Page 1

Master Series

Full-Size Electric Convection Ovens

Installation, Operation and Maintenance Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

models

MCO-ES-10S

MCO-ED-10S

MCO-ES-20S

MCO-ED-20S

MCO-ES-10

MCO-ED-10

MCO-ES-20

MCO-ED-20

Part Number 1955203 rev 4 4/15

MCO-ES-10

Page 2

SAFETY NOTICES

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects or other

reproductive harm. Installation and servicing of this product could expose you to airborne particles of glass wool/

ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers is known to the state of California to cause

cancer.

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

Power Failure

In the event of a power failure, no attempt should be

made to operate this oven.

Notice: CE models discontinued (manufactured up to October, 2014).

Part Number 1955203 rev 4 4/152

Page 3

TABLE OF CONTENTS

SAFETY NOTICES. . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL INFORMATION . . . . . . . . . . . . . . . 5

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . .5

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

DIMENSIONS AND SPECIFICATIONS, MCO

ED/ES 10/20 . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DIMENSIONS AND SPECIFICATIONS, MCO

ED/ES 10/20 S. . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 8

Entry Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Clearance . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation of Double Deck Models . . . . . . . . . . . 8

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATING INSTRUCTIONS. . . . . . . . . . . . 10

Master 200 Solid State Control with

Electromechanical Timer . . . . . . . . . . . . . . . . . . .10

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cool Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Core Probe Operation . . . . . . . . . . . . . . . . . . . 13

Setting Setback Feature . . . . . . . . . . . . . . . . . 13

Master 475 Electronic Programmable Control 14

Manual Cooking. . . . . . . . . . . . . . . . . . . . . . . . . 14

Manual cooking using Cook-N-Hold. . . . . . 14

Programming Product Keys (Master 475) . 14

Cooking Using The Product Keys

(Master 475) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Verifying Hold Time (Master 475) . . . . . . . . . 16

Selecting Fahrenheit or Celsius (Master 475) . .16

Cooking With The Shelf Timer (Master 475) . .

16

PERFORMANCE RECOMMENDATIONS AND

GENERAL SAFETY PRECAUTIONS. . . . . . . 17

PROBLEM/SOLUTIONS . . . . . . . . . . . . . . . . 18

COOKING GUIDE. . . . . . . . . . . . . . . . . . . . . .19

COOK AND HOLD . . . . . . . . . . . . . . . . . . . . .20

CLEANING AND MAINTENANCE . . . . . . . .21

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fan Area Maintenance . . . . . . . . . . . . . . . . . . . . . .21

Motor Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

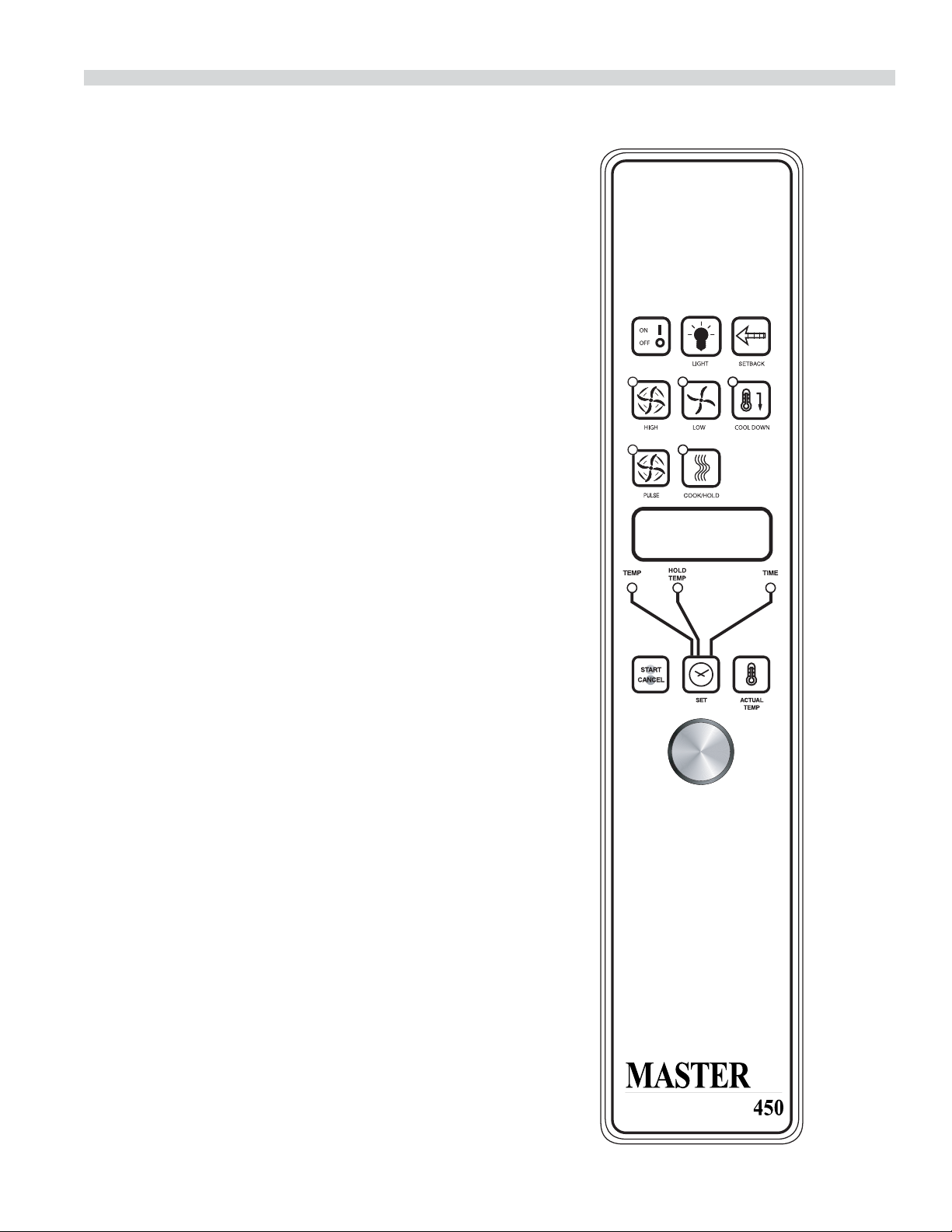

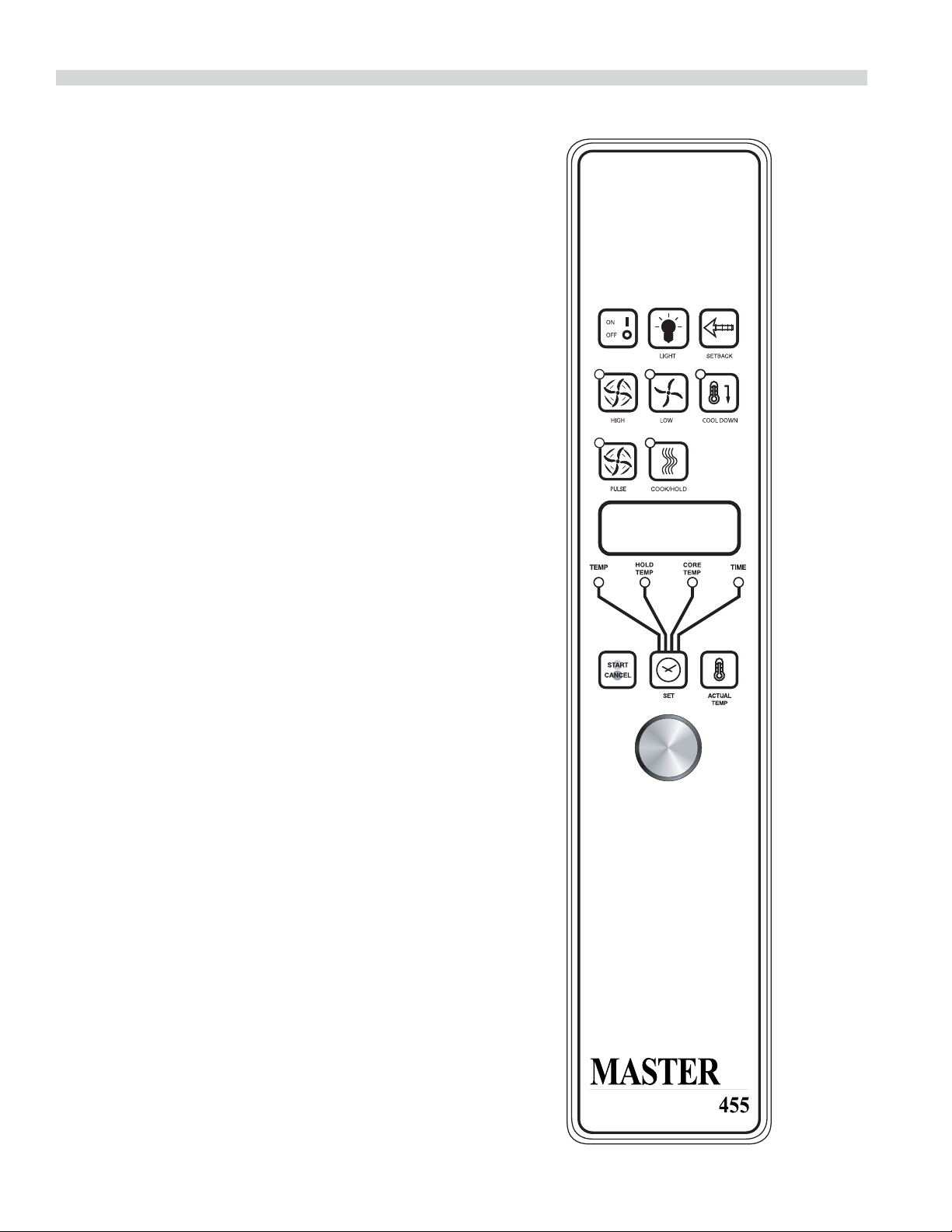

Master 450 Electronic Control with

Cook-N-Hold and Master 455 Electronic Control

with Cook-N-Hold & Core Probe . . . . . . . . . . . . . 11

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controller Keys . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fahrenheit/Celsius. . . . . . . . . . . . . . . . . . . . . . . 12

Operating the Controls . . . . . . . . . . . . . . . . . . 13

Cook-N-Hold Operation . . . . . . . . . . . . . . . . . 13

Part Number 1955203 rev 4 4/15 3

Page 4

THIS PAGE INTENTIONALLY LEFT BLANK

Page 5

GENERAL INFORMATION

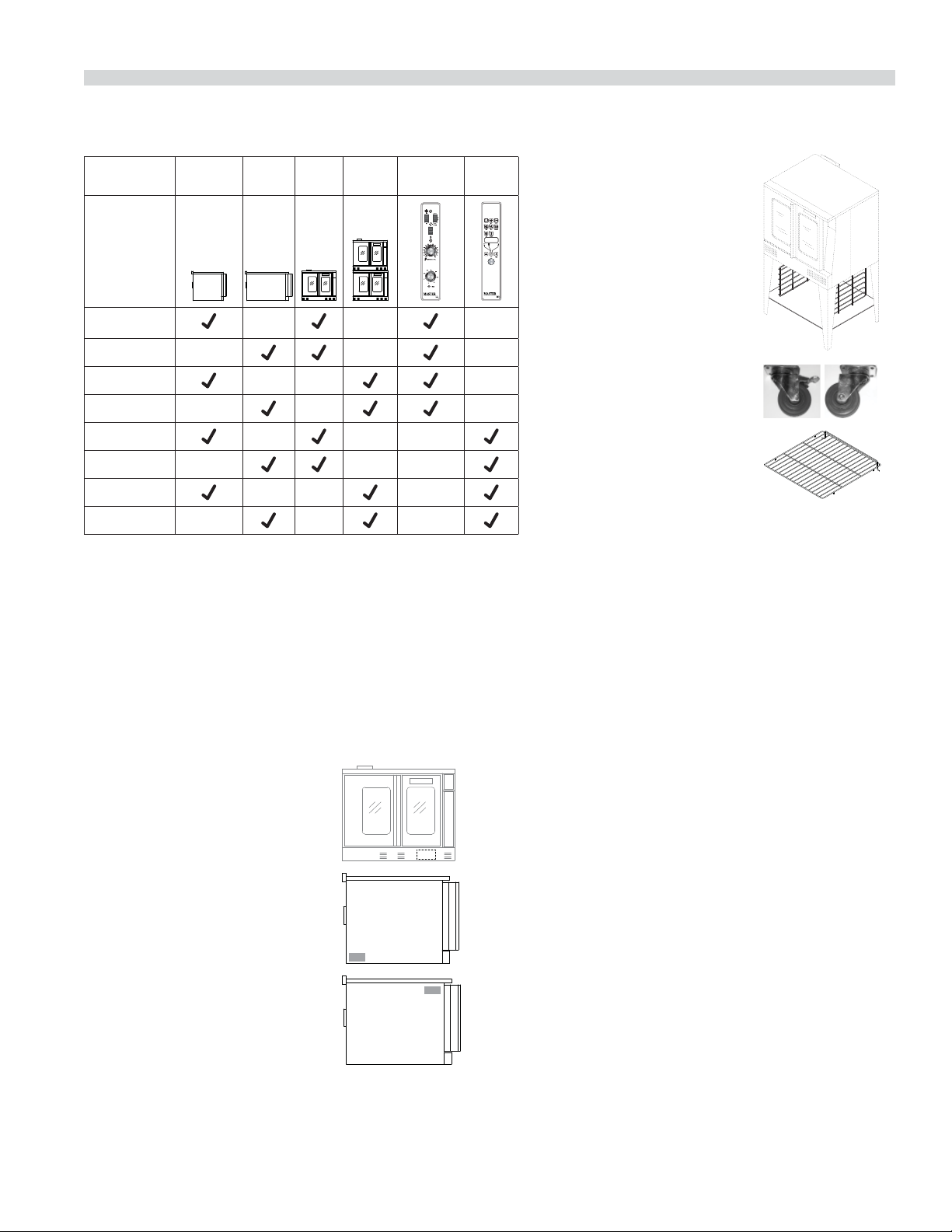

Model Numbers

Model Standard

Depth

MCO-ES-10S

MCO-ED-10S

MCO-ES-20S

MCO-ED-20S

MCO-ES-10

MCO-ED-10

MCO-ES-20

MCO-ED-20

Deep

Depth

Single

Deck

Double

Deck

Master

Control

200

Digital

Control

Warranty

Visit www.Garland-Group.com to view or download a copy of your

warranty.

Accessories

• Stainless steel open base

with rack guides and shelf

(in lieu of 25-inch legs) for

extra rack/pan storage,

single deck oven only

• Swivel Casters (set of 4) with

front brakes

• Extra oven rack

• Removable stainless steel drip pan

Serial Plate Location

When corresponding with the factory or your local authorized

factory service center regarding service problems or replacement

parts, be sure to refer to the particular unit by the correct model

number (including the prefix and suffix letters and numbers) and

the warranty serial number.

Ovens Built prior to 31-MAR-2011

• The serial plate is affixed to the

inside of the lower front cover.

Ovens Built between 01-APR-2011

and

• The serial plate is affixed to the

lower left corner of the left body

panel.

Ovens Built after 02-FEB-2015

• The serial plate is affixed to the

upper right corner of the left

body panel.

Part Number 1955203 rev 4 4/15 5

Page 6

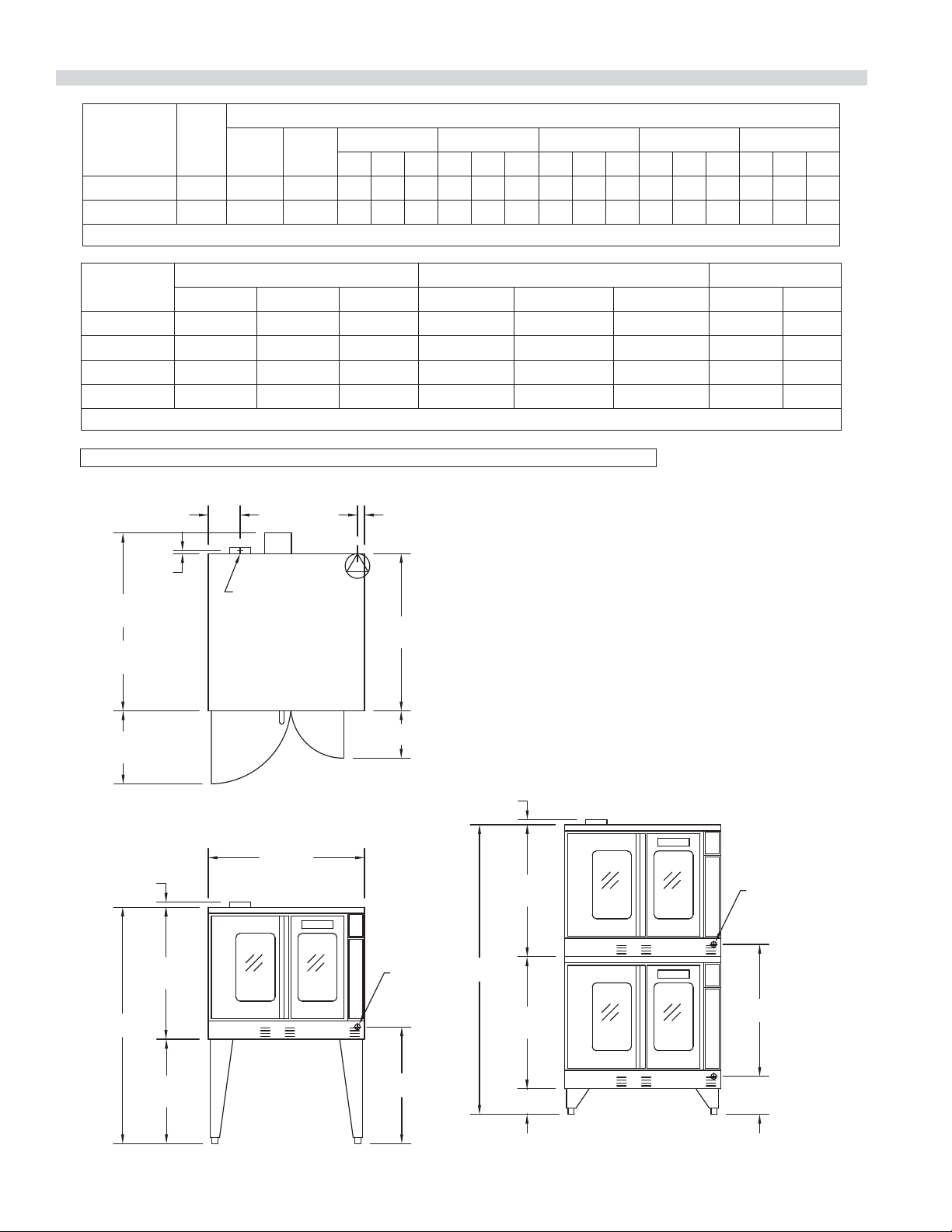

DIMENSIONS AND SPECIFICATIONS, MCO ED/ES 10/20

Nominal Amperes Per Line (includes 3/4 HP fan motor)

208V/3Ph 240V/3Ph 460V/3Ph 380V/3Ph** 415V/3Ph

XYZXYZXYZXYZXYZ

Model**

Total

kW

Load

208V/

1Ph

240V/

1Ph

MCO-ES-10 10.4 50 43 30 30 28 26 26 24 14 14 13 15 13 13 16 14 14

MCO-ED-10 10.4 50 43 30 30 28 26 26 24 14 14 13 15 13 13 16 14 14

**Total kW rating for 380/3 phase models is 9.0

Model

Interior Dimensions (per oven) Exterior Dimensions Ship Info.

W:In(mm) H:In(mm) D:In(mm) W:In(mm) H:In(mm) D:In(mm) Lbs./Kg Cu. Ft.

MCO-ES-10 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 41-1/4 (1048) 515/230 64

MCO-ES-20 29 (736) 24 (610) 24 (610) 38 (965) 70-1/2 (1791)* 41-1/4 (1048) 1030/465 128

MCO-ED-10 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 44-1/2(1130) 545/245 64

MCO-ED-20 29 (736) 24 (610) 28 (711) 38 (965) 70-1/2 (1791)* 44-1/2(1130) 1090/490 128

* Height with legs or with standard casters. Height with low profile casters (double deck) is 68-1/2” (1740mm).

Notice: CE models discontinued (manufactured up to October, 2014).

1-11/16"

[43mm]

38-1/4"

[972mm]

Standard electrical speci cations include motor

requirements. 3/4 HP, 2-speed motor, 1140/950 and

1725/1140 RPM, 60/50 Hz.

NOTE: Double deck ovens are provided with individual

supply connections.

MCO-ES

41-1/4"

[1048mm]

MCO-ED

44-1/2"

[1130mm]

7-3/4"

[197mm]

3/4"

[19mm]

FLUE: 2-3/8" x 5"

[60mm x 127mm]

17-3/4"

[451mm]

1-1/4"

[32mm]

57-1/2"

[1461mm]

32-1/8"

[816mm]

25-3/8"

[645mm]

TOP VIEW

38"

[965mm]

SINGLE DECK

FRONT VIEW

11-1/2"

[292mm]

REAR

CABLE

ENTRANCE

28-3/8"

[721mm]

1-1/4"

[32mm]

70-1/2"

[1791mm]

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

DOUBLE DECK

FRONT VIEW

REAR CABLE

ENTRANCE

32-1/8"

[816mm]

9-1/4"

[235mm]

Part Number 1955203 rev 4 4/156

Page 7

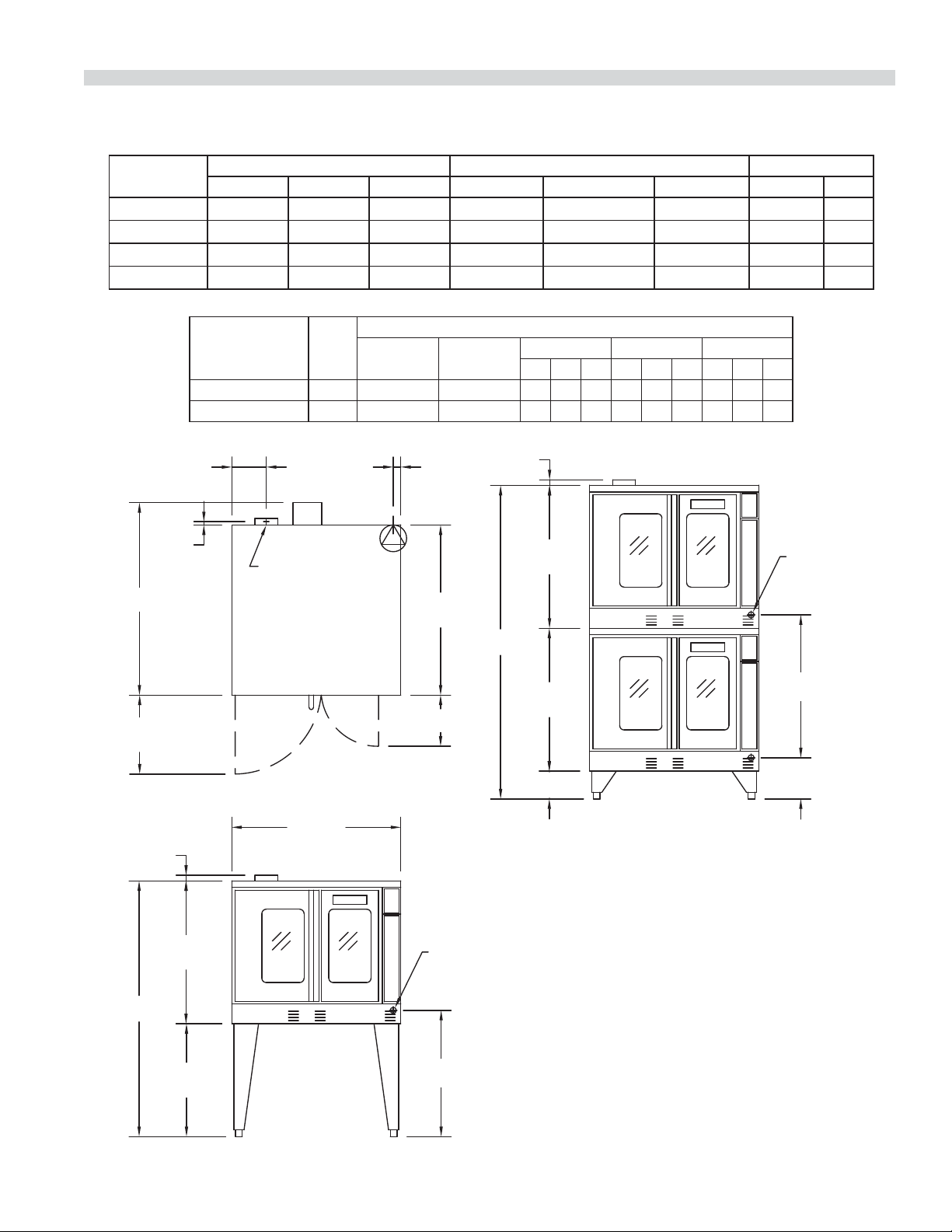

DIMENSIONS AND SPECIFICATIONS, MCO ED/ES 10/20 S

Model

MCO-ES-10S

MCO-ES-20S

MCO-ED-10S

MCO-ED-20S

Interior Dimensions (per oven) Exterior Dimensions Ship Info.

W:In(mm) H:In(mm) D:In(mm) W:In(mm) H:In(mm) D:In(mm) Lbs./Kg Cu Ft

29(436) 24(610) 24(610) 38(965) 57-1/2(1416)

29(436) 24(610) 24(610) 38(965) 70-1/2(1791)*

29(436) 24(610) 28(711) 38(965) 57-1/2(1416)

29(436) 24(610) 28(711) 38(965) 70-1/2(1791)*

41-1/4 (1048)

41-1/4 (1048)

44-1/2(1130)

44-1/2(1130)

515/230 64

1030/465 128

545/245 64

1090/490 128

* Height with or without standard casters. Height with low pro le casters (double deck) is 68-1/2" (1740mm).

Nominal Amperes Per Line (includes 3/4 HP fan motor)

208V/1Ph 240V/1Ph

208V/3Ph 240V/3Ph 460V/3Ph

XYZXYZXYZ

Model**

Total

kW

Load

MCO-ES-10S 10.4 50 43 30 30 28 26 26 24 14 14 13

MCO-ED-10S 10.4 50 43 30 30 38 26 26 24 14 14 13

** NOTE: Double deck ovens are provided with individual supply connections

1-1/4"

[32mm]

32-1/8"

[816mm]

H

[19mm]

D

7-3/4"

[197mm]

3/4"

1-11/16"

[43mm]

FLUE: 2-3/8" x 5"

[60mm x 127mm]

38-1/4"

[972mm]

REAR CABLE

ENTRANCE

17-3/4"

[451mm]

1-1/4"

[32mm]

H

32-1/8"

[816mm]

25-3/8"

[645mm]

TOP VIEW

38"

[965mm]

SINGLE DECK

FRONT VIEW

11-1/2"

[292mm]

REAR CABLE

ENTRANCE

28-3/8"

[721mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

DOUBLE DECK

FRONT VIEW

32-1/8"

[816mm]

9-1/4"

[235mm]

Standard electrical speci cations include motor

requirements. 3/4 H.P., 2 speed motor, 1140/950

and 1725/1140 RPM, 60/50 Hz.

Part Number 1955203 rev 4 4/15 7

Page 8

INSTALLATION

Entry Clearance

• Crated: 47” (1194mm)

• Uncrated: 32-1/2” (826mm)

Installation Clearance

NOTE: Always provide adequate clearance for maintenance

and operation.

• Installation adjacent to combustible and noncombustible wall, minimum clearance:

Left Side Control Side Rear

Single-Deck 1" (26 mm) 1" (26 mm) 3" (77 mm)

Double-Deck 1" (26 mm) 2" (51 mm) 3" (77 mm)

• Installation near high heat producing equipment,

minimum clearance:

Left Side Control Side Rear

Single-Deck 1" (26 mm) 6" (153 mm) 3" (77 mm)

Double-Deck 1" (26 mm) 6" (153 mm) 3" (77 mm)

Notice

Avoid installing ovens near equipment, such as charbroilers or fryers, which generate high heat and high

grease laden air.

• Clearance for Service (recommendation):

Control Side, minimum

Single-Deck 12" (305 mm)

Double-Deck 12" (305 mm)

NOTE: Install units with casters in very tight

locations for ease of service.

IMPORTANT Large objects should not be placed in front

of this oven, which would obstruct the air ow through the

front. Objects should not be placed on the main top rear

of the oven while in use because this could obstruct the

venting system. Install ovens where side body perforated

panels or control sections do not get sprayed with water

wash down spray hoses.

Installation of Ovens Equipped with Casters

A. For an appliance equipped with casters, the installation

shall be made with a connector that complies with the

Standard for Connectors for Movable Appliances, ANSI

Z21.69. Adequate means must be provided to limit the

movement of the appliance without depending on the

connector wiring.

B. The front casters of the unit are equipped with brakes to

limit the movement of the oven without depending on

the connector wiring to limit the appliance movement.

C. A restraint can be attached to the unit. If the restraint is

disconnected, be sure to reconnect the restraint after the

oven has been returned to its originally installed position.

Installation of Double Deck Models

A. Position insert in bottom leg opening and tap insert up

into leg until it seats at collar. Attach six inch (6”) legs to

lower oven section. Raise unit or lay on its left side. Place

the front legs on the oven so as to line up with four (4)

attaching bolt holes. Secure leg to oven frame using (4)

3/8-16 x 3/4 bolts and washers provided. Repeat at rear of

unit.

B. Remove lower front cover of top deck (located under

oven doors). Raise top deck into place and line up body

sides and back of the unit. Fasten the rear of the units

together, with the stacking bracket using (6) 1/4-20

machine screws, lock washers and nuts, (provided).

C. Install the interconnecting ue parts, carefully following

the instructions contained in the stacking kit. Pay

particular attention to the type of ovens you are stacking

and be sure to follow the corresponding instructions.

D. Check leveling of unit four (4) ways (using a common

carpenter’s level on the rack inside the oven).

E. Maintain clearance from combustibles.

CAUTION: Disconnect both ovens from electrical supply

before servicing to protect against shock!

Part Number 1955203 rev 4 4/158

Page 9

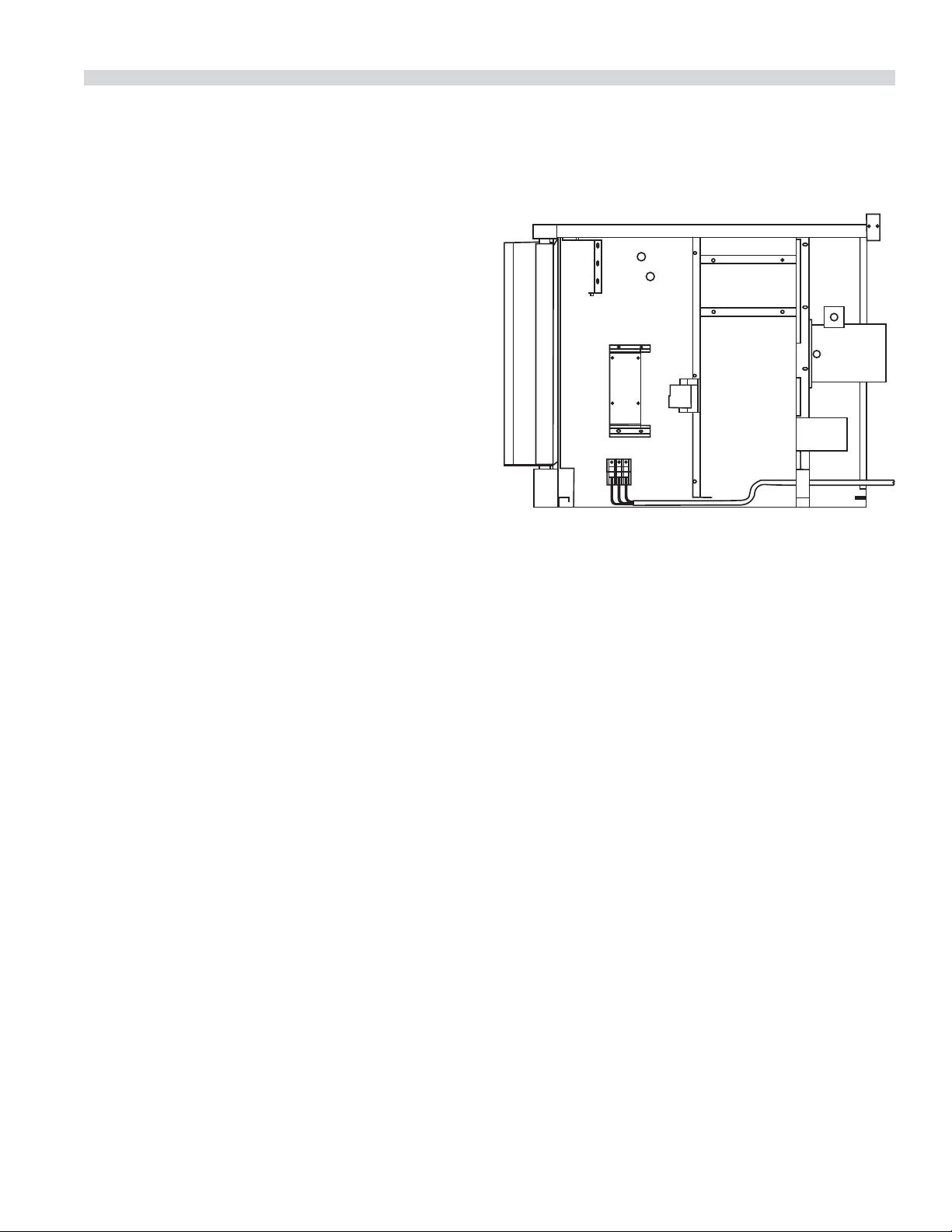

INSTALLATION Continued

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

Installation of the wiring must be made in accordance with

U.L. 197 Commercial Electric Cooking Appliance Standards,

Local and/or National Electrical Code,

ANSI/NFPA 70-1990, or the Canadian Electrical Code, CSA

C22.2 as applicable.

1. Switch panel size

2. Overload protection

3. Wire type

4. Wire size

5. Temperature limitations of the wires

6. Method of connection (Cable, Conduit, etc.)

The service line will enter through the rear of the unit and

is to be connected to the terminal block (see diagram). The

terminal block is accessed by removing the lower front cover.

Removal of the body side is not necessary. Install a main

disconnect switch and a separate fuse or breaker with this

appliance. Use a su cient length of exible conduit between

the main disconnect switch and the appliance so unit can be

moved for service.

Input voltage and phasing must match the units voltage

and phasing. Wiring diagram is attached to the main back of

each oven. Visually check all electrical connections. Energize

electric service to units.

The oven is wired per original factory order. If it is necessary

to change to single-phase or three-phase, please refer to kit

part number 4533009.

Service and unit voltage must agree.

Part Number 1955203 rev 4 4/15 9

Page 10

OPERATING INSTRUCTIONS

Master 200 Solid State Control with

Electromechanical Timer

Modes

In O Mode

When the oven is o , there are no lights or indicators.

Start Up

Press the COOK/OFF/COOL DOWN rocker switch to the

“COOK” position. The green lamp will light indicating the

oven is powered in cook mode.

The oven will begin to heat to the temperature set on the

thermostat dial. The amber lamp will light indicating the heat

is active. As the heat cycles on and o to maintain the set

temperature this light will go on and o accordingly.

The door must be closed for the oven to operate in cook

mode. Opening the door will cause the heat to stop and the

motor and fan will shut o . This is a safety feature.

Fan Speed

The fan speed can be either high (1725RPM) or (1150RPM).

The fan speed is controlled by the left rocker switch marked

high and low.

Lights

The oven lights are activated by pressing the light switch

on the control panel. This is a momentary switch and the

lights will stay lit as long as this button is held in the on

position. Lights will work whenever there is electrical power

connected to the oven.

Cool Down

Pressing the COOK/OFF/COOL down rocker switch to the

COOL DOWN position activates the fan and motor to cool

the oven cavity. The door must be open slightly for the fan

and motor to start. The heat is not active in this mode.

Optimal cool down will be achieved with the door open

slightly. Opening the door too far will shut the fan and motor

o . This is a patented safety feature.

Pressing the button to the OFF position cancels the cool

down and turns the oven o .

Temp era tu re

The temperature range is from 150° to 500°F (66°C) to 250°C)

is controlled by rotating the temperature dial and aligning

the indicator to the desired temperature.

Part Number 1955203 rev 4 4/1510

Page 11

OPERATING INSTRUCTIONS Continued

Timer

The timer is set by rotating the dial clockwise aligning the

indicator to the desired time cycle. The timer will count down

from 2 minutes to 60 minutes. At the end of the timing cycle

the buzzer will sound. The buzzer is turned o by rotating the

dial counter-clockwise to the o position.

NOTE: The timer does not control heating.

Master 450 Electronic Control with

Cook-N-Hold and Master 455 Electronic

Control with Cook-N-Hold & Core Probe

Modes

In O Modes

When the controller is o , the display will show “OFF”.

Pressing the ON/OFF key will activate the controller into

Start Up Mode.

Start Up

In Start Up mode, the controller will heat to the last set

temperature, time and fan speed. The factory defaults are

350°F (177°C), 30 minutes and low fan speed. The display will

indicate “LO” when the oven is below the set temperature.

When the oven cavity reaches the set temperature and is

ready for operation the display will indicate “LOAD”.

NOTE: If the oven temperature goes above the requested

temperature the display will indicate “HI” If the oven

temperature goes above 575°(302°C) the display will indicate

“HELP” and an audible signal will sound. This is a safety

feature.

If the door is opened during a cooking mode, the fan and

heat will stop, and the display will indicate “DOOR” until the

door is closed. This is a patented safety feature.

Pressing the ACTUAL TEMP key will display the actual oven

temperature in 5° increments.

Controller Keys

Pressing the ON/OFF key will activate the oven.

Pressing the LIGHT key will turn the lights on for 30 seconds.

The lights will work if the controller is in the O mode. When

the door is opened, the light will come on and stay on for 30

seconds.

Part Number 1955203 rev 4 4/15 11

Page 12

OPERATING INSTRUCTIONS Continued

Pressing the FAN HIGH key will activate the higher fan speed

and light its LED.

Pressing the FAN LOW key will activate the lower fan speed

and light its LED.

Pressing the FAN PULSE key will activate the lower fan speed

and light its LED. The fan will be active for 30 seconds then

o for 30 seconds, and continuous this cycle.

Pressing the SETBACK key will cool the oven cavity to

a preprogrammed temperature, see: Setting “Set-Back”

Feature. The oven will automatically go into Setback mode

after the pre-programmed non-usage time. The display will

indicate “SETB”. This is an energy-saving feature.

Pressing the COOL DOWN key will deactivate the heat, turn

the fan on high and light its LED. This display will indicate

“OPEN DOOR” if the door is closed, prompting the user

to open the door slightly. With the door open slightly the

display will indicate “COOL”. The Cool down will operate

when the door is closed or opened slightly. Optimal cool-

down will be achieved with the door open slightly. When

the door opens wider, the Cool Down mode will deactivate

and the display will indicate “DOOR”. This is a patented safety

feature. Pressing the COOL DOWN key again will turn the

LED o and stop this mode. Pressing the ON/OFF key will

also cancel Cool down. Cool Down is not active during a

cook.

When the ON/OFF switch is pressed to turn the oven o and

the oven was above 200°F (93°C), the oven will go into an

AUTO COOL DOWN mode. In Auto cool Down, the oven will

run the fan on high until the oven cavity drops below 150°F

(66°C). During this time the display will indicate “AUTO”.

When the oven temperature drops below 150°F (66°C) the

oven turns o . This feature protects the oven motor from

premature failure. Optimal cool-down will be achieved with

door open slightly.

Fahrenheit/Celsius

Factory default is Fahrenheit (F). To change to

Celsius (C), press and hold in the “Phantom Key” located

to the right of “Cook/Hold” key. “F” appears in the display.

Continue to hold until “C” is displayed and then release the

“Phantom key”.

Part Number 1955203 rev 4 4/1512

Page 13

OPERATING INSTRUCTIONS Continued

Operating the Controls

Setting the cook temperature and time are done in the same

manner. Pressing the SET key will light the TEMP LED. The

operator then sets the temperature by rotating the dial on

the controller until the desired temperature is shown on the

display. Pressing the SET key a second time lights the TIME

LED and allows the operator to select the desired cook time

as shown on the display. Pressing the SET key a third time

ends the programming.

Pressing the START/CANCEL key will start the timing cycle.

The display will count down from the Set time in minutes and

seconds (solid colon) or hours and minutes (blinking colon)

then minutes and seconds. When the cycle is completed,

pressing this key will also cancel the “DONE” prompt. To

cancel a timing cycle in progress, press and hold the START/

CANCEL key for 3 seconds.

Cook-N-Hold Operation

Pressing the COOK/HOLD (450 and 455 Controllers Only) key

activates the Cook-N-Hold mode and lights is LED. To verify

the proper hold temperature has been selected, press the

SET key twice. The display will show the hold temperature.

At the end of the cook cycle, an audible alarm will sound, the

display will ash “DONE” and change to count “UP” the time

the oven is on hold. The oven will switch to the programmed

hold temperature.

Setting the cook temperature, hold temperature and time

are done in the same manner. Pressing the SET key will

light the TEMP LED. The operator then sets the temperature

by rotating the dial on the controller until the desired

temperature is shown on the display. Pressing the SET key a

second time will light the HOLD LED and allows the operator

to select the desired hold temperature as shown on the

display. Pressing the SET key a third time lights the TIME

LED and allows the operator to select the desired cook time

as shown on the display. Pressing the SET key a fourth time

ends the programming.

Core Probe Operation

The Core Probe option (455 Controller Only) is only active

when the core probe is plugged into its connector. To set the

core temperature, rst plug the core probe into its connector.

The display will indicate “100” and the CORE TEMP LED will

be on. The operator then sets the temperature by rotating

the dial on the controller until the desired temperature is

shown on the display. Pressing the SET key stores the core

temperature and starts the cooking process.

To set the oven temperature, press the SET key again. The

TEMP LED will light and the oven temperature can be

set by rotating the dial on the controller until the desired

temperature is displayed. Pressing the SET key again will

light the HOLD LED allowing the operator to set the hold

temperature in the same manner.

NOTE: If the hold temperature is not set, the default

hold temperature is 150°F (66°C) or the last programmed

temperature. (Hold temperature range is 140°F (60°C) to

210°F (99°C).

When the core temperature is reached the display will sound

and ash “DONE” for 3 seconds. Automatically, the display

will switch to count “UP” the time the oven is on hold.

Setting Setback Feature

To set or change the setback settings, press and hold the

SETBACK key for two seconds. The TEMP LED will light and a

temperature will be displayed. Set the temperature using the

dial, then press the SET key. The TEMP LED will go out and

the TIME LED will light (“Time” is factory set at 0). Set the time

using the dial, then press the SET key. Press the SET key one

more time to exit programming.

Note: To disable the setback function, set the temperature to

250º F (121ºC) and the time to zero.

Pressing the START/CANCEL key will start the timing

cycle. When the cycle is completed, pressing the key will

also cancel the “DONE” prompt. To cancel a timing cycle

in progress press and hold the START/CANCEL key for 3

seconds.

Part Number 1955203 rev 4 4/15 13

Page 14

OPERATING INSTRUCTIONS Continued

Master 475 Electronic Programmable Control

Manual Cooking

1. Press SET key – TEMP LED will light.

2. Set temperature using the dial (factory preset at 350°F).

3. Press SET key – FAN LED will light.

4. Select fan mode using one of the three (3) fan keys

(HIGH, LOW, PULSE) – the selected FAN LED will light.

5. Press SET key – TIME LED will light.

6. Set cook time using the dial (factory preset at 30:00).

7. Press SET key – ready to cook.

8. Press START/CANCEL to begin manual cooking.

Manual cooking using Cook-N-Hold

1. Press the COOK/HOLD key, that key’s LED will light.

2. Press SET key – TEMP LED will light.

3. Set cook temperature using the dial (factory preset at

350°F).

4. Press Set key – HOLD LED will light.

5. Set hold temperature using the dial (factory preset at

200°F).

6. Press SET key – FAN LED will light.

7. Select fan mode using one of the three (3) fan keys

(HIGH, LOW, PULSE) – the selected FA N LED will light.

8. Press SET key – TIME LED will light.

9. Set cook time using the dial (factory preset at 30:00).

10. Press SET key – ready to cook

11. Press START/CANCEL to begin manual cooking.

Programming Product Keys (Master )

Note: Cooking time(s) is the element of the program that

tells the controller that other information (temperature, fan

speed, etc.) will be inputted into the controller. The rst step

is to enter all the time periods required, followed by the

addition of the other cooking elements.

Part Number 1955203 rev 4 4/1514

Page 15

OPERATING INSTRUCTIONS Continued

1. Press and hold PROG key for three (3) seconds – all the

product key LEDS light.

2. Code will be displayed. The controller is asking for the

access code. Press 4-2-7-5 and the

START/CANCEL key. PROD will be displayed indicating

you have gained access to Product Programming.

3. Press the product key (1-9) into which you want to store

a cooking program. SHLF will be displayed. The control

is asking if you want to program the key as a shelf timer

or with a cooking pro le. Select your answer by pressing

the START/CANCEL key. When the correct answer is

displayed press the SET key. The TIME LED will light.

30:00 will be displayed.

4. Set rst cook time using dial. If more than one cooking

pro le is desired:

• Press the product key where the program is to be

stored (1-9) – PR-2 will be displayed.

• Set the second cook time using the dial (factory

presets for PR-2 through PR-5 are :00).

• Press the same product key (1-9 again – PR-3 will be

displayed.

• Repeat the process for all pro les. When the last

pro le time has been entered, press the SET key OR

If less than ve (5) pro les are desired press the SET key after

the last required pro le – PRE will be displayed, followed

by :00. The controller is asking if you would like a reminder

alarm (pre-alarm) to sound during the cooking process

(factory preset is :00).

5. If a pre-alarm signal is desired – dial in the time that

the alarm is to sound. (Ex. If the product is to be turned

halfway through the 60 minute cooking cycle, set the

pre-alarm to 30 minutes. If pre-alarm is not desired verify

that “:00” is displayed. Press the SET key – TEMP LED will

light, and the display will show the rst pro le cooking

temperature (factory preset to 350°F).

NOTE: the controller will only accept cooking temperatures

for the number of pro les for which a cooking time has been

set. If the product key is pressed after the last programmed

pro le, the rst temperature will be displayed.

• Press SET after the last cooking temperatures has

been entered, HOLD will be displayed.

7. Use the START/CANCEl key to select yes or no. Press the

SET key.

8. If yes was selected, the HOLD LED will light. Enter the

hold temperature using the dial. (factory preset at 200°F)

Press the SET key, FA N will be displayed and the FAN LED

will light.

• Set the fan speed desired for the rst cooking pro le

using the individual fan keys (HIGH, LOW or PULSE),

press the product key and set the fan speed for the

second cooking pro le. Continue until all the pro les

have been assigned a fan speed. Press the SET key

when complete. As with the temperature, if the

product key is pressed after the last programmed

pro le, the rst fan speed will be displayed.

9. FL or ST will be displayed (for ex time or straight time)

(factory preset for ex time). Select ex or straight time

using the START/CANCEL key for the rst pro le. Press

the product key and select straight time or ex time for

the second pro le. Continue until all the pro les have

been assigned straight or ex time. Press the SET key

when complete. If the product key is pressed after the last

programmed pro le, the rst pro le will be displayed.

10 Programming for that product key is complete.

Cooking Using The Product Keys

(Master )

1. On initial start-up, press the product key for the menu

item to be cooked. Wait until Load is displayed.

2. Load the oven.

6 Set the rst cooking temperature using the dial.

• Press the product key – PR-2 will be displayed

followed by the second temperature.

• Set the second cooking temperature using the dial.

• Repeat as you did for cooking time, for all the

pro les desired.

Part Number 1955203 rev 4 4/15 15

3. Press the product key for the loaded menu item.

4. Press the START/CANCEL, key.

5. To cancel the alarm or the holding operation, press the

START/CANCEL key followed by the product key.

Page 16

OPERATING INSTRUCTIONS Continued

Verifying Hold Time (Master )

While a product is being held, press and hold the product

key. The actual hold time will be displayed.

Selecting Fahrenheit or Celsius (Master 475)

Press PROG and ACTUAL TEMP keys at the same time, F or C

will be displayed. (Factory preset for F)

Press the START/CANCEL key to switch between F and C.

When the desired setting is displayed press the PROG and

ACTUAL TEMP keys at the same time.

Cooking With The Shelf Timer (Master )

The shelf timer option is used to independently time each of

the up to six di erent shelves or racks within the oven.

NOTE: To use the shelf timer option, at least one product key

must be programmed with a cooking pro le (temperature,

time, fan speed, ex or straight time). The program key

must be limited to a single cooking pro le to be used with

the shelf timing option. If more than one product key is to

be used, all product keys to be used must feature the same

cooking temperature and fan speed. Flex or straight time and

cooking time can be di erent. The Cook-N-Hold option can

not be used with the shelf timer.

Pressing the desired product key will bring the oven to the

desired cooking temperature, once the oven has reached

the proper cooking temperature as indicated by Load in the

display.

EXAMPLE: Two product pro les contain the same cooking

temperature, fan speed and are both programmed for ex

time – keys 1 and 6.

Two trays of product are going to be cooked in the oven at

the same time. The rst tray will use product key 1 and will

be placed in rack position 2. The second tray will use product

key 6 and will be placed in rack position 4. Once the oven

display indicates LOAD:

1. Load food product into oven on shelf 2.

2. Press product key 1, then shelf key 2.

3. Press the START/CANCEL key to start cooking on shelf 2.

4. Load food product into oven on shelf 4.

5. Press product key 6, then shelf key 4.

6. Press the START/CANCEL key to start cooking on shelf 4.

7. When product on shelf 2 is nished cooking, an audible

alarm will sound and the display will ash DONE, then

SH-2 and the product key 1 LED will be ashing.

8. To turn o the alarm, press product key 1.

9. When the product on shelf 4 is nished cooking, an

audible alarm will sound and the display will ash DONE,

then SH-4 and the product key 6 LED will be ashing.

10. To turn o the alarm, press product key 6.

1. Press the product key containing the desired cooking

pro le (1-9).

2. Press the shelf key for the shelf location to be timed (1-6).

NOTE: product keys and shelf keys are the same keys.

3. Press the START/CANCEL key to begin the cooking/

timing process.

4. When the cooking/timing process is complete for each

shelf, an audible “done” signal will sound and the display

will indicate which shelf is nished. Example: SH-1

5. To turn o the alarm press the product key with the

ashing LED.

Part Number 1955203 rev 4 4/1516

Page 17

PERFORMANCE RECOMMENDATIONS AND GENERAL SAFETY

PRECAUTIONS

1. Preheat oven thoroughly (approx. 20 minutes) before use.

2. As a general rule, temperature should be reduced 25°

to 50° from that used in a standard/convection oven.

Cooking time may also be shorter, so we suggest closely

checking the rst batch of each product prepared.

3. Use the chart of suggested times and temperatures as

a guide. These will vary depending upon such factors

as size of load, temperature, and mixture of product

(particularly moisture) and density of product.

4. Keep a record of the times, temperature, and load sizes

you establish for various products. Once you have

determined these, they will be similar for succeeding

loads.

5. When practical, start cooking the lowest temperature

product rst and gradually work up to higher

temperatures.

6. If you nd that your previous temperature setting is more

than 10° higher than needed for succeeding loads, COOL

DOWN to reach the desired temperature before setting a

new cooking temperature.

7. When loading oven, work as quickly as possible to

prevent loss of heat.

8. Oven will continue to heat even though the timer goes

o . Product should be removed from the oven as soon as

possible to avoid over cooking.

9. Center pans on racks and load each shelf evenly to allow

for proper air circulation within the cavity.

10. When baking, weigh or measure the product in each pan

to assure even cooking.

14. When re-thermalizing frozen casseroles, preheat the oven

100° over the suggested temperature. Return to cooking

temperature when the oven is loaded. This will help

compensate for the introduction of a large frozen mass

into the cavity.

15. Use pan extenders or two inch deep 18” x 26” pans for

batter type products which weigh more than eight

pounds, i.e., Pineapple Upside down Cake.

16. Never place anything directly on the bottom of the oven

cavity. This obstructs the air ow and will cause uneven

results.

17. Never operate the oven if any of the exterior covers are

removed. These covers are necessary for protection

against exposure to live electrical parts and should

only be removed when the oven is being serviced by a

quali ed service personnel.

18. This is a commercial cooking oven not intended for non

commercial cooking installations or non food products.

19. Use appropriate food pans and trays for ovens.

20. Use oven mitts when adding or removing trays/pans from

oven when oven is operational.

21. Use care when removing product from the oven to

prevent spills which could cause serious inquiry to bare

skin and eyes. Higher rack levels on ovens are at eye level.

22. Exterior oven exteriors will become hot during operation

caution should be observed.

23. Proper weight handling and distribution of product in

tray or pan will prevent sudden shifts in product to avoid

spills and inquiry.

11. When cooking six pans, use rack positions 1, 4, 6,8,10 and

12, starting from the top.

12. Do not overload the oven. Six pans are suggested for

most items, i.e., cakes, cookies, rolls, etc. However, the

maximum (13 pans) may be used for sh sticks, chicken

nuggets and hamburgers. Cooking times will have to be

adjusted.

13. Mu n pans should be placed in the oven back to front

or with the short side of the pans facing the front. This

results in the most evenly baked product.

Part Number 1955203 rev 4 4/15 17

24. Do not operate ovens blower fan guard has been

removed.

25. Oven operation sound pressure level should not exceed

70 dB(A).

Note: Moisture will escape around the doors when baking

products with heavy moisture content, such as chicken,

potatoes, etc. This is normal.

Page 18

PROBLEM/SOLUTIONS

Problem Solution

Cakes are dark on the sides and not done in the center Lower oven temperature

Cakes edges are too brown Reduce number of pans or lower oven temperature

Cakes have light outer color Raise temperature

Cake settles slightly in the center Bake longer or raise oven temperature slightly.

Do not open doors too often or for long periods

Cake ripples Overloading pans or batter is too thin

Cakes are too coarse Lower oven Temperature

Pies have uneven color pans Reduce number of pies per rack

or eliminate use of bake pans

Cupcakes crack on top Lower oven temperature

Meats are browned and not done in center Lower temperature and roast longer.

Meats are well done and browned Reduce time. Limit amount of moisture

Meats develop hard crust Reduce temperature or place pan of water in oven.

Rolls have uneven color Reduce number or size of pans.

Part Number 1955203 rev 4 4/1518

Page 19

COOKING GUIDE

The following suggested times and temperatures are provided as a starting guide. Elevation, atmospheric conditions, recipe,

cooking pans and oven loading may a ect your actual results.

PRODUCT TEMPERATURE (ºF) TIME

Cakes

White Sheet Cakes – 5 lbs 300º 20 min

White Sheet Cakes – 6 lbs 300º 22 min

Yellow Sheet Cake – 5 lbs 325º 15 min

Chocolate Layer Cake – 21 oz 300º 22 min

Angel Food Cake 375º 22 min

Brownies 350º 15 min

Breads

Soda Biscuits 400º 6 min

Yeast Rolls 325º 24 min

Sweet Bread 325º 24 min

Corn Bread 350º 22 min

Gingerbread 300º 24 min

Apple Turnovers 350º 25 min

Cream Pu s 300º 25 min

Sugar Cookies 325º 12 min

Chocolate Chip cookies 375º 8 min

Apple Pie (Fresh) 375º 25 min

Blueberry Pie (Fresh) 350º 30 min

Blueberry Pie (Frozen) 300º 50 min

Pumpkin Pie (Frozen) 300º 50 min

Frozen Pizza 300º 6 min

Macaroni & Cheese 350º 15 min

Fish Sticks 350º 16 min

Stu ed Peppers 350º 45 min

Baked Potatoes 350º 60 min

Meats

Chick Parts 350º 45 min

Hamburger Patties-10/lb frozen 350º 8 min

Hamburger Patties - 10/lb fresh 350º 5 min

Hamburger Patties - 4/lb frozen 350º 12 min

Hamburger Patties – 4/lb fresh 350º 8 min

Meatloaf – 4lb 325º 45 min

Bacon 350º 10 min

Roast Beef 20lb 325º 3 hr 15 min

Prime Rib 10lb 300º 1 hr 45 min

Stu ed Port chops 350º 45 min

Lamb chops 375º 40 min

Boneless Veal Roast 300º 3 Hr

Part Number 1955203 rev 4 4/15 19

Page 20

COOK AND HOLD

Please refer to the operating instructions to program the 450 and 455 control units for Cook and Hold feature. The times and

temperatures listed below are to be used as a starting guide. Your actual results may vary greatly depending on your elevation,

atmospheric conditions and other items being cooked at the same time.

Time in Hours

Weight in lbs

8 2.5 3.5 1.5 2 1.25 1.5

9 2.75 3.75 1.75 2.25 1.25 1.75

10 3 4.25 2 2.5 1.5 1.75

11 3.25 4.5 2 2.75 1.5 1.75

12 3.5 5 2.25 3 1.5 2

13 3.75 5 2.5 3.25 1.5 2.25

14 4 5.75 2.5 3.5 1.75 2.5

15 4.25 6 2.75 3.5 2 2.5

16 4.5 6.25 2.75 3.75 2 2.75

17 4.75 6.5 3 4 2.25 2.75

18 4.75 6.75 3.25 4.25 2.25 3

19 5 7.25 3.25 4.25 2.25 3

20 5.25 7.5 3.5 4.5 2.5 3.25

21 5.5 7.75 3.5 4.75 2.75 3.5

22 5.75 7.75 3.5 4.75 2.75 3.5

23 6 8.25 3.75 5 2.75 3.75

24 6 8.75 3.75 5 2.75 3.75

25 6.25 9 4.25 5.5 3 4

26 6.5 9.25 4.25 5.5 3.25 4.25

27 6.75 9.5 4.25 5.75 3.25 4.25

28 7 9.75 4.5 6 3.25 4.25

29 7.25 10 4.75 6.25 3.5 4.5

30 7.25 10.25 4.75 6.25 3.5 4.5

Temperature: 200ºF Temperature: 250ºF Temperature: 300ºF

Rare Medium Rare Medium Rare Medium

Part Number 1955203 rev 4 4/1520

Page 21

CLEANING AND MAINTENANCE

NOTE: Disconnect line cord from power supply before

cleaning or servicing.

Break-In Period

When oven is new, operate it for one hour at 375°F (191°C)

before you begin your normal cooking operation. After

cooling, wipe the interior, including the racks, with a clean

damp cloth.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

1. The oven should always be allowed to cool su ciently

before any cleaning is attempted.

2. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

3. Stubborn stains may be removed by using a non-metallic

abrasive pad, rubbing in the direction of the metal’s grain.

If necessary, for particularly heavy deposits, you may mix

a thin paste of water and scouring powder, and apply

it with a sponge. Be careful to apply light pressure and

remember to rub only in the direction of the grain in the

metal.

4. Clean with soap and water using a non-metallic scouring

pad, if necessary. If dirt and grease have accumulated, a

mild ammonia solution or commercial oven cleaner such

as Easy-O or Dow may be used.

5. To reinstall, reverse procedure. Place the bottom of the

rack guide against the cavity wall. Keeping the top pulled

away from the wall lift up. Push the top of the guide

against the wall and push down locking it into place.

Fan Area Maintenance

If aluminum foil is routinely used to wrap food or cooking

vessels during oven operation, the following preventive

maintenance must be performed:

1. Turn power switch to “O ” position

2. Remove oven racks and rack guides.

3. Remove air ba e and clean any stains or deposits.

4. Check blower wheel and air ba e for particles of

aluminum foil or food deposits. Clean ns of blower

wheel. (CAUTION: edges of blower wheel ns may be

sharp).

5. Reinstall the air ba e, rack guides and oven racks.

This simple practice, if performed on a regular basis will keep

your Garland oven operating at peak performance.

4. The control panel surface is easily cleaned with hot water,

soap and a soft cloth. Do not use hard abrasives, solvent

type materials or metallic scouring pads since these will

scratch or cloud the surface.

5. Never spray the perforated areas of the control panel with

steam or water jets, as this allow moisture into the control

cavity. Moisture could damage the electrical components

or place the operator at risk of electrical shock.

Interior Cleaning

Establish a regular cleaning schedule or wipe o on the same

day when spillovers occur.

1. Cool down oven.

2. Remove oven racks.

3. Lift rack guides on either side of oven o of holders. Racks

and guides may be run through dishwasher while oven

cavity is being cleaned.

Motor Care

The motor on your convection oven is maintenance free

since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions

to follow on the care of your motor. When the motor is

operating, it cools itself internally by air entering at the rear

of the motor case, provided proper clearance has been

allowed.

Since the blower wheel is in the oven cavity it is at the same

temperature as the oven. If the motor is stopped while the

oven is hot, the heat from the blower wheel is conducted

down the shaft and into the armature of the motor. This

action could shorten the life of the motor.

We recommend, at the end of the bake or roasting period,

when the oven will be idle for any period of time, or before

shutting down completely, that the doors be left open

slightly. On the 400 series controllers press the COOL DOWN

key on the control panel. The fan will continue to run until

the oven cools down to 150°F (66°C).

Part Number 1955203 rev 4 4/15 21

Page 22

CLEANING AND MAINTENANCE Continued

At the end of the day, press the ON/OFF key, for the 400

series controllers to activate the Auto Cool Down feature. The

fan will run on high until the oven cavity drops below 150°F

(66°C). When the oven temperature drops below 150°F (66°C)

the oven turns o . This feature protects the oven motor from

pre-mature failure. On the 200 series controllers, push the

rocker switch to COOL position. Once cool set the rocker

switch to OFF.

NOTE: Optimal cool-down will be achieved with the door

open slightly.

Part Number 1955203 rev 4 4/1522

Page 23

Page 24

GARLAND

1177 KAMATO ROAD, MISSISSAUGA, ONTARIO, CANADA. L4W 1X4

8884427526

WWW.GARLANDGROUP.COM

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

your operational needs from one restaurant to multiple locations.

StarCare – Warranty & lifetime service, certi ed OEM parts, global parts inventory, performance audited

ExtraCare — CareCode, 24/7 Support, online/mobile product information

LifeCare – Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

Talk with KitchenCare™ • 1-844-724-CARE • www.mtwkitchencare.com

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

©2014 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved. Continuing product improvement may necessitate change of speci cations without notice.

Part Number 1955203 rev 4 4/15

Page 25

Numéro de Pièce 1955203 rév 4 4/15

©2014 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved. Continuing product improvement may necessitate change of speci cations without notice.

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

Talk with KitchenCare™ • 1-844-724-CARE • www.mtwkitchencare.com

LifeCare – Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

ExtraCare — CareCode, 24/7 Support, online/mobile product information

StarCare – Warranty & lifetime service, certi ed OEM parts, global parts inventory, performance audited

your operational needs from one restaurant to multiple locations.

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

WWW.GARLANDGROUP.COM

8884427526

1177 KAMATO ROAD, MISSISSAUGA, ONTARIO, CANADA, L4W 1X4

GARLAND

Page 26

Numéro de Pièce 1955203 rév 4 4/15 23

du four entrouverte.

NOTA : Le refroidissement optimal est obtenu avec la porte

fois le four refroidi, régler le commutateur à bascule sur OFF.

pousser le commutateur à bascule en position COOL. Une

four d’une usure prématurée. Sur les contrôleurs série 200,

(66°C), le four s’éteint. Cette fonction protège le moteur du

la température du four est descendue au-dessous de 150°F

DÉL « AUTO COOL DOWN » restera allumée. Une fois que

du four soit inférieure à 150°F (66°C). Pendant ce temps, la

grande vitesse jusqu’à ce que la température à l’intérieur

refroidissement automatique. Le ventilateur tournera à

pour les contrôleurs série 400, pour activer la fonction de

À la n de la journée, appuyer sur la touche ON/OFF,

ce que la température du four descende à 150°F (66°C).

commande. Le ventilateur continuera de fonctionner jusqu’à

400, appuyer sur la touche COOL DOWN du tableau de

de laisser les portes entrouvertes. Sur les contrôleurs série

quelle période de temps ou avant de l’arrêter complètement,

de rôtissage, quand le four est au ralenti pour n’importe

Nous recommandons, à la n de la période de cuisson ou

the oven cools down to 150°F (66°C).

key on the control panel. The fan will continue to run until

slightly. On the 400 series controllers press the COOL DOWN

shutting down completely, that the doors be left open

when the oven will be idle for any period of time, or before

We recommend, at the end of the bake or roasting period,

raccourcir la durée de vie du moteur.

est transmise à l’arbre et à l’induit du moteur. Ceci peut

pendant que le four est chaud, la chaleur du ventilateur

à la même température que celui-ci. Si le moteur est arrêté

Étant donné que le ventilateur se trouve dans le four, il est

l’arrière de l’appareil.

son carter, à condition qu’un dégagement su sant existe à

automatiquement par l’air pénétrant dans la partie arrière de

moteur. Lors du fonctionnement du moteur, il se refroidit

quelques suggestions à suivre en ce qui concerne le

durable avec un entretien normal. Nous o rons ci-dessous

autolubri ants étanches. Il est conçu pour o rir un service

donné qu’il est fabriqué avec des roulements à billes

Le moteur de ce four à convection est sans entretien étant

Entretien du Moteur

ENTRETIEN ET NETTOYAGE (suite)

Page 27

Numéro de Pièce 1955203 rév 4 4/1522

2. Retirer les grilles du four.

1. Refroidir le four.

même tout déversement.

Établir un calendrier de nettoyage régulier ou essuyer le jour

Nettoyage Intérieur

fonctionnement impeccable.

maintiendra votre four Garland dans un état de

Cette pratique simple si elle est réalisée régulièrement,

et les crémaillères dans le four.

5. Remettre en place le dé ecteur, les guides de crémaillère

ailettes peuvent être coupants).

les ailettes du ventilateur. (Attention : les bords des

d’aluminium sur le ventilateur et le dé ecteur. Nettoyer

4. Véri er la présence de particules d’aliments ou

dépôts.

3. Retirer le dé ecteur d’air et nettoyer toutes les taches ou

four.

2. Retirer les crémaillères et les guides des crémaillères du

« OFF ».

1. Mettre l’interrupteur d’alimentation en position

suivante:

le four, il est nécessaire d’e ectuer l’entretien préventif

envelopper les aliments ou les récipients de cuisson dans

Si on utilise habituellement du papier aluminium pour

Maintenance de la Zone du Ventilateur

pour le bloquer en place.

le haut du guide contre la paroi et pousser vers le bas

partie supérieure éloignée de la paroi, soulever. Pousser

guide de grille contre la paroi du four. En maintenant la

5. Pour le remontage, inverser la procédure. Placer le bas du

pour l’opérateur.

électriques ou présenter un risque de choc électrique

L’humidité pourrait endommager les composants

fera pénétrer de l’humidité dans l’espace de commande.

zones perforées du panneau de commande, car cela

5. Ne jamais diriger des jets d’eau ou de vapeur sur les

rayer la surface.

ni de tampons à récurer métalliques qui peuvent ternir ou

doux. Ne pas utiliser de produits abrasifs durs, de solvants

facilement avec de l’eau chaude, du savon et un chi on

4. La surface du panneau de commande se nettoie

dans le sens du grain du métal.

Ne pas appliquer de fortes pressions et toujours travailler

poudre de récurage et l’appliquer à l’aide d’une éponge.

importantes, mélanger en pâte ne un peu d’eau et de la

du grain du métal. Si nécessaire, en cas de salissures

tampon de récurage non-métallique utilisé dans le sens

3. Les taches rebelles peuvent être retirées à l’aide d’un

Bien essuyer avec un chi on propre.

retirées à l’aide d’un tampon à récurer non-métallique.

abrasive et d’eau chaude. Les tâches rebelles peuvent être

un chi on humecté d’une solution savonneuse non

2. Essuyer à froid les surfaces exposées et nettoyables avec

four avant toute opération de nettoyage.

1. Il est indispensable de laisser su samment refroidir le

doit être essuyé immédiatement.

Établir un calendrier de nettoyage régulier. Tout déversement

ou Dow.

de nettoyage pour fours du commerce comme Easy-O

une solution peu concentrée d’ammoniac ou un produit

d’accumulation de saleté et de graisse, on peut utiliser

tampon à récurer non-métallique si nécessaire. En cas

4. Nettoyer à l’eau et au savon doux en utilisant un

le nettoyage de l’intérieur du four.

les guides peuvent passer dans le lave-vaisselle pendant

passer les clips, pousser vers le bas et retirer. Les grilles et

du four, soulever la partie supérieure de la paroi du four,

3. Soulever de leurs supports les guides de grilles d’un côté

Nettoyage Extérieur

humide.

l’intérieur, y compris les grilles, avec un chi on propre et

normale de cuisson. Après refroidissement, essuyer

heure à 375°F (191°C) avant de commencer toute opération

Quand le four est neuf, le faire fonctionner pendant une

Période de Rodage

d’alimentation avant le nettoyage ou l’entretien.

REMARQUE: Débrancher le cordon électrique de la source

ENTRETIEN ET NETTOYAGE

Page 28

Température: 200°F Température: 250°F Température: 300°F

TEMPS EN HEURES

Numéro de Pièce 1955203 rév 4 4/15 21

30 7.25 10.25 4.75 6.25 3.5 4.5

29 7.25 10 4.75 6.25 3.5 4.5

28 7 9.75 4.5 6 3.25 4.25

27 6.75 9.5 4.25 5.75 3.25 4.25

26 6.5 9.25 4.25 5.5 3.25 4.25

25 6.25 9 4.25 5.5 3 4

24 6 8.75 3.75 5 2.75 3.75

23 6 8.25 3.75 5 2.75 3.75

22 5.75 7.75 3.5 4.75 2.75 3.5

21 5.5 7.75 3.5 4.75 2.75 3.5

20 5.25 7.5 3.5 4.5 2.5 3.25

19 5 7.25 3.25 4.25 2.25 3

18 4.75 6.75 3.25 4.25 2.25 3

17 4.75 6.5 3 4 2.25 2.75

16 4.5 6.25 2.75 3.75 2 2.75

15 4.25 6 2.75 3.5 2 2.5

14 4 5.75 2.5 3.5 1.75 2.5

13 3.75 5 2.5 3.25 1.5 2.25

12 3.5 5 2.25 3 1.5 2

11 3.25 4.5 2 2.75 1.5 1.75

10 3 4.25 2 2.5 1.5 1.75

9 2.75 3.75 1.75 2.25 1.25 1.75

8 2.5 3.5 1.5 2 1.25 1.5

Saignant À point Saignant À point Saignant À point

Poids en lb

aliments cuits en même temps.

départ. Les résultats e ectifs peuvent varier de façon importante selon l’altitude, les conditions atmosphériques et lest autres

caractéristique de cuisson et maintien au chaud. Les temps et les températures ci-dessous sont a utiliser comme guide de

Consulter les instructions d’utilisation pour la programmation des unités de commande de séries 450 et 455 pour la

CUISSON ET MAINTIEN AU CHAUD

Page 29

Numéro de Pièce 1955203 rév 4 4/1520

Rôti de Veau Sans Os 300° 3 Hr

Côtelettes d’Agneau 375° 40 min

Côtelettes de Porc Farcies 350° 45 min

Côte de Bœuf – 10 lb 300° 1 hr 45 min

Rôti de Bœuf – 20 lb 325° 3 hr 15 min

Bacon 350° 10 min

Pain de Viande - 4 lb 325° 45 min

Galettes de Bœuf - 4/lb (Fraîches) 350° 8 min

Galettes de Bœuf - 4/lb (Congelées) 350° 12 min

Galettes de Bœuf - 10/lb (Fraîches) 350° 5 min

Galettes de Bœuf - 10/lb (Congelées) 350° 8 min

Morceaux de Poulet 350° 45 min

Viandes

Pommes de Terre Au Four 350° 60 min

Poivrons Farcis 350° 45 min

Bâtonnets de Poisson 350° 16 min

Macaronis au Fromage 350° 15 min

Pizza Congelée 300° 6 min

Tarte à la Citrouille (Congelée) 300° 50 min

Tarte aux Bleuets (Congelée) 300° 50 min

Tarte aux Bleuets (Fraîche) 350° 30 min

Tarte aux Pommes (Fraîche) 375° 25 min

Biscuits aux Copeaux De Chocolat 375° 8 min

Biscuits au Sucre 325° 12 min

Choux à la à la Crème 300° 25 min

Chaussons aux Pommes 350° 25 min

Pain d’Épice 300° 24 min

Pain de Maïs 350° 22 min

Pain Viennois 325° 24 min

Petits Pains à la Levure 325° 24 min

Biscuits à la Poudre Levante 400° 6 min

Pains

Carrés au Chocolat 350° 15 min

Gâteau des Anges 375° 22 min

Gâteau Étagé au Chocolat – 21 oz 300° 22 min

Gâteau Jaune Étagé – 5 lb 325° 15 min

Gâteaux Blancs Étagés – 6 lb 300° 22 min

Gâteaux Blancs Étagés – 5 lb 300° 20 min

Gâteaux

PRODUIT TEMPÉRATURE (°F) TEMPS

dé nitifs obtenus.

atmosphériques, l’alimentation en gaz, la recette, les plats de cuisson et le chargement du four peuvent a ecter les résulats

Les temps et les températures suggérés suivants sont fournis comme guide de départ. L’altitude, les conditions

GUIDE DE CAISSON

Page 30

Numéro de Pièce 1955203 rév 4 4/15 19

de l’eau dans le four

Limiter la quantité d’humidité

et prolonger le temps de cuisson.

de cuisson

pendant de longues périodes de temps

température du four. Ne pas ouvrir les portes trop souvent ni

Abaisser la température du four

Si les pains mollets sont de couleur inégale Réduire le nombre ou la taille des moules

Si les viandes ont une croûte dure Réduire la température ou placer un plat avec

Si les viandes sont bien cuites et roussies Réduire le temps de cuisson.

Si les viandes sont dorées mais pas cuites au centre Abaisser la température du four

Si les petits gâteaux se fendent sur le dessus Abaisser la température du four

Si les tartes sont de couleur inégale Réduire le nombre de tartes par grille ou éliminer les moules

Si le gâteau est trop dur Abaisser la température du four

Si le gâteau comporte des rides Surcharge des plats ou pâte trop ne

Si le gâteau s’a aisse légèrement au centre Prolonger le temps de cuisson ou augmenter légèrement la

Si la couleur du gâteau est pâle Augmenter la température

Si les bords du gâteau sont brûlés Réduire le nombre de plats ou la température du four

et n’est pas cuit au centre

Si le gâteau est doré sur les côtés

Problèmes Solutions

PROBLÈMES/SOLUTIONS

Page 31

Numéro de Pièce 1955203 rév 4 4/1518

etc. Cela est normal.

teneur en humidité comme le poulet, les pommes de terre

autour des portes du four lors de la cuisson d’aliments à forte

REMARQUE: Une certaine quantité d’humidité s’échappera

fonctionnement ne devrait pas dépasser 70 dB(A).

25. Le niveau de pression acoustique du four en

grille de protection retirée.

24. Ne pas faire fonctionner le ventilateur du four avec la

déversements et les blessures.

empêcheront les produits de glisser et éviteront les

répartition des produits dans les plats ou les plateaux

23. Une manipulation correcte du poids et une bonne

faire attention à ne pas se brûler.

22. L’extérieur des fours chau e pendant le fonctionnement;

la crémaillère des fours sont à hauteur des yeux.

graves sur la peau nue et aux yeux. Les niveaux élevés de

d’éviter les déversements pouvant causer des blessures

21. Faire attention pour retirer les produits du four a n

plats/plateaux du four quand celui-ci est allumé.

20. Utiliser des gants isolants pour ajouter ou retirer des

19. Utiliser des plats et plateaux alimentaires pour fours.

produits non alimentaires.

des installations de cuisson non commerciales ou à des

18. Ceci est un four de cuisson commercial non destiné à

service quali é.

enlevées quand le four est entretenu par un personnel de

vivre les pièces électriques et devraient seulement être

nécessaires pour la protection contre l’exposition pour

l’unes des sont enlevées. Ces couvertures sont

17. N’actionnez jamais le four si des couvertures extérieures

cuisson inégale.

du four. Cela empêche la circulation de l’air et cause une

16. Ne jamais placer quoi que se soit directement sur le fond

livres, par exemple le gâteau renversé aux ananas.

des aliments enrobés de pâte dont le poids dépasse huit

x26 po d’une profondeur de deux pouces pour la cuisson

15. Utiliser des rehausses de moules ou des moules de 18

dans le four.

l’introduction d’une grande quantité d’aliments froids

compenser la chute de température provoquée par

suggérée après le chargement du four. Cela permet de

suggérée. Revenir ensuite à la température de cuisson

préchau er le four à 100° de plus que la température

14. Pour le réchau age des plats en cocotte congelés,

uniforme.

face à l’avant. Cela permet d’obtenir une cuisson plus

avec l’arrière vers la porte ou avec le côté court du moule

13. Les moules à mu ns doivent être placés dans le four

faudra probablement ajuster les temps de cuisson.

de poisson, des pépites de poulet et des hamburgers. Il

maximum de 13 plats pour la cuisson des bâtonnets

mollets, etc.). Cependant, il est possible d’utiliser un

recommande d’utiliser 6 plats (gâteaux, biscuits, pains

12. Ne pas surcharger le four. Dans la plupart des cas, on

4, 6, 8, 10 et 12, en commençant par le haut.

11. Pour la cuisson de 6 plats, utiliser les positions de grilles 2,

chaque moule pour assurer une cuisson régulière.

10. Pour la pâtisserie, peser ou mesurer les produits dans

l’intérieur du four.

les grilles pour permettre une bonne circulation de l’air à

9. Centrer les plats dans le four et les répartir également sur

vite que possible pour éviter de trop les faire cuire.

minuterie. Les aliments doivent être retirés du four aussi

8. Le four continue à chau er même après l’arrêt de la

éviter les pertes de chaleur.

7. Pour charger le four, travailler aussi vite que possible pour

nouveau le thermostat.

atteindre la température souhaitée avant de régler à

suivantes, utiliser le mode de refroidissement pour

de 10° à la température nécessaire pour les charges

6. Si le réglage de température précédent est plus élevé

progressivement aux températures plus élevées.

la température de cuisson la plus basse et passer

5. Si possible, commencer par cuire les produits ayant

cuisson seront similaires.

fois ces renseignements notés, les autres opérations de

quantités d’aliment pour les di érents produits. Une

4. Noter les temps de cuisson, les températures et les

particulier de l’humidité) et de la densité des produits.

le four, de la température et du mélange de produits, (en

varier en fonction de la quantité d’aliments placés dans

cuisson suggérés comme guide. Ces valeurs peuvent

3. Utiliser le tableau des temps et des températures de

produits.

attentivement la première cuisson de chaque type de

et pour cette raison nous recommandons de surveiller

Le temps de cuisson peut également être plus court

50° par rapport à celle d’un four conventionnel/standard.

2. D’une façon générale, réduire la température de 25° à

utilisation.

1. Bien préchau er le four (environ 20 minutes) avant son

PRÉCAUTIONS GÉNÉRALES DE SÉCURITÉ

RECOMMANDATIONS D’UTILISATION ET

Page 32

Numéro de Pièce 1955203 rév 4 4/15 17

10. Pour arrêter l’alarme, appuyez sur la touche produit 6.

clignote.

ensuite SH-4, alors que la DEL de la touche produit 6

fait entendre et l’a chage indique en clignotant DONE,

9. Lorsque les aliments du niveau 4 sont cuits, une alarme se

produit 1.

8. Pour arrêter l’alarme, appuyez sur la touche

clignote.

ensuite SH-2, alors que la DEL de la touche produit 1

fait entendre et l’a chage indique en clignotant DONE,

7. Lorsque les aliments du niveau 2 sont cuits, une alarme se

cuisson sur le niveau.

6. Appuyez sur la touche START/CANCEL pour démarrer la

niveau 4.

5. Appuyez sur la touche produit 6, ensuite que la touche de

4. Chargez les aliments dans le four sur le niveau 4.

cuisson du niveau 2.

3. Appuyez sur la touche START/CANCEL pour démarrer la

niveau 2.

2. Appuyez sur la touche produit 1, ensuite sur la touche

1. Chargez les aliments dans le four sur le niveau 2.

position de grille 4. Une fois que le four a che le mot LOAD:

plateau utilisera la touche produit 6 et sera placé dans la

produit 1 et sera placé dans la position de grille 2. Le second

four en même temps. Le premier plateau utilisera la touche

Deux plateaux contenant des aliments vont cuire dans le

1 et 6.

sont tous les deux programmés sur temps exible - touches

température de cuisson, la même vitesse du ventilateur et

Exemple: Deux pro ls produit contiennent la même

la DEL clignote.

5. Pour arrêter l’alarme, appuyez sur la touche produit donc

P. ex. : SH-1.

la cuisson est terminée.

fait entendre et l’a chage indique quel est le niveau où

pour chaque niveau, un signal sonore de n de cuisson se

4. Lorsque le processus de cuisson/minuterie est terminé

le processus de cuisson/minuterie.

3. Appuyez sur la touche START/CANCEL pour commencer

INSTRUCTIONS D’UTILISATION (suite)

Page 33

Numéro de Pièce 1955203 rév 4 4/1516

4. Appuyez sur la touche START/CANCEL.

les touches produit et les touches niveau sont les mêmes.

l’emplacement du niveau à minuter (1 - 6). REMARQUE:

2. Appuyez sur la touche de niveau pour indiquer

cuisson désiré (1 - 9).

1. Appuyez sur la touche produit contenant le pro l de

indiqué par le mot LOAD sur l’a chage.

four a atteint la bonne température de cuisson, ce qui est

four à la température de cuisson souhaitée,. Une fois que le

Le fait d’appuyer sur la touche produit désirée amènera le

peut pas être utilisée avec l’option de minuterie de niveau.

de cuisson peuvent être di érents. L’option Cook-N-Hold ne

vitesse du ventilateur. Le temps exible ou xe et le temps

présenter la même température de cuisson et la même

touche produit, toutes les touches produit à utiliser doivent

l’option de minuterie de niveau. S’il faut utiliser plus d’une

doit être limitée à un seul pro l de cuisson à utiliser avec

ventilateur, temps exible ou xe). La touche de programme

avec un pro l de cuisson (température, temps, vitesse du

au moins une touche produit doit être programmée

REMARQUE: Pour utiliser l’option de minuterie de niveau,

à l’intérieur du four.

indépendamment chacun des 6 niveaux ou grilles di érents

L’option de minuterie de niveau est utilisée pour minuter

(Master )

Cuisson avec la Minuterie de Niveau

les touches PROG et ACTUAL TEMP en même temps.

Lorsque l’unité de mesure désirée est a chée, appuyez sur

et de C à F.

Appuyez sur la touche START/CANCEL pour passer de F à C

temps. La lettre F ou C s’a che. (préréglé en usine sur F).

Appuyez sur les touches PROG et ACTUAL TEMP en même

Celsius (Master )

Sélection De L’a chage En Degrés Fahrenheit Ou

au chaud s’a che.

maintenez enfoncée la touche produit. Le temps de maintien

Pendant que le produit est en mode de maintien au chaud,

(Master )

Véri cation du Temps de Maintien au Chaud

sur la touche produit.

chaud, appuyez sur la touche START/CANCEL et ensuite

5. Pour annuler l’alarme ou l’opération de maintien au

chargé.

3. Appuyez sur la touche produit pour l’article du menu

2. Chargez le four.

s’a che.

pour l’article du menu à cuire. Attendez que le mot LOAD

1. Lors du démarrage initial, appuyez sur la touche produit

(Master )

Cuisson avec Utilisation des Touches Produit

10. La programmation de cette touche produit est terminée.

pro l.

dernier pro l programmé, l’appareil a chera le premier

est terminée. Si l’on appuie sur la touche produit après le

pro ls. Appuyez sur la touche SET lorsque l’opération

exible pour le deuxième pro l. Continuez pour tous les

touche produit et sélectionnez le temps xe ou le temps

START/CANCEL pour le premier pro l. Appuyez sur la

Sélectionnez le temps exible ou xe à l’aide de la touche

ou temps xe) (préréglée en usine sur temps exible).

9. L’indication FL or St sera a chée (pour temps exible

première vitesse de ventilateur sera a chée.

touche produit après le dernier pro l programmé, la

c’était le cas avec la température, si l’on appuie sur la

SET lorsque cette opération est terminée. Comme

leur vitesse du ventilateur. Appuyez sur la touche

Continuez jusqu’à ce que tous les pro ls possèdent

du ventilateur pour le deuxième pro l de cuisson.

appuyez sur la touche produit et réglez la vitesse

individuelles du ventilateur (HIGH, LOW ou PULSE),

le premier pro l de cuisson avec les touches

• Réglez la vitesse du ventilateur désirée pour

Le mot FAN s’a che et la DEL FA N s’allume.

(préréglé en usine sur 200°F). Appuyez sur la touche SET.

la température de maintien au chaud avec le cadran

8. Si yes a été sélectionné, la DEL HOLD s’allume. Entrez

ou no. Appuyez sur la touche SET.

7. Utilisez la touche START/CANCEL pour sélectionner yes

s’A che.

dernières températures de cuisson, le mot HOLD

• Appuyez sur la touche SET après la saisie des

la première température.

produit après le dernier pro l programmé, l’appareil a chera

temps de cuisson a été réglé. Si l’on appuie sur la touche

températures de cuisson pour les pro ls pour lesquels un

REMARQUE: Le contrôleur acceptera uniquement les

INSTRUCTIONS D’UTILISATION (suite)

Page 34

Numéro de Pièce 1955203 rév 4 4/15 15

produits.

qu’il est possible d’accéder à la programmation des

START/CANCEL. Le mot PROD s’a che pour indiquer

d’accès. Appuyez sur les touches 4-2-7-5 et la touche

2. Le mot CODE s’a che. Le contrôleur demande le code

cuisson, pour tous les pro ls désirés.

• Répétez de la même manière que pour le temps de

cadran.

• Réglez le deuxième temps de cuisson à l’aide du

PR-2 s’a che suivie de la deuxième température.

• Appuyez sur la touche produit - l’indication

cadran.

6. Réglez la première température de cuisson à l’aide du

de cuisson du premier pro l (préréglé en usine sur 350°F).

DEL TEMP s’allume et l’a chage indique la température

vous que « :00 » est a ché. Appuyez sur la touche SET - la

30 minutes). Si vous ne désirez pas de préalarme, assurezdu cycle de cuisson de 60 minutes, réglez la préalarme sur

sonner. (P. ex. Si le produit doit être retourné à la moitié

l’aide du cadran le temps au bout duquel l’alarme doit

5. Si vous désirez le signal de préalarme, programmez à

pendant le processus de cuisson (préréglé en usine sur :00).

souhaitez obtenir l’alarme de rappel (préalarme) sonore

s’a che, suivie du chi re :00. Le contrôleur demande si vous

touche SET après le dernier pro l requis. L’indication PRE

Si vous désirez moins de cinq (5) pro ls - appuyez sur la

appuyez sur la touche SET OU :

pro ls. Lorsque le dernier temps de pro l est entré,

• Recommencez de la même façon pour tous les

- 9) - l’indication PR-3 s’a che.

• Appuyez de nouveau sur la même touche produit (1

préréglages en usine pour PR-2 à PR-5 sont :00).

• Réglez le second temps de cuisson avec le cadran (les

être sauvegardé (1 - 9) - L’indication PR-2 s’a che.

• Appuyez sur la touche produit où le programme doit

nécessaire d’entrer plusieurs pro ls de cuisson :

4. Réglez le premier temps de cuisson avec le cadran. S’il est

produits s’allument.

pendant trois (3) secondes - tous les DEL des touches

1. Appuyez sur la touche PROG et maintenez-la enfoncée

éléments de cuisson.

les périodes de temps nécessaires, suivies par les autres

dans le contrôleur. La première étape consiste à entrer toutes

(température, vitesse du ventilateur, etc.) vont être entrées

programme qui dit au contrôleur que d’autres informations

REMARQUE: Le temps de cuisson est l’élément du

(Master )

Programmation des Touches Produit

cuisson manuelle.

11. Appuyez sur la touche START/CANCEL pour démarrer la