Garland MCOE5 Installation Manual

Master Series

Half-Size Electric Convection Ovens

Installation, Operation and Maintenance Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

models

MCO-E-5-C

MCO-E-25-C

Part Number 260BGL rev C 4/15

MCO-E-5-C

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects or other

reproductive harm. Installation and servicing of this product could expose you to airborne particles of glass wool/

ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers is known to the state of California to cause

cancer.

Keep appliance area free and clear of combustibles.

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

Power Failure

In the event of a power failure, no attempt should be made

to operate this oven.

Part Number 260BGL rev C 4/15Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Serial Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Entry Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation of Double Deck Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Master 200 Solid State Control with Electromechanical Timer . . . . . . . . . . . . . 8

PERFORMANCE RECOMMENDATIONS & SAFETY PRECAUTIONS . 9

PROBLEM/SOLUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

COOKING GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fan Area Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Motor Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Part Number 260BGL rev C 4/15 Page 3

GENERAL INFORMATION

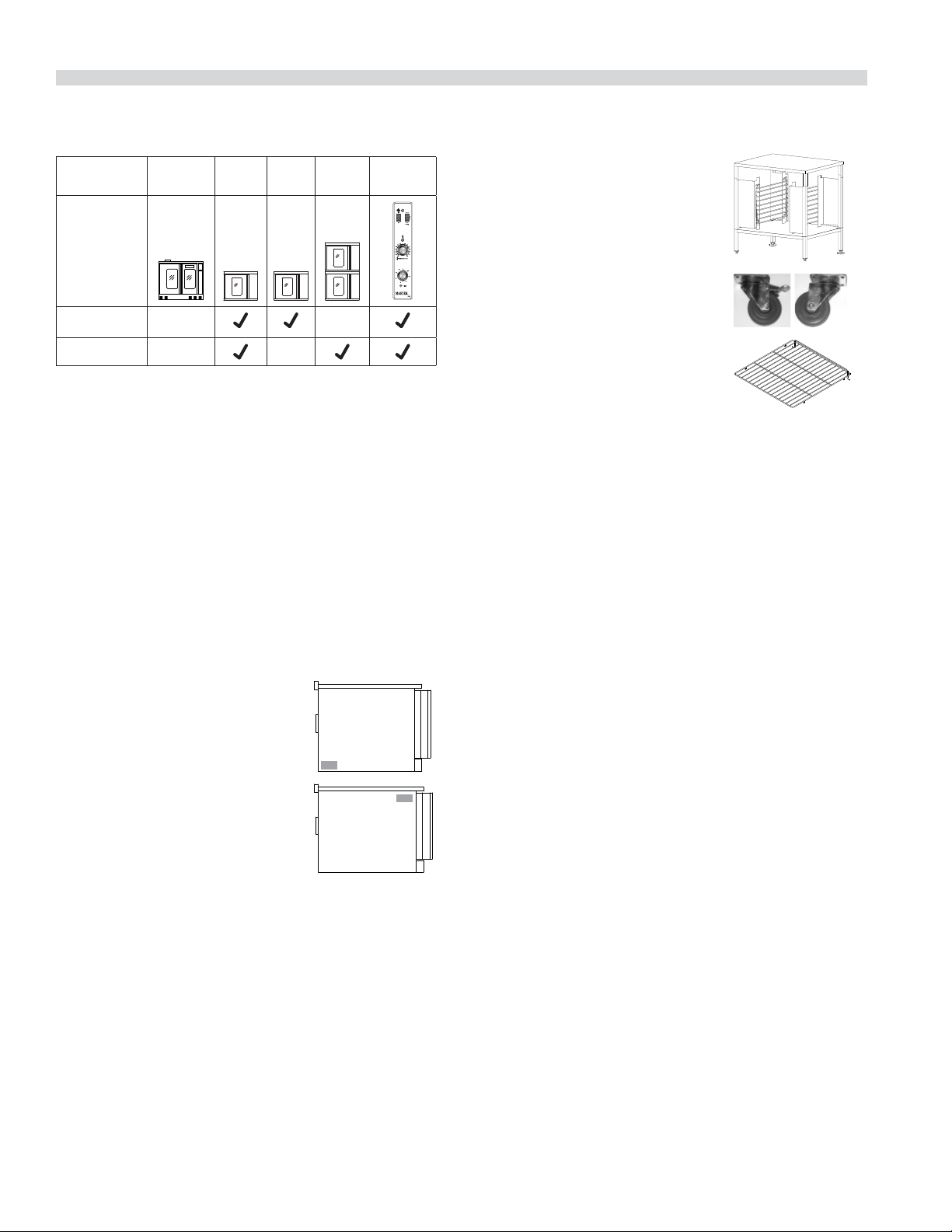

Model Numbers

Model

Full-Size

MCO-E-5-C

MCO-E-25-C

Half-

Size

Single

Deck

Double

Deck

Master

Control

200

Warranty

Visit www.Garland-Group.com to view or download a copy

of your warranty.

Serial Plate Location

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prefix and suffix

letters and numbers) and the warranty serial number.

Accessories

• Stainless steel stand with rack

guides, single deck oven only

• Swivel Casters (set of 4) with

front brakes

• Extra oven rack

A duplicate serial number tag is located behind the control

panel.

Ovens Built between 01-June-2011

and

• The serial plate is affixed to the

lower left corner of the left body

panel.

Ovens Built after 02-FEB-2015

• The serial plate is affixed to the

upper right corner of the left

body panel.

Part Number 260BGL rev C 4/15Page 4

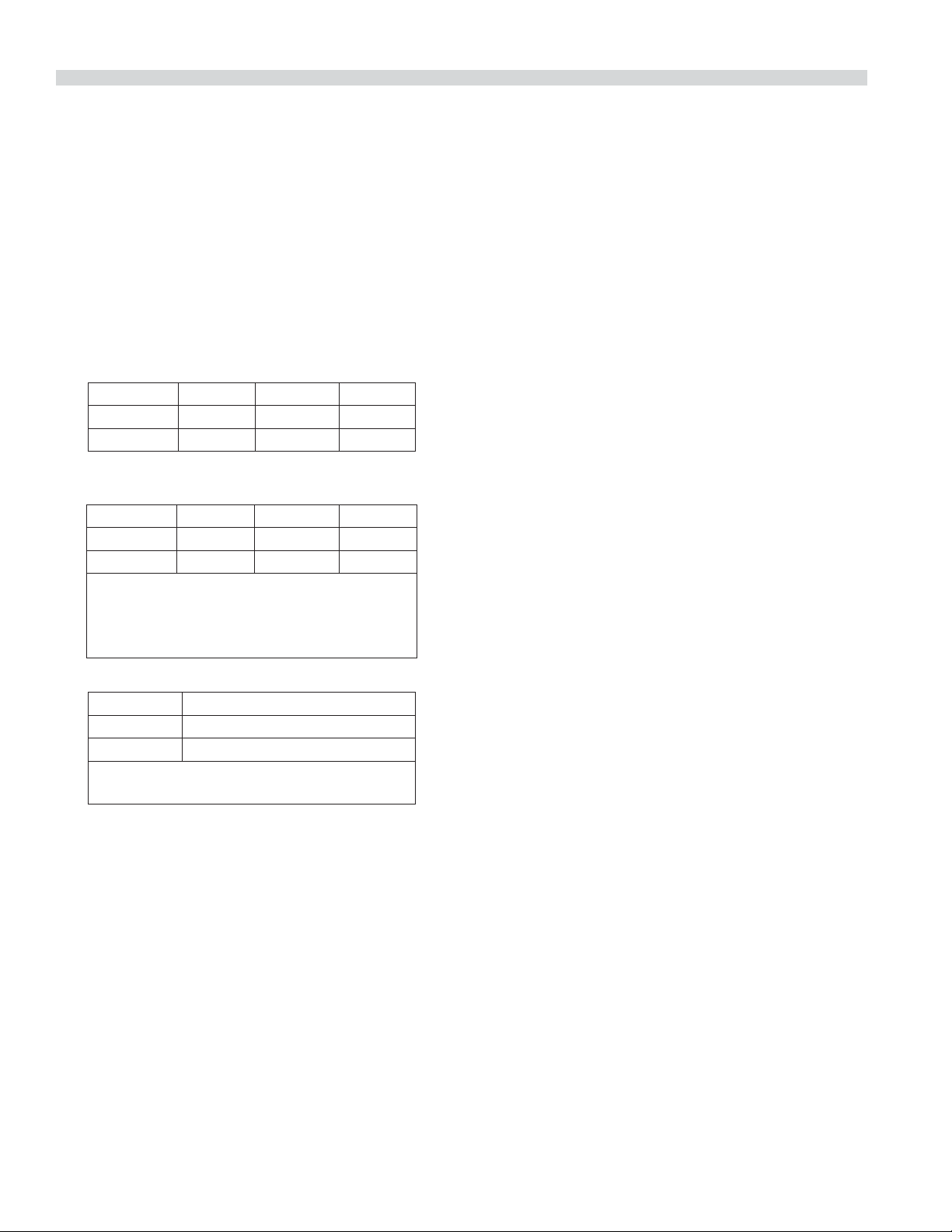

DIMENSIONS AND SPECIFICATIONS

Nominal Amperes Per Line

Package Total kW

Standard 5.6 27 23 23 12 14 20 12 14

Option 7.5 39 33 23 21 22 20 18 19

208V/1Ph 240V/1Ph

208V/3Ph 240V/3Ph

XYZXYZ

Model

MCO-E-5-C 15-1/2” (939mm) 20 (510mm) 21 1/8 “ (537mm) 340/155 38.5

MCO-E-25-C 15-1/2” (939mm) 20 (510mm) 21 1/8 “ (537mm) 680/310 77

* NOTE: Double deck ovens are provided with individual

supply connections

Interior Dimensions (per deck) Shipping Information

Width Height Depth Lbs./Kg Cu. Ft.

Part Number 260BGL rev C 4/15 Page 5

INSTALLATION

Entry Clearance

• Crated: 37” (940mm)

• Uncrated: 31” (788mm)

Installation Clearance

NOTE: Always provide adequate clearance for maintenance

and operation.

• Installation adjacent to combustible and noncombustible wall, minimum clearance:

Left Side Control Side Rear

Single-Deck 1" (26 mm) 1" (26 mm) 1” (26 mm)

Double-Deck 1" (26 mm) 2" (51 mm) 1” (26 mm)

• Installation near high heat producing equipment,

minimum clearance:

Left Side Control Side Rear

Single-Deck 1" (26 mm) 6" (153 mm) 3" (77 mm)

Double-Deck 1" (26 mm) 6" (153 mm) 3" (77 mm)

Notice

Avoid installing ovens near equipment, such as charbroilers or fryers, which generate high heat and high

grease laden air.

• Clearance for Service (recommendation):

Control Side, minimum

Single-Deck 12" (305 mm)

Double-Deck 12" (305 mm)

NOTE: Install units with casters in very tight

locations for ease of service.

WARNING: Care must be taken in installation to allow for

air ow around units, especially when placed near other heat

producing sources. A 4” spacing is recommended for the

control side of the oven from other heat producing sources.

Installation of Double Deck Models

A. Position insert in bottom leg opening and tap insert up

into leg until it seats at collar. Attach 21 1/4” (540mm)

legs to lower oven section. Raise unit or lay on its left side.

Place the front legs on the oven so as to line up with four

(4) attaching bolt holes. Secure leg to oven frame using

(4) 3/8-16 x 3/4 bolts and washers provided. Repeat at

rear of unit.

B. Place the unit that will be the bottom oven upright. Raise

top deck into place and line up body sides and back

of the unit. Fasten the rear of the units together, with

the stacking bracket provided in the stacking bracket

kit,using the instructions provided in the kit.

C. Check leveling of unit four (4) ways (using a common

carpenter’s level on the rack inside the oven).

D. Maintain clearance from combustibles.

CAUTION: Disconnect both ovens from electrical supply

before servicing to protect against shock!

Ventilation

WARNING: Inadequate ventilation may result in a high

ambient temperature at the rear of the oven. Excessive

ambient temperature can cause tripping of the blower

motor’s thermal overload protection device. This condition

must be corrected immediately to avoid damage to the

blower motor.

IMPORTANT : Large objects should not be placed in front

of this oven, which would obstruct the air ow through the

front. Objects should not be placed on main top rear of oven

while in use. This could obstruct the venting system of the

units.

Installation of Ovens Equipped with Casters

A. Adequate means must be provided to limit the

movement of the appliance without depending on the

connector wiring.

B. The front casters of the unit are equipped with brakes to

limit the movement of the oven without depending on

the connector wiring to limit the appliance movement.

C. A restraint can be attached to the unit. If the restraint is

disconnected, be sure to reconnect the restraint after the

oven has been returned to its originally installed position.

Part Number 260BGL rev C 4/15Page 6

INSTALLATION Continued

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

THE ELECTRICAL POWER LINES MUST BE INSTALLED IN

ACCORDANCE WITH:

- The National Electrical Code, ANSI/NFPA No. 70 latest

edition (USA)

- Canadian Electrical Code, CSA C22.2

- Any other applicable National, State or municipal codes and

regulations..

THE FOLLOWING CONDITIONS MUST BE ADDRESSED:

1. Switch panel size

2. Overload protection

3. Wire type

4. Wire size

5. Temperature limitations of the wires

6. Method of connection (Cable, Conduit, etc.)

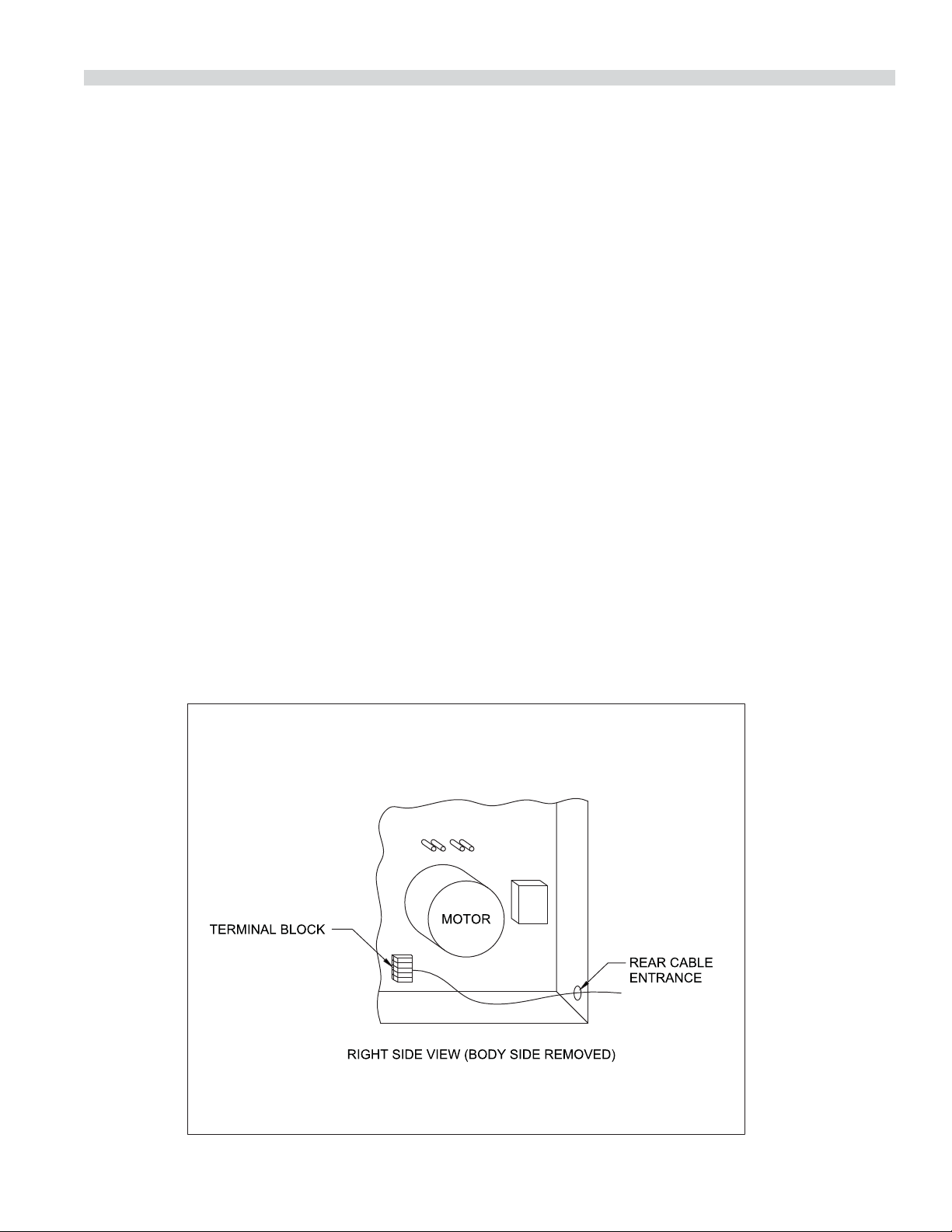

to be connected to the terminal block (see diagram below).

The terminal block is accessed by removing the right side

body panel.

Input voltage and phasing must match the units voltage

and phasing. Wiring diagram is attached to the main back of

each oven. Visually check all electrical connections. Energize

electric service to units. The range is wired standard for three

phase connections. If it is necessary to change to single

phase, please refer to wiring diagram attached to the rear of

the oven. Service and unit voltage must agree.

The service line will enter through the rear of the unit and is

Part Number 260BGL rev C 4/15 Page 7

OPERATING INSTRUCTIONS

Master 200 Solid State Control with

Electromechanical Timer

Modes

In O Mode

When the oven is o , there are no lights or indicators.

Start Up

Press the COOK/OFF/COOL DOWN rocker switch to the

“COOK” position. The green lamp will light indicating the

oven is powered in cook mode.

The oven will begin to heat to the temperature set on the

thermostat dial. The amber lamp will light indicating the heat

is active. As the heat cycles on and o to maintain the set

temperature this light will go on and o accordingly.

The door must be closed for the oven to operate in cook

mode. Opening the door will cause the heat to stop and the

motor and fan will shut o . This is a safety feature.

Fan Speed

The fan speed can be either high (1725RPM) or low

(1150RPM). The fan speed is controlled by the left rocker

switch marked high and low.

Cool Down

Pressing the COOK/OFF/COOL down rocker switch to the

COOL DOWN position activates the fan and motor to cool

the oven cavity. The door must be open slightly for the fan

and motor to start. The heat is not active in this mode.

Optimal cool down will be achieved with the door open

slightly. Opening the door too far will shut the fan and motor

o . This is a patented safety feature.

Pressing the button to the OFF position cancels the cool

down and turns the oven o .

Temp era tu re

The temperature range is from 150° to 500°F (66°C to 250°C)

is controlled by rotating the temperature dial and aligning

the indicator to the desired temperature.

Timer

The timer is set by rotating the dial clockwise aligning the

indicator to the desired time cycle. The timer will count down

from 2 minutes to 60 minutes. At the end of the timing cycle

the buzzer will sound. The buzzer is turned o by rotating the

dial counter-clockwise to the o position.

NOTE: The timer does not control heating.

Part Number 260BGL rev C 4/15Page 8

Loading...

Loading...