Page 1

Operating and assembly instructions

VG 232 RK

Gas cooker

Page 2

1

Preface

1. Important notes Page 3-4

1.1 For your safety Page 3

1.2 Operating for the first time Page 3

1.3 About use Page 4

2. Structure and operating principle Page 5-6

2.1 Structure Page 5

2.2 Special accessories Page 5

2.3 Operating principle Page 6

3. Operation Page 7

4. Cleaning and care Page 8

5. Maintenance Page 9

5.1 General Page 9

5.2 Remedying slight malfunctions yourself Page 9

6. Technical data / Settings table Page 10

VG 232 RK

Page 3

2

Cooking with your new gas cooker will be

even more fun than before.

The appliance offers you the following

advantages:

– Regulation from hot to cold in seconds.

– High safety standard thanks to thermal

protection elements for all burners.

– Thanks to the novel installation method

implemented, installation is child's play!

To ensure that you will be able to use this appliance in all its diversity, read through the operating

and assembly instructions conscientiously before

operating it for the first time. The instructions

contain important notes on use, installation and

maintenance of the appliance.

You will find notes on page 3 that you ought to

observe before operating the appliance for the

first time.

The chapters entitled “Structure and operating

principle" and “Operation" tell you all the

things your cooker is capable of doing and how

to operate the appliance.

The chapter entitled “Cleaning and care" will

make sure that your appliance will stay operable

and beautiful for a long time.

And now we wish you lots of fun cooking.

Preface

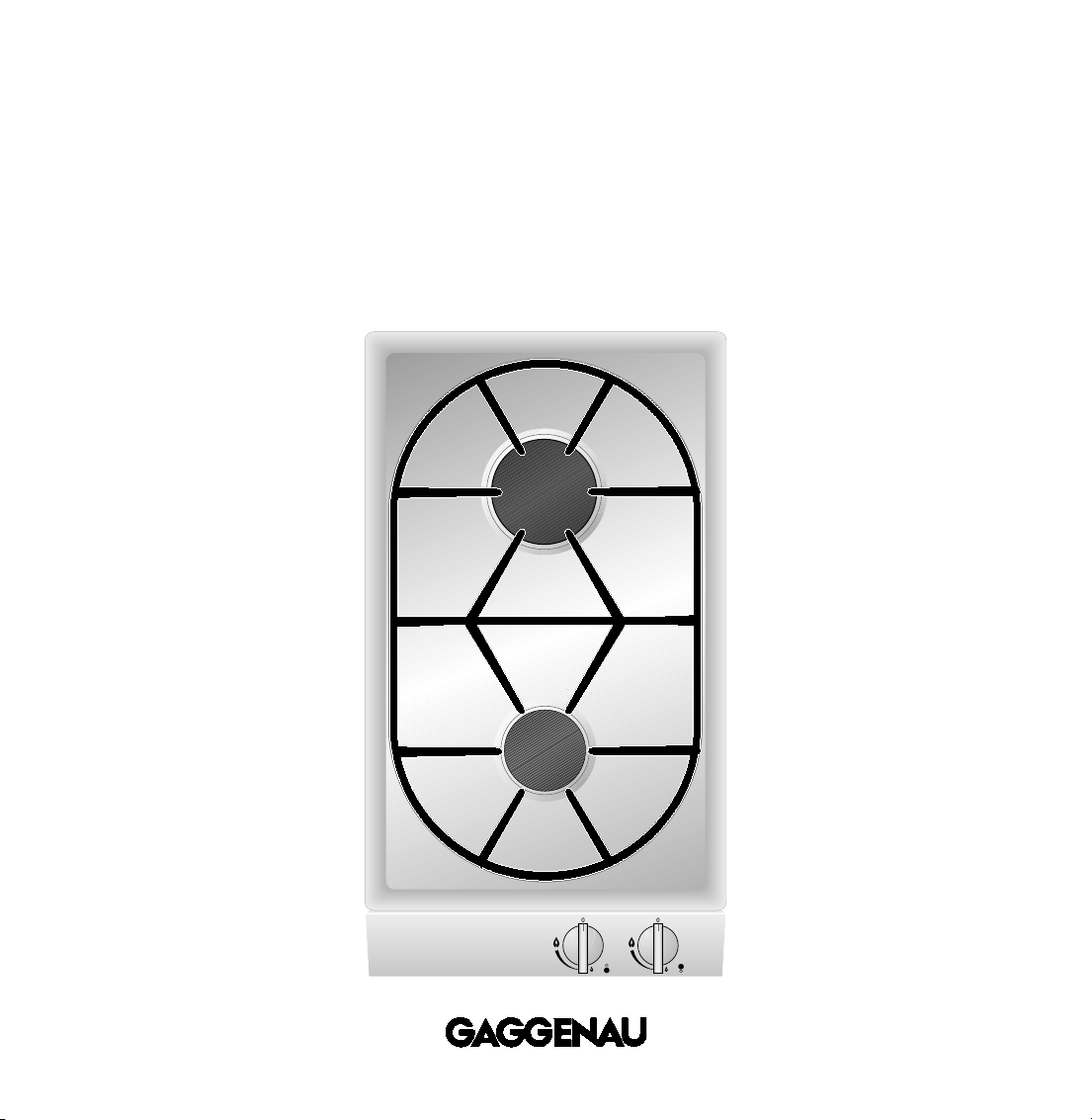

Fig. 1

Page 4

1.1 For your safety

You must not operate the appliance if it is damaged.

When connecting electrical appliances in the proxi-

mity of the appliance, make sure that connecting

leads do not come into contact with hot cooking

surfaces!

As the user, you yourself are responsible for

maintenance and proper use in the household.

Only ever operate the appliance under supervision.

Do not operate the appliance without pots and pans

placed on it. Make sure that all the burner parts are

correctly fitted.

Important: The appliance heats up during operation. Keep children away.

Note:

If you have fitted the appliance cover VD 201-010

(special accessory) on the appliance, it must not be

closed until the appliance has cooled down

completely. Do not operate the appliance with the

cover closed! Heat development may damage the

appliance and the cover. Do not use the appliance

cover as a surface for placing objects or for

keeping things warm.

Do not clean the appliance with a steam cleaning

apparatus or with water pressure - risk of short-

circuits!

Isolate the appliance from the mains during every

maintenance operation. To do this, remove the

mains plug or actuate the corresponding fuse.

Close the gas supply.

Repairs must be carried out by authorised specialists, thus ensuring electrical safety.

No warranty claims can be lodged for any damage

resulting from failure to observe these instructions.

Observe caution with oils and fats. They may

overheat and burn easily.

Foodstuffs that are prepared in fat and oil must only

be prepared under constant supervision!

Technical modifications reserved.

1.2 Operating for the first time

Before operating the appliance for the first time,

please pay attention to the following notes:

The appliance must only be connected by an

authorised specialist.

Read through these instructions attentively before

operating the appliance for the first time.

Note:

The rating plate for this appliance is included on

a separate sheet. Keep the rating plate in a safe

place along with your operating and assembly

instructions.

Remove the packaging from the appliance and

dispose of it properly.

Keep packaging elements away from children.

Thoroughly clean the appliance and accessories

before using them for the first time. This will

eliminate any “newness" smells and soiling

(see chapter entitled “Cleaning and care").

3

1. Important notes

Page 5

1.3 About use

The appliance is intended solely for use in the

household and must not be put to any other uses.

Use the appliance to prepare meals only. It must not

be used to heat up the room in which it is installed.

Use of a gas cooker generates heat and humidity

in the room where it is installed. This is why attention must be paid to good kitchen ventilation.

The natural ventilation openings must be kept

unobstructed. Prolonged use of the appliance

with several or all rings may call for additional

ventilation such as opening a window or a door,

or stronger air extraction by an extractor hood.

To guarantee good combustion, the room in

which the appliance is installed must have

a minimum volume of 10 m

3

and must possess

a door that opens outdoors or a window that

can be opened.

Only ever use the burners after placing pots and

pans on them. Do not heat up any empty pots

or pans; this may result in a build-up of heat. Use

pots and pans with thicker bottoms because heat

distribution is particularly improved in the low

setting. The better the size of pots and pans is

adapted to the burner size, the better the heat of

the gas flame will be exploited and the more costs

will be saved.

Cooking vessels with curved bottoms, e.g. woks,

must not be used.

It is not permitted to use roasting pans, frying pans

or grill stones heated simultaneously by several

burners because the resulting heat build-up may

damage the appliance.

Switch the burners to the low setting whenever you

remove pots or pans briefly. In this way, you reduce

the risk of burns when working next to naked

flames; you also save gas and reduce pollution.

Whenever the gas hob is fitted under a vapour

extractor hood, always cover the rings with pots

or pans. Otherwise, parts of the vapour extractor

hood may become damaged by the extreme heat

development or grease residues in the filter may

ignite. Ensure an adequate supply of air when

using a vapour extractor operating in the

exhaust air mode.

After igniting, keep the control knob pressed for

around 5-8 seconds more because the heat sensor

that opens the gas channel has to warm up first.

In the event of a power failure, you can also ignite

the unit with matches or any other ignition aid. The

thermal protection facility that prevent gas from

flowing out in the open position functions without

restriction.

Pots with a diameter of less than 90 mm or more

than 220 mm should not be used. When using

larger pots, pay attention to keeping to a minimum

distance of 50 mm between the cooking vessel and

combustible surroundings. A minimum distance of

15 mm must be observed between the control knob

and the pot or pan.

In the event of malfunctions, contact your

specialist dealer or your responsible Gaggenau

after-sales service.

Tip: When buying pots, pay attention to the fact

that the manufacturer frequently specifies the top

pot diameter, which is generally larger than the

diameter of the base.

Observe the manufacturer's specification! Use

cooking utensils that the manufacturer states as

being “suitable for gas".

Preferably use the larger cooking zone for brief

cooking, deep fat frying and brief frying of large

quantities. Preferably use the smaller ring for

soaking, warming up and keeping warm, even

when large quantities are involved.

4

Page 6

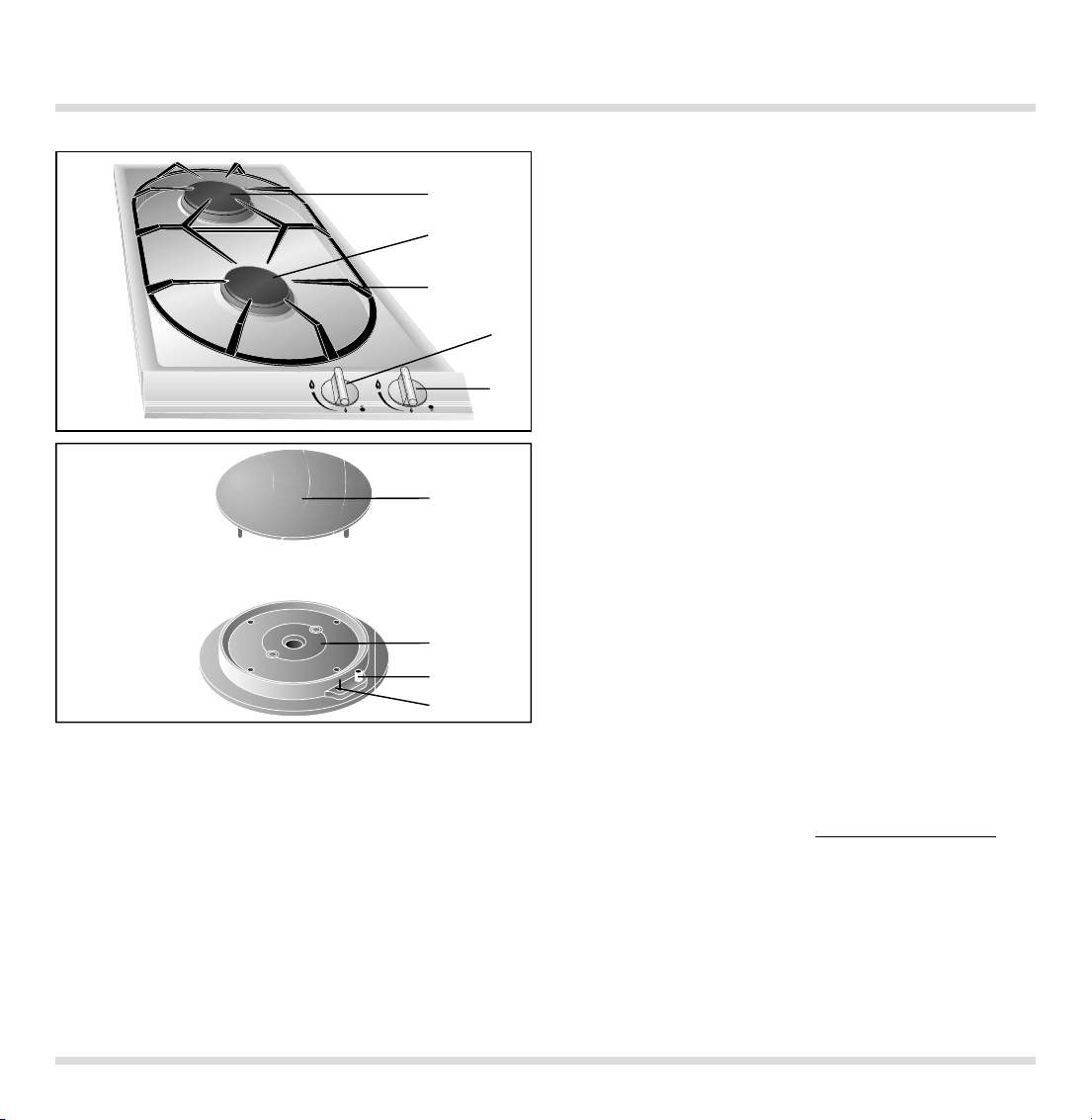

2.1 Structure

2.2 Special accessories

1 High-power burner B 2.8 kW

2 Normal burner A 1.9 kW

3 Pot support

4 Control knob for the front cooking position

5 Control knob for the rear cooking position

6 Burner cover

7 Burner head

8 Spark plug for automatic ignition

9 Thermal sensor for flame monitor

You can order the following special accessories

:

– VV 200-000: Connecting strip

– VD 201-010: Appliance cover (If an appliance

cover is fitted, the pot support must

be removed when closing.)

5

2. Structure and operating principle

6

7

8

9

1

2

3

4

5

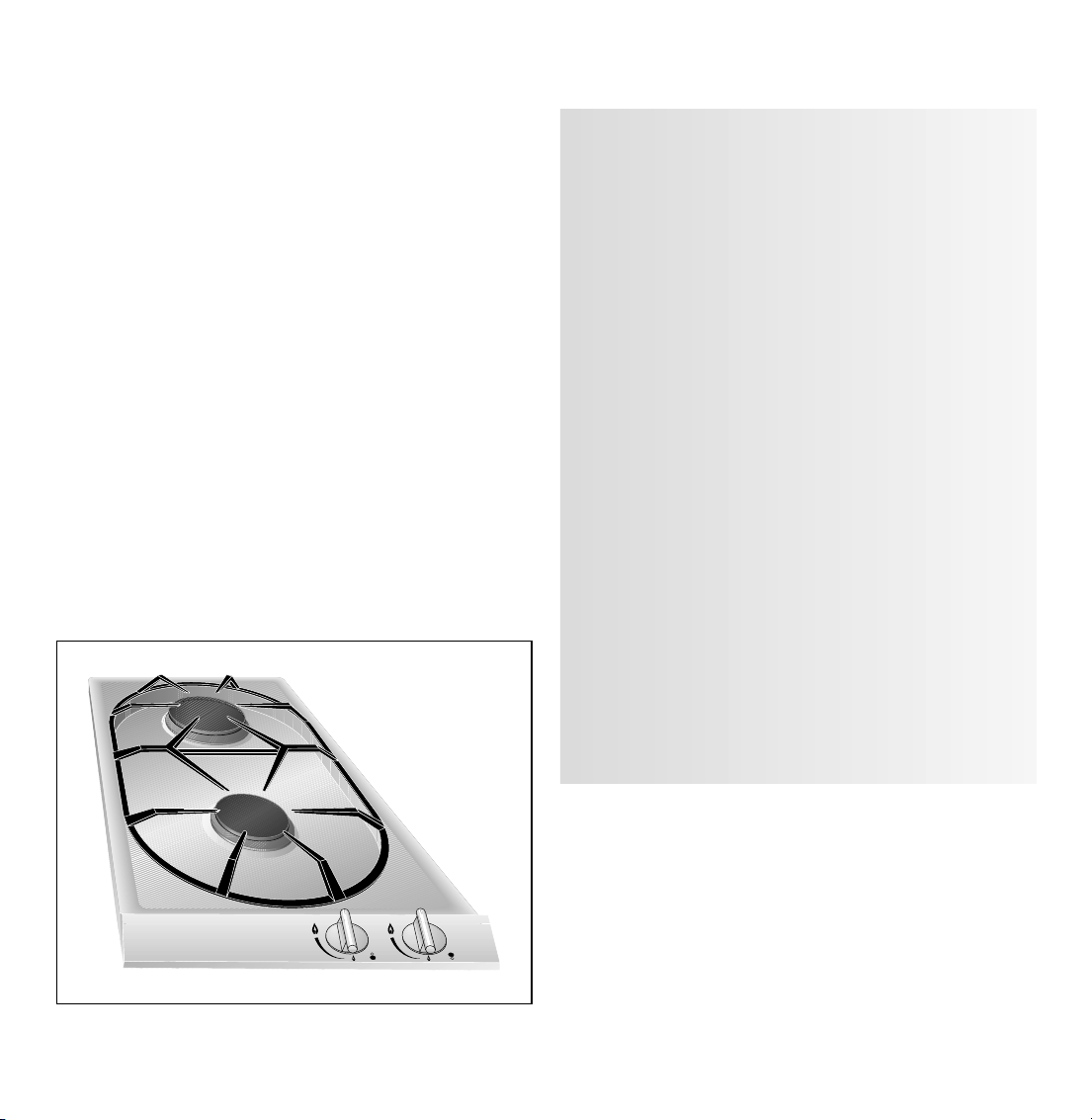

Fig. 2

Fig. 3

Page 7

2.3 Operating principle

The appliance features one-hand operation. That

is to say, the ignition is activated when the control

knob is pressed briefly.

After igniting, keep the control knob pressed for

around 5-8 seconds more because the heat sensor

that opens the gas channel has to warm up first.

The gas hob has 1 normal burner (front burner)

and 1 high-intensity burner (rear burner).

All burners have a thermal protection device that

prevents unburned gas from escaping in the open

position.

The total rated thermal load amounts to:

4.7 kW referred to Hs* (gross calorific value)

4.2 kW referred to Hi(calorific value)

The specified rated load is defined by installation

of the fixed nozzles.

The gas hob is converted to a different gas

type by nozzle replacement (full and low-burning

nozzles) (see nozzle table on page 10).

The symbols on the control panel mean:

0 Off

High setting

Low setting

The flame is infinitely variable between high and

low-setting.

6

Page 8

The cooking positions must only be ignited

when all burner parts are fitted. Otherwise,

malfunctions may occur on the ignition unit.

Switching on:

– Place a pot or a pan on the corresponding

cooking position.

– Fully press in the control knob for the

corresponding cooking position. This activates

the ignition. Keep the control knob pressed!

– Turn the control knob to the left to the “high"

position.

If the flame should not ignite within 2 to 4 seconds,

turn the control knob further to the left to the “low"

position and then back to the “high" position after

ignition. It is often faster to ignite in the low position

because the various gases have a differing ignition

response.

After igniting, keep the control knob pressed

for around 5-8 seconds more because the heat

sensor that opens the gas channel has to warm

up first.

Repeat the operation if the flame should go out

again.

The flame size can be set continuously between full

and low by slowing turning the control knob.

Switchin

g off:

Fully turn the control knob to the left to the 0

position on the left.

3. Operation

7

Fig. 4

Fig. 5

Page 9

Wipe off spilt food immediately, thus ensuring

that it cannot burn in on the hob.

Caution! The burner gets very hot during

operation!

Never use abrasive or caustic cleaning agents.

You should only clean the control panel and the

control knobs with detergent and a a soft cloth.

To ensure perfect functioning, keep the thermal

sensor and the spark plug clean.

Keep the incoming air openings on the rear of

the panel unobstructed and clean.

Please thoroughly clean the appliance before

operating it for the first time and after every

use.

– Wait until the appliance has cooled down.

– Remove the pot grid.

– Remove the burner cover.

– Clean the hob, the burner covers and the

pot grid with commercially available cleaning

agents (not in a dishwasher!), e.g. with warm

soap solution and a dishwashing brush.

– Whenever required, clean the burner head with

a moist cloth.

– Soak burnt-in remainders in a little water and

detergent. This loosens even the most stubborn

of soiling. Do not use any abrasive agents and

abrasive sponges.

– As the result of heat development, slight dis-

coloration can appear on the stainless steel

surface. Do not attempt to scrape away such

discoloration. This damages the surface.

Distribute stainless steel care agents uniformly

and thinly on the hob (not on the control panel!).

This will ensure an even surface and will keep

your hob in a good condition for a long period of

time.

Important: Allow the burner covers to cool down

before cleaning them!

When assembling, place the burner cover (1) on

the burner head (2) so that the four tabs on the

bottom edge of the burner cover engage in the

corresponding tabs on the burner head (see Fig. 6).

Place the pot grids back in position.

4. Cleaning and care

Caution:

Never use high-pressure or steam jet units to

clean your appliance because otherwise the

electrical safety of the appliance will no longer

be guaranteed.

8

Fig. 6

1

2

Page 10

5.1 General

5.2 Remedying slight malfunctions

yourself

In the event of malfunctions, check whether the

gas and electricity supply is in proper working

order, i.e. the gas valve is open and the plug has

been plugged into the socket.

If the power supply is functioning correctly, but your

appliance still does not work, please contact your

dealer or your local Gaggenau customer service

agency. Specify the appliance type (see rating

plate).

Repairs may only be carried out by authorised

technicians, in order to guarantee the safety of the

appliance.

Unauthorised tampering with the appliance will

invalidate any warranty claims.

Only ever use original spare parts.

9

5. Maintenance

Fault Remedy

The burner does not ignite after several attempts. Check whether ...

... the burner is correctly assembled.

... the gas shut-off facility is open.

... the burner is clean and dry.

... the domestic fuse has tripped.

If necessary, inform after-sales service.

The gas flame goes off after ignition. Check whether ...

... the burner covers are fitted correctly,

... the flame has been extinguished by a strong

draught in the room.

The cooking ring burner's electrical igniter is no Check whether there are food remainders

longer functioning. between the ignition electrode and the burner

cover. Carefully remove these.

The flame tips are yellow and not blue. Check whether the burners are dry and clean.

Page 11

Technical data (gas)

Burners: Normal burner

Full burning 1.9 kW

Low burning < 0.35 kW

High-intensity burner

Full burning 2.8 kW

Low burning < 0.56 kW

Gas connection:

R 1/2’’ union nut for R 1/2’’ bracket to DIN 1999,

conical-cylindrical

Technical data, gas

Technical data (electrical)

Rated consumption 0.8 W

Voltage 220 - 240 V

Frequency 50 - 60 Hz

Technical modifications reserved.

10

6. Technical data/ Settings table

Gas family LNG LPG

Pressure 20 mbar 25-28 mbar

A burner, full burning 0.92 0.74

A burner, low burning 0.47 0.36

B burner, full burning 1.24 0.87

B burner, low burning 0.55 0.42

∑ Power 4.7 kW 4.7 kW

∑ Consumption 0.45 m

3

/h 337 g/h

Page 12

11

7.1 Important notes

Please observe the safety notes and the

important notes (Chapter 1).

The installing technician is responsible for

perfect functioning of the appliance at its installation location.

He must explain the operating principle to the user

with reference to the operating instructions and

must show how to switch off the electricity and gas

whenever required.

Caution:

Before connecting the appliance, please check

whether the local connection conditions such as

the gas type, gas pressure and mains voltage and

the appliance settings are correct. Refer to the

adhesive label on the gas connection or the rating

plate for the necessary information. This gas hob

conforms to the categories that are specified on the

rating plate. The rating plate can be found on the

appliance and additionally on the enclosed addendum sheet. By replacing nozzles, it is possible to

set the appliance to any gas listed on the rating

plate.

If the data should not agree, the appliance must

be set to the required gas type and the available

pressure.

As this gas hob is not intended for connection to an

exhaust gas system, pay attention to the applicable

installation conditions.

Note on ventilation:

To ensure good combustion, the room in which this

appliance is installed must have a minimum volume

of 10 m

3

and a door that opens out to outdoors or a

window that can be opened.

The appliance may be installed in kitchen

combinations made of wood or similar combustible

materials without taking additional measures. The

rear wall must consist of non-combustible material.

A minimum distance of 150 mm from heat-sensitive

items of furnishing or contact surfaces (cupboard

side panel) must be observed.

The hob conforms to appliance class 3 and must be

installed in the worktop as shown in the installation

sketch.

The distance between the suspended cupboard

and the worktop must be at least 600 mm.

Attention must be paid to the manufacturer's

specified safety clearance when a vapour extractor

is installed.

Wall trims must be heat-resistant, and the minimum

distance between the hob and the wall trim is at

least 35 mm.

After unpacking, check the appliance for any

transportation damage and report this immediately

to the transportation company.

Technical modifications reserved.

7. Assembly instructions

TYPE HLVG232... RK

VG 232-... FDxxxx Made in ...

AC 220-240V 50/60Hz 0.8 VA Qn

LNG 4050 kcal/h

LPG 337 g/h

Page 13

7.2 Connecting the appliance

Gas connection

The gas connection must be in a location that

permits access to the shut-off valve and which,

if applicable, is visible after opening the door of

the furniture item.

By means of the included R 1/2" connection bracket

(on the appliance end) with the affiliated washer,

the appliance must be connected to a fixed connecting line or a gas safety hose to DIN 3383

Part 1 that corresponds to the type concerned.

An ambient temperature of 70 °K must not be

exceeded if the gas safety consists only partly

of metal. The permissible ambient temperature for

a gas safety hose that consists completely of metal

is 115 °K.

If a flexible line is used, it must be laid in such a

way that it cannot come into contact with moving

parts of the kitchen element (e.g. drawer).

Electrical connection

Electrical connection (AC 220-240 V) is established

by means of a connecting cable with an earthing

contact plug connected to an earthed socket, which

must also be accessible after installation of the gas

hob.

If, after installation of the gas hob, not all poles can

be isolated from the mains by removing the plug,

an isolating device with a contact gap of at least

3 mm must be permanently installed. When establishing connections, make sure that the connecting

lead cannot come into contact with hot parts of the

gas hob or other hot parts.

12

40

73

Fig. 7

Seal

1/2”

Page 14

7.3 Nozzle replacement

Changing over to a different gas type

Only authorised specialists are permitted to

change over to a different gas type.

The nozzles needed for the gas type to be set

are available as a conversion kit. Please specify the

appliance type and the required gas type.

Nozzles can be replaced without having to open

the housing.

Loads for all gases

For all gas types and pressures, the rated load

is achieved by installing the high and low setting

nozzles for the required gas type (see nozzle

table).

The low setting nozzle is screwed in fully at the

works, and so the lowest quantity is set.

Replacing the low-setting nozzle 1

Proceed as follows:

– Disconnect the appliance from the power

supply!

– Remove the cover from the underside of the

appliance under the gas valves.

The low-setting nozzle 1 is located in the gas

valve and is screwed in from below. (see Fig. 8)

– Unscrew the nozzle and insert the new nozzle as

specified in the low-setting nozzle table. The

nozzle must be screwed in fully. Fit the cover

cap again.

If it should be necessary to correct the low-setting

nozzle 1 as the result of deviating gas types and

pressure, the flow rate can be increased by turning

to the left.

13

Fig. 8

See table on Page 10

for details of nozzle settings.

Page 15

Replacing the main nozzle 2

Proceed as follows:

– The main nozzle 2 is visible after detaching the

burner cover (see Fig. 9). It is unscrewed with a

special screw key.

– Unscrew the nozzle and insert the new nozzle as

specified in the main nozzle table. The nozzle

must be screwed in fully and firmly (torque

1.5 Nm) (metallic seal).

– Please do not forget to stick the new adhesive

label included with the nozzle set over the old

adhesive label on the gas connection, thus

documenting the changeover to a different gas

type.

Checking functions

The flames are adjusted correctly if no yellow tips

are visible and if they do not go out when switching

over swiftly from the high to the low setting.

Adjusting the primary air

The primary air setting for different gases is only

defined by the diverse nozzle shapes and therefore

does not require adjustment.

14

Fig. 9

See table on Page 10

for details of nozzle settings.

Page 16

5080006282ind01 en 06.03 SK 15

7.4 Installing the appliance

– Produce the recess for one or several Vario

appliance(s) in your worktop. Proceed as

indicated on the installation sketch and the

dimension table. The dimension table contains

details of the space requirement for the trim

between the appliances.

Important: The angle between the cut surface

and the worktop must amount to 90° (Fig. 10).

– Mark the centre of the recess exactly.

Secure the securing rails on the front and rear

edges of the recess. Make sure that the lugs of

the securing rails lie on the worktop and that the

centre marking of the securing rails is precisely

flush with the centre marking on the worktop

(Fig. 11).

– Lower the appliance into the worktop. Make

sure that the engaging lugs on the appliance

lie exactly on the clamping springs. Press the

appliance firmly into the worktop. The engaging

lugs on the appliance “snap" into the clamping

springs (Fig. 12).

Note: When installing the appliance in granite

or marble worktops, have the holes produced by

a specialist or stick on the securing rails with a

temperature-resistant 2-component adhesive (metal

on stone).

Secure the cover on the appliance before instal-

lation. See assembly instructions VD 201-010.

Note:

Several appliances can also be installed in individual recesses, as long as a minimum clearance

of 40 mm is kept to between the appliances.

1

,4

m

5

5

8

,

5

288

5

1

0

4

9

0

1

1

4

7

8

5

4

5

6

1

2

6

8

m

i

n

.

3

5

m

i

n

.

5

0

4

2

,

5

Fig. 10

Fig. 12

Fig. 11

Page 17

GAGGENAU HAUSGERÄTE GMBH

P.O. BOX 10 0250 · 80076 MÜNCHEN

GERMANY

Y (089) 45 90-03

FAX (089) 4590-2347

www.gaggenau.com

Loading...

Loading...