Page 1

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

Page 2

Thank you for purchasing a Futaba digital

proportional radio control set.

Please read this manual carefully before using

your set.

CONTENTS

•FEATURES............................... 1

•CONTENTS

•TRANSMITTER CONTROLS

•

Inside

•OPERATION

•Transmitter

•CHARGING OF TRANSMITTER AND

DECEIVER Ni-Cad BATTERIES

•TRAINER

•STICK

•RECEIVER, SERVO, SWITCHES, AND Ni-Cad BATTERY

CONNECTIONS AND USAGE PRECAUTIONS ....

•SPLINED HORN............................ 12

•Futaba

•FP-130

•GUARANTEE

AND

RATINGS.

Rear

Trimmer

RF module

................................ 9

MECHANISM

Digital Proportional Frequencies

EXPLODED VIEW

Panel

........................... 5~8

AND

.............................

................... 2

................ 3

..................... 4

....................... 8

................ 8

ITS

ADJUSTMENT ....... 9

............

.....................

~4

10~11

12

13

13

Page 3

• FEATURES

The FP-7FGH was specially developed for model helicopters.

Please read this manual carefully before using your new set.

•RF module systems allows one-touch changing of the frequency band.

•Aileron

and quarter scale models and gliders.

•Servo reversing switch for each channel allows

reversing of the servo direction by simply flipping a switch.

•Two

tor, and rudder channels. Aileron and elevator

dual rate can be switched simultaneously or

independently.

•Newly

stick with adjustable tension and lever head.

•Pitch control -> rudder and throttle ->> pitch

control mixing.

•Throttle hold function for auto-rotation.

•High and Low pitch cab trimmer permits ad-

justment of the best pitch for hovering and

maneuvering.

•Idle

aerobatics.

•Throttle High and Low ATL (Adjustable

Throttle Limiter) allows simple, reliable throttle

linkage hook-up.

•ATV (Adjustable Travel Volume) on AILER-

ON, ELEVATOR & RUDDER channels allows

independent adjustment of the servo left. right,

up. and down throw.

•Trainer system offers an easy training of flight

for beginners. FM systems are not compatible

with AM systems.

•Highest

phisticated designs. The transmitter fits easily

into your hand.

•Neck strap supplied as a standard accessory.

This transmitter has numerous functions which

can be easily operated when using the neck

strap.

to

kinds

designed

up

functions

quality

rudder mixing

of

dual

rates

case

and new open gimbal

used

for

aluminum

is

ideal

on the

static

case

for

giant scale

aileron,

and

dynamic

featuring

eleva-

so-

•Selective squelch circuit is unaffected by other

transmitters on other bands during simultaneous multi-band flights.

•Futaba custom 1C and large capacity capacitor

improve stability against power supply voltage

fluctuations tremendously.

•Same antivibration metal plated

as

the high-quality J Series.

•Throughole printed circuit board is invul-

nerable to shock and vibration.

pin connectors

SERVO FP-S130

•Small, high-quality five-pole micromotor servo.

High-torque 55.6 oz-in (4 kg-cm). high-speed

(0.24

sec/60°), watertight.

•New indirect drive potentiometer improves

vibration and shock resistance and neutral precision.

•Futaba low-power custom 1C provides high

starting torque, narrow dead band, and superior

trackability.

•Fiberglass reinforced PBT (polybutylene tere-

phthalate) injection molded servo case is mechanically strong, and invulnerable to glow fuel.

•Strong polyacetal resin ultra-precision servo

gear features smooth operation, precise neutral,

and very little backlash.

•Thick

film

gold plated connector pins

positive contact and improved reliability against

shock and vibration. The housing is polarized to

prevent reverse insertion.

•Four

special

available.

adjustable splined

horns

ensure

are

1

RECEIVER FP-R107M

•Pulse noise rejection circuit is invulnerable to

noise.

•Small & high sensitivity 7 channel FM receiver

using a specially developed high sensitivity

monolithic 1C IF amplifier.

Page 4

• CONTENTS AND RATINGS

Ratings and specifications are subject to change without prior notice

Model

Transmitter

Receiver

Servo

Switch

Ni-cd battery

Accessories

Charger, extension cord, frequency flag, spare horn, neck strap, mounting screws

Transmitter FP-T7FGH Servo FP-S130

Operating system

Transmitting frequency

Modulation

Power requirement

2

Current drain

: Two-stick, 7 channels for

F3C helicopter

: 72MHz band

27, 29, 35,

MHz band switching possible by changing RF

module.

:

FM

: 9.6V, 8/500mAH inter-

nal ni-cd battery.

: 150mA

40,

72 & 53

FP-7FGH

FP-T7FGH x 1

FP-R107M x 1

FP-S130x4

SWH-5 (R4-SWJ)

NR-4Jx 1

Control system

Operating angle

Power requirement

Current drain

Output torque

Operating speed

Dimensions

Weight

+ pulse width control

1520uS.N

One side 45° or more (including trim)

4.8V (shared with

receiver)

6.0V/8mA (at idle)

55.6 oz .in (4 kg-cm)

0.24 sec/60°

1.52x0.77x 1.36in.

(38.5x 19.5 x 34.5mm)

1.48 oz (42g»

Receiver FP-R107M Charger FBC-2 (A)

Receiving frequency

Crystal change system

Intermediate frequency

Power supply

Current drain

Dimensions

Weight

Receiving range

27,29, 35, 40, 72 & 53MHz.

Precision crystal that permits

frequency change within the

same band.

455kHz

4.8V

Ni-Cad battery, shared with receiver

15mA

1.69 x2.72x0.79in.

(43 x 69 x 20mm)

1.9oz (54g»

500m on the ground, 1000m or

greater in the air when used

with the FP-T7FGH.

Input voltage

Output

Receiver and servo Ni-Cad battery NR-4J

Voltage

Dimensions

Weight

120VAC,50/60Hz.

4VA

Txside9.6V.45mA

Rx side 4.8V, 45mA

4.8V,4/500mAH

2.01 x 2.28 x 0.59in.

(51

x58 x 15mm)

3.35oz (95g)

Page 5

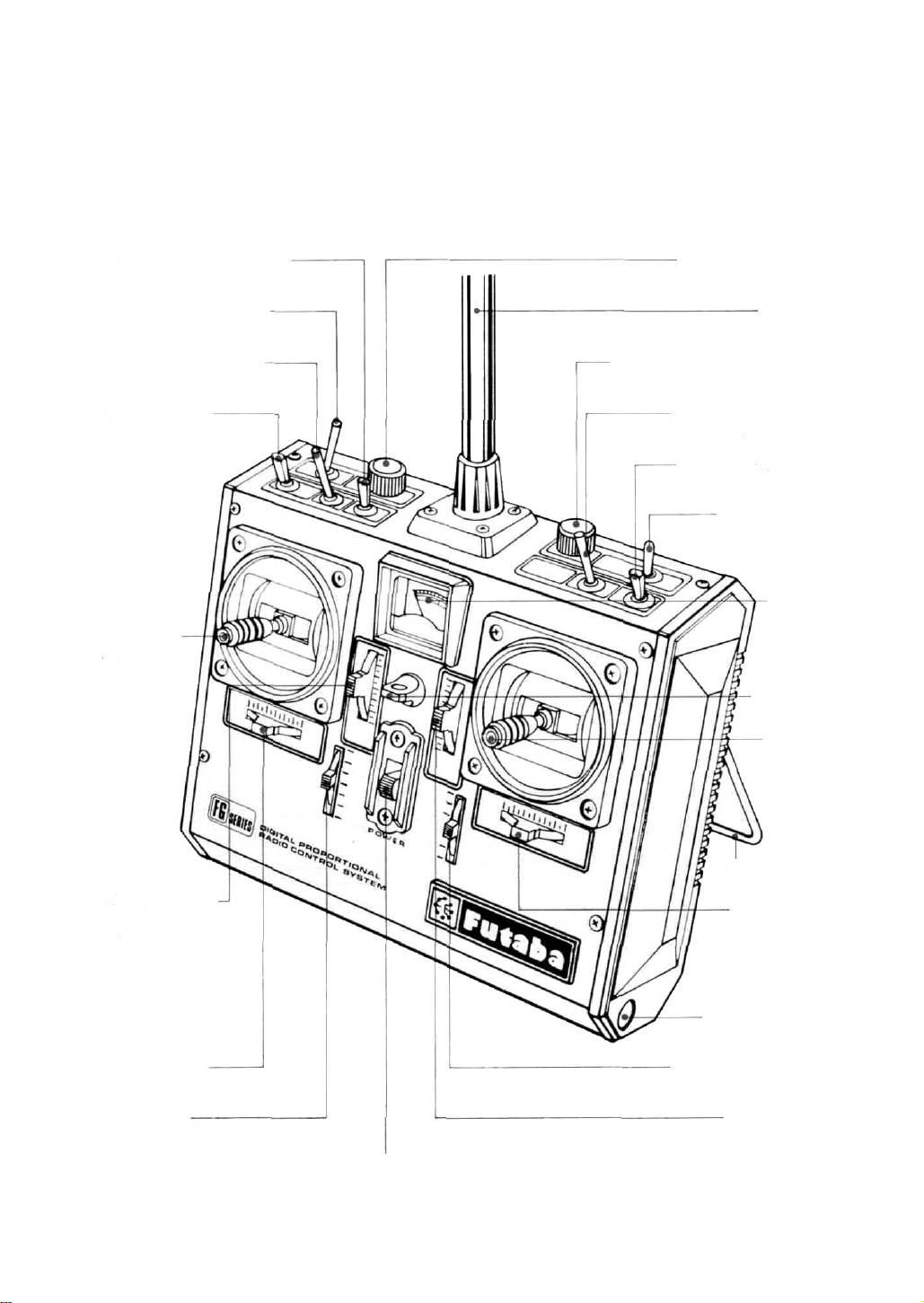

•TRANSMITTER CONTROLS

Names and functions of transmitter controls

161 dle-up ON-OFF switch

18 Throttle hold switch

19 Rudder dual-rate or

VTR on/off switch

5 CH5 landing

gear switch

(rate gyro output

switch)

(3)Throttle

4 Rudder

stick

17 Idle-up trim control

22 Antenna

15Throttle-rudder mixing knob

13 Elevator dual-rate or

VTR on/off switch

12Aileron dual-rate or

VTR on/off switch

14Trainer switch

21

Square

level meter

25 Hook for

neck strap

1 Aileron

2 Elevator

stick

10 Throttle trim

with ATL

(Adjustable

Throttle Limiter)

11

Rudder

(7 CH7 lever

trim

20 Power switch

24

Handle/stand

8 Aileron trim

23 Antenna storage

6 Pitch trim/C H6 lever

9 Elevator trim

Fig.1

Page 6

Left side

Fig. 2

26 Transmitter

NiCad battery

charging jack

27Trainer cord socket

Inside Rear Trimmer Panel

1 Aileron

ATV left-side trimmer

2 Aileron ATV right-side trimmer

5 Aileron -> rudder mixing left-side trimmer

6 Aileron -> rudder mixing

right-side trimmer

8 Elevator ATV

down-side

trimmer

9 Elevator

ATV

up-side

trimmer

28Transmitter

RF module

29 Trimmer panel

Fig. 3

Opening the trimmer panel

Fig. 4

Open by pulling in the arrow direction.

12 Throttle hold point trimmer

15 Rudder ATV left-side trimmer

16 Rudder ATV right-side trimmer

19 Pitch control low-side trimmer

20 Pitch control high-side

trimmer

22 Servo reversing

switches

10 Elevator dual rate trimmer

7 Aileron <-> rudder mixing ON-OFF switch

4 D DR<->VTR switch

3 Aileron dual rate trimmer

17 Rudder dual rate trimmer

14Throttle -> rudder mixing ON-OFF switch

13 Throttle high-side ATL trimmer

11DR->VTR switch

21Throttle -> Pitch control

mixing ON-OFF switch

18 DR->VTR switch

Fig.

5

Page 7

• OPERATION

This section explains the operation of the transmitter controls when the servo reversing switches are in the normal position. When the revers-

ing switches are in the reverse position, opera-

tion is the opposite of that described here.

CD Aileron stick Controls the ailerons.

2 Elevator stick Controls the elevators.

3 Throttle Stick Controls the throttle.

4 Rudder Stick Controls the rudders.

5 CH5 switch Switches the rate gyro output.

6 Pitch trimmer/CH6 lever Trims the pro-

peller pitch control independently from the

throttle.

(7)CH7 lever Spare channel.

8 Aileron trim lever Aileron trimmer.

9

Elevator

10 Throttle

travel

only when the throttle stick is at the low side as

shown in Fig. 6. It is very convenient because

the high side of the throttle position remains

unchanged even when the low side is adjusted.

trim

trim

lever

trim

lever

lever. This

Elevator

w/ATL

lever

acts

trimmer.

Adjustable

as a trimmer

12

Aileron dual rate switch Aileron dual

rate ON-OFF switch. When set to the upper position, dual rate is turned on, and when set to

the lower position, dual rate is turned off. At

dual ON. the deflection can be set as shown in

Fig. 7 with the aileron dual rate trimmer

located on the trimmer panel at the back of the

transmitter. At dual OFF, the operating linearity

can be switched as shown in Fig. 8 with the

VTR (Variable Trace Ratio) switch also located

on the trimmer panel.

Neutral

Deflection is

adjustable

from 40% to

100%

of

the

total travel

Aileron servo

within this

range.

5

Fig.

7

DR side VTR side

Servo throw by

throttle trimming

(30% of total

travel)

11 Rudder trim lever Rudder trimmer.

*Trim lever is used for fine adjustment.

The trim lever is used for neutral position adjustment or correction of the posture of the aircraft after

installation is completed. However, after test flight, try to keep the neutral position as they are making necessary corrections with the rod adjusters, etc.

Servo throw by

throttle stick

Fig.

6

N

Stick deflection N Stick deflection

Fig.

8

Page 8

13 Elevator dual rate switch • Elevator dual

rate ON-OFF switch. Simitar to aileron dual

rate, (dual rate ON) the elevator deflection can

be adjusted with the elevator dual rate trimmer

10 and the servo operating linearity can be

switched with the DR <-> VTR switch 11.

14

Trainer switch Pull on/self-off switch. The

transmitter connected by the trainer cord (MTC) operates and when it is OFF, your-own

transmitter only operates.

15 Throttle-rudder

mixing

knob

Ratchet

knob that sets the throttle to rudder mixing

amount and direction. Mixing amount is 0 —

50%.

16

Idle-up ON-OFF switch This switch is

turned ON when pushed forward.

Throttle servo

l7 and the servo operating linearity can be

switched with the DR <-> VTR switch 18 .

Other functions are the same as those of the

aileron dual rate switch.

20 Power switch

21

Square level meter Level meter indicates

the transmitter output power and indirectly

shows power supply voltage.

22

Antenna

23

Antenna storage The opening is used for

storage of the antenna while carrying the transmitter. It is located at the bottom right side of

the transmitter.

24 Handle/stand

25 Hook for neck strap

26 Transmitter Ni-Cad battery charging

jack

27 Trainer cord socket

28 Transmitter RF module

29 Trimmer panel

6

Non-slip adjustable lever head

The length of the lever head is adjusted to

suit the operator.

Unlock lever head (A) and (B), by turning

them in the arrow direction, set head (A)

to the desired length, then relock the

Low

Idle up amount is adjustable within this

range with the knob 17

17

Idle-up

trim

control

Sets

the

High

Fig.

idling

9

speed

heads.

Lever head (A)

Lever head B

Fig.

10

when the 16 idle-up switch is ON.

18

Throttle hold switch When this switch is

set to ON, the throttle servo stops at the position set at the 12 trimmer and only the pitch

servo operates. This switch is used in auto-rotation

dives.

Both throttle

and

pitch

servos

mix-

ing is performed when this switch if OFF. It is

ON when pushed forward.

19

Rudder dual rate switch Rudder dual

rate ON-OFF switch. Similar to aileron dual

rate, at dual rate ON, the rudder deflection can

be adjusted with the rudder dual rate trimmer

Inside rear trimmer panel

1,2 Aileron ATV

(Adjustable Travel

volume) trimmer [2] RIGHT is for the right

aileron and 1 LEFT is for the left aileron.

The servo travel volume is independently adjustable to the left and right from the neutral

position. Travel adjustment ranges 0 to 100%.

Page 9

Neutral

Right

Adjustable with

rudder ATV right

knob (right full

Aileron)

Adjustable with the

rudder ATV left

knob (left full

Aileron)

Aileron servo Fig. 11

Left

3 Aileron dual-rate trimmer adjusts the

aileron travel when the 12 aileron dual-rate or

VTR switch ON. Travel adjustment ranges 40

to

100%.

4 DR (dual-rate) <-> VTR (Variable Trace

Ratio) switch

5 6 Aileron-rudder MIX trimmer (From

aileron to rudder) Adjust the mixing volume

and the mixingdirection of rudder. After linkage

is completed adjust the MIX direction and

amount with trimmers. MIX amount adjustment ranges 0—100% each, the same adjustment can be done even if the servo is reversed.

7 Aileron -> rudder mixing ON-OFF

switch

8 9 Elevator ATV trimmer 9 UP is for up

and 8 DOWN is for down. The adjustment

range is same as the aileron ATV.

10

Elevator dual-rate trimmer adjusts the

elevator travel when the 13 elevator dual-rate

or VTR on/off switch is

ON.

11 DR <-> VTR switch

12 Throttle hold point trimmer This trim-

mer

sets

the throttle

servo

stop

point

when the

throttle hold switch 18 is set to ON. When the

trimmer is turned counterclockwise, the throt-

tle servo moves to the stow side.

13

Throttle high side ATL trimmer This

trimmer adjusts only the high side of the throt-

tle stick. It is extremely convenient when con-

necting the linkage, since the low side remains

unchanged even when the throttle high side is

adjusted with this trimmer.

Throttle servo

Fig.

12

14 Throttle -> Rudder mixing ON-OFF

Switch This switch turns mixing from the

throttle control (channel 3) to the rudder

(channel 4) ON and OFF.

15 16 Rudder ATV trimmer. The adjust-

ment range is same as the aileron ATV.

17

Rudder

dual-rate

trimmer

Rudder dualrate or VTR trimmer adjusts the rudder travel

when the 19 rudder dual-rate or VTR on/off

switch is ON.

18 DR <-> VTR switch

19,20

Pitch

control

trimmer

The

servo

throw

can be varied from 0 to 100% of the total. Set

for

optimum pitch during normal flight.

20 Pitch control

high side

trimmer

High pitch can be

adjusted within

this range.

Pitch control servo

19 Pitch control

low side

trimmer

Low pitch can be

adjusted within

this range.

Fig. 13

21Throttle -> Pitch control mixing ON-

OFF switch This switch turns mixing from

the throttle control (channel 3) to the pitch

control (channel 6) ON and OFF.

7

Page 10

22 Servo reversing switches These switches

reverse the direction of the servos. It is very

convenient when connecting the linkage.

43 CH7 lever channel

42 CH6 pitch control

41CH5 switch channel

Transmitter RF module

Change this module to switch to any frequency among 27, 29. 35, 40. 53 & 72

MHz bands.

Transmitter

I

6

37 Aileron

38 Elevator

[39]

Throttle

40 Rudder

NORM: Forward

REV: Reverse

Fig. 14

Remove the module by

pulling it forward while

pressing this tab inward.

Fig. 15

CHARGING OF TRANSMITTER AND RECEIVER

Ni-Cad BATTERIES:

8

Charger

FBC-2

NR-4J

Fig.

16

RX

AC-110V

(220V, 240V)

TX

Charging plug

•Connect the charging plug of the FBC-2 charger to the transmitter charging jack, connect the

3P connector of the FBC-2 to the receiver NiCad battery NR-4J, and plug the FBC-2 to a

110VAC (220V,240V) outlet as shown in this

figure. The TX and RX charging LED light; indicating that the batteries are being charged.

•The

times at 10 minutes per flight between rechargings.

•Charge the batteries for about 15 hours. When

the set is not in use for some time, repeat discharge and charge, two to three times before

use. (If the batteries are not used for a long

time, their capacity will go down).

•FBC-2 charges transmitter and receiver Ni-Cad

batteries independently or simultaneously.

Receiver

Recharge the receiver and

transmitter Ni-Cad

batteries as shown

battery

can

be

used

in Fig.

16

about 10

Page 11

TRAINER

Connect the transmitters with the trainer cord

(M-TC, purchased separately) as shown in Fig.

When the switch is in the ON (pull) position,

the student's transmitter operates and when the

switch is in the OFF position, the instructor's

transmitter operates. The transmitter at which

the trainer switch is operated on-off becomes

the instructor's.

(Power switch ON and transmitter operating)

Instructor transmitter

STICK MECHANISM AND ITS ADJUSTMENT

•The new gimbal is open. This

one has been used only for the

most expensive radio controls. It

also has the built-in tension adjustment mechanism on open

gimbal for the first time. You can

adjust tension of spring for your

best stick feeling.

•CP variable resistor improved the

neutral characteristics and resolu-

tion tremendously.

•All molded

grade polycarbonate that virtually

eliminates the effects of temperature and humidity.

parts

made

of

high-

•

Turn with a Phillips

screwdriver.

•When the core rises,

the spring tension

increases.

9

1 To adjust spring tension, remove

case back. Loosen and remove

screw 1 &

from bottom side first.

2 Adjust spring tension with

Phillips screw driver at opening

A, B, C for MODE II transmitters.

2 .

Lift

off

case back

Fig. 18

Module OFF

A

B

C

AD

Page 12

• RECEIVER, SERVO, SWITCHES, AND Ni-Cad BATTERY

CONNECTIONS AND USAGE PRECAUTIONS

The parts inside

the dotted

lines are sold

separately.

CH7 servo

Pitch control servo

(Landing gear servo)

10

Received crystal

FP-R107M 7 channel FM receiver

Antenna

R4-SWJ

Extension

cord

Charging plug

Landing gear

adapter

(Landing gear servo)

When a rate

Rudder

servo

Throttle servo

Elevator servo

Aileron servo

is used, this servo

connects to the

receiver through

the rate gyro.

gyro

Fig.

20

Page 13

Rate gyro FP-G152

Connected servo (rud-

der servo for helicopter)

neutral position trim-

mer (This trimmer is

operative even when

the control box power

switch is set to OFF.)

Connect to receiver

retract or

auxiliary

channel

(for gyro

sensitivity switching)

for Receiver

Five battery pack 6V connector Motor regulated

power supply. (Insert the jumper connectors when

the power supply is shared with the receiver.)

Gyro output polarity switch

Control amp

Gyro body

Control box

Jumper

connector

Remove

these

screws.

and

remove

the

case.

Gyro output

trimmer

Fig.

21

•Connect the servos and switches firmly as

shown in Fig. 20. Then extend the transmitter

and receiver antennas fully.

•Set the transmitter power switch to ON. then

set the receiver power switch to ON. The servos

stop near the neutral position. Operate the

transmitter sticks and check if the corresponding servos faithfully follow operation of the

sticks.

•After setting the pushrods at the servo horns,

check that the direction of operation of the

transmitter sticks and the direction of operation of the rudders are the same.

•Operate each servo horn over its entire operating range and check if the pushrod binds, or is

too loose. Applying unreasonable force to the

servo

horn

will

adversely

affect the

servo

and

quickly drain the batteries. Always make the

operating width of each rudder somewhat larger

than the full stroke (including trim) of the

servo horn. Adjust the servo horns so that

operate

smoothly

even

when the

trim

lever

and

stick lever are operated simultaneouly in the

same direction.

•Be alert for noise.

If engine vibration causes metal parts to touch,

noise will be produced and the receiver and

servos may operate incorrectly. We recommend

the use of noiseless parts.

•When installing the switch, cut a rectangular

hole somewhat larger than the full stroke of the

for Rudder Servo

switch and install the switch so it moves smoothly from ON to OFF. When the switch is

mounted inside the fuselage and is turned ONOFF with wire, install the switch mount as

described above. Install the switch where it will

not come into direct contact with engine oil,

dust, etc.

•Even though the receiver antenna is long.

do

not cut or bundle it.

•The

servos,

Ni-Cad

battery,switches,extension

cords, and crystals of FP-7FGH are the same

as those of the high-quality J Series. The crystals

are extremely precise and are identified by

color (red and green). Use Tx and Rx crystals

of the same color.

•A spare horn is supplied. Use it as needed.

•Wrap the receiver in sponge rubber. Place the

receiver in a plastic bag and wrap a rubber band

around the open end of the bag to waterproof

and dustproof the

receiver.

Do

the

same

with

the receiver/servo battery.

•Use the rubber bands wrapped

around the

receiver to hold the servo and switch leads.

•After mounting is complete, recheck each

part, then make the transmitter antenna as

short as possible, extend the receiver antenna

fully,

and

operate

the

set

from a distance

of

20m to 30m. The movement of each rudder

(servo) should faithfully follow the operation

of each stick of the transmitter.

11

Page 14

SPLINED HORN

This horn permits shifting of the

servo neutral position at the servo

horn. Setting

and shifting the

neutral position

a) Angle divisions

Fig.

22

1) The splined horn has

25

seg-

ments. The amount of change per

segment is;

2) The minimum adjustable angle

is determined by the number of

arms or number of the holes. For

four arms,the minimum adjustable

angle is:

12

horn A

(FSH-6X)

b) Effect

Baseline A

Fig.

23

To shift the holes center line to

the right (clockwise) relative to

baseline A, shift arm 2 to the position of arm 1 and set it to the

position closest to baseline A.

[Example] For a four arm horn,

the angular shift per segment is

14.4°. The shift to the right is 90°

- (14.4 x6) =3.6°

To shift by the same

opposite direction, use the

angle in the

oppo-

site arm number.

horn B

(FSH-6S)

horn C

(FSH-6R)

Fig.

24

For a six arm horn, turn the arm

counterclockwise and set arm 2

to the position of arm 1. The adjustable angle is 60° - (14.4 x 4)

=2.4°.

Arm 3 shift 4.8° to the right, arm

6 shifts 2.4° to the left,and arm 4

shifts 7.2° to the right and left.

Fig.

25

horn D

(FSH-6W)

Fig.

26

Futaba

•The

frequency of Futaba

sets

can

the 27MHz band only.

•However, a 27MHz band set cannot be changed

to 72MHz band, and vice versa.

•Therefore, always attach the correct frequency

flag to the end of the transmitter antenna.

Each frequency band has its own designated

color, as stated above. The frequency flag is

intended for identification purposes.

•Also

change

is changed.

•Futaba paired crystals are precisely matched.

Always use a Futaba crystal set (transmitter,

receiver) when changing the frequency.

•It

is illegal to change crystals of transmitter

the 72-75MHz bands in the U.S.A.

Digital

be

changed among bands

the frequency flag when frequency

Proportional

digital

proportional

(1)~(6)

Frequencies

on

Frequency Channel No. Flag Color

26-27MHz -

26

995

27.045

27.095

27.145

27.195

27.255

72/75MHx • Aircraft only 'Shared

72.030

72.080

72.160

on

72.240

72.320*

72.400

72550

72.590

72

.630

72.670

72.710

72.750

72.790

72330

72.870

72.910

72.960*

75.640

Aircraft/

12

—

—

-

38

40

42

44

46

48

50

52

54

56

—

-

(FOR

U.S.A.)

Car/Boat

Brown

Red

Orange

Yellow

Green

Blue

Brown-Red

(Top Flag/Ribbon-

Bottom Flag/Ribbon)

White/Brown

White/Blue

White/Red

White/Purple

White/Orange

Orange-Grey

Yellow-Black

Yellow-Red

Yellow-Yellow

Yellow-Blue

Yellow-Grey

Green-Black

Green-Red

Green-Yellow

Green-Blue

White/Yellow

White/Green

75MHz-

75.430

75.470

75510

75.550

75.590

75.670

75.710

75.750

75.790

75

.830

75.870

53MHz

License

53.100

53.200

53.300

53.400

53500

53.600

53.700

53.8OO

Car& Boat

62

64

66

68

70

74

76

78

80

82

84

Aircraft/Ca

Required

—

—

-

—

—

only

Blue-Red

(Top Flag/Ribb

Bottom Flag/R

Blue-Yellow

Blue-Blue

Blue-Grey

Purple-Black

Purple-Yellow

Purple-Blue

Purple-Grey

Grey-Black

Grey-Red

Grey-Yellow

r/Boat - FCC Amatuer

Black/Brown

Black/Red

Black/Orange

Black/Yellow

Black/Green

Black/Blue

Black/Purple

Black/Grey

aon-

ibbon)

Not

generally

in

use

Page 15

FP-130 EXPLODED VIEW

No.

1.

Upper case FCS 30

2.

Middle case FCS-30

3.

Bottom case FCS 30

4.

Ball bearing S04130

5.

Potentiometer 139995

6.

VR drive plate S02753

Motor S91243

7.

8.

Motor pinion S02461

1st gear FGS30

9.

2nd gear FGS-30

10.

11.

3rd gear FGS 30

12.

Final gear FGS-30

13.

2nd shaft S02481

14.

Intermediate shaft S02480

Spacer washer 0.3T S02486

15.

Seal ring S90415

16.

17.

0-ring S90426

Servo horn D FSH-6W

18.

Horn mounting screw FSH-41

19.

20.

Printed wiring board S130 AS1220

Lead wire packing S90045

21.

22.

S130 3PB-WRB-300 FPC-8M

Screw 0-ring S90410

23.

24.

Case

S130 Nameplate S60101

25.

Part Name Part No.

mounting

screw

J50085

GUARANTEE

Your NEW FUTABA Digital Proportional R/C system is guaranteed against defects in

workmanship and material for 180 days from the date of purchase when the attached

registration card is returned to us within ten days of purchase.

This Guarantee is null and void if the R/C system has been improperly handled,

damaged in a crash, or tampered with and does not cover the replacement of plastic

housings or electronic components damaged due to the use of improper voltages.

When service is required, please take your equipment to your local authorized service

station or ship it directly to us. All postage, shipping, and insurance changes must be

paid by the user.

This guarantee only applies to the continental U.S.A., Hawaii, and Alaska.

Page 16

To insure prompt service, please follow the instructions qiven below.

1. Charge the batteries for at least 1 8 hours prior to shipment

2. Return the system only Not your complete installation Remove the servos from their mounts and remove the foam

padding from the receiver.

3.

Plugs or other modifications which interfere

your expense.

4. Carefully pack all components individually, using sufficient packing material to prevent damage during shipment.

5. Include a brief but thorough explanation of all problems and service required and tape it to the back of the transmitter Place a label describing the function of the servo on each servo

6. Be sure to Include your full address and tel. Mo.. zip code inside the box as well as on the outside.

7. Include a packing list of all items being returned, and double check to make sure that all items are packed.

8.

Upon

receipt

sent to you. Your equipment will then be repaired and returned to you upon receipt of payment or C.O.D, (cash).

This factory repair service applies only to the continental U.S.A.. Hawaii, and Alaska.

of

FACTORY REPAIR SERVICE

with

factory

your

equipment

at

the

Futaba

factory,

an

test

estimate

procedures

of

the

will

cost

be returned

of

repair

to

(over

factory

$25.00

standard at

only)

will

be

Loading...

Loading...