F300S/F300SQ Ultraviolet Lamp System

Installation, Operation, and Maintenance

Manual No. 509252 Rev R 3/04

FUSION UV SYSTEMS, INC.

910 Clopper Road

Gaithersburg, MD 20878-1357 USA

(301) 527-2660 • FAX (301) 527-2661

F300S/F300SQ Ultraviolet

Lamp System

Installation, Operation, and Maintenance

Manual No. 509252 Rev R 3/04

Applies to systems using P300M/P300MQ/P300MT power supplies,

and I300M/I310M series irradiators Serial Numbers 1001 and later.

(C) Copyright 2004 Fusion UV Systems, Inc. All Rights Reserved.

The products covered herein conform to EC standards.

See Appendix A for details.

FUSION UV SYSTEMS, INC.

910 Clopper Road

Gaithersburg, MD 20878-1357 USA

(301) 527-2660 • FAX (301) 527-2661

Table Of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Indications of Note, Caution, Warning, and Danger . . . . . . . . . 12

Icon Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Irradiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reflector and Cavity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Lamp Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

P300M/P300MQ/P300MT . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

RF Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

System Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Shipping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Returned Material Authorization Number . . . . . . . . . . . . . . . . 22

General Packing Instructions . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Irradiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Magnetrons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

UV Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

RF Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 1. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Ultraviolet Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Microwave Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Personnel Effects of Microwave Radiation . . . . . . . . . . . . . . . . . . . 27

Radio Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ozone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation, Operation, and Maintenance Manual # 509252 Rev R 5

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

UV Curable Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 2. Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mechanical Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 31

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Power Supply Unit(s) Placement . . . . . . . . . . . . . . . . . . . . . . . . . 32

Irradiator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Lamps Mounted in Opposing Configuration . . . . . . . . . . . . . . . . . . 34

UV Light Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

RF Detector Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Remote Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Irradiator Exhaust Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Quartz Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 3. Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical Installation/Setup Checklist . . . . . . . . . . . . . . . . . . . . . . 39

Accessory Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Interconnect Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connection and Program Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installing the External Interlocks Control . . . . . . . . . . . . . . . . 40

User Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Power Supply Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Settings for Six-Position Switch S1 . . . . . . . . . . . . . . . . . . . . 41

Single Unit Programming and Connections . . . . . . . . . . . . . . . . . . 43

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Irradiator Cable H340 Connections . . . . . . . . . . . . . . . . . . . . 44

Input/Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Remote Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Output Ports (J105B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Alternate Function for K5 . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

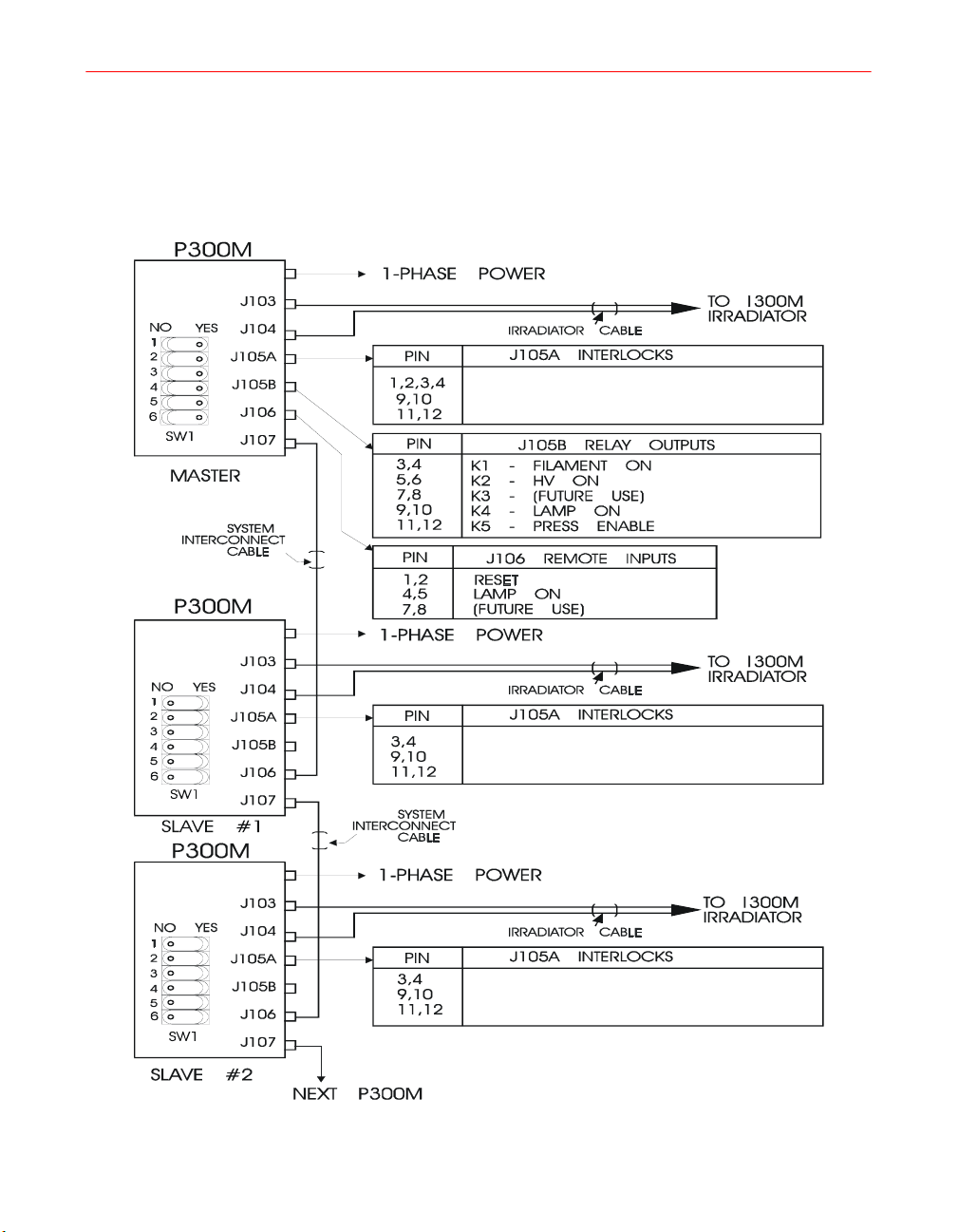

Multiple-Unit Programming and Connections . . . . . . . . . . . . . . . . . 48

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6 F300S/F300SQ Ultraviolet Lamp System

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

System Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Frequency Tapping of HV Capacitors . . . . . . . . . . . . . . . . . . . 51

QRO HV Capacitors (For QRO only) . . . . . . . . . . . . . . . . . . . . 51

High Voltage Transformer Taps . . . . . . . . . . . . . . . . . . . . . . . 51

QRO Transformer Taps (FOR QRO only) . . . . . . . . . . . . . . . . . 52

F300S Relay Coil Resistor Assembly Installation . . . . . . . . . . . . . . 53

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

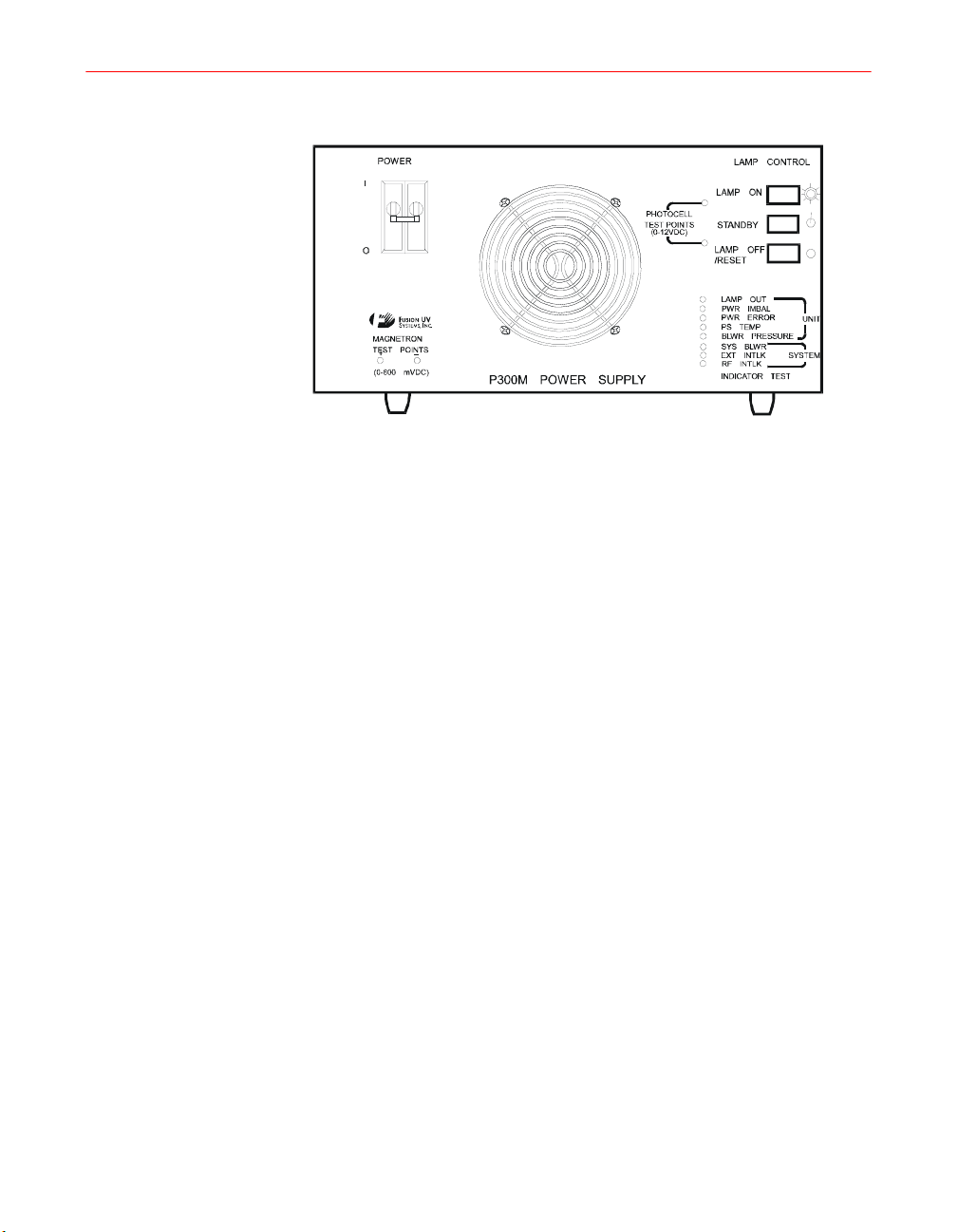

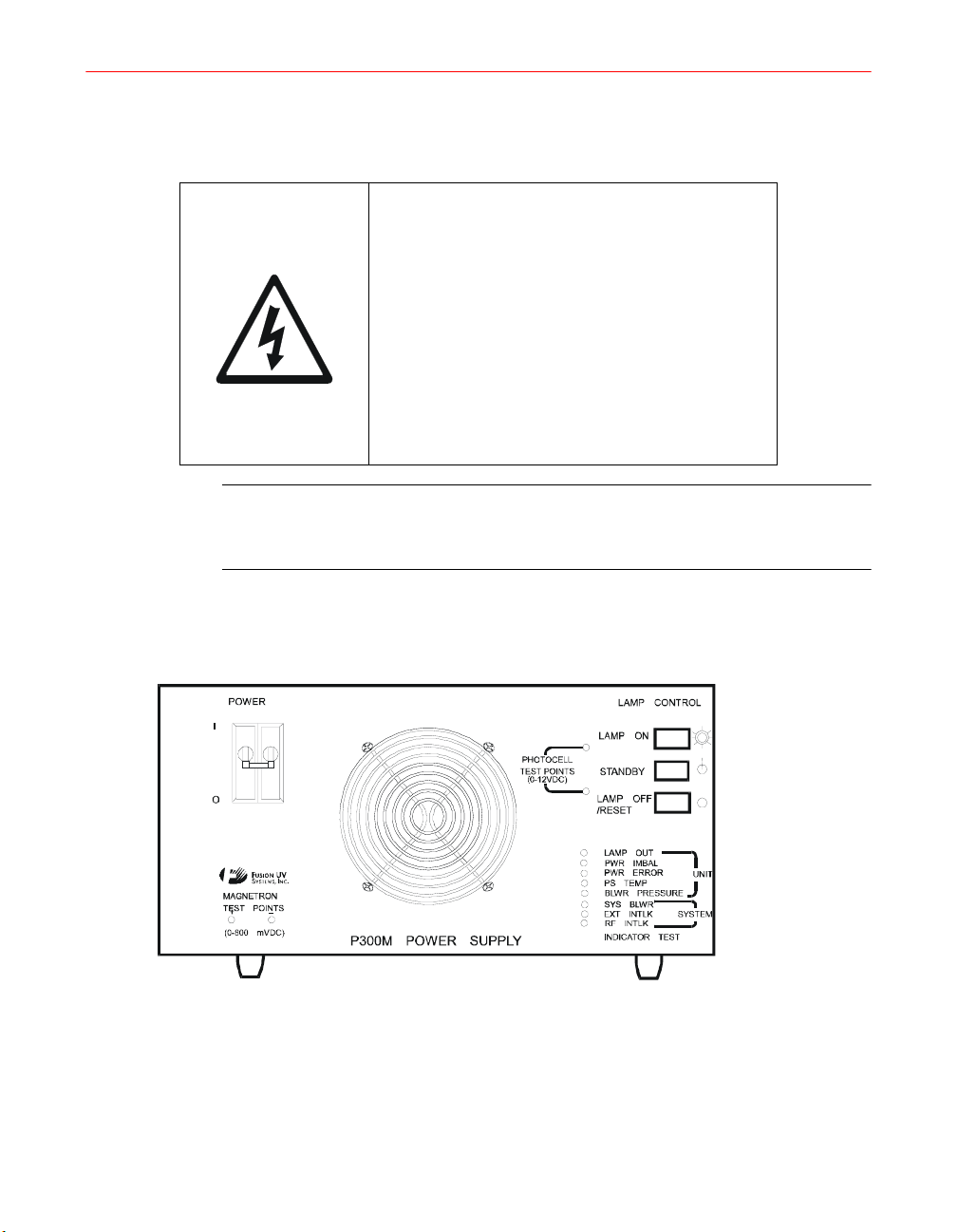

System Operation Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Lamp Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Off/Reset Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Initial Startup Procedure, Single Unit . . . . . . . . . . . . . . . . . . . . . . 56

Initial Startup Procedure, Multiple-Unit Systems . . . . . . . . . . . . . . 57

Master/Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Operating the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Resetting the System After a Fault . . . . . . . . . . . . . . . . . . . . 58

Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operation with Remote Controls . . . . . . . . . . . . . . . . . . . . . . 60

Quick Restart Option (QRO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Electrical Installation and Setup . . . . . . . . . . . . . . . . . . . . . . 63

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Basic Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Safety Interlock Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Fault Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Unit Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

System Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Fault Diagnosis Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Failure Diagnosis Cross-Reference . . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

I300M Irradiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Installation, Operation, and Maintenance Manual # 509252 Rev R 7

Bulb, Screen, and Reflector Maintenance . . . . . . . . . . . . . . . . 79

Cleaning Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Bulb Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Reflector Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Screen Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

I300M Screen Assembly Removal/Replacement . . . . . . . . . . . 80

Lamp Bulb Removal/Replacement . . . . . . . . . . . . . . . . . . . . 81

Reflector Removal/Replacement . . . . . . . . . . . . . . . . . . . . . . 82

I300M Irradiator Housing Removal/Replacement . . . . . . . . . . 86

Direct View Photoresistor Removal/Replacement . . . . . . . . . . . 87

Filament Transformer Removal/Replacement . . . . . . . . . . . . . 88

Magnetron Removal/Replacement . . . . . . . . . . . . . . . . . . . . . 89

Air Pressure Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Air Pressure Switch Replacement . . . . . . . . . . . . . . . . . . 91

I310M/I311M Irradiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Bulb, Screen, and Reflector Maintenance . . . . . . . . . . . . . . . . 91

Cleaning Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Bulb Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Reflector Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Screen Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Screen Assembly Removal/Replacement . . . . . . . . . . . . . . . . 93

Lamp Bulb Removal/Replacement . . . . . . . . . . . . . . . . . . . . 93

Reflector Removal/Replacement . . . . . . . . . . . . . . . . . . . . . . 94

Replacing the RF Gasket Assembly . . . . . . . . . . . . . . . . . 99

I310M/I311M Irradiator Housing Removal/Replacement . . . . . 100

I310M/I311M Scatter View Photoresistor Removal/Replacement . .

100

Direct View Photoresistor Removal/Replacement . . . . . . . . . . 101

Filament Transformer Removal/Replacement . . . . . . . . . . . . 103

Magnetron Removal/Replacement . . . . . . . . . . . . . . . . . . . . 104

Air Pressure Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Air Pressure Switch Replacement . . . . . . . . . . . . . . . . . 105

P300M/P300MQ Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Safety Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Test Point Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8 F300S/F300SQ Ultraviolet Lamp System

Control Card Removal/Replacement . . . . . . . . . . . . . . . 107

Diode Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Capacitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

High Voltage Transformer Removal/Replacement . . . . . . 110

P300MT Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Safety Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Test Point Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Control Card Removal/Replacement . . . . . . . . . . . . . . . . . . . 113

Diode Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Capacitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

High Voltage Transformer Removal/Replacement . . . . . . 116

K300 Modular Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Blower Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Blower Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . 118

Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix A. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Irradiators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

RF Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

System Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . 125

Appendix B. Cables and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Interconnect Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

System Connector Contact Kits . . . . . . . . . . . . . . . . . . . . . . 128

Appendix C. Outline Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Appendix D. Lamp System Maintenance Log . . . . . . . . . . . . . . . . . . . . 139

Appendix E. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

I300M/I310M Irradiator Parts List . . . . . . . . . . . . . . . . . . . . . . . 142

Installation, Operation, and Maintenance Manual # 509252 Rev R 9

P300M/P300MT Power Supply Parts List . . . . . . . . . . . . . . . . . . . 144

P300MQ Quick Restart Option Parts List . . . . . . . . . . . . . . . . . . . 146

K300 Blower Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . 147

Appendix F. Ignitor Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Ignitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Ignitor Bulb Removal/Replacement . . . . . . . . . . . . . . . . . . . . . . 150

Appendix G. Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

10 F300S/F300SQ Ultraviolet Lamp System

Introduction

This manual is designed to be used, not set aside until problems occur. The following

list of chapters and appendixes describes where to find information in this manual.

• This Introduction provides a brief description of the total system, and system

components. It also contains the Fusion UV Systems warranty policy and shipping

instructions for returning equipment.

• Chapter 1, “Safety,” contains important information! This chapter should be read

by all persons who will operate or troubleshoot system equipment.

• Chapter 2, “Mechanical Installation,” gives unpacking instructions, and

instructions for equipment placement, mounting, shielding and exhaust venting.

• Chapter 3, “Electrical System,” explains the power supply software setup,

including single and multiple unit programming and connections. HV capacitor

frequency tapping instructions are also provided.

• Chapter 4, “Operation,” describes steps for initial startup for both single and

multiple unit systems, how to operate master/slave and remote systems, and how

to reset the system after a fault. It also contains setup and operations instructions

for the Quick Restart Option (QRO).

• Chapter 5, “Troubleshooting,” consists mainly of information in table form. There

is a reference table for faults and indications, tables describing unit and system

fault indications, and a fault diagnosis table. The fault diagnosis table provides

faults, causes, and corrective actions.

• Chapter 6, “Maintenance,” covers routine maintenance and removal/replacement

instructions for the irradiator, power supply and modular blower. There is a

maintenance procedure page locator at the front of the chapter.

• Appendix A, “Specifications,” outlines the various characteristics of major

components of the F300S/F300SQ Ultraviolet Lamp System. It also lists agency

approvals and certificates for the relevant systems and components.

• Appendix B, “Cables and Connectors,” provides information on the interconnect

cables and system connector contact kits used with the F300S/F300SQ Ultraviolet

Lamp System.

Installation, Operation, and Maintenance Manual # 509252 Rev R 11

• Appendix C, “Outline Drawings,” contains drawings that provide overview details

for general reference for Fusion UV Systems products. These drawings are not to

be used in designing an installation; contact Fusion directly for current

specifications.

• Appendix D, “Lamp System Maintenance Log,” contains an example of a Fusion

UV Systems form to use for tracking lamp system maintenance.

• Appendix E, “Replacement Parts,” lists the various accessory replacement parts

available for Fusion UV Systems Irradiators.

• Appendix F, “Ignitor Bulb,” applies to lamps manufactured before July 1, 2002. It

describes the operation of the ignitor bulb that provides ignition to the main bulb.

• Appendix G, “Schematics,” contains figures that illustrate the various wiring

diagrams for Irradiator components.

Document Conventions

The products and components discussed in this document are designed and tested for

safe operation; however, they use technologies and resources that have inherent risks.

This section describes the conventions used throughout this manual when discussing

such technologies, so that users can plan and act accordingly when installing,

operating, or troubleshooting equipment.

Indications of Note, Caution, Warning, and Danger

Four categories of notice are indicated in this document; descriptions and examples of

their formatting are provided next.

NOTE: Notes serve to point out additional information about a subject or

process that is important, but not hazard-related.

CAUTION: Cautions generally indicate areas where a user should take

special care to avoid minor or moderate injury. It may also indicate

unsafe practices that could damage equipment or materials.

WARNING: Warnings indicate actions that can cause recoverable physical

harm; or destruction of equipment, data, or products.

12 F300S/F300SQ Ultraviolet Lamp System

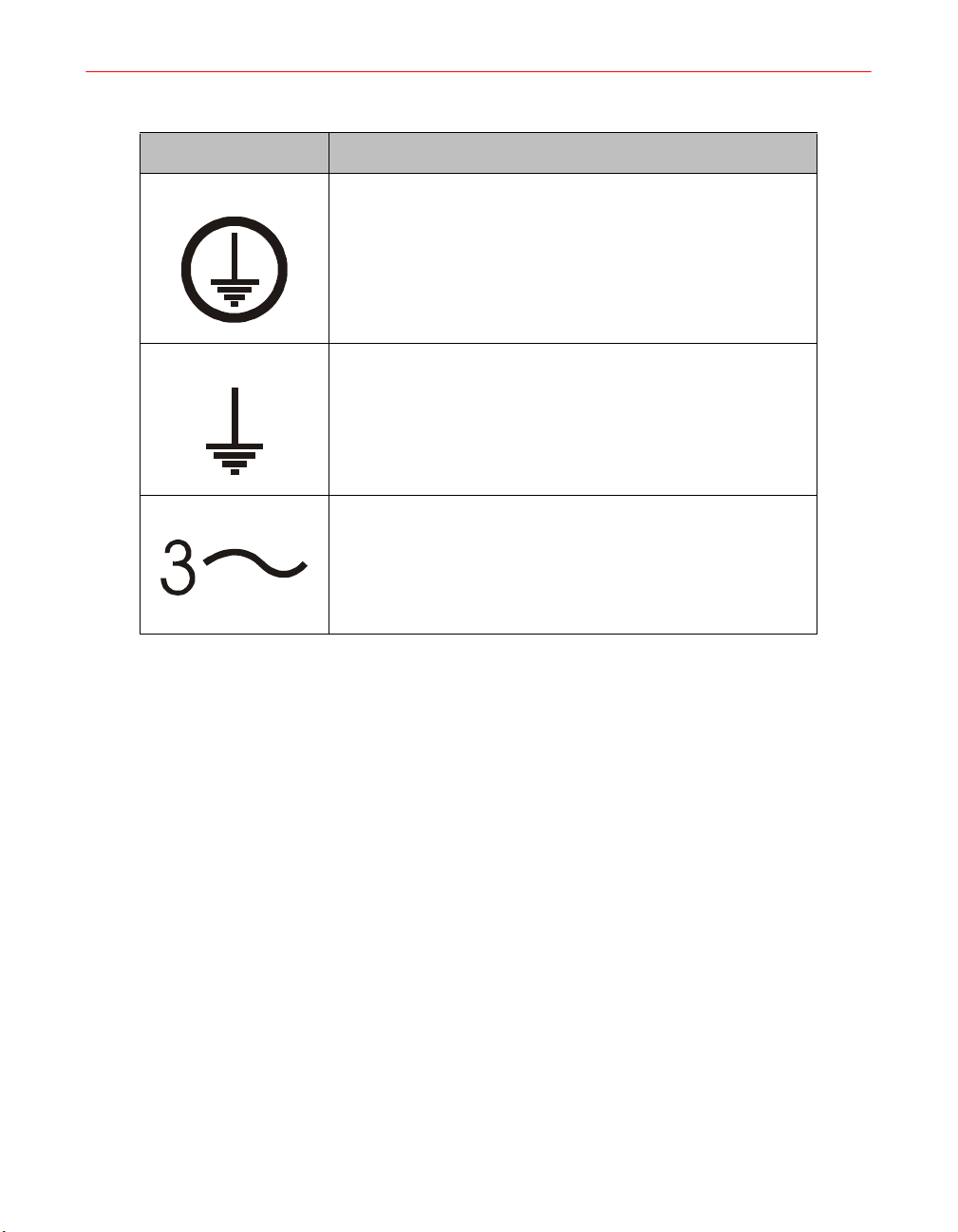

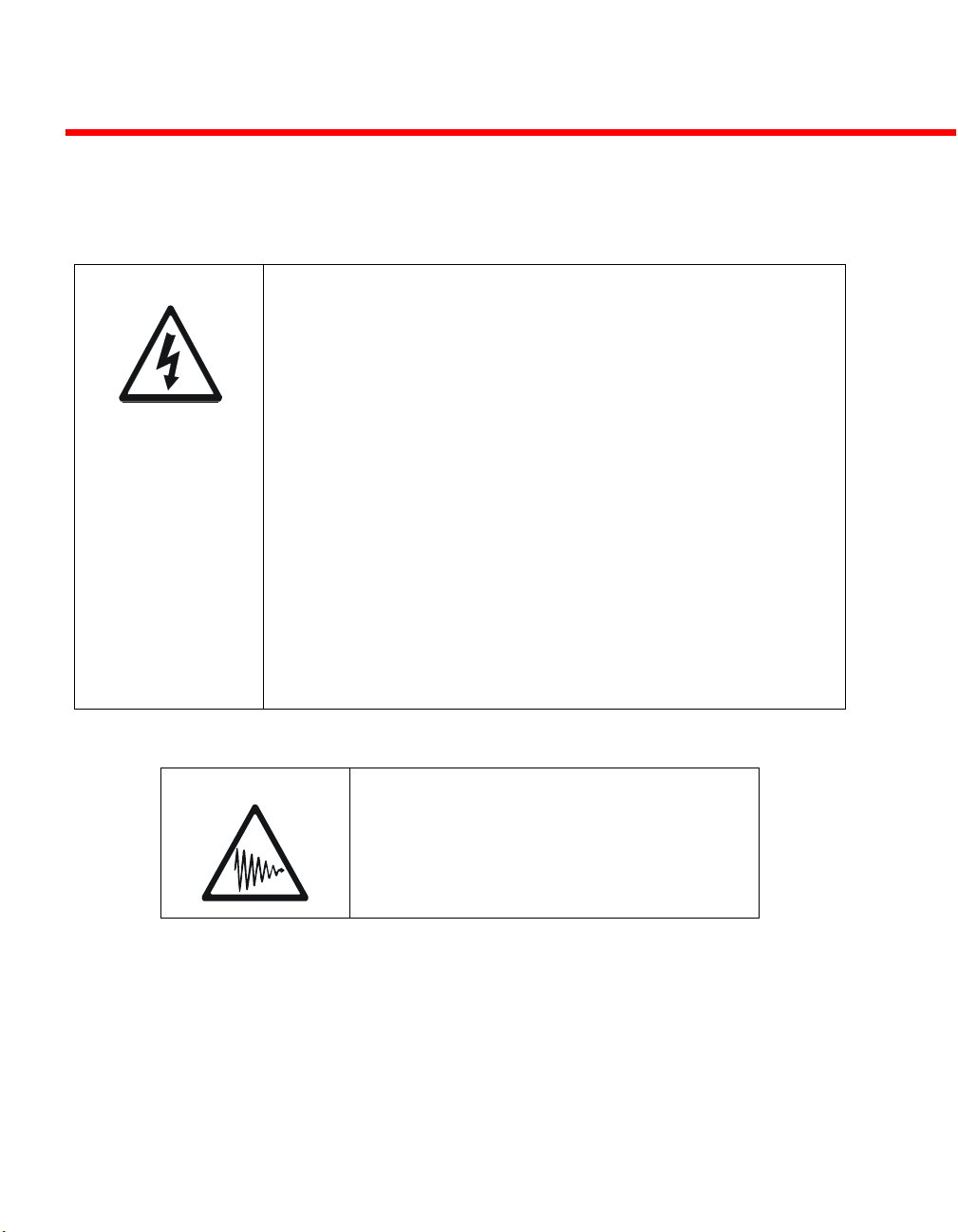

Icon Usage

Several icons are used throughout the documentation to identify the types of hazardous

resources or technologies used when working with a particular aspect of the system.

Table 1, “Icons,” lists these and their definitions. Exercise extreme care by reading the

material thoroughly and following all procedures when working with the various

components.

Icon Definition

DANGER: Danger indications identify conditions where death or

permanent injury to personnel can occur if proper procedures and

precautions are not followed.

Table 1. Icons

CAUTION:

Exclamation Mark: This icon is used for other instances and

items for which a standard symbol does not exist.

CAUTION: Risk of Electric Shock

This icon identifies instances where dangerous or lethal

voltages might be present when working with various

components of the irradiator or site power.

CAUTION: Microwave Radiation

The Fusion UV Lamp System is powered by high

energy RF microwave power which can be dangerous if

misused or inadequately shielded. The lamp system

should never be turned on if the lamp housing and

screen are not intact, or if the microwave leak detector

and interlock are not functioning.

Installation, Operation, and Maintenance Manual # 509252 Rev R 13

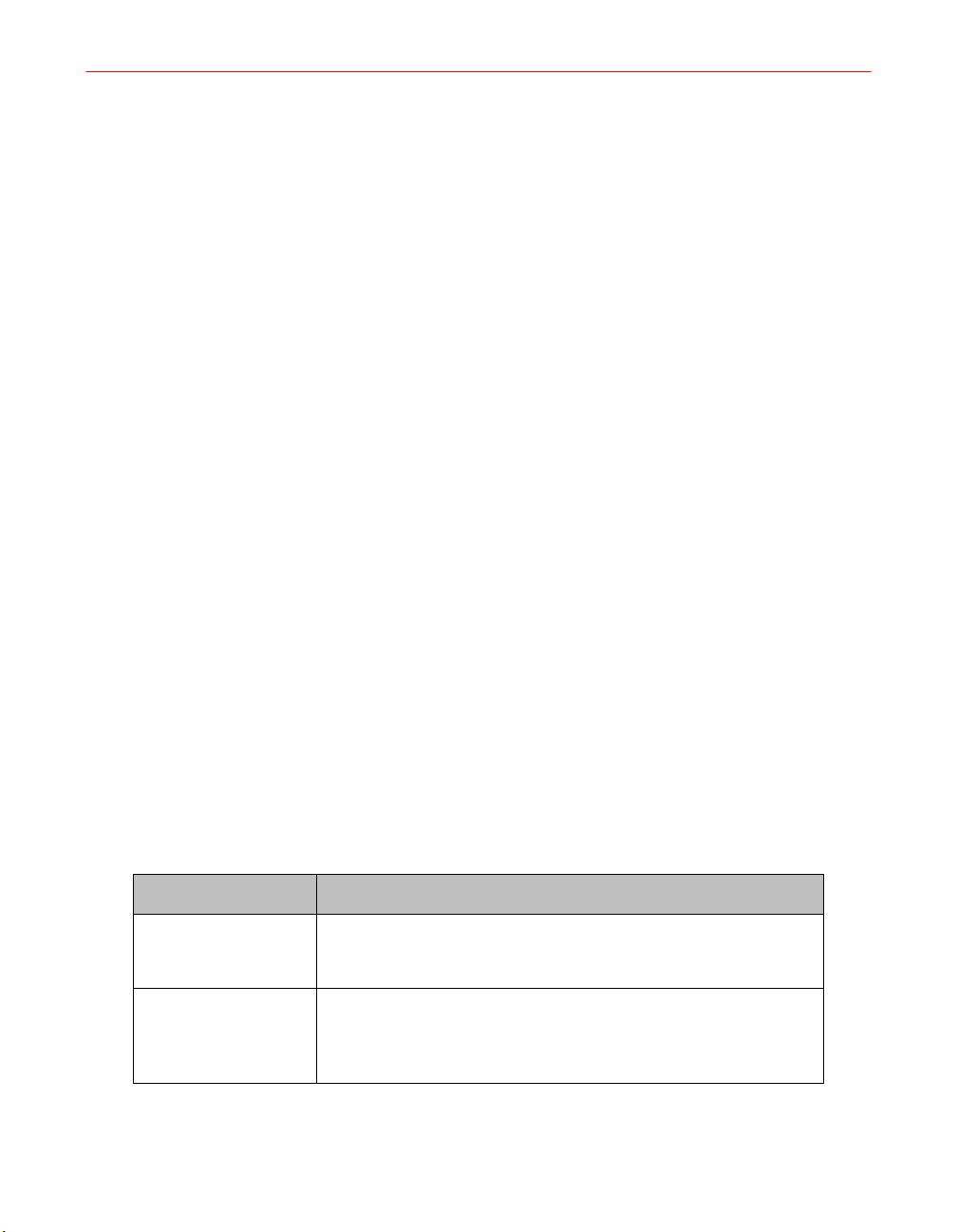

Table 1. Icons (continued)

Icon Definition

CAUTION: Ultraviolet Radiation

This icon identifies instances where damaging levels of

ultraviolet radiation may be present. Adequate shielding

around the equipment and region must be provided, and

personnel should

certified lenses.

should wear gloves and long sleeves to protect their hands

and arms, and ensure that their legs are covered.

CAUTION: Radio Interference

be required to wear goggles with UV

All personnel within ten feet of the lamp

Fusion lamps operate at a fundamental frequency of

2.45 GHz. The unit may cause interference with some

local area networks (LANs) that also operate at this

frequency. Please check with your LAN manufacturer

for compatibility. Ensure that the equipment is properly

maintained and shielded.

CAUTION: Ozone

High concentrations of ozone can cause discomfort, or at

sufficiently high levels be dangerous. Although Fusion lamp

systems make ozone at a level that could barely be detected

by odor and at a factor of five below the level of 0.1 parts per

million allowable for continuous exposure (American

Conference of Governmental Hygienists), all Fusion UV Lamp

Systems should be exhausted to the outdoors.

CAUTION: Hot Temperature, Do Not Touch

Surface temperatures of the lamp during normal

operation may exceed 120

the lamp will also be hot. Observe appropriate

precautions to avoid burns.

14 F300S/F300SQ Ultraviolet Lamp System

o

F. Metal components near

Table 1. Icons (continued)

Icon Definition

Protective Conductor Terminal

Earth (ground) Terminal

Three Phase Alternating Current

System Description

The Fusion Ultraviolet Lamp System has been designed specifically for applications

involving the industrial curing of inks and coatings and may be used effectively for a

wide variety of applications.

An ultraviolet (UV) lamp system for industrial curing must generate extremely intense

radiation in the 200-400 nanometer region. Such radiation, when properly generated

and focused, and used in conjunction with specially formulated UV sensitive inks and

coatings, causes virtually instantaneous curing (drying) of the exposed materials.

The unique properties of the Fusion UV Lamp System are obtained by using

microwave radiation to energize the lamp. Microwave energy at 2450 MHZ is

generated by a power tube (magnetron) of the type widely available for commercial

microwave cooking ovens. The patented Fusion UV Systems lamp has no electrodes,

and consequently overcomes many of the basic limitations of conventional mercury

arc lamps.

Installation, Operation, and Maintenance Manual # 509252 Rev R 15

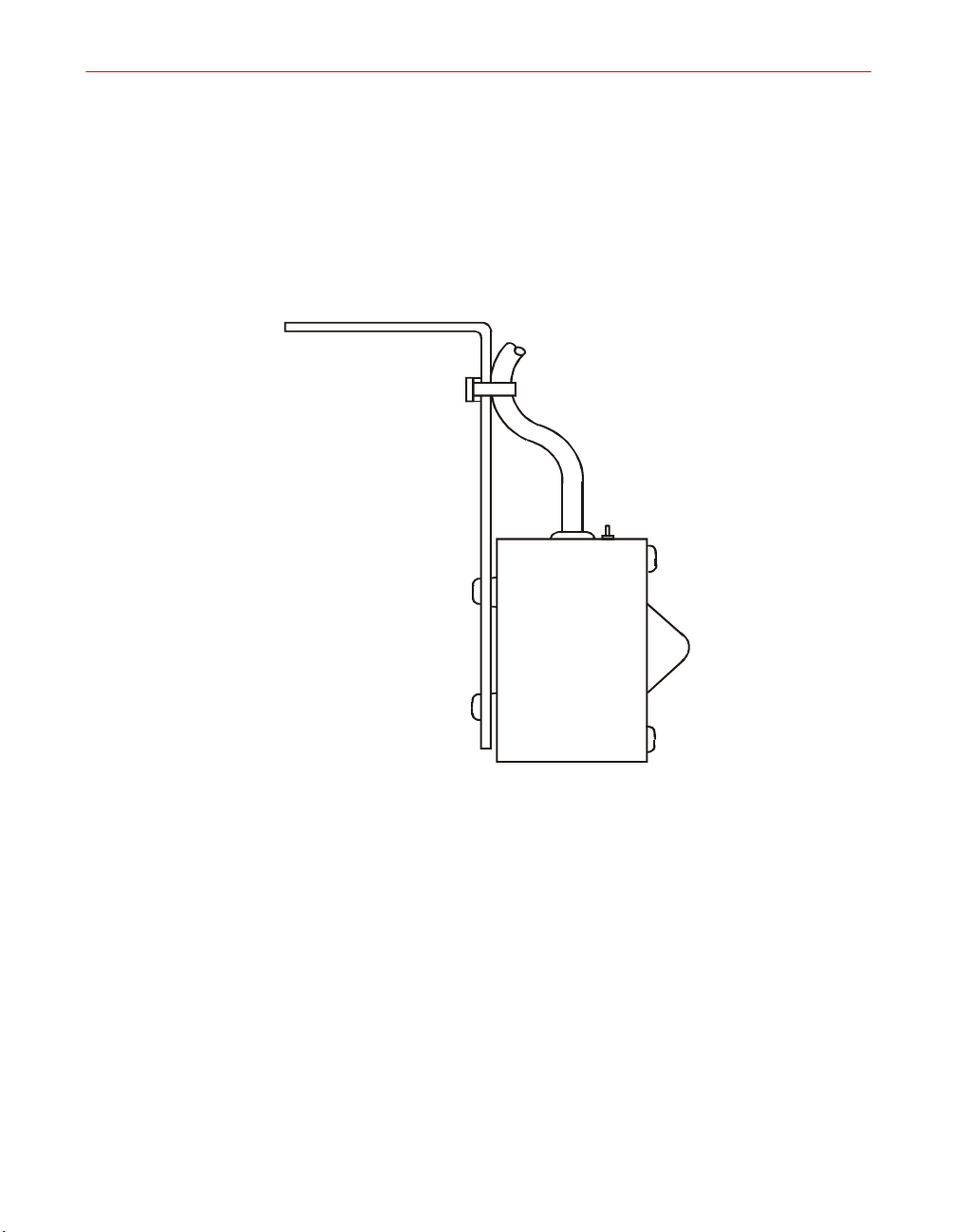

Figure 1. F300S/F300SQ Lamp System

The F300S/F300SQ Fusion UV Lamp System (Figure 1) is modular, consisting of

independent 6-inch (15.2 cm) lamp units and corresponding modular power supplies.

Two lamps can be placed end-to-end to form a 12-inch (30.5 cm) lamp system or can

be placed in a continuous array to form lamps of 18-inch (45.7 cm), etc. This is

possible because the illumination of the lamp is a full 6". When two 6" lamps are

placed end-to-end forming a 12" lamp, material being irradiated in the focal plane

53.3mm (2.1") below the lamp bottom, and at the juncture between the two lamps,

receives sufficient radiation from each 6" module to provide uniform curing over the

entire region.

Microwave energy from a single magnetron is directed into the cavity formed by an

aluminum reflector and a screen over the bottom of the reflector. The lamp bulb is

located inside this chamber. The screen keeps microwaves inside the chamber but

allows UV light to pass through onto the material to be cured.

16 F300S/F300SQ Ultraviolet Lamp System

Electrical inputs to the lamp module are provided by a high voltage/control cable with

a quick-connect fitting which supplies power for the magnetron, filament transformer

and the interlock circuitry.

System Components

The basic F300S/F300SQ system consists of the following items:

• A P300M/P300MQ/P300MT power supply

• An HV Cable H340 (no modular blower)

• An HV Cable H341 (with modular blower)

• An I300 series irradiator

• An RF detector cable H790

• An RF-1 detector

In addition, the user must supply the following if not provided by Fusion UV Systems:

• Cooling for the irradiator, if no modular blower is provided. (See Appendix A,

“Specifications” and Appendix C, “Outline Drawings” for irradiator cooling

requirements.)

• Mechanical mounting of the lamp modules over a substrate, conveyor, or other

transport mechanism

Control

• Light shield surrounding the lamps

• Exhaust system for the light shield

• Any desired interlock mechanisms (see Chapter 3 on page 39)

• Electrical wiring of the power supply into the plant electrical system

The control system of the F300S/F300SQ provides precise control of high voltage and

filament voltage supplies. The control board also monitors cooling air pressure,

detection of RF, power levels, bulb ignition, and interlocks such as transformer

thermal switches. If a problem arises, the control system turns off all high voltage

power to the lamp and flashes a fault LED indicator on the power supply control panel.

Inputs for customer ON/OFF control are available. Outputs allow detection of

STANDBY or LAMP ON operation, or of interlock failures.

Installation, Operation, and Maintenance Manual # 509252 Rev R 17

Cooling

Irradiators

Proper operation of the lamp requires adequate cooling of the magnetron and the bulb.

(See Appendix C, page 129, for irradiator cooling requirements.) Cooling air from a

blower goes through the magnetron cooling fins and into the lamp housing. At this

point, the airflow splits into two paths: one path exhausts through the irradiator

housing vent holes, and the rest of the air flows into the cavity through cooling holes

in the reflector. This airflow cools the bulb and exhausts through the RF screen.

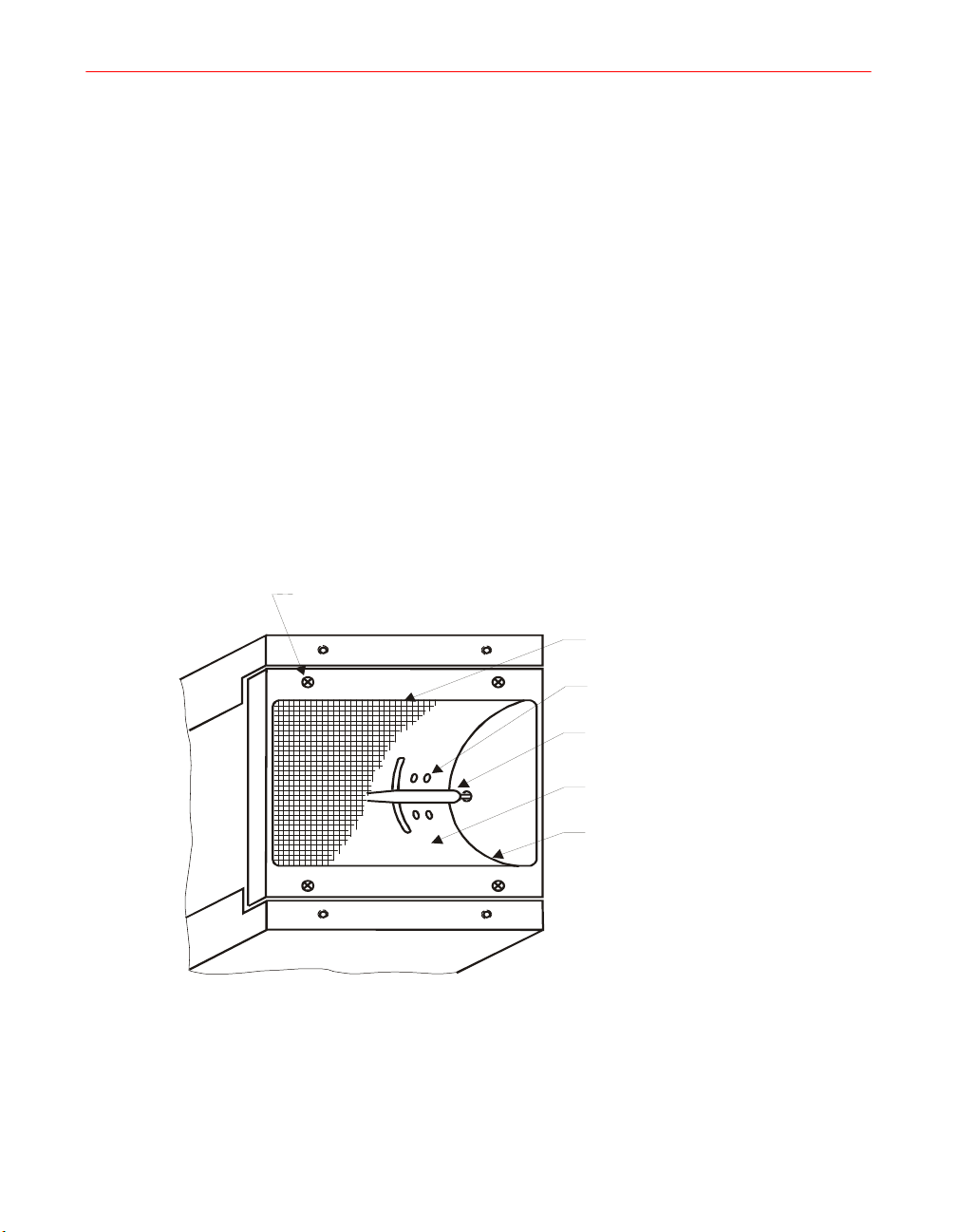

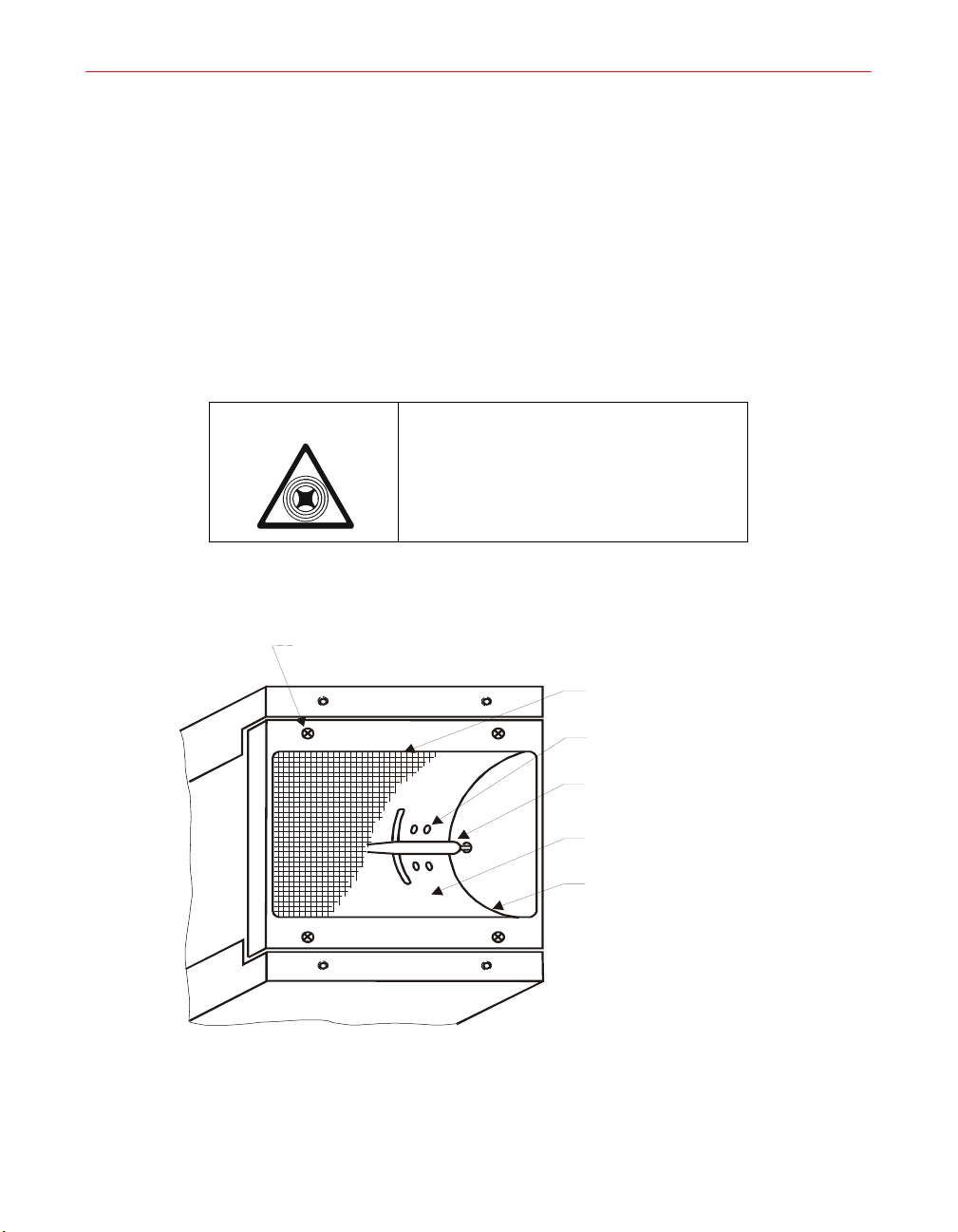

The I300M irradiator family is the heart of the UV system. For example, the model

I300M contains both the 15.2 cm (6") long electrodeless lamp bulb mounted in the

elliptical reflector and the magnetron which energizes the bulb. The reflector is

elliptical in cross-section and the lamp bulb is mounted at the focus of the ellipse,

producing an intense strip of light at the other focus of the reflector (53 mm [2.1"]

below the bottom rails of the lamp).

M3 screen retaining

screws (4) (2 per side)

RF screen

18 F300S/F300SQ Ultraviolet Lamp System

Cooling air holes

Lamp bulb

Cavity

Reflector

Figure 2. Reflector Assembly

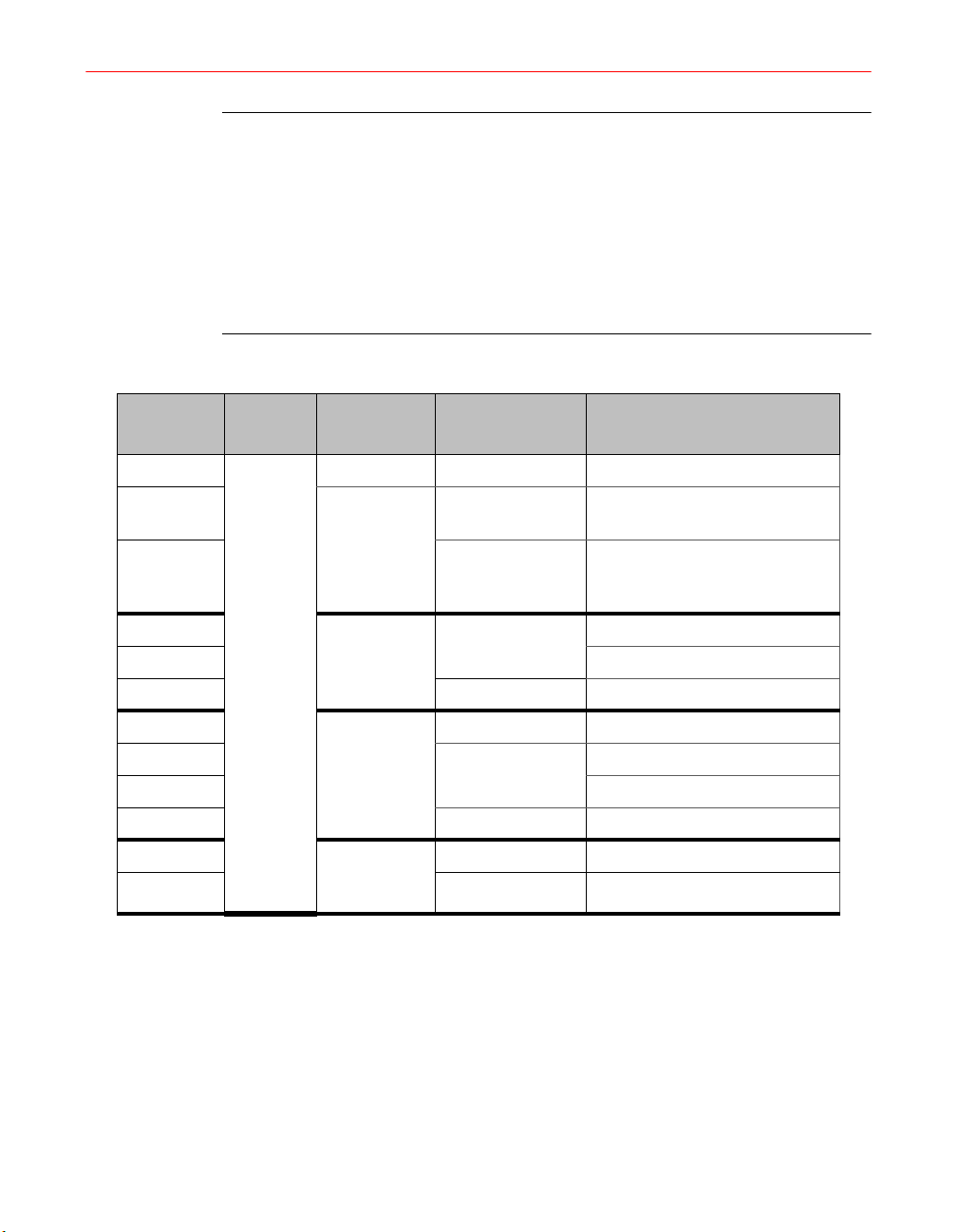

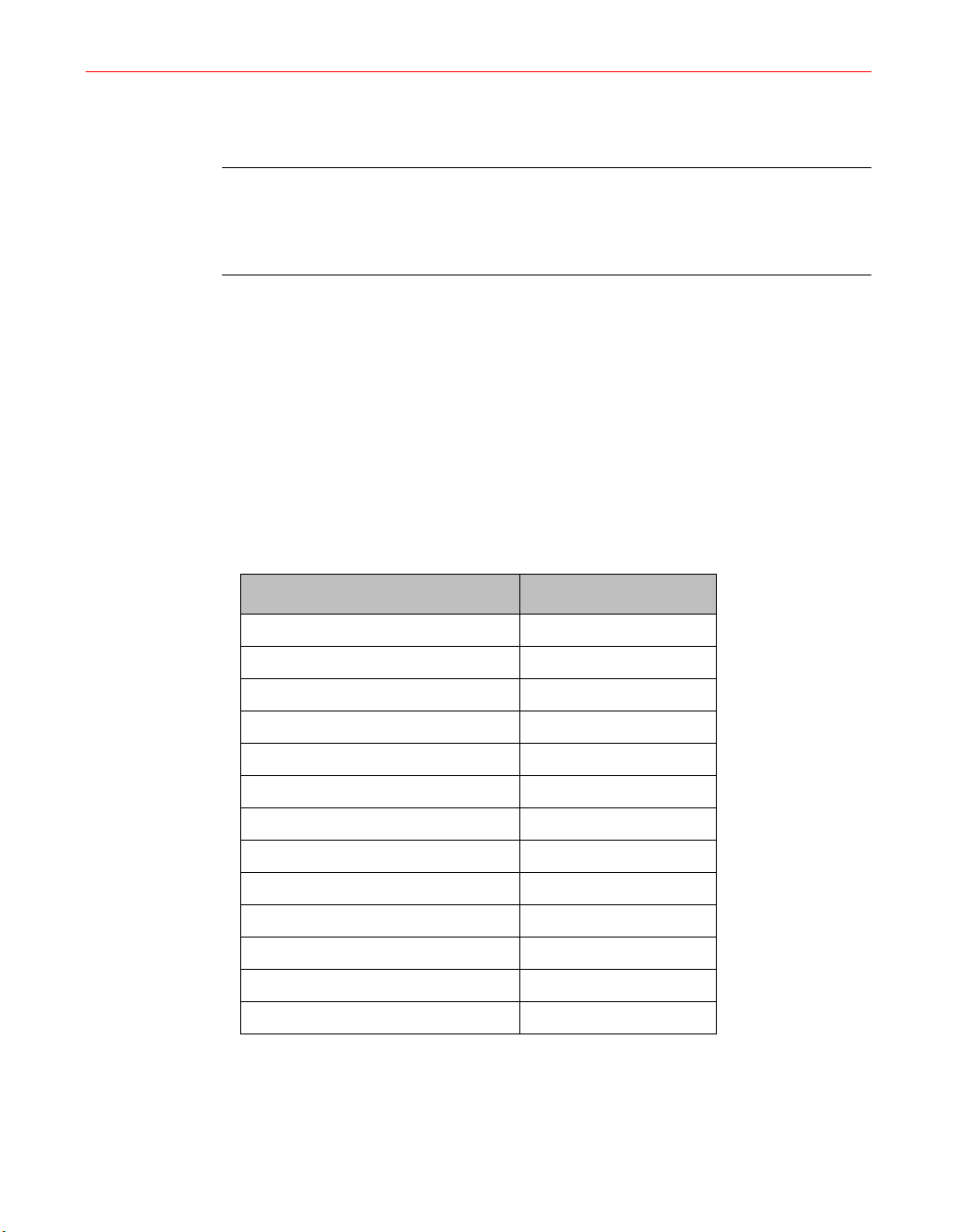

The following table lists the various irradiator models manufactured by Fusion UV

Systems, and describes their high-level differences.

Table 2. Irradiator Models

Irradiator Model Photoresistor Assembly RF Gasket Air Delivery

I300M Direct View Standard Front Connect Plenum

I301M Direct View Standard Top Connect Plenum

I300MB Direct View Standard Modular Blower

I310MP Scatter View I6 Front Connect Plenum

I311MP Scatter View I6 Top Connect Plenum

I310MB Scatter View I6 Modular Blower

I310MP-D Direct View I6 Front Connect Plenum

I311MP-D Direct View I6 Top Connect Plenum

I310MB-D Direct View I6 Modular Blower

Reflector and Cavity

The top of the reflector contains two rectangular slots which admit microwave energy

into the cavity. The slots are fed by one 1800 W, 2450 MHz magnetron located in the

top half of the lamp enclosure and connected to the cavity by a waveguide launcher.

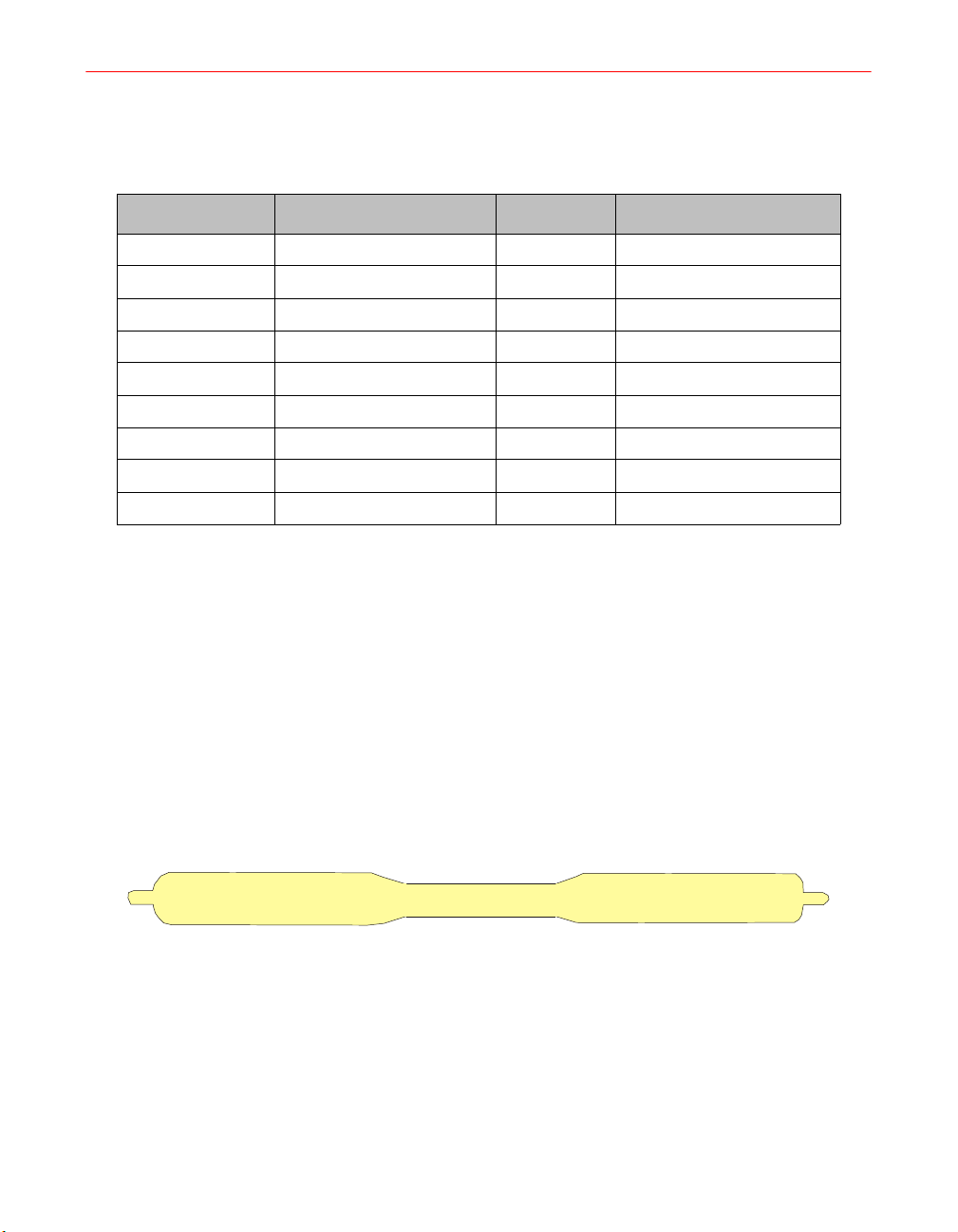

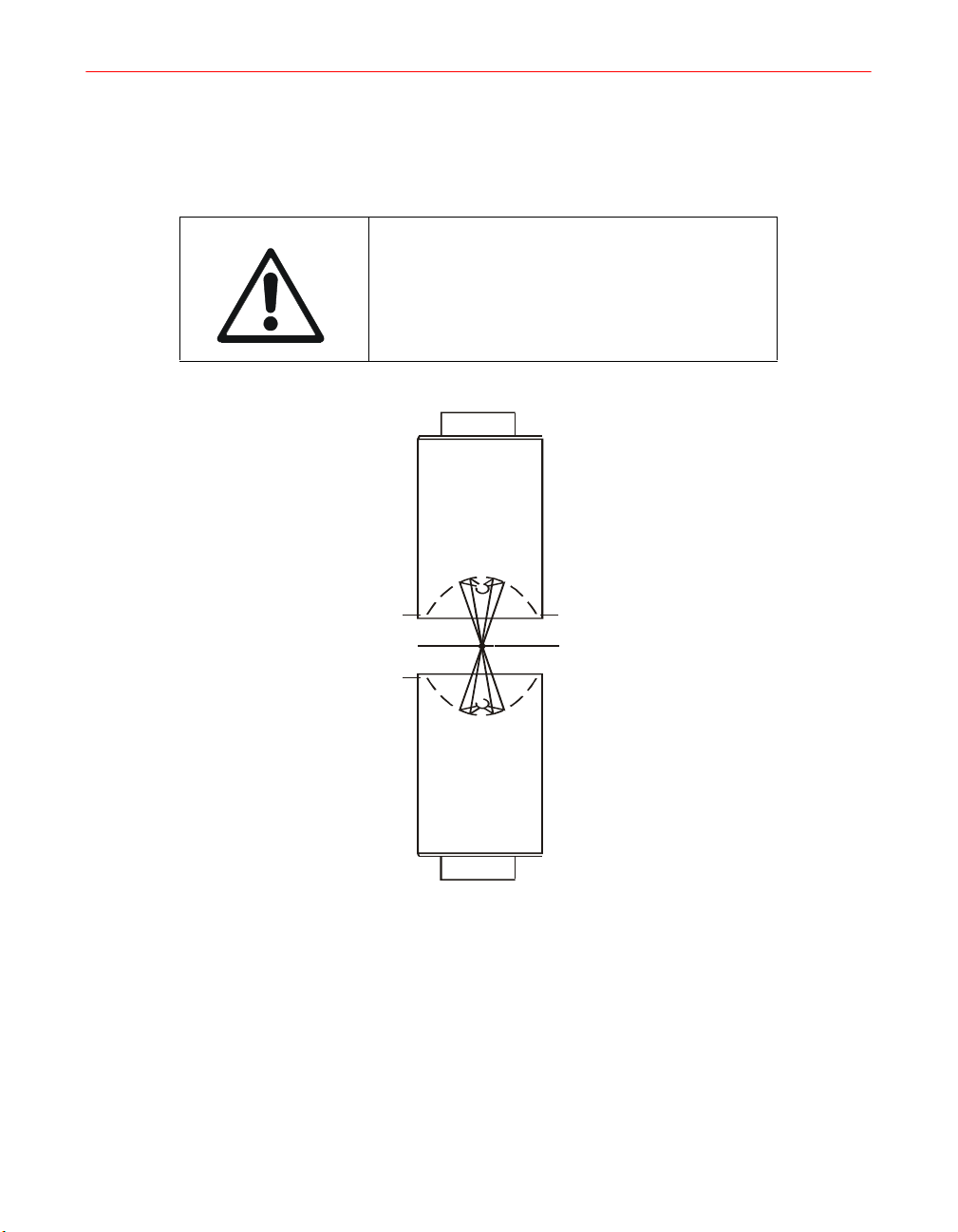

Lamp Bulb

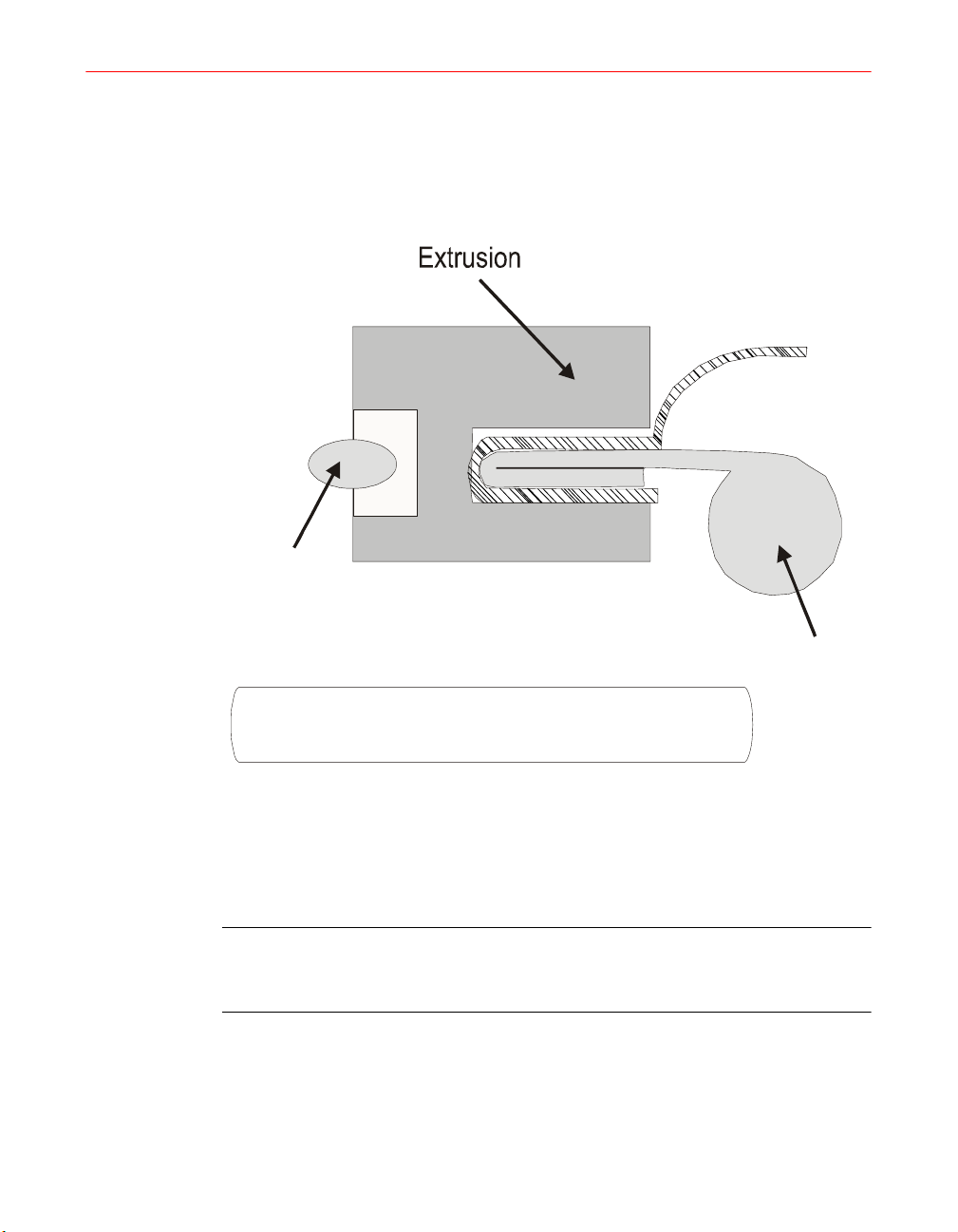

The lamp bulb (Figure 3) is made of quartz and has a tapered shape which optimizes

its UV, thermal, and microwave properties. The short quartz stubs at either end of the

15.3 cm (6") bulb provide mechanical support for quick mounting into spring-loaded

receptacles at the cavity ends. They are not electrodes and have no electrical function.

Figure 3. Lamp Bulb

Access to the cavity for changing the bulb or routine cleaning of the bulb and reflector

is easily accomplished by removing the screws which secure the screen assembly to

the bottom of the lamp. This procedure is explained in detail in Chapter 6,

“Maintenance”. The fine mesh screen must be intact and firmly secured to the lamp if

the system is to work properly and safely. The RF leakage interlock automatically

shuts the system off if excess microwave energy passes through the screen.

Installation, Operation, and Maintenance Manual # 509252 Rev R 19

Mounting

The lamps can be mounted over a moving substrate or web, supported by the bottom

rails. The lamps should be mounted so that the rails sit 53 mm (2.1") above the surface

to be cured. This allows the elliptical reflector to focus the most intense strip of light

very near the substrate.

Power Supply

Each lamp system has its own power supply to house the high voltage circuits

necessary to energize the magnetron, as well as all control and interlock electronics,

and the built-in cooling fan.

The power supply is fully modular. Up to six units may be interconnected and

controlled from a single master unit. Any power supply may assume either Master or

Slave status in a multi-unit installation.

P300M/P300MQ/P300MT

The power supply high voltage circuit consists of a dual half-wave voltage doubler

circuit which supplies a regulated source of high voltage power (approximately

3900V, 700 mA DC) to the magnetron in the irradiator. The capacitors and diodes

provide regulation and rectification to the high voltage transformer outputs.

RF Detector

The system includes a detection device which shuts the system down if microwave

energy in excess of permissible levels is in danger of being released into the work

environment. This might be caused by a faulty RF screen or some other type of damage

to the lamp, or by inadequate or damaged shielding.

The power supply fault detection circuitry searches the system for a functioning RF

detector by means of the System Interconnections Bus. A multi-unit installation must

have at least one RF detector, which is usually connected to the master power supply.

Additional detectors may be connected to slave units.

During the startup sequence, each power supply will automatically perform a

functional test on any installed RF detector (if switch S1-5 is set to “YES”). The

operator may also verify detector operation by pushing a test button on the RF-1

module for 4 seconds. Complete information appears in Chapter 5, “Troubleshooting”.

System Interconnections

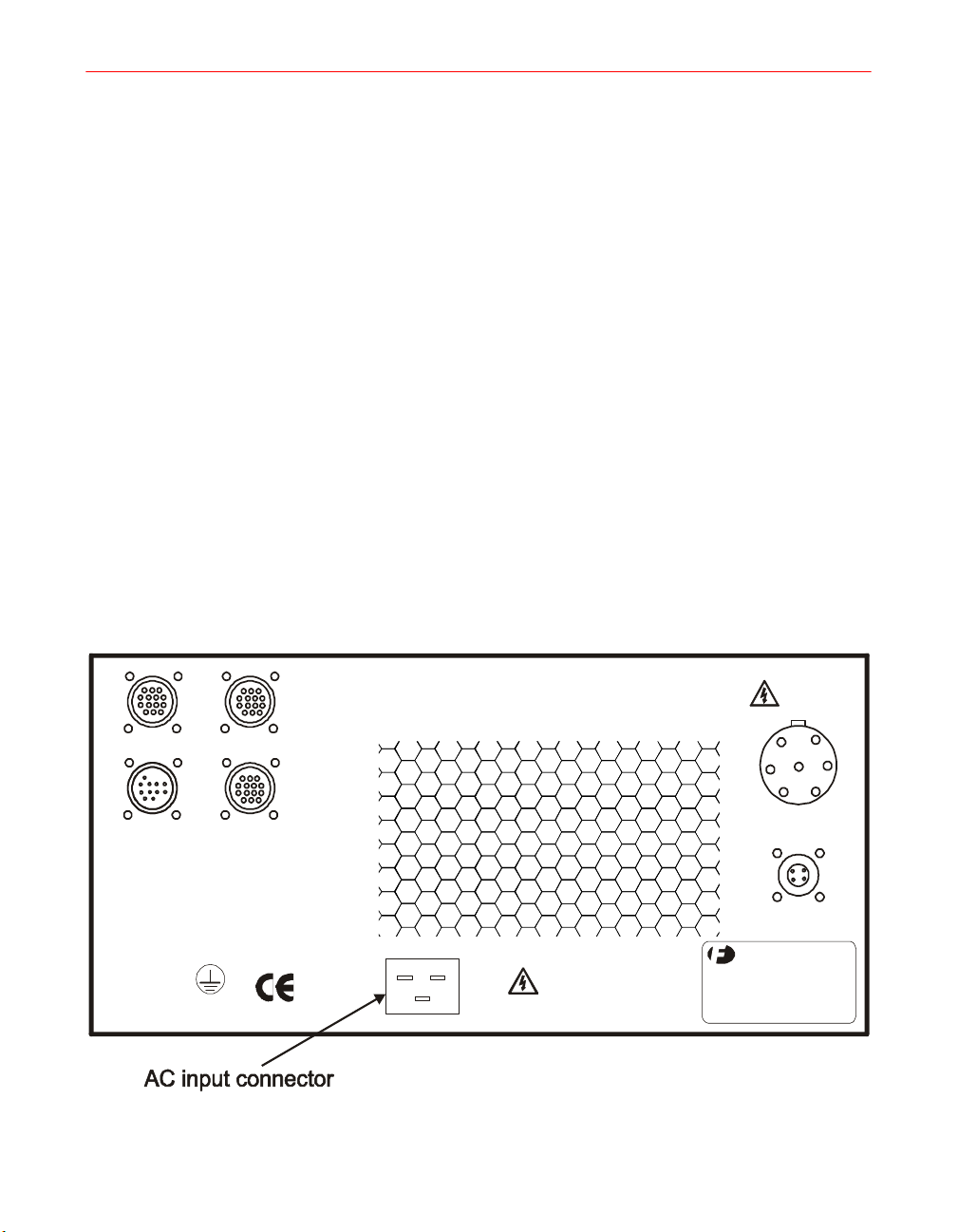

All electrical connections to the power supply are made through connectors at the rear.

Instructions for wiring are provided in Chapter 3, “Electrical System”. The power

supply does not require any routine maintenance other than occasional cleaning of the

interior with compressed air (depending on the environment).

20 F300S/F300SQ Ultraviolet Lamp System

Warranty Policy

Items manufactured by Fusion UV Systems Incorporated are warranted (under normal

and proper use) to be free from defects in material and workmanship. Fusion UV

Systems will repair or replace, at its option, any defective parts when returned to

Fusion by the purchaser, transportation paid. See the Terms & Conditions included

with your sales order for the length of the warranty period.

Equipment may not be returned, whether for warranty or other purposes, without prior

authorization and issuance of a Returned Material Authorization Number by Fusion

UV Systems. After inspection and acceptance, equipment returned for credit will be

subject to a handling and restocking charge.

Fusion UV Systems assumes no expense or liability for repairs made outside its plant

without written consent nor for any labor costs which are so incurred. For equipment

manufactured by others, Fusion UV Systems will pass along to the purchaser whatever

warranty it receives and will not be responsible for any incurred expense outside of

such warranty.

If repair of equipment is required but return of such equipment to Fusion UV Systems

is not feasible, then by mutual consent of Fusion and the purchaser, an authorized

Fusion UV service representative will be sent to the purchaser’s plant to effect

necessary repairs. The purchaser will be charged for the representative’s time and

expense.

Figure 4. P300M Front Panel

The two consumable items in a Fusion UV lamp system are the lamp bulb and the

microwave power tube (magnetron). The special warranties on these components are

detailed on the sales contract.

Installation, Operation, and Maintenance Manual # 509252 Rev R 21

NOTE: Any repairs or alterations, including the use of non-Fusion UV

Systems (Fusion) parts, made by the user of this product without Fusion

UV Systems’ prior written consent shall void all warranties provided by

Fusion UV Systems and such warranties shall cease to be in effect. No

allowance will be granted for such repairs or alterations. No person,

agent, representative, or distributor is authorized to give any warranties

on behalf of Fusion UV Systems, or to accept for Fusion UV Systems any

other liability in connection with any of Fusion UV Systems’ products.

Shipping Instructions

Read the following sections carefully to ensure compliance with the requirements and

recommendations for returning products or components, whether for credit,

replacement, or repairs.

Returned Material Authorization Number

Equipment may not be returned, whether for warranty or other purposes, without prior

authorization and issuance by Fusion UV Systems of a Returned Material

Authorization Number. After inspection and acceptance, equipment returned for credit

will be subject to a handling and restocking charge. Returned equipment must be

shipped prepaid.

General Packing Instructions

If possible, original packaging materials should be reused for return shipment to

Fusion UV Systems. If Fusion UV Systems’ packaging materials are not used,

equivalent packaging, as outlined in the following sections, is to be used.

Power Supply

Secure the chassis to the cover by M5 x 12 mm screws. (There are three on each side

of power supply for the P300M/P300MQ, two on each side of power supply for the

P300MT.)

Box: Bursting Test: 24 kg/cm

Gross Weight Limit: 70 kg (155 lbs.)

Fills: Rigid high density styrofoam or cardboard fills as required to

CAUTION: Packaging materials should not push against connectors or

controls.

22 F300S/F300SQ Ultraviolet Lamp System

2

(350 lbs./sq. in.)

ensure power supply does not shift in box during shipment.

Irradiators

Irradiators should be returned in their original packaging. If this is not available, lamps

must be double boxed, as follows:

The lamp is to be placed in an inner box, using cardboard fills to assure a snug fit. The

RF screen should be protected by taping a piece of cardboard over it. The inner box

should then be placed in an outer box that provides about a two-inch clearance on all

sides. High density styrofoam corner pads should be placed in the corners between the

outer and inner boxes to isolate the lamp from impact.

Box: Bursting test: 24 kg/cm

Gross Wt. Limit: 70 kg (155 lbs.)

Magnetrons

If available, use a special Fusion replacement magnetron shipping box. Otherwise,

magnetrons must be double boxed as described next.

Wrap magnetrons in three layers of plastic “bubble wrap” or equivalent. Place

magnetrons in the box and add loose styrofoam fill. Place this inner box in an outer

box and surround the inner box with loose styrofoam fill.

UV Bulbs

2

(350 lbs./sq. in.)

Place the bulb in a rigid tube (use Fusion UV Systems’ plastic lamp bulb replacement

shipping tube if available.) Secure ends to prevent impact against the tube and wrap

the tube in three layers of plastic “bubble wrap” or equivalent. Ship with loose

styrofoam fill in the box.

Control Cards

The integrated circuits in control board assemblies are susceptible to damage from

static electrical charges which may be transmitted by handling or packaging materials.

To guard against static, place control cards in anti-static bags, if available. If not, wrap

control cards in aluminum foil. Isolate the cards from impact with additional wrapping

of “bubble wrap” or equivalent.

RF Detectors

RF Detectors should be wrapped in two layers of “bubble wrap” or equivalent and

placed in a box with loose styrofoam fill.

Installation, Operation, and Maintenance Manual # 509252 Rev R 23

24 F300S/F300SQ Ultraviolet Lamp System

Chapter 1. Safety

Fusion UV Systems’ Ultraviolet (UV) Lamp Systems have been designed to operate

safely. Many systems are in production in a wide variety of industrial environments

without any problems of worker safety or health hazards. However, like most

industrial equipment, this equipment can present worker safety problems if care is not

taken to install, operate, and maintain it correctly.

The following pages provide information concerning various aspects of worker safety

with regard to this equipment. Because some features of the system may be new to

personnel using the equipment, an attempt has been made to provide a fairly extensive

background on these issues as well as references, where feasible, to further information

or U.S. Government Standards.

Care in installation and operation, coupled with adequate worker training, should

ensure that no unusual safety problems arise.

IMPORTANT: All personnel using the equipment

must become familiar with this safety information.

Installation, Operation, and Maintenance Manual # 509252 Rev R 25

Ultraviolet Radiation

Ultraviolet radiation which is emitted during normal operation of the

Fusion Ultraviolet Lamp System can be dangerous to the eyes and

skin of personnel. Adequate shielding around the system and the

region to be irradiated must be provided. If unsafe levels of light are

allowed to escape during operation, then all personnel in the vicinity

of the lamps should be required to wear goggles with UV certified

lenses. Protection is needed for indirect as well as direct eye

exposure; UV certified lenses are recommended. Discomfort from

excessive eye exposure to ultraviolet light typically occurs about six

hours after exposure. Personnel who experience eye pain after

possible exposure to direct rays from the UV lamp should see a

doctor. Furthermore, in the event that adequate shielding is not

possible, all personnel within ten feet of the lamp should wear gloves

and long-sleeved shirts to protect hands and arms.

There are no present U.S. government standards on worker exposure to ultraviolet

light. However, there is a NIOSH document, “Criteria for a Recommended

Standard...Occupational Exposure to Ultraviolet Radiation” (No. HSM 73-11009),

and several useful publications are available from the Bureau of Radiological Health

of the Food and Drug Administration.

Microwave Radiation

The Fusion UV Lamp System is powered by high energy RF

microwave power. This form of energy is identical to that used in

home microwave ovens and, as in the case of ovens, can be

dangerous if misused or inadequately shielded. In the Fusion UV

lamp, the shielding is adequate only as long as the lamp and the

screen on the bottom of the lamp are intact. Any rip or large hole in

the screen may lead to microwave radiation leakage in dangerous

amounts. The power to the lamp is interlocked to shut off if there is

excessive microwave radiation leakage. The lamp system should

never be turned on if the lamp housing and screen are not intact, or if

the microwave leak detector and interlock are not functioning.

Fusion UV equipment is interlocked to shut down if microwave leakage in excess of 5

mW/cm

26 F300S/F300SQ Ultraviolet Lamp System

2

(milliwatts per square centimeter) is detected.

Personnel Effects of Microwave Radiation

OSHA (U.S. Department of Labor, Occupational Safety, and Health Administration Standard 29CFR 1910.97) and ANSI (American National Standards Institute Standard C95.1-1999) are the only major national organizations with voluntary

guidelines for safe limits of occupational microwave radiation exposure.

The ANSI recommendation is the more stringent of the two guidelines. Conservatively

expressed, it states that a worker should not be exposed to microwave radiation levels

in excess of 8 mW/cm

exposure to much higher levels by stating that over a six-minute period the average

power density to which a worker is exposed to microwave radiation should not exceed

8 mW/cm

2

.

Microwave radiation is considered a non-ionizing electromagnetic radiation, which is

not known to produce genetic damage. The primary effect of this energy is to simply

raise the temperature of a body which absorbs it. For example, 5 mW/cm

cc of water 0.07

level continuously, he would absorb about 30 watts over his whole body. At rest, the

body dissipates about 100 watts. Therefore, this additional heat load is considered safe,

although we do not recommend continuous exposure to levels anywhere near 5

mW/cm

2

.

2

on a continuous basis at 2.45 GHz. It allows for short-term

o

C in one minute. If the average worker were exposed to this energy

2

will raise 1

Fusion UV Systems equipment normally produces low level leakage well below

8mW/cm

2

in the work environment. If a microwave survey meter is used, one should

read levels well below 1 mW/cm

exposed. When a lamp is started, leakage levels may increase by a factor of two or

three for the few seconds it takes to start and couple energy to the bulb. This is

considered safe due to the requirement to average under 8 mW/cm

period.

Radio Interference

Fusion lamps operate at a fundamental frequency of 2.45 GHz. The unit may cause

interference with some local area networks (LANs) that also operate at this frequency.

Please check with your LAN manufacturer for compatibility.

2

where personnel are likely to be continuously

2

over a six-minute

Fusion UV lamps are classified as non-consumer industrial, scientific

and medical equipment, as defined in Federal Communication

Commission (FCC) Rules and Regulations Volume 47, Part 18. As

required by these rules, Fusion UV Systems verifies that their systems

are capable of compliance with applicable technical standards

governing radiated emissions when the equipment is properly

maintained and is installed in an appropriate light shield.

Installation, Operation, and Maintenance Manual # 509252 Rev R 27

Ozone

The Fusion UV Lamp System makes less ozone than a conventional arc lamp. For

example, a pair of lamps running for twelve hours in a non-vented room resulted in a

steady state concentration of less than 0.02 parts per million. This was a level that

could barely be detected by odor and a factor of five below the level of 0.1 parts per

million allowable for continuous exposure (American Conference of Governmental

Hygienists).

All Fusion UV Lamp Systems should be exhausted to the outdoors.

Temperature

Ozone is a gaseous form of oxygen which is formed by ultraviolet light. It

has a characteristic pungent odor to which most people are quite sensitive

(people can typically detect concentrations of several parts per hundred

million). At high concentrations it can cause discomfort or at sufficiently

high levels be dangerous.

Surface temperatures of the lamp during normal operation may

exceed 120

Before attempting service procedures on the lamp, allow the unit

to operate in STANDBY so that the blower continues to run. The

bulb will cool completely in less than one minute. If the blower

is not allowed to run, the bulb will retain heat for several

minutes. Observe appropriate precautions to avoid burns.

Handle the bulb with cotton or surgical gloves or a lint-free towel at all times, as

fingerprints can be etched into the quartz.

o

F. Metal components near the lamp will also be hot.

28 F300S/F300SQ Ultraviolet Lamp System

High Voltage

Insulated electrical cables carry power at 3900 Volts from the power supply to the

lamp. These voltages can be dangerous, so some precautions should be taken in both

the location and protection of these lines. High voltages are exposed within the power

supply chassis, which should never be operated without its cover.

DANGER: Never touch the power supply/lamp cable

connections while the system is ON or in STANDBY. A faulty

magnetron may cause 7000 Volts DC to appear on connector

pins and may cause serious injury.

Do not touch power supply/irradiator harness plug P10 near the

contacts, and do not lay P10 down on any conductive material.

Never troubleshoot the power supply without first disconnecting

all external power and discharging the high voltage capacitors

with an insulated screwdriver.

A high quality cable, rated at 10,000 Volts, is used in all high voltage cables

manufactured by Fusion UV Systems, and can be supplied to users for any additional

connections that may be required.

UV Curable Materials

Please consult your UV materials supplier for recommended precautions regarding the

proper handling and use of these products.

Installation, Operation, and Maintenance Manual # 509252 Rev R 29

30 F300S/F300SQ Ultraviolet Lamp System

Chapter 2. Mechanical Installation

Mechanical Installation Checklist

Before operating the ultraviolet lamp system for the first time, be sure the following

procedures have been completed.

Table 3. Mechanical Installation Checklist

Item Chapter

Review safety procedures Chapter 1, “Safety”

Light shields in place “UV Light Shielding” on page 34

RF detector positioned correctly “RF Detector Mounting” on page 35

Fan connection for exhaust of light shield “Remote Blowers” on page 36

RF screen and lamp bulb inspected Introduction, page 11

This chapter describes the physical installation of the F300S/F300SQ Fusion UV

Lamp System. Directions regarding mounting and shielding of the system are

somewhat general because they will vary depending upon the details of each

individual installation.

Unpacking and Inspection

This Fusion UV lamp system has been thoroughly tested inspected, and packed prior

to shipment. Before unpacking, examine all shipping containers for damage. After

unpacking, examine the equipment for damage. Any damage should be reported

immediately to the shipper and to Fusion UV Systems Incorporated. A delay of more

than 10 days may invalidate future claims for damages.

CAUTION: Irradiators are particularly vulnerable to dust, dirt, metal

chips, and RF screen damage. They are shipped with a protective

covering over the screen. The covering should not be removed until just

prior to installation.

When unpacking, identify and compare each item with the packing list enclosed.

Remember to examine each component for damage. Appendix E, “Replacement Parts”

details the items included with the system which will be required to complete the

installation.

Installation, Operation, and Maintenance Manual # 509252 Rev R 31

Preliminary unpacking and inspection should be completed immediately on receipt of

equipment to allow time for repair or replacement if necessary prior to installing the

equipment.

The P300M/P300MQ power supplies are shipped with six large Phillips head screws

holding the cover to the chassis. There are three screws located on each side. The

P300MT power supply is shipped with four large Phillips head screws holding the

cover to the chassis. There are two screws located on each side of the P300MT.

The four or six cover screws

must be in place before

operation to maintain continuity

of the power supply enclosure

ground circuit.

After the inspection is completed, all components must be carefully re-packed and

stored until actual installation. Save the packing materials. They will be valuable if any

component must be returned to Fusion UV Systems for service. See “Shipping

Instructions” on page 22 for more information.

Power Supply Unit(s) Placement

The mechanical installation of a power supply unit is almost entirely at the user’s

convenience. It can be placed on a sturdy shelf or in a cabinet provided that

approximately 30 cm (12 inches) of space is left behind the power supply for cooling

air to escape, and so that the cable harnesses can be run to the other components. See

Appendix C, page 129 for restricted space clearance minimums.

The P300M/P300MQ power supplies can function in any position, although standard

horizontal mounting is recommended. Mounting the power supply so that the control

panel is facing upward is not recommended because this allows dirt and dust to settle

into the unit. In this position, the horizontal surface that is provided by the inlet finger

guard also can be easily blocked by papers, notebooks, or other flat materials that will

cause thermal overload and system shutdown.

Power supplies are stackable up to three (3) units high. However, a power supply can

weigh up to 40.3 kg (88.6 lbs.), so units should not be stacked to, or installed at, a

height that makes access of chassis removal difficult.

32 F300S/F300SQ Ultraviolet Lamp System

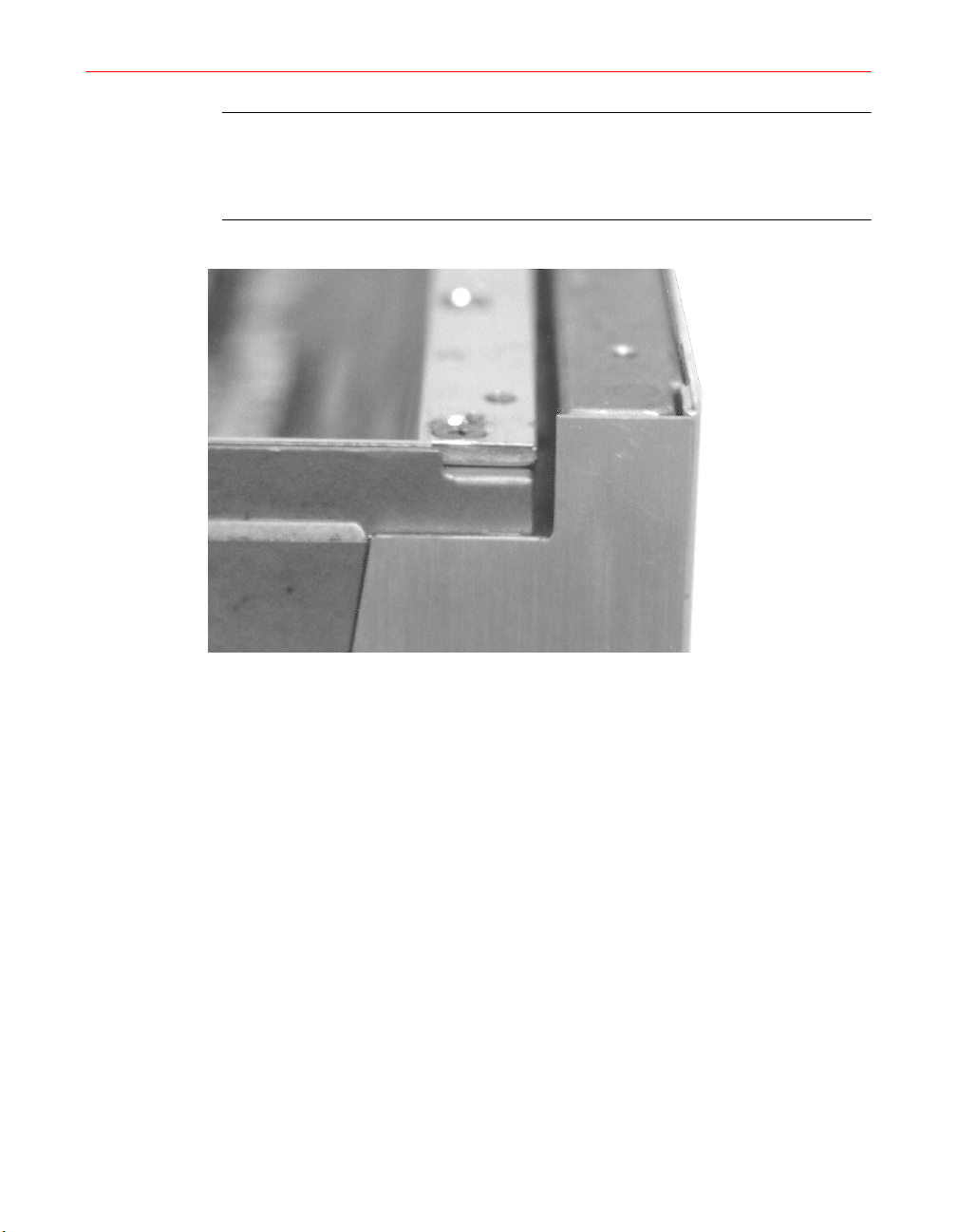

Irradiator Mounting

The irradiator mounting structure must also provide UV shielding and adequate

venting for the cooling air. This is described on the following pages. Each user will

normally design the mounting structure to suit the particular application, and the user

is responsible for providing the required shielding and ventilation. (Irradiator

dimensions are shown in Appendix C, “Outline Drawings” and detailed in the

Appendix A, “Specifications”.

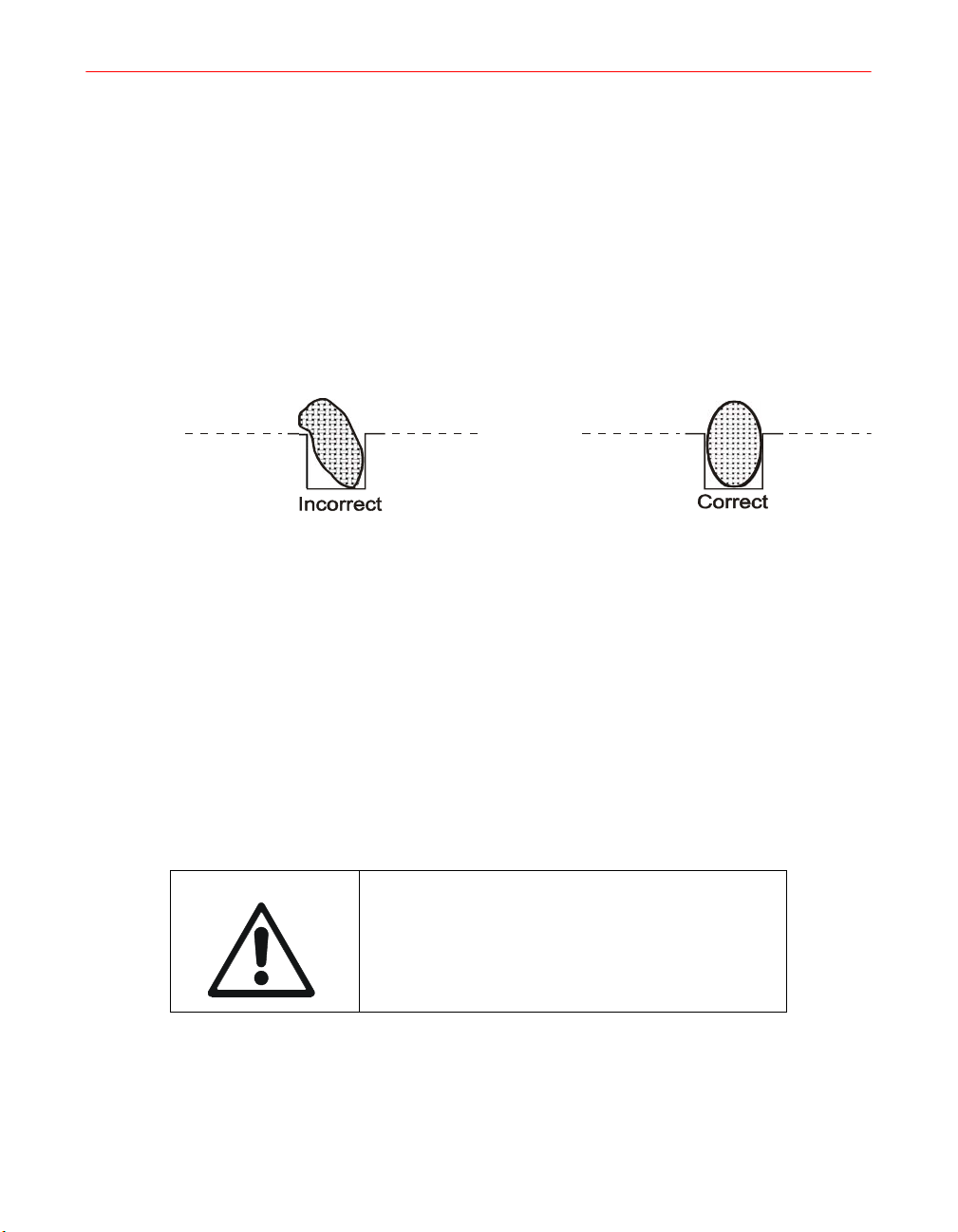

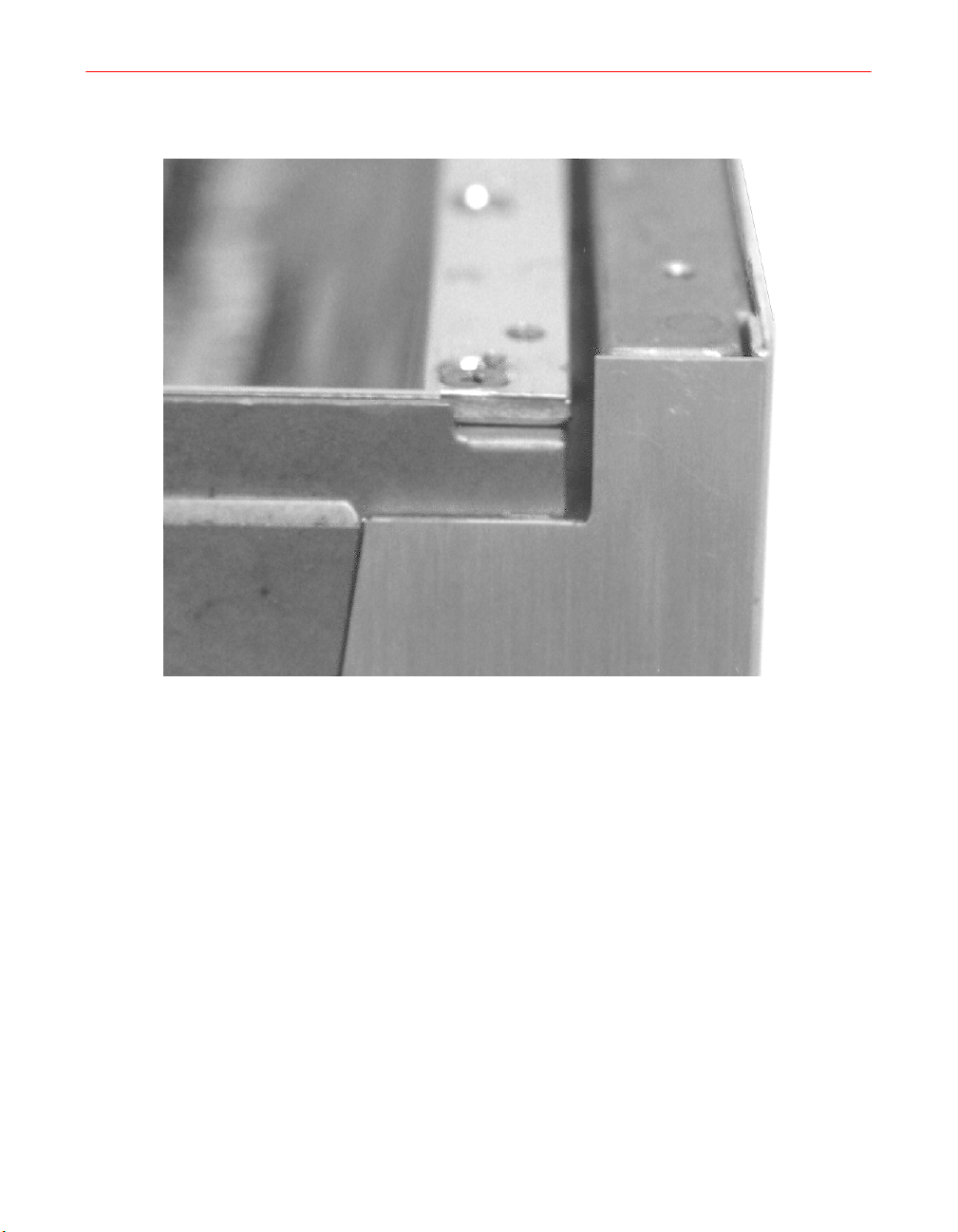

The easiest and most common mounting position is with the irradiator vertical and the

screen at the bottom 53 mm (2.1 in.) above the substrate. Simply rest the module on a

pair of angle irons oriented in the same direction as the lamp bulb. One common

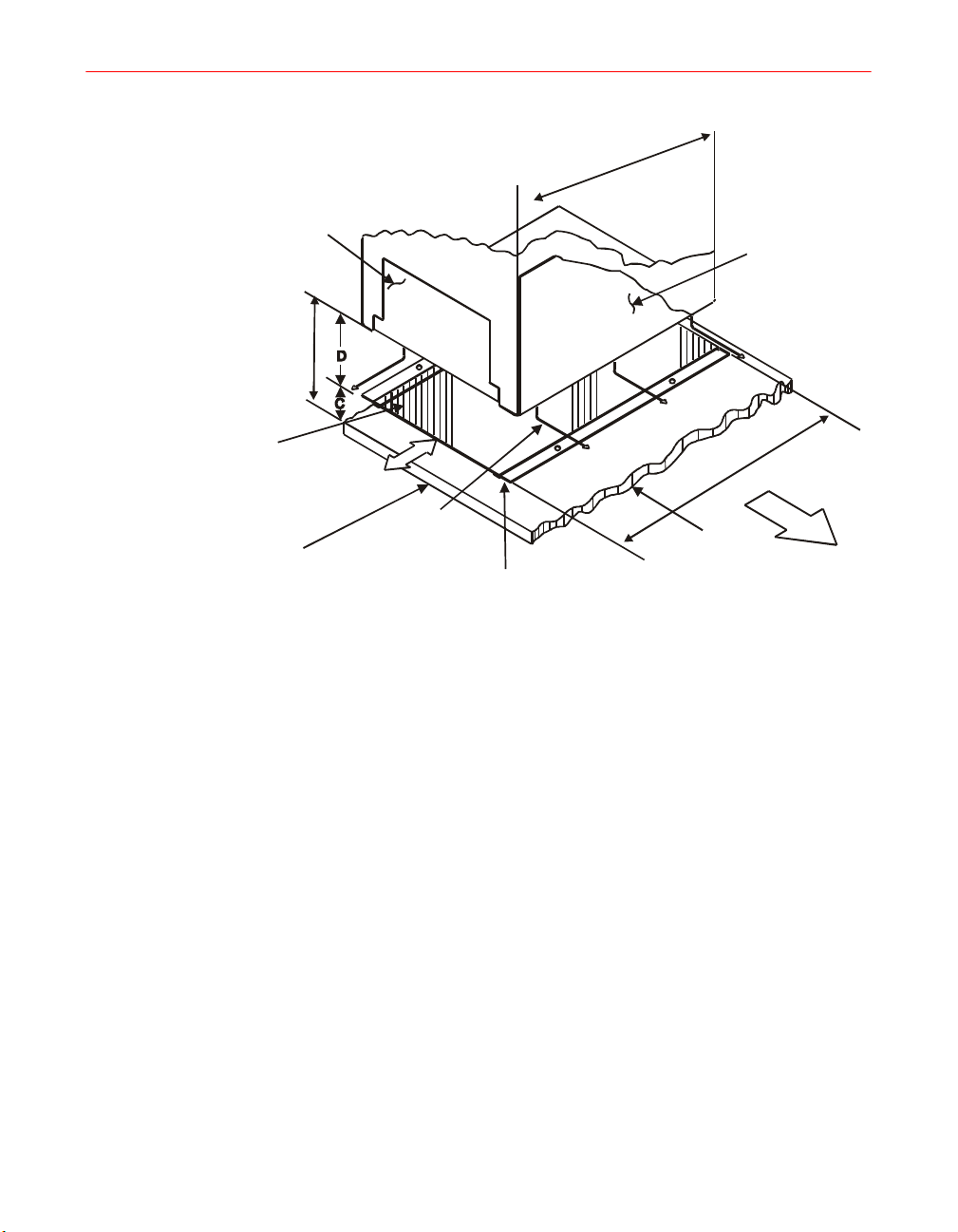

mounting scheme is shown in Figure 5.

Vertical mounting requires that no part of the support can push against the irradiator

screen, causing it to tear. Provisions may be made for raising or lowering the support

structure with respect to the substrate to be irradiated. This allows the user to optimize

the curing by working in focus or somewhat out of focus.

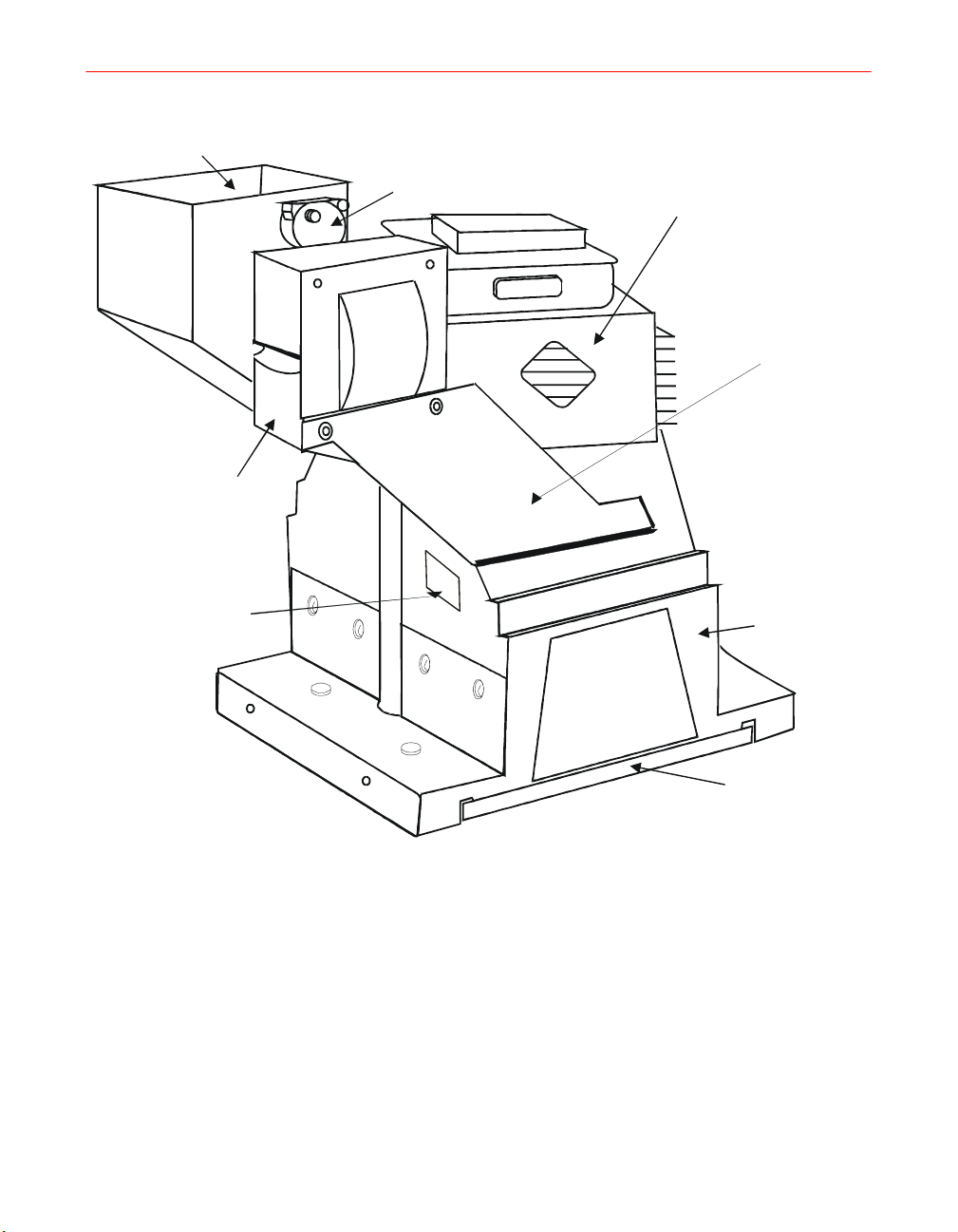

Figure 5. Vertical Mounting Design for Irradiators

Installation, Operation, and Maintenance Manual # 509252 Rev R 33

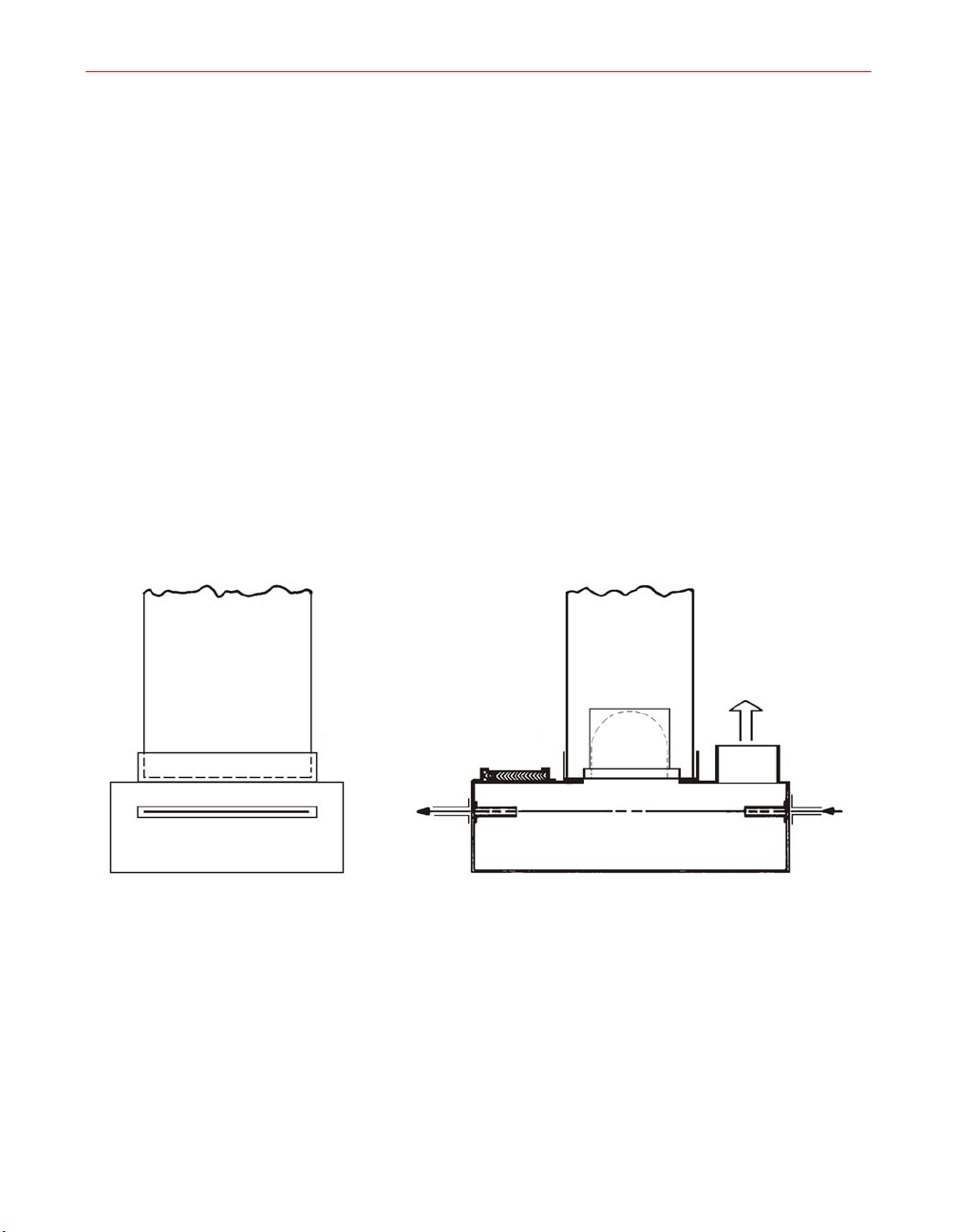

Lamps Mounted in Opposing Configuration

IMPORTANT: If two lamps are to be mounted

opposing each other (as shown in Figure 6 on

page 34), lamp performance and operation

may be impaired. Contact Fusion UV Systems

Technical service department for consultation.

Figure 6. Lamps in Opposing Configuration

UV Light Shielding

Adequate light shielding must be provided for each irradiator in the system. If

shielding is not used, or if UV light escapes around the irradiator support, the operator

must wear a welder’s helmet or UV blocking eye wear. Long sleeved clothing is

required to protect the skin from the effects of UV light.

34 F300S/F300SQ Ultraviolet Lamp System

The louvers which allow the flow of cooling air away from the irradiator must be of a

light shielding design.

(For more information on safety considerations, see Chapter 1, “Safety.”)

RF Detector Mounting

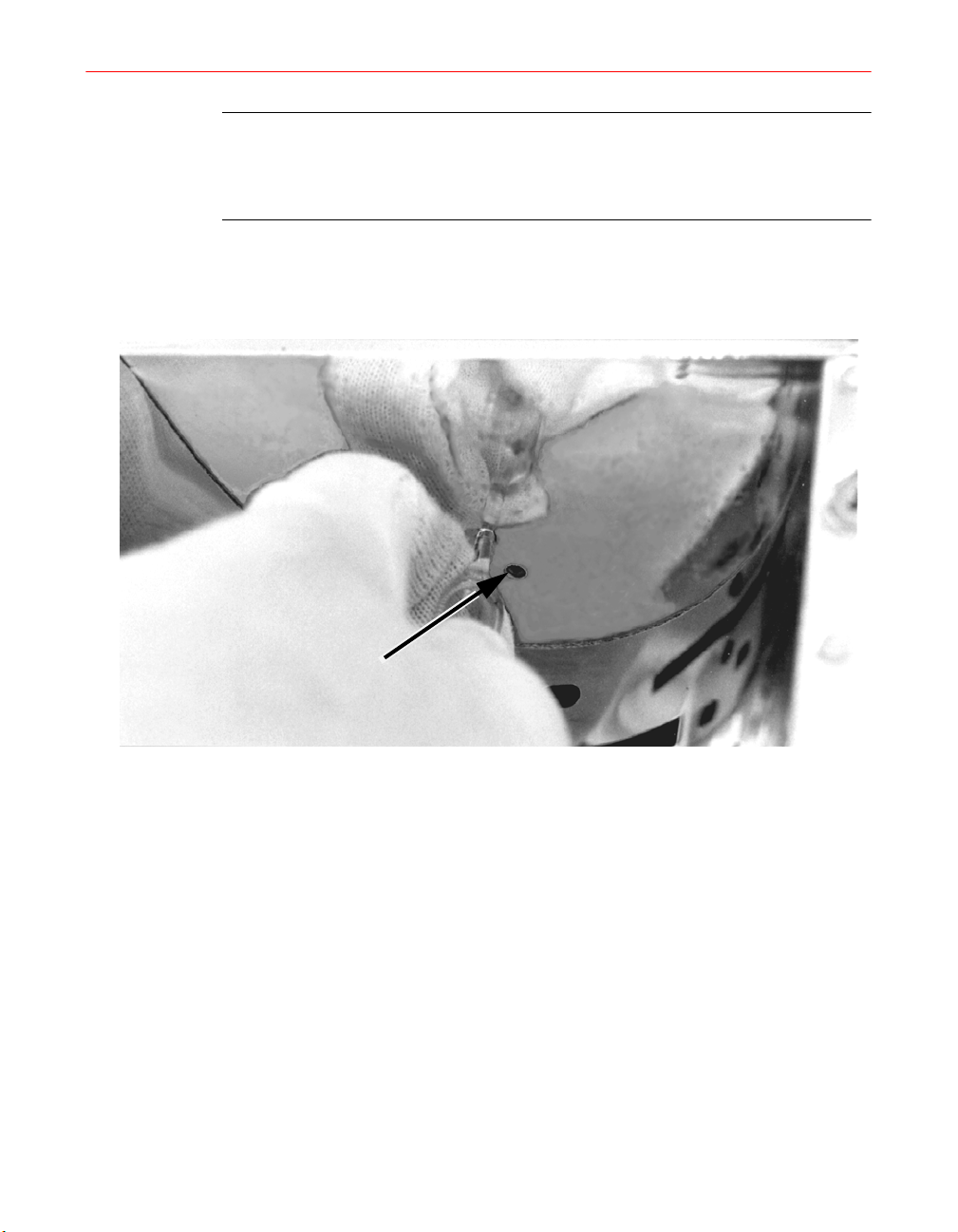

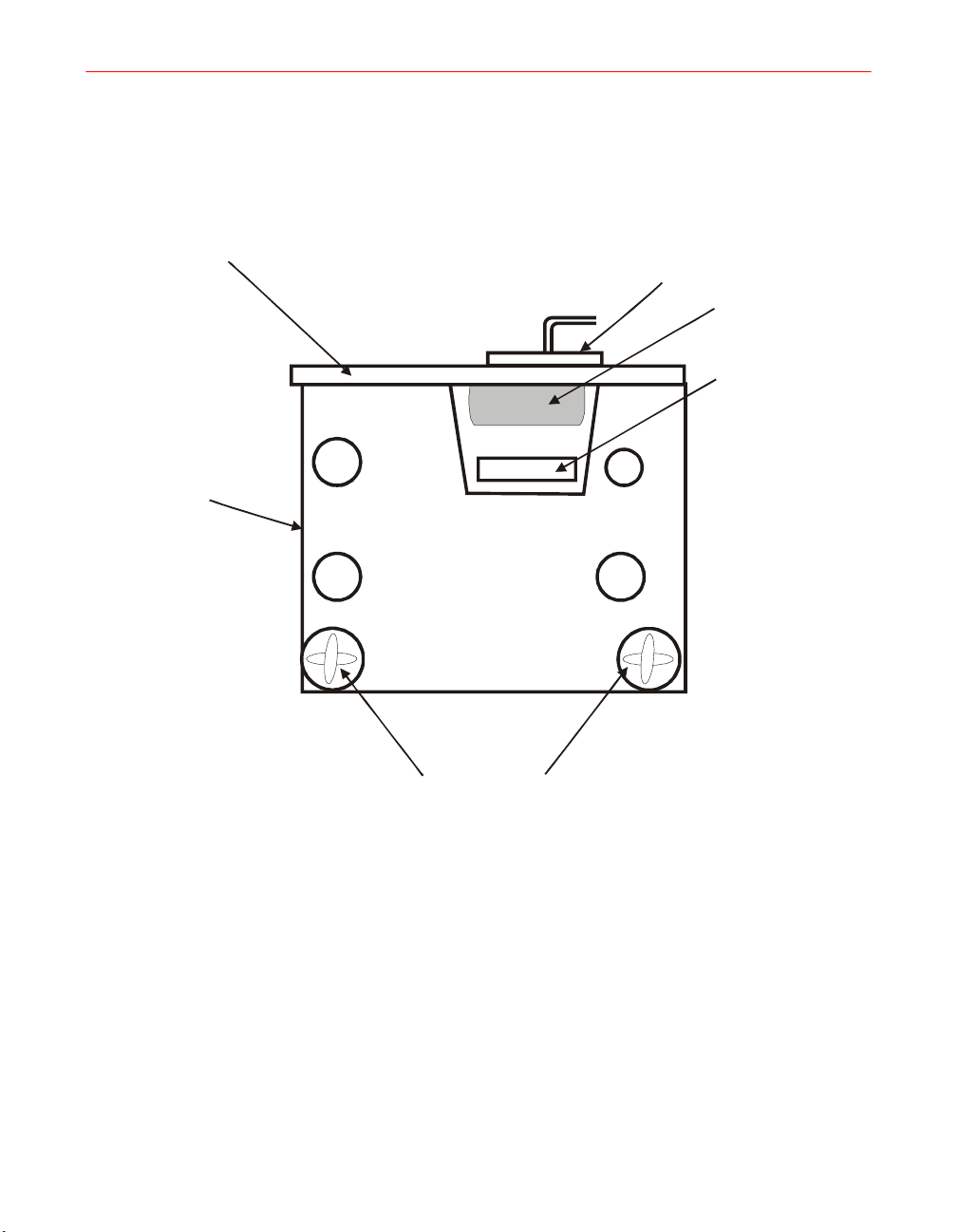

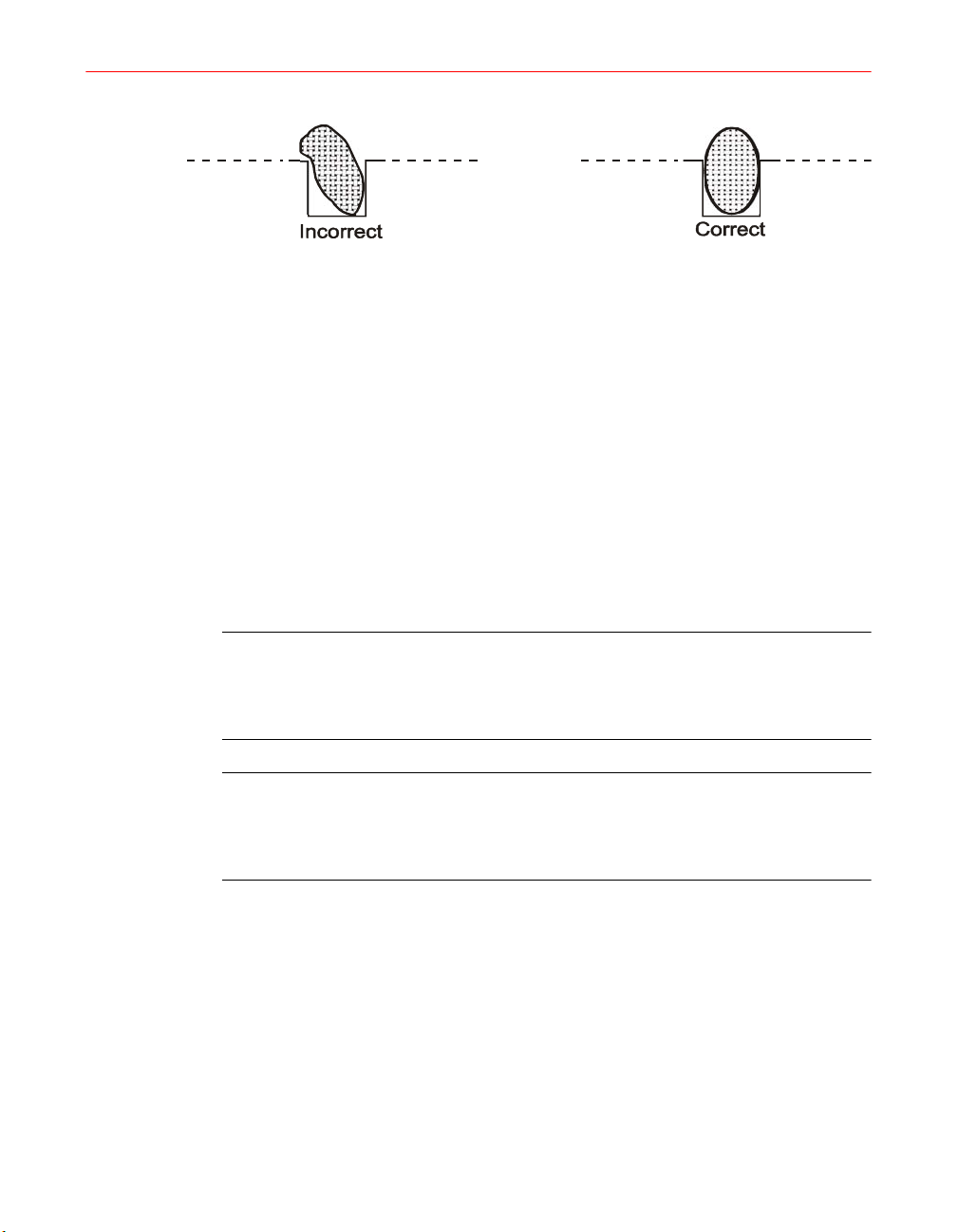

Figure 7 illustrates the proper mounting of the RF Detector.

Figure 7. Fusion UV Systems RF Detector RF-1

One RF detection device must be installed for each light shield. The antenna should

point toward the irradiator screen, which is the potential source of RF leakage.

However, to protect the antenna from heat and UV light, it should be placed outside

the light shield. It may “look” into the light shield through an existing opening, or one

made for this purpose. The tip of the sensing cone should be at least two inches from

the opening of the light shield.

The presence of metal surfaces near the detector may cause false readings; allow a

maximum open area around the device.

The connection of the cable from the RF detector to the power supply is explained in

Chapter 3, “Electrical System”.

Installation, Operation, and Maintenance Manual # 509252 Rev R 35

Remote Blowers

An optional remote blower package is available from Fusion UV Systems. The

package includes an air distribution plenum (for multi-lamp systems), inlet filter box,

and flexible hoses or ducts for cooling the system. The blower delivers 2.8 m

(100 cfm) of air to each irradiator inlet at 695 Pa (2.8" H

“Maintenance” for information on the measurement procedure.

Irradiator Exhaust Venting

Fusion UV Systems recommends that 3.6 m3/min (130 cfm) of air be exhausted from

each irradiator. The air flow must be vented below the irradiator to prevent back

pressure buildup, which would reduce the flow of cooling air. An exhaust fan is

recommended to draw hot air and ozone away from the UV lamp and discharges them

to the outside. The fan must remove at least 30% more air than is supplied to the

irradiator inlets so a negative pressure will exist under the lamps. The makeup air

enters through the UV shielding louvers or any other vents in the light shielding

enclosure.

Light shielding louvers are recommended. At least 142 cm

area is recommended for each irradiator to allow free flow of make-up air. If the

exhaust air is not vented outside the building care should be taken to prevent it from

recirculating into the inlet of the blower(s).

Quartz Plates

O). See Chapter 6,

2

2

(22 sq. in.) of louvered

3

/min

To protect the material being cured, quartz plates may be mounted below the UV lamp

to block the air carrying heat away from the bulb. A typical mounting design is shown

in Figure 8 on page 37. Details of the mounting structure depend upon the position and

location of the irradiator and UV shielding.

Clearance C prevents the substrate from striking and breaking the quartz plate but

varies with the application. Distance D should be at least one inch and as large as

practical to provide maximum area for the escape of cooling air (see Figure 8 on page

37).

36 F300S/F300SQ Ultraviolet Lamp System

m

m

6

.

7

6

)

1

0

6

.

6

(

Irradiator

53.3mm

(2.10)

Quartz plate (pair) P/N 300291

152.4 mm x 152 .4 mm x 2.29 mm

(6.00 in x 6.00 in. x 0.90 in.)

Removal access

for cleaning

Figure 8. Quartz Plates - Example Mounting Design

Irradiator

cooling

air flow

Quartz plate

mounting structure

m

m

2

5

1

0

.

6

(

Substrate

to be cured

Irradiator

mounting

structure

support

)

0

Installation, Operation, and Maintenance Manual # 509252 Rev R 37

38 F300S/F300SQ Ultraviolet Lamp System

Chapter 3. Electrical System

This chapter discusses the electrical installation and electrical setup aspects of the

F300S/F300SQ Ultraviolet Lamp System.

Electrical Installation/Setup Checklist

Before operating the ultraviolet lamp system for the first time, be sure the following

items have been reviewed and/or tested.

Table 4. Electrical Installation and Setup Checklist

Item Chapter

AC input voltage matches equipment label and

connected correctly

Power supply HV capacitors tapped for AC line

frequency

Power supply HV transformers correctly tapped for AC

input voltage

Chapter 3, “Electrical System”

Chapter 3, “Electrical System”,

page 51

Chapter 3, “Electrical System”,

page 51

Programming correct for each unit Chapter 3, “Electrical System”,

page 43, page 44

Interconnection cables secure Chapter 3, “Electrical System”,

page 44, page 49

RF cable secure Chapter 3, “Electrical System”,

page 45, page 49

User inputs (EXTERNAL INTERLOCK, SYSTEM

BLOWER) connected if wanted

Remote inputs (RESET, LAMP ON) connected if

wanted

User outputs (FILAMENT ON, HV ON, FUTURE USE,

LAMP ON, and PRESS ENABLE) connected if wanted

Chapter 3, “Electrical System”,

page 40

Chapter 3, “Electrical System”,

page 45

Chapter 3, “Electrical System”,

page 46

Review normal operating procedures Chapter 4., Operation, on page 55

Accessory Parts List

The Accessory Parts List is located in Appendix E, “Replacement Parts,” and should

be reviewed when setting up your system.

Installation, Operation, and Maintenance Manual # 509252 Rev R 39

Interconnect Cables

The F300S/F300SQ interconnect cables and connector contact kits are listed in

Appendix B, “Cables and Connectors”. See this list for the available varieties and

lengths.

Connection and Program Log

To facilitate operation and maintenance, it is advisable to keep a record of the

input/output connections and programming used on each unit. A blank log form is

included in Appendix D, “Lamp System Maintenance Log” of this manual.

Installing the External Interlocks Control

An input has been made available for use as an external interlock control. When

activated, this circuit will cause the system to shut down. (See Chapter 5,

“Troubleshooting” for details.)

User Connections

Pin removal and crimping tools are required to complete the optional user input/output

connections to P105A and P106. Make these connections as described next.

J105A

INTERLOCKS

J105B J107

(K1-K5)

J106

BUS INPUT

BUS OUTPUTRELAYS

Figure 9. P300M/P300MQ Power Supply Rear Panel

40 F300S/F300SQ Ultraviolet Lamp System

J101

DISC ONNECT POW ER

BEFORE SERVICI NG

J103

HIGH V OLTAGE CABLE

J104

IRRADIATOR

BLOWER CABLE

1. Disassemble the strain relief housing by removing the retaining screws and

unscrewing the housing from the connector body.

2. To connect EXT INTLK or SYS BLWR inputs, remove jumper wires and the

attached pins as indicated in Table 5, Table 6, and Table 7 in this chapter.

3. With a crimping tool, attach wires from user devices to new pins (supplied with

system) and insert the pins in the proper locations.

4. Reassemble the strain relief housing.

Power Supply Programming

P300M/P300MQ/P300MT power supplies may be interconnected to form a complete

system of up to six lamps. Through use of the System Interconnections Bus control

functions, the entire system may be operated by the lamp control switch of one master

power supply, or by a switch on an external control panel.

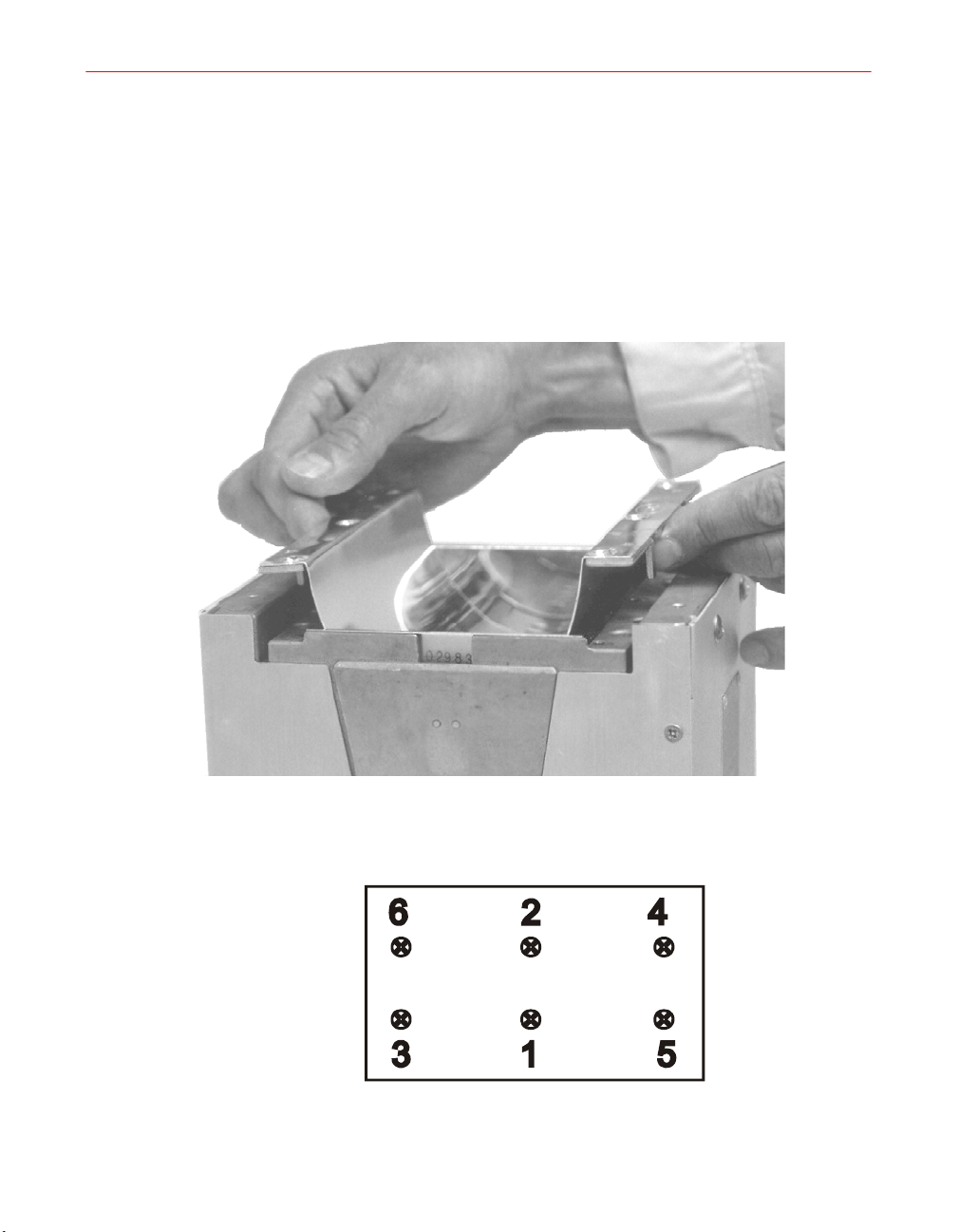

See Figure 10 on page 42 for the location of programming switch S1. To access S1,

remove the six screws on the side of the power supply cover. For programming switch

S1 settings, see the table illustration in Figure 11 on page 43.

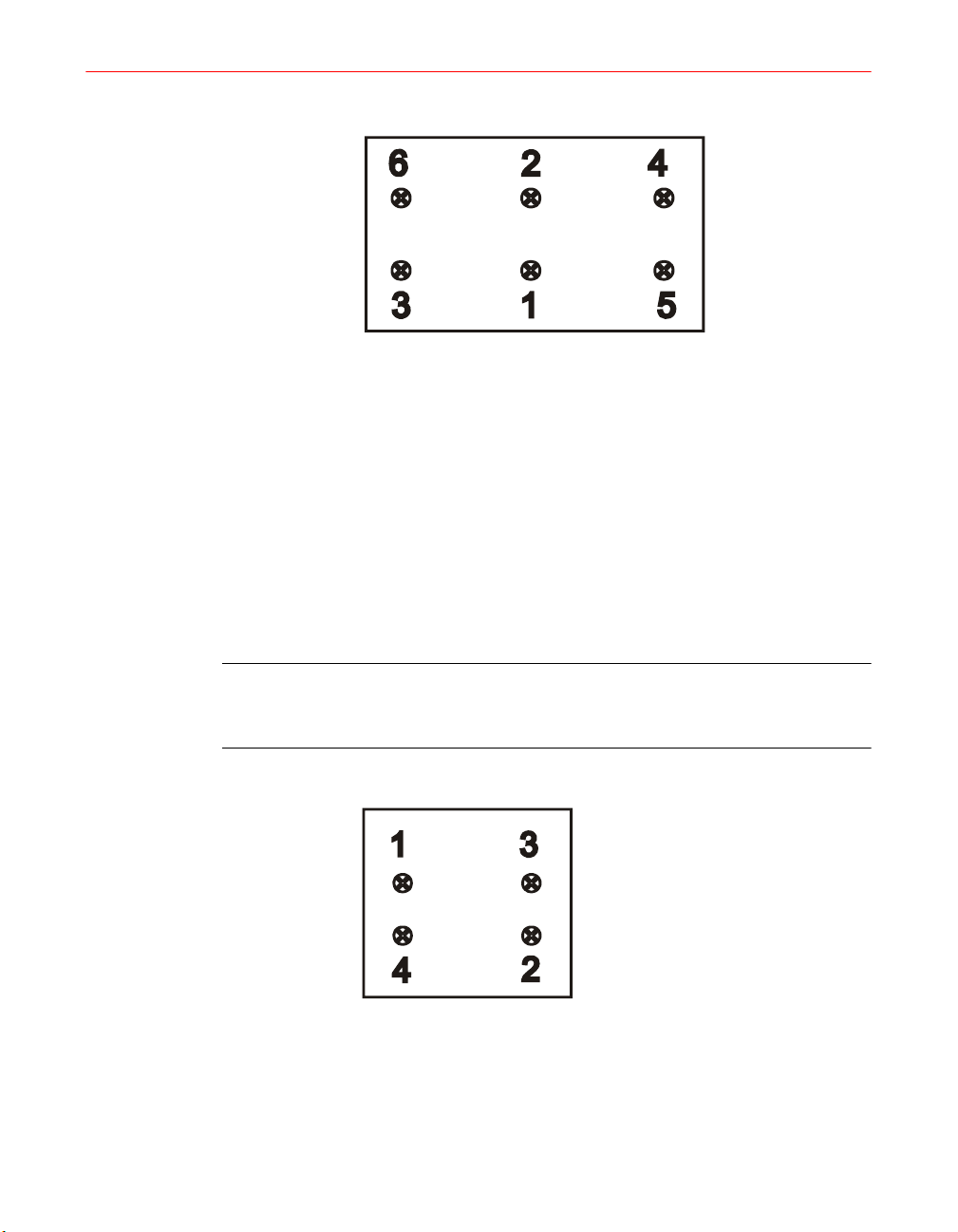

Settings for Six-Position Switch S1

Positions 1, 2, and 3 of S1 (see Figure 10) must be set to determine whether a power

supply is a master or a slave.

Position 4 determines whether a unit fault will turn off all power supplies or only the

unit where the fault occurs.

Position 5 indicates to the system bus whether a power supply (either the master or a

slave) has an RF Detector connected to it. (There must be at least one RF Detector

connected to a system.)

Installation, Operation, and Maintenance Manual # 509252 Rev R 41

TP2

TP1

DS1

JP2

S2

J1

J14

J15

J16

J2

OFF/RST MASTER

ON MASTER

HI / LO MASTER

UNIT TO SYS

RF MASTER

J5

J3

J4

S3

F2

F1

S1

QRO

ASSY P/N 32755X

K1

K2

J11

K3

J6

J7

J8

K4

K5

Figure 10. Location of Programming Switch S1 on PWB

J9

J10

F3q0008

42 F300S/F300SQ Ultraviolet Lamp System

Switch Position

1, 2, and 3

POS6POS5POS4

Figure 11. Table A: Programming Switch S1

Single Unit Programming and Connections

The programming and connections necessary to operate a single-unit F300S/F300SQ

system are summarized in Figure 12.

Installation, Operation, and Maintenance Manual # 509252 Rev R 43

Figure 12. F300/F300SQ Single-unit Installation

Programming

Select one unit as the Master. Set S1-1, 1-2, 1-3, and 1-5 of this unit to “YES.” For

programming switch S1 setting definitions, see Figure 11.

Irradiator Cable H340 Connections

Non-blower version cable H340 connects to J103 and J104 on the power supply; and

to J10 on the irradiator. All connectors are labeled, and keyed so they cannot be

inadvertently interchanged.

Blower version cable H341 connects to J103 and J104 on the power supply, and to J10

and J11 on the irradiator. All connectors are labeled, and keyed so they cannot be

inadvertently interchanged.

44 F300S/F300SQ Ultraviolet Lamp System

Input/Output Connections

The P300M/P300MQ/P300MT has three customer use interlock inputs. A fault

condition on any of these inputs will cause the system to shut down; the fault must be

corrected before the system can be restarted.

There must be one RF detector per system. The remaining interlock inputs are

optional. The system blower and external interlock inputs in the P105A connector

must be jumpered if these inputs are not used.

NOTE: All external switches must have gold contacts or be designed for use

with logic-level signals to ensure reliable operation.

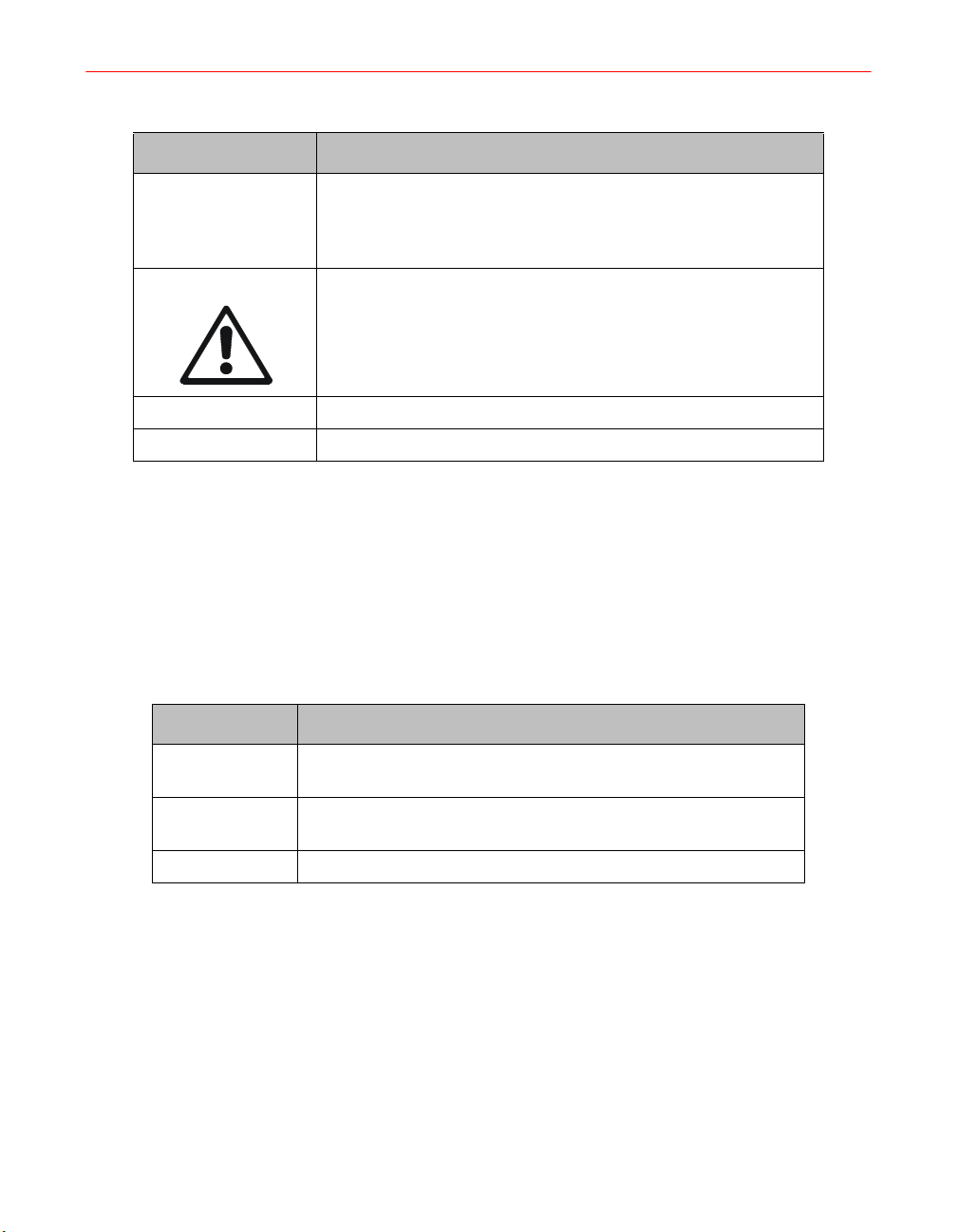

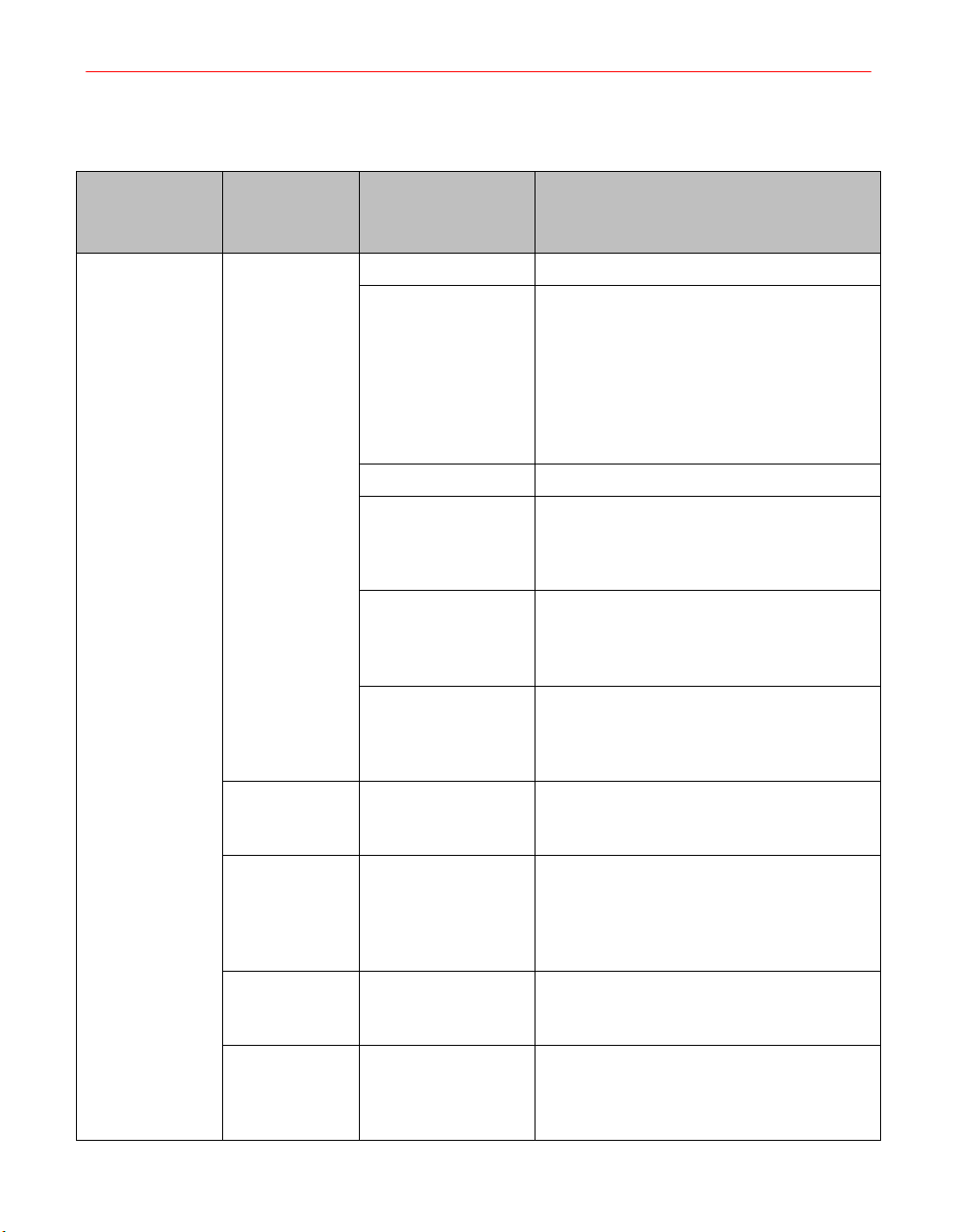

Table 5. J105A Inputs

Interlock Pins

RF Detector

(Master)

RF Detector

(Slave)

SYS Blower 11,12 OPEN

External

Interlock

1,2,3,4 RF trip or

3,4 OPEN

9,10 OPEN

Fault

Condition

no detector

present

CIRCUIT

CIRCUIT

CIRCUIT

Remote Inputs

One switch is required for remote operation of an F300S/F300SQ (to control the

STANDBY/LAMP ON functions). Connections are made through the P106 connector.

Single or Master/Slave systems may be operated remotely.

(Customer Use Interlocks)

Contact

Ratings

12mA @12 VDC Single lamp: One detector per system

Multiple lamps: RF Master must have

RF detector.

12mA @12 VDC Single lamp: N/A

Multiple lamps: Typically jumpered. User

should remove jumper to install

additional RF detectors and set S1-5 to

ON (Yes)

12mA @12 VDC Typically jumpered. User may remove

jumper to install N.O. pressure switch.

Multiple switches should be wired in

series.

12mA @12 VDC Typically jumpered. User may remove

jumper to install N.O. interlock switch.

Multiple switches should be wired in

series.

Application Comments

Installation, Operation, and Maintenance Manual # 509252 Rev R 45

NOTE: A dry contact (such as a relay contact or a PLC containing a relay

contact) with gold contact material should be used to drive the remote inputs.

The cable length to the dry contact should be no more than 6 meters. Shielded

cable should be used to minimize possible electrical interference.

In a multi-lamp system, connections are made to the Master power supply.

If there is a requirement for clearing faults remotely, a Remote Reset switch must

be used.

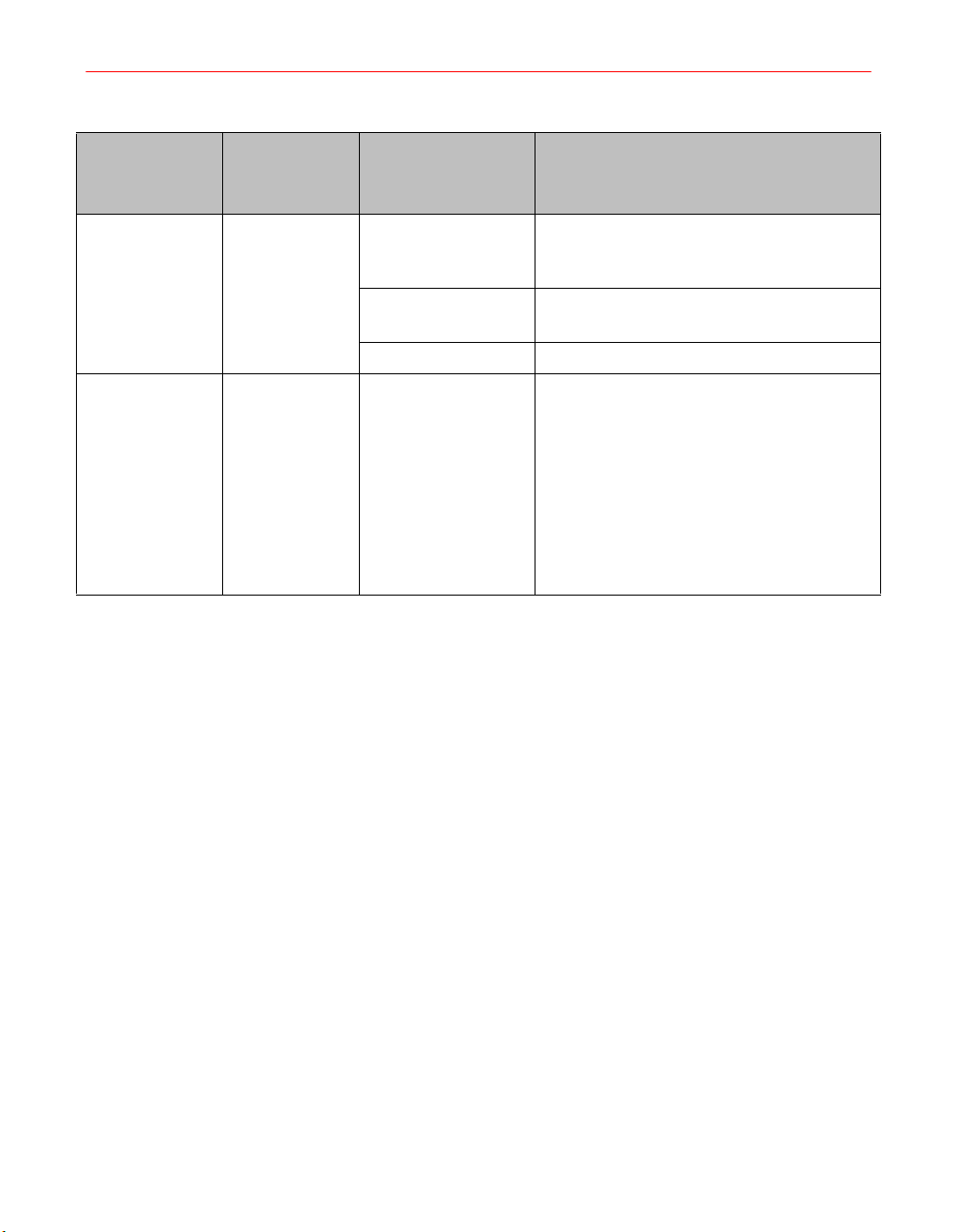

Table 6. J106 Inputs (Remote Operation)

Signal Pins

REMOTE

LAMP ON

REMOTE

RESET

CABLE

SHIELD

Active

Condition

4,5 Closed circuit 12mA @12 VDC Set switch S1-2 of Master

1,2 Closed circuit 12mA @12 VDC Set switch S1-1 of Master

8 N/A N/A Keep cable length to a

Contact

Ratings

Output Ports (J105B)

There are five relay outputs available on the P300M/P300MQ/P300MT through

J105B. These outputs may be used to synchronize customer equipment with the

system. In a multi-lamp system, connections are made to the Master power supply.

Table 7. J105B Outputs (Customer Interface)

J105B

Filament ON (K1) 3, 4 Closed 1 A @120 VAC

HV ON (K2) 5, 6 Closed 1 A @120 VAC

QRO 7, 8 Closed 1 A @120 VAC

Asserted

State

Circuit Ratings Comments

(10mA minimum)

(10mA minimum)

(10mA minimum)

Application Comments

to NO. Leave S1-1 and

S1-5 set to YES.

to NO.

minimum.

K1 contacts close when filament

voltage is applied (STANDBY).

K2 contacts close when high

voltage is applied to lamp.

K3 contacts close when QRO is

active.

46 F300S/F300SQ Ultraviolet Lamp System

Table 7. J105B Outputs (Customer Interface) (continued)

J105B

LAMP ON (K4) 9, 10 Closed 1 A @120 VAC

PRESS ENABLE

(K5)

11, 12 Closed 1 A @120 VAC

Asserted

State

Circuit Ratings Comments

(10mA minimum)

(10mA minimum)

NOTE: When using circuit currents for K1-K5 below 10mA, contact Fusion UV

Systems Customer Service.

Alternate Function for K5

An alternate K5 function may be selected by installing a jumper onto JP2 on the

control card. The STANDBY-READY function is asserted (K5 closed) when the

power supply completes the transition from the STANDBY-WAIT (flashing yellow)

to the STANDBY-READY state (steady yellow). K5 remains closed for the LAMP

ON state (flashing or steady green), the QRO state (alternate flashing of yellow and

green), and the return to the STANDBY-READY state (steady yellow). K5 opens

during the OFF/RESET state and the STANDBY-WAIT state (flashing yellow) from

either the LAMP ON state or from the OFF/RESET state.

K4 contacts close when photocell

is satisfied. Note: If using K4 for

press control, wait 6-8 seconds

for lamp output to stabilize.

K5 contacts remain closed when

no unit or system error exists.

STANDBY

READY

(K5 alt.)

Table 8. Alternate Function for K5

J105B Asserted State Circuit Ratings Comments

11, 12 Closed 1 A @120 VAC

(10mA minimum)

Installation, Operation, and Maintenance Manual # 509252 Rev R 47

K5 contacts close once

STANDBY-READY state is

achieved, and for any higher

state.

Multiple-Unit Programming and Connections

Programming and connections for multiple-unit systems are summarized in Figure 13.

Typically, one unit will operate as the MASTER and all others as slaves to the

ON/OFF commands of this Master unit. Refer to detailed descriptions in Chapter 4,

“Operation” of this manual.

RF DETECTOR

EXT. INTERLOCK (JUMPERED)

SYSTEM BLOWER (JUMPERED)

Figure 13. F300S/F300SQ Multiple Unit Programming & Connections

48 F300S/F300SQ Ultraviolet Lamp System

RF DETECTOR (JUMPERED)

EXT. INTERLOCK (JUMPERED)

SYSTEM BLOWER (JUMPERED)

RF DETECTOR (JUMPERED)

EXT. INTERLOCK (JUMPERED)

SYSTEM BLOWER (JUMPERED)

F3q0011

Programming

Refer to Figure 11 for programming switch S1 settings and set programming switches

of each power supply as follows:

1. Select one unit as the Master. Set S1-1, 1-2, 1-3 and 1-5 of this unit to YES.

2. Set S1-1, 1-2, 1-3, and 1-5 of all slaves to NO.

3. To shut down all units in case of a single-unit fault, set S1-4 on all units to YES

Connections

The following procedure describes how to connect multiple power supplies

(master/slave) within a system.

1. For proper operation, including fault detection, connect each power supply to the

2. Install input/output plugs P105A (with jumpers - provided with system) in

3. The Master power supply must have an RF Detector connected to J105A;

(For a detailed explanation of unit faults, see Chapter 4, “Operation.”)

next using the H760 interconnect cables supplied with the system. Cables run

from J107 of one unit to J106 of the next.

J105A of slave units.

additional RF detectors may be plugged into J105A of the Slave power supplies

by replacing the jumpered plug with the RF detector cable connector.

4. Make interlock connections to the Master using the P105A plug on RF detector

cable harness as indicated in “Input/Output Connections” on page 45 in this

chapter.

NOTES: When installing additional RF detectors on slave power supplies, be

sure to set S1-5 to YES on those power supplies.

If additional RF detectors are used, an RF fault in a slave will automatically be

interpreted as a system fault; this will shut down the entire system.

Additional interlocks such as RF, Remote Blower, and External Interlock may

be connected to a SLAVE unit through P105A. Remove any factory-installed

jumpers.

Installation, Operation, and Maintenance Manual # 509252 Rev R 49

Power Source

NOTE: If a line voltage greater than 230V and a frequency of 50 Hz is used, see

the “F300S Relay Coil Resistor Assembly Installation” on page 53 at the end of

this chapter.

System Power Connections

CAUTION: Measure the main single-phase voltage

of your plant facilities to ensure that it conforms to

the factory-wired operating voltage specified on the

equipment label (rear panel of power supply).

Available line voltage should be within 10% of the

nominal operating voltage.

Fusion UV equipment must be connected in

accordance with local wiring codes. Use applicable

standards for wire sizes, fuse sizes, and disconnect

box locations. Each power supply requires a

separate, fused single-phase circuit with a line

disconnect.

Figure 14. Power Supply Front Panel

Listed current ratings indicate current demands during normal full-power operation.

Your customer-supplied wiring and circuit breaker or fuses should be sized to allow

for heavier current draw at startup. Current ratings are the same for 50 Hz or 60 Hz

systems. The recommended power cord to wire to P101 is:

50 F300S/F300SQ Ultraviolet Lamp System

F3q0004

North American Applications: 3x12 AWG UL listed

International Applications: 3x2.5 mm

Both cable types should have minimum ratings of 16A, 300V, 0-60 °C.

Refer to Table 11 on page 57 in Chapter 4, “Operation,” for the leg currents for each

power supply/voltage combination.

Frequency Tapping of HV Capacitors

If it becomes necessary to configure the system for a line frequency other than that

delivered, the following steps should be followed:

1. Turn the unit POWER switch OFF and unplug the power cord.

2. Remove the power supply cover (six screws).

3. Locate the HV capacitors C101 and C102 (refer to Figure 15 on page 54).

4. Discharge the capacitor by shorting the capacitor terminals with an insulated

screwdriver.

5. Locate the jumper connected to the T terminal of each capacitor.

6. Disconnect the opposite end of this jumper from the capacitor terminal to which

it is connected, and reconnect it to the appropriate terminal for the desired line

frequency (50 for 50 Hz, 60 for 60 Hz).

2

Harmonized, VDE

QRO HV Capacitors (For QRO only)

When the Quick Restart Option is installed, one element of the retrofit is the

replacement of the HV capacitors. These HV capacitors are a different value than the

standard HV capacitors, but the frequency tapping procedure is exactly the same.

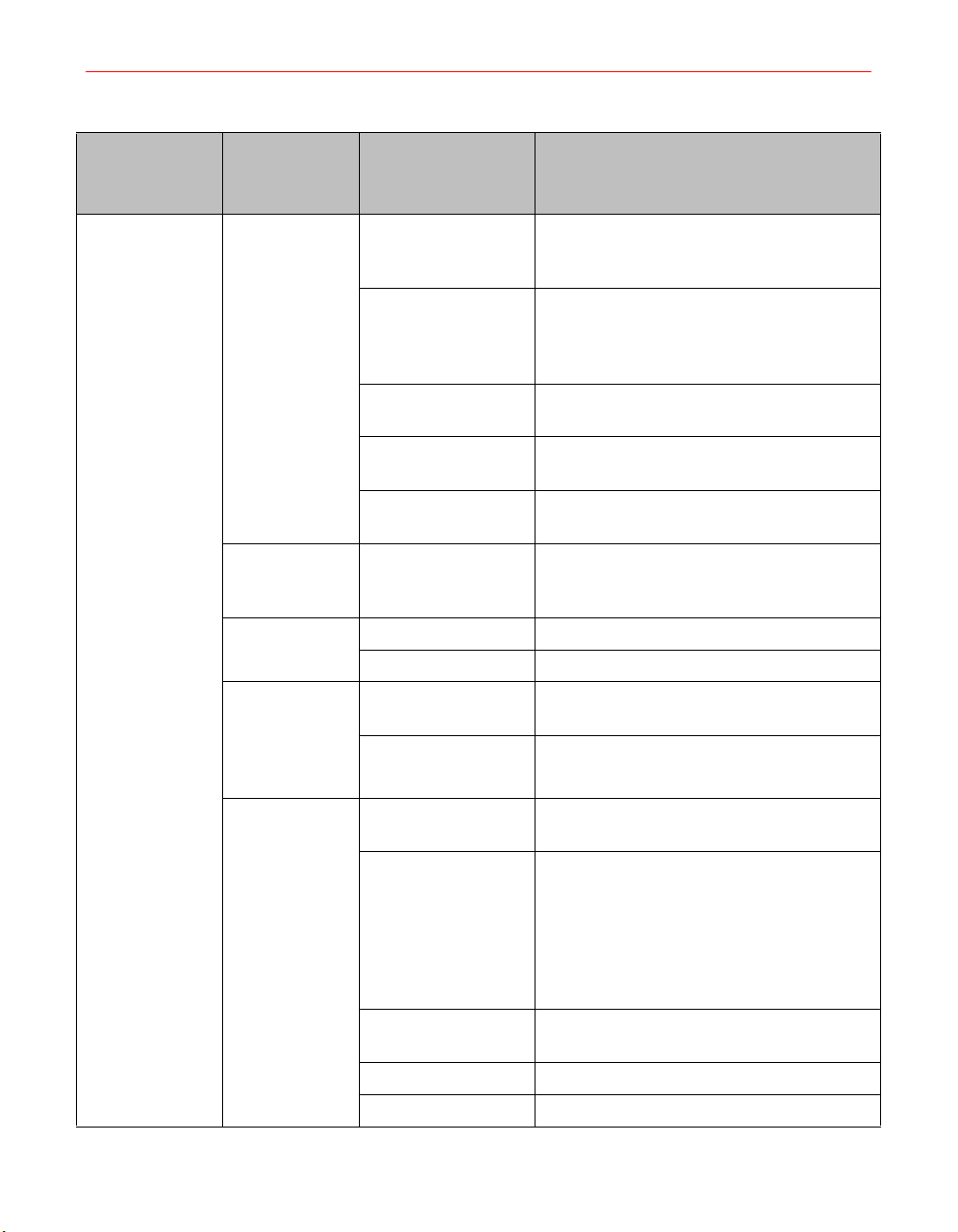

High Voltage Transformer Taps

Standard high voltage transformers have labeled taps. Power supplies are shipped with

transformers tapped according to customer power specifications. If a unit is relocated

or a transformer must be replaced, connections should be installed as shown in the

following table.

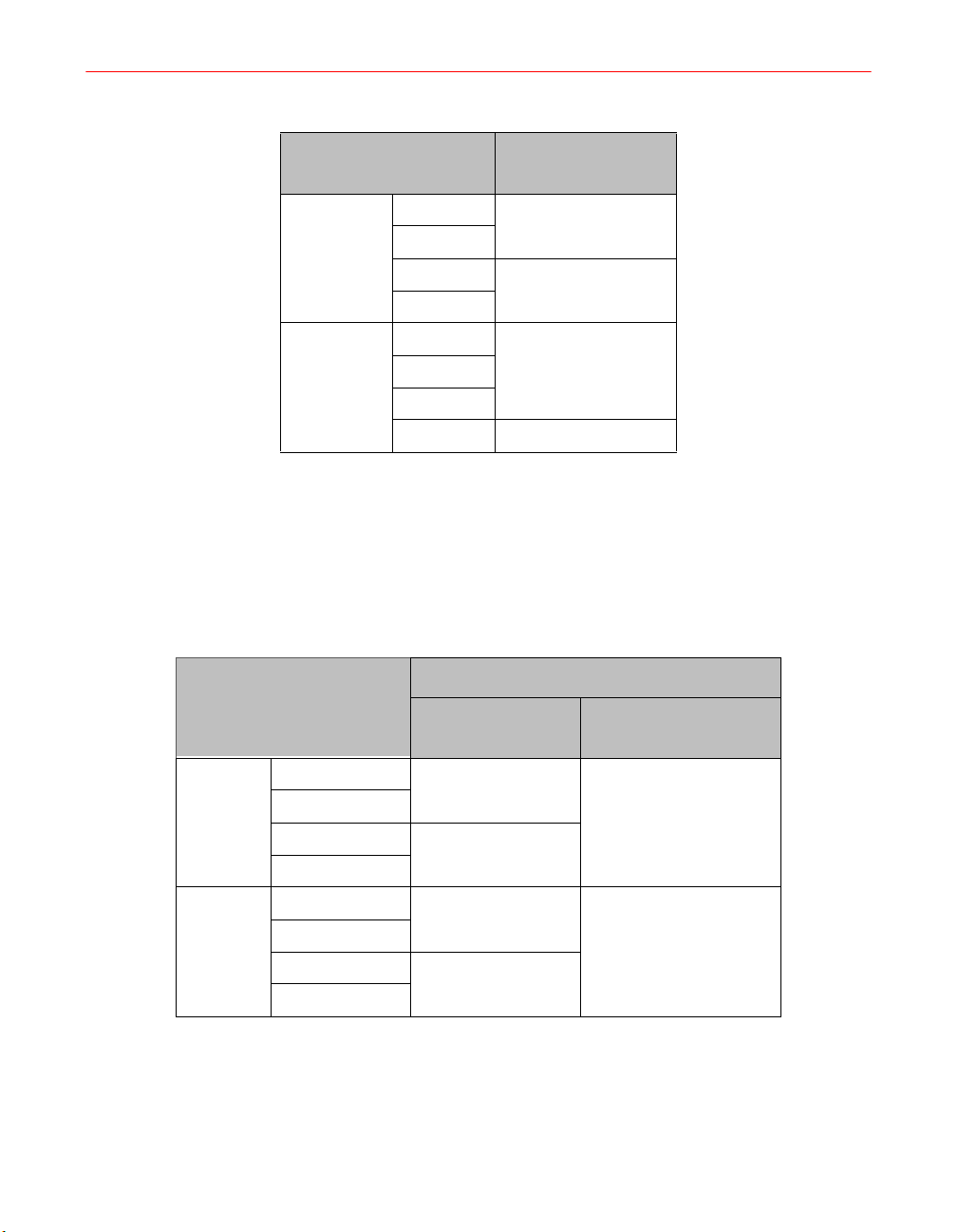

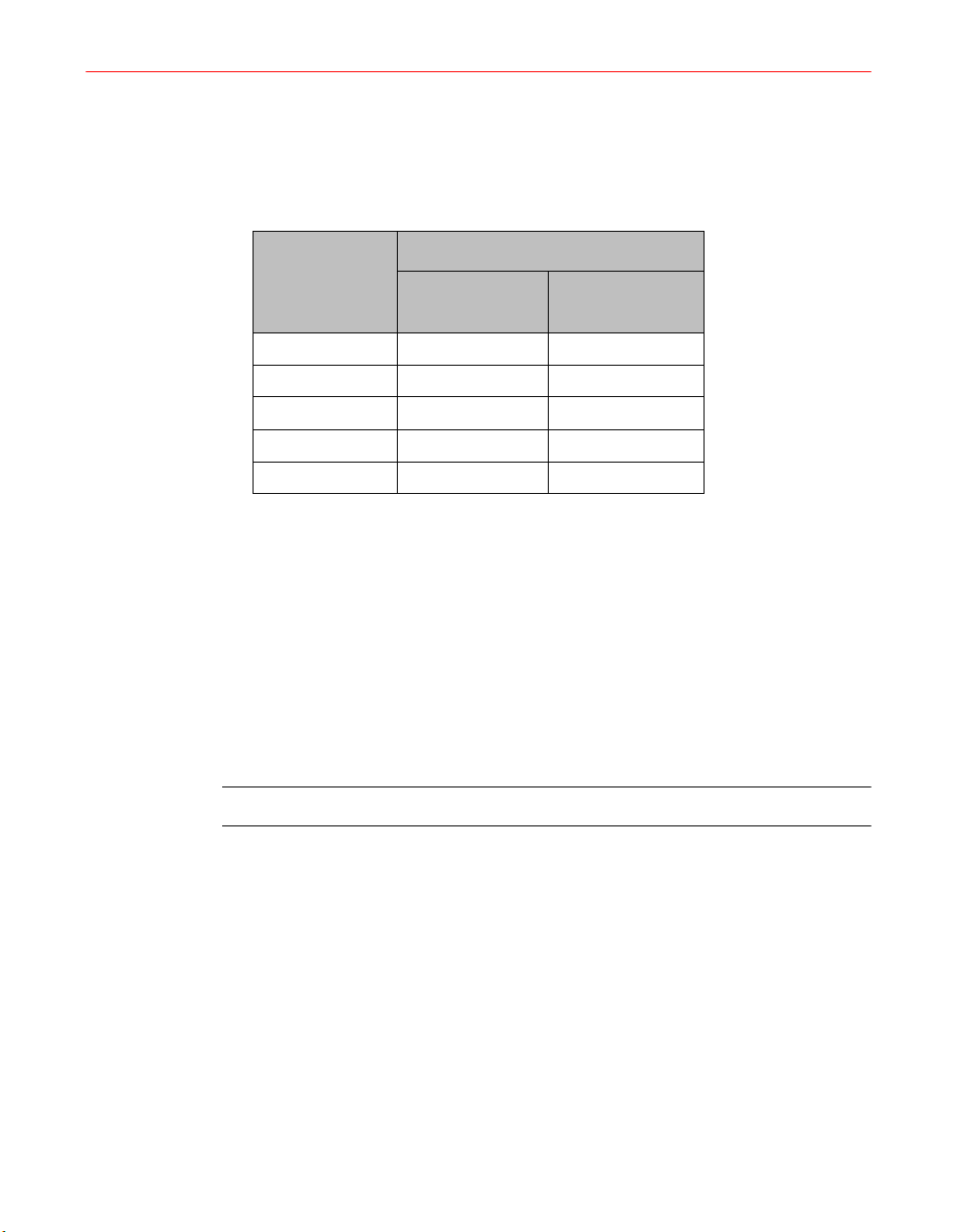

Table 9. High Voltage Transformer Taps

Power

Installation, Operation, and Maintenance Manual # 509252 Rev R 51

HV Plate

Transformer

Primary Tap

Table 9. High Voltage Transformer Taps (continued)

50 Hz

60 Hz

Power

200

208

220

240

200

208

220

240 220, 240

Transformer

200

220, 240

200

QRO Transformer Taps (FOR QRO only)

When the Quick Restart Option is installed, the QRO transformers must be tapped

according to the frequency and voltage specifications of the customer. Should these

specifications change, or if a transformer is replaced, the transformer should be tapped

as follows:

Table 10. QRO Transformer Taps (Optional)

QRO Transformer

Power

Primary Front Tap

HV Plate

Primary and

Secondary Rear Taps

200

50 Hz

60 Hz

52 F300S/F300SQ Ultraviolet Lamp System

208

220

240

200

208

220

240

200V

50 Hz

240V

200V

60 Hz

240V

F300S Relay Coil Resistor Assembly Installation

The relay coil resistor assembly must be used if the line voltage and frequency used

with a P300M/P300MQ/P300MT power supply is 230-240 VAC at 50 Hz (nominal

voltage). These resistor assemblies prevent the premature failure of the relay coils in

high line voltage environments. There are two coil resistor assemblies available in a

retrofit kit (See Appendix E, “Replacement Parts”). One assembly is placed in series

with each of the coils of K101 and K102 in the power supply. These resistors should

also be used when it becomes necessary to configure the system for a line voltage and

frequency of greater than 230 VAC at 50 Hz (nominal voltage.)

Installation Instructions

1. Turn off the power and disconnect power from the power supply.

2. Remove the six cover screws and cover from the P300M/P300MQ power

supply. (Remove the four cover screws and cover from the P300MT power

supply.)

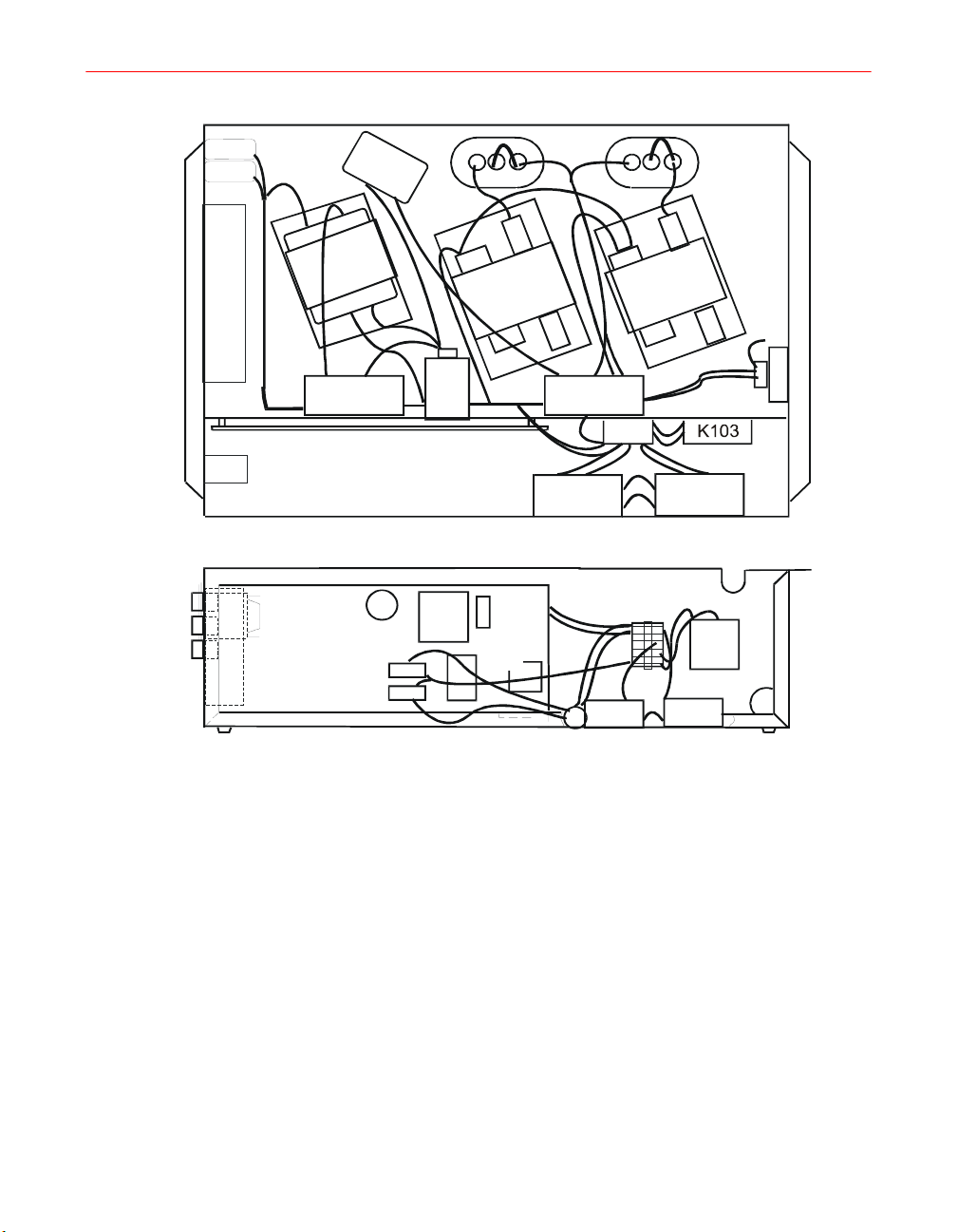

3. Locate relays K101 and K102. K101 is closer to the rear of the power supply