Page 1

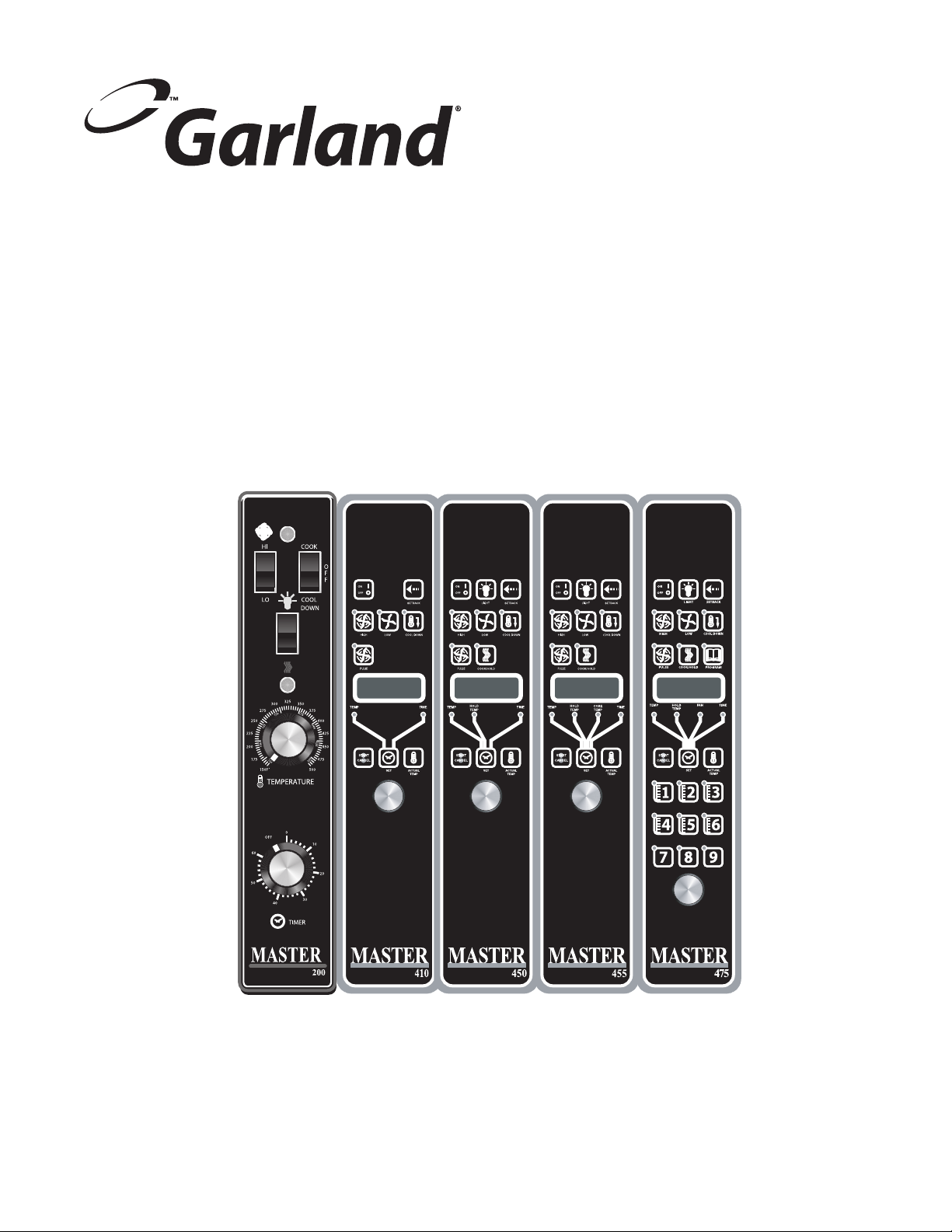

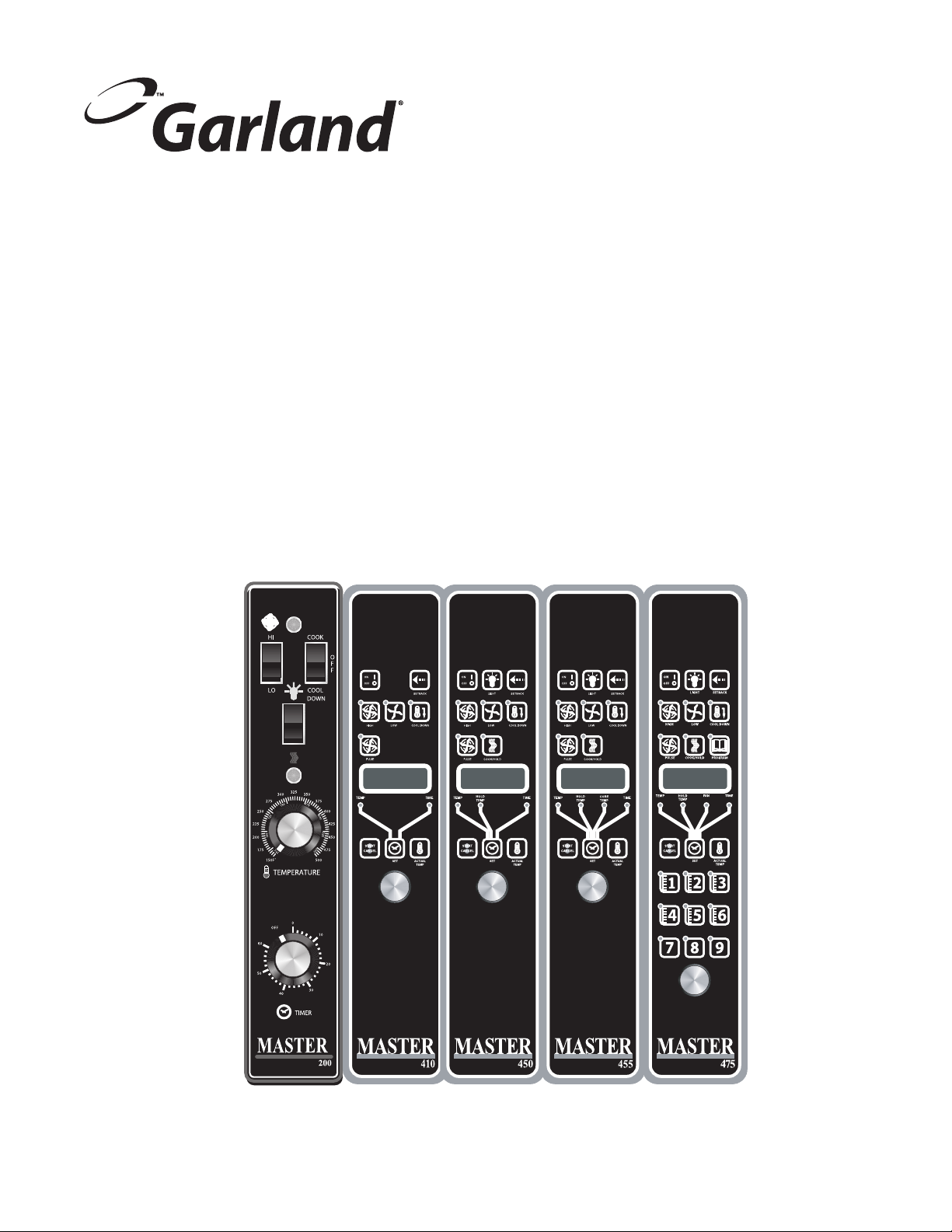

Service Manual For MCO GS/GD

Full Size "Gas" Convection Ovens

With 200, 410, 450, 455, 470, 475 Series

Controllers

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # MCOSM06 Rev 1(11/03/08) © 2006 Garland Commercial Industries, Inc.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

Page 2

Part # MCOSM06 Rev 1 (11/03/08)

Page 3

TABLE OF CONTENTS

Section One Operation Manual .................................................5

Contents....................................................................................6

Dimensions & Specications

Installation

Operation

Performance Recommendations

Cooking Guide

Cook And Hold

Problems / Solutions

Cleaning & Maintenance

Motor Care

..................................................................................8

.................................................................................12

.............................................................................22

.............................................................................23

.......................................................................24

.................................................................................26

Section Two Electronic Pilot & Main Burner .....................................27

Ignition Sequence..........................................................................28

Trouble Shooting Table

Service

G77x Intermittent Pilot Controls

G76x Direct Spark Ignition Controls

....................................................................................30

.................................................................7

............................................................21

....................................................................25

.....................................................................29

.............................................................32

.........................................................35

Section Three Temperature Calibration.........................................39

General Calibration.........................................................................40

200 & 300 Series Controllers Calibration

.....................................................41

Section Four Convection Oven Components ....................................43

Doors......................................................................................44

Door Latch Mechanism

Motor

Door Microswitch

Probes

Key Pad Test

Mco Convection Oven Gas Valve

Relay Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Controls

.....................................................................................48

.....................................................................................51

...............................................................................52

...................................................................................57

.....................................................................47

..........................................................................50

............................................................53

Section Five Trouble Shooting .................................................59

Controller Operational Tests ................................................................60

Controller Fault Finding

Additional Notes

General Trouble Shooting Guide

...........................................................................63

....................................................................61

............................................................64

Section Six Service Bulletins ...................................................67

Section Seven Wiring Diagrams

Part # MCOSM06 Rev 1 (11/03/08) Page 3

...............................................101

Page 4

Page 4

Part # MCOSM06 Rev 1 (11/03/08)

Page 5

Section One

Operation

Manual

Part # MCOSM06 Rev 1 (11/03/08) Page 5

Page 6

CONGRATULATIONS! You have just purchased the nest commercial cooking equipment available anywhere.

Like any other ne, precision built appliance, it should be given regular care and maintenance. Periodic inspections by your

dealer or a qualied service agency is recommended. When corresponding with the factory or your local authorized factory

service center regarding service problems or replacement parts, be sure to refer to the particular unit by the correct model

number (including the prex and sux letters and numbers) and the warranty serial number. The rating plate axed to the

unit contains this information.

CONTENTS

DIMENSIONS & SPECIFICATIONS ...............7

INSTALLATION ................................8

Installation Notes: .....................................8

Installation Of Ovens Equipped With Casters ...........8

Installation Of Double Deck Models . . . . . . . . . . . . . . . . . . . 8

Gas Connection .......................................9

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilation & Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Testing & Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . 11

OPERATION..................................12

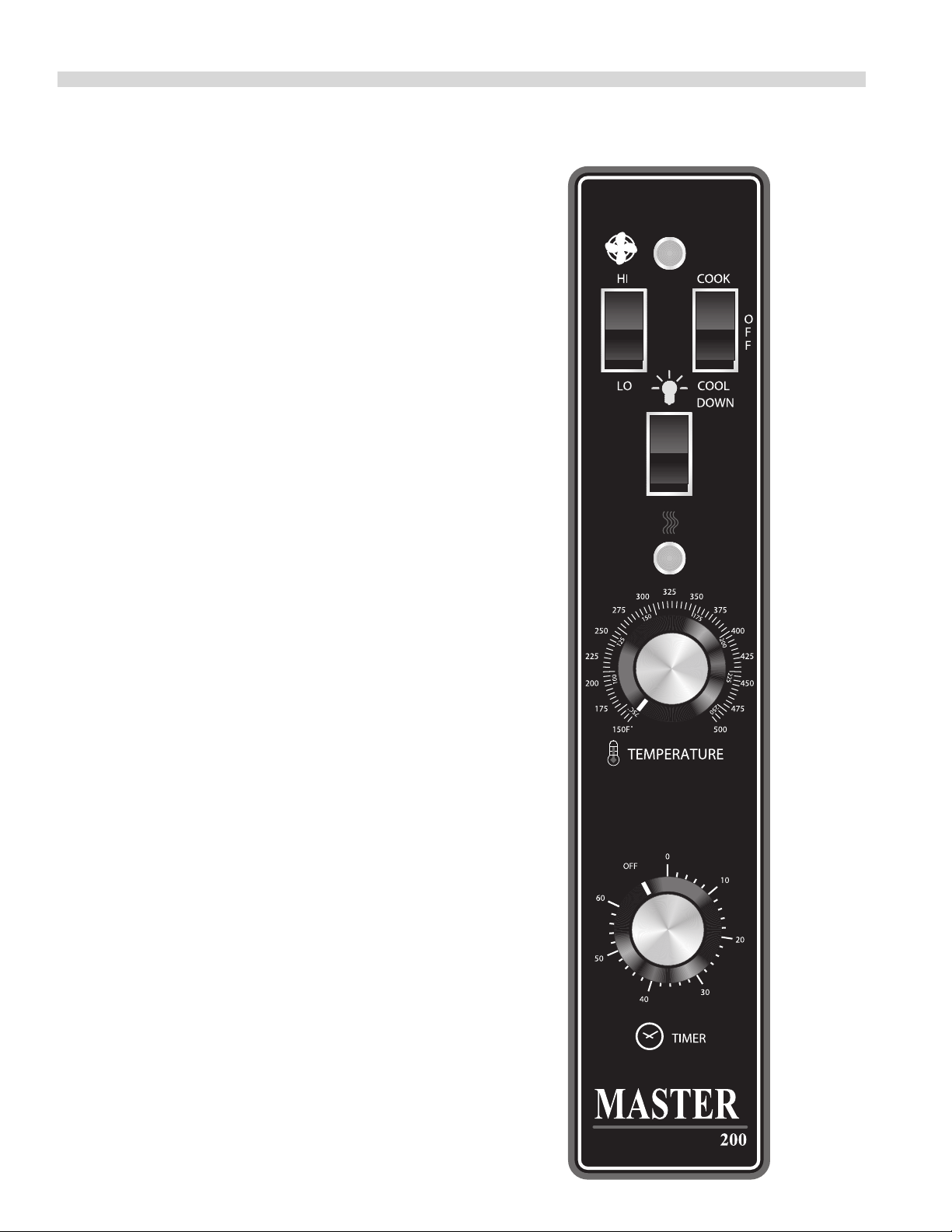

Master 200 Mechanical Control with Timer ............12

In O Mode: ..................................... 12

Start Up:......................................... 12

Fan Speed:....................................... 12

Lights: ........................................... 12

Cool Down: ...................................... 12

Temperature: .................................... 12

Timer: ...........................................12

MASTER 300 Solid State Control ......................13

In O Mode: ..................................... 13

On Start Up: ..................................... 13

Controller Keys .................................. 13

MASTER 410,450, 455 CONTROLS .....................14

In O Mode: ..................................... 14

On Start Up: ..................................... 14

Operating the Controls........................... 15

Cook-N-Hold Operation.......................... 15

Core Probe Operation............................ 16

CHANGING FACTORY SETBACK PROGRAM ........ 16

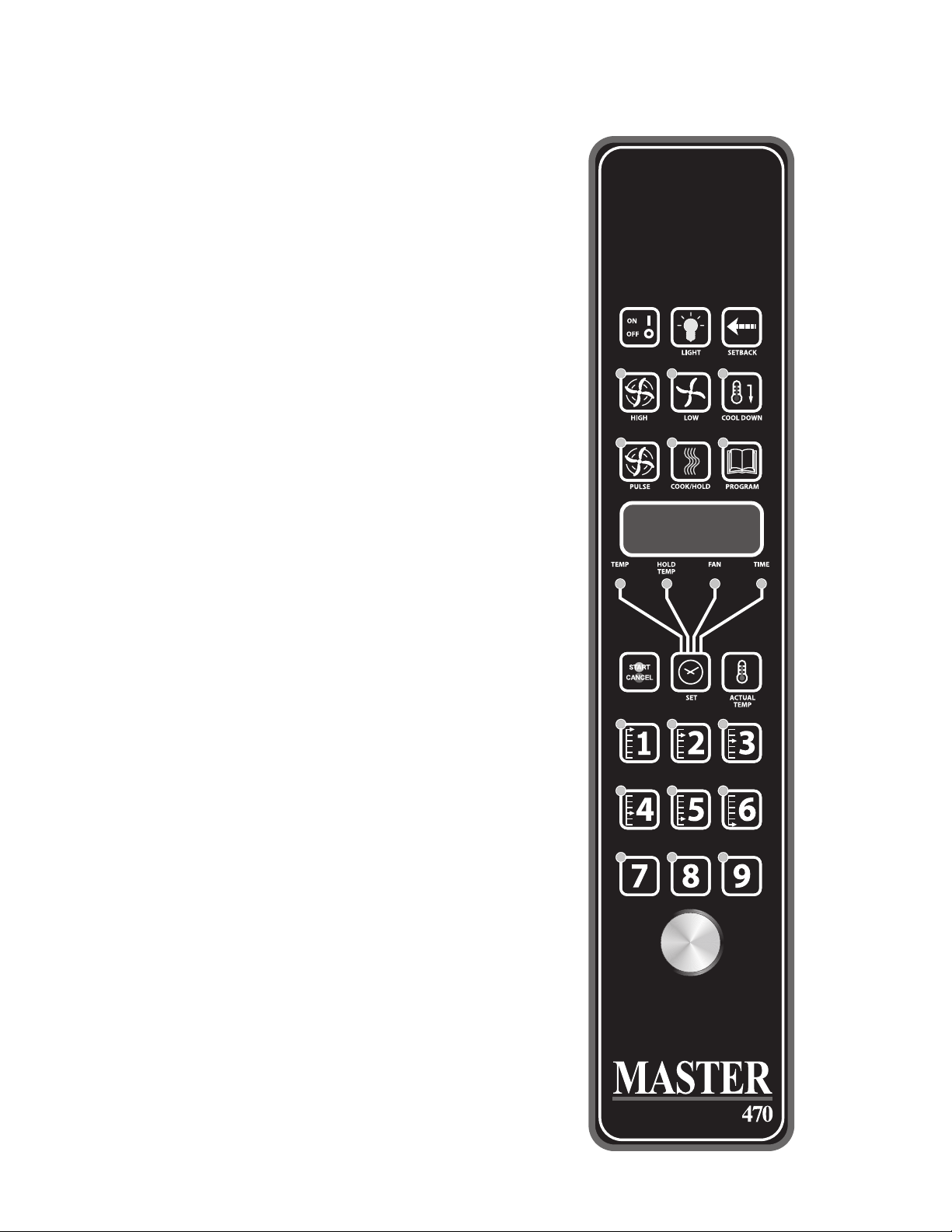

MASTER 470/475 CONTROLS ..........................17

Manual cooking: ................................. 17

Manual cooking using Cook-N-Hold: ............. 17

Programming Product Keys (Master 475): ......... 17

Programming Product Keys (Master 470): ......... 19

Cooking Using The Product Keys(475 and r 470): .. 19

Verifying hold time (475 and 470): ................ 19

Cooking with the Shelf Timer (475 and 470): ......20

PERFORMANCE RECOMMENDATIONS .........21

COOKING GUIDE.............................22

COOK AND HOLD ............................23

PROBLEMS / SOLUTIONS .....................24

CLEANING & MAINTENANCE ..................25

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Interior Cleaning .....................................25

Fan Area Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

MOTOR CARE ................................26

Page 6

Part # MCOSM06 Rev 1 (11/03/08)

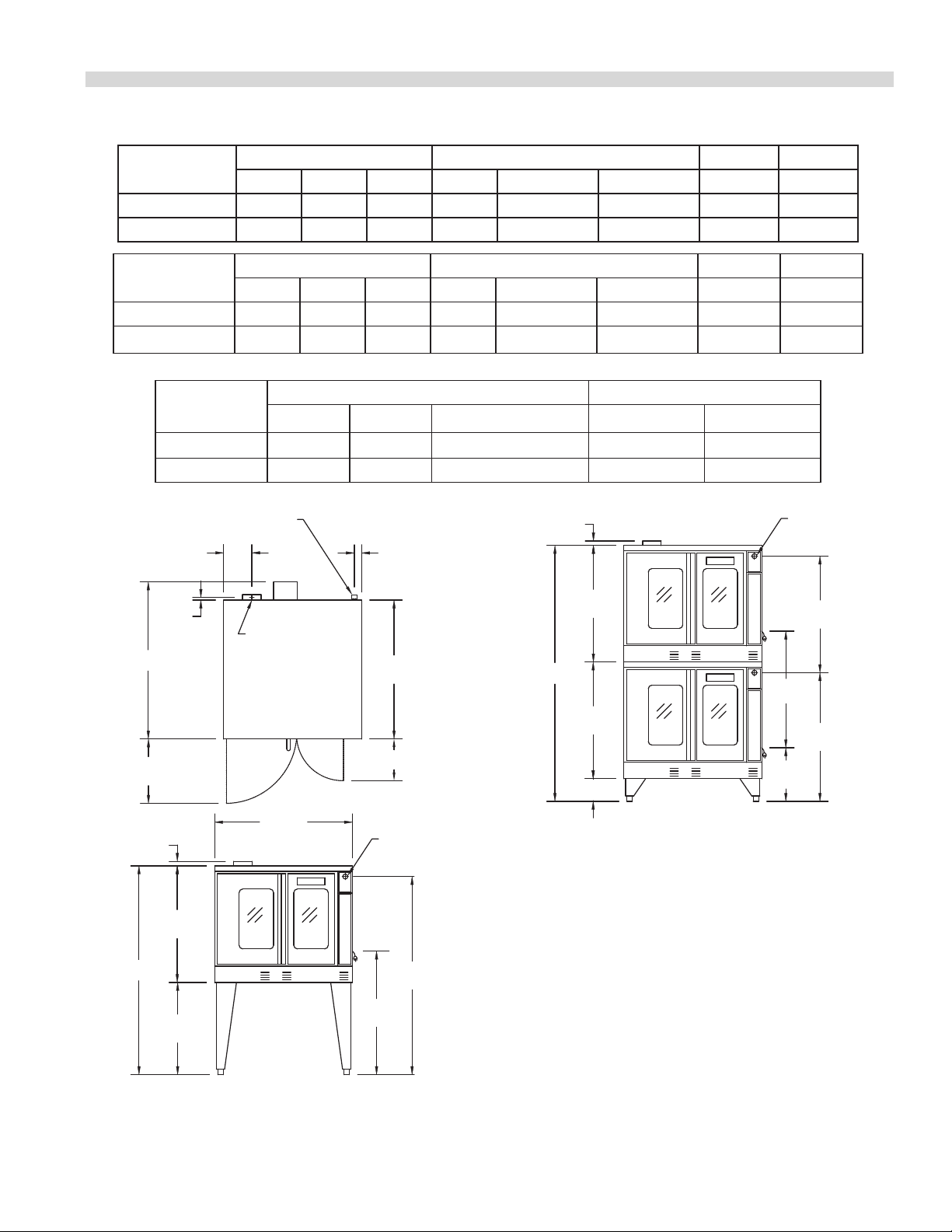

Page 7

7-3/4"

[197mm]

38-1/4"

[972mm]

3/4"

[19mm]

17-3/4"

[451mm]

TOP VIEW

2"

[51mm]

FLUE: 2-3/8" x 5"

[60mm x 127mm]

3/4" N.PT.

GAS INLET

11-1/2"

[292mm]

38"

[965mm]

32-1/8"

[816mm]

25-3/8"

[645mm]

SINGLE DECK

FR ONT VIEW

1-1/4"

[32mm]

34"

[864mm]

54-9/16"

[1386mm]

3/4" REAR

GAS INLET

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

14-3/4"

[375mm]

32-1/8"

[816mm]

35-7/16”

[900mm]

32-1/8"

[816mm]

1-1/4"

[32mm]

DOUBLE DECK

FR ONT VIEW

D

H

H

1" REAR

GAS INLET

DIMENSIONS & SPECIFICATIONS

Single-Deck

Models

Int. Dimensions :In (mm) Ext. Dimensions: In (mm) Ship Wt Ship Dim.

W H D W H * D Lbs/kg Cubic Ft.

Standard Depth 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 41-1/4(1048) 600/273 64

Deep Depth 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 44-1/2(1130) 600/273 64

Double-Deck

Models

Int. Dimensions: In (mm) Ext. Dimensions: In (mm) Ship Wt. Ship Dim.

W H D W H * D 2@Lbs/kg Cubic Ft.

Standard Depth 29 (736) 24 (610) 24 (610) 38 (965) 70-1/2 (1791) 41-1/4(1048) 1150/523 128

Deep Depth 29 (736) 24 (610) 28 (711) 38 (965) 70-1/2 (1791) 44-1/2(1130) 1150/523 128

*Height with or without standard casters. Height with low prole casters (double deck) is 68-1/2" (1740mm).

Input Ratings, Nat & Pro Electrical Specications

Models

BTU/hr

kW Equiv. Gas Inlet 120V/1Ph. 240V/1Ph.

Single Deck 60,000 17. 6 (1 )@ 3/4" NPT (1)@9.4A (1)@ 5.2A

Double Deck 120,000 35.2 (1 )@1" NPT (2)@9.4A (2)@ 5.2A

(Includes

fan motor)

Installation Notes:

Combustible Wall Clearances:

Sides: 1" (25mm)

Back: 3" (76mm)

Entry Clearance:

Crated: 47" (1194mm)

Notes:

Uncrated: 32-1/2" (826mm)

Operating Pressure:

Natural: 4.5" WC (11 mbar)

Propane: 10" WC (25 mbar)

Max 13.8" WC @ 70°F (21°C)

NOTE: Data applies only to

North America

1. Standard electrical specications include motor requirements.

2. (120V units) 115V 3/4 HP, 2-speed motor; 1140 and 1725 rpm 60Hz

3. (240V uni ts) 2 00-240 V, 3/4 HP, 2-spe ed motor; 1140 and 1725 rp m, 6 0Hz

4. A 6 ft. line cord is provided for each 120V deck with a (NEMA #5-15P) plug.

5. Garland recommends a separate 15 AMP circuit for each 120V unit.

Gas Input ratings shown here are for installations up to 2,000-ft. (610m) above sea level. Specify altitudes over 2,000 ft.

Commercial cooking equipment requires an adequate ventilation system. For additional information, refer to the National Fire

Protection Association’s standard NFPA96, "Vapor Removal from Cooking Equipment." (NOTE: For North America only)

Please specify gas type when ordering.

Part # MCOSM06 Rev 1 (11/03/08) Page 7

Page 8

INSTALLATION

Installation Notes:

Combustible and Non-Combustible Wall Clearance: Side:

1.0" (25 mm) Rear: 3.0" (76 mm)

NOTE: Adequate clearance must be provided for servicing

and proper operation.

The importance of the proper installation of Commercial

Gas Cooking Equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer's

specications. Installation must conform to local codes or,

in the absence of local codes, with the National Fuel Code,

ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1,

or the Propane Installation Code, CAN/CGA-B149.2, as

applicable.

Before assembly and connection, check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located behind lower front panel.

Connect a unit stamped "NAT" only to natural gas;

connect a unit stamped "PRO" only to propane.

B. If it is a new installation, have gas authorities check meter

size and piping to assure that the unit is supplied with

sucient amount of gas pressure required to operate the

unit.

C. If it is additional or replacement equipment, have gas

authorities check pressure to make certain that existing

meter and piping will supply fuel at the unit with not

more that 1/2" water column pressure drop.

NOTE: When checking pressure be sure that all other

equipment on the same gas line is on. A pressure regulator

is supplied with GARLAND Convection Ovens. Regulator is

preset to deliver gas at pressure shown on the rating plate.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 PSI (3.45 kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-o

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 PSI

(3.45 kPa).

Installation Of Ovens Equipped With Casters

A. For an appliance equipped with casters, the installation

shall be made with a connector that complies with the

Standard for Connectors for Movable Appliances, ANSI

Z21.69 or Connectors for Moveable Gas Appliances,

CAN/CGA-6.16, and a quick-disconnect device that

complies with the Standard for Quick-Disconnect Devices

for Use With Gas Fuel, ANSI Z21.41, or Quick-Disconnect

Devices for Use with Gas Fuel, CAN1-6.9, and adequate

means must be provided to limit the movement of the

appliance without depending on the connector and the

quick-disconnect device or its associated piping to limit

the appliance movement and the location(s) where the

restraining means may be attached to the appliance shall

be specied.

B. The front casters of the unit are equipped with brakes

to limit the movement of the oven without depending

on the connector and any quick-disconnect device or its

associated piping to limit the appliance movement.

C. The restraint can be attached to the unit near the gas inlet.

If the restraint is disconnected, be sure to reconnect the

restraint after the oven has been returned to its originally

installed position.

Installation Of Double Deck Models

A. Position insert in bottom leg opening and tap insert up

into leg till it seats at collar. Attach six inch (6") legs to

lower oven section. Raise unit or lay on its left side. Place

the front legs on the oven so as to line up with four (4)

attaching bolt holes. Secure leg to oven frame using (4)

3/8-16 x 3/4 bolts and washers provided. Repeat at rear of

unit.

B. Remove lower front cover of top deck (located under oven

doors). Raise top deck into place and line up body sides

and back of the unit. Fasten the rear of the units together,

with the stacking bracket, as shown, using (6) 1/4-20

machine screws, lock washers and nuts, (provided).

C. Install the interconnecting ue parts, carefully following

the instructions contained in the stacking kit. Pay

particular attention to the type of ovens you are stacking

and be sure to follow the corresponding instructions.

Page 8

Part # MCOSM06 Rev 1 (11/03/08)

Page 9

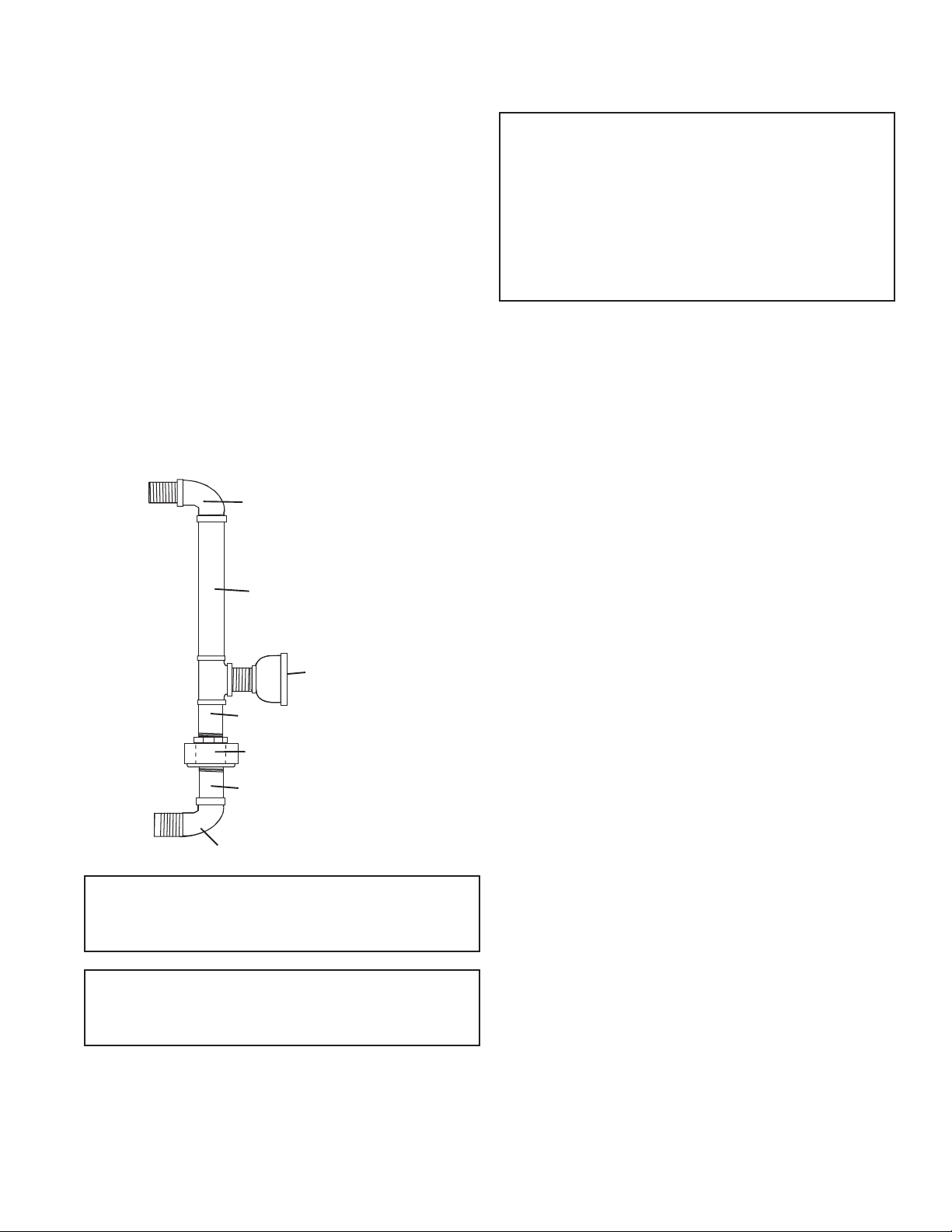

D. Assemble the stacking pipes provided in the stacking

3/4" Union

3" Nipple

3" Nipple

90 Degree Street Elbow

90 Degree Street Elbow

20-1/2" Nipple

3/4" to 1" Bell Reducer

kit as shown in the diagram at the top of this page. This

allows both ovens to be supplied by a single gas line. The

minimum recommended size of a single supply line for

two stacked ovens is 1 inch. Use a pipe thread compound

that is intended for use on propane gas piping and be sure

to check for leaks before nalizing the installation.

E. Check leveling of unit four (4) ways (using a common

carpenter's level on the rack inside the oven).

F. Plug the cord set of each unit into a 115-Volt power supply

outlet.

IMPORTANT

All gas burners and pilots need sufficient

air to operate and large objects should not

be placed in front of this oven, which would

obstruct the airflow through the front.

Objects should not be placed on main top rear

of oven while in use. This could obstruct the

venting system of the unit's flue products.

Gas Connection

G. Maintain clearance from combustibles.

Each gas appliance shall be located with respect to building

construction and other equipment so as to permit access to

the appliance. Such access and clearance may be necessary

for servicing and cleaning.

The 1" NPT inlet at the rear must be considered in piping the

gas supply for double stack units or 3/4" NPT for individual (or

single deck) connections. Undersized gas supply line(s) may

restrict the gas supply and aect performance. If other gas

appliances are supplied by the same supply line, the supply

line must be sized to carry the combined volume without

causing more than 1/2" pressure drop at the manifold of each

appliance on the line at full rate.

Recommended supply pressures are 7" WC, (NAT), and

11" WC, (PRO); ± 5%. (Must not exceed 13.8" WC [NAT], and

15" WC [PRO]).

Electrical Connection

A 15 AMP service must be provided for each oven. For 115

VAC usage, a cord and plug (NEMA #5-15P) is provided but

connection to the electrical service must be electrically

grounded in accordance with local codes, or in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70,

or the Canadian Electrical Code, CSA C22.2, as applicable.

This appliance is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle.

DO NOT CUT OR REMOVE THE

CAUTION:

A wire diagram is axed to the rear of the unit.

GROUNDING PRONG FROM THIS PLUG.

DISCONNECT BOTH UNITS FROM

ELECTRICAL SUPPLY BEFORE SERVICING.

POWER FAILURE

In the event of a power failure, no attempt

should be made to operate this oven.

Part # MCOSM06 Rev 1 (11/03/08) Page 9

Ventilation & Air Supply

Proper ventilation is highly important for good operation.

There are only two choices for properly venting an oven: 1)

canopy hood style or 2) direct venting. The ideal method

of venting a GAS Convection Oven is through the use of a

properly designed canopy, which should extend 6" (150 mm),

beyond all sides of the appliance and 6'6" (1950 mm) from the

oor.

Page 10

A strong exhaust fan will create a vacuum in the room. For an

DRAFT DIVERTER

exhaust system vent to work properly, exhaust and make-up

air must be balanced properly. For proper air balance contact

your local H.V.A.C. contractor.

Direct venting as described above, should be positioned

on the main top and fastened with sheet metal screws

provided. All parts described above are available from the

manufacturer.

All gas burners and pilots need sucient air to operate and

large objects should not be placed in rear and bottom of this

oven, which would obstruct the airow through the front.

INSTALLATION OF A DIRECT FLUE.

When the installation of a canopy type exhaust hood is

impossible the oven may be direct vented. Before direct

venting check your local codes on ventilation, in the absence

of local codes, refer to the National Fuel Code NFPA 54, ANSI

Z223.1 (latest revision).

If the unit is to be connected directly to a direct ue, it is

necessary that draft diverter be installed to insure proper

ventilation.

NOTE: Each oven has been factory tested and adjusted prior

to shipment. It may be necessary to further adjust the oven

as part of a proper installation. Such adjustments are the

responsibility of the installer. Adjustments are not considered

defects in material and workmanship, and they are not

covered under the original equipment warranty.

DO NOT UNDERSIZE VENT PIPE!

This can cause resistance to ow and impede good venting.

We suggest that if a horizontal run must be used it should

rise no less than 1/4" (6.25mm) for each linear foot of run, and

after a total of 180° of bends you should increase the size of

stove pipe by two (2") inches. The ue should rise 2' (60cm) to

3' (90cm) above the roof line or 2' (60cm) to 3' (90cm) above

any portion of a building within a horizontal distance of 10 (3

meters) feet.

The following diagram is only one example from the National

Fuel Gas Code Book NFPA 54, ANSI Z223.1, 7.5.3:

Page 10

Part # MCOSM06 Rev 1 (11/03/08)

Page 11

Termination Less than 10 feet (3 meters) from ridge Termination More than 10 feet (3 meters) from ridge

Less than 10 feet (3 meters)

More than 10' (3 meters)

2' (60cm)

Min.

3' (90cm) Min.

3' (90cm) Min.

Testing & Lighting Instructions

1. Turn on main gas valve. Remove the lower front cover

and the service panel above the control panel. Drop the

control panel and leak test all ttings and connections

upstream from the service valve located on the redundant

combination gas valve. Should any gas leaks be detected,

turn OFF main gas valve, correct the problem and retest.

2. Open shuto valve located on the redundant combination

gas valve. Activate control panel and set to desired

temperature. The pilot and burner is now ignited by direct

spark. Check all ttings again and correct any leaks and

recheck.

Replace all service panels and covers before operation.

NOTE: All electronic ignition systems are supplied with a

redundant gas valve. Therefore, the unit is not supplied with

an external pressure regulator.

NOTE: During installation there will be air in the gas line, this

air will have to bleed o before ignition can be established.

The electronic ignition system has a ninety second lock-out

as a safety device on all units. Therefore, several attempts

may be required before pilot ignition is established, wait ve

minutes after each attempt.

FOR YOUR SAFETY: KEEP YOUR APPLIANCE AREA FREE FROM

COMBUSTIBLES.

TO CONSERVE ENERGY:

Do not waste energy by leaving controls at high temperature

settings during idle periods. Lower settings will keep

oven warm and ready for next use period. Master 400

Series controls have an auto setback feature that is user

programmable to help with these applications.

Part # MCOSM06 Rev 1 (11/03/08) Page 11

Page 12

OPERATION

Master 200 Mechanical Control with Timer

In O Mode:

When the oven is o, there are no lights or indicators.

Start Up:

Press the Cook/O/Cool Down rocker switch to the "Cook"

position. The green lamp will light indicating the oven is

powered in cook mode.

The oven will begin to heat to the temperature set on the

thermostat dial. The amber lamp will light indicating the heat

is active. As the heat cycles on and o to maintain the set

temperature this light will go on and o accordingly.

The door must be closed for the oven to operate in cook

mode. Opening the door will cause the heat to stop. The

motor and fan will shut o. This is a safety feature.

Fan Speed:

The fan speed can be either high (1725 RPM) or (1150 RPM).

The fan speed is controlled by the left rocker switch marked

high and low.

Lights:

The oven lights are activated by pressing the light switch on

the control panel. This is a momentary switch and the lights

will stay lit as long as this button is held in the on position.

Lights will work whenever there is electrical power connected

to the oven.

Cool Down:

Pressing the Cook/O/Cool Down rocker switch to the Cool

Down position activates the fan and motor to cool the oven

cavity. The door must be open slightly for the fan and motor

to start. The heat is not active in this mode.

Optimal cool down will be achieved with the door open

slightly. Opening the door too far will shut the fan and motor

o. This is a patented safety feature.

Pressing the button to the OFF position cancels the cool

down and turns the oven o.

Temperature:

The temperature range is from 150°F to 500°F (66°C to 250°C)

is controlled by rotating the temperature dial and aligning the

indicator to the desired temperature.

Timer:

The timer is set by rotating the dial clockwise aligning the

indicator to the desired time cycle. The timer will count down

from 2 minutes to 60 minutes. At the end of the timing cycle

the buzzer will sound. The buzzer is turned o by rotating the

dial counter-clockwise to the o position as shown on the

control panel.

Page 12

Part # MCOSM06 Rev 1 (11/03/08)

Page 13

MASTER 300 Solid State Control

with Mechanical Timer

In O Mode:

When the controller is o, the unit will have no active

prompts. Pressing the ON/OFF key will activate the controller

into Start Up mode.

On Start Up:

In Start Up mode, the controller will heat to the temperature

indicated on the temperature control. The fan speed will

be that which was most recently set. When the oven cavity

reaches the set temperature and is ready for operation the

"LOAD" LED will light.

Controller Keys

Pressing the ON/OFF key will activate the oven.

Pressing the LIGHT key will turn the lights on for 30 seconds.

The lights will work if the controller is in the O mode. When

the door is opened, the light will come on and stay on for 30

seconds.

Pressing the FAN HIGH key will activate the higher speed fan

and light its LED.

Pressing the FAN LOW key will activate the lower speed fan

and light its LED.

Pressing the COOL DOWN key will deactivate the heat, turn

the fan on high and light its LED. The Cool Down will operate

when the door is closed or opened slightly. When the door

opens wider, the Cool Down mode will deactivate and the

LED will ash. This is a patented safety feature. Optimal cool-

down will be achieved with the door open slightly. If the

doors are closed, the LED will ash. Pressing the COOL DOWN

key again will turn the LED o and stop this mode. Pressing

the ON/OFF key will also cancel Cool Down.

When the door is opened the fan and heat will stop until the

door is closed. This is a patented safety feature.

When the ON/OFF key is pressed to turn the oven o and the

oven is above 200°F (93°C), the oven will go into an Auto Cool

Down mode. In Auto Cool Down, the oven will run the fan on

high until the oven cavity drops below 150°F (66°C). During

this time the "AUTO COOL DOWN" LED will light. When the

oven temperature drops below 150°F (66°C) the oven turns

o. This feature protects the oven motor from pre-mature

failure. Optimal cool-down will be achieved with the door

open slightly. Controller Dials.

Cooking TEMPERATURE is set by rotating the TEMPERATURE

dial to the desired temperature, 150°F (66°C) to 550°F (288°C).

Cooking TIME is set by rotating the TIMER dial to the desired

cooking time, up to 60 minutes.

Part # MCOSM06 Rev 1 (11/03/08) Page 13

Page 14

NOTE: The "PROBE ERROR" LED will light if the oven

temperature probe is malfunctioning or has become

damaged or disconnected. Call for service if this occurs.

MASTER 410 ELECTRONIC CONTROL

MASTER 450 ELECTRONIC CONTROL

WITH COOK-N-HOLD

MASTER 455 ELECTRONIC CONTROL WITH

COOK-N-HOLD & CORE PROBE

In O Mode:

When the controller is o, the display will show "OFF".

Pressing the ON/OFF key will activate the controller into Start

Up mode.

On Start Up:

In Start Up mode, the controller will heat to the last set

temperature, time and fan speed. The factory defaults are

350°F (177°C), 30 minutes and low fan speed. The display will

indicate "LO" when the oven is below the set temperature.

When the oven cavity reaches the set temperature and is

ready for operation the display will indicate "LOAD".

NOTE: If the oven temperature goes above the requested

temperature the display will indicate "HI". If the oven

temperature goes above 575°F (302°C) the display will

indicate "HELP" and an audible signal will sound. This is a

safety feature.

If the door is opened during a Cooking mode, the fan and

heat will stop, and the display will indicate "DOOR" until the

door is closed. This is a patented safety feature.

Pressing the ACTUAL TEMP key will display the actual oven

temperature in 5° increments. Controller Keys.

Pressing the ON/OFF key will activate the oven.

Pressing the LIGHT key will turn the lights on for 30 seconds.

The lights will work if the controller is in the O mode. When

the door is opened, the light will come on and stay on for 30

seconds.

Pressing the FAN HIGH key will activate the higher fan speed

and light its LED.

Pressing the FAN LOW key will activate the lower fan speed

and light its LED.

Pressing the FAN PULSE key will activate the lower fan speed

and light its LED. The fan will be active for 30 seconds then o

for 30 seconds, and continues this cycle.

Page 14

Part # MCOSM06 Rev 1 (11/03/08)

Page 15

Pressing the SETBACK key will cool the oven cavity to a

preprogrammed temperature (factory set at 250°F [121°C]).

The oven will automatically go into Setback mode after the

pre-programmed non-usage time, (see 'Changing Factory

Setback Program'). The display will indicate "SETB". This is an

energy-saving feature.

Pressing the COOL DOWN key will deactivate the heat, turn

the fan on high and light its LED. The display will indicate

"OPEN DOOR" if the door is closed, prompting the user to

open the door slightly. With the door open slightly the display

will indicate "COOL". The Cool Down will operate when the

door is closed or opened slightly. Optimal cool-down will be

achieved with the door open slightly. When the door opens

wider, the Cool Down mode will deactivate and the display

will indicate "DOOR". This is a patented safety feature. Pressing

the COOL DOWN key again will turn the LED o and stop this

mode. Pressing the ON/OFF key will also cancel Cool Down.

Cool Down is not active during a cook.

When the ON/OFF switch is pressed to turn the oven o and

the oven was above 200°F (93°C), the oven will go into an

Auto Cool Down mode. In Auto Cool Down, the oven will

run the fan on high until the oven cavity drops below 150°F

(66°C). During this time the display will indicate "AUTO".

When the oven temperature drops below 150°F (66°C) the

oven turns o. This feature protects the oven motor from pre-

mature failure. Optimal cool-down will be achieved with the

door open slightly.

Operating the Controls

Setting the cook temperature and time are done in the same

manner. Pressing the SET key will light the TEMP LED. The

operator then sets the temperature by rotating the dial on

the controller until the desired temperature is shown on the

display. Pressing the SET key a second time lights the TIME

LED and allows the operator to select the desired cook time as

shown on the display. Pressing the SET key a third time ends

the programming.

Pressing the START/CANCEL key will start the timing cycle.

The display will count down from the Set time in minutes and

seconds (solid colon) or hours and minutes (blinking colon)

the minutes and seconds. When the cycle is completed,

processing this key will also cancel the "DONE" prompt. To

cancel a timing cycle in progress, press and hold the START/

CANCEL key for 3 seconds.

Cook-N-Hold Operation

Pressing the COOK/HOLD (450 and 455 Controllers Only) key

activates the Cook-N-Hold mode and lights its LED. To verify

the proper hold temperature has been selected, press the SET

key twice. The display will show the hold temperature. At the

end of the cook cycle, an audible alarm will sound, the display

will ash "DONE" and change to count "UP" the hold time.

The oven will switch to the programmed hold temperature.

Part # MCOSM06 Rev 1 (11/03/08) Page 15

Page 16

Setting the cook temperature, hold temperature and time

are done in the same manner. Pressing the SET key will

light the TEMP LED. The operator then sets the temperature

by rotating the dial on the controller until the desired

temperature is shown on the display. Pressing the SET key a

second time will light the HOLD LED and allows the operator

to select the desired hold temperature as shown on the

display. Pressing the SET key a third time lights the TIME LED

and allows the operator to select the desired cook time as

shown on the display. Pressing the SET key a fourth time ends

the programming.

Pressing the START/CANCEL key will start the timing cycle.

When the cycle is completed, pressing this key will also cancel

the "DONE" prompt. To cancel a timing cycle in progress press

and hold the START/CANCEL key for 3 seconds.

Core Probe Operation

The Core Probe option (455 Controller Only) is only active

when the core probe is plugged into its connector. To set the

core temperature, rst plug the core probe into its connector.

The display will indicate "100" and the CORE TEMP LED will

be on. The operator then sets the temperature by rotating

the dial on the controller until the desired temperature is

shown on the display. Pressing the SET key stores the core

temperature and starts the cooking process.

To set the oven temperature, press the SET key again. The

TEMP LED will light and the oven temperature can be

set by rotating the dial on the controller until the desired

temperature is displayed. Pressing the SET key again will

light the HOLD LED allowing the operator to set the hold

temperature in the same manner.

NOTE: If the hold temperature is not set, the default hold

temperature is 150°F (66°C) or the last programmed

temperature. (Hold temperature range is 140°F (60°C) to

210°F (99°C).

When the core temperature is reached, the display will sound

and ash "DONE" for 3 seconds. Automatically, the display

will switch to count "UP" the time the oven is on hold.

CHANGING FACTORY SETBACK PROGRAM

To change the factory setback settings, press and hold the

SETBACK key for two seconds. The TEMP LED will light and

a temperature will be displayed (factory preset at 250°F

[121°C]). Set the temperature using the dial, then press the

SET key. The TEMP LED will go out and the TIME LED will light.

Set the time using the dial, then press the SET key. Press the

SET key one more time to exit programming.

Note: To disable the setback function, set the temperature to

250º F (121ºC) and the time to zero..

Page 16

Part # MCOSM06 Rev 1 (11/03/08)

Page 17

MASTER 470/475 ELECTRONIC

PROGRAMMABLE CONTROL

Manual cooking:

1. Press SET key - TEMP LED will light.

2. Set temperature using the dial (factory preset at 350°F).

3. Press SET key - FAN LED will light.

4. Select fan mode using one of the three (3) fan keys

(HIGH, LOW, PULSE) - the selected fan LED will light.

5. Press SET key - TIME LED will light.

6. Set cook time using the dial (factory preset at 30:00).

7. Press SET key - ready to cook.

8. Press START/CANCEL to begin manual cooking.

Manual cooking using Cook-N-Hold:

1. Press the COOK/HOLD key, that key's LED will light.

2. Press SET key - TEMP LED will light.

3. Set cook temperature using the dial (factory preset at

350°F).

4. Press SET key - HOLD LED will light.

5. Set hold temperature using the dial (factory preset at

200°F).

6. Press SET key - FAN LED will light.

7. Select fan mode using one of the three (3) fan keys

( HIGH, LOW, PULSE ) - the selected fan LED will light.

8. Press SET key - TIME LED will light.

9. Set cook time using the dial (factory preset at 30:00).

10. Press SET key - ready to cook.

11. Press START/CANCEL to begin manual cooking.

Programming Product Keys (Master ):

NOTE: Cooking time(s) is the element of the program that tells

the controller that other information (temperature, fan

speed, etc.) will be inputted into the controller. The rst

step is to enter all the time periods required, followed by

the addition of the other cooking elements.

Part # MCOSM06 Rev 1 (11/03/08) Page 17

Page 18

1. Press and hold PROG key for three (3) seconds - all the

product key LEDs light.

2. CODE will be displayed. The controller is asking for the

access code. Press 4-2-7-5 and the START/CANCEL key.

PROD will be displayed indicating you have gained access

to Product Programming.

3. Press the product key (1 - 9) into which you want to store

a cooking program. SHLF will be displayed. The control is

asking if you want to program the key as a shelf timer or

with a cooking prole. Select your answer by pressing the

START/CANCEL key. When the correct answer is displayed,

press the SET key. The TIME LED will light. 30:00 will be

displayed.

4. Set rst cook time using dial. If more than one cooking

prole is desired:

•presstheproductkeywheretheprogramistobestored

(1 - 9) - PR-2 will be displayed.

•setthesecondcooktimeusingthedial(factorypresets

for PR-2 through PR-5 are :00).

•pressthesameproductkey(1-9)again-PR-3willbe

displayed.

•Repeatthisprocessforallproles.Whenthelastprole

time has been entered, press the SET key, OR

If less than ve (5) proles are desired press the SET key

after the last required prole - PRE will be displayed,

followed by :00. The controller is asking if you would like a

reminder alarm (pre-alarm) to sound during the cooking

process. (factory preset is :00).

5. If a pre-alarm signal is desired - dial in the time that the

alarm is to sound. (Ex. If the product is to be turned

halfway through the 60 minute cooking cycle, set the

pre-alarm to 30 minutes). If pre-alarm is not desired verify

that ":00" is displayed. Press the SET key - TEMP Led will

light, and the display will show the rst prole cooking

temperature. (factory preset at 350°F).

6. Set the rst cooking temperature using the dial.

Press the product key - PR-2 will be displayed followed by

the second temperature.

Set the second cooking time using the dial.

Repeat as you did for cooking time, for all the proles

desired.

NOTE: The controller will only accept cooking temperatures

for the number of proles for which a cooking time

has been set. If the product key is pressed after the

last programmed prole, the rst temperature will be

displayed.

Page 18

Part # MCOSM06 Rev 1 (11/03/08)

Page 19

Press SET after the last cooking temperatures has been

entered, HOLD will be displayed.

7. Use the START/CANCEL key to select yes or no. Press the

SET key.

4. If a pre-alarm signal is desired - dial in the time that

the alarm is to sound. (Ex. If the product is to be turned

halfway through the 60 minute cooking cycle, set the prealarm to 30 minutes). If pre-alarm is not desired verify that

":00" is displayed.

8. If yes was selected, the HOLD LED will light. Enter the hold

temperature using the dial. (factory preset at 200°F) Press

the SET key. FAN will be displayed and the FAN LED will

light.

Set the fan speed desired for the rst cooking prole using

the individual fan keys (HIGH, LOW or PULSE), press the

product key and set the fan speed for the second cooking

prole. Continue until all the proles have been assigned

a fan speed. Press the SET key when complete. As with the

temperature, if the product key is pressed after the last

programmed prole, the rst fan speed will be displayed.

9. FL or St will be displayed (for ex time or straight time)

(factory preset for ex time). Select ex or straight time

using the START/CANCEL key for the rst prole. Press

the product key and select straight time or ex time for

the second prole. Continue until all the proles have

been assigned straight or ex time. Press the SET key

when complete. If the product key is pressed after the last

programmed prole, the rst prole will be displayed.

10. Programming for that product key is complete.

Programming Product Keys (Master ):

•PresstheSETkey-TEMPLedwilllight,andthedisplay

will show the cooking temperature. (factory preset at

350°F).

5. Set the cooking temperature using the dial.

Press the SET key. - FAN will be displayed and the FAN LED

will light.

6. Set the fan speed desired using the individual fan keys

(HIGH, LOW or PULSE).

Press the SET key. - FL or St will be displayed (for ex time

or straight time) (factory preset for ex time).

7. Select ex or straight time using the START/CANCEL key.

Press the SET key when complete.

8. Programming for that product key is complete.

Cooking Using The Product Keys

(Master and Master ):

1. On initial start-up, press the product key for the menu

item to be cooked. Wait until LOAD is displayed.

NOTE: The Master 470 controller will only accept a single

cooking prole per product key (one cooking time, one

cook temperature, one fan speed, and one choice for

straight or ex time).

Press and hold PROG key for three (3) seconds - all the

product key LEDs light.

1. CODE will be displayed. The controller is asking for the

access code. Press 4-2-7-5 and the START/CANCEL key.

PROD will be displayed indicating you have gained access

to Product Programming.

2. Press the product key (1 - 9) into which you want to store

a cooking program. SHLF will be displayed. The control

is asking if you want to program the key as a shelf timer

or a cooking prole. Select your answer by pressing the

START/CANCEL key. When the correct answer is displayed,

press the SET key. The TIME LED will light. 30:00 will be

displayed.

3. Set the cook time using dial.

Press the SET key - PRE will be displayed, followed by :00.

The controller is asking if you would like a reminder alarm

(pre-alarm) to sound during the cooking process. (factory

preset is :00).

2. Load the oven.

3. Press the product key for the loaded menu item.

4. Press the START/CANCEL key.

5. To cancel the alarm or the hold, press the START/CANCEL

key followed by the product key.

Verifying hold time (Master and Master ):

While a product is being held, press and hold the product

key. The actual hold time will be displayed.

Selecting Fahrenheit or Celsius (Master 475 and Master

470):

Press PROG and ACTUAL TEMP keys at the same time, F or

C will be displayed. (factory preset for F)

Press the START/CANCEL key to switch between F and C,

When the desired setting is displayed press the PROG and

ACTUAL TEMP keys at the same time.

Part # MCOSM06 Rev 1 (11/03/08) Page 19

Page 20

Cooking with the Shelf Timer

(Master and Master ):

The shelf timer option is used to independently time each of

the up to six dierent shelves or racks within the oven.

NOTE: To use the shelf timer option, at least one product

key must be programmed with a cooking prole

(temperature, time, fan speed, ex or straight time). The

program key must be limited to a single cooking prole

to be used with the shelf timing option. If more than one

product key is to be used, all product keys to be used must

feature the same cooking temperature and fan speed. Flex

or straight time and cooking time can de dierent. The

Cook-N-Hold option can not be used with the shelf timer

operation.

Example: Two product proles contain the same cooking

temperature, fan speed and are both programmed for ex

time - keys 1 and 6.

Two trays of product are going to be cooked in the oven at

the same time. The rst tray will use product key 1 and will be

placed in rack position 2. The second tray will use product key

6 and will be placed in rack position 4. Once the oven display

indicates LOAD:

1. Load food product into oven on shelf 2.

2. Press product key 1, then shelf key 2.

3. Press the START/CANCEL key to start cooking on shelf 2.

4. Load food product into oven on shelf 4.

Pressing the desired product key will bring the oven to the

desired cooking temperature, once the oven has reached

the proper cooking temperature as indicated by LOAD in the

display.

1. Press the product key containing the desired cooking

prole (1 - 9).

2. Press the shelf key for the shelf location to be timed (1 - 6).

NOTE: product keys and shelf keys are the same keys.

3. Press the START/CANCEL key to begin the cooking/timing

process.

4. When the cooking/timing process is complete for each

shelf, an audible "done" signal will sound and the display

will indicate which shelf is nished. Example: SH-1

5. To turn o the alarm press the product key with the

ashing LED.

5. Press product key 6, then shelf key 4.

6. Press the START/CANCEL key to start cooking on shelf 4.

7. When product on shelf 2 is nished cooking, an audible

alarm will sound and the display will ash DONE, then

SH-2, and the product key 1 LED will be ashing.

8. To turn o the alarm, press product key 1.

9. When product on shelf 4 is nished cooking, an audible

alarm will sound and the display will ash DONE, then

SH-4, and the product key 6 LED will be ashing.

10. To turn o the alarm, press product key 6.

Page 20

Part # MCOSM06 Rev 1 (11/03/08)

Page 21

PERFORMANCE RECOMMENDATIONS

1. Preheat oven thoroughly (approximately. 20 minutes)

before use.

2. As a general rule, temperature should be reduced 25°

to 50° from that used in a standard/conventional oven.

Cooking time may also be shorter, so we suggest closely

checking the rst batch of each product prepared.

3. Use the chart of suggested times and temperatures as a

guide. These will vary depending upon such factors as size

of load, temperature and mixture of product (particularly

moisture) and density of product.

4. Keep a record of the times, temperature and load sizes you

establish for various products. Once you have determined

these, they will be similar for succeeding loads.

5. When practical, start cooking the lowest temperature

product rst and gradually work up to higher

temperatures.

6. If you nd that your previous temperature setting is more

that 10° higher than needed for succeeding loads, press

the COOL DOWN key to reach the desired temperature

before setting a new cooking temperature.

7. When loading oven, work as quickly as possible to prevent

loss of heat.

10. When baking, weigh or measure the product in each pan

to assure even cooking.

11. When cooking six pans, use rack positions 2, 4, 6, 8, 10 and

12, starting from the top.

12. Do not overload the oven. Six pans are suggested for most

items, i.e., cakes, cookies, rolls, etc. However, the maximum

(13 pans) may be used for sh sticks, chicken nuggets and

hamburgers. Cooking times will have to be adjusted.

13. Mun pans should be placed in the oven back to front or

with the short side of the pans facing the front. This results

in the most evenly baked product.

14. When re-thermalizing frozen casseroles, preheat the oven

100° over the suggested temperature. Return to cooking

temperature when the oven is loaded. This will help

compensate for the introduction of a large frozen mass

into the cavity.

15. Use pan extenders or two inch deep 18"x26" pans for

batter type products which weigh more than eight

pounds, i.e., Pineapple Upside Down Cake.

16. Never place anything directly on the bottom of the oven

cavity. This obstructs the airow and will cause uneven

results.

8. Oven will continue to heat even though the timer goes

o. Product should be removed from the oven as soon as

possible to avoid over cooking.

9. Center pans on racks and load each shelf evenly to allow

for proper air circulation within the cavity.

NOTE: Moisture will escape around the doors when baking

products with heavy moisture content, such as: chicken,

potatoes, etc.

Part # MCOSM06 Rev 1 (11/03/08) Page 21

Page 22

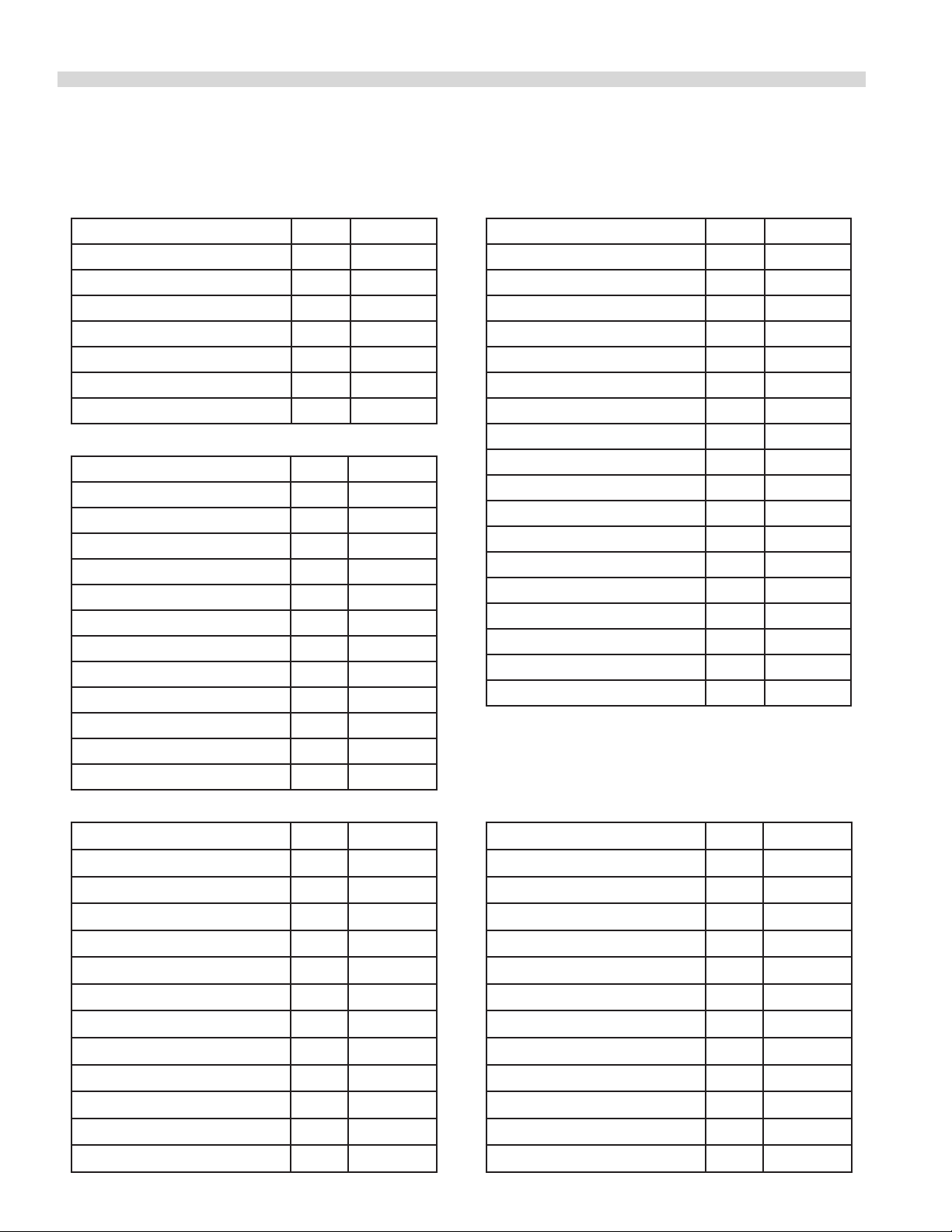

COOKING GUIDE

The following suggested times and temperatures are provided as a starting guide. Elevation, atmospheric conditions, gas

supply, recipe, cooking pans and oven loading may aect your actual results.

Product °F Time

White Sheet Cakes – 5 lb 300° 20 min

White Sheet Cakes – 6 lb 300°

Yellow Layer Cake – 21 oz 325° 15 min

Yellow Sheet Cake – 5 lb 300° 22 min

Chocolate Layer Cake – 21 oz 300° 22 min

Angel Food Cake 375° 22 min

Brownies 350° 15 min

Product °F Time

Chicken Parts 350° 45 min

Hamburger Patties, 10/lb fzn 350° 8 min

Hamburger Patties, 10/lb fresh 350° 5 min

Hamburger Patties, 4/lb fzn 350° 12 min

Hamburger Patties, 4/lb fresh 350° 8 min

Meatloaf – 4# 325° 45 min

Bacon 350° 10 min

Roast Beef - 20# 325° 3 hr 15 min

Prime Rib - 10# 300° 1 hr 45 min

Stued Pork Chops 350° 45 min

Lamb Chops 375° 40 min

Boneless Veal Roast 300° 3 Hr

Product °F Time

Soda Biscuits 400° 6 min

Yeast Rolls 325° 24 min

Sweet Bread 325° 24 min

Corn Bread 350° 22 min

Gingerbread 300° 24 min

Apple Turnovers 350° 25 min

Cream Pus 300° 25 min

Sugar Cookies 325° 12 min

Chocolate Chip Cookies 375° 8 min

Apple Pie (Fresh) 375° 25 min

Blueberry Pie (Fresh) 350° 30 min

Blueberry Pie (Frozen) 300° 56 min

Pumpkin Pie (Frozen) 300° 50 min

Frozen Pizza 300° 6 min

Macaroni & Cheese 350° 15 min

Fish Sticks 350° 16 min

Stued Peppers 350° 45 min

Baked Potatoes 350° 60 min

Page 22

Product °F Time Product °F Time

Part # MCOSM06 Rev 1 (11/03/08)

Page 23

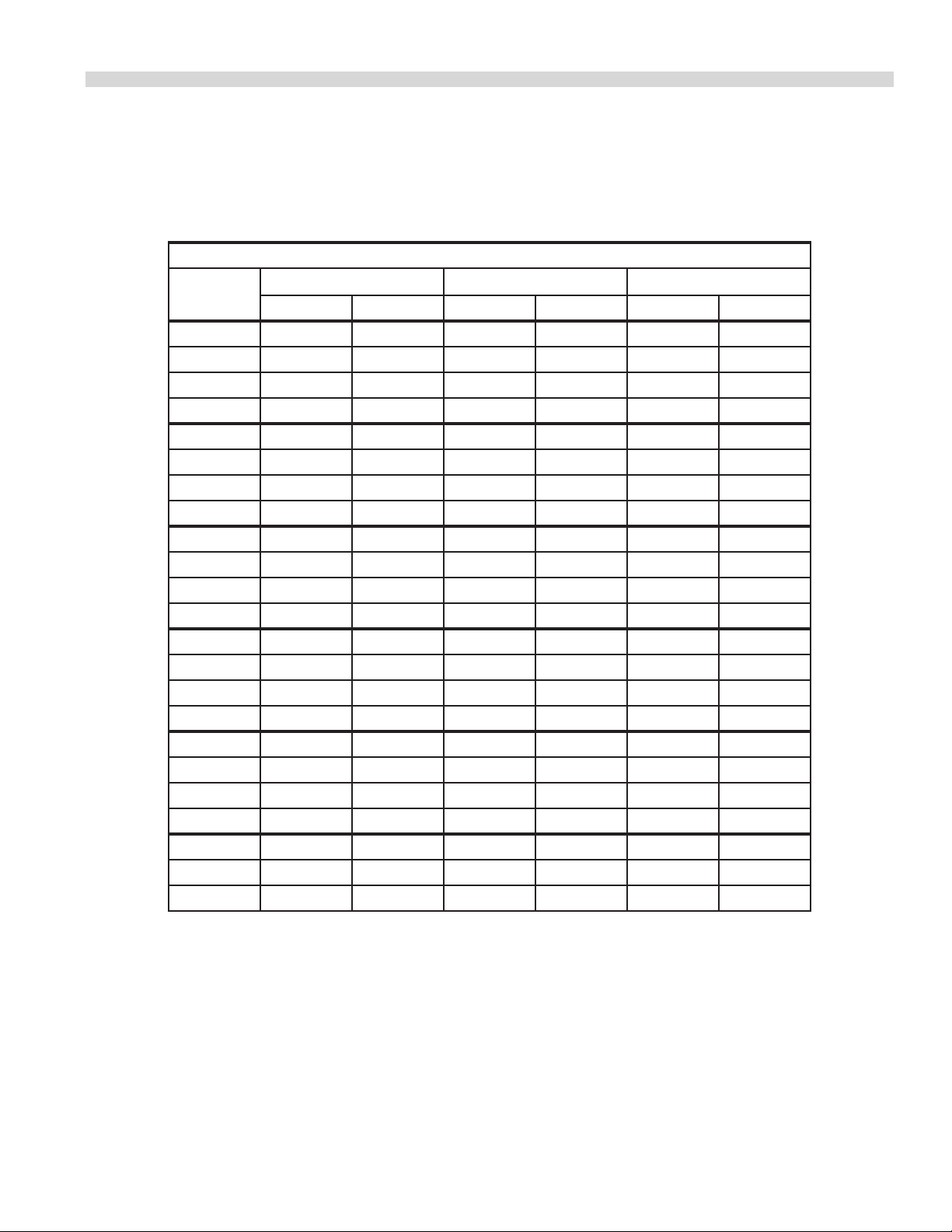

COOK AND HOLD

Please refer to the operating instructions to program the 450 and 455 control units for cook and hold feature. The times and

temperatures listed below are to be used as a starting guide. Your actual results may vary greatly depending on your elevation,

gas supply, atmospheric conditions and other items being cooked at the same time.

Time in Hours

Weight in

lbs

8 2.5 3.5 1.5 2 1.25 1.5

9 2.75 3.75 1.75 2.25 1.25 1.75

10 3 4.25 2 2.5 1.5 1.75

11 3.25 4.5 2 2.75 1.5 1.75

12 3.5 5 2.25 3 1.5 2

13 3.75 5 2.5 3.25 1.5 2.25

14 4 5.75 2.5 3.5 1.75 2.5

15 4.25 6 2.75 3.5 2 2.5

16 4.5 6.25 2.75 3.75 2 2.75

17 4.75 6.5 3 4 2.25 2.75

18 4.75 6.75 3.25 4.25 2.25 3

19 5 7.25 3.25 4.25 2.25 3

20 5.25 7.5 3.5 4.5 2.5 3.25

21 5.5 7.75 3.5 4.75 2.75 3.5

22 5.75 7.75 3.5 4.75 2.75 3.5

23 6 8.25 3.75 5 2.75 3.75

24 6 8.75 3.75 5 2.75 3.75

25 6.25 9 4.25

26 6.5 9.25 4.25 5.5 3.25 4.25

27 6.75 9.5 4.25 5.75 3.25 4.25

28 7 9.75 4.5 6 3.25 4.25

29 7.25 10 4.75 6.25 3.5 4.5

30 7.25 10.25 4.75 6.25 3.5 4.5

Temperature: 200°F Temperature: 250°F Temperature: 300°F

Rare Medium Rare Medium Rare Medium

5.5 3 4

Part # MCOSM06 Rev 1 (11/03/08) Page 23

Page 24

PROBLEMS / SOLUTIONS

Problem Solution

If cakes are dark on the sides and not done in the center Lower oven temperature.

If cakes edges are too brown Reduce number of pans or lower oven temperature.

If cakes have light outer color Raise temperature.

If cake settles slightly in the center

If cake ripples Overloading pans or batter is too thin.

If cakes are too coarse Lower oven temperature.

If pies have uneven color Reduce number of pies per rack or eliminate use of bake pans.

If cupcakes crack on top Lower oven temperature.

If meats are browned and not done in center Lower temperature and roast longer.

If meats are well done and browned Reduce time. Limit amount of moisture.

If meats develop hard crust Reduce temperature or place pan of water in oven.

If rolls have uneven color Reduce number or size of pans.

Bake longer or raise oven temperature slightly.

Do not open doors too often or for long periods.

Page 24

Part # MCOSM06 Rev 1 (11/03/08)

Page 25

CLEANING & MAINTENANCE

NOTE: Disconnect line cord from power supply before

cleaning or servicing.

Break-In Period

When oven is new, operate it for one hour at 450°F before you

begin your normal cooking operation. After cooling, wipe the

interior, including the racks, with a clean damp cloth.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

1. The oven should always be allowed to cool suciently

before any cleaning is attempted.

2. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

3. Painted surfaces should be cleaned using a mild soap

and warm water solution on a sponge or soft Cloth. Dry

thoroughly.

4. Stainless Steel surfaces can often be cleaned adequately

with the same method. Stubborn stains may be removed

by using a non-metallic abrasive pad, rubbing in the

direction of the metal's grain. If necessary, for particularly

heavy deposits, you may mix a thin paste of water and

scouring powder, and apply it with a sponge. Be careful

to apply light pressure and remember to rub only in the

direction of the grain in the metal.

5. The control panel surface is easily cleaned with hot water,

soap and a soft cloth. Do not use hard abrasives, solvent

type materials or metallic scouring pads since these will

scratch or cloud the surface.

6. Never spray the perforated areas or control panel with

steam or water, as this will allow moisture into the control

cavity, which could damage electrical components.

Interior Cleaning

Establish a regular cleaning schedule or wipe o on the same

day when spillovers occur.

1. Cool down oven.

2. Remove oven racks.

3. Lift rack guides on either side of oven o of holders. Racks

and guides may be run through dishwasher while oven

cavity is being cleaned.

4. Clean with soap and water using a non-metallic scouring

pad, if necessary. If dirt and grease have accumulated, a

mild ammonia solution or commercial oven cleaner such

as Easy-O or Dow may be used.

5. To reinstall, reverse procedure. Place the bottom of the

rack guide against the cavity wall. Keeping the top pulled

away from the wall lift up. Push the top of the rack guide

against the wall and push down locking it into place.

Fan Area Maintenance

If aluminum foil is routinely used to wrap food or cooking

vessels during oven operation, the following preventive

maintenance must be performed:

1. Turn power switch to "OFF" position.

2. Remove oven racks and rack guides.

3. Remove air bae and clean any stains or deposits.

4. Check blower wheel and air bae for particles of

aluminum foil or food deposits. Clean ns of blower

wheel. (Caution: edges of blower wheel ns may be

sharp).

5. Reinstall the air bae, rack guides and oven racks.

This simple practice, if performed on a regular basis will

keep your Garland oven operating at peak performance.

Part # MCOSM06 Rev 1 (11/03/08) Page 25

Page 26

MOTOR CARE

The motor on your convection oven is maintenance free since

it is constructed with self-lubricating sealed ball bearings.

It is designed to provide durable service when treated with

ordinary care. We have a few suggestions to follow on the

care of your motor. When the motor is operating, it cools

itself internally by air entering at the rear of the motor case,

provided proper clearance has been allowed.

Since the blower wheel is in the oven cavity it is at the same

temperature as the oven. If the motor is stopped while the

oven is hot, the heat from the blower wheel is conducted

down the shaft and into the armature of the motor. This

action could shorten the life of the motor.

We recommend, at the end of the bake or roasting period,

when the oven will be idle for any period of time, or before

shutting down completely, that the doors be left open

slightly, and press the COOL DOWN key on the control panel.

The fan will continue to run until the oven cools down to

150°F (66°C). At the end of the day, press the ON/OFF key to

activate the Auto Cool Down feature. The fan will run on high

until the oven cavity drops below 150°F (66°C). During this

time the "AUTO COOL DOWN" LED will light. When the oven

temperature drops below 150°F (66°C) the oven turns o.

This feature protects the oven motor from pre-mature failure.

Optimal cool-down will be achieved with the door open

slightly.

Page 26

Part # MCOSM06 Rev 1 (11/03/08)

Page 27

Section Two

Electronic Pilot

& Main Burner

Part # MCOSM06 Rev 1 (11/03/08) Page 27

Page 28

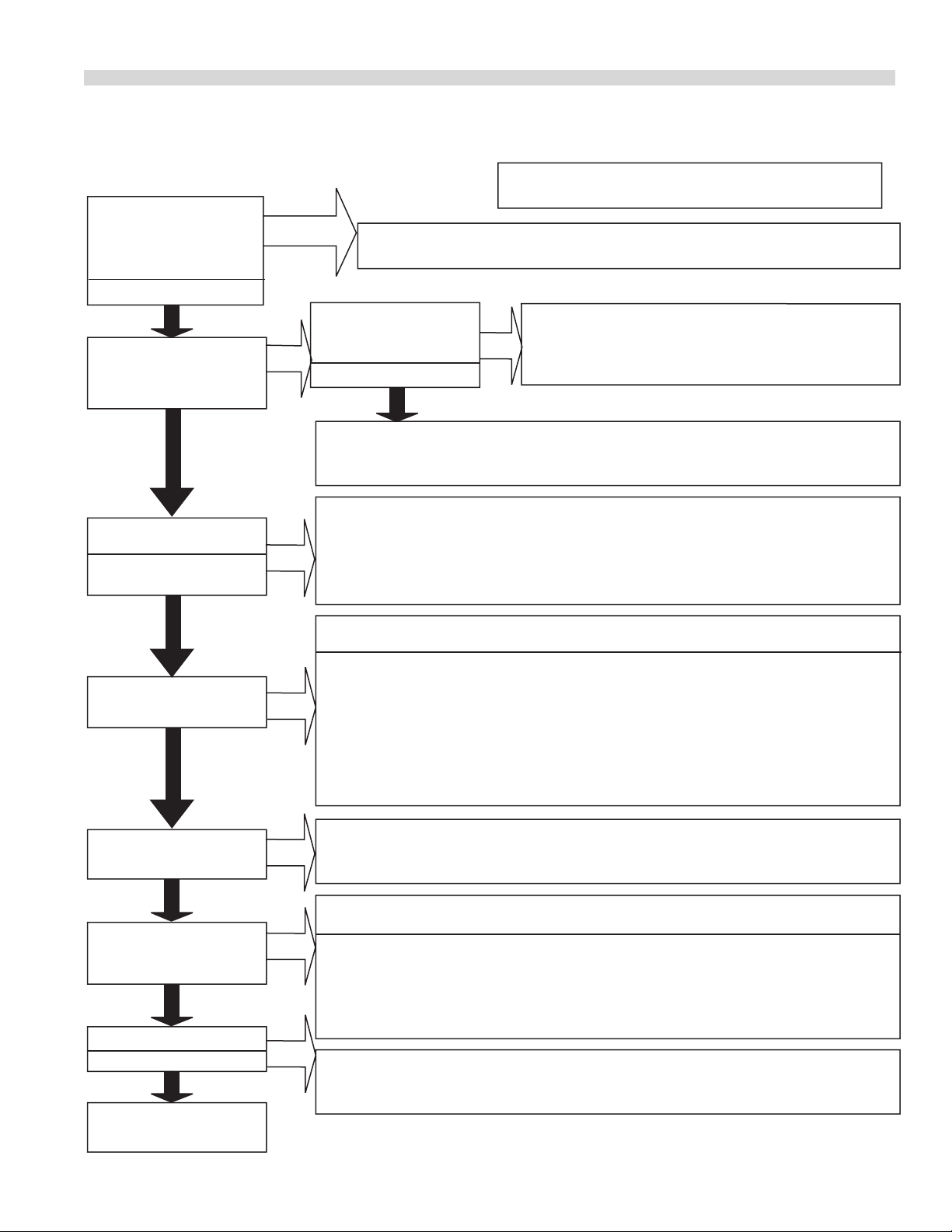

IGNITION SEQUENCE

START

STAGE 1

TRIAL FOR

IGNITION

STAGE 2

MAIN BURNER

OPERATION

END

1. CONTROLLER CALLS FOR HEAT

2. SPARK GENERAT OR POWERED

First valve (Pilot) operator opens

3. PILOT BURNER OPERATION

Pilot burner lights.

Module senses

ame current.

OR Pilot burner does not light.

After 90 seconds system

locks out: must be

manually reset.

4. FLAME CURRENT SENSED

•

Spark generator o.

• Second valve operation (main) opens

POWER INTERRUPTION

System shuts o, restarts

when power is restored

PILOT FLAME FAILURE

Main valve closed.

Module start trail for ignition.

5. MAIN BURNER OPERATION

Module monitors pilot ame current

6. CONTROLLER SATISFIED

Valves close, pilot and main burners are o

First Stage – Trial For Pilot Ignition

On every call for heat (system start), the S86 performs an

internal safe-start check and shows that a ame-simulating

condition is present. During a normal start, the S86 opens the

pilot valve in the gas control. This allows gas to ow to the

pilot burner. Simultaneously the electronic spark generator

in the S86 produces a 30,000 volt pulse output. This voltage

produces a spark at the pilot burner igniter/sensor rod,

igniting the gas ow around the electrode. If the pilot ame

is not detected during the trial for pilot ignition, the S86H

contains a safety lockout timer (90 Seconds) to limit the

ignition period.

Second Stage – Main Burner Operation

When the Pilot ame is established, a ame rectication

circuit is complete to the burner ground. The S86 ame

sensing circuit detects the ame circuit and shuts the spark

generator o. At the same time the second operator (main

gas valve) is opened in the gas control, allowing gas ow

to the burners. This pilot ame ignites the main burner

conventionally.

Safety Lock Out Time.

The safety lockout timer circuit starts timing the moment the

trail for the pilot ignition starts. When the timing periods runs

out, the trial for ignition ends, and the control module goes

into lockout. Before another attempt to start can be made,

the S86 must be reset. Reset by adjusting the thermostat or

controller below room temperature, or to its "OFF" position.

An alternate method is to shut the system power "OFF". If

normal ignition does not occur, use the trouble shooting

table to determine the problem.

Page 28

Part # MCOSM06 Rev 1 (11/03/08)

Page 29

NO

NO

NO

NO

NO

NO

NO

NO

START

YES

YES

YES

YES

YES

YES

YES

YES

TROUBLE SHOOTING TABLE

TURN GAS SUPPLY OFF.

TURN CONTROLLER TO

CALL FOR HEAT POWER

TO MODULE

(24V NOMINAL)

SPARK ACROSS IGNITER/

SENSOR GAP

TURN GAS SUPPLY ON

PILOT BURNER LIGHTS?

Check line voltage power, low voltage transformer, limit controlled and wiring.

Pull ignition lead

and check spark and

module.

Spark okay?

• Checkignitioncable,groundwire,ceramicinsulatorandgapandcorrect.

• Checkbootoftheignitioncableforsignsofmeltingorbuckling.Takeprotectiveactiontoshield

cable and boot from excess temperature.

• Checkthatallmanualgasvalvesareopen,supplytubingandpressurearegood,andpilotburner

orice is not blocked.

• Checkelectricconnectionsbetweenmoduleandpilotoperatorongascontrol.

• Checkfor24VACacrossPV-MV/PVterminalsonmodule.Ifvoltageisokay,replacegascontrol;if

not, replace module.

Note: Before trouble shooting familiarize yourself with

the startup procedure.

•Onmodels with ventdamperplug,makesure ventdamper

had not be installed, the remove. Replace vent damper if

necessa ry.

•Onothermodels,replacemodule

SPARK STOPS WHEN

PILOT IS LIT?

MAIN BURNER LIGHTS?

SYSTEM RUNS UNTIL

CALL FOR HEAT LOSS?

CALL FOR HEAT ENDS

SYSTEM SHUTS OFF?

TROUBLE SHOOTING

ENDS

Note: If S5800B, H; S6810B, H goes into lockout, reset system. For S6800M, wait 6 minutes nominal

for retry or reset system

• Checkcontinuityofignitioncabletogroundwire.

• Cleanamerod.

• Checkelectricalconnectionbetweenamerodandmodule.

• Checkforcrackedceramicamerodinsulator.

• Checkthatthepilotamecoverstheroadandissteadyandblue.

• Adjustpilotame.

• Ifproblempersists,replacemodule.

• Checkfor24VACacrossMV-MV\PVterminals.Ifnovoltage,replacemodule.

• Checkelectricalconnectionsbetweenmoduleandgascontrol.Ifokay,replacegascontrolorgas

control operator.

Note: If S8600B, H; S6810B, H goes into lockout, reset system. For S6800M, wait 6 minutes, nominally

for retry or reset system.

• Checkcontinuityofignitioncableandgroundwire.

Note. If ground is poor or erratic, shutdowns may occur occasionally even though operation is

normal at the time of checkout.

• Checkthatthepilotamecoversamerodandissteadyandblue.

• Ifchecksareokay,replacethemodule.

• Checkforpropercontrolleroperation

• RemoveMVleadatmodule;ifvalvecloses,recheckthetemperaturecontrollerandwiring;ifnot,

replace gas control.

Repeat procedure until trouble free operation is obtained.

Part # MCOSM06 Rev 1 (11/03/08) Page 29

Page 30

SERVICE

Preliminary Check

The following visual checks should be made before trouble

shooting and after installation or maintenance.

1. Check power to the appliance and S86.

2. Manual shuto cocks in the gas line must be open.

3. Make certain all wiring connections are clean and tight.

4. First de-energize the system and wait at least one (1)

minute. This resets the module allowing a return to the

start condition.

5. Review the S86 system normal sequence of operation.

System Trouble Shooting

Start the system by setting the controller above the required

temperature. Observe the system response. Establish the type

of malfunction or deviation from the normal operation. Use

the S286 Intermittent Pilot system trouble shooting table to

check for normal system operation.

Use the table by following the instruction questions in the

box. If the conditions is true or okay (answers yes), go down

to the next box underneath. If the condition is not true of

not okay (answer no), go right to the next box alongside.

Continue checking and answering conditions in each box

encountered, until a problem and/or the repair is explained.

After any maintenance or repair, the trouble shooting

sequence should be repeated until the trouble shooting

procedure ends with a normal system operation.

Check Grounding

Electric grounding connections at the pilot burner,

igniter/sensor and S86 must be clean and tight. If a lead

wire is damaged or deteriorated, use only No. 14 or 18

gauge moisture resistant thermoplastic insulated wire

with 105°C (221°F) minimum ratings as replacement.

Excessive temperature at the ceramic ame rod can also

permit electrical leak to ground. Examine the ame rod and

mounting bracket, and correct if bent out of position. Replace

igniter/sensor if insulator is cracked.

Check Spark Ignition Circuit

The electronic module and step-up transformer in the S86

provides a spark ignition at 30,000 volts (open circuit). This

circuit can be checked at the S86 module as follows:

1. Turn o the manual gas cock to prevent the ow of gas.

2. Disconnect the ignition cable at the S86 stud terminal to

isolate the circuit from the pilot burner/igniter/sensor, and

prepare a shot jumper lead using heavily insulated wire,

such as ignition cable.

3. Energize the S86 touch one of the jumper rmly to the S86

ground terminal (GND). Do not disconnect the existing

ground lead. Move the free end slowly toward the stud

terminal to establish a spark and then pull the lead wire

slowly away from the stud. Not the length of the gap at

which the arching stops.

CAUTION: Do not touch either the stripped end of the jumper

or stud terminal. This is a very high voltage circuit and

electrical shock can result. Perform the test immediately upon

energizing the system – before the S86H goes into safety lock

out and interrupts the spark circuit.

A common ground is required for the pilot burner, the

igniter-sensor, the GND terminal of the S86, and the main

burner. The main burner generally serves as the common

ground. If the ground it poor or erratic, safety shutdowns may

occur occasionally even though operation is normal at time

of check out. Therefore, if nuisance shutdowns have been

reported, be sure to check the grounding.

Note: If the ground circuit path is incomplete, the S86H

system control will allow one trial for ignition before going

into safety lock out.

Page 30

4. An arch length of 1/8" (3.2mm) or more indicates a

satisfactory voltage output. Replace the S86 if not arc

can be established or the maximum gap is less then 1/8"

(3.2mm), and the fuse and power to the S86 input terminal

was okay.

Part # MCOSM06 Rev 1 (11/03/08)

Page 31

Examples Of Unsatisfactory Pilot Flames.

APPEARANCE CAUSE

SMALL BLUE FLAME

Check for lack of gas from:

•Cloggedoricelter

•Cloggedpilotlter

•Lowgassupplypressure

•Pilotadjustedattheminimum

LAZY YELLOW FLAME

WAVING BLUE FLAME

NOISY LIFTING BLOWING FLAME

HARD SHARP FLAME

Check for lack of air from:

•Largeorice

•Dirtylintscreen,ifused

•Dirtyprimaryairopening,ifthereisone

•Pilotadjustedatminimum

Check for:

•Excessivedraftatpilotlocations

•Recirculatingproductsofcombustion

Check for:

•Highgaspressure

This ame is characteristic of manufactured gas

Check for:

•Highgaspressure

•Oricetoosmall

Control Module Flame Sensor Circuit.

The control module provides AC power to theigniter/sensor

that the pilot burner ame recties to a direct current. If the

ame signal back the control module is not at least 1.0 μA

DC, the system will lockout. The output of the ame sensing

circuit cannot be checked directly, so check the ame sensing

circuit indirectly by checking the ame sensing current from

the igniter/sensor to the control module as follows:

Part # MCOSM06 Rev 1 (11/03/08) Page 31

1. Connect a meter (DC micrometer scale) in a series with

the ame signal ground wire (Burner Ground Terminal).

Disconnect the ground wire at the control module. Connect

the red (positive) lead of the meter to the free end of the

ground wire. Connect the black (negative) meter lead to the

quick-connect ground terminal on the control module.

2. Restart the system and read the meter. The ame sensor

currant must be at least 1.0 μA, and the reading must be

steady. If the reading is below the value designated or the

reading is unsteady, check the pilot ame and electrical

connection. Also, replace the igniter/sensor if the ceramic

insulator is cracked.

Page 32

G77x INTERMITTENT PILOT CONTROLS

• Ignition Lockout: Pilot gas did not ignite within the nal

trial-for-ignition time. Open thermostat contacts for 30

seconds, then close to restart the sequence of operation.

(Models with an optional LED will ash the LED to indicate

ignition lockout.)

• Flameout: Loss of proven ame.

• Hard Lockout: The control detected a fault. Open

thermostat contacts for 30 seconds, then close to restart

the sequence of operation. (Models with an optional LED

will turn o the LED to indicate a hard lockout.)

Sequence of Operation

Application Requirements

The following are the application requirements of the G77x

control.

• TheG77xcanbeusedongas-redequipmentwitha

maximum ring rate of 117kW (400,000 BTU/Hr). Any

application over 117kW (40,000 BTU/Hr) must have written

approval in advance from the Johnson Controls Heating

Products Engineering Department.

• AllG77xapplicationsmustusearedundantgasvalve

system where the pilot and main valve seats are in series

and opened in sequence for intermittent pilot ignition.

Operating Mode Denitions

The following denitions describe operating conditions.

• Prepurge: Initial time delay between thermostat contact

closure and trial for ignition.

• Trial for Ignition: Period during which the pilot valve and

spark are activated, attempting to ignite gas at the pilot

burner. The control attempts to prove ame at the pilot

burner within the trial-for-ignition time.

Figure 2 illustrates the sequence of operation of the G77x

control.

The control is energized on a call for heat from the system

thermostat. (Models with an optional LED will turn on the

LED [steady on] until the call for heat is satised.) The vent

damper, if used, is energized and when fully opened, also

energizes the ignition control. If the control is equipped with

the optional prepurge, the appliance prepurge fan or relay

is also energized through the thermostat contacts. In the

prepurge mode, the control will delay for the time selected

(e.g., 15 seconds) before simultaneously opening the pilot

valve and supplying a continual spark at the pilot burner. If

prepurge is not selected, the pilot valve is opened and spark

initiated within one second after the call for heat.

Under normal conditions, the pilot burner gas ignites within

the trial-for-ignition time (e.g., 8 seconds), the pilot ame

sensor detects pilot ame and signals the control to energize

the main valve. The main gas valve will not be energized until

the ame sensor detects the presence of pilot ame. The

spark will continue until ame is sensed at the pilot burner or

the trial-for-ignition time has elapsed, whichever occurs rst.

If the pilot ame is not sensed before the end of the trial-forignition time, the control may:

• Run: Pilot and main gas valves remain energized and spark

is turned o after successful ignition.

• 100% Shuto: For controls with automatic recycle, pilot

gas did not ignite within the trial-for-ignition time. The

control de-energizes the spark circuit and pilot valve.

• Automatic Recycle: If shuto occurs, the control delays for

a specic recycle delay period before beginning another

trial for ignition (models with recycle only).

• Interpurge: Period between trials for ignition when both

the gas valve and spark are deactivated to allow unburned

gas to escape before the next trial. Interpurge occurs

between unsuccessful trials on a multi-trial control or after

a ameout (if the control has an interpurge).

Page 32

• proceedtointerpurge,followedbyanothertrial(three

trial models whose rst two trials produced no ame).

• proceedtoalockout(noautomaticrecyclemodelswhose

nal trial produced no ame).

• proceedtoarecycledelayperiodfollowedbyanothertrial

(automatic recycle models whose nal trial produced no

ame).

Part # MCOSM06 Rev 1 (11/03/08)

Page 33

Figure 2

No

Yes

Yes

No

Maximum

number of trials

attempted?

Yes

No

Yes

No

Yes

No

Yes

De-energize

control and valves

No

Sixteenth

ameout?

Control with

ignition

recycle?

Ignition lockout

(optional LED

ashes)

Yes

No

Recycle delay

period

Shuto

Flame present when

not expected

Hard Lockout

(optional LED

turns o)

Start

Thermostat

call forheat

Prepurge

Flame

present for

30 seconds?

Detected fault

Trial for

ignition

Pilot

ame

sensed?

Energize

main valve

Run

Thermostat

calling for heat?

Flameout?

Interpurge

End

Part # MCOSM06 Rev 1 (11/03/08) Page 33

Page 34

If the pilot burner ame extinguishes during the run state

GROUND

5

24 V

LED

THS 2

PV 1

MV 3

Transformer

Pilot Burner

Assembly

Integral

Igniter/Sensor

Main Burner

Ground

Pilot

Gas Supply

Pilot

Valve

Main

Valve

Ignition Control

Limits in Thermostat

Line Only

(ameout), the control de-energizes the pilot and main gas

valve for the interpurge period. After this period, another

• EnterthelockoutmodeifthecontrolisaG770/G777.The

thermostat contacts must be opened for 30 seconds and

then closed to escape the lockout condition.

trial for ignition is initiated. If the ameout cycle repeats for a

total of 16 times (pilot burner ame established then lost), the

control will:

• Entertheshutomodeandrecycleperiod(5minute

recycle delay for the G775/G779 and 60 minute recycle

for the G776/G778) before beginning another trial for

ignition, starting with prepurge.

Wiring Diagram For Integral Spark/Sense Without Vent Damper

Page 34

Part # MCOSM06 Rev 1 (11/03/08)

Page 35

G76X DIRECT SPARK IGNITION CONTROLS

• Interpurge: Period between trials for ignition when both

the gas valve and spark are deactivated to allow unburned

gas to escape before the next trial. Interpurge occurs

between unsuccessful trials on a multi-trial control or after

a loss of proven ame (ameout).