Page 1

ORIGINAL USER MANUAL

INSTALLATION AND

OPERATION MANUAL

"THE MASTER"

GAS CONVECTION OVEN

(GB, IE) 0086

Français .............................................................................................. Page 17

Deutsch.............................................................................................. Seite 35

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

Manufactured by

CLEVELAND RANGE

1333 East 179TH Street

Cleveland, Ohio 44110

USA

WARNING:

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Part # 1955201 REV 7 (11/28/12) © 2005 Garland Commercial Industries, LLC

Page 2

IMPORTANT INFORMATION

THE BURNER PRESSURE IS FACTORY SET AND LOCKED. IT MUST NOT BE ADJUSTED BY THE USER.

A COMPETENT PERSON MUST MAKE INSTALLATION OF THIS OVEN IN ACCORDANCE WITH THE LOCAL CODES OF

THE COUNTRY OF DESTINATION.

THIS OVEN MUST BE MAINTAINED AND SERVICED BY A FACTORY CERTIFIED SERVICE ENGINEER. A QUALIFIED GAS

ENGINEER MUST MAKE ALL BURNER ADJUSTMENTS AND SETTINGS. GARLAND RECOMMENDS PERIODIC SERVICE

CHECKS BE PREFORMED EVERY SIX MONTHS.

THIS OVEN MUST ONLY BE OPERATED BY QUALIFIED PERSONS. DO NOT OPERATE THE OVEN WITHOUT READING

THIS OPERATION MANUAL.

DO NOT OPERATE THE OVEN UNLESS IT HAS BEEN PROPERLY INSTALLED AND EARTHED.

DO NOT OPERATE THE OVEN UNLESS ALL SERVICE AND ACCESS PANELS ARE IN PLACE AND FASTENED PROPERLY.

THE OVEN DOES NOT EMIT AIRBORNE NOISE IN EXCESS OF A CONTINUOUS A-WEIGHTED SOUND PRESSURE LEVEL

OF 75dB(A).

IT IS THE RESPONSIBILITY OF THE SUPERVISOR OR EQUIVALENT PERSON TO ENSURE THAT USERS OF THIS

EQUIPMENT WEAR SUITABLE PROTECTIVE CLOTHING AND TO DRAW ATTENTION TO THE FACT THAT SOME PARTS

WILL BY NECESSITY BECOME VERY HOT, AND WILL CAUSE BURNS IF TOUCHED ACCIDENTALLY.

WARNING: THIS APPLIANCE MUST NOT BE CLEANED WITH A PRESSURE JET!

Page 2

Part # 1955201 Rev. 7 (11/28/12)

Page 3

CONTENTS

IMPORTANT INFORMATION.............2

DIMENSIONS & SPECIFICATIONS ........4

INSTALLATION .........................5

Statutory Regulations ........................5

Installation Notes: ............................5

National Codes Require: .................. 5

Gas Connections, And Pipe Sizing ........ 5

Conversion Instructions................... 6

Installation Of Double Deck Models ...........6

Gas Connection ..............................6

Electrical Connection ........................7

Ventilation & Air Supply ......................7

Testing & Lighting Instructions ...............7

OPERATION............................8

PERFORMANCE RECOMMENDATIONS ..11

COOKING GUIDE ......................12

COOK AND HOLD .....................13

PROBLEMS / SOLUTIONS ..............14

MOTOR CARE.........................14

CLEANING & MAINTENANCE ...........15

Break-In Period.......................... 15

Exterior Cleaning ........................ 15

Interior Cleaning ........................15

Fan Area Maintenance ...................15

Master 450 Electronic Control With

Cook-N-Hold And Master 455 Electronic

Control With Cook-N-Hold & Core Probe ......8

In O Mode:.............................. 8

On Start Up ..............................8

Controller Keys ........................... 8

Fahrenheit/Celsius........................ 9

Operating the Controls ................... 9

Cook-N-Hold Operation .................10

Core Probe Operation ...................10

Setting Setback Feature .................10

Part # 1955201 Rev.7 (11/28/12) Page 3

Page 4

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

14-3/4"

[375mm]

32-1/8"

[816mm]

35-7/16”

[900mm]

32-1/8"

[816mm]

1-1/4"

[32mm]

DOUBLE DECK

FR ONT VIEW

H

1" REAR

GAS INLET

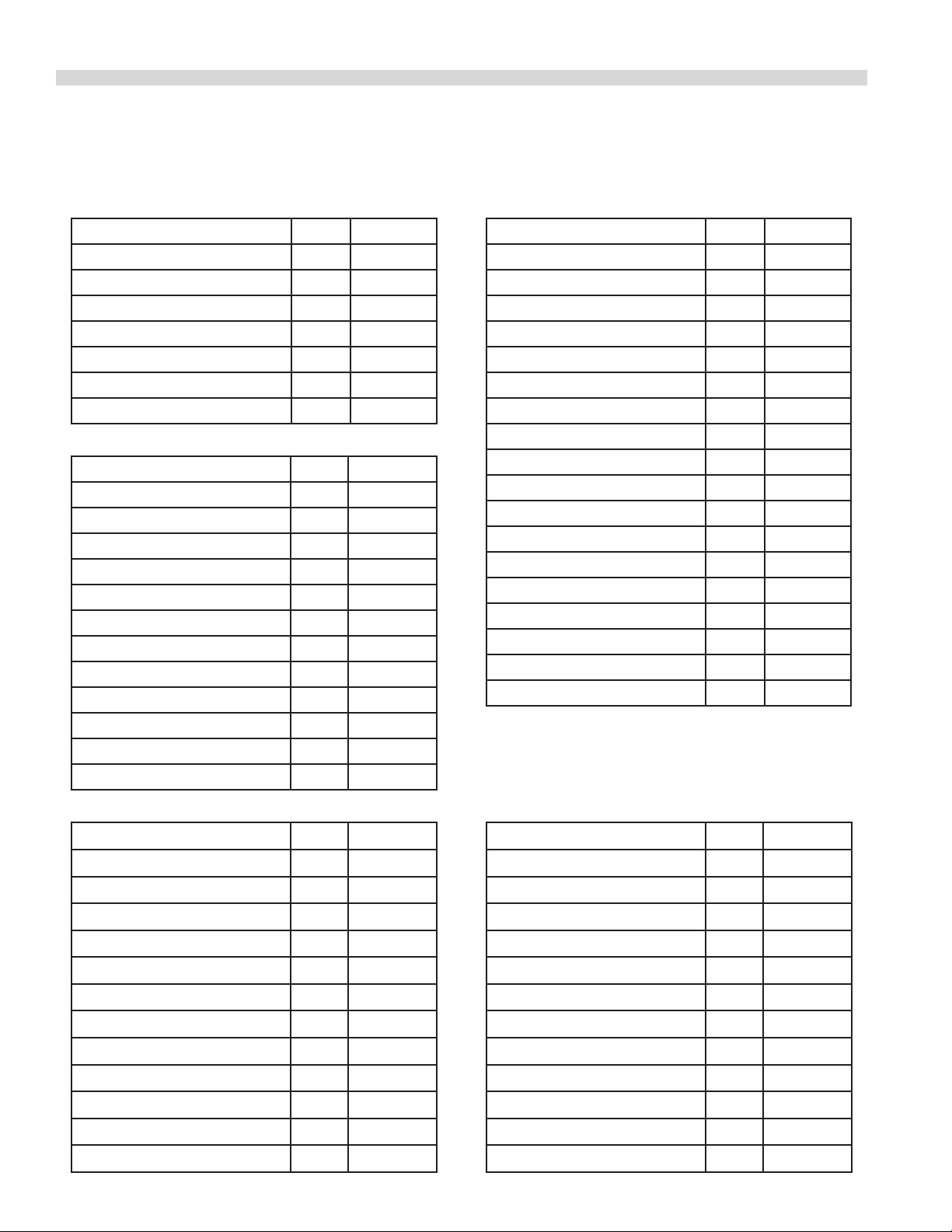

DIMENSIONS & SPECIFICATIONS

Single-Deck

Models

Int. Dimensions :In (mm) Ext. Dimensions: In (mm) Ship Wt Ship Dim.

W H D W H D Lbs/kg Cubic Ft.

Standard Depth 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 41-1/4(1048) 600/273 64

Deep Depth 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 44-1/2(1130) 600/273 64

Double-Deck

Models

Int. Dimensions: In (mm) Ext. Dimensions: In (mm) Ship Wt. Ship Dim.

W H D W H D 2@Lbs/kg Cubic Ft.

Standard Depth 29 (736) 24 (610) 24 (610) 38 (965) 70-1/2 (1791) 41-1/4(1048) 1150/523 128

Deep Depth 29 (736) 24 (610) 28 (711) 38 (965) 70-1/2 (1791) 44-1/2(1130) 1150/523 128

MODEL #

MCO-GS/GD-10CE

MCO-GS/GD-10CE

MCO-GS/GD-20CE

MCO-GS/GD-20CE

GAS

TYPE

INPUT SETTING PRESSURE

MANIFOLD

PRESSURE

NAT 17.5 kW 20 mbar 25 mbar 11.2 mbar 16 mbar G20 1.66 G25 1.91

PRO 17.5 kW 37/50 mbar 25 mbar G31 0.66

NAT 35 kW 20 mbar 25 mbar 11.2 mbar 16 mbar G20 3.32 G25 3.82

PRO 35 kW 37/50 mbar 25 mbar G31 1.32

FLOW RATE

(m3/h)

ELECTRICAL CLEARANCES: In (mm)

1N 230V, 50Hz Combustible Wall Entry

kW Load Nom. Amps Sides Rear Crated Uncrated

1 4 1 (25) 3 (76) 47 (1194) 32.5 (826)

MODEL

MCO-GS/GD-10CE

MCO-GS/GD-20CE

1-1/4"

[32mm]

H

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

AUSTRALIA ONLY - GAS

Gas

Type

Input

(MJ/Hr)

NAT 63.0 0.83 kPA 1.85 mm

PRO 63.0 2.49 kPA 1.15 mm

NAT 126.0 0.83 kPA 1.85 mm

PRO 126.0 2.49 kPA 1.15 mm

DOUBLE DECK

FR ONT VIEW

(Manifold)

Gas Pressure

32-1/8"

[816mm]

14-3/4"

[375mm]

1" REAR

GAS INLET

32-1/8"

[816mm]

35-7/16”

[900mm]

D

17-3/4"

[451mm]

1-1/4"

[32mm]

[816mm]

H

[645mm]

7-3/4"

[197mm]

3/4"

[19mm]

32-1/8"

25-3/8"

3/4" N.PT.

GAS INLET

FLUE: 2-3/8" x 5"

[60mm x 127mm]

TOP VIEW

38"

[965mm]

SINGLE DECK

FR ONT VIEW

2"

[51mm]

38-1/4"

[972mm]

11-1/2"

[292mm]

3/4" REAR

GAS INLET

[1386mm]

34"

[864mm]

54-9/16"

Orice Size

Page 4

Part # 1955201 Rev. 7 (11/28/12)

Page 5

INSTALLATION

Statutory Regulations

The installation of this appliance must be carried out by

a competent person and in accordance with the relevant

regulations, standards, codes of practice and the related

publications of the Country of destination.

AUSTRALIA SPECIFIC CLAUSE

This appliance must be installed in accordance with

the manufacturers instructions, local gas tting

regulations and requirements of AS 5601 / AG 601

installation code. A qualied gas technician should

make all burner adjustments and settings.

Installation Notes:

Combustible and Non-Combustible Wall Clearance:

Side: 1.0" (25 mm)

Rear: 3.0" (76 mm)

This equipment must be installed by a competent factory

trained, certied, licensed and / or authorized service or

installation person.

WARNING. This appliance must be earthed.

This appliance should be connected to a potential

equalization system. To facilitate this a labeled equipotential

bonding point is tted to the rear of the oven.

It is recommended that this oven be connected to a residual

current (earth leakage) device with a tripping current not

exceeding 30mA. The leakage current of this oven will not

exceed 5mA.

A means of disconnection from the supply with all pole

separation of at least 3mm must be incorporated into the

xed wiring.

National Codes Require:

The type of gas for which the oven is equipped is stamped on

the data plate on the inside of the lower front panel. Connect

an oven stamped for Natural Gas (High (H) or Low (L) Caloric

Value) only to Natural Gas; connect those stamped for

Propane Gas only to Propane Gas. When installing gas ovens,

the installation must comply with the latest edition of the

National Gas Installation Requirements.

Gas Connections, And Pipe Sizing

The size of the gas line is very important. If the line is too

small, the gas pressure at the burner manifold will be low. This

will cause slow recovery and delayed ignition. The incoming

gas pressure line should be a minimum of ISO 7-1 1-1/2”. All

single ovens require a 3/4” connection, double stacked ovens

require 1” connections.

Before connecting new pipe the pipe must be blown out to

dispose of any foreign particles. These particles will cause

improper operation.

When using thread compound, use small amounts on male

threads only. Use a compound that is not eected by the

chemical action of LP gases. Avoid applying compound to the

rst two threads to prevent clogging of the burner orices

and control valve.

Have the installer check all gas plumbing with a soap solution

for leaks. DO NOT USE matches, candles or other ignition

sources in checking for leaks.

The oven must be disconnected from the gas supply system

when pressure testing of that system at pressures in excess of

150 mbar.

Check the data plate to determine the proper type of gas

before connecting the quick disconnect or piping from the

building gas supply.

An incoming gas pressure test nipple is provided on the

incoming gas manifold for pressure checks.

Minimum incoming gas pressure for Natural Gas is 15 mbar.

Maximum incoming gas pressure for Natural Gas is 30 mbar.

Minimum incoming gas pressure for LP Gas is 25 mbar.

Maximum incoming gas pressure for LP Gas is 58 mbar

Burner operating pressure can be checked at the outlet side

of the gas valve at the pressure test point on the manifold.

For Australia:

Minimum incoming gas pressure for Natural Gas is 1.13 kPa.

Maximum incoming gas pressure for Natural Gas is 5.00 kPa.

Minimum incoming gas pressure for LP Gas is 2.75 kPa.

Maximum incoming gas pressure for LP Gas is 7.00 kPa.

To adjust the burner pressure, remove the sealing screw from

the pressure test nipple, connect a manometer, turn on the

oven, adjust the screw in the regulator to give the correct

pressure, turn o the oven, remove the manometer, replace

Part # 1955201 Rev.7 (11/28/12) Page 5

Page 6

INSTALLATION Continued

the seal screw in the test nipple and test for gas leaks.

Gas pressures should be checked by the local Gas Company

or an authorized service agency only.

Test all piping and connections for gas leaks. A rich soap

solution should be used for this purpose. Never use a ame.

Conversion Instructions

Servicing must be carried out by a competent person in

accordance with the law.

WARNING: Turn o the gas supply to the appliance at the

service cock and the electrical mains before commencing any

servicing work.

IMPORTANT: Test for gas soundness on completion of any

servicing work.

The following instructions are intended to describe the

operations necessary to convert equipment from operation

on one gas family to that of another.

Ensure that all of the parts necessary to make the conversion

have been supplied as follows:

a. Injector Fittings (One per main burner).

b. Governor Spring (One per unit).

c. Conversion Label (One per unit).

If any of the required parts are missing, contact your Garland

dealer before attempting the conversion.

allows both ovens to be supplied by a single gas line. The

minimum recommended size of a single supply line for

two stacked ovens is 1 inch. Use a pipe thread compound

that is intended for use on propane gas piping and be sure

to check for leaks before nalizing the installation.

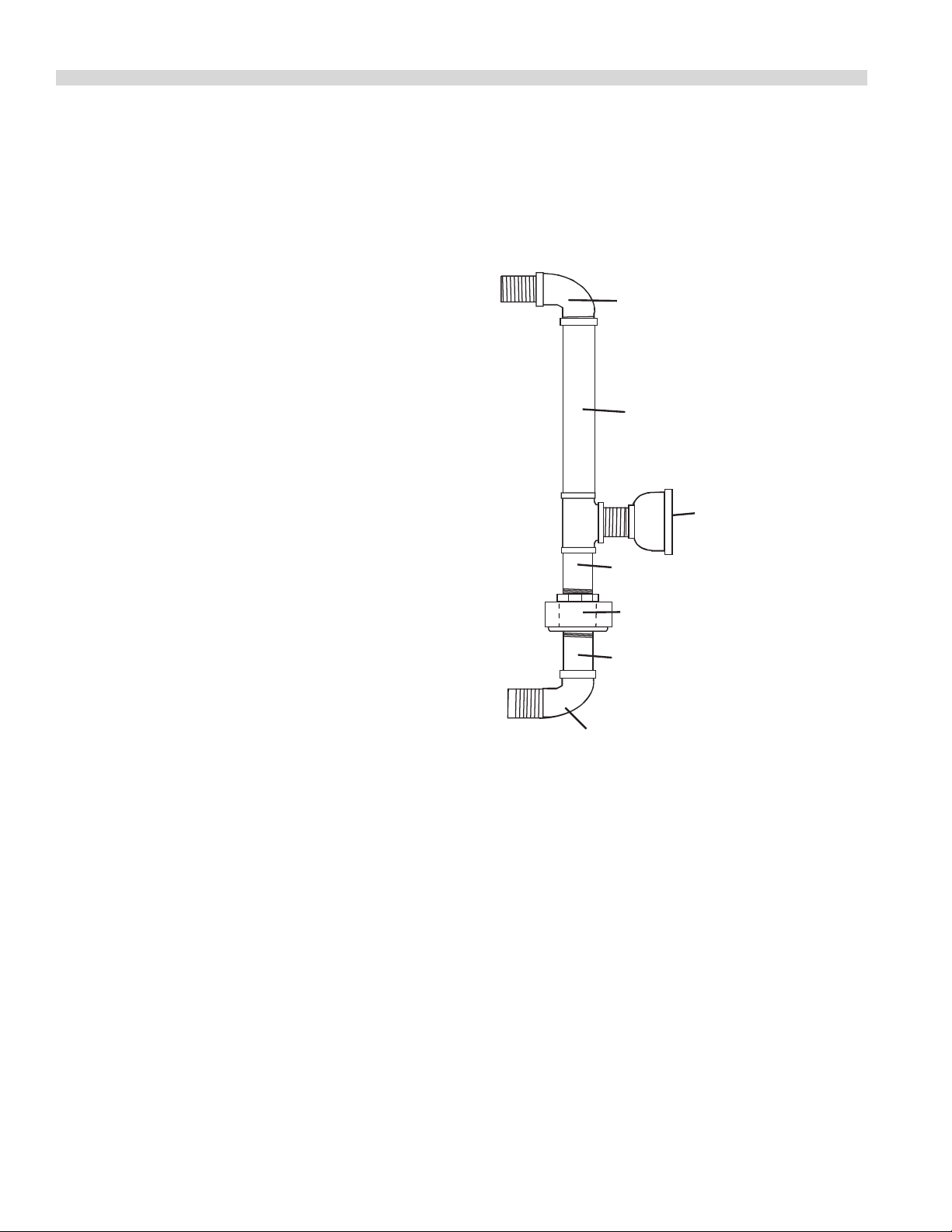

90 Degrees Street Elbow

20 1/2" Nipple

3/4" to 1" BSPT

Bell Reducer

3" Nipple

3/4" Union

3" Nipple

Installation Of

Double Deck Models

A. Position insert in bottom leg opening and tap insert up

into leg till it seats at collar. Attach six inch (6") legs to

lower oven section. Raise unit or lay on its left side. Place

the front legs on the oven so as to line up with four (4)

attaching bolt holes. Secure leg to oven frame using (4)

3/8-16 x 3/4 bolts and washers provided. Repeat at rear of

unit.

B. Remove lower front cover of top deck (located under oven

doors). Raise top deck into place and line up body sides

and back of the unit. Fasten the rear of the units together,

with the stacking bracket using (6) 1/4-20 machine screws,

lock washers and nuts, (provided).

C. Install the interconnecting ue parts, carefully following

the instructions contained in the stacking kit. Pay

particular attention to the type of ovens you are stacking

and be sure to follow the corresponding instructions.

D. Assemble the stacking pipes provided in the stacking

kit as shown in the diagram at the top of this page. This

90 Degrees Street Elbow

E. Check leveling of unit four (4) ways (using a common

carpenter's level on the rack inside the oven).

F. Wire each unit to a 230-Volt power supply.

G. Maintain clearance from combustibles.

Each gas appliance shall be located with respect to building

construction and other equipment so as to permit access to

the appliance. Such access and clearance may be necessary

for servicing and cleaning.

Gas Connection

The 1" BSPT inlet at the rear must be considered in piping the

gas supply for double stack units or 3/4" BSPT for individual

(or single deck) connections. Undersized gas supply line(s)

may restrict the gas supply and aect performance. If other

gas appliances are supplied by the same supply line, the

supply line must be sized to carry the combined volume

without causing more than 1/2" pressure drop at the manifold

of each appliance on the line at full rate.

Page 6

Part # 1955201 Rev. 7 (11/28/12)

Page 7

INSTALLATION Continued

Electrical Connection

Install oven in accordance with local electrical agencies and

code requirements. This equipment must be installed by a

competent factory trained, certied, licensed and/or authorized

service or installation person.

WARNING:

This appliance must be earthed. This appliance should be

connected to a potential equalization system. To facilitate this

a labeled equipotential bonding point is tted to the rear of

the oven.

A wire diagram is axed to the rear of the unit.

CAUTION:

DISCONNECT BOTH UNITS FROM

ELECTRICAL SUPPLY BEFORE SERVICING.

POWER FAILURE

In the event of a power failure, no attempt

should be made to operate this oven.

IMPORTANT

All gas burners and pilots need sufficient

air to operate and large objects should not

be placed in front of this oven, which would

obstruct the airflow through the front.

Objects should not be placed on main top rear

of oven while in use. This could obstruct the

venting system of the unit's flue products.

Testing & Lighting Instructions

1. Turn on main gas valve. Remove the lower front cover

and the service panel above the control panel. Drop the

control panel and leak test all ttings and connections

upstream from the service valve located on the redundant

combination gas valve. Should any gas leaks be detected,

turn OFF main gas valve, correct the problem and retest.

2. Open shuto valve located on the redundant combination

gas valve. Activate control panel and set to desired

temperature. The pilot burner is ignited by direct spark,

main burners are then ignited by the pilot. Check all

ttings again and correct any leaks and recheck.

Ventilation & Air Supply

Proper ventilation is highly important for good operation. The

ideal method of venting a gas convection oven is through

the use of a properly designed canopy, which should extend

6" (150 mm), beyond all sides of the appliance and 6'6" (1950

mm) from the oor.

A strong exhaust fan will create a vacuum in the room. For an

exhaust system vent to work properly, exhaust and make-up

air must be balanced properly. For proper air balance contact

your local H.V.A.C. contractor.

All gas burners and pilots need sucient air to operate and

large objects should not be placed in front of this oven, which

would obstruct the airow through the front.

Replace all service panels and covers before operation.

NOTE: All electronic ignition systems are supplied with a

redundant gas valve. Therefore, the unit is not supplied with

an external pressure regulator.

NOTE: During installation there will be air in the gas line. This

air will have to bleed o before ignition can be established.

The electronic ignition system has a ninety second lock-out

as a safety device on all units. Therefore, several attempts

may be required before pilot ignition is established, wait ve

minutes after each attempt.

FOR YOUR SAFETY: KEEP YOUR APPLIANCE AREA FREE FROM

COMBUSTIBLES.

TO CONSERVE ENERGY:

Do not waste energy by leaving controls at high temperature

settings during idle periods. Lower settings will keep

oven warm and ready for next use period. Master 400

Series controls have an auto setback feature that is user

programmable to help with these applications.

Part # 1955201 Rev.7 (11/28/12) Page 7

Page 8

OPERATION

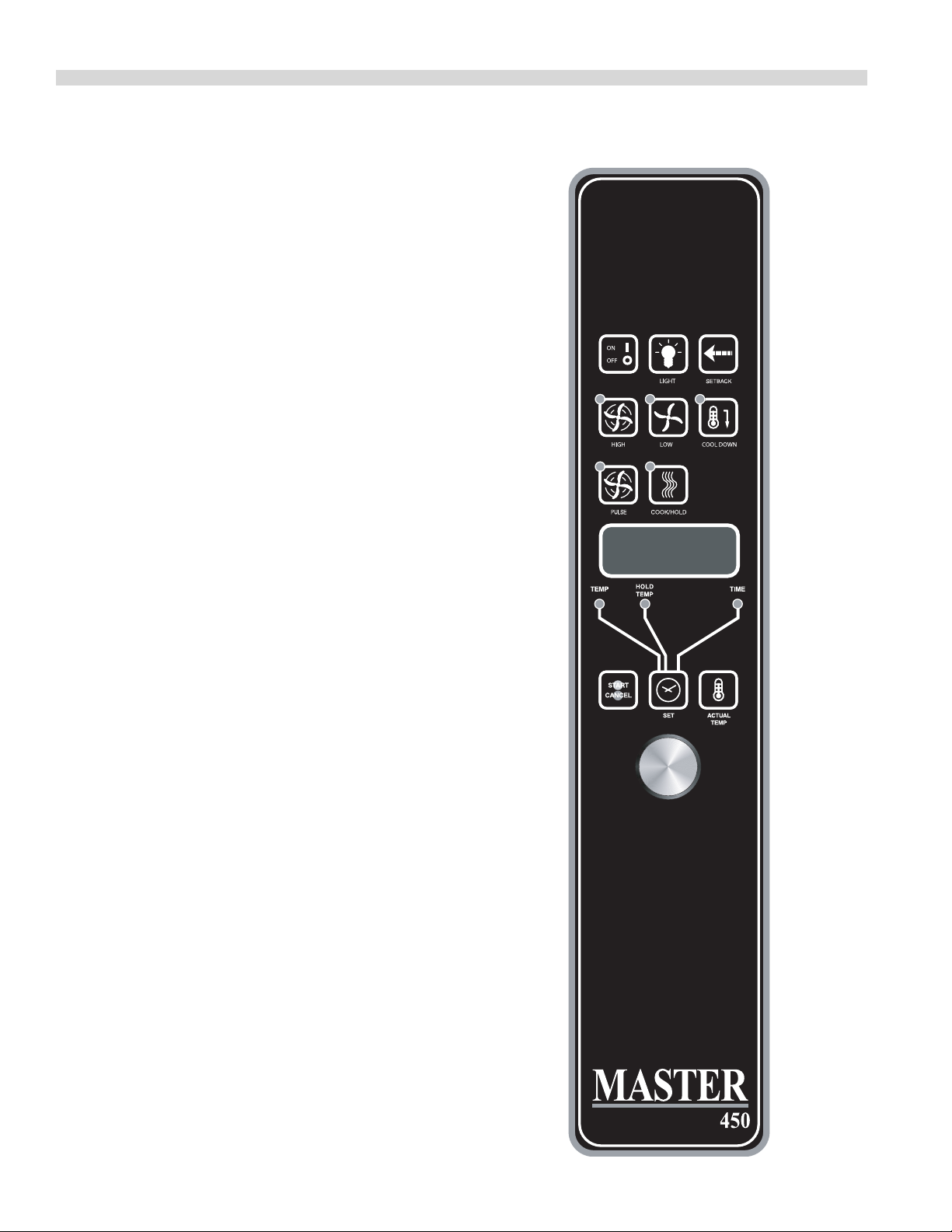

Master 450 Electronic Control

With Cook-N-Hold And

Master 455 Electronic Control With

Cook-N-Hold & Core Probe

In O Mode:

When the controller is o, the display will show "OFF".

Pressing the ON/OFF key will activate the controller into Start

Up mode.

On Start Up

In Start Up mode, the controller will heat to the last set

temperature, time and fan speed. The factory defaults are

350°F (177°C), 30 minutes and low fan speed. The display will

indicate "LO" when the oven is below the set temperature.

When the oven cavity reaches the set temperature and is

ready for operation the display will indicate "LOAD".

NOTE: If the oven temperature goes above the requested

temperature the display will indicate "HI". If the oven

temperature goes above 575°F (302°C) the display will

indicate "HELP" and an audible signal will sound. This is a

safety feature.

If the door is opened during a Cooking mode, the fan and

heat will stop, and the display will indicate "DOOR" until the

door is closed. This is a patented safety feature.

Pressing the ACTUAL TEMP key will display the actual oven

temperature in 5° increments.

Controller Keys.

Pressing the ON/OFF key will activate the oven.

Pressing the LIGHT key will turn the lights on for 30 seconds.

The lights will work if the controller is in the O mode. When

the door is opened, the light will come on and stay on for 30

seconds.

Pressing the FAN HIGH key will activate the higher fan speed

and light its LED.

Pressing the FAN LOW key will activate the lower fan speed

and light its LED.

Pressing the FAN PULSE key will activate the lower fan speed

and light its LED. The fan will be active for 30 seconds then o

for 30 seconds, and continues this cycle.

Pressing the SETBACK key will cool the oven cavity to a

preprogrammed temperature, see: Setting "Set-Back" Feature.

The oven will automatically go into Setback mode after the

pre-programmed non-usage time. The display will indicate

"SETB". This is an energy-saving feature.

Page 8

Part # 1955201 Rev. 7 (11/28/12)

Page 9

OPERATION Continued

Pressing the COOL DOWN key will deactivate the heat, turn

the fan on high and light its LED. The display will indicate

"OPEN DOOR" if the door is closed, prompting the user to

open the door slightly. With the door open slightly the display

will indicate "COOL". The Cool Down will operate when the

door is closed or opened slightly. Optimal cool-down will be

achieved with the door open slightly. When the door opens

wider, the Cool Down mode will deactivate and the display

will indicate "DOOR". This is a patented safety feature. Pressing

the COOL DOWN key again will turn the LED o and stop this

mode. Pressing the ON/OFF key will also cancel Cool Down.

Cool Down is not active during a cook.

When the ON/OFF switch is pressed to turn the oven o and

the oven was above 200°F (93°C), the oven will go into an

Auto Cool Down mode. In Auto Cool Down, the oven will

run the fan on high until the oven cavity drops below 150°F

(66°C). During this time the display will indicate "AUTO".

When the oven temperature drops below 150°F (66°C) the

oven turns o. This feature protects the oven motor from pre-

mature failure. Optimal cool-down will be achieved with the

door open slightly.

Fahrenheit/Celsius

Factory default is Celsius (C). To change to Fahrenheit (F),

press and hold in the "Phantom Key" located to the right of

"COOK/HOLD" key. "C" appears in the display. Continue to

hold until "F" is displayed and then release the "Phantom key".

Operating the Controls

Setting the cook temperature and time are done in the same

manner. Pressing the SET key will light the TEMP LED. The

operator then sets the temperature by rotating the dial on

the controller until the desired temperature is shown on the

display. Pressing the SET key a second time lights the TIME

LED and allows the operator to select the desired cook time

as shown on the display. Pressing the SET key a third time

ends the programming.

Pressing the START/CANCEL key will start the timing cycle.

The display will count down from the Set time in minutes

and seconds (solid colon) or hours and minutes (blinking

colon) the minutes and seconds. When the cycle is completed,

processing this key will also cancel the "DONE" prompt. To

cancel a timing cycle in progress, press and hold the START/

CANCEL key for 3 seconds.

Part # 1955201 Rev.7 (11/28/12) Page 9

Page 10

OPERATION Continued

Cook-N-Hold Operation

Pressing the COOK/HOLD (450 and 455 Controllers Only) key

activates the Cook-N-Hold mode and lights its LED. To verify

the proper hold temperature has been selected, press the SET

key twice. The display will show the hold temperature. At the

end of the cook cycle, an audible alarm will sound, the display

will ash “DONE” and change to count "UP" the hold time.

The oven will switch to the programmed hold temperature.

Setting the cook temperature, hold temperature and time

are done in the same manner. Pressing the SET key will

light the TEMP LED. The operator then sets the temperature

by rotating the dial on the controller until the desired

temperature is shown on the display. Pressing the SET key a

second time will light the HOLD LED and allows the operator

to select the desired hold temperature as shown on the

display. Pressing the SET key a third time lights the TIME LED

and allows the operator to select the desired cook time as

shown on the display. Pressing the SET key a fourth time ends

the programming.

Pressing the START/CANCEL key will start the timing cycle.

When the cycle is completed, pressing this key will also cancel

the “DONE” prompt. To cancel a timing cycle in progress

press and hold the START/CANCEL key for 3 seconds.

Setting Setback Feature

To set or change the setback settings, press and hold the

SETBACK key for two seconds. The TEMP LED will light and a

temperature will be displayed. Set the temperature using the

dial, then press the SET key. The TEMP LED will go out and

the TIME LED will light ("Time" is factory set at 0). Set the time

using the dial, then press the SET key. Press the SET key one

more time to exit programming.

Note: To disable the setback function, set the temperature to

250º F (121ºC) and the time to zero.

Core Probe Operation

The Core Probe option (455 Controller Only) is only active

when the core probe is plugged into its connector. To set the

core temperature, rst plug the core probe into its connector.

The display will indicate "100" and the CORE TEMP LED will

be on. The operator then sets the temperature by rotating

the dial on the controller until the desired temperature is

shown on the display. Pressing the SET key stores the core

temperature and starts the cooking process.

To set the oven temperature, press the SET key again. The

TEMP LED will light and the oven temperature can be

set by rotating the dial on the controller until the desired

temperature is displayed. Pressing the SET key again will

light the HOLD LED allowing the operator to set the hold

temperature in the same manner.

NOTE: If the hold temperature is not set, the default hold

temperature is 150°F (66°C) or the last programmed

temperature. (Hold temperature range is 140°F (60°C) to

210°F (99°C).

When the core temperature is reached, the display will sound

and ash "DONE" for 3 seconds. Automatically, the display

will switch to count“UP” the time the oven is on hold.

Page 10

Part # 1955201 Rev. 7 (11/28/12)

Page 11

PERFORMANCE RECOMMENDATIONS AND GENERAL SAFETY

PRECAUTIONS

1. Preheat oven thoroughly (approx. 20 minutes) before use.

2. As a general rule, temperature should be reduced from

that used in a standard/conventional oven. Cooking time

may also be shorter, so we suggest closely checking the

rst batch of each product prepared.

3. Use the chart of suggested times and temperatures as a

guide. These will vary depending upon such factors as size

of load, temperature, and mixture of product (particularly

moisture) and density of product.

4. Keep a record of the times, temperature, and load sizes

you establish for various products. Once you have

determined these, they will be similar for succeeding

loads.

5. When practical, start cooking the lowest temperature

product rst and gradually work up to higher

temperatures.

6. If you nd that your previous temperature setting is more

that 10°F or 5°C higher than needed for succeeding loads,

COOL DOWN to reach the desired temperature before

setting a new cooking temperature.

7. When loading oven, work as quickly as possible to prevent

loss of heat.

16. Never place anything directly on the bottom of the oven

cavity. This obstructs the airow and will cause uneven

results.

17. Never operate the oven if any of the exterior covers are

removed. These covers are necessary for protection

against exposure to live electrical parts and should

only be removed when the oven is being serviced by a

qualied service personnel.

18. This is a commercial cooking oven not intended for non

commercial cooking installations or non food products.

19. Use appropriate food pans and trays for ovens.

20. Use oven mitts when adding or removing trays/pans from

oven when oven is operational.

21. Use care when removing product from the oven to

prevent spills which could cause serious inquiry to bare

skin and eyes. Higher rack levels on ovens are at eye level.

22. Exterior oven exteriors will become hot during operation

caution should be observed.

23. Proper weight handling and distribution of product in tray

or pan will prevent sudden shifts in product to avoid spills

and inquiry.

8. Oven will continue to heat even though the timer goes

o. Product should be removed from the oven as soon as

possible to avoid over cooking.

9. Center pans on racks and load each shelf evenly to allow

for proper air circulation within the cavity.

10. When baking, weigh or measure the product in each pan

to assure even cooking.

11. When cooking six pans, use rack positions 2, 4, 6, 8, 10 and

12, starting from the top.

12. Do not overload the oven. Six pans are suggested for most

items, i.e., cakes, cookies, rolls, etc. However, the maximum

(13 pans) may be used for sh sticks, chicken nuggets and

hamburgers. Cooking times will have to be adjusted.

13. Mun pans should be placed in the oven back to front or

with the short side of the pans facing the front. This results

in the most evenly baked product.

14. When re-thermalizing frozen casseroles, preheat the oven

100°F or 60°C over the suggested temperature. Return to

cooking temperature when the oven is loaded. This will

help compensate for the introduction of a large frozen

mass into the cavity.

24. Do not operate ovens if blower fan guard has been

removed.

25. Oven operation sound pressure level should not exceed

70 dB(A).

26. Do not spray aerosols in the vicinity of this appliance while

it is in operation.

NOTE: Moisture will escape around the doors when baking

products with heavy moisture content, such as: chicken,

potatoes, etc. This is normal.

15. Use pan extenders or two inch deep 18"x26" pans for

batter type products which weigh more than eight

pounds, i.e., Pineapple Upside Down Cake.

Part # 1955201 Rev.7 (11/28/12) Page 11

Page 12

COOKING GUIDE

The following suggested times and temperatures are provided as a starting guide. Elevation, atmospheric conditions, gas

supply, recipe, cooking pans, and oven loading may aect your actual results.

Product °C Time

White Sheet Cakes – 5 lb 150° 20 min

White Sheet Cakes – 6 lb 150° 22 min

Yellow Layer Cake – 21 oz 165° 15 min

Yellow Sheet Cake – 5 lb 150° 22 min

Chocolate Layer Cake – 21 oz 150° 22 min

Angel Food Cake 190° 22 min

Brownies 175° 15 min

Product °C Time

Chicken Parts 175° 45 min

Hamburger Patties, 10/lb fzn 175° 8 min

Hamburger Patties, 10/lb fresh 175° 5 min

Hamburger Patties, 4/lb fzn 175° 12 min

Hamburger Patties, 4/lb fresh 175° 8 min

Meatloaf – 4# 165° 45 min

Bacon 175° 10 min

Roast Beef - 20# 165° 3 hr 15 min

Prime Rib - 10# 150° 1 hr 45 min

Stued Pork Chops 175° 45 min

Lamb Chops 190° 40 min

Boneless Veal Roast 150° 3 Hr

Product °C Time

Soda Biscuits 205° 6 min

Yeast Rolls 165° 24 min

Sweet Bread 165° 24 min

Corn Bread 175° 22 min

Gingerbread 150° 24 min

Apple Turnovers 175° 25 min

Cream Pus 150° 25 min

Sugar Cookies 165° 12 min

Chocolate Chip Cookies 190° 8 min

Apple Pie (Fresh) 175° 25 min

Blueberry Pie (Fresh) 175° 30 min

Blueberry Pie (Frozen) 150° 56 min

Pumpkin Pie (Frozen) 150° 50 min

Frozen Pizza 150° 6 min

Macaroni & Cheese 175° 15 min

Fish Sticks 175° 16 min

Stued Peppers 175° 45 min

Baked Potatoes 175° 60 min

Page 12

Product °C Time Product °C Time

Part # 1955201 Rev. 7 (11/28/12)

Page 13

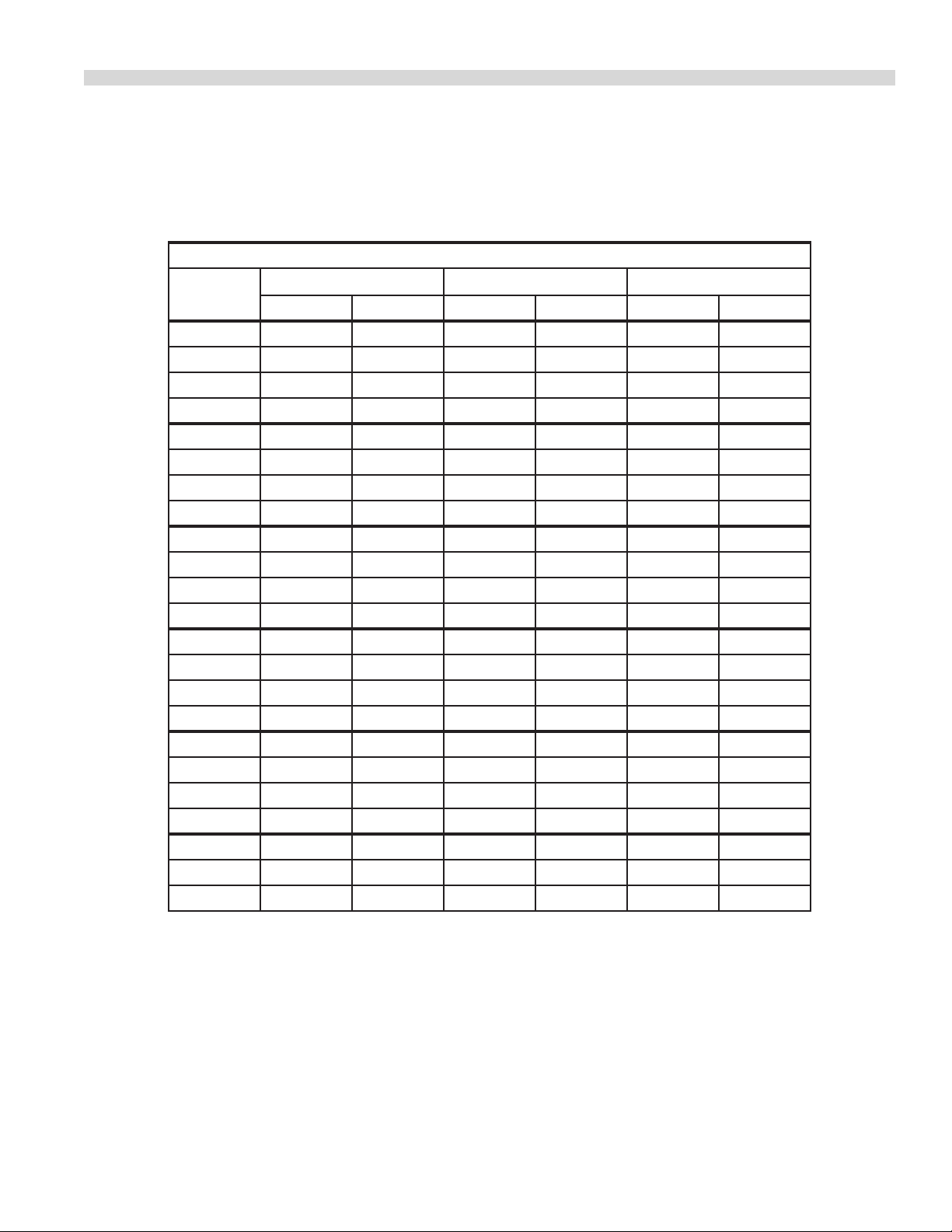

COOK AND HOLD

Please refer to the operating instructions to program the 450 and 455 control units for cook and hold feature. The times and

temperatures listed below are to be used as a starting guide. Your actual results may vary greatly depending on your elevation,

gas supply, atmospheric conditions, and other items being cooked at the same time.

Time in Hours

Weight in

Kgs

3.6 2.5 3.5 1.5 2 1.25 1.5

4.1 2.75 3.75 1.75 2.25 1.25 1.75

4.5 3 4.25 2 2.5 1.5 1.75

5 3.25 4.5 2 2.75 1.5 1.75

5.5 3.5 5 2.25 3 1.5 2

5.9 3.75 5 2.5 3.25 1.5 2.25

6.4 4 5.75 2.5 3.5 1.75 2.5

6.8 4.25 6 2.75 3.5 2 2.5

7.3 4.5 6.25 2.75 3.75 2 2.75

7.7 4.75 6.5 3 4 2.25 2.75

8.2 4.75 6.75 3.25 4.25 2.25 3

8.6 5 7.25 3.25 4.25 2.25 3

9.1 5.25 7.5 3.5 4.5 2.5 3.25

9.5 5.5 7.75 3.5 4.75 2.75 3.5

10 5.75 7.75 3.5 4.75 2.75 3.5

10.5 6 8.25 3.75 5 2.75 3.75

10.9 6 8.75 3.75 5 2.75 3.75

11.4 6.25 9 4.25 5.5 3 4

11.8 6.5 9.25 4.25 5.5 3.25 4.25

12.3 6.75 9.5 4.25 5.75 3.25 4.25

12.7 7 9.75 4.5 6 3.25 4.25

13.2 7.25 10 4.75 6.25 3.5 4.5

13.6 7.25 10.25 4.75 6.25 3.5 4.5

Temperature: 95°C Temperature: 120°C Temperature: 150°C

Rare Medium Rare Medium Rare Medium

Part # 1955201 Rev.7 (11/28/12) Page 13

Page 14

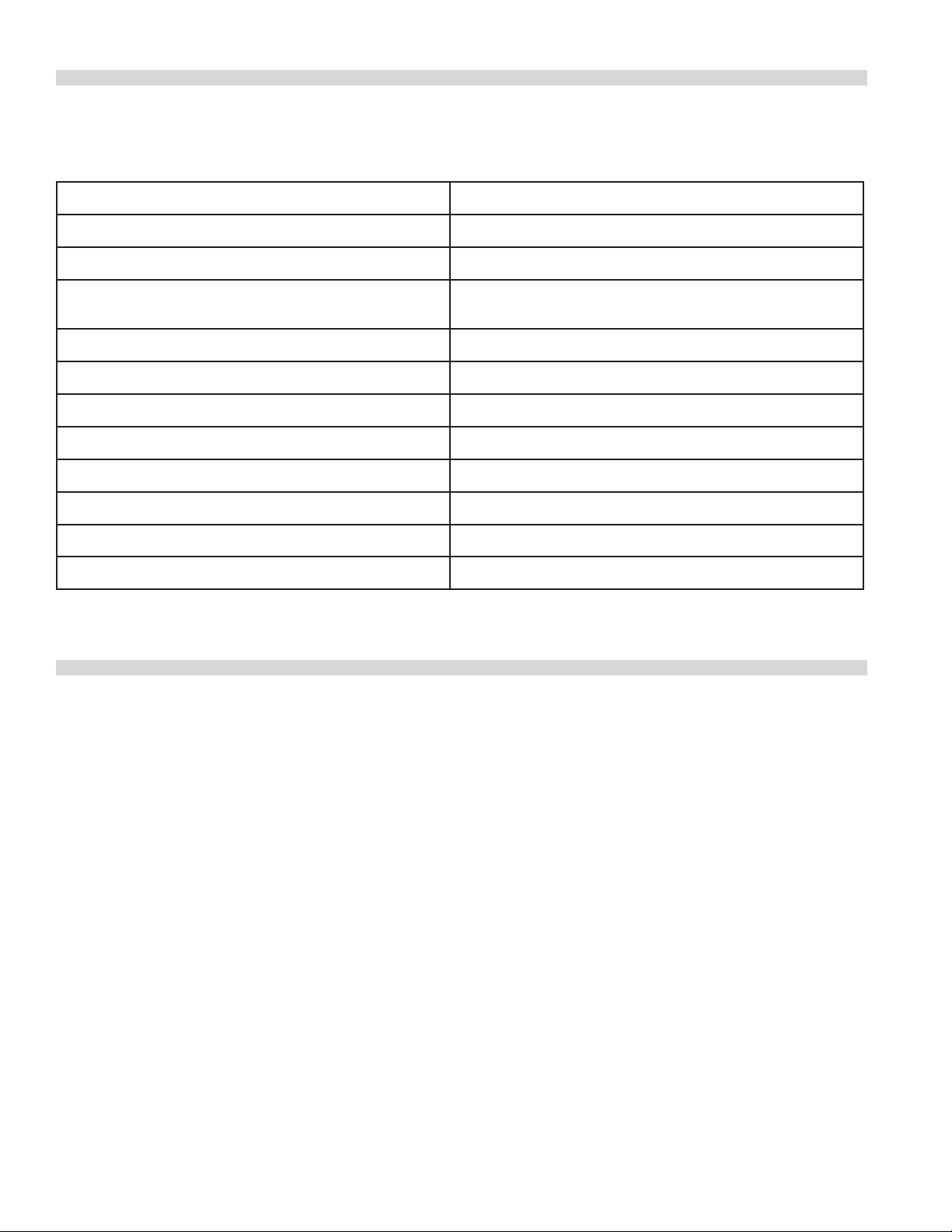

PROBLEMS / SOLUTIONS

Problem Solution

If cakes are dark on the sides and not done in the center Lower oven temperature.

If cakes edges are too brown Reduce number of pans or lower oven temperature.

If cakes have light outer color Raise temperature.

If cake settles slightly in the center

If cake ripples Overloading pans or batter is too thin.

If cakes are too coarse Lower oven temperature.

If pies have uneven color Reduce number of pies per rack or eliminate use of bake pans.

If cupcakes crack on top Lower oven temperature.

If meats are browned and not done in center Lower temperature and roast longer.

If meats are well done and browned Reduce time. Limit amount of moisture.

If meats develop hard crust Reduce temperature or place pan of water in oven.

If rolls have uneven color Reduce number or size of pans.

Bake longer or raise oven temperature slightly.

Do not open doors too often or for long periods.

MOTOR CARE

The motor on your convection oven is maintenance free since

it is constructed with self-lubricating sealed ball bearings.

It is designed to provide durable service when treated with

ordinary care. We have a few suggestions to follow on the

care of your motor. When the motor is operating, it cools

itself internally by air entering at the rear of the motor case,

provided proper clearance has been allowed.

Since the blower wheel is in the oven cavity it is at the same

temperature as the oven. If the motor is stopped while the

oven is hot, the heat from the blower wheel is conducted

down the shaft and into the armature of the motor. This

action could shorten the life of the motor.

We recommend, at the end of the bake or roasting period,

when the oven will be idle for any period of time, or before

shutting down completely, that the doors be left open

slightly. On the 400 series controllers press the COOL DOWN

key on the control panel. The fan will continue to run until the

oven cools down to 150°F (66°C).

At the end of the day, press the ON/OFF key, for the 400

series controllers to activate the Auto Cool Down feature.

The fan will run on high until the oven cavity drops below

150°F (66°C). During this time the "AUTO COOL DOWN" LED

will light. When the oven temperature drops below 150°F

(66°C) the oven turns o. This feature protects the oven motor

from pre-mature failure. On the 200 series controllers, push

the rocker switch to COOL position. Once cool set the rocker

switch to OFF.

Page 14

NOTE : Optimal cool-down will be achieved with the door

open slightly.

Part # 1955201 Rev. 7 (11/28/12)

Page 15

CLEANING & MAINTENANCE

NOTE: Disconnect line cord from power supply before

cleaning or servicing.

Break-In Period

When oven is new, operate it for one hour at 375°F (191°C)

before you begin your normal cooking operation. After

cooling, wipe the interior, including the racks, with a clean

damp cloth.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

1 The oven should always be allowed to cool suciently

before any cleaning is attempted.

2. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

3. Stubborn stains may be removed by using a non-metallic

abrasive pad, rubbing in the direction of the metal's grain.

If necessary, for particularly heavy deposits, you may mix a

thin paste of water and scouring powder, and apply it with

a sponge. Be careful to apply light pressure and remember

to rub only in the direction of the grain in the metal.

4. The control panel surface is easily cleaned with hot water,

soap and a soft cloth. Do not use hard abrasives, solvent

type materials or metallic scouring pads since these will

scratch or cloud the surface.

5. Never spray the perforated areas or control panel with

steam or water, as this will allow moisture into the control

cavity, which could damage electrical components.

Interior Cleaning

Establish a regular cleaning schedule or wipe o on the same

day when spillovers occur.

1. Cool down oven.

2. Remove oven racks.

3. Lift rack guides on either side of oven o of holders. Racks

and guides may be run through dishwasher while oven

cavity is being cleaned.

4. Clean with soap and water using a non-metallic scouring

pad, if necessary. If dirt and grease have accumulated, a

mild ammonia solution or commercial oven cleaner such

as Easy-O or Dow may be used.

5. To reinstall, reverse procedure. Place the bottom of the

rack guide against the cavity wall. Keeping the top pulled

away from the wall lift up. Push the top of the rack guide

against the wall and push down locking it into place.

Fan Area Maintenance

If aluminum foil is routinely used to wrap food or cooking

vessels during oven operation, the following preventive

maintenance must be performed:

1. Turn power switch to "OFF" position.

2. Remove oven racks and rack guides.

3. Remove air bae and clean any stains or deposits.

4. Check blower wheel and air bae for particles of

aluminum foil or food deposits. Clean ns of blower

wheel. (Caution: edges of blower wheel ns may be

sharp).

5. Reinstall the air bae, rack guides and oven racks.

This simple practice, if performed on a regular basis will

keep your Garland oven operating at peak performance.

Part # 1955201 Rev.7 (11/28/12) Page 15

Page 16

Page 17

MANUEL UTILISATEUR

D'ORIGINE

MANUEL D’UTILISATION ET

D’INSTALLATION

FOUR À GAZ À CONVECTION

"THE MASTER"

POUR VOTRE SÉCURITÉ:

NE PAS STOCKER NI UTILISER D’ESSENCE

OU D’AUTRES VAPEURS OU LIQUIDES

INFLAMMABLES À PROXIMITÉ DE CET

APPAREIL OU DE TOUT AUTRE APPAREIL

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

(FR) 0086

LIRE TOUTES LES SECTIONS DU PRÉSENT

MANUEL ET LE CONSERVER POUR S’Y REPORTER

ULTÉRIEUREMENT.

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

Pour votre sécurité

Placer dans un endroit bien en vue les

instructions à suivre en cas d’odeur de gaz

détectée par l’utilisateur. Cette information peut

être obtenue auprès du fournisseur de gaz local.

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être eectués par un agent

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément

aux codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit

dont le numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modié ou réparé avec des pièces

non autorisées ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés,

consulter le site web de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent

document (y compris la conception et les spécications des pièces) peuvent être remplacés ou modiés sans préavis.

FABRIQUÉ PAR

CLEVELAND RANGE

1333 East 179TH Street

Cleveland, Ohio 44110

USA

Pièce n° 1955201 REV 7 (11/28/12) © 2005 Garland Commercial Industries, LLC

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 18

INFORMATIONS IMPORTANTES

LA PRESSION DES BRÛLEURS EST RÉGLÉE ET BLOQUÉE EN USINE. ELLE NE DOIT PAS ÊTRE MODIFIÉE PAR

L'UTILISATEUR.

UNE PERSONNE COMPÉTENTE DOIT FAIRE L'INSTALLATION DE CE FOUR CONFORMÉMENT AUX CODES LOCAUX DU

PAYS DE DESTINATION.

CE FOUR DOIT ÊTRE ENTRETENU ET RÉPARÉ PAR UN INGÉNIEUR D'ENTRETIEN CERTIFIÉ PAR L'USINE. UN INGÉNIEUR

QUALIFIÉ DANS LES APPAREILS À GAZ DOIT EFFECTUER LES RÉGLAGES DE TOUS LES BRÛLEURS. GARLAND

RECOMMANDE UN ENTRETIEN PÉRIODIQUE

DES VÉRIFICATIONS DOIVENT ÊTRE EFFECTUÉES TOUS LES SIX MOIS.

CE FOUR NE DOIT ÊTRE UTILISÉ QUE PAR DU PERSONNEL QUALIFIÉ. NE PAS UTILISER LE FOUR SANS AVOIR LU LE

PRÉSENT MANUEL D’UTILISATION.

NE PAS UTILISER LE FOUR S'IL N'A PAS ÉTÉ CORRECTEMENT INSTALLÉ ET RELIÉ À LA TERRE

NE PAS UTILISER LE FOUR SI LES PANNEAUX D’ENTRETIEN ET D’ACCÈS NE SONT PAS EN PLACE ET FIXÉS

CORRECTEMENT.

LE FOUR N'ÉMET PAS DE BRUIT AÉRIEN SUPÉRIEUR À UN NIVEAU DE PRESSION ACOUSTIQUE PONDÉRÉE A DE 75 dB

(A).

IL INCOMBE AU SUPERVISEUR OU À UNE PERSONNE ÉQUIVALENTE DE S'ASSURER QUE LES UTILISATEURS DE CET

ÉQUIPEMENT PORTENT DES VÊTEMENTS DE PROTECTION CONVENABLES ET D'ATTIRER LEUR ATTENTION SUR LE

FAIT QUE CERTAINES PIÈCES

DEVIENDRONT NÉCESSAIREMENT TRÈS CHAUDES ET CAUSERONT DES BRÛLURES SI ON LES TOUCHE

ACCIDENTELLEMENT.

AVERTISSEMENT : CET APPAREIL NE DOIT PAS ÊTRE NETTOYÉ AVEC UN JET D'EAU!

Page 18

Pièce n° 1955201 Rev. 7 (11/28/12)

Page 19

CONTENTS

INFORMATIONS IMPORTANTES ........18

DIMENSIONS ET SPÉCIFICATIONS ......20

INSTALLATION ........................21

Réglementation légale ......................21

Notes d’installation : ........................21

Exigences des codes nationaux : .........21

Connexions du gaz et dimensions

des tuyaux ............................. 21

Instructions de conversion...............22

Installation des Modèles à Deux Sections ....22

Connexions du gaz .........................22

Connexions Électriques .....................23

Ventilation et alimentation en air ............23

Instructions d'essai et d'allumage ............24

RECOMMANDATIONS D’UTILISATION ET

PRÉCAUTIONS GÉNÉRALES

DE SÉCURITÉ..........................28

GUIDE DE CAISSON ...................29

CUISSON ET MAINTIEN AU CHAUD .....30

PROBLÈMES/SOLUTIONS ..............31

ENTRETIEN DU MOTEUR...............32

ENTRETIEN ET NETTOYAGE ............33

Période de Rodage ......................33

Nettoyage Extérieur .....................33

Nettoyage Intérieur .....................33

Maintenance de la Zone du Ventilateur... 33

FONCTIONNEMENT ...................25

Commande Électronique Master 450

avec Cuisson et Attente et Commande

Électronique Master 455 avec

Cuisson et Attente et Sonde Thermique ......25

En Mode d’arrêt (O):....................25

En Mode de Démarrage (Start Up)........25

Touches du Contrôleur ..................25

Fahrenheit/Celsius.......................26

Utilisation des Commandes ..............26

Fonctionnement en Mode Cuisson-

attente..................................27

Fonctionnement avec la Sonde

Thermique ..............................27

Réglage de la fonction Setback

(retour au point de consigne) ............ 27

Pièce n° 1955201 Rev. 7 (11/28/12) Page 19

Page 20

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

14-3/4"

[375mm]

32-1/8"

[816mm]

35-7/16”

[900mm]

32-1/8"

[816mm]

1-1/4"

[32mm]

DEUX SECTIONS

VUE AVANT

H

ENTRÉE ARRIÈRE

GAZ 1 PO

DIMENSIONS ET SPÉCIFICATIONS

ENTRÉE ARRIÈRE

Modèles à simple

section

Dimensions int. : Po (mm) Dimensions ext. : Po (mm) Poids d'expéd. Dim. d'expéd.

L H P L H P Lb/kg Pi³

Profondeur stand 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 41-1/4(1048) 600/273 64

Profondeur extra 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 44-1/2(1130) 600/273 64

Modèles à deux

sections

Dimensions int. : Po (mm) Dimensions ext. : Po (mm) Poids d'expéd.. Dim. d'expéd.

L H P L H P 2@Lb/kg Pi³.

Profondeur stand 29 (736) 24 (610) 24 (610) 38 (965) 70-1/2 (1791) 41-1/4(1048) 1150/523 128

Profondeur extra 29 (736) 24 (610) 28 (711) 38 (965) 70-1/2 (1791) 44-1/2(1130) 1150/523 128

MODÈLE n°

TYPE

DE GAZ

ENTRÉE

PRESSION DE

RÉGLAGE

PRESSION DU

COLLECTEUR

DÉBIT

MCO-GS/GD-10CE NAT 17.5 kW 20 mbar 25 mbar 11.2 mbar 16 mbar G20 1.66 m/h G25 1.91 m/h

MCO-GS/GD-10CE PRO 17.5 kW 37/50 mbar 25 mbar G31 0.66 m/h

MCO-GS/GD-20CE NAT 35 kW 20/ mbar 25 mbar 11.2 mbar 16 mbar G20 3.32 m/h G25 3.82 m/h

MCO-GS/GD-20CE PRO 35 kW 37/50 mbar 25 mbar G31 1.32 m/h

ÉLECTRIQUES DÉGAGEMENTS: Po (mm)

1N 230V, 50Hz Mur combustible Entrée

Charge kWAmpérage

nom.

Côtés Arrière

En

caisse

1 4 1 (25) 3 (76) 47 (1194) 32.5 (826)

NGC

(MJ/H)

Collecteur

Pression du gaz

GAZ 1 PO

32-1/8"

[816mm]

14-3/4"

[375mm]

32-1/8"

[816mm]

35-7/16”

[900mm]

AUSTRALIE SEULEMENT - GAZ

MODÈLE

MCO-GS/GD-10CE

MCO-GS/GD-20CE

1-1/4"

[32mm]

H

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

Type

de gaz

NAT 63.0 0.83 kPA 1.85 mm

PRO 63.0 2.49 kPA 1.15 mm

NAT 126.0 0.83 kPA 1.85 mm

PRO 126.0 2.49 kPA 1.15 mm

DEUX SECTIONS

VUE AVANT

Déballé

Taille

d'Orice

D

17-3/4"

[451mm]

1-1/4"

[32mm]

[816mm]

H

[645mm]

7-3/4"

[197mm]

3/4"

[19mm]

32-1/8"

25-3/8"

3/4 PO N.PT.

ENTRÉE GAZ

[51mm]

CONDUIT DE FUMÉES 2-3/8 x 5 PO

[60mm x 127mm]

VUE DE DESSUS

38"

[965mm]

UNE SECTION

VUE AVANT

38-1/4"

[972mm]

11-1/2"

[292mm]

ENTRÉE ARRIÈRE

GAZ ¾ PO

34"

[864mm]

2"

54-9/16"

[1386mm]

Page 20

Pièce n° 1955201 Rev. 7 (11/28/12)

Page 21

INSTALLATION

Réglementation légale

L’installation de cet appareil doit être faite par une

personne compétente et conformément aux règlements

concernés, codes de pratique et publications connexes du

pays de destination.

CLAUSE SPÉCIFIQUE À L'AUSTRALIE

Cet appareil doit être installé conformément aux

instructions du fabricant, aux règlements locaux

relatifs aux raccords de gaz et aux exigences du code

d'installation AS 5601 / AG 601. Un ingénieur qualié

dans les appareils à gaz doit eectuer les réglages de

tous les brûleurs.

Notes d’installation :

Dégagements par rapport aux murs combustibles et

incombustibles :

Côté : 1,0 po (25 mm)

Arrière : 3,0 po (76 mm)

Cet équipement doit être installé par un réparateur ou un

installateur compétent, formé en usine, homologué, certié

et/ou autorisé.

AVERTISSEMENT. Cet appareil doit être correctement relié à la

terre.

Cet appareil doit être connecté à un système de régulation

de tension. Un point de liaison équipotentielle étiqueté est

prévu à l’arrière du gril.

Il est recommandé de connecter ce gril à un dispositif à

courant résiduel (mise à la terre), le courant de fuite de ce gril

ne doit pas dépasser 30 mA.

Une intensité de déclenchement ne dépassant pas . 5 mA.

Un moyen de coupure de l’alimentation avec une séparation

des contacts d’au moins 3 mm doit être intégré au câblage

xe.

l’allumage. Le diamètre de la conduite d’arrivée du gaz doit

au minimum être de ISO 7-1 1-1/2po. Tous les fours à section

unique ont besoin d'une connexion 3/4 po, les fours à deux

sections ont besoin de connexions 1 po.

Avant de brancher un tuyau neuf, celui-ci doit être nettoyé à

l’air comprimé pour éliminer toutes les particules étrangères.

Ces particules peuvent causer un mauvais fonctionnement.

En cas d’utilisation de graisse à letage, utiliser de petites

quantités sur les lets mâles seulement. Utiliser une graisse

qui n’est pas aectée par l’action chimique du gaz de pétrole

liquéé. Éviter d’appliquer de la graisse sur les deux premiers

lets pour ne pas boucher les orices des brûleurs et le

robinet de commande.

Demander à l’installateur de vérier s’il y a des fuites sur

les conduites de gaz avec une solution d’eau savonneuse.

NE PAS UTILISER d’allumettes, bougies ou d’autres sources

d’allumage pour vérier la présence de fuites.

Le gril doit être débranché du système d’alimentation en

gaz lors des essais de pression du système à des pressions

supérieures à 150 mbars.

Vérier le type de gaz sur la plaque signalétique avant de

brancher le raccord rapide ou la canalisation d’alimentation

en gaz du bâtiment.

Un raccord d’essai de pression du gaz est prévu sur le

collecteur d’arrivée du gaz pour les essais de pression.

La pression minimale d'alimentation pour le gaz naturel est

de 15 mbar.

La pression maximale d'alimentation pour le gaz naturel est

de 30 mbar.

La pression minimale d'alimentation pour le gaz de pétrole

liquéé est de 25 mbar.

La pression maximale d'alimentation pour le gaz de pétrole

liquéé est de 58 mbar.

La pression de fonctionnement de brûleur peut être vériée

sur le côté de sortie du clapet à gaz au point test de mesure

de pression sur la tubulure.

Exigences des codes nationaux :

Pour l'Australie :

Le type de gaz pour lequel le gril est équipé est estampillé sur

la plaque signalétique à l’intérieur du panneau inférieur avant.

Brancher uniquement sur le gaz naturel un gril estampillé

pour le gaz naturel à haute (H) ou basse (L) valeur calorique

et brancher uniquement sur le gaz propane un gril estampillé

pour ce combustible. Lors de l’installation des grils à gaz,

l’installation doit être conforme à la dernière édition des

codes et règlements d’installation en vigueur.

La pression de gaz entrante minimum pour le gaz naturel est

le kPa 1.13.

La pression de gaz entrante maximum pour le gaz naturel est

le kPa 5.00.

La pression de gaz entrante minimum pour le gaz de LP est le

kPa 2.75.

La pression de gaz entrante maximum pour le gaz de LP est le

kPa 7.00.

Connexions du gaz et dimensions des tuyaux

Le diamètre de la conduite de gaz est très important. Si la

conduite est trop petite, la pression au collecteur des brûleurs

sera faible. Cela causera une récupération lente et retardera

Pièce n° 1955201 Rev. 7 (11/28/12) Page 21

Pour ajuster la pression des brûleurs, retirer la vis d'étanchéité

du raccord d’essai de pression et brancher un manomètre,

allumer le four, régler la vis sur le régulateur pour obtenir

la pression correcte, éteindre le four, retirer le manomètre,

remettre en place la vis d’étanchéité sur le raccord d’essai et

Page 22

INSTALLATION suite

vérier la présence de fuites de gaz.

Les pressions de gaz ne devraient être vériées que par la

compagnie de gaz locale ou un organisme d’entretien agréé

Vérier la présence de fuites sur tous les tuyaux et raccords.

Utiliser pour cela une solution contenant beaucoup de savon.

Ne jamais utiliser de amme.

Instructions de conversion

Les réparations doivent être eectuées par une personne

compétente selon la réglementation.

AVERTISSEMENT : Couper l'alimentation en gaz de l'appareil

au robinet de service ainsi que le courant électrique avant de

commencer tout travail de réparation.

IMPORTANT : Vérier s'il y a des fuites de gaz après tout travail

de réparation.

Les instructions suivantes sont destinées à décrire les

opérations nécessaires pour convertir l'équipement pour qu'il

fonctionne avec une autre famille de gaz.

Vérier que toutes les pièces nécessaires pour eectuer la

conversion ont été fournies comme suit :

a. Raccords d'injecteur (un par brûleur principal).

D. Assembler les tuyaux d'empilage fournis dans l'ensemble

d'empilage comme indiqué dans le schéma en haut

de cette page. Cela permet d'alimenter les deux fours

avec une seule conduite de gaz. La taille minimale

recommandée pour une conduite d'alimentation unique

pour deux fours empilés est de 1 po. Utiliser de la graisse

à letage prévue pour une utilisation sur des conduites

de gaz propane et vérier qu'il n'y a pas de fuites avant de

naliser l'installation.

Coude mâle-femelle à 90°

Mamelon 20-1/2 po

Réducteur Bell

3/4 po à 1 po BSPT

Mamelon 3 po

b. Ressort de régulateur (un par unité).

c. Étiquette de conversion (une par unité).

Si une des pièces nécessaires manque, contacter le

concessionnaire Garland avant d'essayer de faire la

conversion.

Installation des Modèles à Deux Sections

A. Placer l’insert dans l’ouverture inférieure du pied et

l’enfoncer dans le pied jusqu’à ce qu’il soit en place à

la bride à collier. Fixer les pieds de six pouces (6 po) à

la section inférieure du four. Soulever l’appareil ou le

coucher sur le côté gauche. Placer les pieds avant sur

le four de manière à les aligner avec les quatre (4) trous

des boulons de xation. Fixer les pieds au châssis du

four en utilisant les quatre (4) boulons de 3/8-16 x 3/4 et

les rondelles fournis. Faire la même chose à l’arrière de

l’appareil.

B. Retirer le couvercle inférieur avant de la section supérieure

(situé sous les portes du four). Mettre la section supérieure

en place et aligner les côtés de la carrosserie et l’arrière

de l’appareil. Fixer l’arrière des appareils ensemble avec la

bride d’empilage, en utilisant huit (6) vis à métaux de 1/420, les rondelles de blocage et les écrous fournis.

Raccord union 3/4 po

Mamelon 3 po

Coude mâle-femelle à 90°

E. Vérier que l’appareil est de niveau dans les quatre sens

en posant un niveau de charpentier ordinaire sur la grille à

l’intérieur du four.

F. Câbler chaque unité à une alimentation électrique 230

volts.

G. Maintenir le dégagement nécessaire par rapport aux

matières combustibles.

Chaque appareil à gaz sera disposé conformément à la

construction du bâtiment et aux autres équipements de

manière à pouvoir accéder à l'appareil. Cet accès et le

dégagement peuvent être nécessaires pour l'entretien et le

nettoyage de l'appareil..

Connexions Du Gaz

C. Installer les pièces d'interconnexion des conduits de

fumée en suivant scrupuleusement les instructions

contenues dans l'ensemble d'empilage. Faire très

attention au type de fours à empiler et bien suivre les

instructions correspondantes.

Page 22

On devra utiliser l'entrée de 1 po NPT à l'arrière de l'appareil

lors de l'installation de la conduite d'alimentation en gaz

pour les appareils à deux sections empilées ou l'entrée ¾ po

NPT pour les connexions individuelles (une section). Une

conduite de gaz sous-dimensionnée peut limiter le débit du

gaz et aecter les performances. Si d'autres appareils sont

Pièce n° 1955201 Rev. 7 (11/28/12)

Page 23

INSTALLATION suite

alimentés par la même conduite, cette conduite doit avoir un

diamètre susant pour alimenter tous les appareils installés

sans provoquer de chute de pression supérieure à ½ po au

collecteur de chaque appareil branché sur la conduite, à plein

régime.

Connexions Électriques

Installez le four selon les agences électriques locales et

codez les conditions. Cet équipement doit être installé par

une personne qualiée, certiée, autorisée et/ou autorisée

compétente d'usine de service ou d'installation.

AVERTISSEMENT. Cet appareil doit être mis à la terre. Cet

appareil devrait être relié à un système de péréquation

potentiel. Pour faciliter ceci un point de liaison équipotentiel

marqué est adapté derrière le four.

Un schéma de câblage est xé à l'arrière de l'appareil.

AVERTISSEMENT :

DÉBRANCHER LES DEUX APPAREILS DE

L'ALIMENTATION ÉLECTRIQUE AVANT DE

PROCÉDER À LEUR ENTRETIEN.

IMPORTANT

Tous les brûleurs à gaz et les veilleuses

ont besoin de suffisamment d'air pour

fonctionner, et on ne devra pas placer

d'objets de grande taille devant le four, car ils

pourraient empêcher la circulation de l'air à

l'avant de l'appareil. On ne devra pas placer

d'objets à l'arrière du four supérieur pendant

son fonctionnement. Cela peut obstruer

le système de ventilation des fumées de

l'appareil. .

PANNE D'ÉLECTRICITÉ

En cas de panne d'électricité, ne pas essayer de

faire fonctionner ce four.

Ventilation et Alimentation en Air

Une bonne ventilation est extrêmement importante pour

que cet appareil fonctionne correctement. La méthode idéale

pour ventiler un four à convection à gaz est d'utiliser une

hotte correctement conçue, qui doit se prolonger de 6 po

(150 mm) sur tous les côtés de l'appareil et être placée à 6 pi 6

po (1 950 mm) du sol.

Un ventilateur d'extraction puissant crée un vide d'air dans

la pièce. Pour qu'un système d'évacuation d'air fonctionne

correctement, les quantités d'air évacué et d'air frais doivent

être bien équilibrées. Pour obtenir cet équilibre, contacter le

spécialiste local en chauage et climatisation.

Tous les brûleurs et veilleuses à gaz ont besoin de

susamment d'air pour fonctionner et on ne devra pas placer

d'objets de grande taille à l'arrière et en bas du four, car cela

empêcherait la circulation de l'air à l'avant de l'appareil.

Pièce n° 1955201 Rev. 7 (11/28/12) Page 23

Page 24

INSTALLATION suite

Instructions d'essai et d'allumage

1. Ouvrir le robinet principal de gaz. Retirer le couvercle

inférieur avant et le panneau d'entretien au dessus

du panneau de commande. Abaisser le panneau de

commande et rechercher les fuites sur tous les raccords

et toutes les connexions en amont du robinet d'entretien

situé sur le robinet de gaz combiné redondant. Si une

fuite de gaz est détectée, mettre le robinet principal de

gaz en position fermée, corriger le problème et refaire un

essai.

2. Ouvrir le robinet d'arrêt située sur le robinet combiné

redondant de gaz. Activer le panneau de commande et

régler la température désirée. La veilleuse et le brûleur

sont maintenant allumés par une étincelle directe. Vérier

encore une fois tous les raccords, réparer les fuites et

eectuer une nouvelle vérication.

Remettre en place les panneaux d'entretien et les

couvercles avant d'utiliser l'appareil.

NOTA: Tous les systèmes d'allumage électronique sont

fournis avec un robinet de gaz redondant. Pour cette raison,

l'appareil n'est pas livré avec un régulateur de pression

extérieur.

NOTA: De l'air pénètrera dans la canalisation de gaz pendant

l'installation, et cet air doit être purgé avant de procéder à

l'allumage de l'appareil. Le système d'allumage électronique

est doté d'un verrouillage de 90 secondes comme dispositif

de sécurité sur tous les appareils. Par conséquent, il peut être

nécessaire de refaire plusieurs tentatives avant l'allumage de

la veilleuse. Attendre cinq minutes après chaque tentative.

POUR LA SÉCURITÉ DE L'UTILISATEUR, ÉLOIGNER TOUTE

MATIÈRE COMBUSTIBLE DE LA ZONE ENTOURANT LE FOUR.

POUR ÉCONOMISER L'ÉNERGIE:

Ne pas gaspiller l'énergie en laissant les commandes sur

les réglages forts pendant les périodes d'inactivité. Des

réglages plus bas maintiendront le four chaud et prêt pour

la période d'utilisation suivante. Les commandes de la série

Master 400 possèdent une fonction automatique de point de

consigne programmable par l'utilisateur pour en simplier les

applications..

Page 24

Pièce n° 1955201 Rev. 7 (11/28/12)

Page 25

FONCTIONNEMENT

Commande Électronique Master 450 avec

Cuisson et Attente et Commande Électronique

Master 455 avec Cuisson et Attente et Sonde

Thermique

En Mode d’arrêt (O):

Lorsque le contrôleur est désactivé, l’achage indique

« OFF » . Le fait d’appuyer sur la touche ON/OFF active le

contrôleur en mode de démarrage (Start Up).

En Mode de Démarrage (Start Up)

En mode de démarrage, le contrôleur commande le

chauageselon les derniers réglages eectués en matière de

température, de durée de cuisson et de vitesse du ventilateur.

Le valeurs par défaut réglées en usine sont de 350°F (177°C),

30 minutes et basse vitesse du ventilateur. L’achage indique

« LO » lorsque la température du four est inférieure à la

température sélectionnée. Lorsque l’intérieur du four atteint

la température sélectionnée et que le four est prêt à être

utilisé, l’achage indique « LOAD » .

REMARQUE: Si la température du four dépasse la

température sélectionnée, l’achage indique « HI » , et si

la température du four dépasse 575°F (302°C) l’achage

indique « HELP » et le signal sonore retentit. Ceci est une

fonction de sécurité.

Si la porte est ouverte pendant le mode de cuisson, le

ventilateur et le chauage s’arrêtent et l’achage indique

« DOOR » jusqu’à ce que la porte soit fermée. Ceci est une

fonction de sécurité .

Quand on appuie sur la touche ACTUAL TEMP, la

température réelle du four est indiquée sur l’achage par

incréments de 5 degrés.

Touches du Contrôleur

On appuie sur la touche ON/OFF, pour mettre en marche le

four.

Quand on appuie sur la touche LIGHT, l’éclairage s’allume

pendant 30 secondes. Les lampes fonctionnent si le

contrôleur est en mode d’arrêt (O). Lorsque la porte du four

est ouverte, la lumière s’allume et reste allumée pendant 30

secondes.

Quand on appuie sur la touche FAN HIGH, le ventilateur

fonctionne à haute vitesse et sa DEL s’allume.

Quand on appuie sur la touche FAN LOW, le ventilateur

fonctionne à basse vitesse et sa DEL s’allume.

Quand on appuie sur la touche FAN PULSE, le ventilateur

fonctionne à basse vitesse et sa DEL s’allume. Le ventilateur

fonctionne pendant 30 secondes à basse vitesse, s’arrête

pendant 30 secondes, puis recommence le cycle.

Pièce n° 1955201 Rev. 7 (11/28/12) Page 25

Page 26

FONCTIONNEMENT suite

En appuyant sur la touche SETBACK, on refroidit le four

jusqu’à une température préprogrammée, voir : Réglage de

la fonction « Set-back » (retour au point de consigne). Le four

revient automatiquement en mode de retour au point de

consigne après le temps de non utilisation préprogrammé.

L’achage indique « SETB ». Il s’agit d’une fonction destinée à

économiser l’énergie.

Quand on appuie sur la touche COOL DOWN, le chauage

est désactivé, le ventilateur fonctionne à haute vitesse et sa

DEL est allumée. L’achage indique « OPEN DOOR » si la

porte est fermée, demandant à l’utilisateur d’entrouvrir la

porte. Avec la porte entrouverte, l’achage indique « COOL

». La fonction Cool Down (refroidissement) fonctionne avec la

porte fermée ou entrouverte. Le refroidissement optimal est

atteint avec la porte entrouverte. Lorsque la porte est plus

largement ouverte, le mode de refroidissement est désactivé

et l’achage indique « DOOR » . Ceci est une fonction brevetée.

Si on appuie à nouveau sur la touche COOL DOWN, la DEL

s’éteint et on désactive ce mode de fonctionnement. En

appuyant sur la touche ON/OFF, on désactive également le

mode de refroidissement. Le mode de refroidissement n’est

pas activé pendant la cuisson.

Si on appuie sur la touche ON/OFF pour arrêter le four et

si la température du four est supérieure à 200°F (93°C), le

four entre en mode Auto Cool Down (refroidissement

automatique). En mode de refroidissement automatique,

le ventilateur fonctionne à haute vitesse jusqu’à ce que la

température intérieure du four descende au-dessous de

150°F (66°C). Pendant ce temps, l’achage indique

« AUTO ». Lorsque la température du four est inférieure 150°F

(66°C), le four s’arrête. Cette fonction protège le moteur du four

contre une panne prématurée. On obtient un refroidissement

optimal du four avec la porte entrouverte.

Fahrenheit/Celsius

Le défaut d’usine est Fahrenheit (F). Pour changer en (C)

Celsius, pression et prise dans « touche fantôme » située à

la droite de la touche de « Cook/Hold ». « F » apparaît dans

l’achage. Continuez à tenir jusqu’à ce que « C » soit montré

et puis à libérer « la touche fantôme ».

Utilisation des Commandes

Le réglage de la température et du temps de cuisson se

fait de la même manière. Quand on appuie sur la touche

SET, la DEL TEMP s’allume. L’utilisateur règle la température

en tournant le cadran du contrôleur jusqu’à ce que la

température désirée soit indiquée sur l’achage. Si on appuie

une deuxième fois sur la touche SET, la DEL TIME s’allume

ce qui permet à l’utilisateur de choisir le temps de cuisson

comme indiqué sur l’achage. En appuyant une troisième

fois sur la touche SET, on arrête la programmation.

En appuyant sur la touche START/CANCEL, on lance le cycle

de la minuterie. Une fois le cycle terminé, en appuyant sur

ce touche on annule également le message « DONE ». Pour

annuler un cycle de la minuterie pendant le cycle, maintenir

enfoncée pendant 3 secondes la touche START/CANCEL.

Page 26

Pièce n° 1955201 Rev. 7 (11/28/12)

Page 27

FONCTIONNEMENT suite

Fonctionnement en Mode Cuisson-attente

Quand on appuie sur la touche COOK/HOLD (Contrôleurs 450

et 455 uniquement) on active le mode Cook-N-Hold (cuisson

et attente) et sa DEL s’allume. Pour vérier que l’on a choisi la

bonne température d’attente, appuyer deux fois sur la touche

SET. L’achage indique la température d’attente. À la n du

cycle de cuisson, le message « DONE » clignote sur l’achage

et le signal sonore retentit pendant 3 secondes, après quoi

l’achage indique « HOLD » et le four passe à la température

d’attente programmée.

Le réglage de la température de cuisson, de la température

d’attente et du temps de cuisson se fait de la même façon.

Quand on appuie sur la touche SET, la DEL TEMP s’allume.

L’utilisateur règle alors la température en tournant le

cadran du contrôleur jusqu’à ce que la température désirée

apparaisse sur l’achage. Quand on appuie une deuxième

fois sur la touche SET, la DEL HOLD s’allume et l’utilisateur

peut régler la température d’attente souhaitée indiquée sur

l’achage. Quand on appuie une troisième fois sur la touche

SET, la DEL TIME s’allume et l’utilisateur peut sélectionner

le temps de cuisson désiré indiqué sur l’achage. Quand

on appuie un quatrième fois sur la touche SET, on arrête la

programmation.

Quand on appuie sur la touche START/CANCEL, on lance le

cycle de la minuterie. Une fois le cycle terminé, on appuie

sur cette touche pour eacer également le message « DONE

». Pour annuler un cycle de la minuterie pendant le cycle,

maintenir enfoncée la touche

START/CANCEL pendant 3 secondes.

Fonctionnement avec la Sonde Thermique

Lorsque la température intérieure de l’aliment est atteinte,

le signal sonore retentit et le message « DONE » clignote

sur l’achage pendant 3 secondes. L’achage passe

automatiquement à « HOLD » . Pour terminer ce cycle, la

sonde thermique doit être retirée du connecteur.

Réglage de la fonction Setback

(retour au point de consigne)

Pour congurer ou modier les réglages de retour au point

de consigne, maintenir enfoncée la touche SETBACK pendant

deux secondes. La DÉL TEMP s’allume et une température

s’ache. Régler la température avec le cadran, puis appuyer

sur la touche SET. La DÉL TEMP s’éteint et la DÉL TIME s’allume

(le « Temps » est réglé à 0 en usine). Régler le temps avec le

cadran, puis appuyer sur la touche SET. Appuyer encore une

fois sur la touche SET pour sortir du mode de programmation.

REMARQUE: Pour désactiver la fonction de réduction de

puissance,r régler la température sur 250º F (121ºC) et le

minuterie sur zéro.

.

L’option Core Probe (sonde thermique) (Contrôleur 455

uniquement) est activée uniquement lorsque la sonde

thermique est branchée sur son connecteur. Pour régler la

température de l’intérieur de l’aliment, brancher d’abord la

sonde thermique dans son connecteur. L’achage indique

« 100 » et la DEL CORE TEMP s’allume. L’utilisateur règle alors

la température en tournant le cadran du contrôleur jusqu’à

ce que la température souhaitée apparaisse sur l’achage.

Quand on appuie sur la touche SET, la température à

l’intérieur de l’aliment est enregistrée et le processus de

cuisson commence.

Pour régler la température du four, appuyer à nouveau sur

la touche SE T. La DEL TEMP s’allume et on peut régler la

température du four en tournant le cadran du contrôleur

jusqu’à ce que la température désirée s’ache. Quand on

appuie à nouveau sur la touche SET, la DEL HOLD s’allume et

l’utilisateur peut régler la température d’attente de la même

manière.

REMARQUE: Si la température d’attente n’est pas réglée,

l’appareil utilisera la température d’attente par défaut de

150°F (66°C) ou la dernière température programmée. (La

gamme des températures d’attente va de 140°F (60°C) à 210°F

(99°C).

Pièce n° 1955201 Rev. 7 (11/28/12) Page 27

Page 28

RECOMMANDATIONS D’UTILISATION ET

PRÉCAUTIONS GÉNÉRALES DE SÉCURITÉ

1. Bien préchauer le four (environ 20 minutes) avant son

utilisation.

2. D’une façon générale, réduire la température par rapport

à celle d’un four conventionnel/standard. Le temps de

cuisson peut également être plus court et pour cette

raison nous recommandons de surveiller attentivement la

première cuisson de chaque type de produits.

3. Utiliser le tableau des temps et des températures de

cuisson suggérés comme guide. Ces valeurs peuvent

varier en fonction de la quantité d’aliments placés dans

le four, de la température et du mélange de produits, (en

particulier de l’humidité) et de la densité des produits.

4. Noter les temps de cuisson, les températures et les

quantités d’aliment pour les diérents produits. Une

fois ces renseignements notés, les autres opérations de

cuisson seront similaires.

5. Si possible, commencer par cuire les produits ayant

la température de cuisson la plus basse et passer

progressivement aux températures plus élevées.

6. Si le réglage de température précédent est plus élevé

de 10°F ou 5°C à la température nécessaire pour les

charges suivantes, utiliser le mode de refroidissement

pour atteindre la température souhaitée avant de régler à

nouveau le thermostat.

7. Pour charger le four, travailler aussi vite que possible pour

éviter les pertes de chaleur.

8. Le four continue à chauer même après l’arrêt de la

minuterie. Les aliments doivent être retirés du four aussi

vite que possible pour éviter de trop les faire cuire.

14. Pour le réchauage des plats en cocotte congelés,

préchauer le four à 100°F ou 60°C de plus que la

température suggérée. Revenir ensuite à la température

de cuisson suggérée après le chargement du four. Cela

permet de compenser la chute de température provoquée

par l’introduction d’une grande quantité d’aliments froids

dans le four.

15. Utiliser des rehausses de moules ou des moules de 18 x26

po d’une profondeur de deux pouces pour la cuisson des

aliments enrobés de pâte dont le poids dépasse huit livres,

par exemple le gâteau renversé aux ananas.

16. Ne jamais placer quoi que se soit directement sur le fond

du four. Cela empêche la circulation de l’air et cause une

cuisson inégale.

17. 17. Ne jamais utiliser ce four si un des panneaux extérieurs

est déposé. Ces panneaux sont nécessaires pour la

protection des pièces électriques sous tension et ne

doivent être déposés que pendant l'entretien du four par

du personnel d'entretien qualié.

18. Ceci est un four de cuisson commercial non destiné à

des installations de cuisson non commerciales ou à des

produits non alimentaires.

19. Utiliser des plats et plateaux alimentaires pour fours.

20. Utiliser des gants isolants pour ajouter ou retirer des plats/

plateaux du four quand celui-ci est allumé.

21. Faire attention pour retirer les produits du four an

d'éviter les déversements pouvant causer des blessures

graves sur la peau nue et aux yeux. Les niveaux élevés de

la crémaillère des fours sont à hauteur des yeux.

9. Centrer les plats dans le four et les répartir également sur

les grilles pour permettre une bonne circulation de l’air à