Page 1

INSTRUCTION MANUAL

D60506

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

FP-6VA

FM 6 CHANNEL

AIRPLANE R/C SET

FOREWORD

Thank you for selecting the Futaba SKYSPORT-6A.

The SKYSPORT-6A is an easy-to-use digital proportional R/C

set for all classes of R/C aircraft hobbyists, from beginners to

advanced pilots. It has an outstanding array of functions

needed by all classes of pilots.

To enjoy its functions to the fullest and to ensure safe flying,

please read this manual carefully before using your set.

After reading this manual, store it in a safe place. If you encounter any difficulties while using your set, please refer to the appropriate sections in this manual.

In addition to this manual, please read all of the manuals in-

cluded with your airplane, engine and other flight related equip-

ment you may use.

To help ensure safe use, pay particular attention to the precautions printed throughout this manual and indicated by an excla-

mation mark [!].

ATTENTION

1. Application of Product

This product is not intended for use in any application other

than for the control of models for hobby and recreational purposes. This product is subject to regulations of the Ministry of

Radio/Telecommunications and is restricted under Japanese

law to such purposes. The laws of other countries may similarly restrict the use of this product. Futaba is not responsible

for

any use that is not in compliance with applicable law.

2. Exportation of Product

If the product is exported from Japan, the prior approval of

the Ministry of Radio/Telecommunications is required regarding the country of destination. If this product is reexported

from other countries, it may be subject to restrictions on such

reexport and prior approval of government authorities may be

required.

3. Modification, Adjustment & Replacement of Parts

Futaba is not responsible for any use of this product that is

not in compliance with applicable law and disclaims all responsibility for any modification or alteration of the

product,including the incorporation of the product into other

products by third parties, that is not in compliance with applicable law.

THE FOLLOWING STATEMENT APPLIES TO THE RECEIVER:

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERA-

TION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

(1)THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED

OPERATION. (For U.S.A.)

1. No part of this manual may be reproduced in any form without prior

written permission.

2. The contents of this manual are subject to change without prior

notice.

3. This manual has been carefully written, but please feel free to write

to Futaba if you find that any corrections or clarification's that should

be made.

4. Futaba is not responsible for the results of the use of this product by

the customer.

5. Futaba and SKYSPORT are a registered trademark.

PRECAUTIONS

To use your R/C set safely, please observe the following precautions:

(Operating precautions)

[!] When powering up the system, first turn on the transmitter

power, then turn on receiver power. When powering down

the system, first turn off the receiver power, then turn off the

transmitter power. If the power is turned on or off in the reverse order the control servos may move erratically causing

engines or electric motors to race unexpectedly and possibly

resulting in serious injury to the user or bystanders. Before

turning on the power, set the throttle stick to the maximum

slow position.

[!] Extend the transmitter antenna to its full length. If the antenna

is not extended fully, the transmitter output will drop and the

range of receivable transmission will be shortened.

[!] Never fly two or more models on the same frequency at the

same time. Before flight, use a frequency monitor or other

device to check that the frequency is not in use. Simultaneous flight on the same band is extremely dangerous because it will cause interference and loss of control. Differences in modulation method or signal format (AM, FM, PCM,

etc.) does not mean that flights can be made on the same

band.

ATTENTION:

The product that you have purchased contains a

rechargeable battery. The battery is recyclable. At

the end of it's useful life, under various state and

local laws, it may be illegal to dispose of this battery

into the municipal waste stream. Check with your

local solid waste officials for details in your area for

recycling options or proper disposal.

[!] Do not forget to recharge the Nicd battery before each flight.

Needless to say, a dead battery will cause loss of control and

a crash. Always check the discharge time on the ground and

provide a margin of safety when determining the remaining

flight time. When recharging the Nicd battery, observe the

charging current and charging time specified on the battery.

Charging the battery at a current and time exceeding the

specified values will not only damage the battery by overcharging, but will also cause overheating and other dangerous conditions.

-1-

Page 2

[!] Do not fly on rainy days. Even in a drizzle, water can enter the

transmitter through the antenna and sticks and cause faulty

operation. The resulting loss of control may cause a crash

the engine to race and is very dangerous.

[!] When placing the transmitter on the ground during flight

preparations, make certain that the transmitter cannot be

easily toppled by the wind or other means. If it tips over while

the engine is running and the throttle stick is inadvertently

moved to the high position as result, serious injury to the operator or others could result.

[!] Always test your digital proportional R/C set before flight.

a simple test method, before starting the engine, retract the

transmitter antenna fully and operate each servo from a distance of about 5m and check if the servos follow the movement of their control sticks. If a servo does not follow the

movement of its control stick, extend the transmitter antenna

to its full length, increase the distance on the ground, and

repeat the test. If the receiving range is still short, discontinue

flight and check the set.

or

As

(Flying field)

[!] In general, when a model is flown at high speed and / or the

flying range is large, even more caution is necessary. A safe

method is to fly at an exclusive flying field belonging to a club,

etc. However, the presence of spectators, wind direction, etc.

must be constantly monitored. In areas near high tension

lines, high buildings, and communication facilities, consideration must be given not only to normal flight dangers, but also

to possible loss of control caused by radio wave interference.

Because R/C radio waves have a fairly long range, a location

at least 3 km / 2 miles from other R/C flying fields and R/C

control circuits is necessary.

SET CONTENTS

Set name

Transmitter

Receiver

Servos

Battery

(Transmitter)

Battery

(Receiver)

Battery charger

Others

FP-R116FB, FP-R138DF, or FP-R127DF

FP-S3001x4orFP-S148x4

Receiver switch, Extension cord,

Servo horns, Flat screwdriver

SKYSPORT-6A

FP-T6VA

NT-8iB

NR-4J

x1

RATINGS

Transmitter FP-T6VA

Operating system: Two-stick, 6 channels, w/airplane function

Transmitting frequency: 29, 35. 36, 40, 41, 50, 60 or 72MHz band

Modulation: FM (Frequency Modulation)

Power requirement: 9.6V Nicd battery(NT-8iB)

Current drain: 180mA

Receiver FP-R116FB

Receiving frequency: 29, 35. 36. 40, 41 or 60MHz band

Intermediate frequency: 455kHz

Power requirement: 4.8V or 6V Nicd battery (shared with servos)

Current drain: 22mA

Size: 33.4X50.4X20.5mm

Weight: 30g/1.06oz

Receiver FP-R138DF

Receiving frequency: 35MHz band

Intermediate frequency: 1st IF 10.7MHz. 2nd IF 455kHz

Power requirement: 4.8V or 6V Nicd battery (shared with servos)

Current drain: 12mA

Size: 65X36X21,5mm

Weight: 39g/1.38oz

Receiver FP-R127DF

Receiving frequency: 50 or 72MHz band

Intermediate frequency: 1 st IF 10.7MHz, 2nd IF 455kHz

Power requirement: 4.8V or 6V Nicd battery (shared with servos)

Current drain: 10mA

Size: 64.3X35.8X21.0mm

Weight; 40.5g /1.43oz

Servo FP-S3001/FP-S148

Control system: Pulse width control

Operating angle: One side 45 degree min. (including trim)

Power requirement: 4.8V or 6V Nicd battery (shared with receiver)

Current drain: 8mA (at idle)

Output torque: 3kg-cm / 42oz-in

Operating speed: 0.22 sec/60 degree

Size: 40.4x19.8x36mm

Weight: 45.1g / 1.59oz(S3001),44.4g/

Nicd battery NT-8JB

Voltage: 9.6V

Capacity: 500mAh

Nicd battery NR-4J

Voltage: 4.8V

Capacity: 500mAh

Dimensions: 51x58x15r

Weight; 95g/3.35oz

Product Support

(Do Not Remove From Department)

1.57oz(S148)

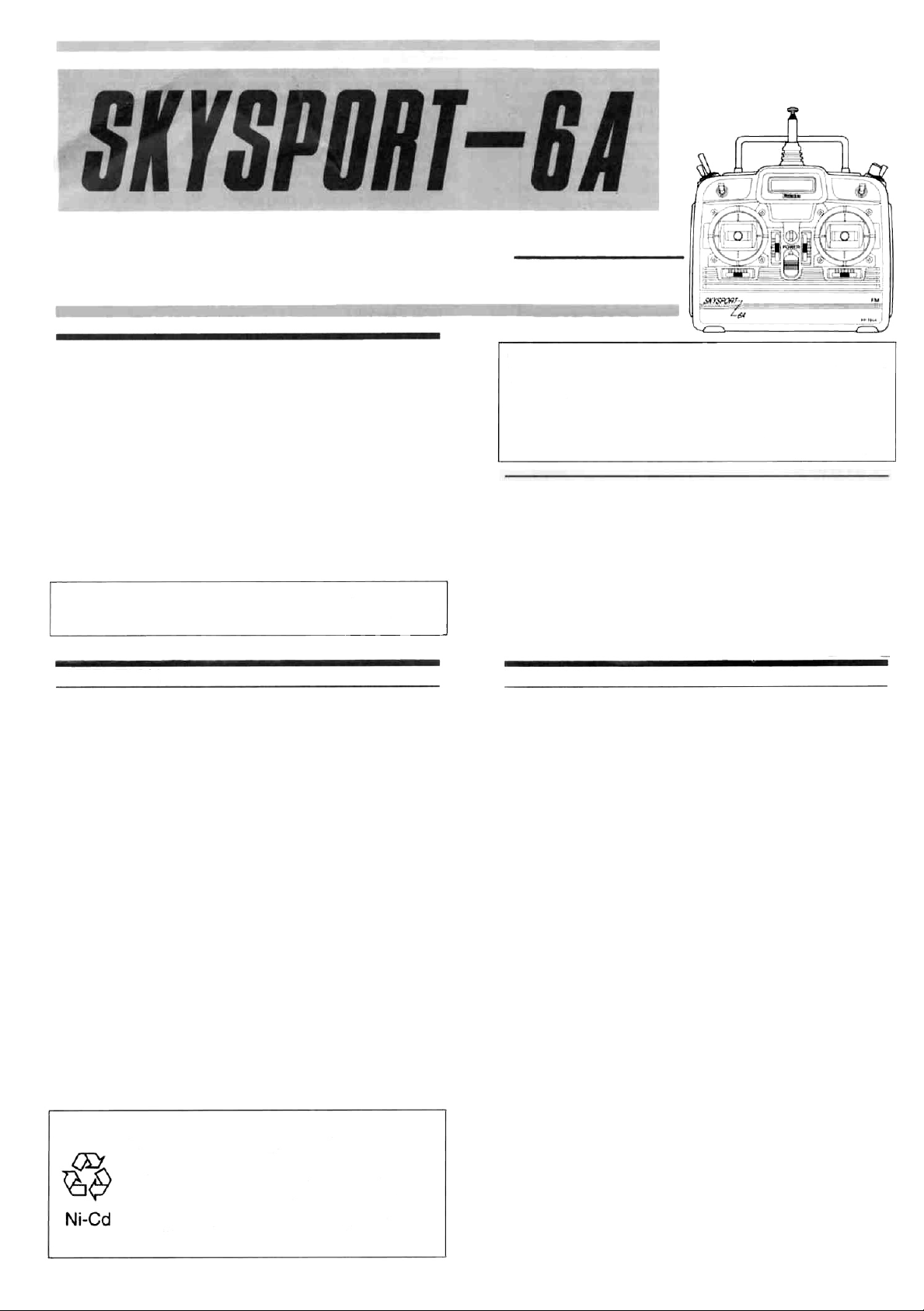

TRANSMITTER CONTROLS / OPERATION

This section describes how to operate the

transmitter. The numbers in the text correspond to the numbers in FIG.1.

For a definition of special terms, see

"GLOSSARY OF TERMS" on page 8.

Servos operation

1. |Aileron| 2. [Elevator] 3. [Throttle|

4. [Rudder]

Servos trimming

5. Aileron trim lever 6. Elevator trim lever

7. Throttle trim lever with ATL

The throttle trim affects the throttle only

when the throttle stick is in the low

range (engine is at low speed). Linkage

adjustment for the high range throttle

(engine is at high speed) is simplified

since the throttle trim only affects the

low range of the throttle movement.

8. Rudder trim lever

-2-

Page 3

Switches and knobs

9. Elevator -> flap mixing switch (ELV -> FLP)

When this switch if pulled forward, the mixing function is

turned on and the flaps are linked with elevator operation.

However, this switch is effective only when elevator -> flap

mixing is active (ACT).

10.

Flap knob (FLAP)

Normally, this knob is used as CH6. When flaperon mixing is

active (ACT), this knob acts as the flap trimmer.

11. aileron dual rate switch (AILERON D/R)

This switch toggles the aileron servo travel (RATE1 ,

RATE2). RATE1; upper position RATE2; down position

12. Elevator dual rate switch (ELEVATOR D/R)

This switch toggles the elevator servo travel (RATE1,

RATE2). RATE1; upper position RATE2; down position

13. Landing gear switch (GEAR)

This switch activates the landing gear channel. (CH5 switch)

14.

Power switch

The transmitter is turned on when this switch is set to the

upper position.

15. Trainer switch (TRAINER)

This switch is turned on when set to the pulled forward position (spring-loaded type).

Others

16. Level meter

[!] This meter indicates the transmitter power supply voltage.

When the needle deflects to the boundary between the silver

and red ranges, recharge the Nicd battery.

17.

Hook

Hook for neck strap.

18.

Antenna

[!] When using the transmitter, extend the antenna to its full

length.

19.

Carrying bar

Use this handle to carry the transmitter.

20. Battery cover

Open this cover when adjusting the trimmers on the trimmer

panel and when changing the Nicd battery.

21. Charging jack

This is the transmitter Nicd battery charging jack.

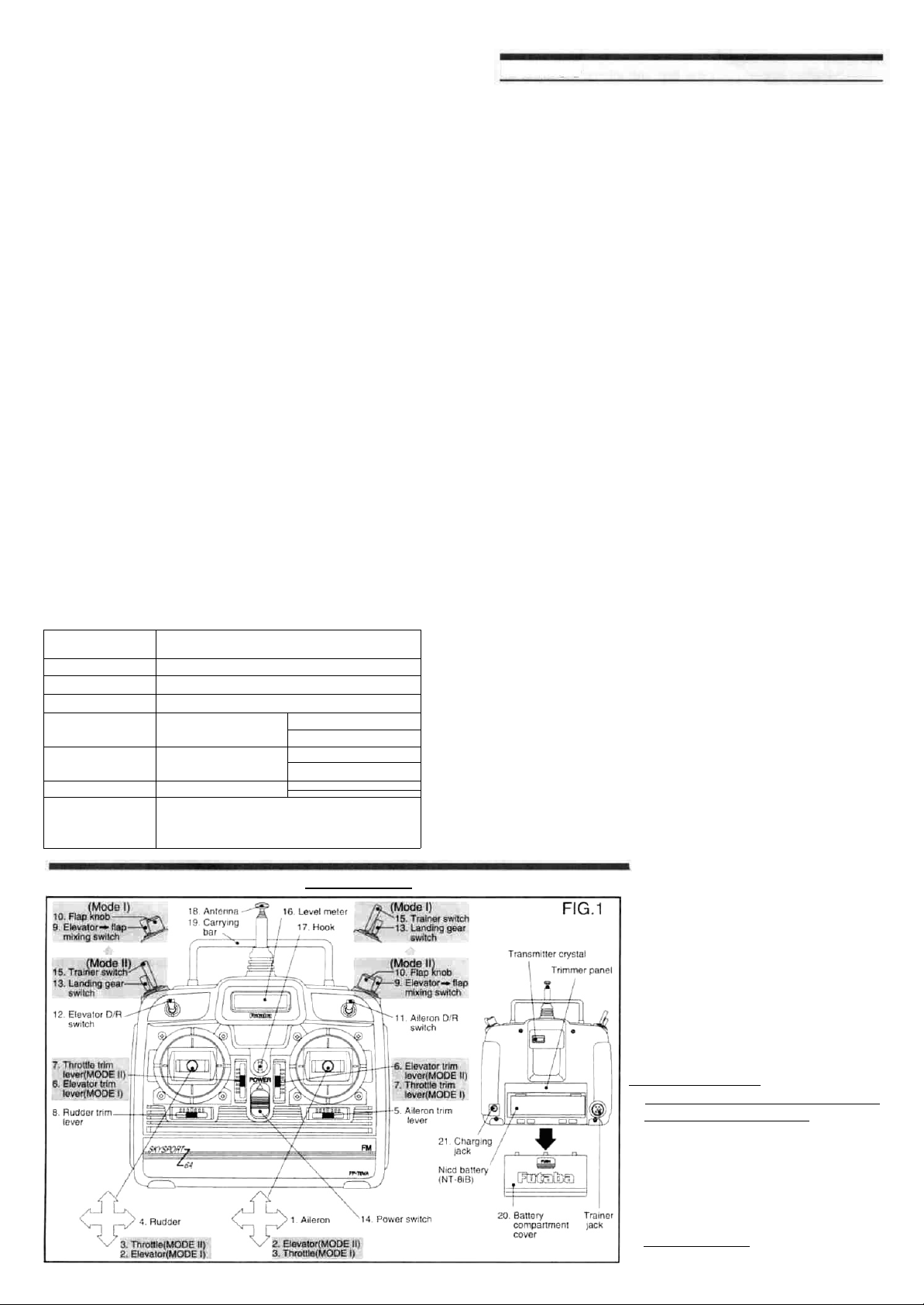

(Charging the Nicd battery)

[!] Never try to charge a dry cell battery. It will cause the battery

to overheat or explode and is very dangerous.

[!] Always charge the Nicd battery before using your R/C set.

Connect the charger's transmitter and receiver connectors to

the transmitter charging jack and

receiver servo Nicd battery as

shown in the figure(FIG.2). The

charging LEDs light to show that

the battery is being charged.

* The normal charging time is

about 15 hours. When you have

not used your R/C set for some

time, repeatedly charge and discharge the batteries two or three

times before use.

* The transmitter and receiver Nicd batteries can be charged

simultaneously or independently.

(Non-slip adjustable lever head)

The length of the lever head

of the sticks can be adjusted

as desired. Adjust the stick

length to fit your hand. (FIG.3)

1) Unlock lever heads A and B

by turning them in the directions shown by the arrows.

2) Adjust the stick to the most comfortable length and lock it by

turning head B in the directions opposite that shown by the

arrow.

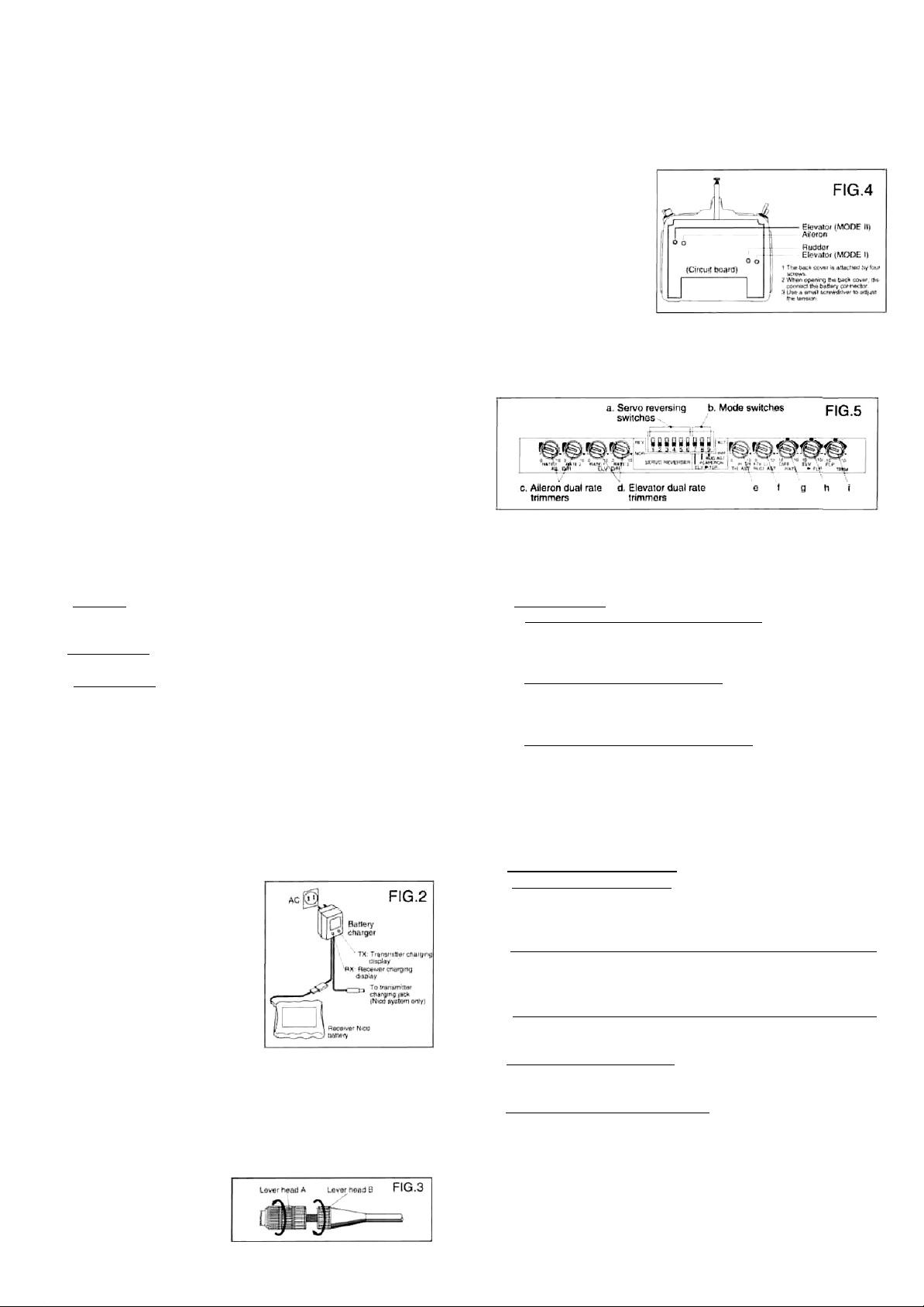

(Stick lever spring tension adjustment)

The stick lever spring

tension can be adjusted

by removing the transmitter back cover and

turning the screw for

each stick as shown in

the figure (FIG.4). Adjust

the spring tension for the

best stick feel. When adjusting the stick spring,

set the throttle stick to the

center.

(Trimmer panel)

a. Servo reversing switch (SERVO REVERSER)

The servo reversing switches reverse the direction of travel of

the servos. The lower position is the normal position.

(Channels 1 to 6) (DIP switch Nos. 1 to 6)

b. Mode switches

1. Elevator -> flap mixing ACT/INH switch

To activate the mixing function, set this switch to the ACT

(upper) position. To deactivate the mixing function, set this

switch to the INH (lower) position. (DIP switch No. 7)

2. Flaperon mixing ACT/INH switch

To activate the mixing function, set this switch to the ACT

(upper) position. To deactivate the mixing function, set this

switch to the INH (lower) position. (DIP switch No. 8)

3. Rudder AST function ACT/INH switch

To activate the rudder and throttle AST functions, set this

switch to the ACT (upper) position. The throttle ATV function can be activated by setting this switch to the INH

(lower) position. Select the desired function.

c. Aileron dual rate trimmer (AIL D/R)

This trimmer sets the rate corresponding to both directions of

the aileron dual rate switch. (RATE1, RATE2)

When it is turned clockwise, the servo travel increases.

d. Elevator dual rate trimmer (ELV D/R)

This trimmer sets the rate corresponding to both directions

the elevator dual rate switch. (RATE 1, RATE2)

When it is turned clockwise, the servo travel increases.

e.

Throttle

(TH.ATV) H side

This trimmer adjusts the servo travel of the selected function.

When it is turned clockwise, the servo travel increases.

f. Rudder AST trimmer (RUD.AST) or Throttle ATV trimmer

(TH.ATV) L side

This trimmer adjusts the servo travel of the selected function.

When it is turned clockwise, the servo travel increases.

g. Aileron differential trimmer (DIFF.RATE)

This trimmer adjusts the aileron differential amount when the

flaperon mixing function is active.

h. EIevator -> flap mixing trimmer (ELV->FLP)

This trimmer adjusts the mixing operation direction and

amount.

i. Flap trimming function trimmer (FLP.TRIM)

This trimmer adjusts the flap trimming operation direction and

variation width when the flaperon mixing function is active.

AST

trimmer

(TH.AST) or throttle

ATV

trimmer

of

-3-

Page 4

CONNECTION OF RECEIVER, SERVOS, ETC.

bag and securing the open end of the bag with a rubber band.

Do the same with the receiver and servo battery.

Servo horns

Spare horns are supplied. Use them as needed.

Extension cord

Use the servo extension cord if needed for your particular

fuselage.

Digital Proportional Frequencies For U.S.A.

• The frequency of Futaba digital proportional sets can be

changed within their own band. There are 2 different bands

for you to choose from (27 MHz and 72-75 MHz). Please see

chart listed below for specific frequency and its intended use.

Please note there are specific frequencies allocated for air-

craft only and surface only use.

• The frequency can be changed within the same BAND. How-

ever, Futaba recommends that you return your system to our

factory service department for frequency changing, as tuning

may be necessary for proper operation. Changing frequency

from one band to another is NOT possible.

Always change frequency flag when frequency is changed.

The frequency flag is to be attached to the top of antenna and

the channel designation to the base. (See Drawing)

• It is illegal to change crystals on 72-75 MHz bands in the

U.S.A. unless performed by a licensed technician.

Antenna Frequency Flag

(Installation precautions)

When installing the receiver, servos, and other parts to the fuselage, observe the following precautions:

Servo travel

Operate each servo horn over its full travel and check that the

pushrod does not bind and or is not too loose. Unreasonable

force applied to the servo horn will adversely affect the servo

and drain the battery pack very quickly. Make sure that the

free travel range of each control surface or mechanism

somewhat larger than the full control travel (including trim) of

the servo horn. Adjust the servo horns so that they move

smoothly even when the trim lever and stick are operated simultaneously in the same direction.

Servo installation

Install the servos with the rubber

grommets and eyelets supplied with

the set. (FIG.8) Do not tighten the

screws too tight. If the servo case directly contacts the fuselage, the rub-

ber bushing will not serve its pur-pose.

Receiver power switch installation

When installing the switch harness to the fuselage, cut a rectangular hole slightly larger than the full travel of the switch in

the fuselage and install the switch so that it moves smoothly

from ON to OFF. Also install the switch where it will not be

exposed to engine oil or dust and dirt. Generally, install the

receiver switch on the opposite side of the muffler exhaust.

Receiver antenna

Although the receiver

antenna may appear to

be too long, do not cut it

or fold it back. Changing the length of the receiver antenna will

lower the receiving sensitivity and shorten the

flight range. Generally,

the antenna can be strung out towards and attached to the

vertical stabilizer. (FIG.9)

Receiver vibration and water proofing

The receiver contains precision electronic parts. Besides being susceptible to vibration and shock, the entry of water will

also cause erroneous and dangerous results and has been

associated with crashes and other accidents. Wrap the receiver in foam rubber or take other vibration countermeasures. Also waterproof the receiver by placing it in a plastic

"Install the antenna by stretching

it slightly with a rubber band, etc.

"Use a rubber bushing so that the antenna

will not be broken by abrasion where it

comes through the fuselage and always

knot it inside the fuselage so that it will

not come out.

FIG.9

The flag can be attached to.

and removed from. the

Attach the frequency flag to the flag

holder as shown in the figure.

antenna with one touch.

1 Slick the channel No. sticker

on the flag board.

2 Attach the flag board to the

antenna as shown in the

figure

Frequency, Channel No. Flag Color For U.S.A.

26-27 MHz-Aircraft/car/boat

Color

26.995 Brown

27.045 Red

27.095 Orange

27.145 Yellow

27.195 Green

27.255 Blue

50/53 MHz-Aircraft/car/boat-Fcc Amature Licence required (2

and 3 channels not produced on these frequencies).

Channel

50.800 RCOO 53.100 Black-Brown

50.820 RC01 53.200 Black-Red

50.840 RC02 53.300 Black-Orange

50.860 RC03 53.400 Black-Yellow

50.880 RC04 53.500 Black-Green

50.900 RC05 53.600 Black-Blue

50.920 RC06 53.700 Black-Violet

50.940 RC07- 53.800 Black-Gray

50.960 RC08

50.980 RC09

No. Color

72MHz-Aircraft only

72.010 11 72.210 21 72.410 31 72.610 41 72.810 51

72.030 12 72.230 22 72.430 32 72.630 42 72.830 52

72.050 13 72.250 23 72.450 33 72.650 43 72.850 53

72.070 14 72.270 24 72.470 34 72.670 44 72.870 54

72.090 15 72.290 25 72.490 35 72.690 45 72.890 55

72.110 16 72.310 26 72.510 36 72.710 46 72.910 56

72.130 17 72.330 27 72.530 37 72.730 47 72.930 57

72.150 18 72.350 28 72.550 38 72.750 48 72.950 58

72.170 19 72.370 29 72.570 39 72.770 49 72.970 59

72.190 20 72.390 30 72.590 40 72.790 50 72.990 60

75 MHz-Car/boat only

75.410 61 75.610 71 75.810 81

75.430 62 75.630 72 75.830 82

75.450 63 75.650 73 75.850 83

75.470 64 75.670 74 75.870 84

75.490 65 75.690 75 75.890 85

75.510 66 75.710 76 75.910 86

75.530 67 75.730 77 75.930 87

75.550 68 75.750 78 75.950 88

75.570 69 75.770 79 75.970 89

-4-

75.590 70 75.790 80 75.990 90

Page 5

ADJUSTMENTS

1. General fuselage adjustments

Make the basic fuselage linkage connections and adjustments specified in the fuselage manufacturer's assembly

manual. In particular, check that the center of gravity is within

the specified range.

Also make the receiver, servo, and battery connections in accordance with "CONNECTION OF RECEIVER, SERVOS,

ETC." instructions on page 4.

[!] Be sure to read and follow all of the "(Installation precau-

tions)".

Before starting adjustment, carefully read the "Transmitter

Operation and Control Surface Movement" section below.

(Transmitter Operation and Control Surface Movement)

* Turn all nine trimmers fully clockwise (to the number 10)

with the miniature screwdriver supplied.

* Set all the switches (DIP switch No. 1 to 9) to the lower

position.

(Turn on the transmitter and receiver power switches

and make the adjustments described below.)

2) Make the basic adjustments (deflection angle) specified in

the airplane design drawings or instruction manual.

3)Check the direction of operation of each servo.

If a servo moves in the wrong direction, switch its reversing

switch. (In this way the direction of operation can be

changed without changing the linkage.)

[!] Be especially careful of the direction of operation of the ai-

leron servos.

Servo reversing switch

(Setting)

The servo reversing switches (SERVO REVERSER)

(DIP switch Nos. 1 to 6) on the trimmer panel can be set

for each channel.

The following descriptions assume that the transmitter is held

in the hands in the normal position.

a)When the aileron stick is moved to the right, the right wing

aileron is raised, the left wing aileron is lowered, and the

plane will bank to the right. When the stick is moved to the

left, the reverse maneuvers are performed.

b)When the elevator stick is pulled back. the elevator is

raised and the airplane climbs (Up operation). When the

elevator stick is pushed forward, the elevator is lowered

and the airplane dives (Down operation).

c)When the throttle stick is pulled back, the engine throttle

lever arm moves to the slow (low speed) side. When the

throttle stick is pushed forward, the engine throttle lever

arm moves to the high (high speed) side.

d)When the rudder stick is pushed to the right, the rudder is

deflected to the right and the nose of the airplane turns to

the right. When the rudder stick is pushed to the left, the

rudder is deflected to the left and the nose of the airplane

turns to the left.

The lower (NOR) position is the normal position and the

upper (REV) position is the reverse position.

4)Check the neutral adjustment and left and right (up and

down) travel of each servo.

If the neutral position has changed, or the travel is incorrect, readjust it by changing the servo horn position on the

splined shaft or by changing the hole position on the servo

horn. (Adjust the neutral position by servo horn position

when the transmitter trimmer is at the center.)

5)Check the engine throttle linkage.

The throttle is opened fully when the throttle stick is set to

the high position (pushed forward) and is closed fully when

the throttle stick is set to the maximum slow position (pulled

back).

6) The throttle or rudder servo travel can be trimmed with the

following throttle ATV or throttle AST/rudder AST function.

Select the function you want to use.

Throttle ATV functioni

(Function)

The high and low throttle servo travel can be adjusted

independently. Use this function to compensate for

throttle linkage variations. The travel rate can be adjusted from 30% to 100% of the total servo travel (each

side) as shown in the figure.

(Adjustment procedure)

1) Initial trimmer and switch setting

Before making any adjustments, open the battery cover at the

back of the transmitter and set the trimmers and DIP switches on

the trimmer panel to the initial state shown below.

(Setting)

To activate the throttle ATV function, set the rudder AST

(RUD.AST) ACT/INH switch (DIP switch No. 9) on the

trimmer panel to the INH (lower) position. (Be aware that

the rudder AST function and throttle ATV function cannot

be used simultaneously.)

* High side travel adjustment:

Adjust the high side travel with the high side trimmer (H)

-5-

Page 6

of the TH.ATV trimmers on the trimmer panel. Adjust the

high side travel to between high side trimmer positions 0

(30%) and 10(100%).

* Low side travel adjustment:

Adjust the low side travel with the low side trimmer (L) of

the TH.ATV trimmers on the trimmer panel. Adjust the

low side travel between low side trimmer positions 0

(30%) and 10(100%).

Throttle AST function

(Function)

This function sets the throttle servo travel. In this case,

the high side and low side can be adjusted simultaneously. Use this function to compensate for throttle

linkage variation. The travel rate can be adjusted from

30% to 100% of the total servo travel as shown in the

figure.

(Adjustment)

To activate the throttle AST function, set the rudder AST

(RUD.AST) ACT/INH switch (DIP switch No. 9) on the

trimmer panel to the ACT (upper) position. (The rudder

AST function can be used simultaneously, but the throttle

ATV function cannot be used simultaneously.)

* Travel adjustment:

Adjust the servo travel with the TH.AST trimmer on the

trimmer panel. Adjust the travel rate between throttle

AST

trimmer positions 0 (30%) and 10 (100%).

7)After connecting the linkages and checking the operating

directions and amounts, start the engine and adjust the

engine needle, then fly the airplane and trim the servos.

2. Aileron/elevator dual rate (D/R) function

(Function)

The maximum travel of the aileron and elevator servos can

be altered by operating their respective dual rate switch.

For instance, when the switch is in the down (RATE2) position, the deflection angle is the normal deflection angle.

When the switch is set to the upper (RATE1) position, spins,

snap rolls, and other aerobatics that require a maximum deflection angle can be performed by adjusting the deflection

angle to an angle greater than the normal deflection angle.

Since the respective rates can be adjusted by setting the

switch to the upper and down positions, the direction of the

switch can be set as desired.

Rudder AST function

(Function)

This function adjusts the rudder servo travel. In this case,

the left and right travels can be adjusted simultaneously.

Use this function in rudder linkage correction. The travel

rate can be adjusted from 30% to 100% of the total servo

deflection angle as shown in the figure.

(Adjustment)

To activate the rudder AST function, set the rudder AST

(RUD.AST) ACT/INH switch on the trimmer panel to the

ACT position. The throttle AST function can be used simultaneously, but the throttle ATV function cannot be

used simultaneously.)

* Travel adjustment:

Adjust the servo travel with the RUD.AST trimmer on the

trimmer panel. Adjust the travel to between rudder AST

trimmer positions 0 (30%) and 10 (100%).

Throttle trim lever with ATL function

(Function)

As shown in the figure, when the throttle stick is set to the

maximum slow side, the throttle trim influence is also at

it's maximum. When the throttle stick is in the high side

the throttle trim has no influence. This greatly simplifies

throttle linkage adjustment. (The high side linkage

should be set first.)

(Switch operation)

The aileron dual rate switch (AILERON D/R) is at the front top

right side of the transmitter. The upper position is RATE1 and

the down position is RATE2.

The elevator dual rate switch (ELEVATOR D/R) is at the front

top left side of the transmitter. The upper position is RATE1

and the down position is RATE2.

(Rate adjustment)

Each rate can be adjusted with the RATE1 and RATE2 trimmers

on the trimmer panel behind the battery cover at the back of the

transmitter. The rate can be adjusted from 30% (position 0) to

100% (position 10) of the maximum deflection angle.

(Setting procedure)

1) Turn on the transmitter and receiver power.

2) Switch the dual rate switch of the channel you want to the position for the rate that you want to set.

3) Set the stick to the maximum travel in either

4) Using the trimmer, adjust the servo horn to the desired angle.

(Adjust each rate by repeating steps 1 through 4.)

* When not using the dual rate function, set the RATE1

RATE2 trimmers to 100% (fully clockwise).

direction.

3. Flaperon mixing

(with aileron differential function)

and

-6-

Page 7

(Function)

This function lets you mix the flap and aileron functions by

using the same control surfaces (ailerons) and servos for

both controls. Two aileron servos are mounted in the wing.

Aileron operation is accomplished normally, i.e. left and right

ailerons moved up and down in opposite directions. Flap operation is accomplished by moving the left and right ailerons

in the same direction. (Flap operation can be performed without the need for separate flap surfaces.)

* With this function the left and right ailerons can be operated

differentially. (Aileron differential function). Roll axis can be

compensated in this way. With aileron differential the aileron

down deflection angle is typically smaller that the up angle.

* The flap control knob rate can be adjusted.

(Adjustment)

Connect the aileron servos to receiver output channels 1 and

6. Adjustment when CH1 is connected to the right wing and

CH6 is connected to the left wing is described below. (The

trimmer adjustment direction may be reversed, depending on

the servo mounting direction and linkage method.)

1)Activate mixing:

To activate flaperon mixing, set the flaperon ACT/INH

switch (DIP switch No. 8) on the trimmer panel behind the

battery cover at the back of the transmitter to the ACT (upper) position. To deactivate flaperon mixing, set the switch

to the INH (lower) position.

2)Aileron differential adjustment:

Adjust the aileron differential with the DIFF.RATE trimmer

on the trimmer panel.

First set the DIFF.RATE trimmer fully clockwise (to number

10) so that differential is not applied. When the roll axis

must be compensated after test flying, make the adjustments described below. However, the trimmer adjustment

position depends on the direction in which the deflection

angle decreases.

(left half of trimmer).

In both cases the deflection angle decreases as the knob is

turned toward position 0 (trimmer center).

4. Elevator ->

(Function)

This function is used when the aircraft has flaps or is using

the flaperon mixing function. This can be used, for example,

to deploy flaps when pulling up elevator. Cleaner loops and

other aerobatic maneuvers can be performed using this function. Adjust the mixing amount to the optimal positions for

your model.

flap mixing

* Applying differential by reducing the low side of the aileron:

Adjust between DIFF.RATE trimmer positions 0 and 10

(right half of trimmer). At position 10, differential is not applied. At position 0 (trimmer center), the reducing amount is

maximum.

* Applying differential by reducing the high side of the aileron:

Adjust to between DIFF.RATE trimmer positions 0 to -10

(left half of trimmer). At position -10, differential is not ap-

plied. At position 0 (trimmer center), the reducing amount is

maximum.

3) Flap control knob rate adjustment

Adjust the flap control knob rate with the FLP.TRIM trimmer

on the trimmer panel. The flap control knob operating direction can be set at the same time.

* Lowering the flaps by turning the flap knob clockwise (CW):

Adjust the flap control knob to between FLP.TRIM positions 0 and 10 (right half of trimmer).

* Lowering the flaps by turning the flap knob counterclockwise

(CCW):

Adjust to between FLP.TRIM trimmer positions 0 and -10

(Operation)

The elevator -> flap mixing ON/OFF switch is at the right side

of the transmitter. It is turned on when pulled forward.

(Adjustment)

1)Activate the mixing function:

To activate the elevator -> flap mixing function, set the elevator -> flap mixing ACT/INH switch (DIP switch No. 7) on

the trimmer panel to the ACT (upper) position. To deactivate the mixing function, set the ACT/INH switch to the INH

position.

2) Mixing amount adjustment:

Adjust the mixing amount with the ELV.->FLP trimmer on

the trimmer panel. The adjustment range is -100 to +100%

(positions-10 to +10). The mixing direction can be adjusted

at the same time.

* Applying mixing which lowers the flaps when the elevator is

raised:

Adjust between ELV->FLP trimmer positions 0 and 10

(right half of trimmer). At position 10, the mixing amount is

maximum and at position 0, the mixing amount becomes 0.

Adjust the mixing amount to the optimal position for your

aircraft.

* Applying mixing which raises the flaps when the elevator is

lowered:

Adjust between ELV->FLP trimmer position 0 and -10 (left

half of trimmer). At position -10, the mixing amount is maximum and at position 0, the mixing amount becomes 0. Set

the mixing amount to the optimal position for your aircraft.

-7-

Page 8

5. Using the trainer function

You can practice flying with the aid of another pilot or help

another pilot fly by connecting the SKYSPORT-6A transmitter to another SKYSPORT-6A , PCM1024Z, 7UA, or 5UA

Series with a special trainer cable (sold separately).

(Use)

The model is controlled by the instructor transmitter when the

trainer switch is OFF and is controlled by the student transmitter when trainer switch to ON.

(Usage precautions)

* Never turn on the student transmitter power switch.

* Make the student transmitter and instructor transmitter set-

tings the same.

* Make sure the modulation method of the other transmitter

is FM (PPM).

GLOSSARY OF TERMS

The abbreviations used with the SKYSPORT-6A are defined

below in alphabetical order.

ACT (activate)

Means that a function is turned on. Its opposite is INH (inhibit).

To activate a function, its ACT/INH switch is set to the ACT

position. If the switch is not in the ACT position, the function is

not activated^

AILERON/AIL.

An auxiliary airfoil at the left and right wings of an airplane to

control its rolling.

AST (Adjustable Servo travel)

This feature allows adjustment of the travel of the servo

certain channel. It is used when setting up the linkages.

ATL (Adjustable Throttle Limit)

This feature allows movement of the throttle trim lever that

operates only when the throttle stick is in the SLOW position.

It is convenient because it does not affect the HIGH side of

the throttle.

ATV (Adjustable Travel Volume)

This feature allows independent adjustment of the servo

travel in each direction. It is convenient when setting up the

linkages.

D/R (Dual Rate)

This function allows switching to one of two deflection angles

while flying. The deflection angle best for the aircraft can be

set for one switch position and spins, snap rolls, and other

aerobatics that require a maximum deflection angle can be

performed easily by setting up maximum deflection for the

other switch position.

DIFF. (aileron differential)

This feature allows application of a differential to the right

wing aileron and left wing aileron when the wing has two aileron servos. It is used to correct undesirable tendencies and to

compensate the roll axis.

ELV.->FLP. (elevator->flap mixing)

This feature applies mixing from the elevators to the flaps

when the fuselage has flaps. When mixing is applied so that

the flaps are lowered when the elevators are raised, loops

and other aerobatics can be performed cleanly. The mixing

amount should be adjusted optimally for individual aircraft.

ELEVATOR / ELV.

A horizontal airfoil for making an airplane go up or down.

FLAPERON

This is a mixing function that gives the ailerons a flap function.

It is a convenient method of mixing aileron operation and flap

operation using only two aileron servos at the wings. (Flap

operation can be performed without the need for separate

flap surfaces.)

of a

FLP. (Flap)

A movable auxiliary airfoil attached to the center of a wing to

increase the lift at slow speed when taking off and landing.

With models it can also be mixed with the elevator and used

in circular aerobatics.

FLP.TRIM (Flap trim)

This feature switches the flap servo deflection angle between

normal operating angle and trim angle. It is convenient when

mixing the flaps with other channels.

GEAR (Landing gear)

This is for airplane landing gear.

Since the landing gear is normally extended or retracted, this

channel can only be turned fully on or off. It cannot be

stopped midway.

INH (Inhibit)

Means that the function is turned off (stopped). It is the opposite of ACT (activate). When a function is not used, its ACT/

INH switch is always set to the INH position.

NOR (Normal)

Used to represent the default or normal state of a function.

For example, the servo reversing function has a normal side

and a reverse side.

RATE

In the dual rate function for example, this is the rate of servo

travel in percentage relative to the normal servo travel. The

rate is adjusted with a trimmer for each function.

REV (Reverse)

Represents the servo reversing function that lets you reverse

the normal direction of servo movement, or the setting position of a switch (reverse position). It is used when the direction of the transmitter stick and the direction of servo movement are opposite of the desired movement after the servos

are mounted in the fuselage and each airfoil and servo are

connected by pushrods, etc. The direction of movement can

be corrected without changing the linkage.

RUD (Rudder)

A hinged directional surface attached to the vertical trailing

edge of the tail of an aircraft.

TH (Throttle)

Used to controls the fuel at the intake of an engine. When it is

opened, a large amount of fuel is drawn into the engine and

the engine speed increases. When it is closed, the engine

speed slows.

TRIM

A fine adjustment device that sets the deflection angle of

each airfoil for stable flight.

(OTHERS)

Mixing

A function that allows two or more different channels to be

operated together in a linked or dependent manner.

For example, when mixing is applied from elevators to flaps,

the elevator servo and flap servo can be operated simultaneously by operation of the elevator stick.

REPAIR SERVICE

Before requesting repair, please refer to this instruction manual

again and verify your settings. If you are still experiencing

trouble, please request service as follows:

Address

Your nearest Futaba dealer.

Repair

information

Describe the trouble in as much detail as possible.

1)Symptom: Including the state of the set when the trouble

occurred.

2) Digital proportional set used: Transmitter, receiver, and

servo model numbers.

3) Fuselage: Fuselage name and mounting conditions.

4) Your name, address, and telephone number.

Warranty contents

Read the warranty card supplied with your set.

* The warranty contents differ with geographic locations.

FUTABA CORPORATION

Makuhari Techno Garden BIdg.. B6F I -3 Nakase. Mihama-ku. Chiba 261-01. Japan

Phone: (043) 296-5119 Facsimile: (043) 296-5124

FUTABA CORPORATION OF AMERICA

4 Studebaker. Irvine California 92718, U.S.A.

Phone: 714-455-9888 Telex: 23-0691227 Facsimile: 714-455-9899

-8-

Loading...

Loading...