Page 1

Document 502-20-0149-001 iss1, Mar 2015, CN36575-041

Installation and User Guide

Auteldac 5

Zone 1 Ex Certified

Hazardous Area Telephone

GAI-TRONICS

A Division of Hubbell Ltd

Page 2

1 Auteldac 5

CONTENTS

1

SAFETY INFORMATION .............................................................. 2

2

PRODUCT DESCRIPTION ........................................................... 3

2.1

FEATURES ................................................................................... 4

3

INSTALLATION ............................................................................. 5

3.1

Dimensions .................................................................................... 5

3.2

Pre- installation .............................................................................. 5

3.3

Mounting Methods ......................................................................... 8

3.4

Connections and Cabling ............................................................ 10

3.5

Option Settings ............................................................................ 18

3.6

Reassembling the telephone enclosure ...................................... 20

4

OPERATION ............................................................................... 23

4.1

Keypad functions (18-button versions only) ................................ 24

4.2

Headset Operation ...................................................................... 25

5

MAINTENANCE .......................................................................... 26

5.1

Procedures .................................................................................. 26

5.2

Possible Operating Faults ........................................................... 26

5.3

Fault Finding & Field Repairs ...................................................... 27

6

TECHNICAL SPECIFICATIONS ................................................. 27

6.1

Hazardous Area Certification ...................................................... 27

6.2

Regulatory Compliance and Related Standards ......................... 29

6.3

Physical characteristics ............................................................... 32

6.4

Environmental specifications ....................................................... 32

6.5

Recycling information. ................................................................. 33

Page 3

Auteldac 5 2

1 SAFETY INFORMATION

▲

IMPORTANT

:

ALL POSSIBLE MEASURES MUST BE TAKEN TO ENSURE

WATER, FLUID OR DUST DOES NOT CONTAMINATE THE

INTERNAL COMPONENTS OF THIS TELEPHONE WHILST

UNPACKING, PREPARING OR INSTALLING IT, OR BY

NEGLIGENCE.

FAILURE TO OBSERVE THIS PRECAUTION WILL INVALIDATE

CERTIFICATION AND YOUR WARRANTY

▲

Please read these instructions thoroughly before starting

installation. These products must be installed by competent

personnel familiar with the hazardous area regulations, as well

as electrical and telephone installations.

▲

The case must not be opened in the hazardous area unless all

connections are isolated outside the hazardous area.

▲

All glands and blanking plugs must be fitted with appropriate

seals to maintain the required IP rating.

▲

CAUTION: small

metal objects may stick to the handset: please

check before use

▲

Some versions of this product are supplied with long handset

or headset cables, which could present a trip hazard. Therefore

care must be taken when using the handset/headset at extended

distances, so that personnel or equipment in the vicinity are not

impeded, trapped or entangled by the cord. Also, care must be

taken to stow these long cord handset/headsets so they do not pose

an entanglement or tripping hazard.

▲

Noise level hazard.

The telephone ringer can develop a sound

level in excess of 90dBA @ 1 metre. Therefore, it is the installer’s

responsibility to take the necessary measures to comply with any

applicable regulations, for example the European directive

2003/10/EC on the minimum health and safety requirements

regarding the exposure of workers to the risks arising from physical

agents (noise).

Page 4

3 Auteldac 5

2 PRODUCT DESCRIPTION

Auteldac 5 Hazardous Area Telephone at a glance

Rear case

Front case

Ringer

Handset

Keypad

Main PCB

User

terminals

Gland

entries

Page 5

Auteldac 5 4

2.1 FEATURES

Auteldac 5 is an Ex certified telephone built to withstand arduous

industrial atmospheres and environmental extremes. Features include:

• IEC Ex zone 1 certified for safe operation in hazardous areas

• Carbon loaded glass filled polyester body - rugged and corrosion

free.

• Weather resistant up to IP66

• Rugged handset with curly cord or armoured stainless steel cord.

• Noise-cancelling handset option

• Magnetic hook-switch with no external moving parts

• Selectable Timer – can be set to go back on hook after 7 minutes

• Integral 90dBA ringer with volume adjustment.

• Selectable dial and recall modes

• Integral ring relay to activate external devices (see below)

• Integral hook relay to activate external devices (see below)

• Parallel telephone line connection terminal block

• One touch dial memories (18 button version only)

• Hearing aid compatible inductive coupling as standardLarge, silicone

rubber pushbuttons with alphanumeric keys

• Available in keypad (18 button) and no- keypad (hotline) versions

• Headset option available

Page 6

5 Auteldac 5

3 INSTALLATION

Please read all these instructions thoroughly before starting installation.

3.1 Dimensions

Four 7mm-clearance holes in the Rear Casing (outside the environmental

seal) allow it to be screwed or bolted to a wall, or to a pole-side mounting kit

(part no 100-02-0208-001).

The holes are arranged in a rectangle, as follows -

• Horizontal separation between centres: 145.0mm (5.7in)

• Vertical separation between centres: 270.0mm (10.6in). The lower pair

are about 10mm (0.4in) up from the bottom edge of the unit.

Handset cord lengths:

Standard curled cord: 320mm extending to 1m (13 to 39in).

Standard stainless steel cord: 755mm (29.7in).

Other cord lengths are available as special options: contact GAI-Tronics for

details.

3.2 Pre- installation

The Auteldac 5 telephone is connected by hard-wiring - (unlike a plug

and socket on internal telephones). Because of this, installation must

Page 7

Auteldac 5 6

be carried out by trained personnel. Contact GAI-Tronics if installation

service is required.

The telephone is supplied suitable for vertical mounting only. Before

installing the unit, please take note of the following:

• Glands. Glands are not supplied. All glands and cables should

comply with IP54 or better to meet ‘Increased Safety’ (‘e’ type)

requirements. Only ‘e’ type glands and suitable cables should be

used and must be fitted correctly. Note that the environmental

rating of the telephone will not exceed that of the glands, i.e. in

order to maintain an IP66 rating, glands must also meet IP66.

• Headset versions – Earth connection. If fitted with a headset

socket, the unit must be connected to an equipotential bonding

system for the whole area in which the intrinsically safe equipment

is being used. See section 3.4.2 for details.

• Cable entries - Auteldac 5 has 2 cable entry gland positions.

Before installing, give consideration to the options available and

review the alternative connection schemes in section 3.4.8 to

ensure that the required connections can be made using the

available glands.

If a high voltage is connected to the relay contacts (for example to

activate a mains-powered beacon) then that cable must be

segregated from all other cables and routed through its own gland.

Upon installation care should be taken to ensure that incoming

cables are cleanly routed with a view to maintaining segregation

between hazardous voltage cabling and the telephone's internal

wiring (i.e. handset, hookswitch, ringer and headset if fitted).

ALL POSSIBLE MEASURES MUST BE TAKEN TO ENSURE

WATER, FLUID OR DUST DOES NOT CONTAMINATE THE

INTERNAL COMPONENTS OF THE TELEPHONE WHILST

UNPACKING, PREPARING AND INSTALLING IT IN INCLEMENT

WEATHER CONDITIONS OR BY NEGLIGENCE.

FAILURE TO TAKE THIS PRECAUTION WILL INVALIDATE YOUR

WARRANTY AND CERTIFICATION

The telephone body must NOT be opened, nor glands removed or

cables disconnected unless all supplies to the telephone, including

telephone line cables, power cables and external devices have been

isolated outside the hazardous area. Terminals for incoming cables are

‘e’ type and must be carefully connected so as to make an ‘e’ type

termination.

Page 8

7 Auteldac 5

The Code of Practice for ‘e’ type enclosures is specified in IEC60079-

14. The installer and all service personnel should be familiar with the

relevant sections of these documents.

If only one gland entry is used, the black Ex e sealing plug must be

fitted to the unused entry.

1. Place the telephone on its base on a firm horizontal surface.

2. Using a 5mm Allen key, release the Front Casing from the Rear

Casing. The screws are not captive in the Front Casing.

3. Noting their positions, disconnect the ribbon cable(s) and the ringer

cable from the front section. See 3.6.

4. Take care when removing the Front Casing from the Rear Casing

and storing the Front Casing not to damage the internal electronics,

specifically the headset switch terminals or headset socket if fitted.

To do so will violate the certification of the telephone product.

5. Check the condition of the sealing gasket (in the recess running

round the edge of the front section), especially if the telephone has

been previously used. If this seal shows any sign of damage or

deterioration, it must be replaced prior to installing the telephone.

6. Remove the RED blanking plug from the cable entry hole leaving the

Ex e certified (usually BLACK) blanking plug in situ.

NOTE: The Ex e plug must be used to seal the unused gland

hole; failure to do so will invalidate the certification of the

telephone product.

7. Select the appropriate size Ex gland for the cable used.

8. Take care when inserting the selected gland into the threaded cable

entry hole. Follow the gland manufacturer’s instructions particularly

with respect to sealing, installation and earthing.

9. After the glands have been fitted, select the required mounting

method and follow the appropriate instructions below.

Page 9

Auteldac 5 8

3.3 Mounting Methods

3.3.1 Wall Mounting

To ensure weatherproof integrity when wall mounted, external cables

should enter the enclosure from the bottom via the two 20mm gland

entries provided.

IMPORTANT WARNING:

DO NOT DRILL ANY EXTRA HOLES AS THIS WILL INVALIDATE

YOUR WARRANTY AND THE CERTIFICATION.

1. Remove rubber feet from the Rear Casing if fitted. Ensuring that the

cable entries are at the bottom, offer the Rear Casing up to the

vertical surface and mark through the fixing holes.

Do not use the Rear Casing as a template to drill the holes.

Work only from the marked positions.

2. Drill the holes in the vertical surface to suit the best method of fixing.

3. Ensure the Rear Casing is securely attached to the vertical surface

using the four 7mm diameter screw holes provided. No sealing

washers are necessary.

IMPORTANT: Do not use countersunk headed fixing screws. Only

use round head, socket cap head or pan head screws. Take care not

to over tighten the screws as doing so may damage the case and

will invalidate your warranty and the certification.

4. Remove the terminal cover to allow access to the cable glands and

terminals. Retain the cover to refit prior to putting the telephone into

use.

5. Pass the cable through the gland and tighten, following the gland

manufacturer’s instructions.

6. Continue the installation procedure with the connection of individual

wires from the cable as described under sections 3.4 onwards.

Page 10

9 Auteldac 5

3.3.2 Pole-side Mounting

Kit No 100-02-0208-001

This accessory kit is for mounting GAI-Tronics telephones on to the side

of round poles of 100mm to 200mm diameter, or on to square or

rectangular section uprights of 100mm to 150mm across the mounting

surface. For flat mounting on surfaces greater than 150mm across use

the wall mounted method.

Pole side mounting

NOTE:

Banding straps (large scale worm-drive clamps) are not included in this

kit and must be obtained separately. For details of where mounting kits

can be obtained, refer to GAI-Tronics .

1. Remove rubber feet from the Rear Casing if fitted. Attach the pole

mounting clamp assemblies to the Rear Casing using the M6 x 25

screws provided. Tighten to a torque of 4.5Nm max.

IMPORTANT: avoid the use of power tools. Spinning the nuts too

quickly can cause a rapid increase in heat which can cause the nuts

to seize as a result of galling or cold-welding.

2. Ensuring that the glands are at the bottom, pass a proprietary

banding strap round each of the pole mounting clamps and the

support pole. Tighten securely.

3. Remove the terminal cover to allow access to the cable glands and

terminals. Retain the cover to refit prior to putting the telephone into

use.

4. Continue the installation procedure with the connection of individual

wires from the cable as described under sections 3.4 onwards.

5. Secure the telephone Front Casing to the Rear Casing.

6. Re-tighten the straps firmly and trim off any excess band material.

For security the driving head of the band may also be sawn off.

Page 11

Auteldac 5 10

3.4 Connections and Cabling

IMPORTANT WARNING:-

ISOLATE MAINS AND TELEPHONE LINE OUTSIDE THE

HAZARDOUS AREA BEFORE OPENING THE CASE.

ALL TERMINALS MUST BE CONNECTED IN ACCORDANCE WITH

THIS INSTALLATION GUIDE. ANY DEVIATION FROM THIS MAY

RESULT IN AN UNSAFE INSTALLATION AND VIOLATE THE

CONDITIONS OF THE CERTIFICATION.

The connections to the Auteldac 5 are made via 2 terminal blocks below the

main PCB. The cabling between the entry glands and the terminal blocks is

covered by a terminal cover, secured by 2 screws as shown. Remove this

cover to allow access to the terminals.

The terminal cover must be secured in place before re-assembling the

telephone prior to use. The terminal cover provides the required isolation

between the cabling in the rear section and the circuitry in the front section

and is critical to the product's certification.

Terminal cover

screws

Terminal blocks

Terminal cover

Page 12

11 Auteldac 5

3.4.1 Connection to the Telecommunications Network

The telephone line is connected to the terminals marked A and B as

shown on the terminal cover. The terminals marked “TE” are for

connection to a telecommunications earth – an optional connection

back to the PABX to allow ELR (Earth Leg Recall) to function if

required.

There are two sets of telephone line terminals – connected in

parallel to allow the connection of other approved equipment in

parallel with Auteldac 5 without the need for a junction box. Note

that the order of terminals is reversed between the two sets. The two

sets of terminals are interchangeable.

To maintain safe operation of this product the telephone line must

not exceed the following:

• Um = 253V rms

• Rated voltage on hook = 70Vdc + Ring Voltage, where the

maximum ring voltage can be either:

• 70V rms if continuous, or

• 100V rms if cadenced with a duty cycle having a

maximum on time of 50%

Note: ring voltage maximum frequency is 60Hz

• Rated voltage off hook = 40V

• Maximum power = 15W (in accordance with EN60950-1

Clause 1.4.11 and 1.2.13.8)

Note: these are safety parameters only and correct operation under

these conditions is not implied.

For correct operation the telephone line should comply with the

following:

Page 13

Auteldac 5 12

• Ring Voltage: 30V to 100V rms, 20Hz to 50Hz

• Line voltage 20 to 70 Vdc

• Loop current ≥ 15mA

3.4.2 Earth Connection (Headset Version Only)

IMPORTANT: If fitted with a headset socket, Auteldac 5 must be

connected to an equipotential bonding system for the whole area in

which the intrinsically safe equipment is being used.

Versions with a headset socket are supplied with earth studs and

link wires, and must be connected to earth as shown.

This earth connection is a condition of the certificate for headset

versions.

3.4.3 Gland continuity connection

Auteldac 5 is provided with 2 earth bonding screws which can be

used as a continuity connection between glands if 2 metal glands

are used. If the unit does not have a headset socket, reverse one of

the earth bonding screws as shown below, paying particular

attention to the sequence of nuts and washers fitted, to provide an

external continuity point.

If the unit is fitted with a headset socket, one of the earth bonding

screws will already be in this position, (see above) in which case this

screw can be used for gland continuity as well.

3.4.4 Ring Relay Contact

(Galvanically isolated, volt-free contact)

The connection from the telephone to the external load must be

installed such that the apparatus continues to comply with the

requirements of EN 60950-1.

Page 14

13 Auteldac 5

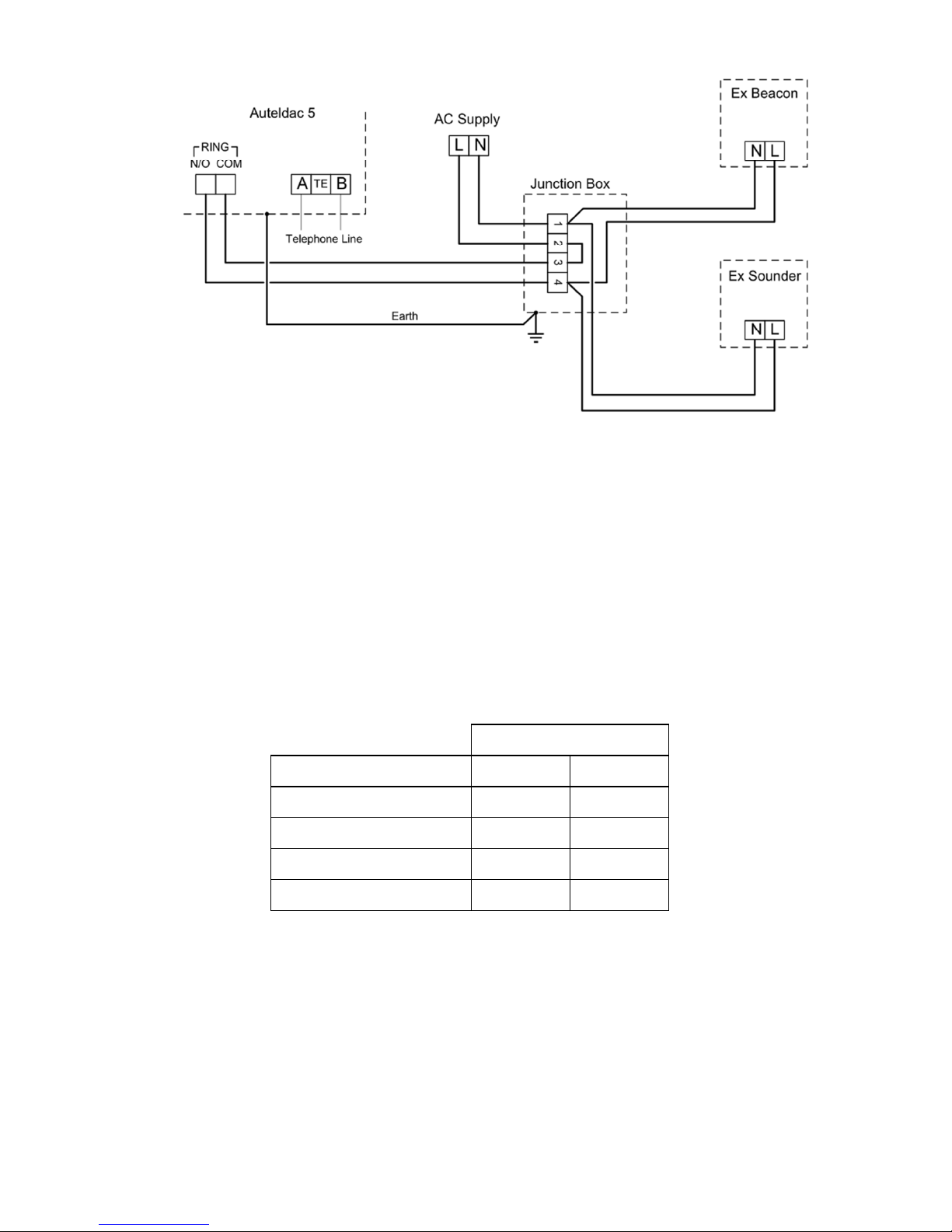

Typical connection scheme for a beacon and sounder

CONTACT RATING:

Maximum voltage = 250V rms (nominal 230V)

Maximum current = 3A rms

Note: no fusing or transient protection is provided; this must be

installed externally.

Note: The minimum ring voltage required to operate the ring relay

depends on the frequency of the ring signal and the loudness setting

of the Auteldac 5 ringer. Approximate minimum values for ring

voltage (in V rms) for each case are shown in the table below:

Ring frequency

Volume setting 50Hz 25Hz

Quiet

35 39

Medium

36.5

40

Loud

39 46

V.Loud

54.5

62

The relay fitted to the Auteldac 5 has a continuous current rating of

3A. It has been brought to our attention that some beacons, whilst

having a current rating well below this figure, actually generate

current spikes far in excess of this during making and breaking of the

relay contacts. These current spikes can cause the relay contacts to

fail.

GAI-Tronics have been working closely with a leading beacon

manufacturer to resolve this issue and our recommendations are:

Page 15

Auteldac 5 14

• Restrict the use of beacons to non AC variants only or those

with a maximum flash intensity of 5 joules.

• Where beacons with greater than 5 joule flash intensity are

required, the beacons should be purchased directly from GAITronics, who will ensure compatibility with the Auteldac 5 and

that certification parameters are not compromised.

3.4.5 Hook Switch State Indicator Contact

(Optically isolated, volt-free contact)

The connection from the telephone to the hook switch state indicator

must be installed such that the apparatus continues to comply with

the requirements of EN 60950-1

Maximum voltage = 250Vrms

Maximum current = 150mA rms

Note: no fusing or transient protection is provided; this must be

installed externally.

3.4.6 Headset

If a headset socket is fitted, a suitable, certified headset may be

connected as follows:

The headset socket is defined with the following apparatus terminal

parameters:

Vo = 8.51V

Io = 0.414A

Po = 0.673W

Ci = 0.6µF

Li = negligible

The capacitance and either the inductance or inductance to

resistance ratio (L/R) of the load connected to the hazardous area

terminals for the headset must not exceed the following values:

Group Capacitance Inductance or L/R ratio

(µF) (mH) (µH/Ω)

IIC 5.3 0.1 15

IIB 499 0.41 61

IIA 1000 1.6 240

The above load parameters apply where:

Page 16

15 Auteldac 5

1. The external circuit contains no combined lumped

inductance Li and capacitance Ci greater than 1% of the

above values, or

2. The inductance and capacitance are distributed as in a

cable, or

3. The external circuit contains either only lumped inductance

or lumped capacitance in combination with a cable

In all other situations e.g. the external circuit contains combined

lumped inductance and lumped capacitance, up to 50% of each of

the L and C values is allowed.

The headset must only be used in accordance with the

manufacturer’s instructions supplied with it.

3.4.7 Optional Headset Extension lead

A separate headset extension lead is available as an optional extra,

allowing the operator to extend the headset cord by up to a further 4

metres. Note: Refer to section 1 for hazard warnings regarding long

corded Headsets & handsets.

3.4.8 Alternative cabling schemes

Depending on the options used, different cabling permutations are

possible; some examples are shown below.

Upon installation care should be taken to ensure that incoming

cables are cleanly routed with a view to maintaining segregation

from the telephone's internal wiring (i.e. handset, hookswitch, ringer

and headset if fitted). Segregation must also be maintained between

telephone line and cables to the contacts.

For clarity, the illustrations below are shown with the terminal cover

removed.

The terminal cover must be secured in place before reassembling the telephone prior to use. The terminal cover

provides the required isolation between the cabling in the rear

section and the circuitry in the front section and is critical to the

product's certification.

Page 17

Auteldac 5 16

The telephone line terminals can be used to connect approved

apparatus in parallel as shown below:

B TE A

Single telephone line connection

(with optional telecom earth)

B TE A

Single telephone line connection

(with optional telecom earth),

showing earth bond connection

for headset version.

PABX Other apparatus PABX Other apparatus

Alternative options for using the parallel line terminals for connecting other

approved apparatus in parallel with Auteldac 5 – using a multiple pair cable

fed through one gland or alternatively using separate cables each fed through

its own gland. Earth continuity connection between glands shown.

Page 18

17 Auteldac 5

For clarity, all the illustrations above are shown with the terminal

cover removed.

The terminal cover must be secured in place before reassembling the telephone prior to use. The terminal cover

provides the required isolation between the cabling in the rear

section and the circuitry in the front section and is critical to the

product's certification.

HOOK RING PABX Other apparatus

Example showing both the HOOK and RING contacts in use as well as a

parallel line connection. Note that the cabling to the contacts is fed through a

separate gland to the telephone line cable. Earth continuity connection

between glands is also shown.

Page 19

Auteldac 5 18

3.5 Option Settings

Auteldac 5 has three functions that have optional settings (Australian

versions have a fourth option setting in addition). These are set using

DIP switches on the internal circuit boards as described below.

The telephone casing must be open to set these options.

ISOLATE MAINS AND TELEPHONE LINE OUTSIDE THE

HAZARDOUS AREA BEFORE OPENING THE CASE.

3.5.1 Ringer Loudness

Ringer loudness is set by SW1 on the keypad PCB as follows:

V.LOUD (>90dBA) SW1-1 ON

LOUD (approx. 85dBA) SW1-2 ON

MEDIUM (approx. 75dBA) SW1-3 ON

QUIET (approx. 65dBA) all switches OFF

Any setting is overridden by any louder one, eg if SW1-1 is

ON the ringer will be v.loud regardless of whether any other

switches are on or not.

IMPORTANT WARNING: Ringer high noise level hazard:

Note: the telephone ringer can develop a sound level in

excess of 90dBA @ 1 metre. Therefore, it is the installer’s

responsibility to take the necessary measures to comply with

any applicable regulations, for example the European directive

2003/10/EC on the minimum health and safety requirements

regarding the exposure of workers to the risks arising from

physical agents (noise).

Main Ribbon

Cable

Ringer cable to

Rear section

Page 20

19 Auteldac 5

3.5.2 Recall Mode

Recall mode is set by switches 1 & 2 of SW2 on the keypad

PCB as follows, being either a timed-break recall (TBR) with

one of 3 durations, or earth leg recall (ELR):

SW2-1

OFF ON

SW2-2

OFF 100ms 250ms

ON 600ms ELR

3.5.3 Dialling method

Dialling method is selected by switches 3 & 4 of SW2 on the

keypad PCB as follows:

ON OFF

SW2-3

Tone dialling

(87ms/87ms

burst/pause

time)

Pulse dialling

10pps, mark

space ratio

set by SW2-4

SW2-4

Pulse dialling,

make/break

33ms/66ms

Pulse dialling,

make/break

40ms/60ms

3.5.4 Call Timer

The call timer is set by SW3 on the keypad PCB as follows:

SW3-1

OFF ON

No call timer

Call will terminate

after 7 minutes.

Page 21

Auteldac 5 20

3.5.5 Line impedance (Australian version only)

For Australian versions, the line impedance is set by SW1 on

the main (encapsulated) PCB in the rear section as follows:

Impedance

600Ω Z-Complex

SW1-4 OFF ON

SW1-3 - -

SW1-2 ON OFF

SW1-1 ON OFF

3.6 Reassembling the telephone enclosure

1. Check the condition of the sealing gasket (in the recess running round

the edge of the front section), especially if the telephone has been

previously used. If this seal shows any sign of damage or

deterioration, it must be replaced prior to installing the telephone.

2. Reconnect the internal cable(s) from the Rear Casing to the Front,

making sure each connector is correctly orientated. There is a keyway

on each connector to help. Do not forcibly fit the connector(s).

IMPORTANT – FAILURE TO ENSURE THE CORRECT

ORIENTATION OF THE CONNECTOR(S) WILL VIOLATE THE

CONDITIONS OF THE CERTIFICATION

Factory

setting only

– do not

change

SW1

Impedance

setting

Page 22

21 Auteldac 5

Internal cable positions

Versions with no headset socket

Versions with headset socket

NOTE: earth straps and smaller ribbon cable are only fitted on versions which

have a headset socket.

3. Upon installation, care should be taken to ensure that incoming cables

are cleanly routed with a view to maintaining segregation from the

Page 23

Auteldac 5 22

telephone's internal wiring (i.e. handset, hookswitch, ringer and

headset switch / socket if fitted).

4. Ensure that the terminal cover is fitted. The terminal cover provides

the required isolation between the cabling in the rear section and the

circuitry in the front section and is critical to the product's certification.

5. Offer the Front Casing to the Rear Casing, with the internal cables

arranged as shown above; ensure that the cable(s) will not be trapped

when the Front Casing is tightened down. Take care that the large

ribbon cable can lay flat and that the insulation can not become

damaged.

IMPORTANT - DAMAGED INSULATION WILL VIOLATE THE

CONDITIONS OF THE CERTIFICATION.

6. Tighten the three screws firmly to secure the front case to the rear.

7. Auteldac 5 is now ready for use.

Page 24

23 Auteldac 5

4 OPERATION

Note that features may vary according to the model supplied.

• To make a call, lift the handset, wait for dial tone, dial required digits

(or press required memory button or Last Number Redial where

fitted) and wait for connection.

• For CB versions (i.e. no buttons are fitted)with no buttons, no dialling

is possible – the call must be connected by the exchange sensing

the telephone off hook.

• To end a call, replace the handset in its cradle.

• To receive a call, lift the handset when ringing is heard.

• Take care, when using either the handset or optional headset, not to

allow cables to tangle or snare around the body or neck.

Memory

buttons

Numeric

keypad

Store

button

Recall

button

Headset

Panel.

Last

Number

Redial

Page 25

Auteldac 5 24

4.1 Keypad functions (18-button versions only)

Last Number Redial

Press LR to redial the last dialled number.

Recall Function

Press R to send a “recall” signal to the exchange. The type of recall

can be selected (see section 3.5.2).

Programming

The three memory buttons, M1, M2 and M3 may each be programmed

with up to 17 digits for one touch memory dialling.

The telephone needs to be connected to a telephone line (ie powered)

to program it, and the case does not need to be opened, so it can be

programmed in the hazardous area.

To program a number:

• Lift the handset

• Press S

• Enter the required digits

• Press S again

• Press the required memory button, M1, M2 or M3

• Replace the handset

Page 26

25 Auteldac 5

4.2 Headset Operation

(refer to section 1 for hazard warning)

The Auteldac 5 can be supplied fitted with a headset panel, permitting

hands-free operation using a suitable, certified headset.

To use:

1. Insert headset plug into marked connector, observing keyway.

2. To make or answer a call, turn the switch to the ‘I’ position.

3. To terminate the call, turn the switch to the ‘0’ position.

To remove the headset, pull the body of the connector to release the

latching mechanism. Do not attempt to disconnect the headset by

pulling the cable as damage may result. A dust cover is provided.

Ensure that the dust cover is fitted to protect the socket when not in

use.

NOTE: If the handset is lifted during a call using the headset, the handset

microphone will be muted. The handset can be used normally if a call is not

in progress via the headset.

The headset must be used in accordance with the manufacturer’s manual

(supplied with headset).

Page 27

Auteldac 5 26

The headset interface of the Auteldac 5 has been certified as intrinsically

safe. Therefore, it is permissible to connect and disconnect the headset in a

hazardous area.

5 MAINTENANCE

The Auteldac 5 is based on highly reliable integrated circuits.

Under normal operation, the telephone is maintenance free.

5.1 Procedures

A programme of regular external visual inspection and cleaning is

recommended, with particular attention being paid to -

On all models:

•

Overall cleanliness of the telephone:

Wipe clean as necessary with a cloth dampened with clear water.

If heavily soiled, a little dishwashing liquid may be used in addition.

NOTE: high pressure hoses should not be used for cleaning.

•

Security of the installation on wall, pole or post.

•

Security and integrity of cable entries.

•

Security of the three body screws.

•

Cleanliness, integrity and condition of the handset:

Wipe clean as necessary with a cloth dampened with clear water,

and disinfect the handset.

Note that the handset has an anti-static coating – take care not to

damage this by excessive rubbing or the use of chemicals or

solvents (e.g. petroleum spirit). Do not allow liquid to penetrate the

earpiece or mouthpiece.

•

Security and condition of the handset cable.

On headset models, refer to headset manufacturer’s manual for

cleaning, hygiene and maintenance of headset.

5.2 Possible Operating Faults

The following operating and installation conditions could give rise to faults.

During installation, or in the event of a fault, please ensure that the following

do not occur:

• Water ingress

• Incorrect positioning of internal cables (Section 3.6)

• Damage to any internal components

• Overstressing of screws

• Insecure fixing

Page 28

27 Auteldac 5

• Incorrect installation of glands (Section 3.2)

• Incorrect wiring or cable connections (Section 3.4)

• Improper reassembly following connection

• Additional holes drilled in casing

5.3 Fault Finding & Field Repairs

The Auteldac 5 contains no user serviceable parts and in the event

of damage or failure must be replaced with a tested telephone of

the correct type.

Refer to section 5.2 for a list of possible fault conditions.

6 TECHNICAL SPECIFICATIONS

6.1 Hazardous Area Certification

It is the responsibility of the installer or user to determine whether or not

Auteldac 5 is suitable for use in a given location or particular

circumstances.

6.1.1 Dust Certification

Certain models (only those fitted with curly cord handsets and with no

headset connector) are certified for use in the presence of combustible

dust. These models have a YELLOW certification label, whereas gasonly models have a BLUE certification label. Certification details are

listed below.

6.1.2 IEC Ex Certification

Certificate number: IECEx BAS 14.0165

Certification details:

Gas certified variants (BLUE certification label):

Ex e ib mb IIC T4 Gb (-20°C ≤ Ta ≤ +60°C)

Ex e ib mb IIC T5 Gb (-20°C ≤ Ta ≤ +50°C)

Gas & Dust certified variants (YELLOW certification label):

Ex e ib mb IIC T4 Gb (-20

°

C ≤ Ta ≤ +60°C)

Ex e ib mb IIC T5 Gb (-20°C ≤ Ta ≤ +50°C)

Page 29

Auteldac 5 28

Ex ib tb IIIC T180°C Db (-20°C ≤ Ta ≤ +60°C)

A copy of the IECEx certificate is available from www.gai-tronics.co.uk.

6.1.3 ATEX Hazardous Area Certification

Certificate number: Baseefa14ATEX0362

Certification details:

Gas certified variants (BLUE certification label):

II 2 G Ex e ib mb IIC T4 Gb (-20°C ≤ Ta ≤ +60°C)

Ex e ib mb IIC T5 Gb (-20°C ≤ Ta ≤ +50°C)

Gas & Dust certified variants (YELLOW certification label):

II 2 GD Ex e ib mb IIC T4 Gb (-20°C ≤ Ta ≤ +60°C)

Ex e ib mb IIC T5 Gb (-20°C ≤ Ta ≤ +50°C)

Ex ib tb IIIC T180°C Db (-20°C ≤ Ta ≤ +60°C)

Standards:

IEC 60079-0: 2011

Edition: 6

Explosive atmospheres - Part 0: Equipment -

General requirements

IEC 60079-7: 2006

Edition: 4

Explosive atmospheres - Part 7: Equipment

protection by increased safety 'e'

IEC 60079-11:2011

Edition: 6

Explosive atmospheres - Part 11: Equipment

protection by intrinsic safety 'i'

IEC 60079-18 : 2009

Edition: 3

Electrical apparatus for explosive gas

atmospheres - Part 18: Construction, test and

marking of type of protection encapsulation 'm'

electrical apparatus

Additionally, dust certified variants certified to:

IEC 60079-31:2013

Edition: 2

Explosive atmospheres Part 31: Equipment

dust ignition protection by enclosure "t"

Page 30

29 Auteldac 5

A copy of the ATEX certificate is available from www.gai-tronics.co.uk.

6.2 Regulatory Compliance and Related Standards

Auteldac 5 is fully compliant with the following:

6.2.1 European Directives:

94/9/EC

Equipment and protective systems intended for

use in potentially explosive atmospheres

(ATEX) Directive

(See certification details below).

1999/5/EC Radio Equipment and Telecommunications

Terminal Equipment (R&TTE) Directive.

2011/65/EC Restriction of the use of certain hazardous

substances in electrical and electronic

equipment (recast) (RoHS 2) Directive

Standards:

EN60079-0:2012 Electrical apparatus for explosive gas

atmospheres Part 0: General

requirements.

EN60079-7:2007 Electrical apparatus for explosive gas

atmospheres Part 7: Increased safety

‘e’.

EN60079-11:2012 Electrical apparatus for explosive gas

atmospheres Part 11: Protection by

intrinsic safety ‘i’.

EN60079-18:2009 Electrical apparatus for explosive gas

atmospheres Part 18: Construction, test

and marking of type of protection

encapsulation ‘m’ electrical apparatus.

Additionally, dust certified variants certified to:

EN60079-31:2014 Explosive atmospheres Part 31:

Equipment dust ignition protection by

enclosure "t"

Page 31

Auteldac 5 30

6.2.1.1 CE Declaration of Conformity

Page 32

31 Auteldac 5

6.2.2 EMC

EN55022

(Class B)

Information technology equipment. Radio disturbance

characteristics.

EN55024 Information technology equipment. Immunity

characteristics

6.2.3 Telephony standards (European)

ETSI TBR21 Terminal Equipment (TE);

Attachment requirements for pan-European approval

for connection to the analogue Public Switched

Telephone Networks (PSTNs) of TE (excluding TE

supporting the voice telephony service) in which

network addressing, if provided, is by means of Dual

Tone Multi Frequency (DTMF) signalling

ETSI TBR38 Public Switched Telephone Network (PSTN);

Attachment requirements for a terminal equipment

incorporating an analogue handset function capable of

supporting the justified case service when connected

to the analogue interface of the PSTN in Europe

6.2.4 Australian standards

Australian versions of Auteldac 5 are compliant with the following:

EMC AS/NZS CISPR 22 – Information technology

equipment – Radio disturbance

characteristics – Limits and methods of

measurement

Safety IEC 60950-1 (Including AS/NZS 60950.1

deviations) – Specification for information

technology equipment, including electrical

business equipment.

IEC 60950-22 - Equipment installed

outdoors

Telephony AS/ACIF S002 – PSTN Interface testing

AS/ACIF S004 – Acoustic testing

Page 33

Auteldac 5 32

6.2.5 Other standards and testing

Suitable for inductively coupling to Hearing Aids

having a `T' switch position. Use of this facility for

any other purpose than that for which it was

intended may cause degradation in quality of a

connection.

Tested to ETS 300-381

The GAI-Tronics Quality Management System has

been approved by LRQA to ISO9001.

Certificate No. 861888

6.3 Physical characteristics

Casing

material

Carbon loaded glass filled polyester body - rugged

and corrosion free

Handset

Material

Cycoloy (2800) with stainless steel or polyester

curled cord.

Weight 3.2kg (7lbs)

Dimensions 190W x 292H x 140D mm overall

(7.5 x 11.5 x 5.5 in)

Standard handset cord lengths:

Curled cord: 320mm extending to 1000mm (13-39in)

Armoured steel cord: 755mm (29.7in)

6.4 Environmental specifications

Storage temperature range -20oC to +60oC (-4°F to 140°F)

Operating temperature range -20oC to +60oC (-4°F to 140°F)

NB refer to certification details

Maximum relative humidity 95% non condensing

Telephone enclosure IP

Rating:

IP66 (curly cord variants)

IP54 (steel cord variants)

(NB the handset itself is excluded from this

rating)

High pressure hoses should not be used on this product.

Page 34

33 Auteldac 5

6.5 Recycling information.

The symbol shown here and on the product means that the

product is classed as Electrical or Electronic Equipment and

should not be disposed with other household or commercial

waste at the end of its working life.

The Waste of Electrical and Electronic Equipment (WEEE)

Directive has been put in place to recycle products using best

available recovery and recycling techniques to minimise the

impact on the environment, treat any hazardous substances

and avoid the increasing landfill.

Business users should contact their suppliers and check the

terms and conditions of the purchase contract and ensure that

this product is not mixed with other commercial waste for

disposal.

Page 35

Auteldac 5 34

Page 36

35 Auteldac 5

GAI-TRONICS

A division of Hubbell Ltd.

Brunel Drive

Stretton Park

Burton upon Trent

Staffordshire

DE13 0BZ

www.gai-tronics.co.uk

Tel: +44 (0)1283 500 500

Fax: +44 (0)1283 500 400

If you have any difficulties, please call.

The policy of GAI-Tronics is one of continuous improvement,

therefore the Company reserves the right to change

specifications without notice.

The contents of this publication are confidential, are the property of GAI-Tronics, and may not

be reproduced, wholly or in part, without their written permission.

E&OE.

6.5.1

Loading...

Loading...