Page 1

GARLAND

BUILT TO LEAD... BUILT TO LAST

A WELBILT COMPANY

SERVICE MANUAL

THE “MASTER”

GAS CONVECTION

OVENS

Models covered in this manual are:

MCO-GS-10M:

M

ASTER CONVECTION

M

ASTER CONVECTION OVEN

M

ASTER CONVECTION

M

ASTER CONVECTION

185 East South Street Freeland, Pennsylvania 18224

DIRECT “ON-SITE” SERVICE 1-800-451-1165

Oven - GAS S

- GAS S

Oven - GAS D

Oven - GAS D

GARLAND Commercial Industries, Inc.

TANDARD DEPTH

MCO-GS-10E:

TANDARD DEPTH

MCO-GD-10M:

EEP DEPTH

MCO-GD-10E:

EEP DEPTH

GENERAL INFORMATION 1-800-424-2411

-(10)S

-(10)Single D

-(10)S

-(10)S

INGLE DECK

INGLE DECK ELECTRONIC CONTROL

INGLE DECK

ECK ELECTRONIC CONTROL

Manual C

Manual C

ONTROL

ONTROL

FORM #GCI-MCOVN PRINTED IN THE U.S.A.

Page 2

This service manual is designed to answer questions related to model operational requirements,

troubleshooting and disassembly/assembly procedures. It contains electronic ignition operation, trouble-

shooting and electronic control operations that include diagnostic codes, ladder diagrams, wire diagrams and

troubleshooting. It also includes BTU ratings, orifice size and gas pressure technical data for each model.

For example; if you need to know information on manual controls (manual controls - controls the oven with hydraulic

thermostat, electric mechanical timer.) refer to SECTION 2: OVERVIEW OF OPERATIONAL SEQUENCES,

Sequence of Operation. This book is broken down into sections, each section will list the applicable topics. Use the

Table of Contents to locate the topic and function that you are attempting to trouble-shoot.

Table of Contents

SECTION 1: SPECIFICATION & DIMENSIONS............................................................................3

GAS CONVECTION OVEN "GAS SPECIFICATIONS”...............................................................................................4

DIMENSIONS & SPECIFICATIONS ............................................................................................................................4

SECTION 2: OVERVIEW OF OPERATIONAL SEQUENCES.......................................................4

MANUAL CONTROLS - "M” .......................................................................................................................................5

Sequence of Operation.............................................................................................................................................5

Manual Ladder Diagram...........................................................................................................................................5

CALIBRATION OF THERMOSTAT .............................................................................................................................5

Instrumentation.........................................................................................................................................................5

Weighting..................................................................................................................................................................6

Thermostat Operation...............................................................................................................................................7

ELECTRONIC CONTROLS - “E”................................................................................................................................8

Sequence of Operation (With the Oven Doors Closed) ...........................................................................................8

Electonic Ladder Wire Diagram................................................................................................................................8

ELECTRONIC CONTROL FAILURE CODES .............................................................................................................9

CHART FOR INTERNAL OVEN TEMPERATURE SENSOR......................................................................................9

ROBERTSHAW COM6000 CONTROLLER................................................................................................................9

USER PREFERENCE OFFSET FOR THE ELECTRONIC CONTROLLERS ...........................................................10

COM6000 UPO MODE...........................................................................................................................................11

COM6700 UPO MODE...........................................................................................................................................11

ELECTRONIC PILOT & MAIN BURNER IGNITION SEQUENCE ............................................................................12

FIRST STAGE - TRIAL FOR PILOT IGNITION .....................................................................................................12

SECOND STAGE - MAIN BURNER OPERATION ................................................................................................12

SAFETY LOCKOUT TIME......................................................................................................................................12

SERVICE ....................................................................................................................................................................13

PRELIMINARY CHECK..........................................................................................................................................13

SYSTEM TROUBLE SHOOTING...........................................................................................................................13

S86 CHECKOUT AND TROUBLE SHOOTING.....................................................................................................14

CHECK SPARK IGNITION CIRCUIT .....................................................................................................................15

CONTROL MODULE FLAME SENSOR CIRCUIT.................................................................................................15

2

Page 3

SECTION 3: COMPONENT ACCESS OF FUNCTIONAL COMPONENTS..................................16

DOOR GASKET REPLACEMENT............................................................................................................................17

TO REMOVE DOORS FROM THE OVEN................................................................................................................ 18

INSTALLATION OF OVEN DOORS.........................................................................................................................19

INSTALLING AND ADJUSTMENT OF THE DOOR CHAIN.....................................................................................19

DISASSEMBLY OF THE LEFT DOOR..................................................................................................................... 19

DISASSEMBLY OF THE RIGHT DOOR (W/O WINDOW).......................................................................................20

TO REPLACE OR ADJUST DOOR LATCH MECHANISM......................................................................................22

TO REPLACE CONVECTION OVEN MOTOR ASSEMBLY.................................................................................... 22

CONVECTION OVEN MOTOR ASSEMBLY............................................................................................................23

MAIN BURNER, PILOT BURNER & DOOR MICRO-SWITCH LOCATION ............................................................24

SECTION 4: COMMON WIRE DIAGRAMS.................................................................................25

SECTION 1: SPECIFICATION & DIMENSIONS

3

Page 4

GAS CONVECTION OVEN "GAS SPECIFICATIONS”

TOTAL

MAIN

BURNER

ORIFICE

PILOT

PILOT

ORIFICE

GAS

PRES. W/C

B.T.U.'S ORIFICE AMT. ORIFICE AMT. NAT PRO

NAT PRO

MCO

40,000

MCO

60,000

MCO

* - Gas pressure measured at burner manifold. ** - Gas pressure measured at redundant gas valve

pressure tap.

All models (single deck ovens) amperage rating is 6.2 (each oven). Manifold size is ¾" N.P.T. (National

Pipe Thread). NOTE: Two-speed motor, 1140 and 1725 R.P.M., 60 Hz, clock-wise motor rotation looking

into oven cavity. NOTE: Each deck supplied with a 6 ft. power supply cord for 120-volt units.

DIMENSIONS & SPECIFICATIONS

1-1/2

[38mm]

32

[813mm]

57-1/2

[1461mm]

25-1/2

[648mm]

Single Deck

INTERIOR DIMENSIONS (per oven) EXTERIOR DIMENSIONS SHIP WEIGHT/DIM

Model # W H D W H (w/legs) D Lb./KG Cu. Ft.

MCO-GS-10 29”(736mm) 24”(610mm) 24”(610mm) 38”(965mm) 57½”(1460mm) 39”(991mm) 510/232 42 cu. ft.

MCO-GS-20 29”(736mm) 24”(610mm) 24”(610mm) 38”(965mm) 70½”(1791mm) 39”(991mm) 1020/464 84 cu. ft.

MCO-GD-10 29”(736mm) 24”(610mm) 28”(711mm) 38”(965mm) 57½”(1460mm) 43”(1092mm) 510/232 42 cu. ft.

MCO-GD-20 29”(736mm) 24”(610mm) 28”(711mm) 38”(965mm) 70½”(1791mm) 43”(1092mm) 1020/464 84 cu. ft.

80,000

38

[965mm]

(Front View)

INPUT CHART - Natural or Propane Gas ELECTRICAL CHARACTERISTICS

Model #

MCO-GS-10 60,000 17.6 One @ ¾” NPT One @ 6.2 Amps One @ 3.1 Amps ½ HP

MCO-GS-20 120,000 35.2 One @1” NPT Two @ 6.2 Amps Two @ 3.1 Amps ½ HP

MCO-GD-10 60,000 17.6 One @ ¾” NPT One @ 6.2 Amps One @ 3.1 Amps ½ HP

MCO-GD-20 120,000 35.2 One @ 1” NPT Two @ 6.2 Amps Two @ 3.1 Amps ½ HP

5

/64”

(.0781”)

5

/64”

(.0781”)

5

/64”

(.0781”)

1/2 N.P.T.

[13mm]

GAS INLET

54-9/16

[1386mm]

38

[965mm]

BTU/HR

#55

#55

#55

1-7/16

[37mm]

43-1/4 DEEP

[1099mm] DEEP

39-1/4 STD

[997mm] STD

17-3/4

[451mm]

KW

Equiv.

7-3/4

[197mm]

2

3

4

2-3/8 x 5

[60mm x 127mm]

FLUE

(Top View)

Gas Inlet

NAT PRO

.020" .012"

.020" .012"

.020" .012"

1-1/2

[38mm]

1-7/8

[48mm]

REAR GAS INLET

38-1/4

[972mm]

120V/1 Phase

70-1/2

[1791mm]

*

1

1

1

32

[813mm]

32

[813mm]

6-1/2

[165mm]

38

[965mm]

Double Deck

240V/1 Phase Motor

(Front View)

4.5"

4.5"

4.5"

**

5.0”

5.1”

5.5”

32

[813mm]

19

[483mm]

10.0"

10.0"

10.0"

3/4 N.P.T.

[19mm]

GAS INLET

35-9/16

[903mm]

SECTION 2: OVERVIEW OF OPERATIONAL SEQUENCES

4

Page 5

Understanding the sequence of operation is necessary in properly trouble-shooting this appliance. In this section the

sequence of operation will be covered first, as well as calibration and operation of components, and basic trouble

shooting techniques for that specific model. Follow each sequence carefully, and get to understand its operation

before moving on to trouble shooting.

MANUAL CONTROLS - "M"

Sequence of Operation (Starting with the oven doors in closed position.)

1. Turn the Mode Switch to the “Cook” position. This sends line voltage to the timer.

And with the doors closed, line voltage is sent via the door switch to the thermostat

and the Hi/Lo Fan switch.

2. Select Hi or Lo speed, the motor will now be operational.

O

F

F

COOK

COOL

DOWN

POWER

ON

TIMER

HIGH

LOW

3. Rotate the temperature dial to desired temperature. The thermostat will now call for

heat sending line voltage to the 24 volt transformer. With the motor operating, the

centrifugal switch is closed, completing the neutral circuit to the transformer.

4. The 24v transformer now sends 24 volts to the ignition module.

TEMP

5. The *ignition sequence starts and oven temperature begins to rise.

*See “Ignition Sequence” later in this manual.

Below is a simplified power diagram:

Hi/Lo Sw.

Door Sw. Mode Sw.

Line

Light Sw.

CALIBRATION OF THERMOSTAT

INSTRUMENTATION

Hi/Lo Sw.

Timer

Thermostat

Hi Speed

Lo Speed

24 Volt

Transformer

Ign. Module

Neutral

Motor

Centrif. Sw.

5

Page 6

A thermocouple type test instrument is preferred for measuring oven temperatures accurately. Mercury thermometers

are acceptable providing they can be proven accurate.

Regardless of the type instrument used, it is most desirable to double-check it just before making an oven temperature

check. This can be done simply and quickly by placing the thermocouple tip (or immersing the entire mercury

thermometer) in boiling water. Note: Mercury oven thermometers should be the "total immersion type." The

resulting reading should be within several degrees of 212°, -depending on the altitude.

Generally, a mercury thermometer can drop in excess of 25° when the doors are opened to check oven tem perature.

This condition makes it extremely difficult to get a true temperature reading.

Almost all ranges today have oven burners which cycle "on and off." The high and low points of the resulting

temperature "swing" (differential) in the oven must be measured-and averaged-to determine the true operating

temperature. A thermocouple type test instrument is best suited to measure these temperature changes quickly and

accurately, and without opening the oven door.

With an accurate, thermocouple test instrument or mercury thermometer, it is still difficult to measure these changing

oven temperatures and then, average them correctly. This is why we recommend that the thermocouple tip or the bulb

of the thermometer be "weighted." Weighting (adding mass) to the test instrument compensates for oven temperature

changes by making the test instrument less sensitive to these constant changes in temperature. Note: How this

weighting can be done is discussed later.

Measuring these changing high and low temperatures points in an oven is possible with either type of test device

without weighting but is subject to possible inaccuracies. This is most true at low temperature setting because, in this

area, the function of "time" becomes a factor. The simple averaging of temperatures, then, may not produce the true

operating temperature. "Weighting" provides the compensation for both time and temperature that is necessary.

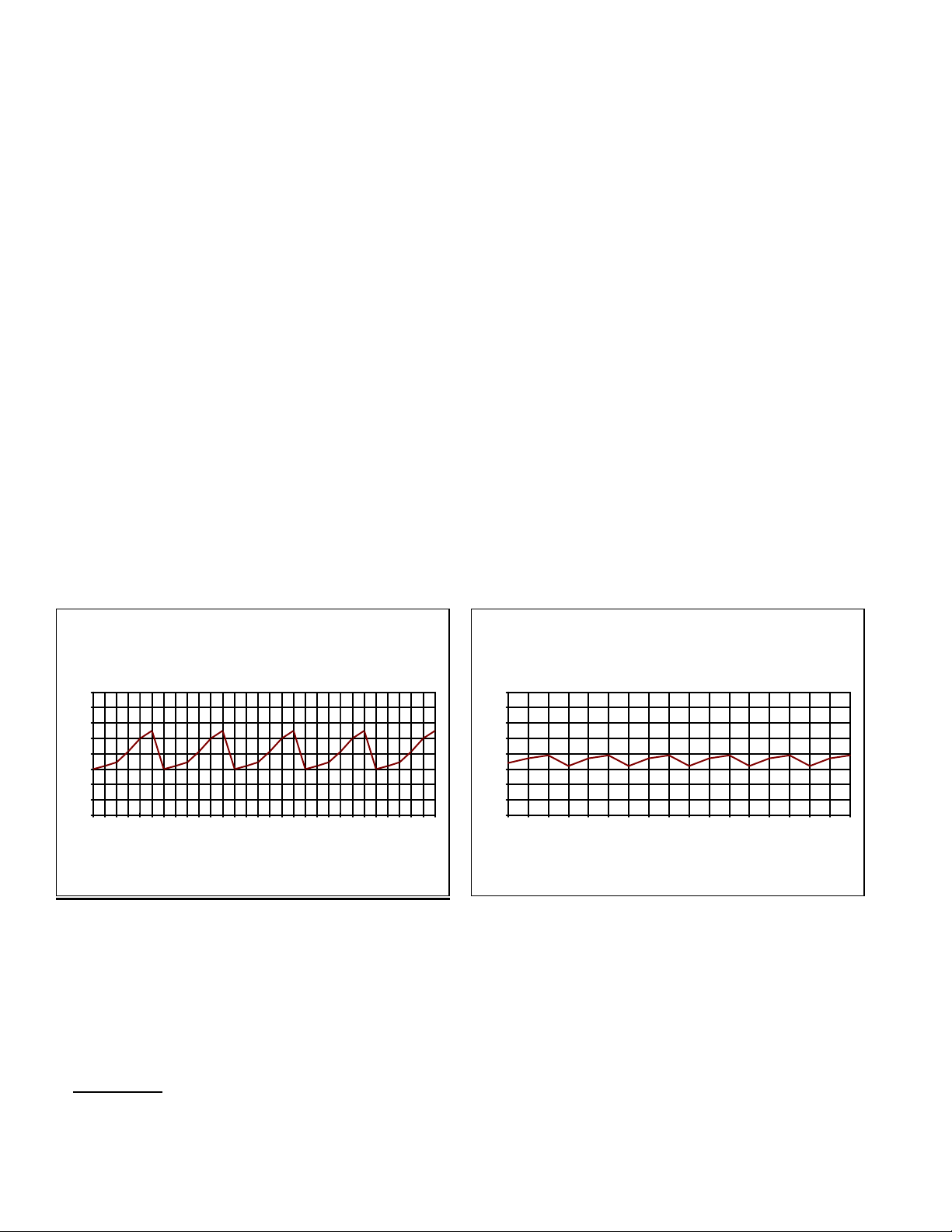

We produced (next page) test curves showing actual results in the low temperature area showing the difference in

results when using an unweighted and a weighted thermocouple or thermometer. Tests were made with the same

control, same oven and dial at 170° mark (not move d).

Chart No.1

260

240

220

200

180

160

140

120

100

Unweighted Thermocouple dial setting 170 F

260

240

220

200

180

160

140

120

100

Weighted Thermocouple Dial Setting 170F

Chart No.2

From the above, it can be seen that an error of 15° is possible. Chart #1, unweighted thermocouple indicates an

erroneous average oven temperature of 185°. Chart #2, weighted thermocouple indicates the "average" or true

temperature to be 170°.

WEIGHTING

A thermocouple can be weighted by clamping the tip between two one-inch squares of 1/16" thick aluminum. The

thermocouple can also be weighted (just as successfully) by using a letter-size sheet of aluminum foil. Fold the foil

6

Page 7

five times doubling the thickness with each fold. After the fifth fold, place the thermocouple tip in the center of the

aluminum piece and fold once more. Finally, fold in the sides so that the foil clings to the thermocouple tip.

A mercury thermometer can be weighted in much the same way by wrapping several layers of aluminum foil around

the bulb end thus creating the necessary mass. This procedure is a must if you open an oven door to check

temperature.

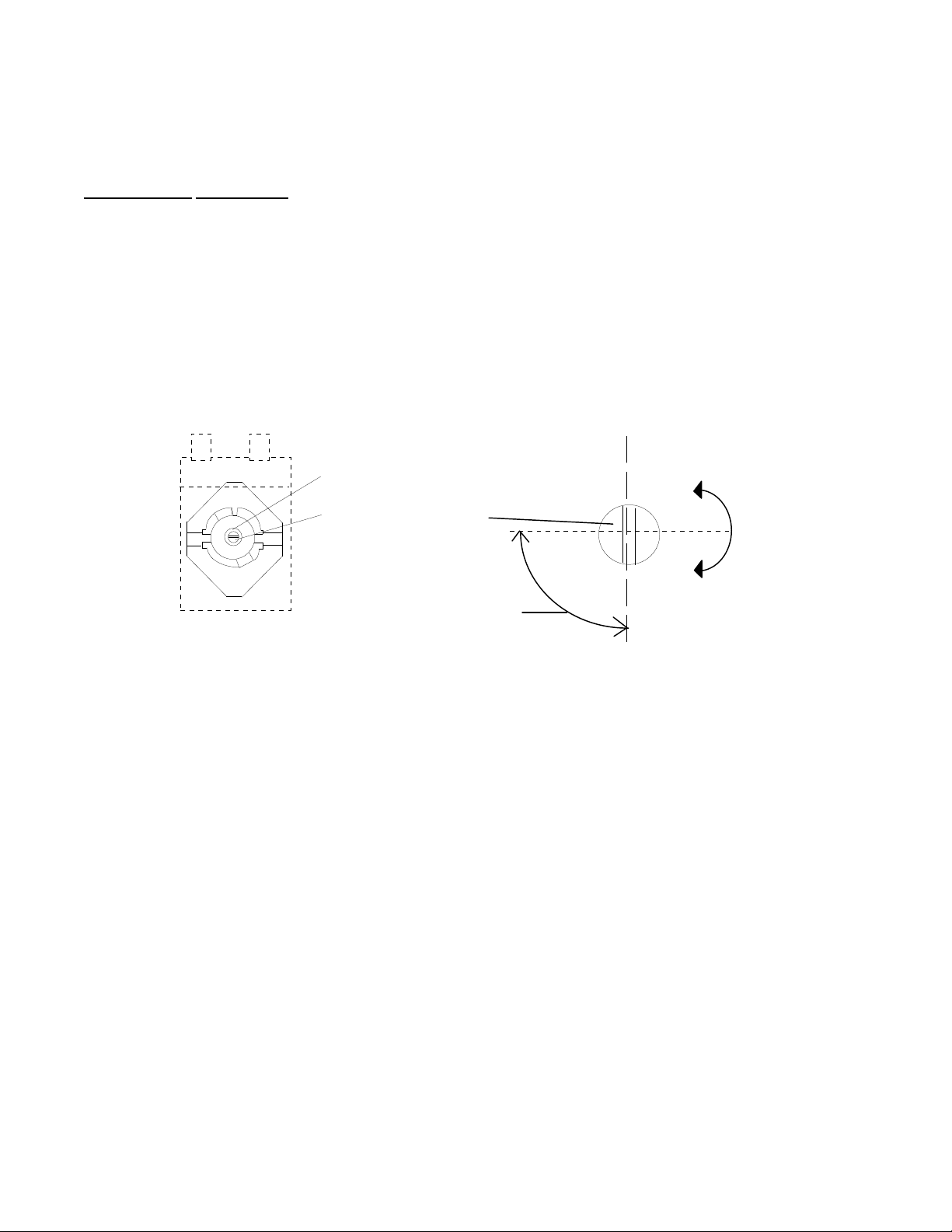

THERMOSTAT OPERATION

It is normal for a hydraulic thermostat cycling with a temperature swing of 45° to 50°. When checking calibration first;

allow the thermostat to cycle a minimum of four (4) times, second; place your temperature sensor in the geometric

center of the empty oven. Once the oven has been allowed to preheat record the temperature at which the burners

cycle "ON and OFF". Average the two readings, that average should be +-20° of the set point temperatu re.

Example: Thermostat set point at 300°, first cycl e Off at 325°. Cycle back ON at 291°. The average of 325° and

291° is 308°. This thermostat is with the +-20° to lerance. If the thermostat is cycling beyond the 20° tolerance and the

appliance is under warranty recalibrate the thermostat or if not under warranty consult owner for proper action. If

the thermostat is out of calibration more than fifty 50°, it will not likely hold an attempt of recalibration, we suggest that

the thermostat be replaced.

"B" Dial Shaft

"A" Calibration Screw Head

1/4" Turn

Increase

Decrease

- CALIBRATION NOTES -

7

Page 8

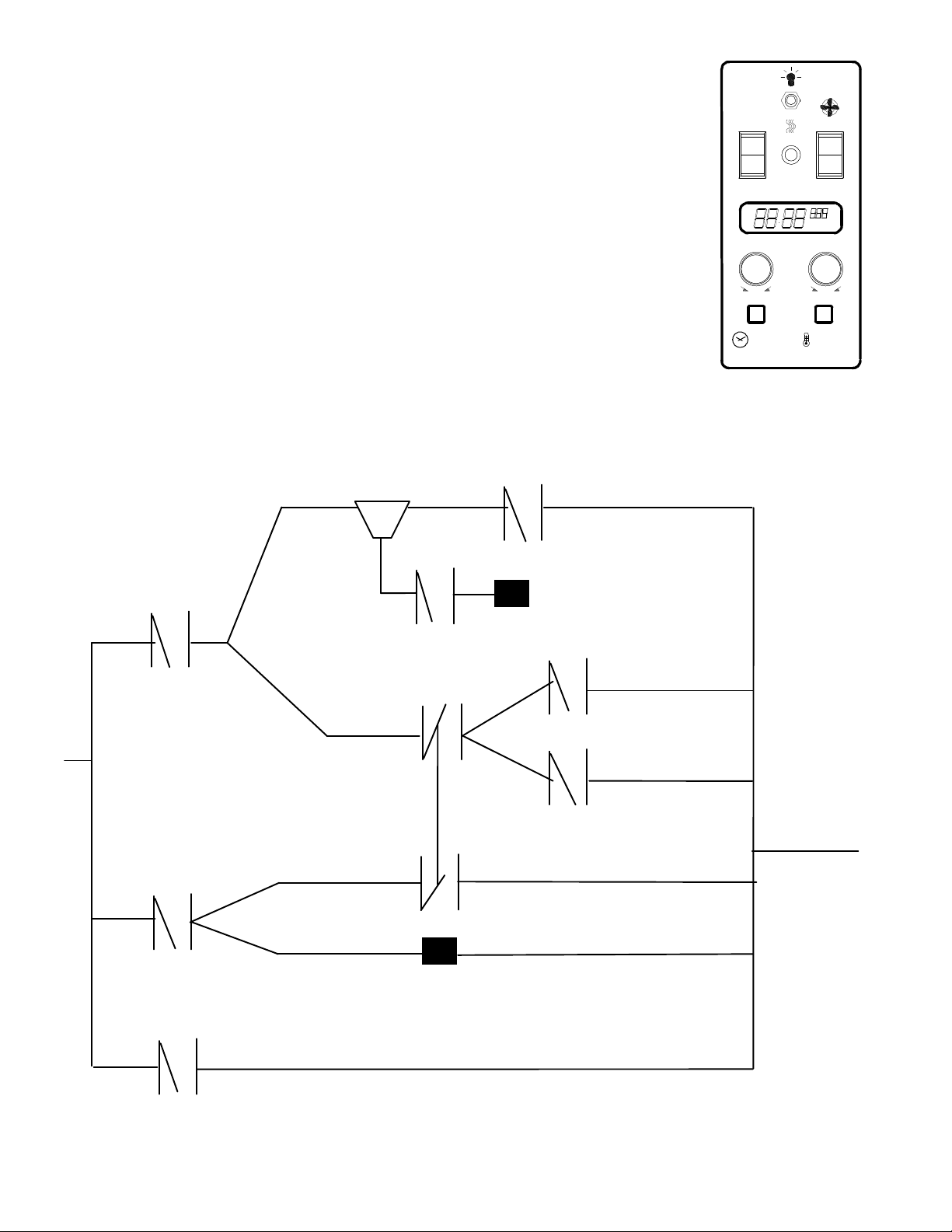

ELECTRONIC CONTROLS - “E”

Sequence of Operation (With the Oven Doors Closed)

1. Line Voltage is supplied to the Mode Switch, Door Switch and the Momentary Light

Switch.

2. Set Mode Switch to COOK and close the oven doors. Line Voltage is sent from Mode

Switch to power up the Controller and to the AUX relay on the controller. With the

oven doors closed Line Voltage is sent to the 24 volt transformer.

3. Set desired temperature. The controller’s relays now close.

4. The AUX relay sends Line Voltage to the motor relay coil, closing the circuit to the

Hi/Lo Fan Switch. The motor now operational causes the centrifugal switch to close

and send the Neutral Voltage to the 24 Volt Transformer.

5. The bake relay completes the circuit from the 24 volt transformer to the ignition

module and *ignition occurs, heating the oven.

Below is a simplified power diagram:

24 Volt

Transformer

Motor

Centrifugal Switch

COOK

O

F

F

COOL

DOWN

+- - +

START

TIMER

TIMER

0-12 HOUR

HEAT

HIGH

LOW

CANCEL

TIMER

TEMP

140-500F

Door Sw.

Mode Sw.

24 V

Thermostat

Ign. Module

Hi Speed

Motor Relay

Lo Speed

Neutral

AUX

COM6000

Light Sw.

8

Page 9

ELECTRONIC CONTROL FAILURE CODES

The GARLAND digital control has a self-diagnostic program. If a problem occurs within the digital controller, you may

see one of the "F" codes.

Below is a listing of the "F" codes with explanations:

-F1- Relay output is enabled when not cooking. If this failure code appears in the display, the cook relay may be on

even if the control is not cooking. The control should be replaced.

-F2- Over temperature alarm. If this failure code appears in the display the control is sensing an oven temperature

50° or more above the maximum set temperature (500°). This failure may be caused by a faulty sensor.

Check the sensor connection for loose wires.

Replace the sensor and check for proper operation.

If failure continues replace the control.

-F3- Open sensor circuit. If this failure appears in the display, the control is sensing an open circuit at the sensor

input. This failure is most often caused by a poor connection or broken sensor.

Check sensor connection and leads for broken wires of loose connections. Replace sensor and check for

proper operation. If failure continues replace control.

-F4- Shorted sensor circuit. If this failure appears in the display, the control is sensing a short circuit at the sensor

input. This failure is most often caused by loose wires at the connection of shorted sensor leads.

Check sensor connection and leads for loose wires. Replace sensor and check for proper operation. If failure

continues replace control.

-F5- Relay outputs not enabled when cooking. If this failure appears in the display the control cannot turn the

relays on even when cooking. The control should be replaced.

-F6- No 60 Hz input. The control does not sense the input power. This failure mode is most often the result of a

failed component in the control. However, this failure may also be the result of a very noisy power line. Look

for any large electrical noise producing machinery (such as mixers, compressors, dishwashers etc.). If

possible, turn these machines off. Reapply power to the oven. If the failure repeats, replace the control. If

the failure does not repeat, an electronic control may not work in this application because of noise. You must

-F7- The control has detected that calculated EEPROM check sum is not the same as the expected check sum

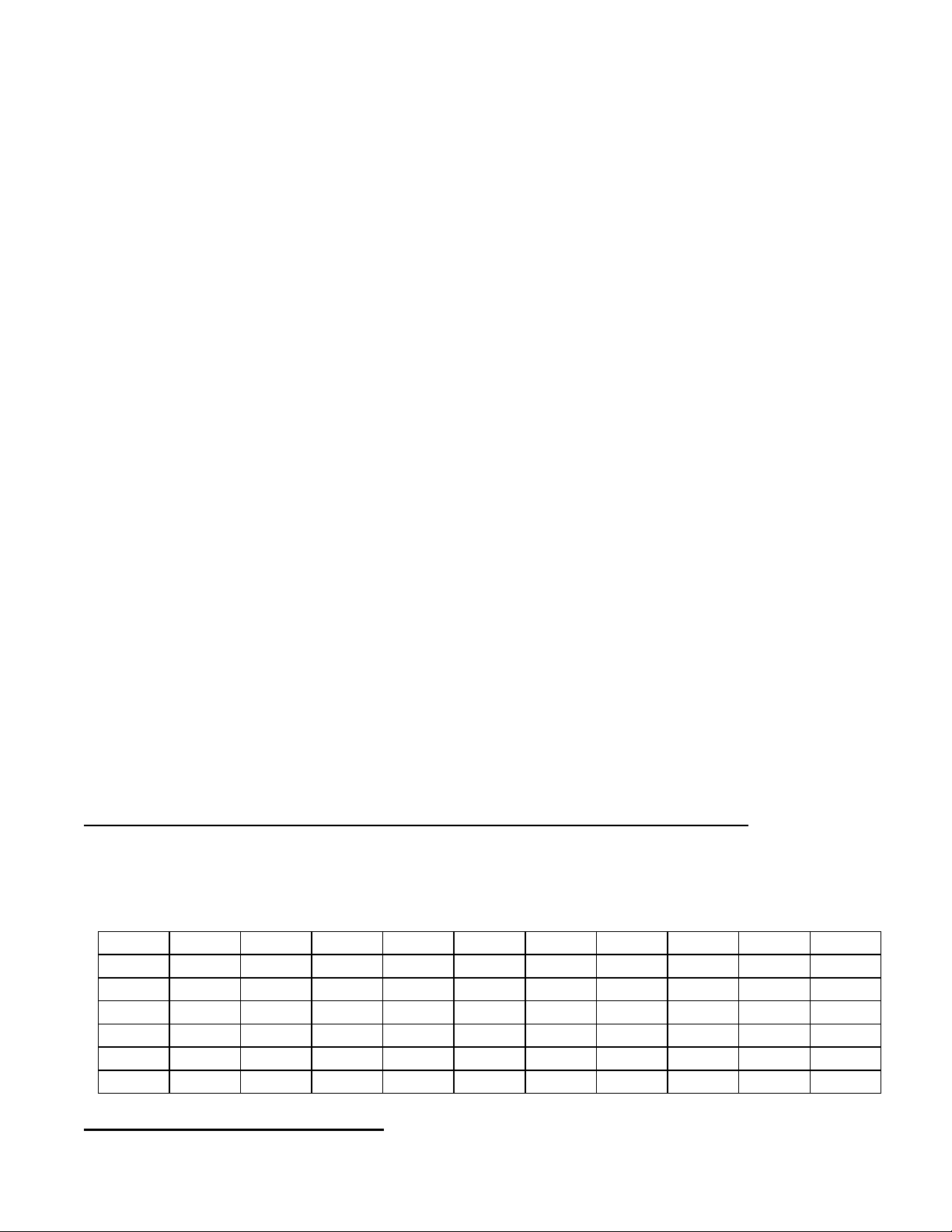

RESISTANCE vs. TEMPERATURE CHART FOR INTERNAL OVEN TEMPERATURE SENSOR

The chart below will provide the Ohms at various temperatures. This will enable you to determine if the temperature

probe is operable.

The chart is in Degrees Fahrenheit. How to use chart, for 350°, read down to 300 then across to 50, answer is

1654Ohms of resistance.

isolate the supply circuit.

retrieved from the EEPROM. When the control detects this error code, it will disable outputs before the alarm

sounds.

TEMP 0° 10° 20° 30° 40° 50° 60° 70° 80° 90°

0°

100°

200°

300°

400°

500°

ROBERTSHAW COM6000 CONTROLLER

932 953 974 995 1016 1038 1059 1080 1101 1122

1143 1163 1184 1205 1226 1247 1267 1288 1309 1329

1350 1370 1391 1411 1432 1452 1472 1493 1513 1533

1553 1574 1594 1614 1634 1654 1674 1694 1714 1733

1753 1773 1793 1813 1832 1852 1871 1981 1911 1930

1949 1969 1988 2008 2027 2046 2065 2085 2104 2123

9

Page 10

The controller needs voltage to operate and is capable of operating on three (3) different line voltages, 115 Vac,

120V

208 Vac, 240 Vac. On the back of the Robertshaw COM6000 there are several ¼” male spade terminal or pin

connections. The below is a drawing of the rear of a Robertshaw COM6000 Controller along with a definition of each

of the pin connections.

240V

E5

208V

E4 E3

E2

NEUTRAL

AUX

BAKE

DOOR

E9

E10

E11

E12

E8

REAR VIEW

E1

E6

E7

GROUND

PROBE

+- - +

START

TIMER

FRONT VIEW

CANCEL

TIMER

OPERATION OF THE TEMPERATURE FUNCTION

When the controller is powered up, the LED will be illuminated. To enter a cook temperature, rotate the right dial. The

digits will go up as you rotate the dial to the right and decrease if rotated to the left. The controller determines if the

oven is at set temperature by the RTD sensing probe. If the controller senses that the oven is below the displayed set

temperature, the controller activates the bake relay, calling for heat. At the same time the temperature digits begin to

blink indicating that the controller is calling for heat. Once the controllers’ set temperature is satisfied the temperature

digits will stop flashing and remain constant, and deactivating the bake relay. NOTE: The temperature digits will

remain constant unless the set temperature is altered. If altered, the digits will again blink until the new set

temperature is reached. The controller will hold a tolerance of +/- 5°. To access the actual oven temperature, depress

the start key for three (3) seconds and the temperature will now display the actual oven temperature.

OPERATION OF THE TIMER FUNCTION

To enter a desired cook time rotate the left time dial. The digits will display, (in the first hour), minutes & seconds.

Above the first hour, the timer will display in hours & minutes. The diplay will continue to blink until the “START

TIMER” key is depressed. The resolution of the timer can be altered to display only hours and minutes if desired, see

User Preference Programming in the following pages. At the end of the timed period an alarm will sound until operator

depresses the “Cancel Timer” key. The timer (in standard mode), has no effect on the bake relay.

OPERATION OF THE COOK’n HOLD FUNCTION

When the controller has a HOLD temperature programmed, the controller operates a little differently. As noted earlier,

set cook temperature and time. When the timer counts down to 00:00 the alarm will sound for five (5) seconds and

the word HOLD will now be displayed in the time side of the LED display. The “AUX” relay will also be deactivated at

this time and stop the oven fan. At the same time the cook temperature will change to the new hold temperature that

was preprogrammed in the controller. This new temperature will now blink, indicating that a new set temperature must

be reached. Once this new set temperature is reached the digit will go constant. After reaching the new set

temperature the “AUX” relay (oven fan) and “Bake” relay (heat) will cycle together. To cancel, depress the “Cancel

Timer” key on the control. This controller will remain in this COOK’n HOLD program until removed, see User

Preference Programming in the following pages.

OPERATION OF THE PULSE FUNCTION

When Pulse Program has been entered in the controller, the “AUX” relay will open for 30 seconds and close for 30

seconds. The 30 seconds open & closed is a factory preset time and cannot be altered in the field. The controller will

remain in this Pulse Program until removed, see User Preference Programming in the following pages.

USER PREFERENCE OFFSET FOR THE ELECTRONIC CONTROLLERS

10

Page 11

The User Preference Offset is designed to enable the user to adjust the controlling temperature. There are two

different styles of controllers used by GARLAND at the present time. They are the Robertshaw COM6000 and

COM6700 Series. To determine which of the controllers you are working on, look at the back of the controller and you

will see a sticker with a printed number like “PN:100-289-03”, below this number is the controller style number. For

example: COMA-6704-GL. This indicates that controller is in the COM6700 Series. Or if the number was “COM6000-GA” it would indicate that it is a COM 6000.

COM6000 UPO MODE

Entry Exit

UPO - User Preference Offset. Used by the user to adjust the controlling temperature +/- 50º in 1º

increments.

1. Set the time digits to 00:00.

2. Set the temperature digits to X10º.

3. Depress both the Start and Cancel buttons for five seconds.

TO CHANGE FAHRENHEIT TO CELSIUS (and vise versa)

1. Set the time digits to 00:00.

2. Set the temperature digits to X20º.

3. Depress both the Start and Cancel buttons for five seconds.

4. Rotate either dial to display FFF or CCC in the temperature display

TIMER RESOLUTION CHANGING

1. Set the time digits to 00:00.

2. Set the cook temp to X30º

3. Depress both the Start and Cancel buttons for five seconds.

4. Rotate either dial to display “HR” or “MN”.

CHANGE THE HERTZ

1. Set the time digits to 00:00.

2. Set the cook temp to X40º

3. Depress both the Start and Cancel buttons for five seconds.

4. Rotate either dial to display “50” or “60” Hz.

TO SET HOLD TEMPERATURE

1. Set the time digits to 00:00.

2. Set the cook temp to X50º

3. Depress both the Start and Cancel buttons for five seconds.

4. The word “hold” will now be displayed in the time display. Rotate either dial to

set hold temperature.

TO SET OVEN INTO PULSE MODE

1. Set the time digits to 00:00 and temperature digits to 000°.

2. Depress both the Start and Cancel buttons.

3. Rotate either dial to display “con” for continuous operation or “cyc” for cycling

fan on & off.

1. Depress the

Cancel button to

lock-in

1. Depress the

Cancel button to

lock-in.

1. Depress the

Cancel button to

lock-in.

1. Depress the

Cancel button to

lock-in.

1. Depress the

Cancel button to

lock-in.

1. Depress the

Cancel button to

lock-in.

COM6700 UPO MODE

11

Page 12

Entry Exit

UPO - User Preference Offset. Used by the user to adjust the controlling temperature +/- 50º in 1º

increments.

1. Set the time digits to 00:00.

2. Set the temperature digits to X10º.

3. Depress & hold the Start button for five seconds.

4. “UPO” & Current UPO will be displayed. Turn TEMP or TIME dial to adjust.

TO CHANGE FAHRENHEIT TO CELSIUS (and vise versa)

1. Set the time digits to 00:00.

2. Set the temperature digits to X20º.

3. Depress & hold the Start button for five seconds.

4. Rotate either dial to display FFF or CCC in the temperature display

TIMER RESOLUTION CHANGING

1. Set the time digits to 00:00.

2. Set the cook temp to X30º

3. Depress & hold the Start button for five seconds.

4. Rotate either dial to display “HR” or “MN”.

CHANGE THE HERTZ

1. Set the time digits to 00:00.

2. Set the cook temp to X40º

3. Depress & hold the Start button for five seconds.

4. Rotate either dial to display “50” or “60” Hz.

CHAIN PROGRAMMING

1. Press Pgm Mode on/off.

2. Select Pgm # (1-5).

3. Enter Event 1 parameters (time, temp, fan speed etc.). Press Event # key to

chain 2nd event.

4. Enter Event 2 parameters.

5. Continue procedure up to six events.

1. Depress the

Actual Temp

button to lock-in.

1. Depress the

Actual Temp

button to lock-in.

1. Depress the

Actual Temp

button to lock-in.

1. Depress the

Cancel button to

lock-in.

1. Press Pgm

Mode on/off to

exit program

mode.

ELECTRONIC PILOT & MAIN BURNER IGNITION SEQUENCE

FIRST STAGE - TRIAL FOR PILOT IGNITION

On every call for heat (system start), the S86 performs an internal safe-start check shows that a flame-simulating

condition is present. During a normal start, the S86 opens the pilot valve in the gas control. This allows gas to flow to

the pilot burner. Simultaneously, the electronic spark generator in the S86 produces a 15,000 volt spark pulse output.

This voltage produces a spark at the pilot burner ignitor/sensor rod, igniting the gas flowing around the electrode. If

the pilot flame is not detected during the trial for pilot ignition, the S86H contains a safety lockout timer (90 Seconds) to

limit the trial for pilot ignition period.

SECOND STAGE - MAIN BURNER OPERATION

When the pilot flame is established, a flame rectification circuit is completed to the burner ground. The S86 flame

sensing circuit detects the flame current and shuts the spark generator off. At the same time, the second operator

(main gas valve) is opened in the gas control, allowing gas flow to the main burners. The pilot flame ignites the main

burner conventionally.

SAFETY LOCKOUT TIME

12

Page 13

The safety lockout timer circuit starts timing the moment the trial for pilot ignition starts. When the timing period runs

out, the trial for ignition ends, and the control module goes into lockout. Before another attempt to start can be made,

the S86 must be reset. Reset by adjusting the thermostat or controller or to its "OFF" position. An alternate method is

to shut the system power "OFF". If normal ignition does not occur, use the trouble shooting table to determine the

problem.

SERVICE

PRELIMINARY CHECK

The following visual checks should be made before trouble shooting and after installation or maintenance.

1. Check power to appliance and S86.

2. Manual shutoff cocks in gas line to appliance must be open.

3. Make certain all wiring connections are clean and tight.

4. First de-energize the system and wait at least one (1) minute. This resets the module allowing a return to start

5. Review the S86 system normal sequence of operation.

SYSTEM TROUBLE SHOOTING

Start the system by setting the thermostat or controller above required temperature. Observe system response.

Establish type of malfunction or deviation from normal operation. Use the S86 Intermittent Pilot System Trouble

Shooting Table to check for normal system operation.

Use table by following instruction questions in box. If the condition is true or okay (answer yes), go down to next box

underneath. If the condition is not true or not okay (answer no), go right to the next box alongside. Continue checking

START

STAGE 1

TRIAL FOR

IGNITION

STAGE 2

MAIN BURNER

OPERATION

END

condition. Then energize the system.

1111

THERMOSTAT (CONTROLLER) CALLS

FOR HEAT

2222

SPARK GENERATOR POWERED

First valve (pilot) operator opens

3333

PILOT BURNER OPERATION

Pilot burner lights.

Module senses flame

current.

4444

FLAME CURRENT SENSED

•

Spark generator off.

•

Second valve operation (main) opens.

5555

MAIN BURNER OPERATION

Module monitors pilot flame current.

6666

THERMOSTAT (CONTROLLER) SATISFIED

Valves close, pilot and main burners are off.

OR Pilot burner does not light.

After 90 seconda system

locks out; must be manually

a

Shutoff/lockout timing is stamped on module.

reset.

POWER INTERRUPTION

System shuts off, restarts

when power is restored.

PILOT FLAME FAILURE

Main valve closed.

Module starts trial for ignition.

13

Page 14

and answering conditions in each box encountered, until a problem and/or the repair is explained. After any

with the startup and checkout procedure.

TURN GAS SUPPLY OFF.

POWER TO MODULE (24v

maintenance or repair, the trouble shooting sequence should be repeated until the trouble shooting procedure ends

with a normal system operation.

START

TURN THERMOSTAT

(CONTROLLER) TO CALL

YES

IGNITOR/SENSOR GAP

YES

TURN GAS SUPPLY ON

PILOT BURNER LIGHTS?

YES

YES

YES

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS

SYSTEM SHUTS OFF?

YES

S86 CHECKOUT AND TROUBLE SHOOTING

FOR HEAT

NOMINAL)

SPARK ACROSS

SPARK STOPS WHEN

PILOT IS LIT?

MAIN BURNER

LIGHTS?

CALL FOR HEAT

LOSS?

YES

TROUBLESHOOTING

ENDS

NO

NO

NO

• Check continuity of ignition cable to ground wire.

• Clean flame rod.

NO

• Check electrical connection between flame rod and module.

• Check for cracked ceramic flame rod insulator.

• Check that pilot flame covers rod and is steady and blue.

• Adjust pilot flame.

• If problem persists, replace module.

• Check for 24 Vac across MV-MV\PV terminals. If no voltage, replace module.

NO

• Check electrical connections between module and gas control. If okay, replace

NO

• Check continuity of ignition cable and ground wire.

• Check that pilot flame covers flame rod and is steady and blue.

• If checks are okay, replace module.

NO

• Check for proper thermostat (controller) operation.

• Remove MV lead at module; if valve closes, recheck temperature controller and

Check line voltage power, low voltage transformer, limit controller, thermostat

(controller) and wiring.

Pull ignition lead and

check spark at module.

Spark okay?

YES

• Check ignition cable, ground wiring, ceramic insulator and gap, and correct.

• Check boot of the ignition cable for signs of melting or buckling. Take protective

action to shield cable and boot from excessive temperature.

• Check that all manual gas valves are open, supply tubing and pressure are good,

and pilot burner orifice is not blocked.

• Check electrical connections between module and pilot operator on gas control.

• Check for 24 Vac across PV-MV\PV terminals on module. If voltage is okay,

replace gas control; if not, replace module.

NOTE: If S8600B,H; S8610B, H goes into lockout, reset system. For S8600M,

wait 6 minutes nominal for retry or reset system.

gas control or gas control operator.

NOTE: If S8600B,H; S8610B, H goes into lockout, reset system. For S8600M,

wait 6 minutes nominal for retry or reset system.

NOTE: If ground is poor or erratic, shutdowns may occur occasionally even

though operation is normal at the time of checkout.

wiring; if not, replace gas control.

Repeat procedure until troublefree operation is obtained.

NOTE: Before troubleshooting, familiarize yourself

• On models with vent damper plug, make sure vent

NO

damper had not been installed, then remove.

Replace vent damper if necessary.

• On other models, replace module.

14

Page 15

CHECK GROUNDING

A common ground is required for the pilot burner, the ignitor-sensor, the GND terminal of the S86, and the main

burner. The main burner generally serves as the common ground. If the ground is poor or erratic, safety shutdowns

may occur occasionally even though operation is normal at the time of the checkout. Therefore, if nuisance

shutdowns have been reported, be sure to check the grounding.

NOTE: If the ground circuit path is incomplete, the S86H system control will allow one trial-for-ignition

before going into safety lockout.

Electrical grounding connections at the pilot burner, ignitor/sensor and S86 must be clean and tight. If lead wire is

damaged or deteriorated, use only No. 14 of 18 gauge, moisture-resistant, thermoplastic insulated wire with 105°C.

(221°F) minimum rating as replacement. Excessive temperature at the ceramic flame rod insulator can also permit

electrical leakage to ground. Examine the flame rod and mounting bracket, and correct if bent out of position.

Replace ignitor/sensor of insulator is cracked.

CHECK SPARK IGNITION CIRCUIT

The electronic module and step-up transformer in the S86 provides spark ignition at 15,000 Volts (open circuit). This

circuit can be checked at the S86 module as follows:

1. Turn off the manual gas cock to prevent the flow of gas.

2. Disconnect the ignition cable at the S86 stud terminal to isolate the circuit from the pilot burner/ignitor/sensor, and

prepare a short jumper lead using heavily insulated wire, such as ignition cable.

3. Energize the S86. Touch one end of the jumper firmly to the S86 ground terminal (GND). Do not disconnect the

existing ground lead. Move the free end slowly toward the stud terminal to establish a spark and then pull the

lead wire slowly away from the stud. Note the length of the gap at which arcing stops.

CAUTION: Do not touch either stripped end of jumper or stud terminal. This is a very high voltage circuit

and electrical shock can result. Perform the test immediately upon energizing the system before the S86H goes into safety lockout and interrupts the spark circuit.

4. An arc length of 1/8" (3.2 mm) or more indicates satisfactory voltage output. Replace the S86 if no arc can be

established or the maximum gap is less than 1/8" (3.2 mm), and the fuse and power to the S86 input terminal

was okay.

CONTROL MODULE FLAME SENSOR CIRCUIT

The control module provides AC power to the ignitor/sensor which the pilot burner flame rectifies to direct current. If

the flame signal back to the control module is not at least 1.0 µA DC, the system will lockout. The output of the flame

sensing circuit cannot be checked directly, so check the flame sensing circuit indirectly by checking the flame sensing

current from the ignitor/sensor to the control module as follows:

1. Connect a meter (DC micrometer scale) in series with the flame signal ground wire (Burner Ground Terminal).

Disconnect the ground wire at the control module. Connect the red (positive) lead of the meter to the free end of

the ground wire. Connect the black (negative) meter lead to the quick-connect ground terminal on the control

module.

2. Restart the system and read the meter. The flame sensor current must be at least 1.0 µA, and the reading must

be steady. If the reading is below the value designated or the reading is unsteady, check the pilot flame and

electrical connections as described above. Also, replace the ignitor/sensor if the ceramic insulator is cracked.

EXAMPLES OF UNSATISFACTORY PILOT FLAMES

15

Page 16

APPEARANCE

SMALL BLUE FLAME

CAUSE

Check for lack of gas from:

• Clogged orifice filter

• Clogged pilot filter

• Low gas supply pressure

• Pilot adjustment at minimum

LAZY YELLOW FLAME

WAVING BLUE FLAME

NOISY LIFTING BLOWING FLAME

Check for lack of air from:

• Large orifice

• Dirty lint screen, if used

• Dirty primary air opening, if there is one

• Pilot adjustment at minimum

Check for :

• Excessive draft at pilot locations

• Recirculating products of combustion

Check for:

• High gas pressure

HARD SHARP FLAME

SECTION 3: - A

CCESS OF FUNCTIONAL COMPONENTS

This flame is characteristic of manufactured gas

Check for:

• High gas pressure

• Orifice too small

16

Page 17

This section will give you the best way to access component for replacement.

COMPONENT LOCATIONS:

Top Front Center

Door Chain

Door Catch

Right Front

Control Panel

24v Transformer, Ignition module

Redundant gas valve

Lower Front

Door Micro-Switch

Data Plate, Burner Package

Inside Oven

Oven Convection Motor

Oven Interior Lights

Single Deck

(Front View)

Door Gasket Replacement

1. Open oven doors

17

Page 18

2. Locate stainless steel door gasket, mounted to oven front frame.

3. Remove the #10 Phillips sheet metal screw that attach the retainer to the oven's front

frame.

4. Remove stainless steel door gasket.

5. Replace stainless steel door gasket and to reverse above procedure to re-install.

1

2

To Remove Doors from the Oven

1. Remove top front cap veneer.

FILE NAME

JIT03418

2

3

18

Page 19

2. Remove door chain assembly (NOTE: The “A” model does not come equipped with door

chain).

3. Remove flat head metal screw 1/4”-20x1/2” from bearing retainer.

4. Push the door toward hinge and lift up. NOTE: Bottom bearing retainer will stay in place.

5. Remove the right door in the same manner.

1

2

3

4

To Reinstall Doors onto Convection Oven

1. Reverse procedure above.

2. Close doors.

3. Reinstall the door chain.

Installing and Adjusting Door Chain

4. Make sure two links are between

sprocket and door rod, and there

should be 8 regular links plus one

master link on the forward side of

each chain.

5. Tighten up turn buckles, the right

door should close approximately ½”

before the left door.

Turnbuckles

6. Secure the turnbuckles by tightening

lock nuts.

8 Links

2 Links

Locking Nuts

Door Stop Bolt

FILE NAME

JIT03459

Disassembly of the Left Door

19

Page 20

7

NOTICE: DEPENDENT DOOR SHOWN

6

3

4

5

8

2

7

1

7

To disassemble left door:

1. Once the door has been removed from the oven (refer to instructions on the previous page),

remove the 12 truss head 10 x ½ Phillips screws

2. Remove 2 allen head cap screws from the door handle

3. Carefully pry off the door panel

4. Remove 2 hex head m.s. ¼ -20 x ½ from the door liner

the door liner

5. Lift out the door frame

6. Carefully pry off the door window

7. To remove door catch

8. To reassemble - reverse above procedure.

NOTE: There is a seam one side of the bezel that is part of the door window

working from the opposite side that the seam is on and work around the window

towards that seam.

Disassembly of the Right Door (w/o window)

.

.

remove 2 pan head Phillips screws.

from the door window bezel

for door liner

.

.

.

that attach hold down straps

.

, reinstall

to

20

Page 21

5

NOTICE: DEPENDENT RIGHT HAND DOOR SHOWN.

1

2

3

4

1. Once the door has been removed from the oven (refer to instructions on page 19), remove 9

truss head s.m.s. 10 x ½

.

2. Pry the door liner

3. To reassemble, reverse above procedure.

from the top, bottom and left side (as shown) from the door panel

apart from the door panel

. This will expose the door frame

.

21

Page 22

To Replace or Adjust Door Latch Mechanism

1. Open oven doors.

2. Remove 2 pan head Phillips screws.

3. Lift door latch mechanism up and out of door

assembly.

4. To adjust latch mechanism , loosen lock nut & and

adjust by tightening or loosening adjustment nut.

To Replace Convection Oven Motor Assembly

(Drawing Below)

1. Open doors and remove all oven racks.

2. Remove 4 #10 sheet metal screws (that secure air baffle)

and remove air baffle.

3. Remove six hex nut 1/4-20x7/16" (2A) and lock washers

(4A) from motor mounting studs.

4. Place a piece of cardboard on oven floor to protect from

scratching or chipping.

1

3

6

2

4

5

5. Pull entire motor assembly (1A) away from rear oven wall

into oven cavity and place on cardboard.

6. Disconnect wiring, be sure to note wire locations.

7. To reinstall reverse above procedure.

1A

FILE NAME

JIT00024

4A

2A

Convection Oven Motor

22

Page 23

Assembly

7

6

2

1

3

5

5

FILE NAME

JIT00012

4

8

9

1. Assemble motor mount plate, * insulation, motor mount plate inner together by

fastening four flat head m.s. 1/4-20x2½" into the four holes noted on the above drawings.

2. Secure each flat head m.s. 1/4-20x2½" with a flat washer and three hex nuts 1/4-20 .

3. Attach motor mounting plate to motor . Insert the four flat head m.s. 1/4-20x2½" through

the mounting tabs on motor as shown. Secure with two hex nuts 1/4-20 .

4. Insert shaft of motor through the hub of the blower wheel . Space the blower wheel

¼" away from the inner motor mounting plate .

5. Secure the blower wheel to the shaft of the motor by tightening the two set screws

on the blower wheel hub. Use a torque wrench and tighten to 180 inch pounds for proper

securing.

***** For warranty replacement we require that you use the motor assembly. Order motor

assembly part # CK1003090 - 2 Speed, 115 Vac, or CK1003091 2 Speed, 208/240 Vac (Export

or Special), CK1003092 - 1 Speed, 115,208,240 Vac.

23

Page 24

Main Burner, Pilot Burner Removal & Door Micro Switch Location

3

4

2

1

To access the Burners, Pilot or Door Switch - remove the lower combustion chamber, (not show).

This exposes these components, also you will note that the rating or data plate is on the inside of

the combustion shroud.

For ovens that are 80,000 B.T.U.’s there are four burners, 60,000 B.T.U.’s there are three burners

as shown in the above illustration, and 40,000 B.T.U.’s there are two burners. On 40,000 B.T.U.

models the pilot is located where the left or first burner usually is. The two main burners are

located in the center of the burner manifold. By centering the burners it provides more uniform

heating of the oven cavity.

24

Page 25

SECTION 4: - C

OMMON WIRE DIAGRAMS

25

Page 26

26

Page 27

27

Page 28

28

Loading...

Loading...