Page 1

Operating and assembly instructions

VG 231

Gas cooker

Page 2

1

Preface

1. Important notes Page 3-4

1.1 For your safety Page 3

1.2 Operating for the first time Page 3

1.3 About use Page 4

2. Structure and operating principle Page 5-6

2.1 Structure Page 5

2.2 Special accessories Page 5

2.3 Operating principle Page 6

3. Operation Page 7

4. Cleaning and care Page 8

5. Maintenance Page 9

5.1 General Page 9

5.2 Remedying slight malfunctions yourself Page 9

6. Technical data / Table Page 10

7. Practical tips Page 11-12

7.1 Accessories Page 11

7.2 Cooking in the wok Page 11

7.3 Recipes Page 12

8. Assembly instructions Page 13-18

8.1 Important notes Page 13

8.2 Gas connection / electrical connection Page 14

8.3 Nozzle replacement Page 15-17

8.4 Installing the appliance Page 18

VG 231

Page 3

2

Cooking with your new gas hob will be even

more fun than before.

The appliance offers you the following

advantages:

– Regulation from hot to cold in seconds

– High safety standard thanks to thermal

protection elements for the burner

– Thanks to the novel installation method

implemented, installation is child's play!

To ensure that you will be able to use this

appliance in all its diversity, read through

the operating and assembly instructions

conscientiously before operating it for the first

time. The instructions contain important notes on

use, installation and maintenance of the appliance.

You will find notes on page 3 that you ought to

observe before operating the appliance for the

first time.

The chapters entitled “Structure and operating

principle" and “Operation" tell you all the

things your cooker is capable of doing and how to

operate the appliance.

The chapter entitled “Cleaning and care" will

make sure that your appliance will stay operable

and beautiful for a long time.

And now we wish you lots of fun cooking!

Preface

Fig. 1

Page 4

1.1 For your safety

You must not operate the appliance if it is damaged.

When connecting electrical appliances in the pro-

ximity of the appliance, make sure that connecting

leads do not come into contact with hot cooking

surfaces!

As the user, you yourself are responsible for

maintenance and proper use in the household.

Only ever operate the appliance under supervision.

Make sure that the burner parts are correctly fitted.

The appliance must only be operated with a wok, a

pot or a pan on a ring.

Note:

If you have fitted the appliance cover VD 201-010

(special accessory) on the appliance, it must not be

closed until the appliance has cooled down

completely. Do not operate the appliance with the

cover closed! Heat development may damage the

appliance and the cover. Do not use the appliance

cover as a surface for placing objects or for

keeping things warm.

Important: the appliance heats up during

operation. Keep children away

Do not clean the appliance with a steam cleaning

apparatus or with water pressure – risk of short-

circuits!

Isolate the appliance from the mains during every

maintenance operation. To do this, remove the

mains plug or actuate the corresponding fuse.

Close the gas supply.

Repairs must be carried out by authorised

specialists, thus ensuring electrical safety.

No warranty claims can be lodged for any damage

resulting from failure to observe these instructions.

Observe caution with oils and fats. They may

overheat and burn easily. Foodstuffs that are

prepared in fat and oil (e.g. French fries) must only

be prepared under constant supervision!

Technical modifications reserved.

1.2 Operating for the first time

Before operating the appliance for the first time,

please pay attention to the following notes:

The appliance must only be connected by an

authorised specialist.

Read through these instructions attentively before

operating the appliance for the first time.

Note:

The rating plate for this appliance is included on

a separate sheet. Keep the rating plate in a safe

place along with your operating and assembly

instructions.

Remove the packaging from the appliance and

dispose of it properly.

Keep packaging elements away from children.

Thoroughly clean the appliance and accessories

before using them for the first time. This will

eliminate any “newness" smells and soiling (see

chapter entitled “Cleaning and care").

3

1. Important notes

Page 5

1.3 About use

The appliance is intended solely for use in the

household and must not be put to any other uses.

Use the appliance to prepare meals only. It must not

be used to heat up the room in which it is installed.

Use of a gas cooker generates heat and humidity

in the room where it is installed. This is why

attention must be paid to good kitchen ventilation.

Ventilation openings must be kept unobstructed.

Prolonged use of the appliance may call for

additional ventilation such as opening a window or

a door, or stronger air extraction by an extractor

hood.

To guarantee good combustion, the room in

which the appliance is installed must have a

minimum volume of 10 m

3

and must possess a

door that opens outdoors or a window that can

be opened.

Do not operate the cooking position without a pot

or a pan or a wok placed on it. Do not heat up any

empty pots or pans; this may result in a build-up

of heat. Use pots and pans with thicker bottoms

because heat distribution is particularly improved

in the low setting. The better the size of pots and

pans is adapted to the burner size, the better the

heat of the gas flame will be exploited and the

more costs will be saved.

It is not permitted to use grilling stones because the

resulting build-up of heat may damage the

appliance.

Switch the burners to the low setting whenever you

remove pots or pans briefly, thus saving gas and

reducing pollution.

Whenever the gas hob is fitted under a vapour

extractor hood, always cover the rings with pots

or pans. Otherwise, parts of the vapour extractor

hood may become damaged by the extreme heat

development or grease residues in the filter may

ignite. Ensure an adequate supply of air when using

a vapour extractor operating in the exhaust air

mode.

After igniting, keep the control knob pressed for

around 5-8 seconds more. The thermal sensor

must be heated for 5-8 seconds before the knob

can be released.

In the event of a power failure, you can also

ignite the unit with matches or any other ignition

aid. The thermal protection facility that prevent gas

from flowing out in the open position functions

without restriction.

Pots with a diameter of less than 100 mm or more

than 320 mm should not be used. When using

larger pots, pay attention to keeping to a minimum

distance of 100 mm between the cooking vessel

and combustible surroundings. A minimum distance

of 15 mm must be observed between the control

knob and the pot or pan.

In the event of malfunctions, contact your

specialist dealer or your responsible Gaggenau

after-sales service.

Tip: when buying pots, pay attention to the fact that

the manufacturer frequently specifies the top pot

diameter, which is generally larger than the

diameter of the base.

Observe the manufacturer's specification! Use

cooking utensils that the manufacturer states as

being “suitable for gas".

4

Page 6

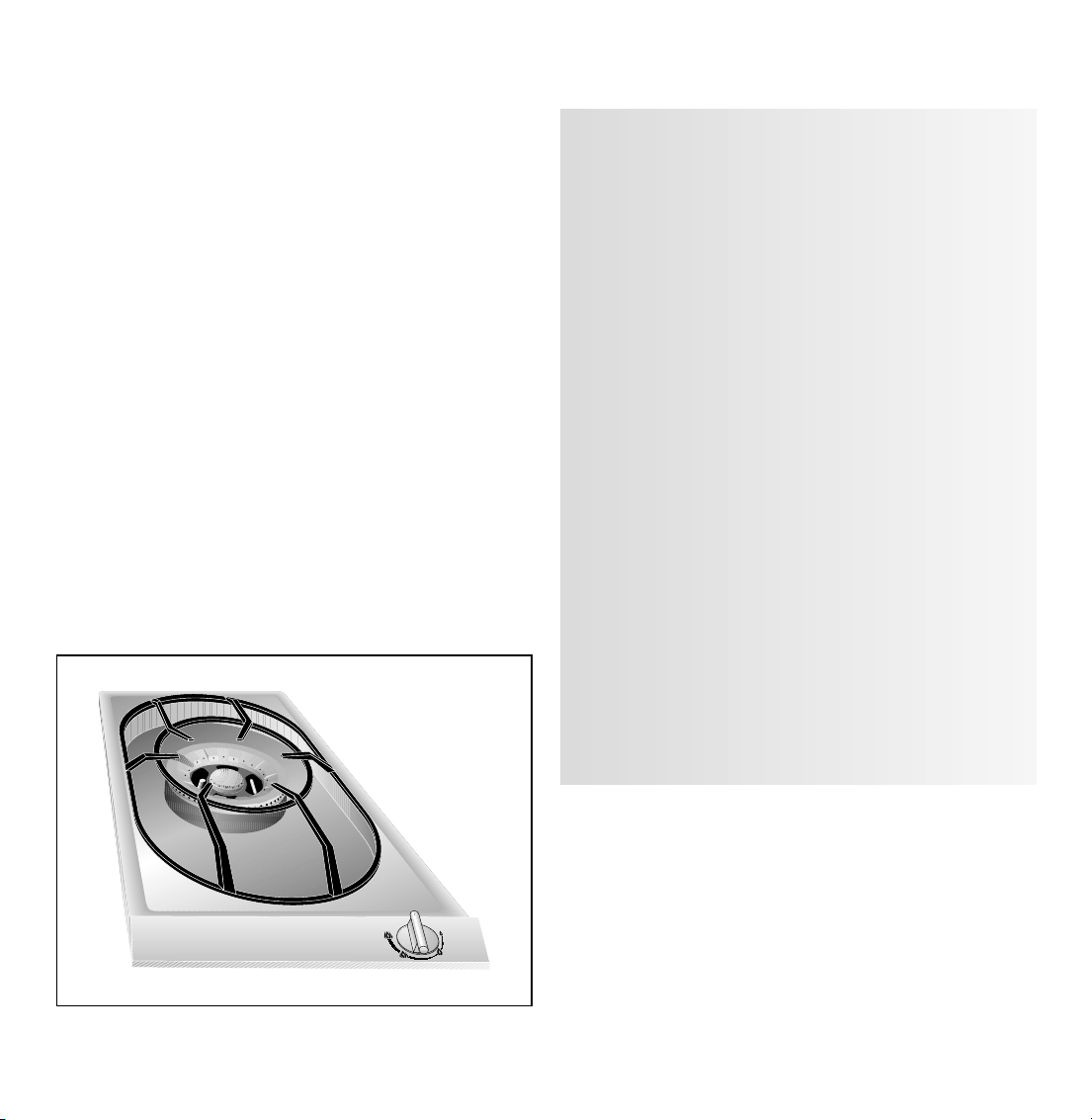

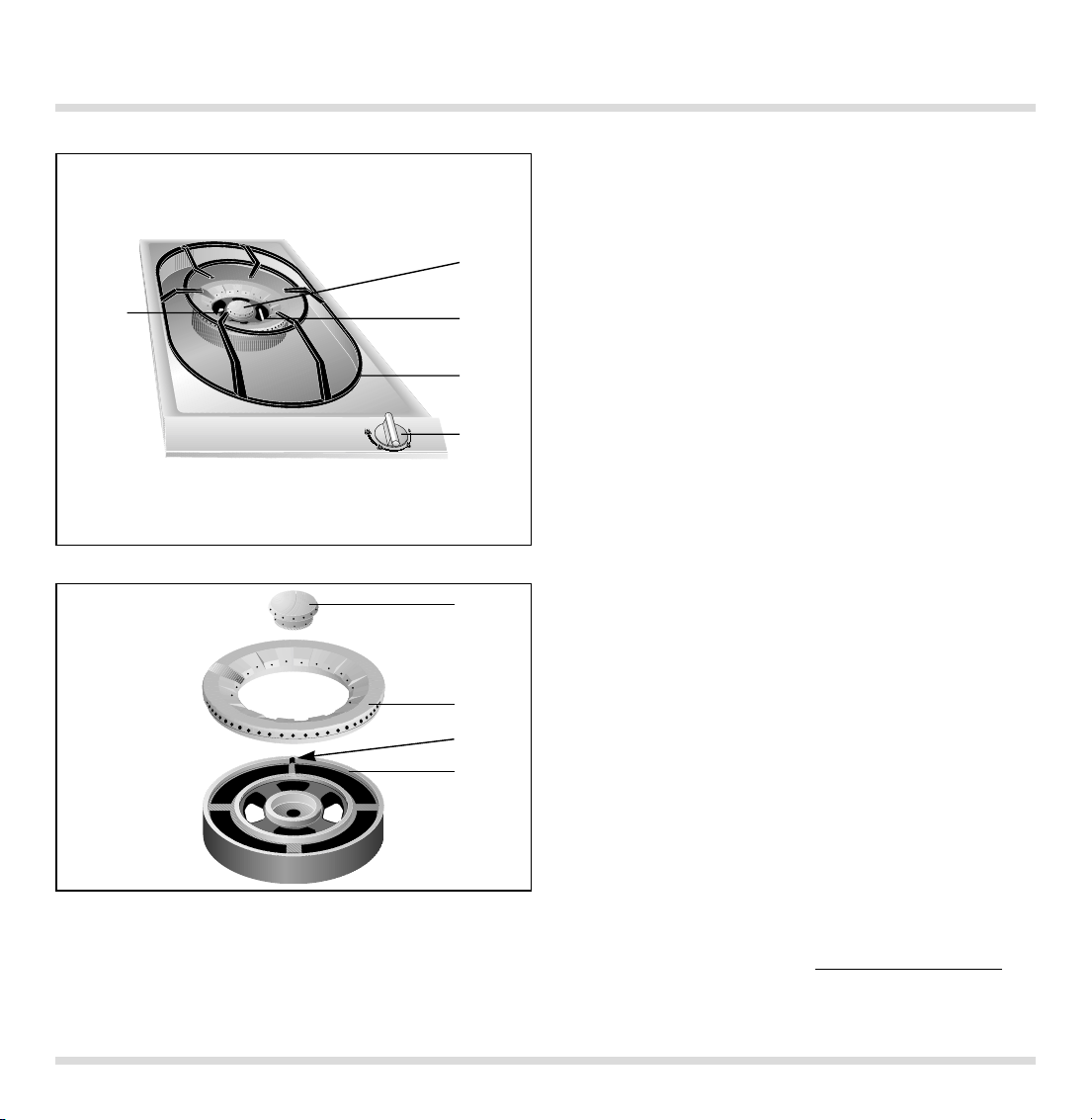

2.1 Structure

2.2 Special accessories

1 Spark plug for automatic ignition

2 Wok burner 0.25 - 5 kW

3 Thermal fuse for flame monitor

4 Pot support

5 Control knob for the cooking position

6 Burner cover

7 Burner ring

8 Burner head recess

9 Burner head

You can order the following special accessories:

– VV 200-000: connecting trim

– VD 201-010: appliance cover

5

2. Structure and operating principle

Fig. 2

Fig. 3

6

7

8

9

3

5

4

2

1

Page 7

2.3 Operating principle

The appliance features one-hand operation. That is

to say, the ignition is activated when the control

knob is pressed briefly.

After igniting, keep the control knob pressed for

around 5-8 seconds more because the heat sensor

that opens the gas channel has to warm up first.

The burner has a thermal protection device that

prevents unburned gas from escaping in the open

position.

The total rated thermal load amounts to:

5.0 kW referred to Hs* (gross calorific value)

4.5 kW referred to Hi(calorific value)

The specified rated load is defined by installation

of the fixed nozzles.

The gas hob is converted to a different gas type

by nozzle replacement (full and low-burning

nozzles) (see nozzle table).

The symbols on the control panel mean:

0 Off

High position of outer and inner flame rings

Low position of outer flame ring

High position of inner flame ring

Outer flame ring off

High position of inner flame ring

Outer flame ring off

Low position of inner flame ring

The flame is infinitely variable between high and

low-setting.

6

Page 8

The cooking positions must only be ignited

when all burner parts are fitted. Otherwise,

malfunctions may occur on the ignition unit.

Switching on (Fig. 4):

– Place a pot or a pan on the corresponding

cooking position.

– Press in the control knob fully and keep it

pressed. This activates the ignition.

– Turn the control knob to the left to the

“high" position.

If the flame should not ignite within 2 to 4 seconds,

turn the control knob further to the left to the

“low" position and then back to the “high"

position after ignition. It is often faster to ignite in

the low position because the various gases have a

differing ignition response.

Once the flame is burning, keep the control knob

pressed for another 5-8 seconds. The thermal

sensor must be heated for 5-8 seconds before the

knob can be released.

Repeat the operation if the flame should go out

again.

The flame size can be set continuously between full

and low by slowing turning the control knob.

Switching off (Fig. 5):

Fully turn the control knob to the left to the 0

position on the left.

7

3. Operation

Fig. 4

Fig. 5

Page 9

Wipe off spilt food immediately, thus ensuring that

it cannot burn in on the hob.

Caution! The burner gets very hot during

operation!

Never use abrasive or caustic cleaning agents.

Keep the air inlet openings on the rear of the

panel unblocked and clean.

You should only clean the control panel and the

control knobs with detergent and a a soft cloth.

To ensure perfect functioning, keep the thermal

sensor and the spark plug clean.

Please thoroughly clean the appliance before

operating it for the first time and after every

use.

– Wait until the appliance has cooled down.

– Remove the pot grid.

– Remove the burner cover and the burner ring.

– Clean the hob, the burner covers and the pot

grid with commercially available cleaning

agents (not in a dishwasher!), e.g. with warm

soap solution and a dishwashing brush.

– Whenever required, clean the burner head with

a moist cloth.

– Soak burnt-in remainders in a little water and

detergent. This loosens even the most stubborn

of soiling. Do not use any abrasive agents and

abrasive sponges.

– As the result of heat development, slight dis-

coloration can appear on the stainless steel

surface. Do not attempt to scrape away such

discoloration. This damages the surface.

Distribute stainless steel care agents uniformly

and thinly on the hob (not on the control panel!).

This will ensure an even surface and will keep

your hob in a good condition for a long period of

time.

When assembling the appliance (Fig. 6), make sure

that the burner head (5) is placed on the burner

base (7) in such a way that the twist protector (4) is

held in place by the thermal element (6). Place the

burner ring (2) on the burner head (5) from above.

The locking lug on theunderside of the burner ring

must fit in the recess (3). Place the burner cover (1)

in the centre of the burner head. Fit the pot support.

4. Cleaning and care

Caution:

Never use high-pressure or steam jet units to

clean your appliance because otherwise the

electrical safety of the appliance will no longer be

guaranteed.

8

Fig. 6

1

2

3

5

4

6

7

Page 10

5.1 General

5.2 Remedying slight malfunctions

yourself

In the event of malfunctions, check whether the

gas and electricity supply is in proper working

order, i.e. the gas valve is open and the plug has

been plugged into the socket.

If the power supply is functioning correctly, but your

appliance still does not work, please contact your

dealer or your local Gaggenau customer

service agency. Specify the appliance type (see

rating plate).

Repairs may only be carried out by authorised

electricians, in order to guarantee the safety of

the appliance.

Unauthorised tampering with the appliance will

invalidate any warranty claims.

Only ever use original spare parts.

9

5. Maintenance

Fault Remedy

The burner does not ignite after several attempts. Check whether ...

... the burner is correctly assembled.

... the gas shut-off facility is open.

... the burner is clean and dry.

... the domestic fuse has tripped.

If necessary, inform after-sales service.

The gas flame goes off after ignition. Check whether ...

... the burner cover and the burner ring are

correctly fitted.

... the flame has been extinguished by a strong

draught in the room.

The cooking ring burner's electrical Check whether there are food remainders

igniter is no longer functioning. between the ignition electrode and the burner

cover. Carefully remove these.

The flame tips are yellow and not blue. Check whether the burner is dry and clean.

Page 11

10

Technical data (gas)

Burners: super strong burner

Stage 4 full flame 5.0 kW

Stage 3 small outer flame

plus stage 2 full inner flame 1.0 kW

Stage 2 full inner flame < 0.50 kW

Stage 1 low flame < 0.25 kW

Gas connection:

R 1/2’’ union nut for R 1/2’’ bracket to DIN 1999,

conical-cylindrical

Technical data (electrical)

Rated consumption 0.8 W

Voltage 220 - 240 V

Frequency 50 - 60 Hz

Technical modifications reserved.

6. Technical data / Table

Countries AT BE CH DE BE FR LU NL DE BE CH DK ES AT DE

DK ES FI FR FI FR GB GR

GB GR IE IS IE IS IT LU

IT LU NL PT NL NO PT SE

SE

Gas family Natural gas Natural gas Natural gas But/Prop But/Prop

Gas type H / E (G 20) L (G 25) LL (G 25) 3 + (G30/31) (G30/31)

Pressure 20 mbar 25 mbar 20 mbar 28-30/37 mbar 50 mbar

Nozzle, full burn, outer 1.55 1.55 1.73 1.00 0.87

Nozzle, low burn, outer 0.75 0.75 0.84 0.51 0.45

Nozzle, full burn, inner Nr. 34 Nr. 34 Nr. 44 Nr. 13 Nr. 7

Nozzle, low burn, inner 0.41 0.41 0.45 0.27 0.25

Air gap adj /outer [mm] 22222

Air gap adj /inner [mm] 33366

∑ Power 5 kW 5 kW 5 kW 5 kW 5 kW

∑ Consumption 0.48 m

3

/h 0.55 m3/h 0.55 m3/h 364 g/h 364 g/h

Page 12

7.1 The wok and accessories

(not included in the scope of delivery)

– The “original wok" is the ideal wok for your gas

cooker.

– The wok looks like a hollow semisphere with a

long handle or wooden handle. It has a rounded

base and slanted sides. The thin steel passes the

heat swiftly to the inside, but soon cools down

again as soon as the flame is set to a lower

setting. Therefore, ingredients cannot overcook.

– The diameter is between 35 and 40 cm for

4 persons.

– Woks may consist of various materials. Cast-iron

woks are more stable and keep the heat longer.

– They have a round, high cover. Therefore, they

are also capable of steaming and stewing.

– The semicircular grid is hooked in on the edge of

the wok. On it, you can steam ingredients, you

can allow deep fried foods to drip or you can

keep browned foods warm.

– Use the chan (rounded spatula) or the wooden

pan reversing implement.

– Use a ladle to remove foods.

– Use the strainer to lift deep fried foods from the

fat or large pieces out of a sauce.

– You can use bamboo baskets for steaming.

7.2 Cooking in the wok

You can fry, steam, deep fry, stew and cook normally.

Stir frying is the special cooking method for the

wok. Ingredients cut into small pieces are cooked

as briefly as possible under strong heat and

constant stirring. In the large, round pan everything

can be stirred and turned faster and with greater

ease than in a conventional frying pan. Thanks to

stirring, ingredients do not burn onto the pan.

Surplus oil drains off towards the middle. In next to

no time, you obtain delicious roasted foods, the

pores in meat close and fish becomes nices and

juicy. Vegetables stay crispy, and aromas and

healthy vitamins are retained.

Important: the cooking time is so short that all

ingredients should be ready for cooking before you

begin. The correct sequence is also important. First

place the ingredients with the longest cooking time

in the wok. For example, these are hard-fibred

vegetables such as carrots. Soft vegetables such as

mushrooms or sprouts are added later.

Proceed as follows:

– Pour sufficient oil into the wok to coat the surface.

We advise you to use peanut or or soya oil.

– Heat up the oil to just before the smoking point;

only then begin with stir frying.

– Cut the food into pieces of equal size, but not too

small, thus making sure they will not burn.

– If you are cooking larger quantities, work with

portions as otherwise not all of the food will reach

the hot base of the wok.

– Meals that are ready ca be kept warm on a

minimal flame. Clean the wok after every use and

rub its inside with oil. This will prevent rusting.

11

7. Practical tips

Page 13

7.3 Recipes

Beef in oyster sauce

Ingredients for 4 persons

500 g fillet of beef

1/2 teaspoon of black pepper (freshly ground)

2 tablespoons of dark soya sauce

1 tablespoon of wheat flour

5 dried Tongku mushrooms

300 g of oyster mushrooms

2 spring onions, 1 fresh red chili

4 cloves of garlic

1 thumb-sized piece of fresh ginger

3 tablespoons of oyster sauce, 1 tablespoon of fish

sauce

1 teaspoon of sugar, 4 tablespoons of rice wine

– Rinse the meat in cold water, dab it dry, remove

tendons and skin, and cut it into approximately

1 cm cubes. Mix with pepper, soya sauce and

flour and then marinate the mixture, covered up,

for about one hour in the fridge.

– In the meantime, wash the Tongku mushrooms.

Soak them in hot water for about 20 minutes.

– Clean the oyster mushrooms. Rinse them briefly

in running water and cut them into large pieces.

– Wash the spring onions and cut them in half

alongsides. Cut the spring onions into

approximately 3 cm long pieces. Wash the chili

and cut it in half alongside, remove the base of

the stalk, remove the pips and cut it into strips.

– Wash you hands thoroughly!

– Peel the garlic and ginger and chop it up finely.

– Carefully squeeze out the Tongku mushrooms

and quarter them.

– Heat oil in the wok. First singe the meat in

portions, stirring it at the same time. Briefly roast

the garlic and ginger and add the meat cubes.

Reduce the heat. Add the Tongku and oyster

mushrooms, spring onions, oyster and fish sauce

and the sugar and allow to cook for about 2 min-

utes in medium heat.

– Add the chili strips and allow them to heat up. Stir

in the rice wine. Garnish the meal with the chili

strips.

Chicken in basil and tomato sauce

Ingredients for 4 persons

100 g of shallots

500 g of fillet of chicken breast

750 g of tomatoes

1 large bunch of basil

2 tablespoons of oil

200 g of crème fraîche

salt

freshly ground black pepper

– Peel the shallots and cut them into cubes. Rinse

the fillets of chicken breast in cold running water

and cut them uniformly into cubes.

– Score the tomatoes and place them briefly in

boiling water or steam. Lift them out and skin

them, then chop them into coarse cubes.

– If necessary, rinse the basil and shake it well to

dry it, and then place a few leaves aside for

garnishing. Cut or chop the others.

– Heat up the oil in the wok. While constantly

stirring, singe the chicken meat in portions and

remove it from the wok. Briefly roast the shallots

until they are glassy. Add the meat.

– Add the chopped tomatoes and the crème fraîche

to the wok. Stir all ingredients and spice them

with the finely cut basil, salt and pepper. While

stirring, simmer for a few minutes.

– Season the sauce with salt and pepper and serve

the dish garnished with basil leaves.

Tip: if necessary, add to wine to the sauce to

improve taste.

12

Page 14

8.1 Important notes

Please observe the safety notes and the

important notes (Chapter 1).

The installing technician is responsible for

perfect functioning of the appliance at its

installation location. He must explain the operating

principle to the user with reference to the operating

instructions and must show how to switch of the

electricity and gas whenever required.

Caution:

Before connecting the appliance, please check

whether the local connection conditions such as

the gas type, gas pressure and mains voltage and

the appliance settings are correct. Refer to the

adhesive label on the gas connection or the rating

plate for the necessary information. This gas hob

conforms to the categories that are specified on

the rating plate. The rating plate can be found on

the appliance and additionally on the enclosed

addendum sheet. By replacing nozzles, it is

possible to set the appliance to any gas listed on

the rating plate. If the data should not agree, the

appliance must be set to the required gas type and

the available pressure.

As this gas hob is not intended for connection to an

exhaust gas system, pay attention to the applicable

installation conditions.

Note on ventilation:

To ensure good combustion, the room in which this

appliance is installed must have a minimum volume

of 10 m

3

and a door that opens out to outdoors or a

window that can be opened.

In Germany

, the gas hob must be installed and

connected by a fitter who has been approved by

the gas supply company. At the same time, the

guidelines such as DVGW-TRGI 86 and TRF 1988

and the regulations of the gas supply companies

and of the responsible authorities must be

observed.

In Switzerland

, the respectively applicable

regulations of SVGW and of the Association of

Cantonal Fire Insurance Companies as well as the

manufacturer's installation conditions must be

observed when installing the appliance.

In Austria

, the ÖVGW-TR Gas (G1) and ÖVGW-TR

Flüssiggas (G2-Part 1) regulations and the local

construction and trade regulations must be

observed when installing the appliance.

The appliance may be installed in kitchen

combinations made of wood or similar combustible

materials without taking additional measures. The

rear wall must consist of non-combustible material.

A minimum distance of 150 mm from heat-sensitive

items of furnishing or contact surfaces (cupboard

side panel) must be observed.

The hob conforms to appliance class 3 and must be

installed in the worktop as shown in the installation

sketch.

The distance between the suspended cupboard

and the worktop must be at least 600 mm. Attention

must be paid to the manufacturer's specified safety

clearance when a vapour extractor is installed. Wall

trims must be heat-resistant, and the minimum

distance between the hob and the wall trim is at

least 35 mm.

After unpacking, check the appliance for any

transportation damage and report this immediately

to the transportation company.

Technical modifications reserved.

13

8. Assembly instructions

VG 231-... FDxxxx

AC 220-240V 50/60Hz Qn 5,0 kW

0,8 VA

Page 15

14

8.2 Connecting the appliance

8.2.1 Gas connection

8.2.2 Electrical connection

Gas connection

The gas connection

must be in a location that

permits access to the shut-off valve and which, if

applicable, is visible after opening the door of the

furniture item.

By means of the included R 1/2” connection bracket

(on the appliance end) with the affiliated washer,

the appliance must be connected to a fixed

connecting line or a gas safety hose to DIN 3383

Part 1 that corresponds to the type concerned.

An ambient temperature of 70 °K must not be

exceeded if the gas safety hose consists only partly

of metal. The permissible ambient temperature for

a gas safety hose that consists completely of metal

is 115 °K.

If a flexible line is used, it must be laid in such a

way that it cannot come into contact with moving

parts of the kitchen element (e.g. drawer).

Electrical connection

Electrical connection (AC 220-240 V) is established

by means of a connecting cable with an earthing

contact plug connected to an earthed socket, which

must also be accessible after installation of the gas

hob.

If, after installation of the gas hob, not all poles can

be isolated from the mains by removing the plug,

an isolating device with a contact gap of at least

3 mm must be permanently installed. When

establishing connections, make sure that the

connecting lead cannot come into contact with hot

parts of the gas hob or other hot parts.

If damaged, the mains cable must be replaced by

a special mains connecting cable. The mains

connecting cable must only be connected by the

manufacturer or the manufacturer's after-sales

service.

The mains connecting cable must at least

correspond to the type H05-VV-F-3G 0.75.

40

103

Fig. 7

Seal

1/2”

Page 16

8.3 Nozzle replacement

Changing over to a different gas type

Only authorised specialists are permitted to

change over to a different gas type. The nozzles

needed for the gas type to be set are available as a

conversion kit. Please specify the appliance type

and the required gas type.

– Disconnect the appliance from the power

supply.

– Remove the pot support, the burner ring, the

burner cover and the burner head.

– If the appliance is connected rigidly to a gas

main, it must be disconnected from the gas

network. If it is connected via a gas safety hose,

the appliance only needs to be pushed out of its

mount from below and taken out of the worktop.

– Undo the securing nut (SW 11) of the

thermocouple and the two securing screws that

become visible under the detached burner head

(Fig. 8).

– Remove the hob.

– Pull off the control knob. After undoing the

securing screws (1) on the left and right (Fig. 9),

you can remove the control panel by lifting (2)

and pushing (3) it out of the latch (Fig. 10).

15

Fig. 9

Fig. 10

2

1

3

Fig. 8

Page 17

16

Replacing the low setting nozzles (Fig. 11)

The low setting nozzles for the inner (2) and outer

(1) burners are located in the gas valve. They must

be replaced according to the new gas type and as

specified in the low setting nozzle table. Screw in

the nozzles fully and check that they are tight

(metallic seal).

If it should be necessary to correct the low-setting

nozzles (1) and (2) as the result of deviating gas

types and pressure, the flow rate can be increased

by turning to the left.

Replacing the main nozzles

Main nozzle replacement for the outer burner

(Fig. 12)

Replace the main nozzle (3) (SW 10) for the high

setting according to the new gas type and as

specified in the nozzle table. Beforehand, loosen

the screw (2) and push away the air regulation

sleeve (1) and fix it in place with the screw (2).

Check the absence of gas leaks on the installed

main nozzle. According to the new gas type, stick

the included adhesive label over the data specified

on the gas connection.

Adjust the air gap according to the table entitled

“Air gap adjustment" for the outer burner.

Main nozzle replacement for the inner burner

(Fig. 13)

Remove the supply line by undoing the union nut

(4) (SW 8). Unscrew the injector screw (5) (SW 12)

and, using a small screwdriver, remove the nozzle

(6) from the injector (7). Install the nozzle

according to the new gas type (see data in the

nozzle table). To do this, fit the nozzle (6) on the

front of the injector screw (5) and screw both of

them into the injector. Plug in the supply line and

screw it in. Check for the absence of leaks. Adjust

the air gap as detailed in the table entitled “Air gap

for inner burner".

Fig. 13

distance in mm

Fig. 12

1

2

3

4 5 6 7

See table on Page 10 for details of nozzle settings.

Fig. 11

2

1

Caution: the flame must neither go off nor flash

back when you change over swiftly from the high

to the low setting.

Page 18

17

First air regulation

First air regulation may be necessary to always

achieve a stable and low-noise flame in the event of

deviating gas types and pressures.

First air regulation for outer burner (Fig. 14)

After undoing the screw (2) (7 mm), move the air

regulation sleeve (1) in the direction of the nozzle

(3)or away from the nozzle up to a maximum

distance of 12 mm until the flames burn stably and

with low noise. Yellow tips must not be visible in the

flames. The flame must not go off when you switch

swiftly from the high to the low setting. Firmly screw

in the screw (2) again.

First air regulation for outer burner (Fig. 15)

The throttle spring (4) is generally positioned on

the hexagon shaft. If required, shift the throttle

spring. For exact details, refer to the table entitled

“Air gap for inner burner". The air gap must

never be entirely sealed off.

Air gap

Fig. 15

See table on Page 10 for details of nozzle settings.

distance in mm

Fig. 14

1

4

2

3

Page 19

8.4 Installing the appliance

– Produce the recess for one or several Vario

appliance(s) in your worktop. Proceed as

indicated on the installation sketch and the

dimension table. The dimension table contains

details of the space requirement for the trim

between the appliances.

Important: the angle between the cut surface

and the worktop must amount to 90° (Fig. 16).

– Mark the centre of the recess exactly. Secure

the securing rails on the front and rear edges of

the recess. Make sure that the lugs of the securing

rails lie on the worktop and that the centre

marking of the securing rails is precisely flush

with the centre marking on the worktop (Fig. 17).

– Lower the appliance into the worktop. Make

sure that the engaging lugs on the appliance lie

exactly on the clamping springs. Press the

appliance firmly into the worktop. The engaging

lugs on the appliance “snap" into the clamping

springs (Fig. 18).

Note: When installing the appliance in granite or

marble worktops, have the holes produced by a

specialist or stick on the securing rails with a

temperature-resistant 2-component adhesive (metal

on stone).

18 5080003239ind02 en 11.04 SK

Note:

Several appliances can also be installed in

individual recesses, as long as a minimum

clearance of 40 mm is kept to between the

appliances.

1

,

4

m

8

8

8

,

5

2

8

8

510

490

1

1

4

7

8

5

4

5

6

1

268

min. 35

min.

50

4

2

,

5

Fig. 17

Fig. 16

Fig. 18

Secure the cover on the appliance before

installation. See assembly instructions

VD 201-010.

Loading...

Loading...