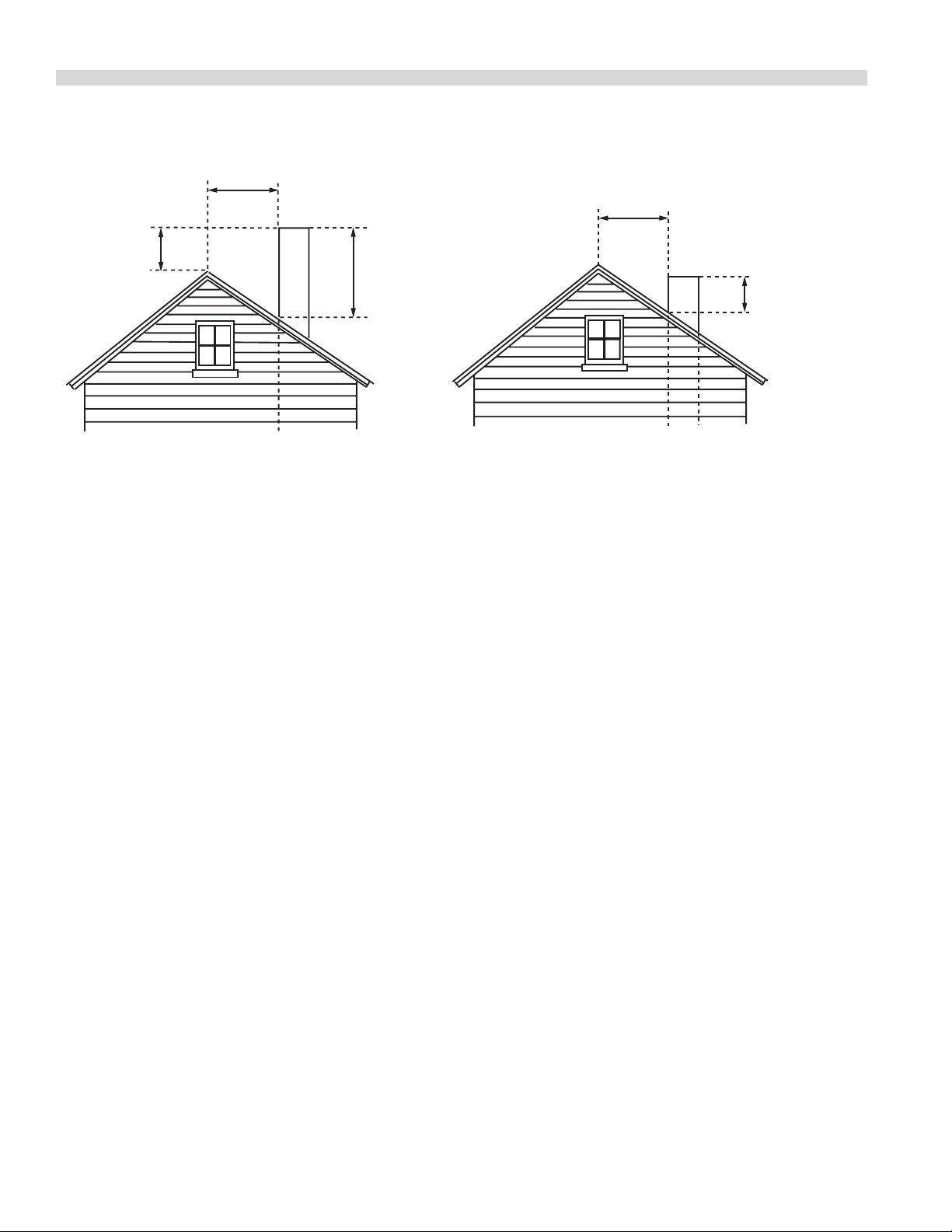

The following diagram is only one example from the National

Fuel Gas Code Book NFPA 54, ANSI Z223.1, 7.5.3:

Part # 260BGS Rev.A (06/01/11) Page 7

Termination Less than 10 feet (3 meters) from ridge Termination More than 10 feet (3 meters) from ridge

Less than 10 feet (3 meters)

More than 10' (3 meters)

2' (60cm)

Min.

3' (90cm) Min.

3' (90cm) Min.

INSTALLATION continued

Testing & Lighting Instructions

1. Turn on main gas valve. Remove the lower front cover

and the service panel above the control panel. Drop the

control panel and leak test all ttings and connections

upstream from the service valve located on the redundant

combination gas valve. Should any gas leaks be detected,

turn OFF main gas valve, correct the problem and retest.

2. Open shuto valve located on the redundant combination

gas valve. Activate control panel and set to desired

temperature. The main burners are ignited by direct spark.

Check all ttings again and correct any leaks and recheck.

Replace all service panels and covers before operation.

NOTE: All electronic ignition systems are supplied with a

redundant gas valve. Therefore, the unit is not supplied with

an external pressure regulator.

NOTE: During installation there will be air in the gas line. This

air will have to bleed o before ignition can be established.

The electronic ignition system has 3 cycles of four second

ignition attempts before the ignition module is "Locked Out".

There is a ve minutes interval between each attempt. This is

a safety device on all units. Therefore, several attempts may

be required before the ignition is established.

If the ignition module becomes, "Locked Out" the oven will

need to be turned o and then back on to restart the ignition

process again.

FOR YOUR SAFETY: KEEP YOUR APPLIANCE AREA FREE FROM

COMBUSTIBLES.

TO CONSERVE ENERGY:

Do not waste energy by leaving controls at high temperature

settings during idle periods. Lower settings will keep oven

warm and ready for next use period.

Page 8

Part # 260BGS Rev.A (06/01/11)

OPERATION

Master 200 Solid State Control With

Electromechanical Timer

In O Mode

When the oven is o, there are no lights or indicators.

Start Up

Press the Cook/O/Cool Down rocker switch to the “Cook”

position. The green lamp will light indicating the oven is

powered in cook mode.

The oven will begin to heat to the temperature set on the

thermostat dial. The amber lamp will light indicating the heat

is active. As the heat cycles on and o to maintain the set

temperature this light will go on and o accordingly.

The door must be closed for the oven to operate in cook

mode. Opening the door will cause the heat to stop. The

motor and fan will shut o. This is a safety feature.

Fan Speed

The fan speed can be either high (1725RPM) or (1150 RPM).

The fan speed is controlled by the left rocker switch marked

high and low.

Lights

The oven lights are activated by pressing the light switch on

the control panel. This is a momentary switch and the lights

will stay lit as long as this button is held in the on position.

Lights will work whenever there is electrical power connected

to the oven.

Cool Down

Pressing the Cook/O/Cool Down rocker switch to the Cool

Down position activates the fan and motor to cool the oven

cavity. The door must be open slightly for the fan and motor

to start. The heat is not active in this mode.

Optimal cool down will be achieved with the door open

slightly. Opening the door too far will shut the fan and motor

o. This is a patented safety feature.

Pressing the button to the OFF position cancels the cool

down and turns the oven o.

Temperature

The temperature range is from 150°F to 500°F (66°C to 250°C)

is controlled by rotating the temperature dial and aligning

the indicator to the desired temperature.

Timer

The timer is set by rotating the dial clockwise aligning the

indicator to the desired time cycle. The timer will count down

from 2 minutes to 60 minutes. At the end of the timing cycle

the buzzer will sound. The buzzer is turned o by rotating the

dial counter-clockwise to the o position as shown on the

control panel. (NOTE: The timer does not control heating. )

Part # 260BGS Rev.A (06/01/11) Page 9

Loading...

Loading...