Page 1

INSTALLATION AND OPERATION MANUAL

GARLAND ELECTRIC FRYERS, MODELS: 36ES11, 36ES11SF,

36ES11BL, 36ES11SFBL, 36ET11, 36ST11SF, 36ES21,

36ET21, 680-31F, 680-31SF, 680-31FBL,

680-31SFBL, E24-31F & E24-31SF

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Part # 1009086 (01/31/08) © 2004 Garland Commercial Industries, Inc.

Part # 19009086 (01/31/08) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # 1009086 (01/31/08)Page 2

Page 3

Part # 19009086 (01/31/08) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION..........................................2

SPECIFICATIONS....................................................4

INTRODUCTION.....................................................5

Uncrating ........................................................................5

Extended Warranty ..............................................................5

Rating Plate ......................................................................5

INSTALLATION......................................................5

Siting ............................................................................5

Legs .............................................................................5

Electrical Connection ............................................................5

Storage Base Models ............................................................6

Counter top/Modular Models – Rated Greater Than 48 Amperes ...................6

Counter Top/Modular Models – Rated Less Than 48 Amperes ......................7

Ventilation .......................................................................7

OPERATION.........................................................7

Preparation Before Use ...........................................................7

Proper Method of Filling the Fryer Tank ...........................................8

Fryers With Automatic Basket Lifts ................................................8

Fryers With Manual Lift Baskets ...................................................8

High Temperature Cuto/Reset ...................................................8

Suggestions For Quality Fried Products ...........................................8

CLEANING AND MAINTENANCE......................................9

Fry Tank .........................................................................9

Elements .......................................................................10

General Cleaning ...............................................................10

Stainless Steel ..................................................................10

Page 4

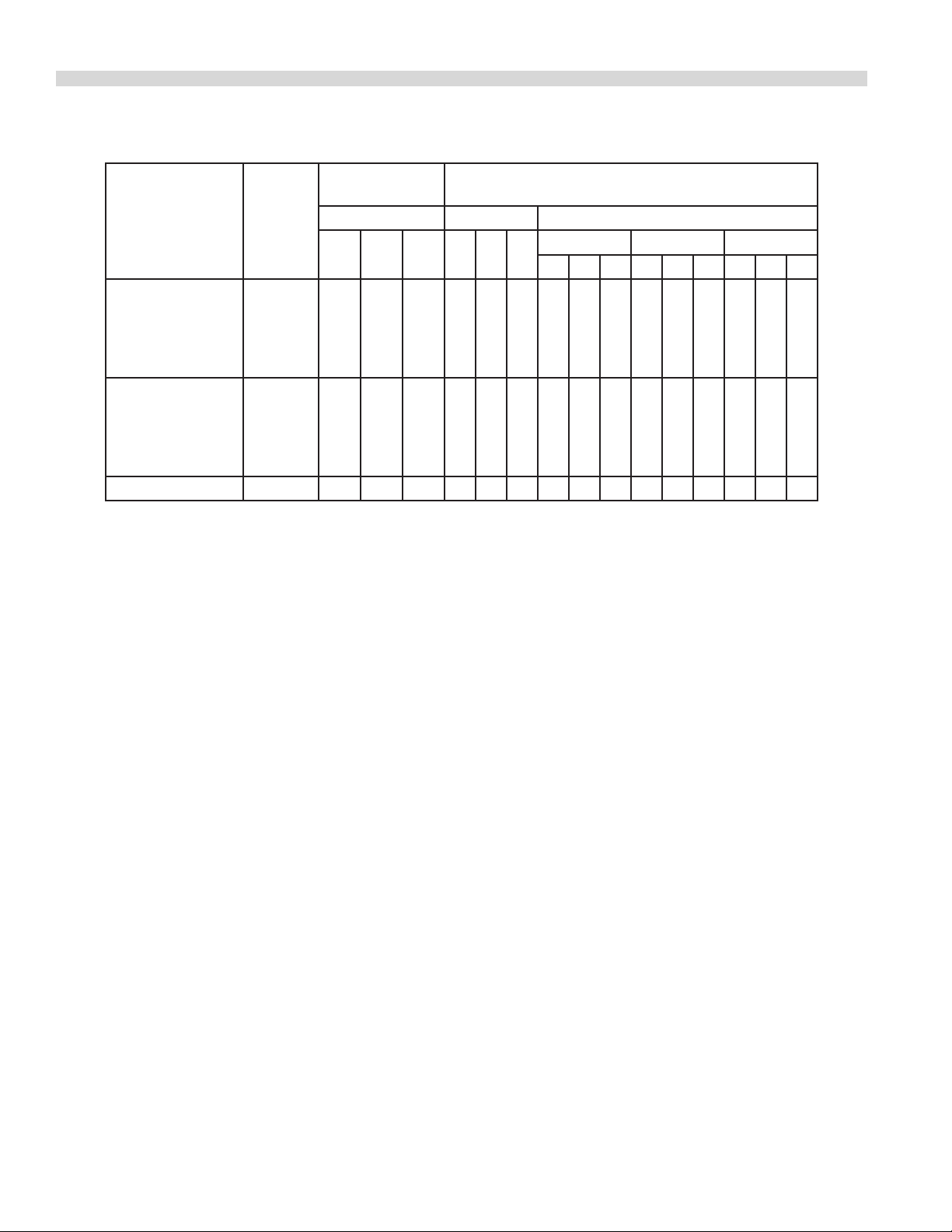

SPECIFICATIONS

THREE PHASE

KW PER PHASE

MODEL

36ES11 36ES11BL

36ST11

680-31F

680-31FBL

E24-31F

36ES11SF 36ES11

SFBL 36ET11SF

680-3SF

680-31SFBL

E24-31SF

36ES21, 36ET21 20 4.8 5.6 9.6 96 85 43 60 44 64 54 39 57 28 20 29

TOTAL

KW

12 4 4 4 58 51 26 33 33 33 30 30 30 15 15 14

16 4.5 4.5 7 776835493849433343221722

208, 240, 460 1 PHASE THREE PHASE

X-Y Y-Z X-Z

208

NOMINAL AMPERES PER LINE

208 240 460

240

460

XYZXYZXYZ

Part # 1009086 (01/31/08)Page 4

Page 5

Part # 19009086 (01/31/08) Page 5

INTRODUCTION

Uncrating

Garland strongly recommends this unit be inspected for

possible freight damage now while carrier driver is on site.

1. Remove carton. In case of damage, all packaging

materials must be retained for carrier inspection.

2. Inspect top, sides, front and rear with special attention to:

A. All knobs and dials in place?

B. Legs attached and square?

C. Body parts dented or scratched?

D. Check handles, tops and body paint for rub marks,

scraps.

3. With carrier driver on your site, note damage on freight

bill. Call carrier for inspection.

If you are checking equipment after carrier has departed,

you have approximately fteen (15 ) days to request a

freight damage inspection be made by the carrier’s agent. If

concealed damage claim is led with carrier beyond 15 days,

Garland cannot be held responsible and carrier will make it

incumbent upon the consignee to oer reasonable evidence

that the carrier was at fault.

Extended Warranty

With a tradition of superior equipment quality and

performance, oers you, our valued customer, an additional

one year limited warranty beyond our standard one year

coverage.

This additional coverage for parts and labor may be

purchased on a new equipment order or up to 60 days after

the equipment purchase. Please contact your Equipment

Dealer or Maintenance & Repair Center (list enclosed) to take

advantage of this exceptional oer.

Thank you for using Garland products. It is our pleasure to

serve you.

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

INSTALLATION

Siting

Proper placement of the fryer will ensure operator and

satisfactory performance. Adequate clearance must be

provided for servicing, ventilation (if applicable), and

proper operation. The fryer must be kept free and clear of

combustible material.

Legs

All units are shipped with N.S.F. approved legs. These legs

must be installed to provide clearance of 6” between the

oor and bottom of the unit in order to meet National

Sanitation foundation requirements.

1. Locate unit in its nal position

2. Raise the rear and block it. Insert the bullet foot into the

leg cone. Tap with mallet until the bullet foot seats up to

the collar. Unit may now be leveled by adjusting hex head

portion of the bullet foot. Repeat for all four legs.

3. All that remains is to install the automatic basket lift

holders (if applicable).

Electrical Connection

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply characteristics agree.

Page 6

INSTALLATION Continued

The Garland 36E series complies with the standards CSA

C222 no. 109-latest edition, the UL197-latest edition and the

NSF #4 latest edition. The installation & Connection of this

appliance must comply with the current codes. In Canada

– the Canadian Electrical Code part 1 and in the USA-The

National Electrical Code.

1. Switch panel size.

2. Overload protection.

3. Wire type.

4. Wire size.

5. Temperature limitations of the wires.

6. Method of connection (Cable, conduit, etc.)

The service line will enter through the rear of the unit and

is to be connected to the terminal block. Input voltage and

phasing must match the units voltage and phasing.

Visual check all electrical connections.

Energize electric service to units.

According to Underwriters Laboratories, Inc. Specications,

fryers with rated loads above 48 Amperes require divided

branch circuits with overcurrent protection (circuit breaker,

fuses, etc.).

NOTE: Select following installation instruction according to

appropriate model.

Storage Base Models

The internal wiring connection can be accomplished from

the front of the unit.

1. Open front door in storage base and remove eld wiring

to terminal box (F.W.T. box) cover, located internally at

rear of cabinet base, by removing fasteners from front

cover. On some models, the fryer tank can be removed for

added convenience.

2. Provide proper output cable hole by removing rings in

F.W.T. box knockout and add appropriate cable for supply

wire.

3. Feed input power cable through rear, snap connector

hole in cabinet base and then into F.W.T. box through

knockout hole/clamp added per 2 above.

4. Attach power input, lead wires to input power terminal

block (single or three phase) according to appliance wire

diagram.

5. Replace F.W.T. box cover and attach with two (2) fasteners.

Upon completion of power input supply connection test

fryer for operation by following the procedure as described

in the section “Proper Method of Filling Fryer Tank”.

Counter top/Modular Models – Rated Greater

Than 48 Amperes

NOTE: An externally mounted Field Wiring terminal box

(F.W.T. box) is factory supplied with counter top and modular

models rated greater than 48 amperes, per Underwriters

Laboratories, Inc. requirements.

1. Locate the F.W.T. box, supplied with fryer, and take o

cover by removing the front fasteners.

2. Place F.W.T. box in convenient mounting location and

attach to surface through holes inside rear of box 3.

Provide proper size “Input Power Cable” hole in F.W.T. box

knockout (located below terminal block) add appropriate

cable clamp for input power supply cable.

3. Provide proper size “Input Power Cable” hole in F.W.T. box

knockout (located below terminal block) add appropriate

cable clamp for input power supply cable.

4. Provide proper output branch circuit “appliance supply

Cable” hole in F.W.T. box knockout located below circuit

breakers and add appropriate cable clamp to secure

cable.

NOTE: The appliance supply cable between F.W.T. box and

dryer is NOT factory supplied.

5. Place input power supply cable through knockout hole

provided in F.W.T. box (per 3 above) and attach to eld

wiring terminal block (single or three phase as required)

according to appliance diagram supplied.

6. Using wiring diagram as a guide, identify and number

wires on each end of “appliance supply Cable”.

7. Place output branch circuit, “appliance supply Cable”,

through knockout hole provided in F.W.T. box per

(4 above) and attach at proper circuit breaker (output

branch circuit) terminals (see wiring diagram).

8. Open appliance front control panel by removing

fasteners.

9. Run “appliance Supply Cable” to counter top/module

fryer. Feed cable rst through rear snap connector hold

and then through knockout in bottom of wiring chamber.

Part # 1009086 (01/31/08)Page 6

Page 7

Part # 19009086 (01/31/08) Page 7

INSTALLATION Continued

10. Attach “appliance Supply Cable” to the 3 or 5 pole

terminal block & ground terminal located rear knockout

in wiring compartment.

“IMPORTANT”. Individual wires of the “appliance Supply

Cable” MUST connected to same number terminals that

correspond to the numbered circuit breaker (branch circuit)

terminals located in the F.W.T. box (per 7 above).

11. Recheck for proper wiring connections following wiring

diagram.

12. Replace front control panel and F.W.T. box cover and

secure with fasteners.

Upon completion of power input supply connection test

fryer for operation by following the procedure as described

in the section “Proper Method of Filling Fryer Tank”.

Counter Top/Modular Models – Rated Less

Than 48 Amperes

1. Open front cover of the eld wiring compartment by

removing fasteners. The eld wiring compartment is

located lower front on 36ES21 models and at rear on

36ES11, E24 (remove tank for front access).

2. Feed input power supply through rear snap connector

and/or through knockout into eld wiring.

3. Attach input power cable leads to the terminal block,

either single or three phase arrangement, as required

according to wiring diagram.

4. Close eld wiring compartment cover by replacing

fasteners (replace tank if required).

Upon completion of power input supply connection test

fryer for operation by following the procedure as described

in the section “Proper Method of Filling Fryer Tank”.

Ventilation

Proper ventilation is required for the safe removal of grease

laden air generated during the frying process. Local and/or

National codes dictate the type of ventilating system to

be used with this appliance. Care should be taken in the

positioning of the ventilating system to prevent grease from

dripping from the hood into the fryer.

OPERATION

Preparation Before Use

After the fryer has been properly installed and checked for

operation, it will be necessary to clean the protective coating

from the fry tank as follows:

1. Have power to the fryer turned “OFF” at the service

disconnect box.

2. Remove baskets from the fry tank.

3. If applicable, remove the automatic basket lift holders by

lifting them o the raising rods. These are right and left

basket holders. Note the position for replacement.

4. Lift the element handle until the heating elements are in

full raised position.

5. Lift the tank out of the fryer for cleaning. If a special fry

tank cleaner is used, carefully follow the manufacturer’s

instructions for its use. Ammonia, vinegar solution or

baking soda solution may be used for cleaning the tank.

Rinse tank thoroughly with clean, hot water and dry

completely.

6. Replace the tank in the fryer. If the tank has the optional

drain valve, make sure that this valve is tightly closed.

Page 8

OPERATION Continued

7. With the circuit breakers and toggle switch on the fryer

in the “OFF” position, turn on the power at the service

disconnect box.

Proper Method of Filling the Fryer Tank

The clean tank is now ready to be lled with frying

compound as follows:

1. If solid frying compound is used, pack it in and around

the heating elements, using enough to cover the heating

elements.

2. Set circuit breakers in the “ON” position.

3. Set the thermostat dial to 200 degrees F. (If a higher

setting is used to melt solid shorting, it may cause

scorching). The red pilot light will glow and remain on

until the preset temperature is reached. Maintain the 200

degrees F. temperature, adding solid shortening until 30

pounds have been melted. At this point, the thermostat

may be set to the frying temperature. It should be noted

that the manufacturers of quality frying compound

recommend a maximum frying temperature of 375

degrees F in standard fryers (GARLAND Models: 36ES11,

36ES11BL, 36ET11, 36ES21, 36ET21, 680-31F, 680-31FBL,

E24-31F) and a maximum of 350 degrees Fahrenheit

in fast recovery fryers (GARLAND Models: 36ES11SF,

36ET11SFBL, 36ET11SF, 680-31SF, E24-31SF).

If a liquid frying compound is used, you need only to ll the

tank to the “FULL” mark stamped on the inner sides, front or

back of the fry tank (DO NOT OVER FILL). The toggle switch

should be set to the ‘on” position and thermostat may be

immediately set to the desired frying temperature.

The fryer is ready to be used as follows.

Fryers With Automatic Basket Lifts

Replace the basket lift basket holders in the proper right or

left position, making sure that the rides are riding inside the

rollers.

When the red pilot light cycles “OFF” the fryer is ready. Fill

the fryer basket(s) no more than half full. Place the basket(s)

on the basket lift holder(s). Set the timer dial at the time

required, according to the recipe used. Press the button in

the center of the timer dial. The basket will be automatically

lowered into the preheated frying compound. When

the timed cycle has been completed, the gasket will be

automatically raised out of the hot frying compound and will

drain back into the tank.

Fryers With Manual Lift Baskets

If your fryer is not equipped with the automatic basket lift

features, you must lower the properly lled basket into the

preheated frying compound by hand. When the prescribed

frying period is completed, you must return to the fryer and

raise the basket manually from the frying compound. The

basket may then be hung on the side fry tank handles for

draining.

If you have the optional drain shelf or the fry-mate the

nished product would be emptied to either item for

draining, freeing the basket for additional loading.

The fryer should be permitted to recycle to the desired

temperature between successive loads, as indicated when

the red pilot light cycles o.

High Temperature Cuto/Reset

Your GARLAND Fryer is equipped with a protective

secondary thermostat. If the operating thermostat fails to

control the temperature, the secondary (Hi-Limit) thermostat

will take over. It will cut o power to the heating elements if

the frying compound reaches a temperature if not less than

430 degrees F., not more than 450 degrees F.

A red reset button located in the rotating head should be

pressed to restore power to the heating elements. The reset

button will be ineective until the temperature of the frying

compound drops 50 degrees F. If this condition occurs, it

could indicate that the operation thermostat has become

damaged. The fryer should be checked and repaired by a

qualied service technician if required. Continued operation

of the fryer in this condition will lead to a poor quality

product and deterioration of the frying compound.

Suggestions For Quality Fried Products

Clean equipment is vital to the quality of fried foods. Fresh,

uncontaminated frying compounds produce better fried

foods.

A. Taste the frying compound once a day. Your patrons do,

when they eat the product.

B. Filter the frying compound daily. Merely straining the

shorting is inadequate. Your food equipment supplier can

recommend a proper lter and cone or a lter system.

C. Drain or dry foods before frying. Excessive moisture and

water breaks down frying compound.

Part # 1009086 (01/31/08)Page 8

Page 9

Part # 19009086 (01/31/08) Page 9

OPERATION Continued

D. Do not salt or otherwise season food over the fryer.

This practice contaminates the frying compound and

accelerates its deterioration.

E. Do not shake breaded items over the fryer.

F. Keep the fry tank covered when not in use. This will

prevent air from oxidizing the frying compound and will

keep impurities out.

Do not overheat the frying compound. Follow the

temperature recommended in tested recipes. The company

which provides your frying compound can provide tested

recipes and techniques for use with their shortening.

CLEANING AND MAINTENANCE

This booklet provides many basic tips in operating and

cleaning your GARLAND Fryer. Your supplier of frying

compound can provide additional assistance and

information concerning the use of their products on your

fryer.

Fry Tank

Watch for the signs of shortening break down. An unusual

darkening of the shortening or smoking are the rst signs of

break down. Foaming, objectionable change in avor of the

product and fuming also indicate a break down of the frying

compound.

Set the thermostat at 200 degrees or lower when not frying.

Darkened frying compound and incorrect baser or breading

can cause a fried product to appear to be done. Use a tested

recipe or obtain batter or breading specially prepared for

fryers.

In either of the above procedures, the heating elements

should be raised to permit and uid shortening to drain from

the elements back into the fryer tank.

Refer to the rst section to remove the tank. If the heating

elements have been turned on, make sure that they are cool

before attempting to remove the tank.

In order to clean the fryer tank, you must rst remove the

frying compound. As in the section “Preparation Before First

Use”, remove the fryer baskets and automatic basket holders

(if applicable) and set the circuit breaker and toggle switch to

the “OFF” position.

If you have the fryer tank with the optional drain valve and

the frying compound is in a uid state, you need merely

place a vessel of the proper size in the compartment beneath

the drain valve and open the valve. When the fryer tank has

been emptied, close the drain valve and remove the vessel.

If the frying compound has solidied, it will be necessary

to melt it until it becomes uid enough to ow through the

drain valve. Care should be taken when the vessel of warm,

melted shortening is removed from the compartment. Filer

the shortening and hold it in a covered vessel if it is to be

used again.

If your fryer tank does not have the optional drain valve, it

will be necessary to dip the liquid shortening or scoop the

solid shortening from the fryer tank.

Use some of the uid shortening to ush the crumbs and

residue from the tank. Discard this shortening.

Wash the tank with soap detergent or one of the special fryer

tank cleaning agents available. If the latter is used, carefully

follow the instructions provided with that product.

Remove stubborn stains or carbon deposits, using a sti

nylon brush or wooden spatula. Remove all traces of

cleaning compound by carefully rinsing with hot water or

neutralizer, if required. Dry tank completely. Remember,

moisture accelerates the breakdown of frying compound.

Before replacing the tank, clean the fryer top with soap or

detergent solution on a sponge. Rinse the top with a sponge

soaked in clean hot water. Dry hot water. Replace the tank.

Page 10

CLEANING AND MAINTENANCE Continued

Elements

Advanced design of the special inconnel steel heating

elements permits burn-of for easy cleaning. Merely raise

the elements and heat elements until the soil is burned o.

DO NOT EXCEED TEMPERATURE SETTING OF 250 DEGREES

FAHRENHEIT FOR THIS ELEMENT BURN OFF PROCEDURE.

General Cleaning

The compartment interior and exterior are easily cleaned,

using a mild soap or detergent solution. Although the

electrical components are well shielded, it would be wise

to shut o the power to the fryer while using wet cloths or

sponges.

Stainless Steel

Stainless steel should be cleaned using a mild detergent, a

soft cloth and hot water. If necessary to use a nonmetallic

scouring pad, always rub in the direction of the grain in the

metal to prevent scratching.

Use a water based stainless cleaner (Dracket Twinkle), if you

want a high shine. Note there will be toning of the stainless

steel due to heat, this is normal.

Part # 1009086 (01/31/08)Page 10

Page 11

Pièce nº 1009086 (01/31/08)Page 10

spécial, suivre les instructions du fabricant du produit.

spécial pour bassin de friteuse. En cas d’utilisation de produit

sous l’action de la chaleur. Ceci est normal.

brillante. Il est bon de noter que l’acier inoxydable brunit

à base d’eau (Dracket Twinkle) assure une apparence très

L’utilisation de produits de nettoyage pour acier inoxydable

frotter dans le sens du grain du métal pour éviter de le rayer.

d’utiliser un tampon à récurer non métallique, toujours

doux, d’un chi on et d’eau chaude. S’il est nécessaire

L’acier inoxydable doit être nettoyé à l’aide de détergents

L’acier Inoxydable

mouillé.

la friteuse pendant l’utilisation d’éponges ou de chi ons

est prudent de débrancher l’alimentation électrique de

doux. Même si les pièces électriques sont bien isolées, il

nettoyer avec une solution de savon ou de détergent

L’intérieur et l’extérieur du compartiment sont facile à

Nettoyage Général

DES PROCÉDURES DE BRÛLAGE.

DÉPASSER LE RÉGLAGE DE TEMPÉRATURE DE 250 °F LORS

fonctionner jusqu’à ce que les salissures brûlent. NE PAS

le nettoyage. Soulever les éléments chau ants et les faire

gainé d’Inconel permet aux dépôts de brûler pour faciliter

La conception moderne des éléments chau ants en acier

Laver le bassin avec du savon, du détergent ou un produit

et les miettes du bassin. Jeter cette partie de produit.

Utiliser un peu de produit pour friture pour rincer les résidus

qu’ils sont froids avant de retirer le bassin.

Si les éléments chau ants ont été mis en marche, s’assurer

Consulter la première section pour le démontage du bassin.

pour leur permettre de s’égoutter dans le bassin.

Dans les deux cas, il faut faire monter les éléments chau ants

liquide ou solide du bassin.

option, il faut vider manuellement le produit pour friture

Si la friteuse n’est pas équipée d’un robinet de vidange en

récipient fermé s’il doit être réutilisé.

chaud. Filtrer le produit pour friture et le conserver dans un

manipulant le récipient contenant le produit pour friture

passer par le robinet. Il faut faire preuve de prudence en

le faire fondre a n de le rendre su samment liquide pour

Si le produit pour friture s’est solidi é, il sera nécessaire de

retirer le récipient et fermer le robinet.

robinet et de l’ouvrir. Lorsque le bassin de la friteuse est vide,

récipient de taille approprié dans le compartiment sous le

et si le produit pour friture est liquide, il su t de mettre un

Si la friteuse est équipée d’un robinet de vidange en option

Éléments Chau ants

bassin en place.

propre humidi ée d’eau chaude. Bien assécher. Remettre le

savon ou de détergent. Rincer le dessus avec une éponge

la friteuse avec une éponge trempée dans une solution de

Avant de remettre le bassin en place, nettoyer le dessus de

l’interrupteur à bascule en position d’arrêt.

de levage (le cas échéant) et mettre les disjoncteurs et

les paniers de la friteuse et les dispositifs automatiques

section « Préparation pour la première utilisation », retirer

le produit pour friture. Conformément aux indications de la

Pour nettoyer le bassin de la friteuse, il faut en premier, retirer

Du Bassin De Friture

décomposition du produit pour friture.

assécher le bassin et ne pas oublier que l’eau accélère la

chaude ou avec un produit neutralisant, si nécessaire. Bien

traces de produit de nettoyage en faisant un rinçage à l’eau

brosse dure en Nylon ou une spatule en bois. Enlever toutes

Enlever les taches tenaces ou dépôts de carbone avec une

dans la friteuse.

informations supplémentaires sur l’utilisation de son produit

de produit pour friture est en mesure d’o rir aide et

et de nettoyage de la friteuse « GARLAND » Votre fournisseur

Le présent manuel o re de nombreux conseils d’utilisation

NETTOYAGE ET ENTRETIEN

Page 12

actuels.

spécialement préparés pour les équipements de cuisson

éprouvée ou utiliser de la pâte à frire ou un produit à paner

le produit ni comme bien cuit. Utiliser une recette

chapelure de mauvaise qualité peuvent faire paraître

Un produit pour friture bruni ou une pâte à frire ou une

n’est pas utilisée.

Régler le thermostat sur 200°F ou plus bas lorsque la friteuse

décomposition du produit.

saveur du produit et de la fumée indiquent également une

produit. L’apparition de mousse, un changement notable de

de fumée sont les premiers signes de décomposition du

brunissement inhabituel du produit ou le dégagement

Surveiller les signes de décomposition du shortening. Un

shortening.

recettes et des techniques éprouvées à utiliser avec son

Le fournisseur de produit pour friture peut fournir des

recommandations de température des recettes éprouvées.

Ne pas surchau er le produit pour friture. Suivre les

produit pour friture et aider à le maintenir propre.

n’est pas utilisée, ceci a n d’empêcher l’air d’oxyder le

F. Maintenir le bassin de la friteuse fermé lorsque celle-ci

friteuse.

E. Ne pas secouer les aliments panés au-dessus de la

accélère sa détérioration.

Cette pratique contamine le produit pour friture et

D. Ne pas saler, ni assaisonner les aliments dans la friteuse.

pour friture

L’humidité excessive et l’eau décomposent le produit

C. Égoutter ou assécher les aliments avant de les faire frire.

ltration.

recommander un bon ltre avec cône ou système de

Votre fournisseur d’équipements pour cuisine peut

simplement le produit à la passoire n’est pas su sant.

B. Filtrer le produit pour friture tous les jours. Passer

jour. Vos clients le font en consommant le produit ni.

A. Il convient de goutter le produit pour friture une fois par

Pièce nº 19009086 (01/31/08) Page 9

améliore la qualité du produit frit ni.

aliments de qualité. Un produit pour friture frais et propre

La propreté de l’équipement est essentielle pour obtenir des

Frits De Qualité

Suggestions Pour Obtenir Des Produits

mauvaise qualité et de détériorer le produit pour friture.

de telles conditions, on risque d’obtenir un produit nal de

de service quali é. Si l’on continue d’utiliser la friteuse dans

alors véri ée et éventuellement réparée par un technicien

thermostat fonctionnel est endommagé. La friteuse doit être

50 °F. Si cela se produit, c’est une indication possible que le

avant que la température du produit pour friture ait baissé de

éléments. Le bouton de réarmement ne fonctionnera pas

trouvant dans la tête rotative pour remettre en chau e les

Il faudra appuyer sur un bouton rouge de réarmement se

450 °F.

pour friture atteint une température comprise entre 430 et

coupe l’alimentation des éléments chau ants si le produit

thermostat secondaire (limite maximale) entre en action et

normal ne contrôle pas correctement la température, le

secondaire de protection. Si le thermostat fonctionnel

Cette friteuse GARLAND est dotée d’un thermostat

Coupure Haute Température/Réarmement

quand la température désirée est atteinte.

les indications du témoin lumineux rouge qui doit s’éteindre

température réglée entre les chargements en se basant sur

Laisser à la friteuse le temps nécessaire pour revenir à la

un autre cycle de friture.

produit ni peut y être transvasé, libérant ainsi le panier pour

Si on dispose d’une étagère d’égouttage en option, le

s’égoutter.

alors être accroché sur les poignées latérales du bassin pour

manuellement le panier pour le sortir du bain. Le panier peut

est écoulé, il faut retourner à la friteuse et soulever

dans le bain de friture chaud. Lorsque le temps de cuisson

des paniers, il faut descendre manuellement le panier

Si la friteuse n’est pas équipée d’un dispositif de levage

Friteuses À Levage Manuel Des Paniers

UTILISATION suite

Page 13

Pièce nº 1009086 (01/31/08)Page 8

dessus du bassin.

automatiquement de la friture chaude pour s’égoutter auLorsque le temps programmé est écoulé, le panier sort

descend automatiquement dans la friture préchau ée.

bouton au centre du cadran de la minuterie. Le panier

désirée, en fonction de la recette utilisée. Appuyer sur le

support(s). Régler le cadran de la minuterie sur la valeur

mi-hauteur maximum. Placer le(s) panier(s) dans le(s)

prête. Remplir le(s) panier(s) de la friteuse à

Lorsque le voyant lumineux rouge s’éteint, la friteuse est

les rails glissent bien sur les roulements.

leurs positions respectives gauche ou droit, en s’assurant que

Remettre les supports du dispositif de levage du panier dans

De Levage Des Paniers

Les Friteuses À Dispositif Automatique

La friteuse est prête à être utilisée comme suit.

thermostat à la température désirée de friture.

« ON » et il est possible de régler immédiatement le

être mis en position

friteuse (NE PAS TROP REMPLIR). L’interrupteur à bascule doit

sur les côtés internes, à l’avant ou à l’arrière du bassin de la

de remplir le bassin jusqu’à la marque « FULL » estampillée

En cas d’utilisation de produit pour friture liquide, il su t

36ET11SFBL, 36ET11SF, 680-31SF et E24-31SF).

la chaleur (GARLAND modèles 36ES11SF, 36ES21,

de 350 °F pour les friteuses à récupération rapide de

680-31 FBL, E24-31 F) et une température maximale

BL, 36ET11, 36ES21, 36ET21, 680-31F,

friteuses standards (GARLAND modèles 36ES11, 36ES11

une température de friture maximale de 375 °F pour les

produits pour friture de haute qualité, recommandent

de friture. Il est bon de noter que les fabricants de

il est possible de régler le thermostat à la température

que le poids total de 30 livres soit atteint. A ce moment,

température de 200 °F et ajouter du shortening jusqu’à ce

jusqu’à ce que la température soit atteinte. Maintenir la

Le voyant lumineux rouge s’allume et reste allumé

température plus élevée risque de faire brûler le produit).

3. Régler le cadran du thermostat sur 200 °F (une

2. Mettre les disjoncteurs en position de marche.

pour les recouvrir.

autour des éléments chau ants en quantité su sante

1. En cas d’utilisation de produit pour friture solide, le placer

pour friture, comme suit :

Le bassin propre est maintenant prêt à être rempli de produit

Du Bassin De Friture

Méthode Correcte De Remplissage

boîtier de coupure.

friteuse en position d’arrêt et brancher l’alimentation au

7. Mettre les disjoncteurs et l’interrupteur à bascule de la

est bien fermé.

un robinet de vidange en option, s’assurer que le robinet

6. Remettre le bassin dans la friteuse. Si le bassin possède

l’assécher complètement.

du bassin. Bien rincer le bassin à l’eau propre et chaude et

vinaigrée ou du bicarbonate de soude pour le nettoyage

fabricant. On peut utiliser de l’ammoniac, une solution

bassin de friture, suivre les instructions d’utilisation du

d’utilisation d’un produit de nettoyage spécial pour

5. Retirer le bassin de friture pour le nettoyage. En cas

celui-ci se trouve complètement en position haute.

4. Soulever la poignée de l’élément chau ant jusqu’à ce que

et droit des supports.

supports des tiges. Bien noter les emplacements gauche

automatique de levage des paniers en enlevant les

3. Le cas échéant, retirer les supports du dispositif

2. Retirer les paniers du bassin de friture.

d’alimentation.

1. Débrancher l’alimentation électrique au boîtier

protection de la cuve de la friteuse comme suit :

la friteuse, il sera nécessaire de nettoyer le revêtement de

Après l’installation et la véri cation du fonctionnement de

Préparation Avant Utilisation

UTILISATION

Page 14

Pièce nº 19009086 (01/31/08) Page 7

depuis la hotte dans la friteuse.

système de ventilation, a n d’éviter l’écoulement de graisse

devra faire particulièrement attention au positionnement du

de système de ventilation à utiliser avec cet appareil. On

friteuse. Les codes locaux ou nationaux prescrivent le type

des vapeurs grasses générées pendant la cuisson en

Une ventilation adéquate est nécessaire pour l’élimination

Ventilation

de remplissage du bassin de friture ».

les procédures décrites dans la section « Méthode correcte

d’entrée, véri er le fonctionnement de la friteuse en suivant

A la n des opérations de connexion de l’alimentation

bassin si nécessaire).

en place les dispositifs de xation (remettre en place le

4. Fermer le compartiment de câblage extérieur en remettant

(paragraphe 7 ci-dessus).

disjoncteurs (circuit de dérivation) situés dans le boîtier FWT

les numéros correspondent aux numéros des bornes des

de l’appareil » DOIVENT être connectés aux bornes dont

IMPORTANT : les ls individuels du « câble d’alimentation

trou défonçable dans le compartiment de câblage.

ou 5 du bornier et à la borne de terre se trouvant près du

10. Fixer le « câble d’alimentation de l’appareil » aux bornes 3

l’entrée défonçable dans le bas de la boîte de connexion.

câble par le trou du connecteur à pression arrière puis par

friteuse de comptoir/ modulaire. Faire d’abord passer le

9. Passer le « câble d’alimentation de l’appareil » vers la

retirant les dispositifs de xation.

8. Ouvrir le panneau de commande avant de l’appareil en

sur le schéma de câblage.

en monophasé ou triphasé selon le cas, comme indiqué

3. Fixer les ls du câble d’alimentation d’entrée au bornier,

pour le câblage extérieur.

connecteur à pression arrière et/ou l’entrée défonçable

2. Faire passer le câble d’alimentation d’entrée par le

le bassin de friture pour accéder par l’avant).

36ES21 et à l’arrière sur les modèles 36ES 11, E24 (retirer

câblage extérieur est situé en bas, à l’avant des modèles

extérieur en retirant les xations. Le compartiment de

1. Ouvrir le couvercle avant du compartiment de câblage

Puissance Inférieure À 48 Ampères

sortie) (voir le schéma de câblage).

du disjoncteur correspondant (circuit de dérivation de

boîtier FWT (paragraphe 4 ci-dessus) et le xer aux bornes

d’alimentation de l’appareil », par le trou défonçable du

7. Passer le circuit de dérivation de sortie, « câble

d’alimentation de l’appareil ».

et numéroter les ls à chaque extrémité du « câble

6. En utilisant le schéma de câblage comme guide, identi er

câble de l’appareil fourni.

ou triphasé selon les cas) conformément au schéma de

dessus) et le xer au bornier de câblage extérieur (mono

le trou défonçable du boîtier FWT (voir paragraphe 3 ci-

5. Passer le câble d’alimentation d’entrée de l’appareil dans

Modèles Modulaires/De Comptoir – D’une

boîtier FWT et l’appareil N’EST PAS FOURNI PAR L’USINE.

de remplissage du bassin de friture ».

les procédures décrites dans la section « Méthode correcte

d’entrée, véri er le fonctionnement de la friteuse en suivant

A la n des opérations de connexion de l’alimentation

xation appropriés.

couvercle du boîtier FWT et les xer avec les dispositifs de

12. Remettre en place le panneau de commande avant et le

câblage.

11. Véri er les branchements en les comparant au schéma de

REMARQUE : Le câble d’alimentation de l’appareil entre le

appropriée pour immobiliser le câble.

(sous les disjoncteurs) et ajouter un serre-câble de taille

le câble d’alimentation de l’appareil dans le boîtier FWT

4. Percer une entrée défonçable de taille appropriée pour

pour le câble d’alimentation.

le bornier) et ajouter un serre-câble de taille appropriée

le câble d’alimentation d’entrée dans le boîtier FWT (sous

3. Percer une entrée défonçable de taille appropriée pour

INSTALLATION suite

Page 15

Pièce nº 1009086 (01/31/08)Page 6

situés à l’arrière du boîtier.

commode et le xer à la surface en utilisant les trous

2. Placer le boîtier FWT dans un endroit de montage

le couvercle en retirant les dispositifs de xation avant.

1. Localiser le boîtier FWT, fourni avec la friteuse et enlever

aux exigences des Underwriters Laboratories Inc.

d’une puissance supérieure à 48 ampères, conformément

installé en usine pour les modèles modulaires et de comptoir

REMARQUE : Un boîtier de connexion externe (FWT) est

Supérieure À 48 Ampères

Modèles Modulaires/De Comptoir – Puissance

de remplissage du bassin de friture ».

les procédures décrites dans la section « Méthode correcte

d’entrée, véri er le fonctionnement de la friteuse en suivant

A la n des opérations de connexion de l’alimentation

avec les deux (2) dispositifs de xation.

5. Remettre en place le couvercle du boîtier FWT et le xer

sur le schéma de câblage.

en monophasé ou triphasé selon le cas, comme indiqué

4. Fixer les ls du câble d’alimentation d’entrée au bornier,

ci-dessus.

FWT par le trou défonçable/serre-câble ajouté au point 2

connecteur dans la base de l’armoire puis dans le boîtier

3. Passer le câble d’alimentation par l’arrière, dans le trou du

serre-câble approprié pour le câble d’alimentation.

les anneaux défonçables du boîtier FWT et en ajoutant le

2. Obtenir un trou d’entrée de câble su sant en enlevant

plus de facilité.

modèles, il est possible de retirer le bassin de friture pour

les dispositifs de xation du couvercle avant. Sur certains

se trouvant à l’intérieur, à l’arrière de l’armoire, en retirant

le couvercle du boîtier FWT (câblage extérieur à bornes),

1. Ouvrir la porte avant de la base de rangement et retirer

fusibles, etc.).

protection contre les surintensités (disjoncteur,

ampères ont besoin de circuits à dérivations divisées avec

les friteuses dont la charge nominale est supérieure à 48

Selon les spéci cations des Underwriters Laboratories,

Brancher l’alimentation électrique des appareils.

Véri er visuellement toutes les connexions électriques.

tension et au nombre de phases de l’appareil.

d’entrée et le nombre de phases doivent correspondre à la

et doit être connectée au bornier. La tension d’alimentation

La ligne d’alimentation doit entrer dans l’appareil à l’arrière

6. Méthode de connexion (câble, conduit, etc.).

5. Limitations thermiques des câbles.

4. Calibre de câble.

3. Type de câble.

2. Protection contre les surcharges.

1. Taille du panneau de commande.

l’électricité, partie 1 et aux É.-U. le National Electrical Code.

aux codes en vigueur. Au Canada, le Code canadien de

L’installation et les connexions doivent être conformes

- dernière édition et la norme NSF#4 - dernière édition.

norme CSA C22.2 n° 109 - dernière édition, la norme UL197

Les appareils GARI.AND de série 36E sont conformes à la

correspondent.

électriques de l’appareil et celles de la ligne d’alimentation

plaque signalétique pour s’assurer que les caractéristiques

Avant de procéder à toute connexion électrique, véri er la

Connexions Électriques

de levage automatique du panier (le cas échéant).

3. La seule chose qui reste à faire c’est d’installer le dispositif

de l’appareil.

La connexion électrique interne peut être faite depuis l’avant

Modèles À Base De Rangement

en fonction du modèle concerné.

REMARQUE : Sectionner l’instruction d’installation suivante

Recommencer l’opération pour les quatre pieds.

niveau en réglant la partie à tête hexagonale du pied.

bien en place dans le collier. L’appareil peut être mis de

cône. Taper avec un maillet jusqu’à ce que le pied soit

2. Soulever l’arrière et le bloquer. Insérer le pied dans le

1. Disposer l’appareil dans sa position nale.

INSTALLATION suite

Page 16

Pièce nº 19009086 (01/31/08) Page 5

Foundation.

conformément aux exigences de la National Sanitation

minimale de 6 po entre le plancher et le fond de l’appareil

Ces pieds doivent être installés a n d’assurer une distance

Toutes les unités sont livrées avec des pieds approuvés N.S.F.

Pieds

l’appareil contient ces informations.

numéro de série ou de code. La plaque signalétique xée sur

lettres de pré xe et de su xe et les numéros) ainsi que le

en indiquant le numéro de modèle correct (comprenant les

pièces de rechange, référez-vous à cet appareil particulier

en ce qui concerne des problèmes de réparation ou des

Pour contacter l’usine ou votre revendeur d’équipement

Plaque Signalétique

friteuse doit être installée loin de tout matériau combustible.

l’entretien, la ventilation (le cas échéant) et l’utilisation. La

Un dégagement su sant doit être prévu pour assurer

facilité d’utilisation et un fonctionnement satisfaisant.

Un bon emplacement pour la friteuse assurera la

Emplacement

INSTALLATION

réclamation pour dommages cachés est formulée auprès

de transport par le représentant du transporteur. Si une

pour formuler une demande d’inspection des dommages

transporteur, le client dispose d’environ quinze (15) jours

En cas de véri cation de l’équipement après le départ du

véri er lui-même.

le bordereau de transport. Demander au transporteur de

3. Le livreur se trouvant sur place, noter les dommages sur

notre plaisir.

Merci d’utiliser les équipements GARLAND. Vous servir est

exceptionnelle.

et de réparation (liste jointe) pour pro ter de cette o re

achat. Contacter le concessionnaire ou le centre d’entretien

d’équipement neuf ou dans les 60 jours qui suivent cet

d’oeuvre peut être achetée au moment de toute commande

Cette couverture supplémentaire des pièces et de la main-

standard d’un an.

limitée supplémentaire d’un an en plus de notre couverture

équipements, vous o re à vous, son client, une garantie

Avec sa tradition de qualité et de performances de ses

Garantie Prolongée

la faute du transporteur.

demandera au plaignant de produit une preuve évidente de

pourra pas être tenue pour responsable et le transporteur

du transporteur après le délai de 15 jours, GARLAND ne

et les rayures.

carrosserie pour détecter les marques de frottement

D. Véri er les poignées, les dessus et la peinture de

rayées?

C. Les pièces de carrosserie sont-elles bosselées ou

B. Les pieds sont-ils xés et d’équerre?

A. Les boutons et les cadrans sont-ils tous en place?

particulièrement attention aux points suivants :

2. Inspecter le dessus, les côtés et l’arrière en faisant

le transporteur.

d’emballage doivent être conservés pour inspection par

1. Retirer le carton. En cas de dommage, tous les matériaux

chau eur livreur est sur place.

tout dommage survenu durant le transport pendant que le

immédiatement à l’inspection de l’appareil a n de détecter

GARLAND recommande instamment de procéder

Déballage

INTRODUCTION

Page 17

Pièce nº 1009086 (01/31/08)Page 4

36ES21, 36ET21 20 4.8 5.6 9.6 96 85 43 60 44 64 54 39 57 28 20 29

E24-31SF

680-31SFBL

16 4.5 4.5 7 776835493849433343221722

12 4 4 4 58 51 26 33 33 33 30 30 30 15 15 14

XYZXYZXYZ

460

208 240 460

AMPÉRAGE NOMINAL PAR LIGNE

240

208

X-Y Y-Z X-Z

208, 240, 460 UNE PHASE TROIS PHASES

kW PAR PHASE

TROIS PHASES

kW

TOTAL

680-3SF

SFBL 36ET11SF

36ES11SF 36ES11

E24-31F

680-31FBL

680-31F

36ST11

36ES11 36ES11BL

MODÈLE

SPÉCIFICATIONS

Page 18

Pièce nº 19009086 (01/31/08) Page 3

L’acier Inoxydable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Nettoyage Général . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Éléments Chau ants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Du Bassin De Friture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

NETTOYAGE ET ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Suggestions Pour Obtenir Des Produits Frits De Qualité . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Coupure Haute Température/Réarmement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Friteuses À Levage Manuel Des Paniers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Les Friteuses À Dispositif Automatique De Levage Des Paniers . . . . . . . . . . . . . . . . . . . . .8

Méthode Correcte De Remplissage Du Bassin De Friture . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Préparation Avant Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Modèles Modulaires/De Comptoir – D’une Puissance Inférieure À 48 Ampères . . . . . .7

Modèles Modulaires/De Comptoir – Puissance Supérieure À 48 Ampères . . . . . . . . . .6

Modèles À Base De Rangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Connexions Électriques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Pieds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Emplacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plaque Signalétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Garantie Prolongée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INFORMATIONS IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TABLE DES MATIÈRES

Page 19

Pièce nº 1009086 (01/31/08)Page 2

AVERTISSEMENT

est reconnue par l’état de Californie comme causant le cancer.

verre/fibres céramiques. L’inhalation de ces particules de laine de verre ou de fibres céramiques

L’installation et l’entretien de ce produit peut vous exposer aux poussières de laine de

le cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction.

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant

INFORMATIONS IMPORTANTES

Page 20

Pièce nº 19009086 (01/31/08) Page 1

Pièce n° 1009086 (01/31/08) © 2004 Garland Commercial Industries, Inc.

Télécopieur : 081-848-0041

Téléphone : 081-561-0433

ANGLETERRE

Swallow eld Way, Hayes, Middlesex UB3 1DQ

Enodis UK LTD.

Télécopieur : 905-624-5669

Téléphone : 905-624-0260

CANADA

1177 Kamato Road, Mississauga, Ontario L4W 1X4

GARLAND COMMERCIAL RANGES, LTD.

Télécopieur : (570) 636-3903

Téléphone : (570) 636-1000

Freeland, Pennsylvanie 18224

185 East South Street

GARLAND COMMERCIAL INDUSTRIES

conception et les spéci cations des pièces) peuvent être remplacés ou modi és sans préavis.

de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent document (y compris la

ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés, consulter le site web

numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modi é ou réparé avec des pièces non autorisées

codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit dont le

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément aux

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être e ectués par un agent

SIGNALÉTIQUE.

ÉLECTRIQUES FIGURANT SUR LA PLAQUE

EST CONFORME AUX CARACTÉRISTIQUES

VÉRIFIER QUE L’ALIMENTATION ÉLECTRIQUE

CODE ANSI / NFPA – ÉDITION EN VIGUEUR.

LOCAUX. AUX É.-U. – LE NATIONAL ELECTRICAL

DE L’ÉLECTRICITÉ, PARTIE 1 ET/OU LES CODES

VIGUEUR: AU CANADA – LE CODE CANADIEN

DEVRONT ÊTRE CONFORMES AUX CODES EN

L’INSTALLATION ET LES CONNEXIONS

L’ÉQUIPEMENT.

AVANT D’INSTALLER OU DE RÉPARER

D’UTILISATION ET D’ENTRETIEN

MENT LES INSTRUCTIONS D’INSTALLATION,

SURES OU LA MORT. LIRE SOIGNEUSE-

DES DOMMAGES MATÉRIELS, DES BLES-

ENTRETIEN MAL FAITS PEUVENT CAUSER

MODIFICATIONS, DES RÉPARATIONS OU UN

UNE INSTALLATION, DES RÉGLAGES, DES

AVERTISSEMENT

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

ULTÉRIEUREMENT.

POUR VOTRE SÉCURIT:

MANUEL ET LE CONSERVER POUR S’Y REPORTER

LIRE TOUTES LES SECTIONS DU PRÉSENT

680-31FBL, 680-31SFBL, E24-31F & E24-31SF

FRITEUSES ÉLECTRIQUES DE GARLAND,

APPAREIL OU DE TOUT AUTRE APPAREIL

INFLAMMABLES À PROXIMITÉ DE CET

OU D’AUTRES VAPEURS OU LIQUIDES

NE PAS STOCKER NI UTILISER D’ESSENCE

36ET11, 36ST11SF, 36ES21, 36ET21, 680-31F, 680-31SF,

MODÈLES: 36ES11, 36ES11SF, 36ES11BL, 36ES11SFBL,

MANUEL D’UTILISATION ET D’INSTALLATION

Loading...

Loading...