Page 1

RS301CR/RS302CD

Command Type Servo for Robot

User’s Manual Ver.1.0

Instruction Manual

Caution

Read this instruction manual before use.

Keep this manual handy for immediate reference.

For models

Page 2

CONTENTS

1.FOR SAFETY

● WARNING SYMBOLS ............................................................................................. 4

● CAUTIONS FOR USE ............................................................................................. 4

● WARNINGS IN HANDLING BATTERIES ............................................................. 5

● Cautions for Storage ................................................................................................. 5

2.INTRODUCTION

● Features .................................................................................................................... 6

● Part Names / Handling Instructions ........................................................................ 7

3.CONNECTION

● System Configuration ............................................................................................... 8

● Pin Assignment ...................................................................................................... 8

● Cautions when connecting ....................................................................................... 9

4.CONTROL METHOD

● Abstract ................................................................................................................... 10

● Packet Format ......................................................................................................... 11

Short Packet ............................................................................................... 11

Long Packet ................................................................................................ 14

Return Packet ............................................................................................. 15

● Memory Map ........................................................................................................... 17

● Invariable ROM area .............................................................................................. 17

No.0 /No.1 Model Number ............................................................. 17

No.2 Firmware Version ................................................................. 17

● Variable ROM area ................................................................................................. 18

No.4 Servo ID ................................................................................ 19

No.5 Servo Reverse ........................................................................ 19

No.6 Baud Rate .............................................................................. 19

No.7 Return Delay ...................................................................... 20

No.8 /No.9 /No.10 /No.11 Angle Limit ........................................... 20

No.14 /No.15 Temperature Limit .................................................. 20

No.24 /No.25 Compliance Margin ................................................. 21

2

Page 3

No.26 /No.27 Compliance Slope .................................................... 21

No.28 /No.29 Punch ....................................................................... 21

● Variable RAM Area ................................................................................................. 23

No.30 /No.31 Goal Position ............................................................ 24

No.32 /No.33 Goal Time ................................................................. 24

No.35 Maximum Torque ................................................................ 24

No.36 Torque Enable ..................................................................... 25

No.42 /No.43 Present Position ....................................................... 25

No.44 /No.45 Present Time ............................................................ 26

No.46 /No.47 Present Speed .......................................................... 26

No.48 /No.49 Present Load ........................................................... 27

No.50 /No.51 Present Temperature .............................................. 28

No.52 /No.53 Present Voltage ....................................................... 29

5.REFERENCE

● SPECIFICATIONS ................................................................................................. 30

● DIMENSIONS ........................................................................................................ 31

● TROUBLESHOOTING ........................................................................................... 32

3

Page 4

1.FOR SAFETY

To use this product safely, please pay your full attention to the followings. Be sure to

read this instruction manual prior to using this product.

Warning Symbols

The warning symbols used in this text are defined as follows:

Indication

Indicates a hazard that will cause severe personal injury, death, or

Danger

Warning

Caution

Symbols: ; Prohibited ; Mandatory

substantial property damage if the warning is ignored.

Indicates a hazard that can cause severe personal injury, death, or

substantial property damage if the warning is ignored.

Indicates a hazard that will or can cause minor personal injury, or

property damage if the warning is ignored.

Cautions for Use

Caution

Do not disassemble or alter the servo.

Otherwise, it may cause breakage in the gear box, fire on the servo or explosion of

the battery.

Do not use any battery as a power supply other than the specified battery.

The product is designed to be operated by Futaba’s 9.6V Ni-MH battery only. Do not

use any other batteries.

Do not touch the servo case during or some time after operating the servo.

Otherwise, you may get burned on the finger as the motor or electronic circuit in the

servo gets very hot.

Do not let the servo get covered with sandy dust or water.

Otherwise, the servo may stop moving or have a short circuit. The servo is not

designed to be waterproof or dust-proof.

Do not use this product for any application other than indoor hobby-robots.

Futaba is cleared of all responsibility to the results caused by the usage of this

product for any application other than indoor hobby-robots.

Meaning

4

Page 5

Do not turn the servo horn forcibly.

Otherwise, the servo will be damaged.

Do not leave the servo locked.

If the servo continues to be locked due to a strong external force, it may cause smoke,

fire or damage.

Warnings in Handling Batteries

Warning

Do not use any battery charger other than the specified charger.

Otherwise, the battery may be get damaged, fire, smoke or liquid leakage. Be sure to

use batteries recommended by Futaba.

Do not use battery packs connected in parallel.

Connecting battery packs in parallel may cause abnormal heat generation or

explosion due to the differences between charging voltages.

Do not disassemble or alter battery packs.

Otherwise, it may cause fire, explosion or liquid leakage. And please be aware that

such battery packs will be no longer guaranteed even if their warranties are not

expired.

Do not use batteries if any abnormal symptoms are seen.

If you find any abnormal symptoms such as cracks in coating film, abnormal heat

generation from batteries or deformation of batteries, never use the battery because

it may cause serious consequences.

Cautions for Storage

Caution

Do not store the servos in the following conditions.

Places where the temperature is over 60℃ or below -20℃.

Places where the Sun directly shines over the servos.

Places where it is very high in humidity.

Places where there is a strong vibration.

Places where there is a lot of dust.

Places where static electricity tends to be induced.

Places where infants can reach.

◆ Storing the servos in the places shown above may cause deformation and failure of the servos,

or hazard.

5

Page 6

2.INTRODUCTION

Features

RS301CR/RS302CD servo is especially designed for robotic applications, having the

following features.

● Small and Lightweight

RS301CR and RS302CD are small and

lightweight servos specially designed for

robots, which are 28g and 21g

respectively.

● Interactive high speed

RS485 communication

RS485 half duplex communication

carries out bidirectional high-speed

communication up to 460kbps. RS485 is

used for the communication between the

robot’s processor unit and servos at very

high speed.

● Command type control

The servo can be controlled by commands

sent from the robot’s processor unit

through RS485. And a single command can

convey multiple data, including a period of

time to move and a target position. This

relieves the robot’s processor unit from load

significantly.

● Data Feedback

Various kinds of information about the

servo such as angular position, load,

temperature, current and alarm can be

obtained via RS485.

● Compliance control

With this feature, the movement of the

trembling its arms and legs and to absorb

turbulence from external force.

● Calibration

Angular position of every

RS301CR/RS302CD servo is calibrated by

our standard gauge before their shipment.

Even if another RS301CR/RS302CD servo

is employed, it does not require any

bothersome work for adjusting its angular

position.

● 12bit-A/D converter

for precise positioning

Angular feedback using the 12bit-A/D

converters makes it possible to position the servo

angle precisely.

● Wiring from the output shaft

Wires pass through the backside of the

output shaft to avoid getting wires

entwined in operation.

● Horn with a mark for reference position

凹 marks are placed on the

circumference of the servo horn in order

to make sure the reference position even

after being built in. ( one 凹 for 0°

position, two for 90°, three for 180°

and four for 270°).

RS301CR/RS302CD is controlled in

accordance with the distance between the

present and target positions. This enables

the robot to move very smoothly without

6

Page 7

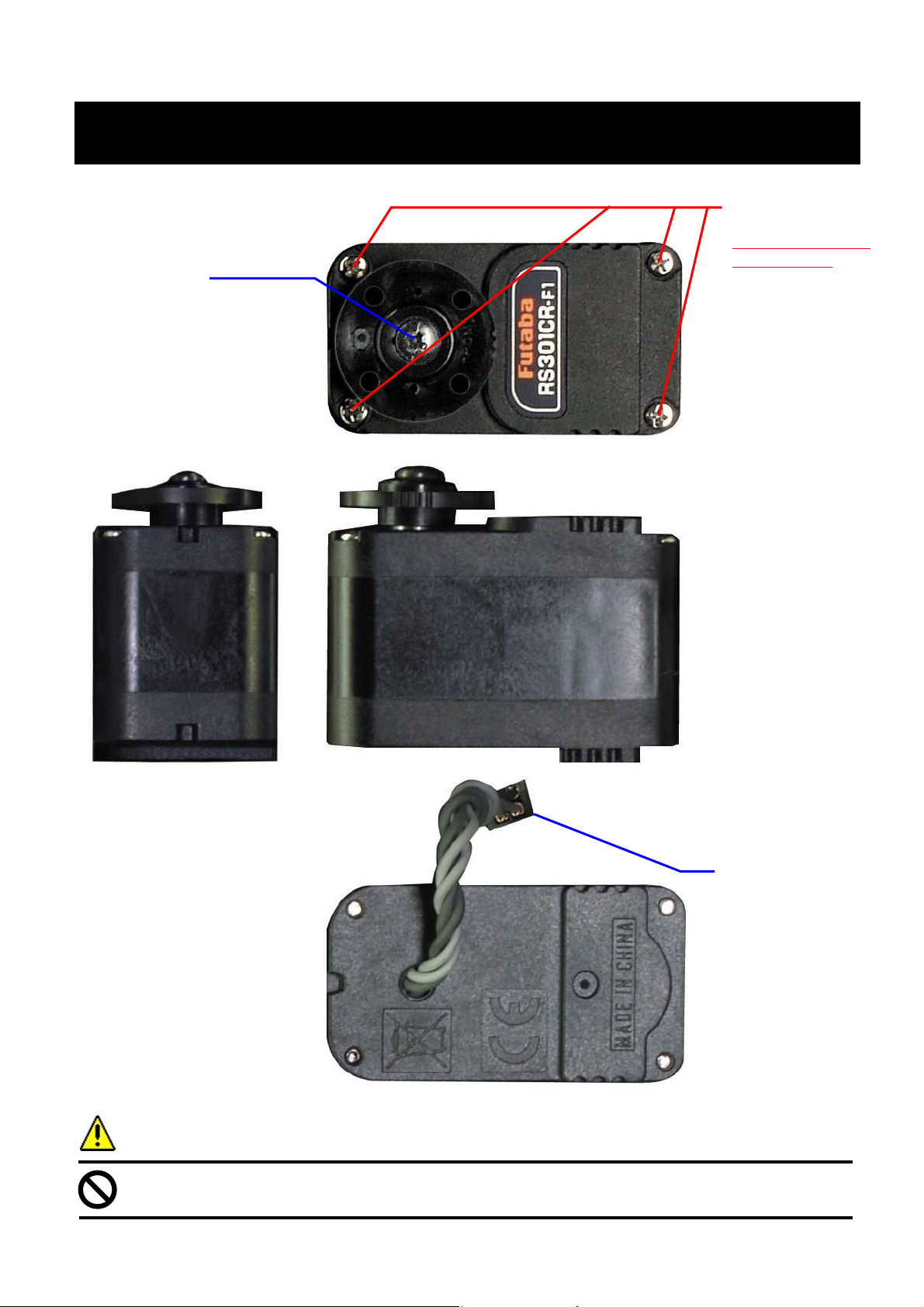

Output-axis

Part Names / Handling Instructions

Screws for fixing

the servo to a case

※ Do not remove

these screws.

Connecter

Fig.2.1 Part names

Caution

Removing the screws for fixing the servo with a case may damage the servo.

7

Page 8

3.CONNECTION

)

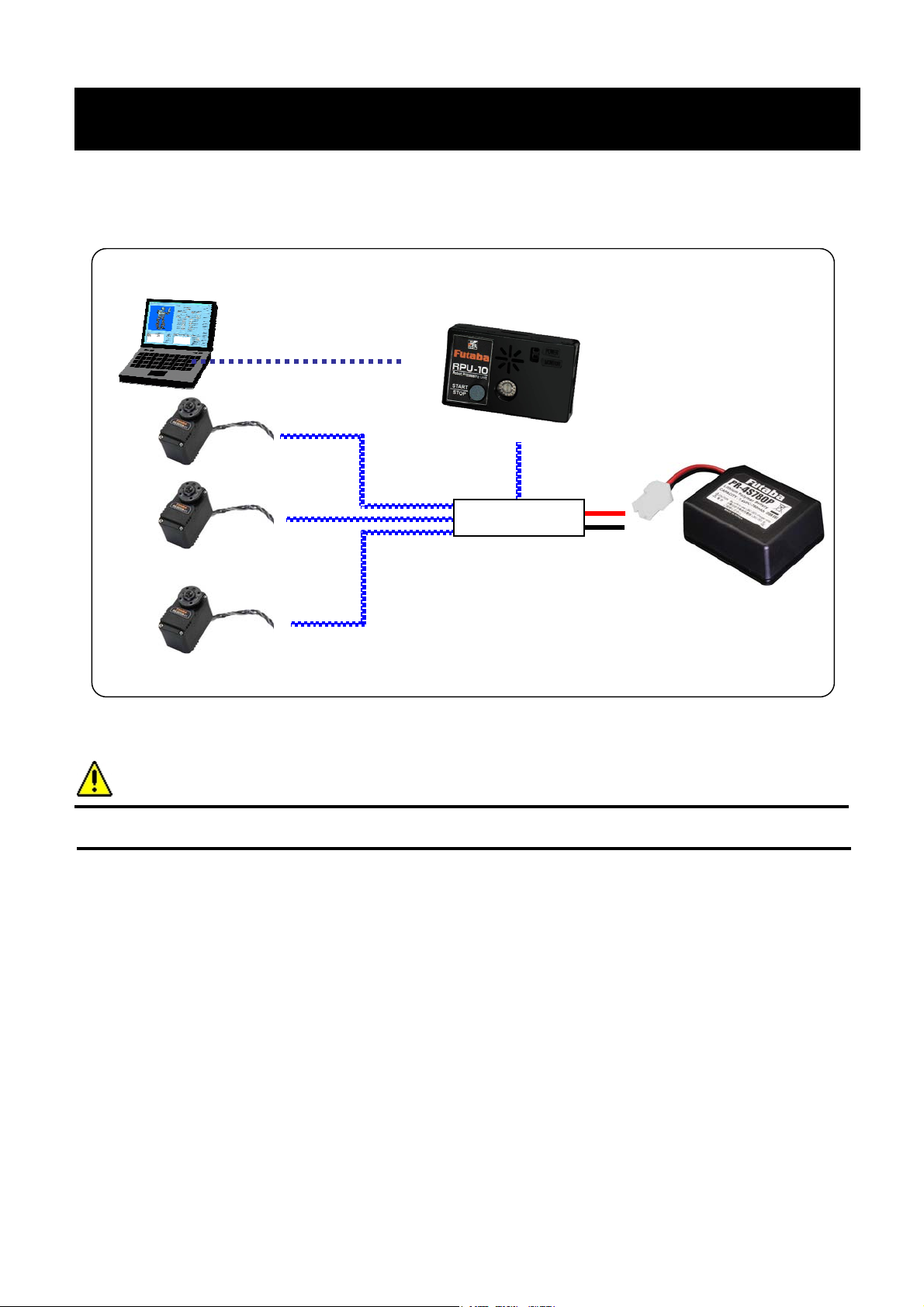

System Configuration

The following figure shows a robotic system using RS301CR/RS302CD servos, RPU-10

processor unit and etc.

RS301CR

RS302CD

Battery (PR-4S780P

Motion editor

Control softwar

Processing Unit (RPU-10 etc.)

RSC-U485

Fig. 3.1 Robotic system configuration

Pin Assignment

Pin assignment of the RS301CR/RS302CD servo is shown below.

②④

①③

① Gray :RS485(D-)

② Black :RS485(D+)

③ Gray :VCC(7.4V)

④ Black :GND

Fig. 3.2 Pin assignment

8

Page 9

Cautions when Connecting

Please refer to the figure below for connecting RS301CR/RS302CD and RPU-10.

Please prepare it by your self

PC

RPU-10

RS232C

PR-4S780P

Allowable current for relay connectors is 2A and for servo harness is 3A each for continues use.

RS301CR/RS302CD

Fig. 3.3 Operating with RPU-100

Relay box

Set your PC’s communication parameters as follows;

Baud rate :115.2 bps

(adjustable between 9.6kbps and 460kbps, Refer to Table 4.6 Baud rate in p.19)

Data bit length :8 bits

Parity :none

Stop bit :1 bit

Flow control :none

9

Page 10

4.CONTROL METHOD

Abstract

● Communication Protocol

The communication protocol of the RS301CR/RS302CD servo is based on RS485

(IEEE485) half duplex communication. Data transmission and reception are carried out

alternatively on the same signal line.

Normally, the RS301CR/RS302CD servo stands by in reception mode. But, when it

receives from RPU-10 a command to send the servo’s data and status, it switches to

transmission mode, sends them out and finally returns to reception mode.

● Memory Map

The RS301CR/RS302C servo has its own memory area to store data necessary for its

movement. This memory area is called “Memory Map”.

This memory map is divided into two groups. One is “RAM area” in which data will be

erased when the power is turned off. The other one is “ROM area” in which data is held

even after the power is turned off.

● Servo ID

You can set ID numbers to RS301CR/RS302C servos individually.

These ID numbers are used to identify servos during communication. The default

number of every servo is set to “1”. When you use multiple servos in a single

communication network, give them different ID numbers.

● Packet

A packet is a block that is used for sending a command to or receiving data from

RS301CR/RS302C servos. Packets are divided into the following three groups, having

different formats.

(1) Short Packet(→p.11)

Short packets are used for sending the data in the memory map toward a single servo.

(2) Long Packet(→p.14)

Long packets are used for sending the data in the memory map toward multiple servos

simultaneously.

(3) Return Packet(→p.16)

This is a packet that is sent from a servo when a return packet is requested.

10

Page 11

Packet Format

●Short Packet

Short packets are used for sending the data in the memory map toward a single servo.

Packet structure

Header ID Flags Address Length Count Data Sum

Header

“xH” denotes Hexadecimal number.

ID

This is a servo’s ID. The valid numbers are from 1 through 127 (00H ~ 7FH). When ID is set to 255,

commands are commonly effective to all servos. The processor unit cannot obtain any data from servos

at this time.

Flags

This is a line head of a packet. FAAFH is used for short packets.

Each bit has the following meaning.

Table 4.1 Send packet flags

Bit Function

7 Reserved

6 Write in Flash ROM

5 Reboot servo

4 Initialize memory map data

3

2

1

0

Return-packet’s address

Bit7: Reserved

Set this bit always at “0.”

Bit6: Write in Flash ROM

Setting this bit to “1” (Flags=40H) and sending a packet of address=FFH, length = 00H

and count = 00H to a servo will write the data of the memory map from No.4 through

29(04H~1DH) into the non-volatile Flash ROM. It takes about 1 second for writing.

11

Page 12

Ex)Write the data of the ID1 servo into the Flash ROM.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

40

00 BE

FF

00

The servo’s memory should be renewed with the data you want to write into the Flash

ROM by transferring the data by using a short packet beforehand.

The servo ID becomes effective only after receiving a packet. The ID returns to the

previous number on the next boot up unless the ID is written into the Flash ROM.

Caution

Never turn off the power while the Flash ROM is being written.

Bit5:Reboot servo

Setting this bit to “1” (Flags=20H) and sending a packet of address=FFH, length = 00H

and count = 00H to a servo will reboot a servo.

Ex)Reboot the ID1 servo.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

20

00 DE

FF

00

Setting both Bit6 and Bit5 to “1” makes it possible to write Flash ROM and reboot the

servo consecutively.

Ex)Write into the Flash ROM of the ID1 servo and reboot the servo.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

60

00 9E

FF

00

Bit4:Initialize the contents of memory map No.4 ~ No.29

Setting this bit to “1” (10H) and sending a packet of address=FFH, length = FFH, count =

00H and data=FFH to a servo will initialize the memory map from No.4 through No.29 to

their initial values.

Please refer to initial values in the “ROM area of Memory Map” (p.18) for more details.

Ex) Initialize the memory map from No.4 through No.29 to their initial values.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

Caution

10

FF EE

FF

00

If you reset to the factory initial value, the ID becomes 1.

12

Page 13

Bit3 ~ Bit0:Address assignment of a return packet

(1) Data return from predetermined addresses

Setting the Bit3 through Bit0 like the table below when sending a short packet makes it

possible to receive the data of the specified addresses in the servo’s memory map. The Bit0

indicates whether to require a return packet (Bit0=1) or not (Bit0=0). Please refer to the

Table 4.1 Send packet flags (p.11) for setting these bits in sending short packets. The

RS485 half duplex communication, which is used to communicate with servos, does not

allow addressing more than one servo that can send a return packet. After requesting a

return packet, do not send next data until completing reception of the return packet.

Table 4.2 Address assignment of return packet

Bit 3 2 1 0 Function

0 0 0 0 No return packet

0 0 0 1 Return ACK/NACK packet

0 0 1 1 Return the data of the memory map No.00 ~ No.29

0 1 0 1 Return the data of the memory map No.30 ~ No.59

0 1 1 1 Return the data of the memory map No.20 ~ No.29

1 0 0 1 Return the data of the memory map No.42 ~ No.59

1 0 1 1 Return the data of the memory map No.30 ~ No.41

1 1 1 1

Return the specified number of bytes of data starting from the

specified address.

(2) Data return from user-defined addresses

Setting the Bit3 through Bit0 to “1” and sending a short command with the starting ad-

dress whose data you want to receive, the length of data and the count=00H makes it possible to return the specified number of bytes of the data starting from the specified address.

Available addresses in the memory map are from No.00 to No.139 (00H~8BH).

Ex) Return the data in the memory map addresses from No.42 (2AH) through No.43

(2BH) of the ID1 servo.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

0F

02 26

2A

00

(3) ACK/NAK Packet

If a servo receives a request of sending ACK the Flags being set at Bit0=1, Bit1=0,

Bit2=0 and Bit3=0, the servo send ACK.

The return packet is constituted by only one byte of data like bellow:

Return packet = 07H: “ACK”

13

Page 14

Address

This notation indicates an address on the memory map. Using this address makes it possible

to write the data of the specified number of bytes determined by the “Length” into the

memory map.

Length

Count

Data

Sum

This notation indicates the length of a data block.

Length = the number of bytes of data

This notation indicates the number of servos, which should be set at “1” for a short packet.

This notation indicates the data to be stored in the memory map.

This is the check sum of a packet using 8 bits. Check sum is the value obtained from XOR

operation on all bytes from ID through Data in a packet by a unit of a byte.

If the number of bytes from ID through Data in a packet is two or larger, divide them

byte-by-byte and conduct XOR operation on them.

Ex) Send a command ordering ID1 servo to move to 0 degree.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

00

02 1C

1E

00 00 01

The check sum of the transmission data above is as follows:

01H XOR 00H XOR 1EH XOR 02H XOR 01H XOR 00H XOR 00H

●Long Packet

The long packet is used to send the data in the memory map to multiple servos. Please

note, however, that the memory address and the length of the data to be sent are the same

to all the servos.

Packet structure

Header ID Flags Address Length Count

Header

“xH” denotes Hexadecimal number.

ID

This notation indicates the front of a packet. Set “FAAFH” for long packets.

Length

VID

Data

Number of servos = Count

VID

Data

VID

Data

Sum

This should be always kept at 00H.

Flags

This should be always kept at 00H.

14

Page 15

Address

Length

Length = the number of bytes of data + 1

Count

them.

VID

servos is sent with VID and Data as one set.

Data

the number of servos is written with VID and Data as one set.

Sum

This indicates an address on the memory map. Using this address makes it possible to write

the data of the specified number of bytes determined by the “Length” into the memory maps of

multiple servos.

This is used to specify the number of bytes of the data for a servo.

This notation indicates the number of servos that data is sent to. VID and data are sent to all of

This field represents the ID of each servo which sends data. Data corresponding to the number of

This field is the data of one servo which is written to the memory map. Data corresponding to

This field is made up of eight bits which represent the check sum of the packet. The check sum

is the XOR, in byte units, of the set bits from the ID field to the end of the Data field of the

packet string. If there is a packet of 2 bytes or more between the ID and DATA fields, delimit it

into single bytes before XORing.

Hdr ID Flg Adr Len Cnt VID Dat VID Dat VID Dat Sum

FA AF 00

00

03 ED

1E

64 00 03

01 64 00 02 F4 01 05

The check sum of the send data above is:

00H XOR 00H XOR 1EH XOR 03H XOR 03H XOR 01H XOR 64H XOR 00H XOR 02H XOR 64H

XOR 00H XOR 05H XOR F4H XOR 01H

15

Page 16

●Return Packet

ID

A return packet is the packet returned from the servo when the Flag field requests a

servo to send a return packet.

Packet structure

Header ID Flags Address Length Count Data Sum

Header

This field represents the servo ID.

Flags

represents a servo state.

Bit Value Function

7 0:Normal, 1:Error Temperature error(Torque off over temperature limit)

6 N/A Reserved

5 0:Normal, 1:Error Temperature alarm

4 N/A Reserved

3 N/A Reserved

This field denotes the beginning of the packet. For a short packet, the header is FDDFH.

This field represents the flags which are set in the packet. Each bit shown in the table below

Table 4.3 Return packet flags

2 N/A Reserved

1 0:Normal, 1:Error Received packet error

0 N/A Reserved

Address

Length

is: Length = Number of return VID + Data bytes

Count

Sum

end of the data field of a command packet.

This field represents the servo memory map address No.

This field represents the length of one data block. The length of one return packet data block

This field represents the number of servos. For a return packet, 1 is always set here.

This field is the check sum. It is the XOR, in byte units, of all the set bits from the ID field to the

16

Page 17

●Invariable ROM area

Memory Map

Table 4.4 Invariable ROM area

Area

Invariable

ROM

Adress No.

DEC HEX

00 00H 10H(20H) Model Number L R

01 01H 30H Model Number H R

02 02H 01H Firmware Version R

03 03H 00H Reserved -

Initial

Name Property

value

( ) For RS302CD

●No.0 / No.1 Model Number(2Bytes, Hex Number, Read Only)

This field represents the model No. (servo model). For the RS301CR, it is:

Model Number L = 10H

Model Number H = 30H

For RS302CD, they are as follows.

Model Number L = 20H

Model Number H = 30H

●No.2 Firmware Version(1Byte, Hex Number, Read Only)

This field represents the servo firmware version. Its value varies depending on the

version at production (0x01 in the example below).

Firmware Version = 01H

※ Storing two-byte data to memory map

Two-byte data is stored to the memory map in two individual 8-bit bytes of H (High byte)

and L (Low byte).

Ex.) Issue a 29.2 degrees operation command to servo ID=23.

The command angle is saved to the Target Position item. The commanded value is 29.2

degrees, but since this is 0x0124 in hexadecimal notation, the data actually stored is:

Target Position(L) = 24H

Target Position(H) = 01H

17

Page 18

●Variable ROM area

Table 4.5 Variable ROM area

Area

ROM

Adress No.

DEC HEX

04 04H

05 05H

06 06H

07 07H

08 08H

09 09H

10 0AH

11 0BH

12 0CH

13 0DH

14 0EH

15 0FH

16 10H

17 11H

Initial

Name Property

value

01H Servo ID RW

00H Reverse RW-

07H Baud Rate RW

00H Return Delay RW

DCH CW Angle Limit L RW

05H CW Angle Limit H RW

24H CCW Angle Limit L RW

FAH CCW Angle Limit H RW

00H Reserved -

00H Reserved -

50H(46H) Temp Limit L R

00H Temp Limit H R

00H Reserved -

00H Reserved -

18 12H

19 13H

20 14H

21 15H

22 16H

23 17H

24 18H

25 19H

26 1AH

27 1BH

28 1CH

29 1DH

00H Reserved -

00H Reserved -

00H

Reserved -

00H Reserved -

00H Reserved -

00H Reserved -

02H CW Compliance Margin

02H CCW Compliance Margin

RW

RW

0AH(0FH) CW Compliance Slope RW

0AH(0FH) CCW Compliance Slope RW

B4H(C8H) Punch L RW

00H Punch H RW

( ) For RS302CD

18

Page 19

●No.4 Servo ID(1Byte, Hex Number, Read/Write)

Value

Baud rate

Value

Baud rate

Value

Baud rate

00H

9,600bps

05H

57,600bps

0AH 460,800bps

01H 14,400bps

06H

76,800bps

02H 19,200bps

07H 115,200bps

03H 28,800bps

08H 153,600bps

04H

38,400bps

09H 230,400bps

This data represents the servo ID. Its initial value is 01H.

The setting range is 1 ~ 127 (01H ~ 7FH).

Ex) Rewrite servo ID1 to ID5.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

00

01 00

04

01 05

The relevant servo begins to operate under the new ID as soon as the ID rewrite

command is received.

Note that after the ID was rewritten, if it was not written to the flash ROM, when the

power is turned off, it will return to the previous ID.

●No.5 Servo Reverse(1 Byte,Hex Number,Read/Write)

This shows rotation directions of the servo. The initial value of 00H means the normal

rotation and 01H means the reverse rotation.

If the servo is set with 01H, the limited range of rotation angles is also reversed.

●No.6 Baud Rate(1Byte, Hex Number, Read/Write)

This data represents the communication speed.

The value assigned to each baud rate is shown below.

Table 4.6 Baud rate

(Date Bits : 8 bit,Stop Bit :1 bit,Parity : None,Flow Control : None)

Its initial value is 07H (115,200bps).

※When a value other than the set values listed above was set, the communication speed becomes

115,200bps.

Ex.) Set Baud Rate of servo ID=1 to 38,400bps.

Write Baud Rate=04H. At this time, a command with 1 set in bits 5 and 6 of the Flag

field is sent and writing to ROM and restarting of the servo are executed simultaneously.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

60

01 63

06

01 04

19

Page 20

●No.7 Return Delay(1 Byte,Hex Number,Read/Write)

This indicates the delay time for reply when the return packet is required.

The servo sends the return packet in 100μs after receiving data with the setting of 0.

The parameters of No.7 are in units of 001H = 50μs.

If you want to set the delay time for reply to 1ms, write 18 (12H). (1ms=100μs+18x50μs)

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

60

01 74

07

01 12

●No.8~No.11 Angle Limit(2Bytes, Hex Number, Read/Write)

These data specify the CW (clockwise rotation), CCW (counterclockwise rotation), and

maximum operating angle based on 0 degree. Set these bits to match the usage

environment.

The rotation limit angle is the maximum value, which can be initially set (±123

degrees). Never set an angle exceeding this value, because the servo may be damaged.

Even if a command value greater than the rotation limit angle is given, the maximum

operating angle is not exceeded.

The setting range is

CW Angle Limit →0°(0000H) ~ +150°(05DCH)

CCW Angle Limit →0°(0000H) ~ -150° (FA24H).

Ex. 1) Set the CW angle limit of servo ID=1 to 100.0 degrees.

Since the angle is set in 0.1 degree units, when 100.0 degrees is specified, 1000(03E8H) is

set. CW Angle Limit L = E8H, CW Angle Limit H = 03H

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

00

02 E1

08

01 E8 03

Ex. 2) Set the CCW set values of servo ID=1 to -100.0 degrees (FC18H).

CCW Angle Limit L = 18H , CCW Angle Limit H = FCH

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

00

02 EE

08

01 18 FC

●No.14 / No.15 Temperature Limit(2Bytes, Hex Number, Read Only)

If an overload is applied to a servo, the heat generated by the motor, etc. will cause the

internal temperature to rise. If the internal temperature exceeds the temperature set here,

the torque will be disabled so trouble will not occur at the servo and the red LED on the

servo will light. To reset the stopped state, send a No. 36 Torque Enable command.

20

Page 21

*Note that rewriting this memory map value will null and void the product warranty.

●No.24 / No.25 Compliance Margin(1Byte, Hex Number, Read/Write)

These data specify the allowable range of the servo stop position. If the present value is

within the range set here relative to the specified target position, the servo is judged to

have reached the target position and is stopped. CW and CCW can be set individually.

Setting is in approximately 0.1 Degree units.

The initial value is 02H(0.2 degree). We recommend that the initial value not be changed

because in most cases, it is the optimum value.

The setting range is 00H ~ FFH (approximately 25.5 degrees).

※ Please refer to the chart in”●No.28/No29 Punch”.

●No.26 / No.27 Compliance Slope(1Byte, Hex Number, Read/Write)

These data set the range of the torque which attempts to return the servo to the target

position when the present position has deviated from the target position. In the range

specified here, the torque which attempts to return the servo to the target position is

proportion to the difference between the target position and the present position. The CW

and CCW directions can be set individually. Hunting can be reduced and shock can be

absorbed by using this function.

Setting is in approximately 1.0 degree units.

The setting range is 00H ~ 96H (approximately 150 degrees).

The initial values are 0AH(10 deg.) for RS301CR, and 0FH(15 deg.) for RS302CD.

※ Please refer to the chart in ”●No.28/No29 Punch”.

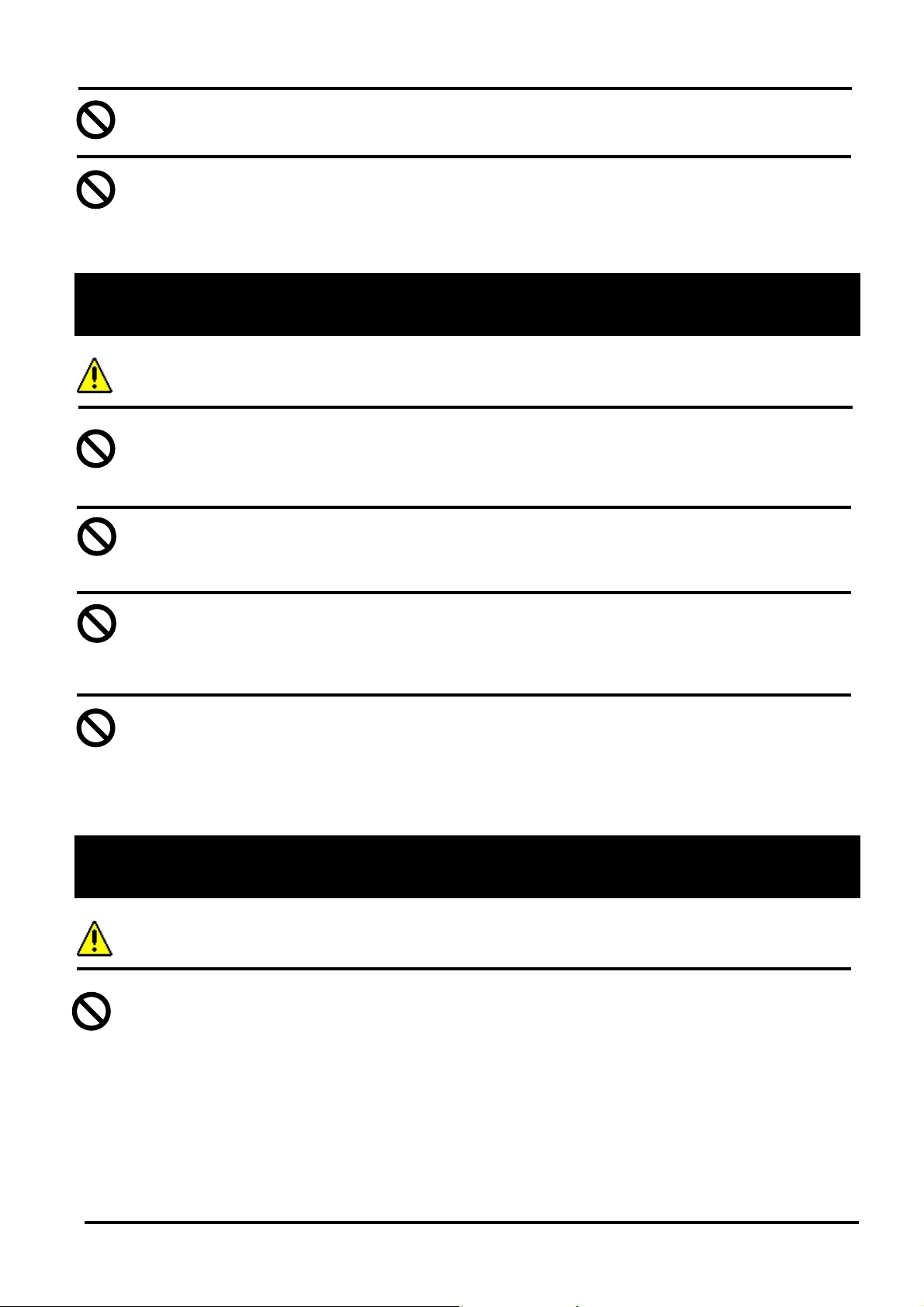

●No.28 / No.29 Punch(2Bytes, Hex Number, Read/Write)

The minimum current applied to the internal motor when a servo is driven can be set.

The region in which the servo does not operate even when a minute movement command is

given can be reduced and the servo can be more accurately stopped at the target position by

setting this value to the optimum value.

The setting should be by 0.01% of the maximum torque.

The setting range is 00H ~ 2710H(100%).

The initial value for RS301CR is B4H(1.8%) and for RS302CD is C8H(2.0%).

21

Page 22

C D

84 03

CCW

Target position

CCW

CW

A B

Fig. 4.1 Compliance control

Ex. 1) Set punch to 0064H(1%).

Hdr ID Flg Adr Len Cnt Dat Sum

Punch

Punch

Position

CW

A: CCW Compliance Slope

B: CCW Compliance Margin

C: CW Compliance Margin

D: CW Compliance Slope

FA AF 01

00

02 7A

1c

01 64 00

Ex. 2) Servo ID=1 is set as follows:

CW Compliance Margin = 03H

CCW Compliance Margin = 03H

CW Compliance Slope = 14H

CCW Compliance Slope = 14H

Punch = 0064H

The 6 bytes from memory addresses 24 to 29 are set at one time.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

00

06 7A

18

01 03 03 14 14 64 00

22

Page 23

●Variable RAM Area

Table 4.7 Variable RAM area

Area

Adress No.

Initial

Name Property

DEC HEX

30 1EH 00H Goal PositionL RW

31 1FH 00H Goal PositionH RW

32 20H 00H Goal TimeL RW

33 21H 00H Goal TimeH RW

34 22H 00H Reserved -

35 23H 64H(4DH) Max Torque RW

36 24H 00H Torque Enable RW

37 25H 00H Reserved RW

38 26H 00H Reserved RW

39 27H 00H Reserved RW

40 28H 00H Reserved -

41 29H 00H Reserved -

42 2AH 00H Present Position L R

43 2BH 00H Present Position H R

value

RAM

44 2CH 00H Present Time L R

45 2DH 00H Present Time H R

46 2EH 00H Present Speed L R

47 2FH 00H Present Speed H R

48 30H 00H Present Current L R

49 31H 00H Present Current H R

50 32H 00H Present Temperature L R

51 33H 00H Present Temperature H R

52 34H 00H Present Voltage L R

53 35H 00H Present Voltage H R

54 36H 00H Reserved R

55 37H 00H Reserved R

56 38H 00H Reserved R

57 39H 00H Reserved R

58 3AH 00H Reserved -

59 3BH 00H Reserved -

( ) For RS302CD

23

Page 24

●No.30 / No.31 Goal Position(2Bytes, Hex Number, Read/Write)

A servo can be moved to the specified angle. The center of the movement range is 0

degree. Viewed from the top of the servo (nameplate side), the CW (clockwise rotation)

direction is “+” and the CCW (counterclockwise rotation) direction is “-“. When the “No.5

Servo Reverse” is 01H, CW direction is “-” and the CCW direction is “+”.

The goal position unit is about 0.1 deg. To make 90 degrees the target position, set “900”

(900→384H). When an angle larger than the limit angle set at memory addresses No. 8~11

was commanded, the servo operates up to this limit angle. When the Torque is changed

from disable to enable, the servo holds the present position where it was enabled.

Ex. 1) Move servo ID=1 to 90.0°(900→384H).

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01 00 1E 02 9B01 8403

Ex. 2) Move servo ID=1 to -90.0 degrees (-900→FC7CH).

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01 00 1E 02 9C01 7CFC

●No.32 / No.33 Goal Time(2Bytes, Hex Number, Read/Write)

The movement duration of a servo up to the goal position can be set. The duration is set

is 10ms units. When a command value exceeding the maximum speed of the servo was set.

the servo moves at its maximum speed.

Ex. 1) Move servo ID=1 to 90.0 degrees (900→384) in 5 seconds (since this is 5000ms,

500(01F4H).

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01 00 20 04 A501 84 03 F4 01

Ex. 2) Move servo ID=1 to -120.0 degrees (-1200→FB50H) in 10 seconds (since this is

10000ms, 1000(03E8H).

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01 00 20 04 6401 50 FB E8 03

●No.35 Maximum Torque(1Byte, Hex Number, Read/Write)

The maximum torque output by the servo can be set. The servo torque can be set in 1% units with the

torque of the servo described in this manual as 100%. However, consider this an approximate standard.

Even if a value over 100% is set, the maximum torque becomes 100%.

64H(100%)is the initial value for RS301CR,and 4DH(77%)is for RS302CD.

24

Page 25

The setting range is between 0H and 64H.

Ex) Set the maximum torque of servo ID=1 to 80% (50H).

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

00

01 72

23

01 50

●No.36 Torque Enable(1Byte, Hex Number, Read/Write)

The servo torque can be enabled and disabled. 01H enables the torque and 00H disables

the torque. When the power is turned on, the torque is disabled (00H). When 02H is set, the

servo enters the brake mode and the servo horn can be freely rotated by hand, but a weak

torque is generated.

*When the Torque is changed from disable to enable, the servo holds the present

position.

Ex. 1) Enable servo ID=1 torque.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

Ex. 2) Disable servo ID=1 torque.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

00

00

01 24

24

24

01 01

01 25

01 00

Ex. 3) Set servo ID=1 to the brake mode.

Hdr ID Flg Adr Len Cnt Dat Sum

●No.42 / No.43 Present Position(2Bytes, Hex Number, Read Only)

The present angle of a servo can be read. The angle information

of the present position can be obtained in 0.1 degree units within a

range of -150 degrees in the CCW (counterclockwise rotation)

direction and 150 degrees in the CW (clockwise rotation) direction

with the center of the variation range as 0 degree as shown in the

Fig. 4-2.

-150°

Ex.) Read the present position of servo ID=1.

Fig. 4-2 servo range

To obtain the value of address Nos. 42 and 43 of the servo as a

return packet, send a “Flag” bit 3=1, bit2=0, bit1=0, bit0=1 send packet. After this packet is

sent, the value of memory map address Nos. 42 to 59 is returned from the servo(See the

Flags item of “Short packet” on p.13 for more information.) Here, The Torque Enable

command and the flag of memory map address Nos. 42 ~ 59 are sent to servo ID=1.

0°

+150

25

Page 26

If you send only flags, set [COUNT] =1 with [ADRESS]=0 and [LENGTH]=0, and

nothing should be written in「Data」.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01

09

01 2D

24

01 01

Return Packet

Hdr ID Flg Adr Len Cnt Sum

FD DF 01

00

Memory Map No. 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

2A

12

0001 84 03 00 00 00 00 06 00 BA 03 00 00 00 00 00 00 00 00

As the 2 bytes from the beginning of the return packet data are memory map address

Nos. 42 and 43, the present position is 0384H(90.0 degrees).

●No.44 / No.45 Present Time(2Bytes, Hex Number, Read Only)

The present time is the time that has elapsed from reception of the command by the

servo to the start of movement. When movement is complete, the present time is held last

data.

Ex.) Read the present time of servo ID=1.

To obtain the value of memory map address Nos. 44 and 45 of the servo as a return

packet, send a Flag bit3=1, bit2=0, bit1=0, bit0=1 send packet. After this packet is sent, the

value of memory map address Nos. 42 to 59 is returned from the servo. (See the Flags item

of “Short packet” on p.11 for more information.)

If you send only flags, set [COUNT] =1 with [ADRESS]=0 and [LENGTH]=0, and

nothing should be written in「Data」.

Hdr ID Flg Adr Len Cnt Dat Sum

FA AF 01 09 24 01 2D01 01

Return Packet

Hdr ID Flg Adr Len Cnt Dat Sum

FD DF 01 00 2A 12 0001 5C FF 37 02 00 00 07 00 BA 03 00 00 00 00 00 00 00 00

Memory Map No. 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

The value 0237H (5670ms) from memory map address Nos. 44 and 45 of the return

packet is the present time. (As the receive data is in 10ms units, when multiplied by 10, the

receive data becomes ms units.)

26

Page 27

● No.46/No.47 Present Speed(2 Byte,Hex Number,Read)

You can get the servo’s current rotation speed on deg/sec basis.

Ex.)To read the current rotation speed of the servo in ID=1

If you want to get the values of No.46 and No.47 in the servo’s memory map as return

packets, send the packets with the bits of 1 to 3 in the “Flag” set to bit3=1、bit2=0、bit1=0

and bit0=1. After sending, the values for the items between No.42 and No.59 in the

memory map will be sent back to you from the servo.

(Please refer to Flags for “Send-Packet” on Page 11 for details.)

If you send only flags, set [COUNT] =1 with [ADRESS]=0 and [LENGTH]=0, and

nothing should be written in「Data」.

Send flags for return packets between No.42 and No.59 in the memory map.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

09

00

00

01 09

Return Packet

Hdr ID Flg Adr Len Cnt Dat Sum

FD DF 01

Memory Map No. 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

00

12 3D

2A

01 5C FF 37 02 2C 01 07 00 BA 03 00 00 00 00 00 00 00 00

The present rotation speed is 012CH (300deg/sec), which is identified by the values of

No.46 and No.47 in the return packet. If you change the unit of the incoming data to a

decimal number, the values show angle rates since the incoming data is based on deg/sec.

● No.48/No.49 Present Load(2 Byte,Hex Number,Read)

This shows the load (electric current) on the servo.

The data can be read on mA basis. Please use this data just as a guide since there are

servos, which do not show “0” in case of no load.

Ex.)To read the current load on the servo in ID=1

If you want to get the values of No.48 and No.49 in the servo’s memory map as return

packets, send the packets with the bits of 3 to 0 in the “Flags” set to bit3=1,bit2=0,bit1=0

and bit0=1. After sending, the values for the items between No.42 and No.59 in the

memory map will be sent back to you from the servo. Read the data that fall under No.48

and No.49. (Please refer to Flags for “Short Packet” on Page 12 for details.)

If you send only flags, set [COUNT] =1 with [ADRESS]=0 and [LENGTH]=0, and

nothing should be written in ”Data”.

27

Page 28

Ex.) To send flags for the return packets between No.42 and No.59 in the memory map.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

09

00

00

01 09

Return Packet

Hdr ID Flg Adr Len Cnt Dat Sum

FD DF 01

Memory Map No. 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

00

12 32

2A

01 4E FB 00 00 00 00 06 00 BA 03 00 00 00 00 00 00 00 00

The present load is 0006H, which is identified by the values of No.48 andNo.49 in the

return packet

It shows that the motor is live with electricity of 6mA at this time

● No.50/No.51 Present Temperature (2 Byte,Hex Number,Read)

This shows the present temperature on the board of the servo. Each temperature sensor

has its own characteristics and there is a difference of about ± 3℃ between one another

in measuring temperature. An alarm flag is raised 10℃ before reaching the preset

temperature. If the temperature goes up higher than the preset temperature, an error flag

for temperature is raised one second later, and at the same time the servo comes into the

break mode, which situation is like deadening the torque a little bit. When it is in the break

mode, the value for “Torque ON” of No.36 in the memory map becomes 2.

Please be aware that Torque-On-Command does not function unless resetting is carried

out or turning on the power again if temperature limit works. Also, be careful not to burn

yourself since the temperature around the servo motor is somewhere between 120℃ and

140℃ when errors in temperature happen. Please make sure that the temperature goes

down sufficiently before you use it again.

Ex.)To read the current temperature of the servo in ID=1

If you want to get the values of No.50 and No.51 in the servo’s memory map as return

packets, send the packets with the bits of 3 to 0 in the “Flags” set to bit3=1,bit2=0,bit1=0

and bit0=1. After sending, the values for the items between No.42 and No.59 in the

memory map will be sent back to you from the servo.

(Please refer to the Flags on Page 11 for details.)

If you send only flags, set [COUNT] =1 with [ADRESS] =0 and [LENGTH] =0, and

nothing should be written in ”DATA”.

Ex.)To send flags for return packets between No.42 and No.59 in the memory map.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

09

00

00

01 09

28

Page 29

Return Packets

Hdr ID Flg Adr Len Cnt Dat Sum

FD DF 01

Memory Map No. 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

00

12 A6

2A

01 4E FB 00 00 00 00 06 00 2D 00 00 00 00 00 00 00 00 00

The current temperature is 002DH(45℃), which is identified by the values of No.50 and

No.51 in the return packet.

● No.52/No.53 Present Voltage (2 Byte,Hex Number,Read)

This shows the voltage that is currently used for the servo. Although the meter is

indicated in units of 10mV, there is an approximately ± 0.5V difference between voltage

sensors since each sensor has its own characteristics.

Ex.)To read the current voltage of the servo in ID=1

If you want to get the values of No.52 and No.53 in the servo’s memory map as return

packets, send the packets with the bits of 3 to 0 in the “Flags” set to

bit3=1,bit2=0,bit1=0,and bit0=1. After sending, the values for the items between No.42

and No.59 in the memory map will be sent back to you from the servo.

(Please refer to Flags on Page 11 for details.)

If you send only flags, set [COUNT] =1 with [ADRESS] =0 and [LENGTH] =0, and .

nothing should be written in ”DATA”.

Ex.)To send flags for return packets between No.42 and No.59 in the memory map.

Hdr ID Flg Adr Len Cnt Sum

FA AF 01

09

00

00

01 09

Return Packet

Hdr ID Flg Adr Len Cnt Dat Sum

FD DF 01

Memory Map No. 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

00

12 40

2A

01 4E FB 00 00 00 00 06 00 2D 00 E4 02 00 00 00 00 00 00

The current voltage is 02E4H (7.4V), which is identified by values of No.52 and No.53 in

the return packet.

29

Page 30

5. REFERENCE

Specifications

APPLICATION ROBOT ACTUAT0R

FEATURES RS485 SERIAL COMMINUCATION

OTHERS MOTOR CONTROL by SOFTWARE

SIZE(L×W×H): RS301CR 35.8 × 19.6 × 25.0 [mm]

RS302CD 35.8 × 19.6 × 25.0 [mm]

WEIGHT : RS301CR 28 [g]

RS302CD 21 [g]

Operation Current

:IN SUSPENSION RS301CR 40±20 [mA]

(ROOM TEMPERATURE, No Load, 7.4V) RS302CD 40±20 [mA]

:IN WORKING RS301CR 110±40 [mA]

(ROOM TEMPERATURE, No Load, 7.4V) RS302CD 100±40 [mA]

MAXIMUM OUTPUT TORQUE: RS301CR 7.1 [kg・cm]

(7.4V) RS302CD 5.0 [kg・cm]

MAXIMUM SPEED: RS301CR 0.11 [sec/60°]

(7.4V) RS302CD 0.16 [sec/60°]

fs

ROTATION DIRECTION:

CW CURRENT POSITION<COMMAND POSITION (CLOCKWISE)

CCW CURRENT POSITION<COMMAND POSITION (ANTICLOCKWISE)

OPERATING ANGLE:

CW 150[degree] (ON THE BASIS OF 0 degree)

CCW 150[degree] (ON THE BASIS OF 0 degree)

(CLOCKWISE)

(ANTICLOCKWISE)

SUPPLY VOLTAGE: 7.2 ~ 7.4[V]

OPERATING TEMPERATURE RANGE: 0 ~ +40[℃]

STORAGE TEMPERATURE RANGE : -20 ~ +60[℃]

OTHERS: BATTERY: LITHIUM POLYMER BATTERY

RS485 COMMUNICATION MAXIMUM BAUD RATE: 460kbps

(DEPENDING ON THE COMMUNICATION ENVIRONMENT)

PROTOCOL: 8BIT, 1STOP BIT, NO PARITY, ASYNCHRONOUS

30

Page 31

DIMENSIONS

Figure 0-1 Dimensions with using Joint-Ball

31

Page 32

TROUBLESHOOTING

If your servo does not operate, it intermittently stops operating, or it operates

erroneously, take the action shown in the table below. If this does not correct the trouble,

please contact a Futaba dealer.

Table 0-1 Check list

Check point Check item Action

Battery Dead battery.

Incorrect loading voltage.

Connecter Faulty contact connection.

Dirty contacts.

Servo horn Looseness of screws Fasten the screws

Command ID, baud rate, check sum Conform the command packet rules

Cable Short-circuit Change the cable

Replace the battery.

Charge the LiPo battery.

Reload the batteries in the correct polarity.

Change the recommanded battery

If the contact pin is deformed, correct it.

Wipe with a dry cloth

Before requesting repair, read this instruction manual again and recheck your system.

Should the problem continue, request repair service as follows:

Describe the problem in as much detail as possible and send it with a detailed packing

list together with the parts that require service.

_Symptom (Including when the problem occurred)

_System(Application configuration)

_Model Numbers and Quantity

_Your Name, Address, e-mail address, and Telephone Number.

If you have any questions regarding this product, please consult your local Futaba dealer.

32

Page 33

33

Loading...

Loading...