Garland 35-280 Installation Manual

INSTALLATION AND

OPERATION MANUAL

GAS FRYER

MODEL 35-280

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1009012 (12/07) © 2005 Garland Commercial Industries, Inc.

Part # 1009012 Rev 9 (12/07) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

NOTE: Before leaving the factory, the fryer was tested with oil in the frypot; therefore, it is necessary to clean the frypot

before adding frying compound. Rinse the frypot with clean water, then put some fryer cleaner on a damp cloth, full

strength, and wipe the entire frypot clean. Rinse it thoroughly and wipe dry. The fryer is now ready for use. If the fryer

does not have a stainless steel frypot and is not to be used immediately after cleaning, coat the entire frypot surface

with shortening or cooking oil to prevent rusting.

Part # 1009012 Rev 9 (12/07)Page 2

TABLE OF CONTENTS

Contents

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pre-Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Clearances: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Frypot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Ventilation and Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Radiation Shield and Flue Riser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using the fryer for the rst time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Stand By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Complete Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety Concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Optimum Operation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Suggestions for Quality Fried Food . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Routine Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Painted Finishes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Draining and Filtering Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ADJUSTMENTS AND TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Thermostat Calibration Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Part # 1009012 Rev 9 (12/07) Page 3

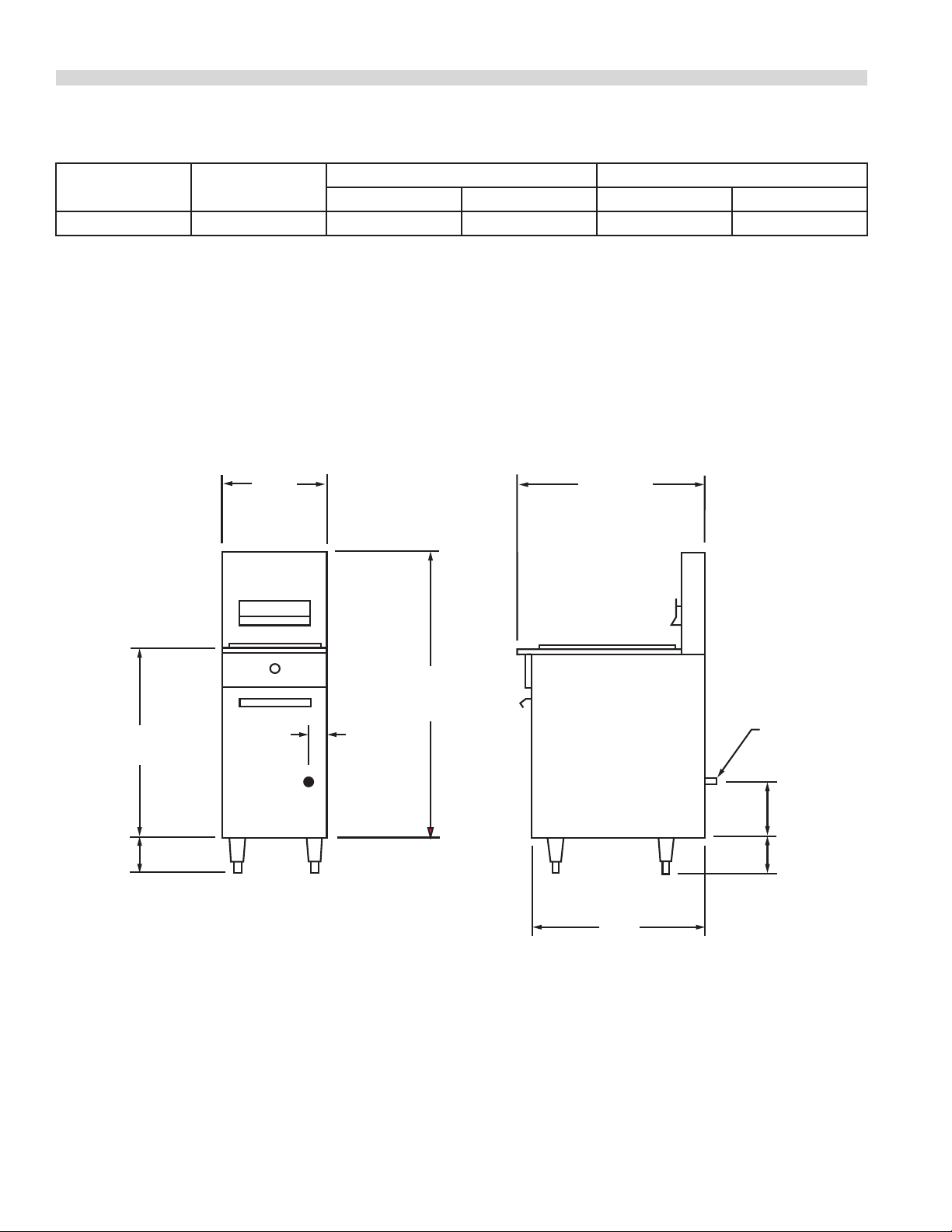

DIMENSIONS AND SPECIFICATIONS

31-1/4"

[794mm]

9-1/4"

[235mm]

6"

[152mm]

29"

[737mm]

3/4" N.P.T.

GAS INLET

17"

[432mm]

31-3/8"

[797mm]

6"

3"

[76mm]

47-3/8"

[1203mm]

Model 35-280

MODEL # OF BURNERS

35-280 9 #51 110,000 #57 110,000

Operating Gas Pressure: Natural: 4.0” w/c, Propane: 9.0” w/c

Orice Input Orice Input

NATURAL PROPANE

Part # 1009012 Rev 9 (12/07)Page 4

INSTALLATION

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product has been certied as commercial cooking

equipment and must be installed by professional personnel

as specied.

Pre-Installation Instructions

Before assembly and connection check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located on inner door panel. Connect

a unit stamped “NAT” only to natural gas; connect those

stamped “PRO” only to propane gas.

B. If it is a new installation have the gas authorities check

meter size and piping to assure that the unit is supplied

with sucient amount of gas pressure required to

operate the UNIT.

C. If it is additional or replacement equipment have gas

authorities check pressure to make certain that existing

meter and piping will supply fuel to the unit with not

more than 1/2” water column pressure drop.

NOTE: When checking gas pressure be sure that all other

equipment on the same gas line is on.

NOTE: The appliance and its individual shut-o valve (not

supplied by manufacturer) must be disconnected from

the gas supply piping system during any pressure testing

of that system at pressures in excess of 1/2 PSIG (3.45

kP2). The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-o (not

supplied by manufacturer) during any testing of the gas

supply piping system at test pressures equal to or less than

1/2 PSIG 3.45 kP2).

NOTE: In Canada, the installation shall be in accordance

with CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE

or CAN/CGA-B149.2 PROPANE GAS INSTALLATION CODE and

local codes where applicable.

NOTE: Adequate clearance must be provided for servicing

and proper operation.

NOTE: Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

The importance of proper installation of commercial

gas cooking equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

specications. In addition, compliance with the National

Fuel Gas code ANSIZ223.1-1988/NFPA and/or Local code is

required to assure safe and ecient operation.

Appliances shall be installed in a location in which the

facilities for ventilation permit satisfactory combustion of gas

and proper venting. Appliances shall be located so as not to

interfere with proper circulation of air within the conned

space. When buildings are so tight that normal inltration

does not provide the necessary air, outside air shall be

introduced.

Casters

A pressure regulator is supplied as standard equipment

with GARLAND Restaurant Series Gas Fryers. The pressure

regulator is “built-in” to the fryer, (the regulator is part of the

combination safety valve). Installation must conform with

the national Fuel Gas code ANSI Z223.1-1988 or latest edition

NFPA No. 54 – Latest Edition and National Electrical Code

ANSI/NFPA 70-1990 or latest edition and /or local code to

assure safe and ecient operation.

Part # 1009012 Rev 9 (12/07) Page 5

A. The installation shall be made with a connector that

complies with tthe Standard for Connectors for Movable

Gas Appliances, ANSI Z21.69 /CSA 6.16, and a quickdisconnect device that complies with the Standard for

Quick-Disconnect Devices for Use With Gas Fuel, ANSI

Z21.41 / CSA 6.9..

Loading...

Loading...