Page 1

SATELLITE COMPASS

SC-120

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

x

A

A

*00080919206**00080919206*

*00080919206**00080919206*

*OME72490P10**OME72490P10*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

faxfa

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. OME-72490OME-72490

0798-65-42000798-65-4200

::

Printed in JapanPrinted in Japan

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION : MAR.MAR. 20012001

P1P1 :: FEB.FEB. 26,200426,2004

(( KAMIKAMI ))

SC-120SC-120

* 0 0 0 8 0 9 1 9 2 0 6 ** 0 0 0 8 0 9 1 9 2 0 6 *

*OME72490P10**OME72490P10*

* O M E 7 2 4 9 0 P 1 0 ** O M E 7 2 4 9 0 P 1 0 *

Page 3

SAFETY INSTRUCTIONS

Safety Instructions for the Operator Safety Instructions for the Installer

WARNING

Do not open the equipment.

Only qualified personnel should work inside

the equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

Immediately turn off the power at the

switchboard if the equipment is emitting

smoke or fire.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Do not place liquid-filled containers on

the top of the processor unit.

WARNING

Do not open the cover unless totally

familiar with electrical circuits and

service manual.

Improper handling can result in electrical

shock.

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it

may get wet from rain or water splash.

Water in the equipment can cause fire,

electrical shock or damage to the equipment.

Fire or electrical shock may result if the

liquid enters the equipment.

CAUTION

No one navigation device should ever

be solely replied upon for the navigation

of a vessel.

Always confirm position against all available aids to navigation, for safety of vessel

and crew.

Use the proper fuse.

Use of a wrong fuse can result in damage

to the equipment.

NOTICE

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

Standard

Compass

Display unit

SC-602

Processor unit

SC-1201/1201D

Antenna unit

SC-1203F

DGPS beacon

antenna GR-8

0.5 m 0.3 m

1.3 m

0.3 m 0.3 m

0.3 m 0.3 m

Steering

Compass

0.8 m

i

Page 4

TABLE OF CONTENTS

FOREWORD ..................................................................................................................iv

SYSTEM CONFIGURATION...........................................................................................v

EQUIPMENT LIST..........................................................................................................vi

SOFTWARE VERSION LIST.........................................................................................vii

SPECIFICATIONS.....................................................................................................SP-1

1 PRINCIPLE OF OPERATION................................................................................. 1-1

2 INSTALLATION...................................................................................................... 2-1

2.1 Mounting Considerations..................................................................................................... 2-1

2.1.1 SC-series antenna unit .............................................................................................2-1

2.1.2 Display unit, processor unit....................................................................................... 2-3

2.2 Installing the Antenna Units................................................................................................. 2-4

2.2.1 SC-series antenna unit .............................................................................................2-4

2.2.2 DGPS antenna unit................................................................................................... 2-7

2.3 Installing the Proc essor Unit................................................................................................ 2-9

2.3.1 Deck mount............................................................................................................... 2-9

2.3.2 Bulkhead mount...................................................................................................... 2-10

2.3.3 Installation on the underside of a desk................................................................... 2-12

2.3.4 Adjusting for orientation error................................................................................. 2-14

2.4 Installing the Display Unit.................................................................................................. 2-14

2.4.1 Desktop, overhead mounting.................................................................................. 2-14

2.4.2 Flush mounting....................................................................................................... 2-15

2.5 Wiring.................................................................................................................................2-16

2.6 Initial Settings .................................................................................................................... 2-19

2.6.1 Confirming satellite s tatus; cho osing mounting method......................................... 2-19

2.6.2 Choosing heading source....................................................................................... 2-20

2.6.3 Heading data format............................................................................................... 2-21

2.7 Connection of External Equipment.................................................................................... 2-22

2.8 Installing the DGPS Beacon Receiver Kit......................................................................... 2-22

3 OPERATION........................................................................................................... 3-1

3.1 Controls................................................................................................................................ 3-1

3.2 Tu rning the Power On/Off.................................................................................................... 3-2

3.3 Panel Illumination, Display Contrast.................................................................................... 3-2

3.4 Choosing a Display..............................................................................................................3-3

3.4.1 Description of displays.............................................................................................. 3-3

3.5 Alarms..................................................................................................................................3-5

3.6 Confirming Satellite Status.................................................................................................. 3-6

3.7 GPS Setup........................................................................................................................... 3-7

3.7.1 Displaying the GPS setup menu............................................................................... 3-7

3.7.2 GPS SETUP menu description................................................................................. 3-7

ii

Page 5

3.8 Output Data..........................................................................................................................3-8

3.8.1 Heading .....................................................................................................................3-8

3.8.2 Navigation data .........................................................................................................3-9

3.8.3 Interface ....................................................................................................................3-9

3.8.4 Log pulse.................................................................................................................3-10

3.8.5 Talker identifier mnemonics ....................................................................................3-10

3.9 System Setup..................................................................................................................... 3-11

3.9.1 Geodetic data.......................................................................................................... 3-11

3.9.2 Units of measurement .............................................................................................3-12

3.9.3 Using local time.......................................................................................................3-12

3.9.4 Time format .............................................................................................................3-12

3.9.5 Demonstration mode............................................................................................... 3-13

3.10 DGPS Setup.......................................................................................................................3-13

3.10.1 Manual DGPS setup ...............................................................................................3-13

3.10.2 Programming user beacon stations ........................................................................ 3-15

3.10.3 Editing user beacon stations...................................................................................3-16

3.10.4 Erasing individual user stations ..............................................................................3-17

3.10.5 Erasing all user beacon stations .............................................................................3-17

3.11 OTHERS Menu .................................................................................................................. 3-18

3.12 TRIP Menu .........................................................................................................................3-19

3.13 Resetting Distance Run .....................................................................................................3-19

4 MAINTENANCE, TROUBLESHOOTING............................................................... 4-1

4.1 Preventive Maintenance ......................................................................................................4-1

4.2 Troubleshooting ...................................................................................................................4-2

4.3 Diagnostics...........................................................................................................................4-2

4.4 Program Number .................................................................................................................4-5

4.5 Clearing Data .......................................................................................................................4-5

4.6 Replacement of Battery .......................................................................................................4-6

4.7 Replacement of Fuse...........................................................................................................4-7

4.8 Error Messages....................................................................................................................4-7

APPENDIX ..................................................................................................................A-1

Menu Tree.....................................................................................................................................A-1

Geodetic Chart Codes ..................................................................................................................A-2

Digital Interface .............................................................................................................................A-3

Input/Output Ports...................................................................................................................... A-10

Parts Location .............................................................................................................................A-11

Parts List .................................................................................................................................... A-12

PACKING LISTS .........................................................................................................A-1

OUTLINE DRAWINGS ................................................................................................D-1

INTERCONNECTION DIAGRAMS..............................................................................S-1

INDEX...................................................................................................................Index-1

Declaration of Conformity

iii

Page 6

FOREWORD

A Word to the Owner of the SC-120

FURUNO Electric Company thanks you for purchasing the FURUNO SC-120

Satellite Compass. We are confident you will discover why the FURUNO name

has become synonymous with quality and reliability.

For over 50 years FURUNO Electric Company has enjoyed an enviable

reputation for quality and reliability throughout the world. This dedication to

excellence is furthered by our extensive global network of agents and dealers.

Your satellite compass is designed and constructed to meet the rigorous

demands of the marine environment. However, no machine can perform its

intended function unless properly installed and maintained. Please carefully read

and follow the operation and maintenance procedures set forth in this manual.

We would appreciate feedback from you, the end-user, about whether we are

achieving our purposes.

Thank you for considering and purchasing FURUNO.

Features

The SC-120 is a new satellite compass designed with FURUNO’s advanced

GPS kinematic technology. This compass finds a wide range of applications for

any type of ships and mobile units at sea or on land.

The main features are

•

Perfect for use as heading sensor for Radar/ARPA, AIS, ECDIS, scanning

sonar, and video plotter

•

There are no mechanical parts such as gimbals or rotating motor, thus the

compass is free from routine maintenance

•

The performance is not affected by geomagnetism thus it is suitable for use on

any vessel

•

No need for speed correction like a gyrocompass

•

Short settling time - four minutes

•

Provides all necessary functions as a GPS navigator.

iv

Page 7

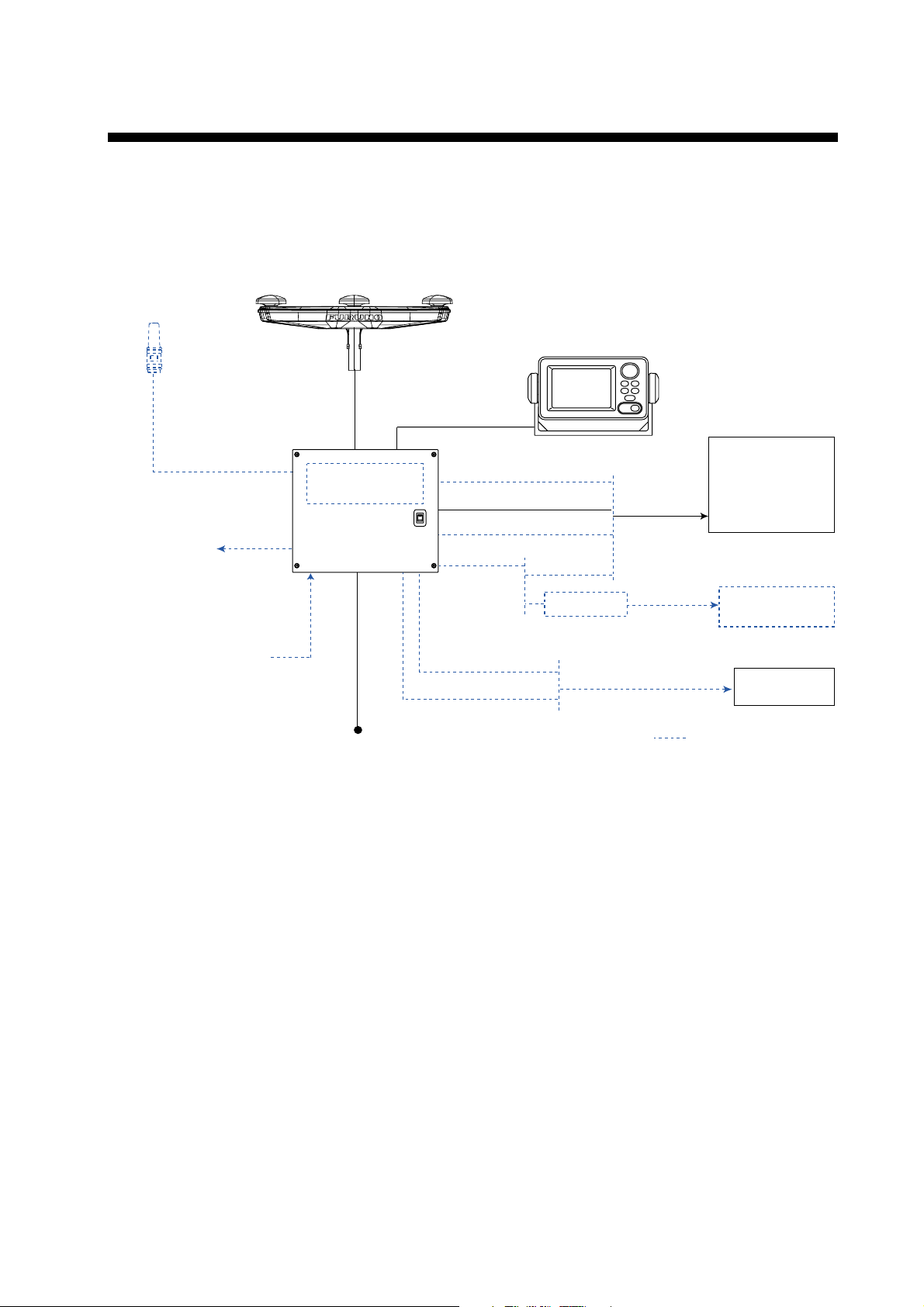

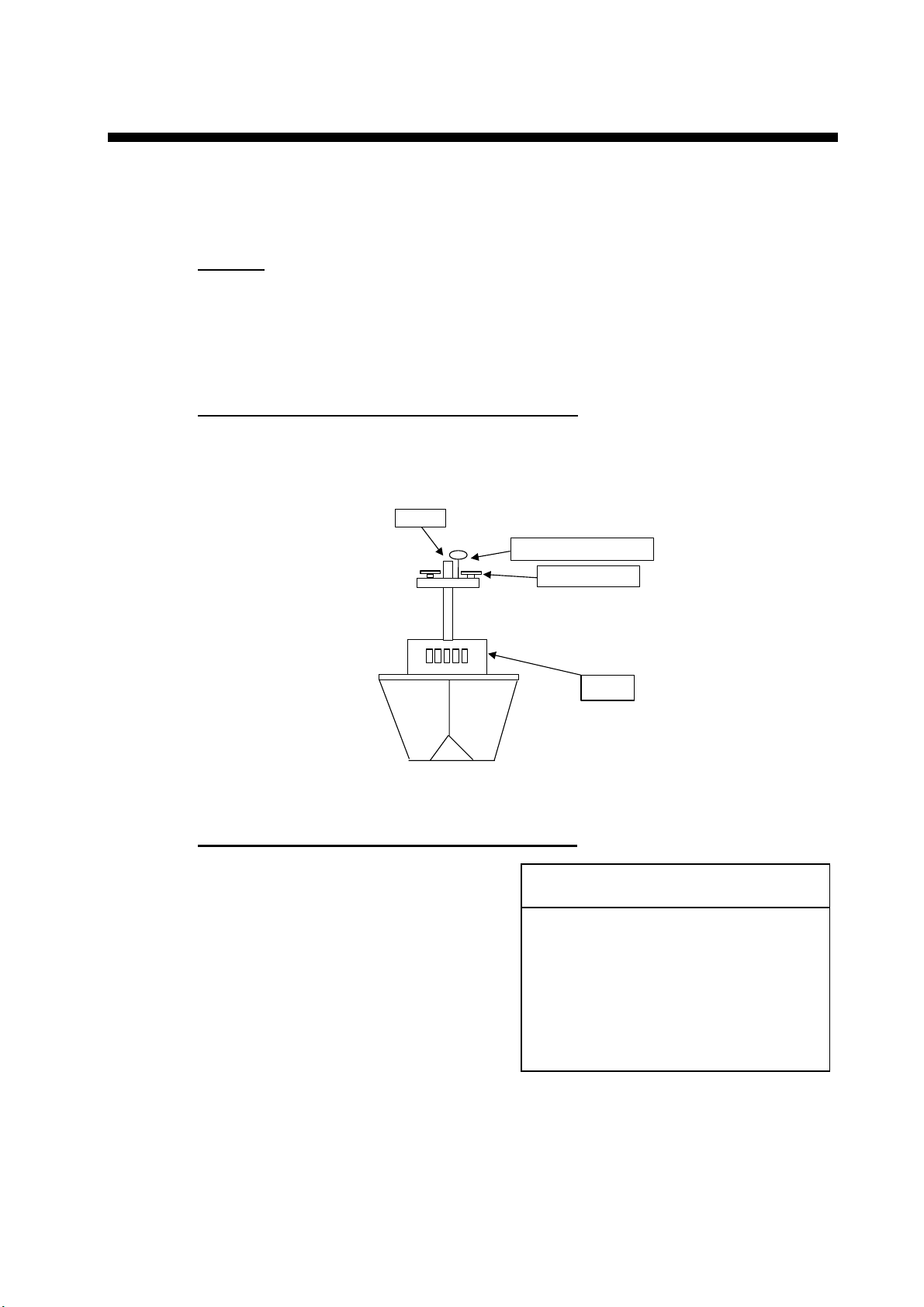

SYSTEM CONFIGURATION

The SC-120 consists of three SC-series antennas, a display unit and a

processor unit. The tri-antenna system helps reduce the influence of ship's

motion (rolling).

Antenna Unit

DGPS

Beacon Antenna

GR-800-1-S

Speed alarm/

Heading alarm

(Contact)

Gyro heading may be

supplied through AD-100

Gyro Converter

(For primary gyrocompass

and backup SC-120) or

Doppler Speed Log

Beacon Receiver Kit

Processor Unit

SC-1201/SC-1201D

SC-1203

Display Unit

SC-602

GR-7001

Heading Data

Repeater I/F

2 ports

12-24 VDC

System configuration

Analog data

GPS fix

COG, SOG

Time/Date

Pitch/Roll

Radar

Autopilot

VideoPlotter

Current Indicator

Scanning Sonar

ECDIS

Repeater Compass

Autopilot

Radar,

Plotter, etc.

Option

v

Page 8

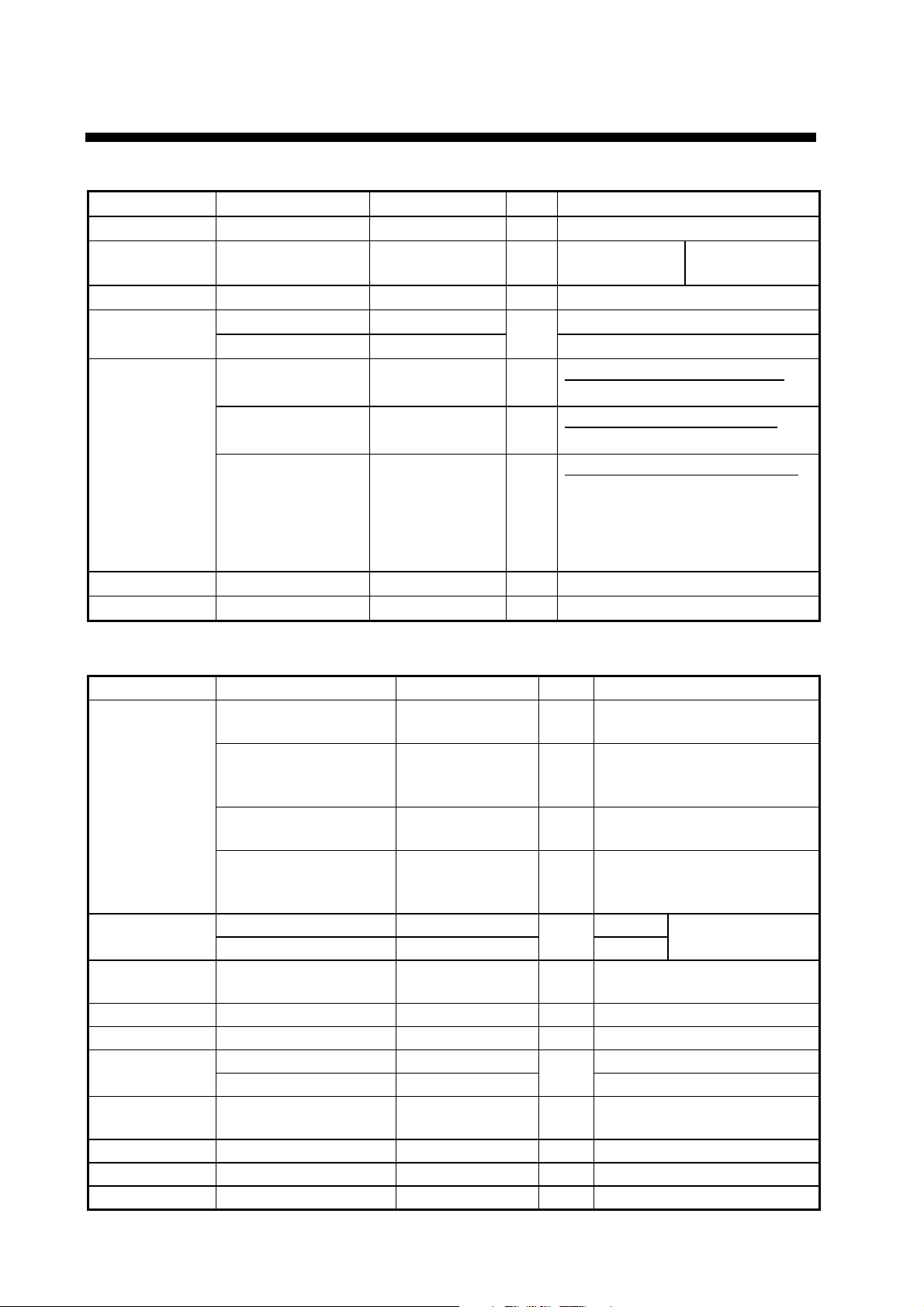

EQUIPMENT LIST

Standard supply

Name Type Code No. Qty Remarks

Antenna Unit SC-1203F — 1

DGPS

Antenna

Display Unit SC-602 — 1

Processor Unit

Installation

Materials

Accessories FP14-02801 — 1 Cover

Spare Parts SP20-00901 004-377-600 1 Accessories for Processor Unit

GR-800-SC-1-S — 1

SC-1201 —

SC-1201-D — 1 With beacon receiver

CP20-02210 000-041-743 1

CP20-02203 — 1

CP20-02220 000-041-748 1

No whip

antenna

Accessories for Antenna Unit

CP20-02241

Accessories for Display Unit

Tapping screw, 5X20, 4 pcs.

Accessories for Processor Unit

MJ-A3SPF0013-035

MJ-A6SPF0007-100

MJ-A7SPF0006-100

CP20-02221

For

SC-1201-D

Optional equipment

Name Type Code No. Qty Remarks

MJ-A6SPF0003-050 000-117-603 1

MJ-A6SPF0007-100 000-125-237 1

Cable Assy.

MJ-A6SPF0012-100 000-133-817 1

MJ-A7SPF0003-050 000-136-730-01 1

Antenna

Cable Set

DGPS Beacon

Receiver Kit

Flush Mount F OP20-29 000-041-405 1 For display unit

Flush Mount S OP20-17 000-040-720 1 For display unit

Extension

Cable

Antenna

Cable Set

Whip Antenna FAW-1.2 000-130-046 1 1.2 m

Whip Antenna 04S4176 000-112-845 1 2.6 m

Flange OP20-31 004-378-230 1

CP20-01700 004-372-110 30 m

CP20-01710 004-372-120 1 50 m

GR-7001-K 000-041-738 1

OP08-15-30 004-396-440 For DGPS, 30 m

OP08-15-60 004-396-450 1 For DGPS, 60 m

OP08-17 004-392-510 1 For DGPS antenna

For AD-10 output,

connector at one end, 5 m

For AD-10 output,

connector at both ends,

10 m

Cross for NMEA output,

10 m

For beacon/log/alarm

signal output, connector at

one end, 5 m

3 pcs, for

SC-1203

vi

Page 9

SOFTWARE VERSION LIST

DISPLAY UNIT: 205-1312-009

PROCESSOR UNIT: 205-1311-016

GPS1: 205-1313-004

GPS2: 205-1313-004

GPS3: 205-1313-004

DGPS: 085-0182-002

vii

Page 10

This page is intentionally left blank .

Page 11

SPECIFICATIONS OF SATELLITE COMPASS

SC-120

1 GENERAL

1.1 Receiver Type 12 discrete channels GPS

1.2 RX Frequency 1575.42 MHz (L1)

1.3 Class of Service Standard Positioning service (SPS) using the C/A code on the L1

frequency

1.4 Processing All-in-view, 8-state Kalman filter

1.5 Position Accuracy 10 m (GPS), or 5 m (DGPS), 95% of the time

1.6 Heading Accuracy ±0.6° (95% static accuracy)

1.7 Follow-up 25°/s rate-of-turn

1.8 Settling Time 4 minutes

2 DISPLAY

2.1 Display Type 4.5 inch monochrome LCD, 120 x 64 dots

2.2 Effective Area 95 mm (W) x 60 mm (H)

2.3 Contrast 64 steps

2.4 Display Mode Heading, Nav data, Steering, Compass rose, Rate of turn and Speed

modes

3 INTERFACE

3.1 Heading Output 3 ports: AD-10 or IEC 61162-1 Ed.2

1 port: NMEA 0183 (Ver1.5/2.0)

IEC 61162 Sentences: HDT, HDM, VTG, ZDA, GGA, ROT

3.2 COG, SOG, L/L Output 1 port: IEC 61162-1 Ed.2

1 port: RS-232C level

IEC 61162 Sentences: VTG, GGA, ZDA, GLL, ROT,

PFEC, Gpatt (FURUNO P-sentences)

ATT (Proprietary): incl. pitch, roll and yaw data

$PFEC,GPatt,xxx.x,+xx.x,+xx.x<CR><LF> (Ver. 1.5)

$PFEC,GPatt,xxx.x,+xx.x,+xx.x*hh<CR><LF> (Ver. 2.0)

3.3 Log Output 1 port: 200/400 pulse/nm (closure signal)

3.4 Alarm Output 1 port: Alarm signal (closure signal)

3.5 Heading Input 1 port: Backup Heading (AD-10/IEC 61162 format) from external

heading device

Sentences: HDT, HDG, HDM

(VBW, VHW, VLW for tide direction and speed)

3.6 Beacon Data Input 1 port: RTCM SC-104 format for RS-232C

SP - 1 E7249S01H

Page 12

Sentences: MSK, GGA

5 POWER SUPPLY

12-24 VDC: 1.1-0.5 A

6 ENVIRONMENTAL CONDITION AND EMC

6.1 Ambient Temperature

Display/Processor Unit -15°C to +55°C, Designed for protected area

Antenna Unit -25°C to +70°C, Designed for exposed area

6.2 Damp heat 93%±3% at 40°C

6.3 Waterproofing

Antenna Unit IPX6

Display Unit IPX5

Processor Unit IPX0

6.4 Vibration IEC 60945

6.5 EMC IEC 60945

7 COATING COLOR

7.1 Display/Processor Unit Panel: N3.0 Newtone No.5 (dark gray)

Cover: 2.5GY5/1.5 (light gray)

7.2 Antenna Unit N9.5 (white)

8 STANDARDS APPLICABLE

IMO MSC.116(73) THD standards

ISO 22090-3 Under development

IMO A. 694(17) General requirements

IEC 60945 version 4 General requirements (EMC tested to 2 GHz)

IMO A.819 (19) Performance standard for shipborne GPS

IEC 61108-1 Performance standard for shipborne GPS

ITU-R M.1371 for AIS Rate of turn

SP - 2 E7249S01H

Page 13

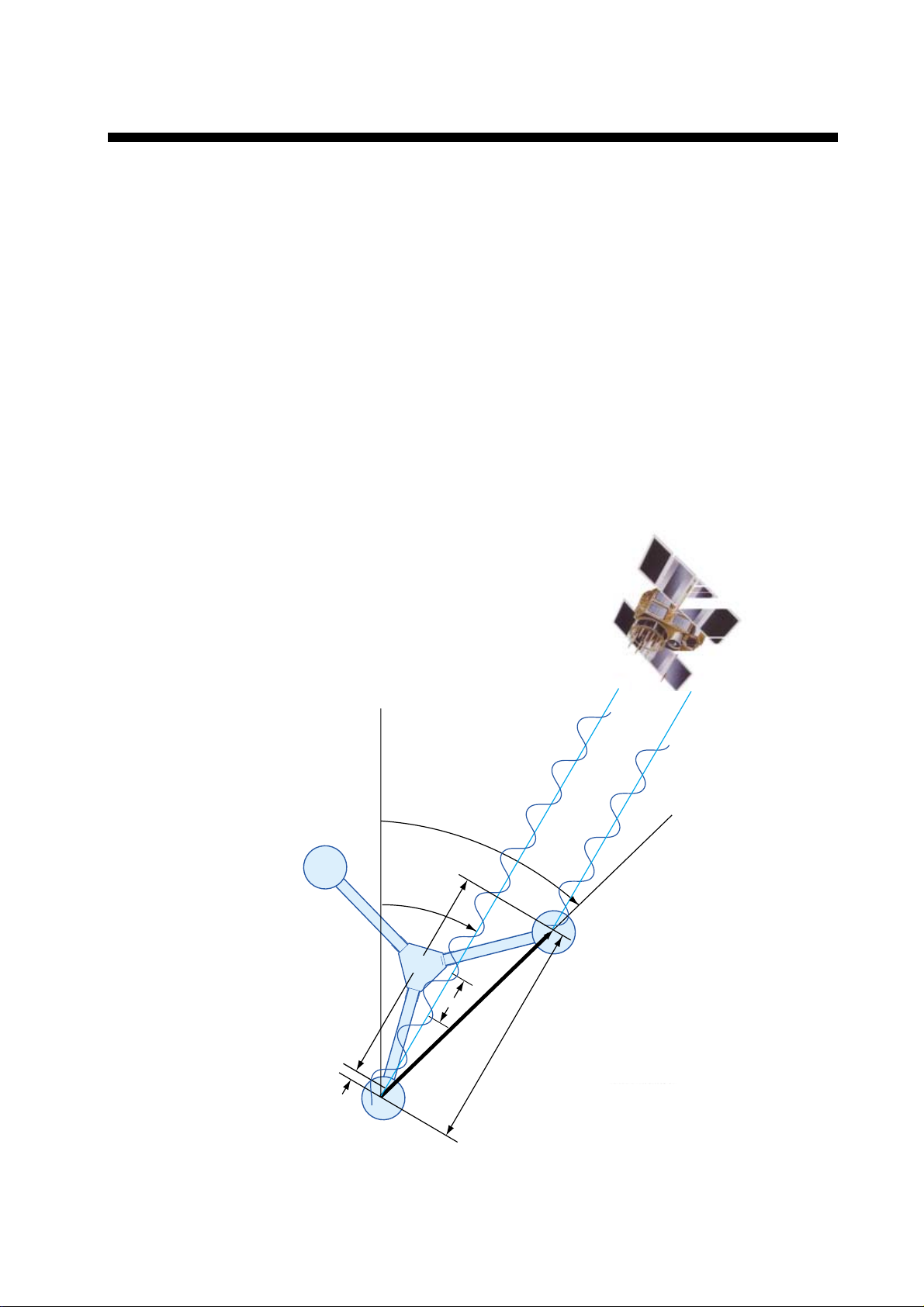

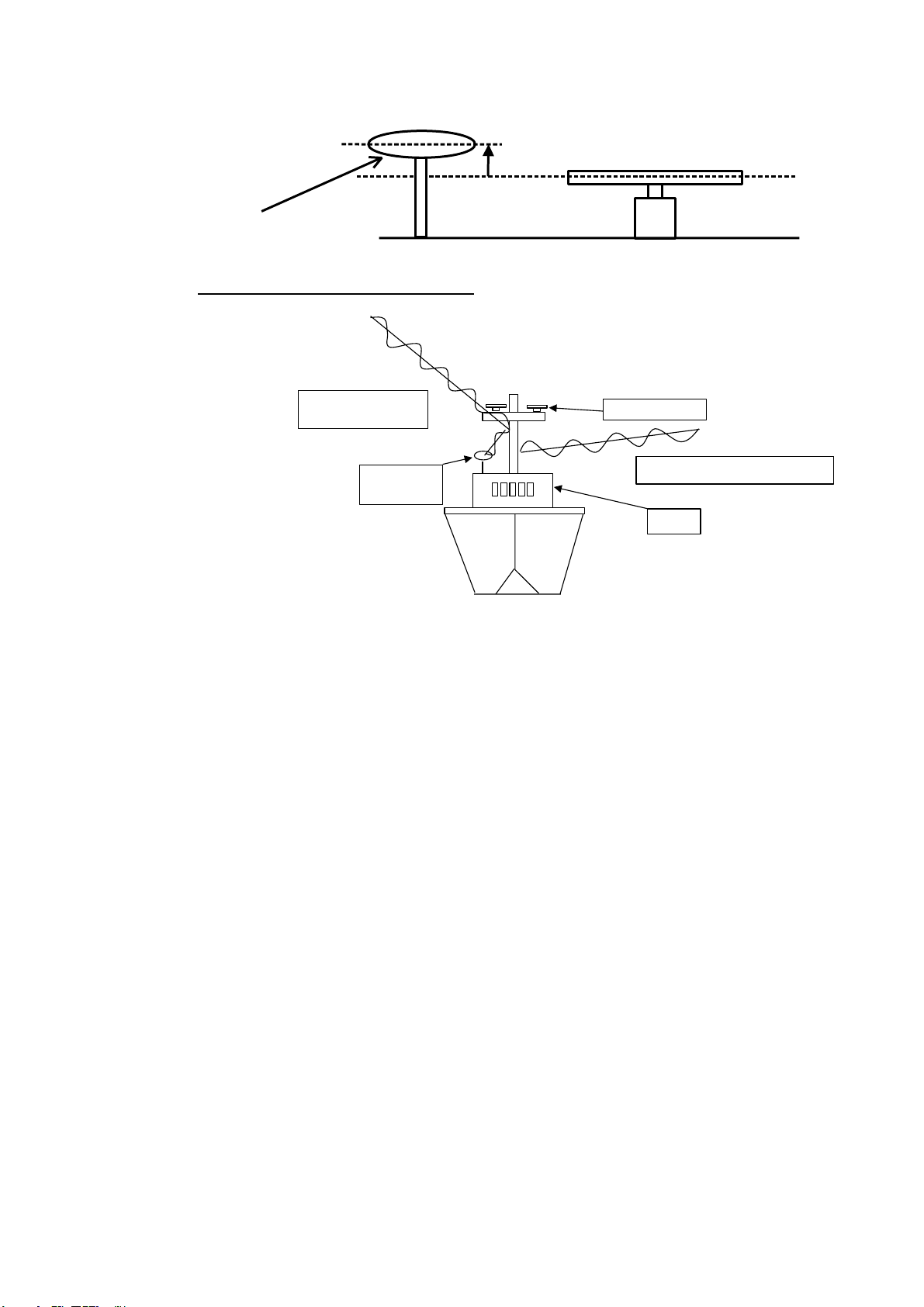

1 PRINCIPLE OF OPERATION

Own ship's heading can be determined by decoding the data in the carrier

frequency in addition to ordinary GPS parameters. In principle, a pair of two

antennas A1(ref) and A2(fore), each connected with an associated GPS engine

and processor, are installed along the ship's fore-and-aft line. GPS systems at

A1 and A2 calculate the range and azimuth to the satellite. Difference in range

between A1 and A2 is ∆λ + nλ where λ is 19 cm. “n” is automatically found

during the initialization stage by receiving three satellites. A fraction of a carrier

wavelength, ∆λ, is processed by FURUNO’s advanced kinematic technology in

geographical survey, thus determining a vector (range and orientation) A1 to A2.

In reality, a third antenna is used to reduce the influence of pitch, roll and yaw,

and five satellites are processed to obtain 3D data. If the GPS signal is blocked

by a tall building or the vessel is under a bridge, the 3-axis solid-state angular

rate gyros in the processor unit take place of the satellite compass, maintaining

the current heading continuously.

Heading

Antenna A3

Fore-and-aft line

∆λ

Antenna A1

θ

nλ

λ

Difference between the

range from satellite to

Vector to decide heading

antenna 1 and the range

to antenna 2.

Antenna A2

Principle of satellite compass operation

1-1

Page 14

This page is intentionally left blank .

Page 15

2 INSTALLATION

2.1 Mounting Considerations

2.1.1 SC-series antenna unit

General

• Keep the length of antenna cable in mind when selecting a mounting location.

The cable comes in lengths of 15 meters (standard supply), or 30 m or 50 m

(optional lengths).

• Select a location where vibration and shock are minimal.

Installing the antenna above superstructures

The antenna must be mounted above all other structures on the vessel to obtain

an unobstructed view of the satellites regardless of vessel heading. Failure to do

so will cause shadows and multipath reflection problems.

Mast

SC-series Antenna

Radar Antenna

Exam ple of proper installat ion

Installing the antenna below superstructures

If it is not possible to mount the

antenna above all superstructures on

the vessel, as shown in the illustration

above, shading and multipath

problems may occur on at least one

heading, and possibly more. To

possibly avoid those problems,

observe the guidelines in this section.

If the antenna is installed below any

superstructure, the installation must

be done over a two-day period, following

the procedure in the service manual.

At least 12 hours are required to capture

tracking data to measure multipath indexes

and locate areas of shading.

Bridge

NOTICE

2-1

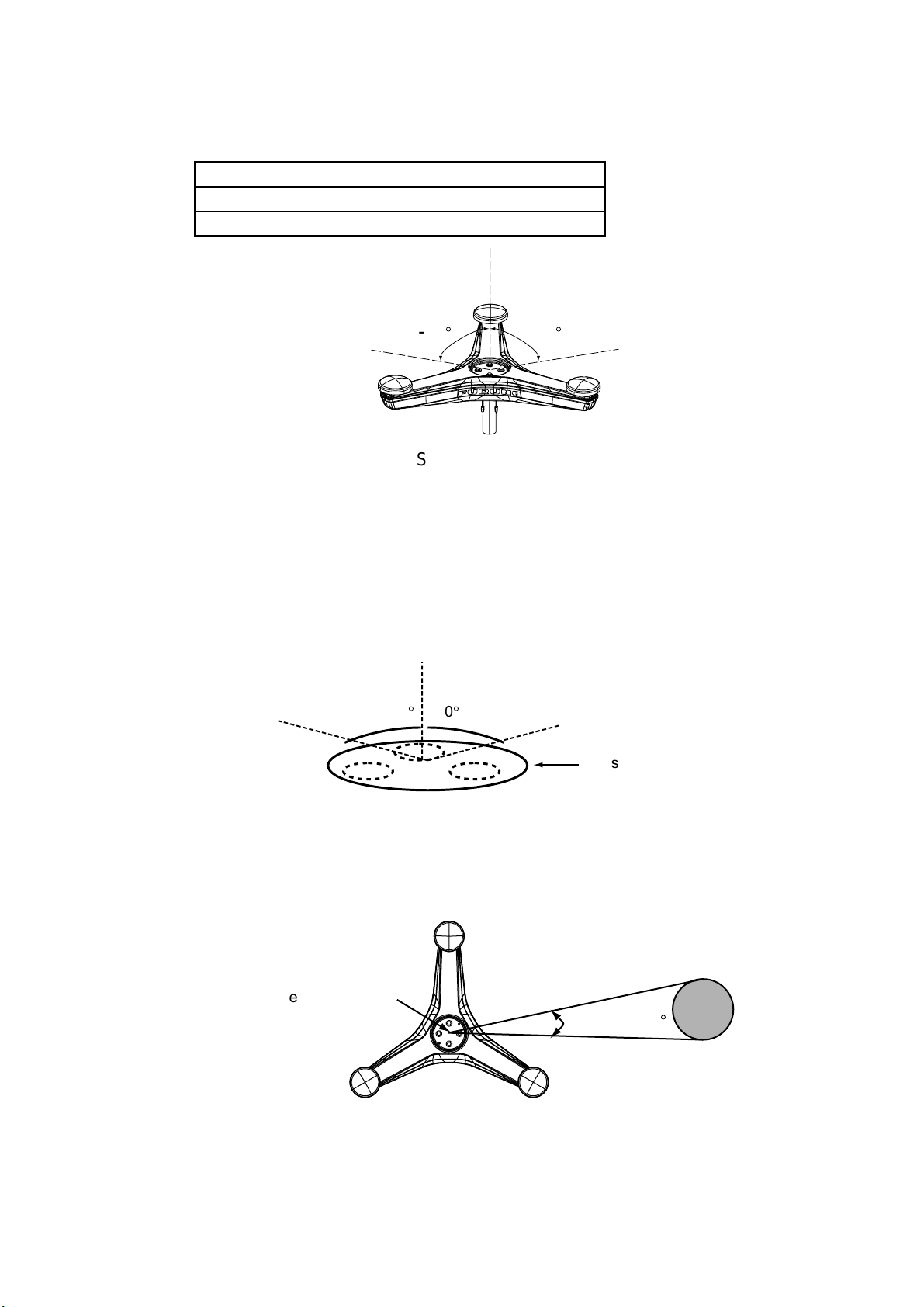

Page 16

2. INSTALLATION

• The horizontal separation between the antenna and masts must be as

follows:

Mast diameter Separation distance (minimum)

10 cm 1.5 m

30 cm 3 m

• Keep the length of antenna cable in mind when selecting a mounting location.

The cable comes in lengths of 15 meters (standard supply), or 30 m or 50 m

(optional lengths).

-80

°

+80

°

Separation degrees

• The field of view above the antenna should be as shown below, ±80° against

zenith. To avoid reflections from masts and the like, locate the antenna well

away from the shadows of the radar mast, etc.

Zenith

-80°+80

SIDE VIEW

°

SC-series antenna

Antenna and field of view

• Referring to the figure below, locate the antenna away from objects which

might block reception, such as a mast.

SC-series Antenna

Less than 10

°

2-2

Mast, etc.

Page 17

• Locate the antenna above the radar antenna, out of the radar beam.

Sc-series Antenna

Example of improper installation

Location influenced

by reflected wave.

NO! UNSUITABLE LOCATION

SC-series antenna located

below all other structures

SC-series

Antenna

Exam ple of improper ins tallation

2.1.2 Display unit, processor unit

Radar Antenna

Radar Antenna

Reception blocked by mast.

Bridge

• Choose a location where vibration and shock are minimal.

• Install the units well away from locations subject to rain and water splash.

• Locate the units well away from air conditioner vents.

• Keep the units out of direct sunlight because of heat that can build up inside

their cabinets.

• Choose a well-ventilated location.

• For the display unit, choose a location where it can be easily operated.

• Leave sufficient space around the units to permit access for maintenance. See

the outline drawing for recommended maintenance space.

2-3

Page 18

2. INSTALLATION

2.2 Installing the Antenna Units

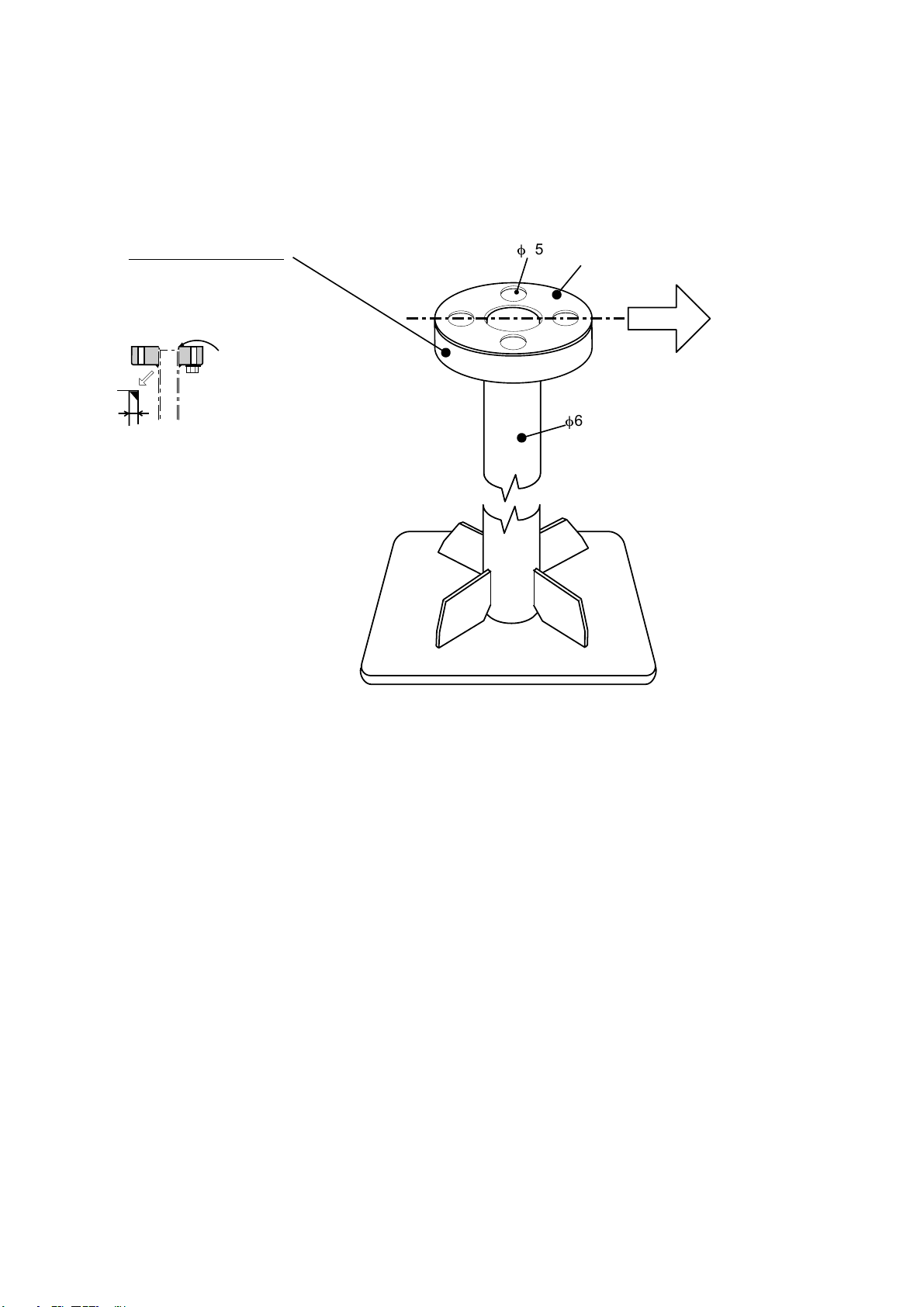

2.2.1 SC-series antenna unit

1. Prepare an installation post for the antenna in accordance with the illustration

shown below.

f

Recommended Flange

(Option)

Name: Flange

Type: OP20-31

Code No.: 004-378-230

Weld all the way around.

15

Gasket

(supplied in installation materials)

BOW

Post should be constructed from

stainless steel and measure

4mm or larger in thickness.

3 mm or less

The width of welding should be

within 3 mm from the mast so

that the welding does not touch

the spring washer.

Installation post

f

60.5 mm

Bow direction is

between antennas

#1 and #2.

2-4

Page 19

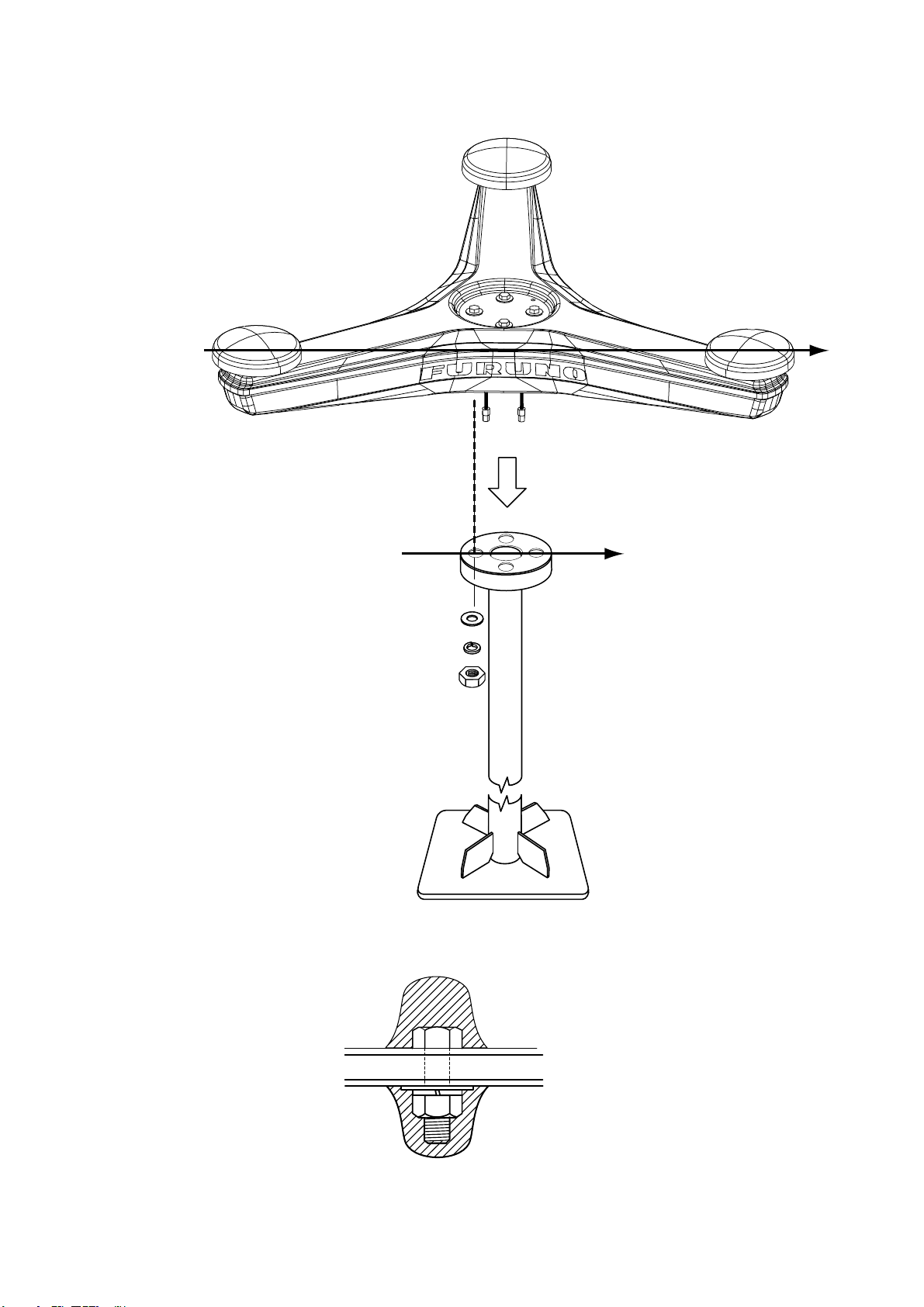

2. Fix the antenna unit to the post as shown below.

3

2. INSTALLATION

1

Set the antenna

unit to the flange.

Spring washer

(Torque: 29.58 Nm)

2

Fix the antennas #1 and #2 on

the fore-and-aft line of the ship,

with the #2 a ntenna forward

of the #1.

Flat washer

Nut

Fastening antenna unit to a post

3. Coat each nut, bolt and washer with silicone rubber for waterproofing.

Coat bolt, nut and

washer completely

with silicone rubber.

Coating bolt, nut and washer with si licone rubber

2-5

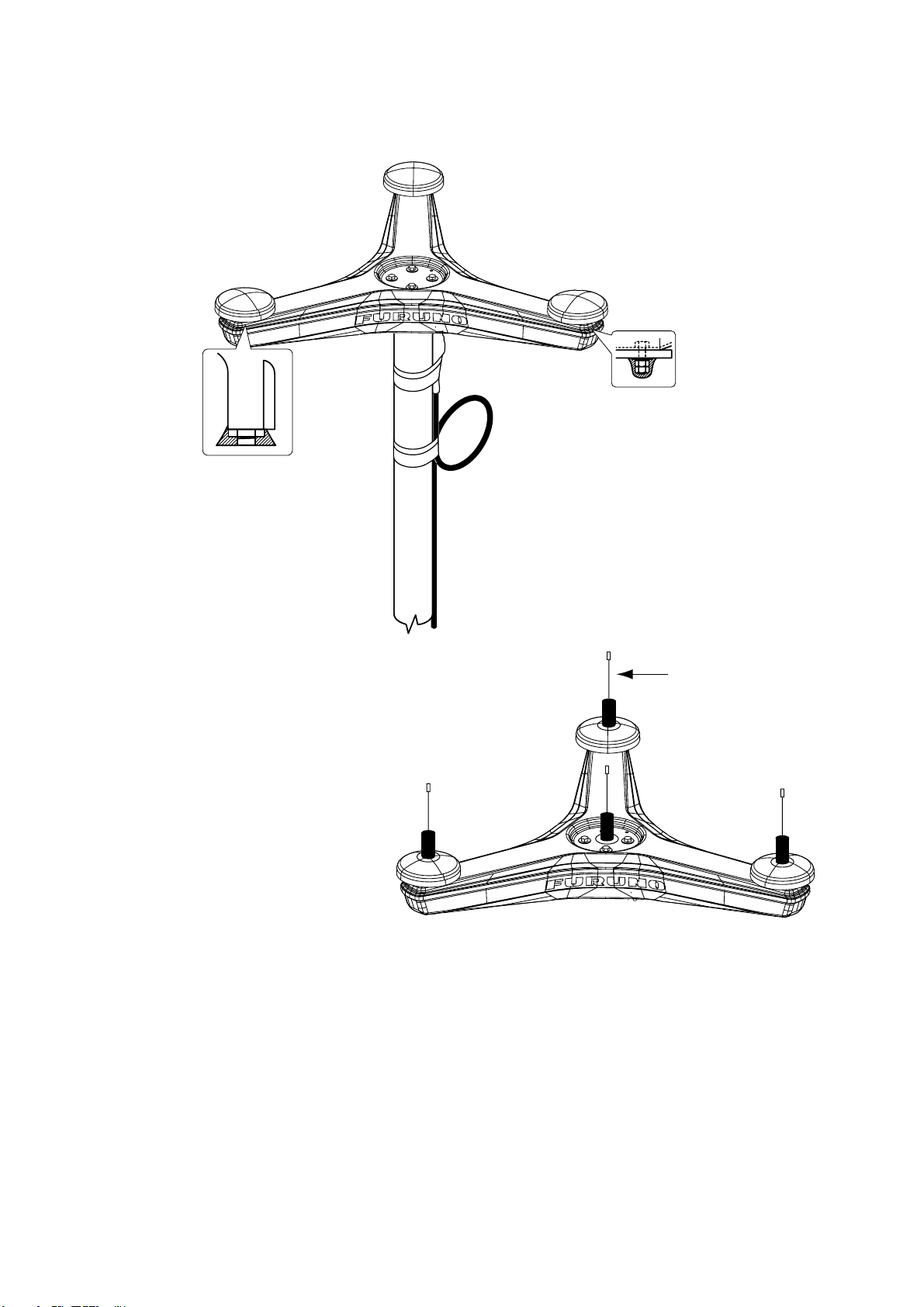

Page 20

2. INSTALLATION

4. As shown below, make a loop in the antenna cable and fasten the antenna

cable to the antenna post with two cable ties.

Coat with Three

Bond 1211

(supplied).

Coat bolt threads with

Three Bond. Fasten bolt

with nuts and then coat

nuts with Three Bond also.

Fix antenna cable.

5. Coat bolt threads with

Three Bond 1211.

Fasten bolts with nuts.

Coat nuts at the

bottom of each

antenna element with

Three Bond 1211.

6. Paint post and support

plate with

anti-corrosive paint.

7. Attach “bird-repellent

fixtures” (supplied) to

each antenna element

and center cover as shown right. Antenna e lement

Bird-repellent fixture

2-6

Page 21

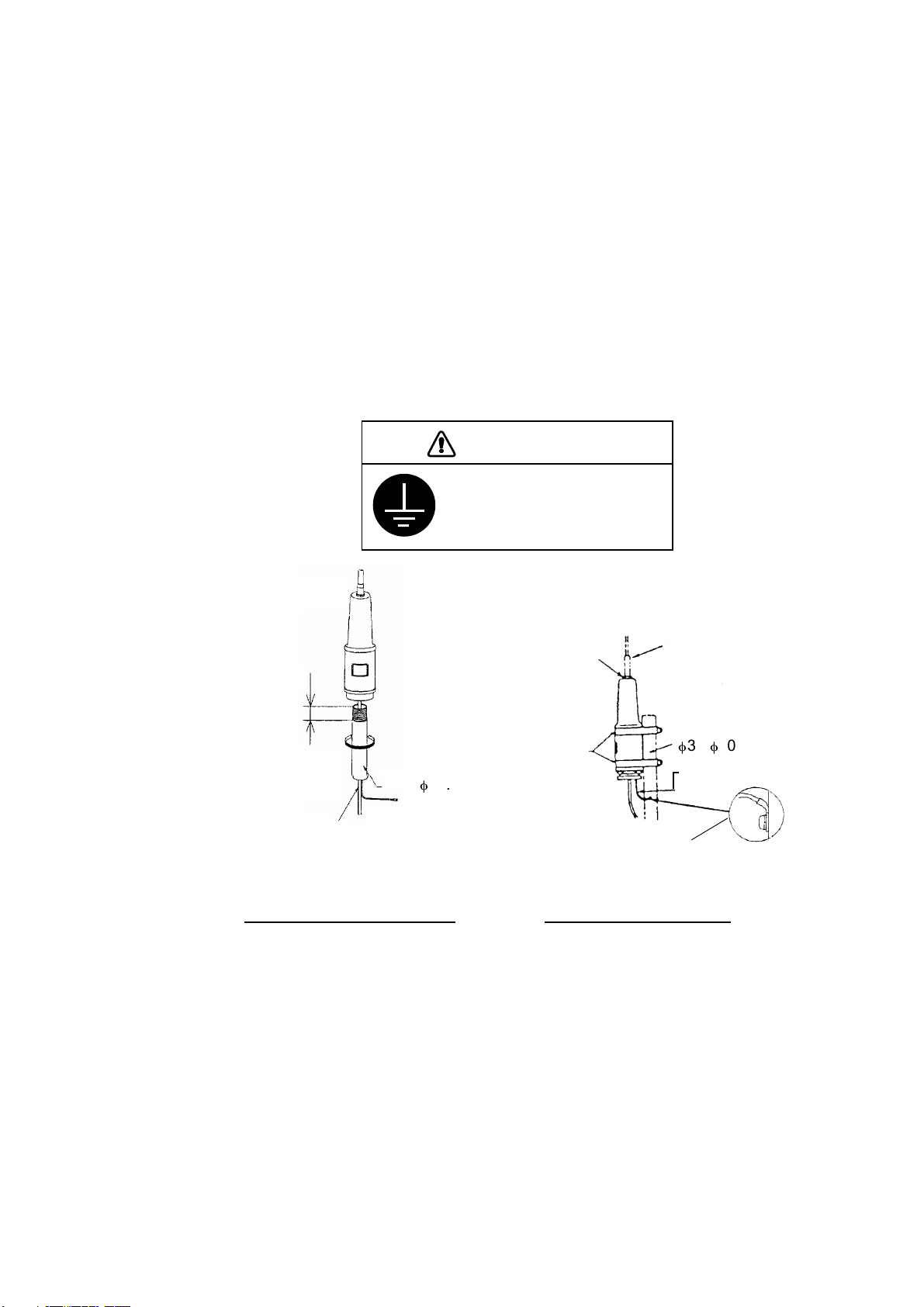

2.2.2 DGPS antenna unit

Choose a mounting location for the DGPS antenna considering the points

mentioned below. DPGS is not necessary for heading determination, however it

can improve the accuracy of GPS position fixing

• Separate the DGPS antenna at least three meters from a radio antenna.

• Do not install the DGPS antenna within the radar beam.

1. Mount the DGPS antenna by one of the methods below.

• Screw it into a one-inch threaded pipe.

• Fasten it to a steel post (φ35-φ90) with stainless steel hose clamps (local

supply).

2. INSTALLATION

CAUTION

Ground the antenna to

prevent receiving problems.

DGPS Antenna (preamp)

GR-800-SC-1-S

Whip Antenna

Post

(

f

35-f90)

Ground Wire (0.3 m)

50

Witt Threads

(W25-14)

Pitch: 1.8143

Qty: 14

Pipe

Ground to the ship’s body

Antenna cable

Note: Screw the pipe into the

preamp BEFORE mounting the pipe.

Mounting onto a threaded pipe

as shown the right figure.

f

27.2

Spring Washer

Hose

Clamp

Tap M4 threads in mast.

Fasten ground wire with an

M4 screw.

Mounting with hose clamps

Mounti ng the DGPS antenna

2. Set the spring washer to the whip antenna (local supply) and screw the whip

antenna into the antenna housing. Coat the washer with silicone sealant to

prevent loosening.

3. Drill a tapping hole in the post for an M4 screw and fasten the ground wire

there.

2-7

Page 22

2. INSTALLATION

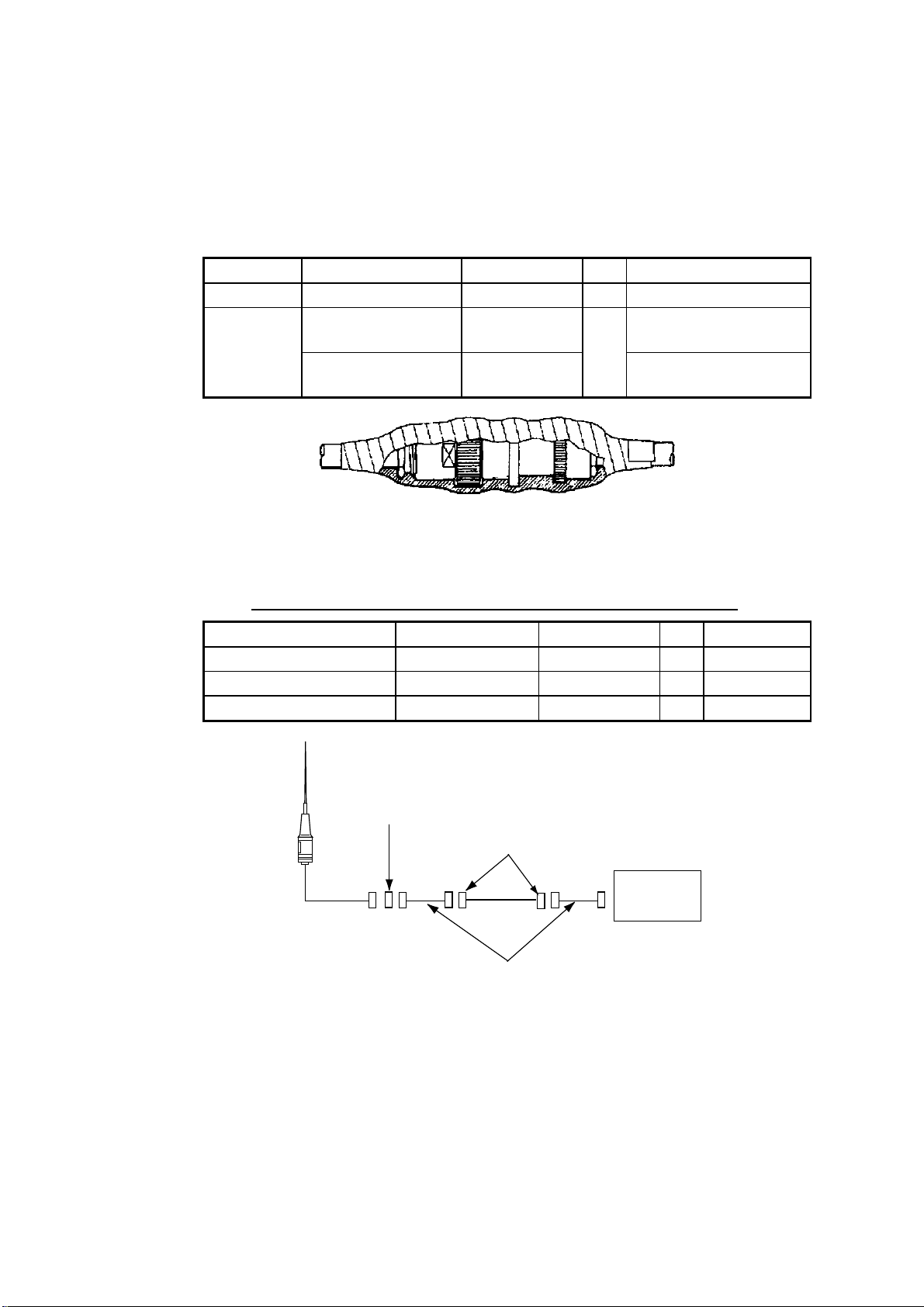

4. The DGPS antenna is supplied with a 15 m cable. If extension is necessary

use the extension cable (option). Cover the extension connectors with

vulcanizing tape and vinyl tape, for waterproofing. Tie tape ends with a cable

tie.

Extension Cable: Type: OP08-15-30, Code No.: 004-396-440 (30 m)

Connector TNC-SA-JJ 000-139-113 1

Cable

For coaxial cable RG-10UY (local supply, max. length 60 m), use the optional

antenna cable set.

Type: OP08-15-60, Code No.: 004-396-450 (60 m)

Name Type Code No. Qty Remarks

TNC-PS-3D L30M 000-139-078 30 m, connector at

both ends

TNC-PS-3D L60M 000-139-080

1

60 m, connector at

both ends

Waterpr oofing the extension connector

Antenna cable set Type: OP08-17, Co de No.: 004-392-510

Name Type Code No. Qty Remarks

Converter Cable Assy. NJ-TP-3DXV-1 000-123-809 2

Connector TNC-SA-JJ 000-139-113 1

Connector N-P-7 000-501-514 2

*TNC-SA-JJ

*N-P-7

Processor

15 m

RG-10UY

* Converter cable assy. (supplied with antenna cable set)

Unit

Cable connection when usi ng c able RG-10UY

2-8

Page 23

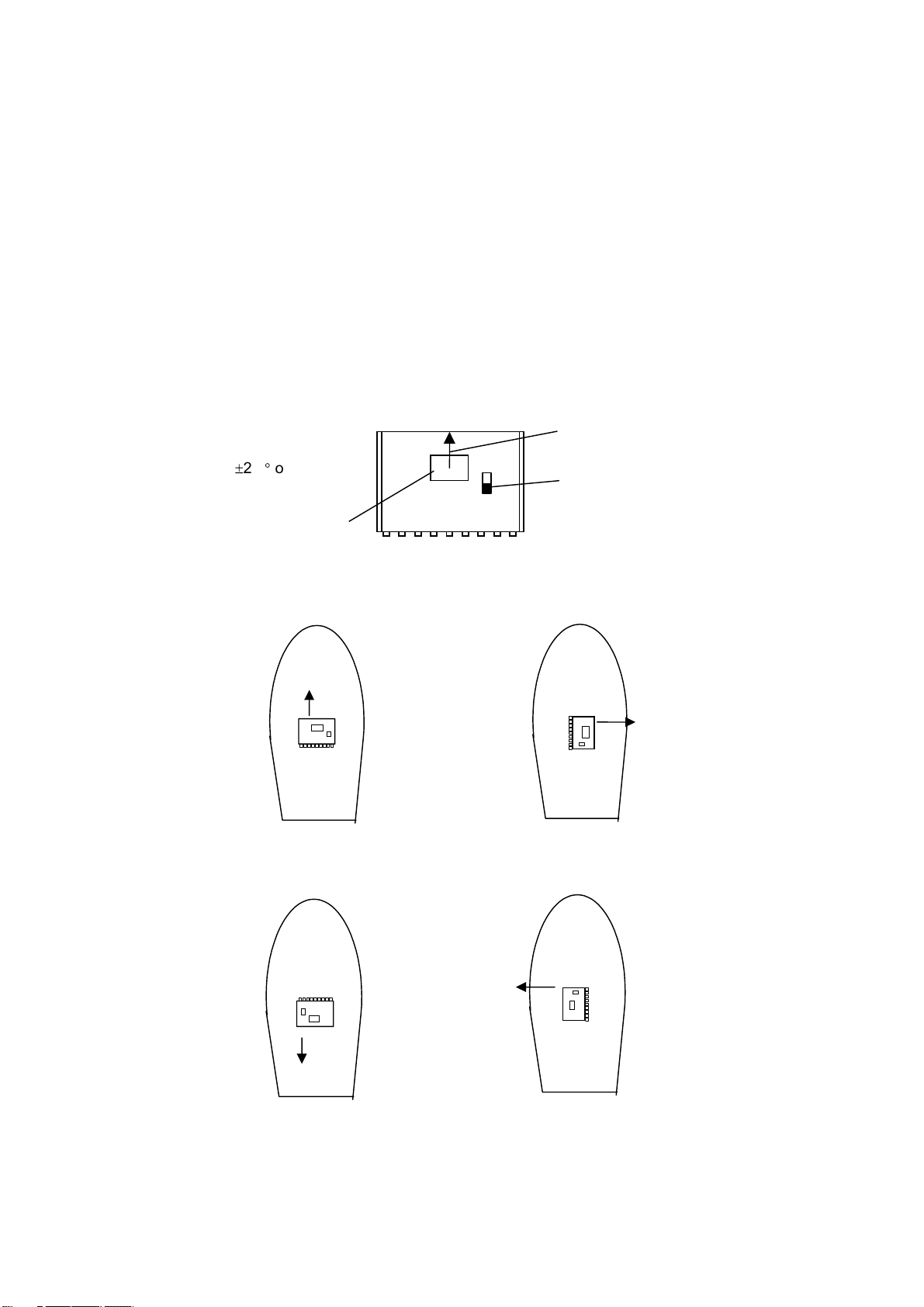

2.3 Installing the Processor Unit

The processor unit should be mounted aligned with the ship’s fore-and-aft line. It

can be mounted on the deck, bulkhead, or on the underside of a desk. Choose a

mounting location which allows you to easily view the power lamp on the top of

the unit and which is within

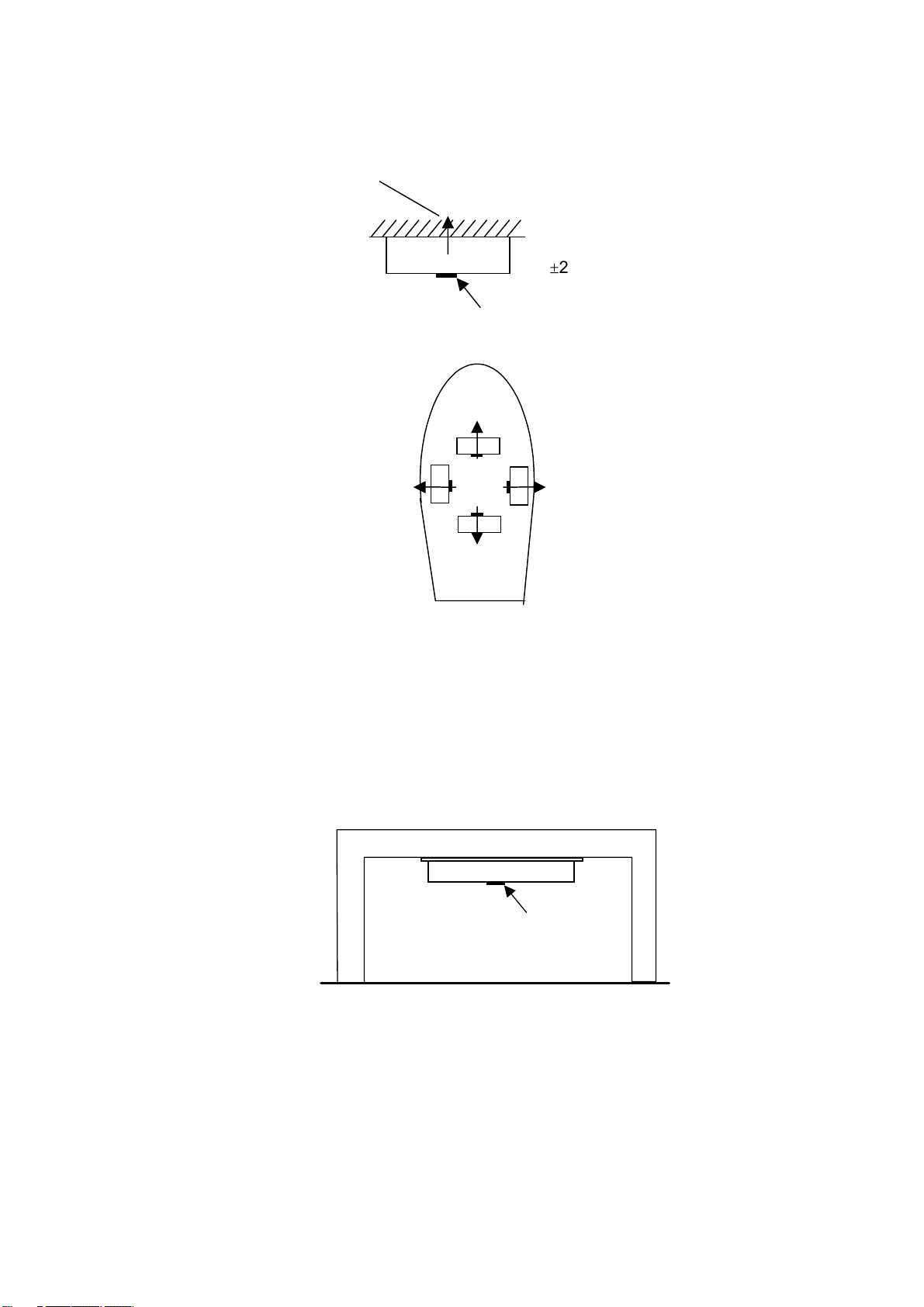

2.3.1 Deck mount

1. The processor unit is factory adjusted for deck mounting. Fasten the

processor unit to the mounting location with tapping screws (5 x 20, 4 pcs.).

The unit can be oriented in one of the directions shown in the figure below.

After the unit is installed you will specify the mounting method from the menu.

Mount processor unit

so reference

direction is within

±

2.5° of

fore-and-aft line.

Name plate

±2.5° of the ship’s fore-and-aft line.

Reference Direction

POWER switch

(power lamp)

2. INSTALLATION

Port

Bow

Stern

Bow

Connectors

Processor Unit, top view

Bow

Mounting Method: "Floor"

(Deck)

Mounting Direction: A

Starboard

DIRECTION "A" DIRECTION "B"

Mounting Method: "Floor"

(Deck)

Mounting Direction: C

Port

Stern

Bow

Mounting Method: "Floor"

(Deck)

Mounting Direction: B

Starboard

Mounting Method: "Floor"

(Deck)

Mounting Direction: D

Port

Stern

Starboard

DIRECTION "C" DIRECTION "D"

Port

Stern

Starboard

Processor u nit orientat ion, deck mounting

2. Fasten the ground wire between the ground terminal on the processor unit

and the ship’s superstructure.

2-9

Page 24

2. INSTALLATION

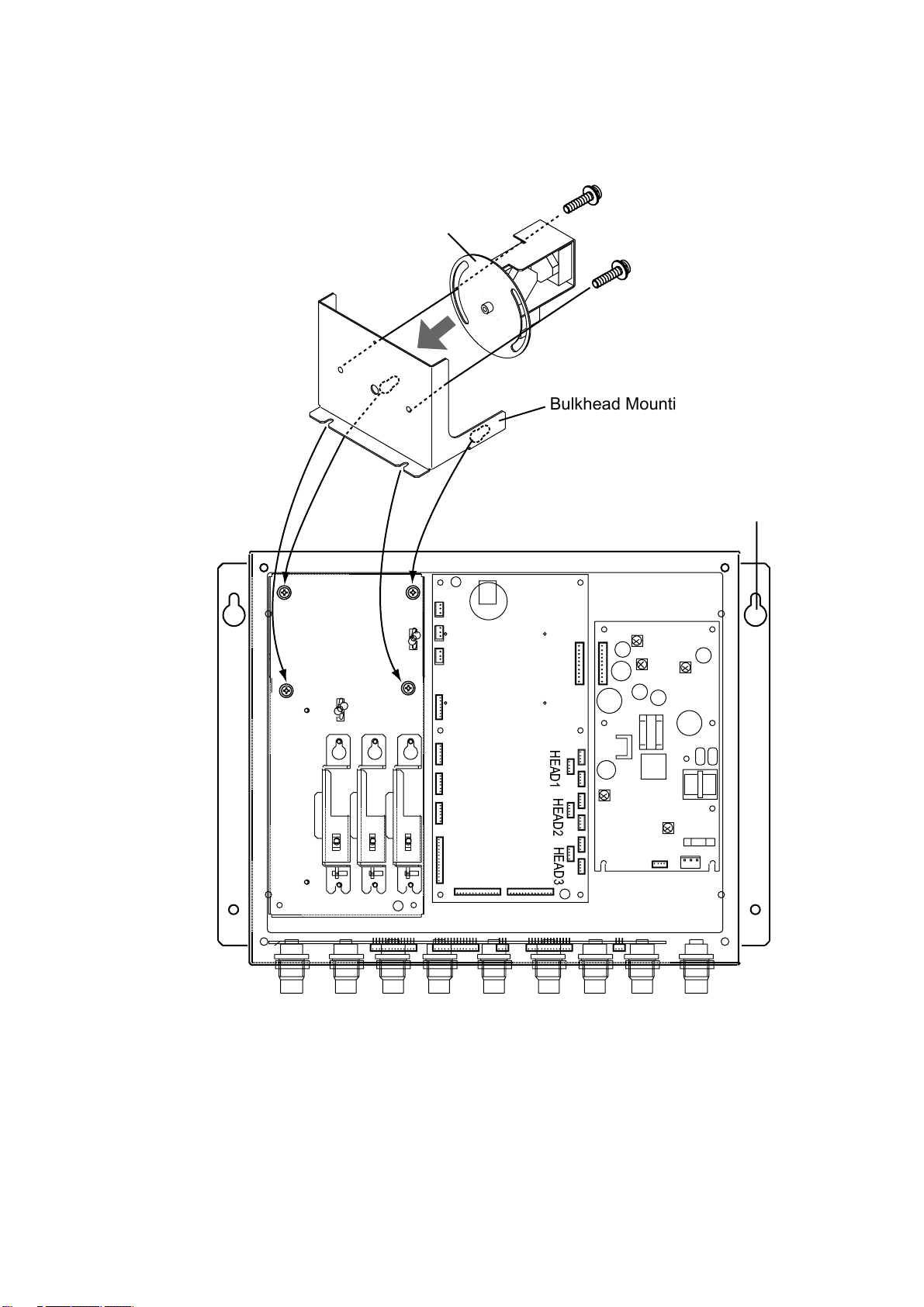

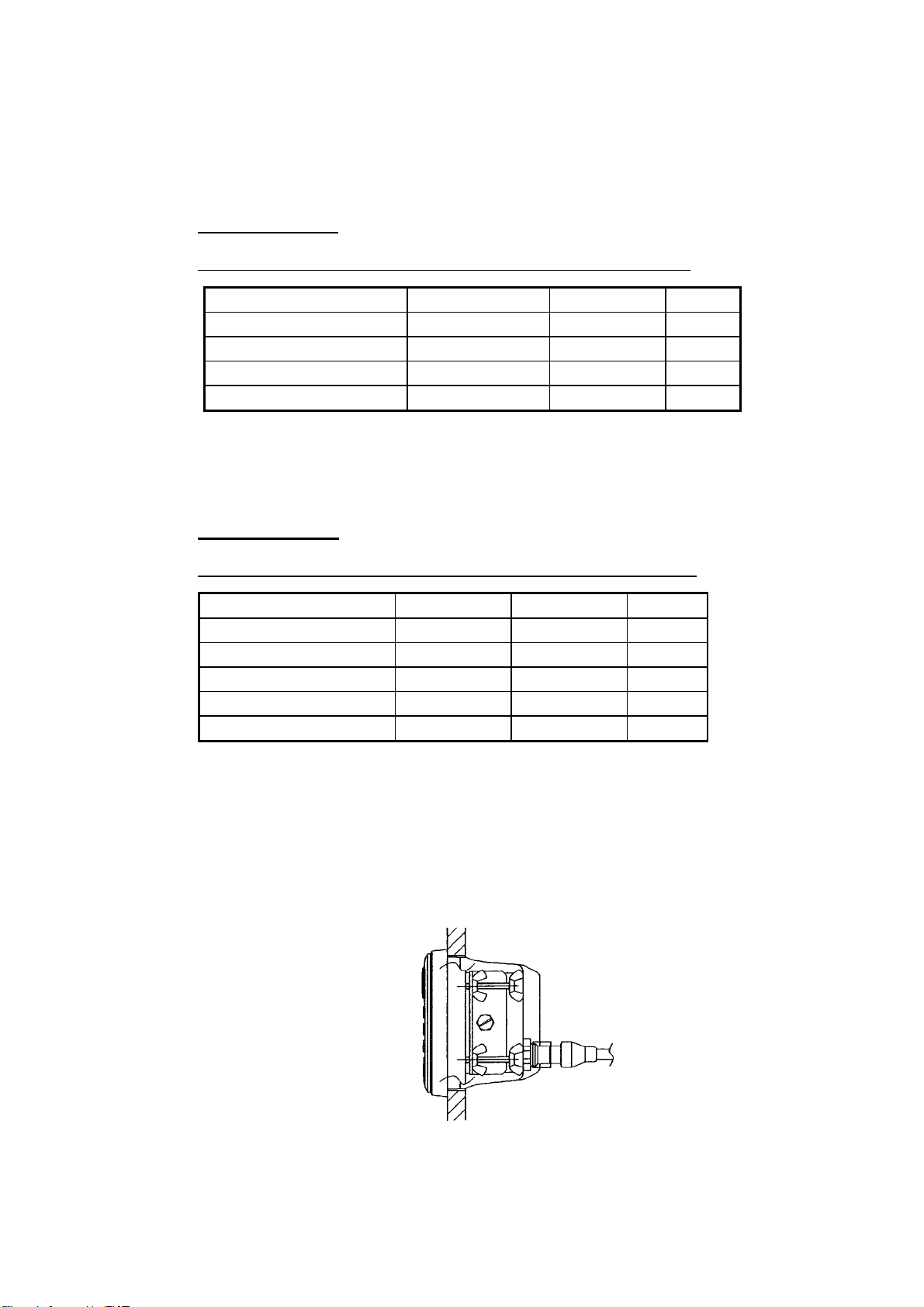

2.3.2 Bulkhead mount

For mounting on a bulkhead, use the bulkhead mounting plate supplied with the

installation materials.

1. Unfasten four screws from the top cover to open the front panel.

2. Unfasten two screws to dismount the angular rate sensor.

Angular Rate Sensor

BEACON

20P8171

Processor u nit, top vi ew

3. Fasten the bulkhead mounting plate to the angular rate sensor. Align the

center graduation on the angular rate sensor with the hole of the bulkhead

mounting plate and tighten fixing screws.

Hole of bulkhead

Scale

Center Mark

mounting plate

Angular Rate Sensor

Mounting Base

Fixing Screw

2-10

Angular rate s ensor, top view

Page 25

2. INSTALLATION

4. Loosen four screws on the angular rate sensor mounting base, and then

fasten the bulkhead mounting plate to the angular rate sensor mounting

base.

Angular Rate Sensor

Bulkhead Mounting Plate

Top Fixing

Hole (x2)

Angular

Rate

Sensor

Mounting

Base

BEACON

HEAD1

20P8171

HEAD2

HEAD3

Processor u nit, top vi ew

5. Close the top cover of the processor unit.

6. Partially screw in two tapping screws for the top fixing holes of the processor

unit in the mounting location. Hang the processor unit on the tapping screws,

using the top fixing holes. Screw in two tapping screws for the bottom fixing

holes, and then tighten the top fixing holes.

2-11

Page 26

2. INSTALLATION

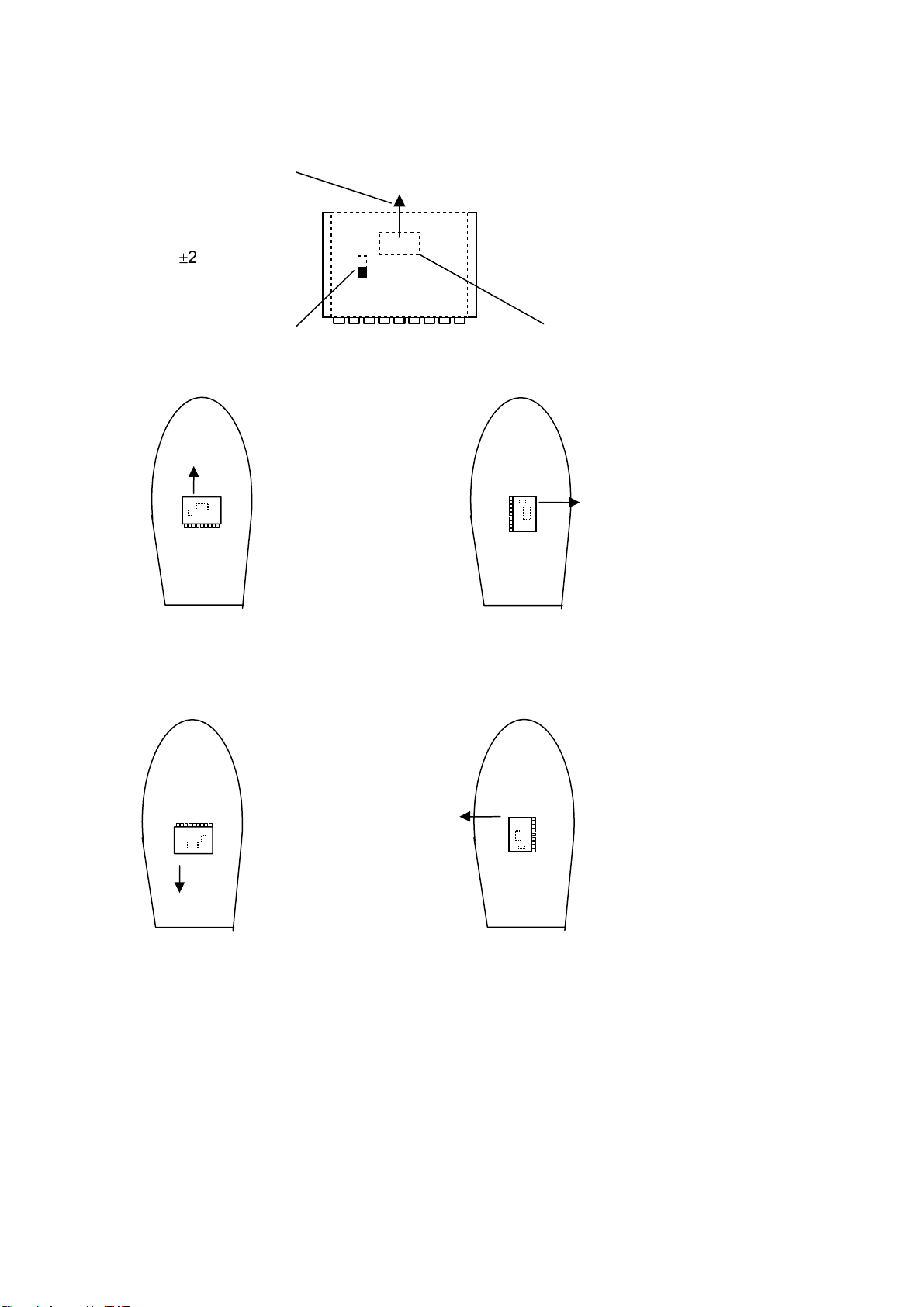

The unit can be oriented as shown in the figure below. After the unit is

installed you will specify the mounting method from the menu.

Reference Direction

Bulkhead

Name Plate (other side)

Mount processor unit so

reference direction is within

±

2.5° of fore-and-aft line.

Mounting Method: "Wall"

(Bulkhead)

Mounting Direction: A

Direction B

Mounting Method: "Wall"

(Bulkhead)

Mounting Direction: C

Direction D

Mounting Method: "Wall"

(Bulkhead)

Mounting Direction: D

Direction

A

Direction

C

Processor u nit orientat ion, bulkhead mounting

7. Fasten the ground wire between the ground terminal on the processor unit

and the ship’s superstructure.

2.3.3 Installation on the underside of a desk

The processor unit may be mounted on the underside of a desk as shown in the

figure below. Do not install it on the overhead.

Desk

Mounting Method: "Wall"

(Bulkhead)

Mounting Direction: B

2-12

Name Plate

Installation of processor unit on the unders ide of a desk

Page 27

The reference direction is as shown below. The mounting method is the same as

that for mounting on the deck.

Reference Direction

Mount processor unit so

reference direction is

within

±

2.5° of

fore-and-aft line.

2. INSTALLATION

Port

POWER switch

(power lamp)

Bow

Mounting Method: Invert

Mounting Direction: A

Starboard

DIRECTION "A" DIRECTION "B"

Stern

Bow

Mounting Method: Invert

Mounting Direction: C

Connectors

Processor Unit, rear view

Port

Bow

Stern

Bow

Name plate (other side)

Mounting Method: Invert

Mounting Direction: B

Starboard

Mounting Method: Invert

Mounting Direction: D

Port Starboard

DIRECTION "C" DIRECTION "D"

Stern

Processor u nit orientation, installation on the un der s ide of a desk

Mount the processor unit on a level surface with its name plate facing the bow,

stern, port or starboard.

Port

Stern

Starboard

2-13

Page 28

2. INSTALLATION

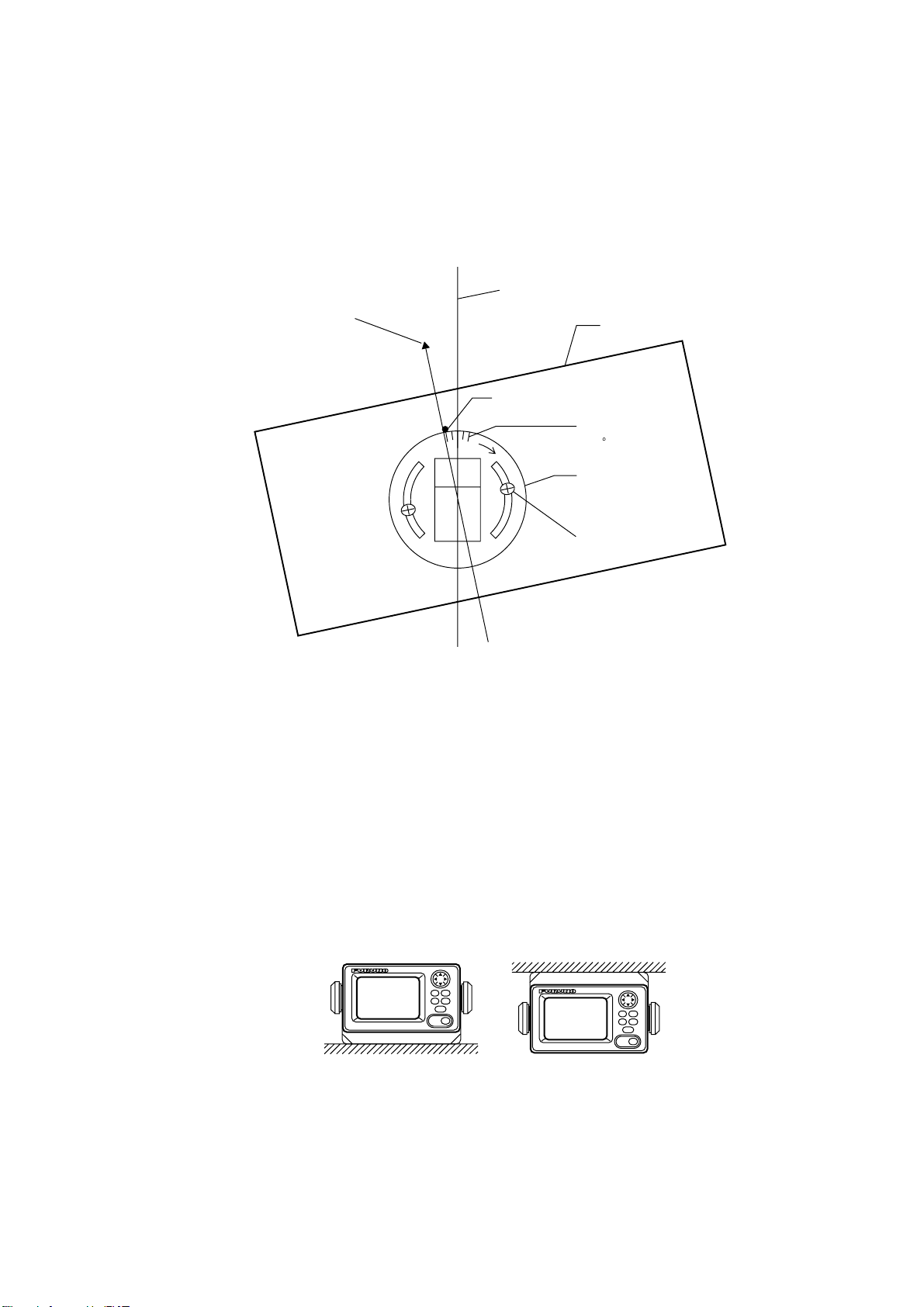

2.3.4 Adjusting for orientation error

It may be impossible to perfectly align the processor unit on the fore-and-aft or

port-and-starboard line. Open the top cover, loosen the two fixing screws on the

angular rate sensor and turn. For example, if the orientation error is 2.5° to port,

rotate the sensor 2.5° starboard. The range of adjustment is -45° to +45°. Close

the top cover after completing the adjustment.

Reference

Direction

Fore-aft line or Port-starboard

direction

Processor Unit

Alignment hole on processor unit

Scale, every

°

2.5

Bulkhead Mounting

Plate

Angular rate s ensor, top view

2.4 Installing the Display Unit

2.4.1 Desktop, overhead mounting

1. Fasten the hanger to the mounting location with four tapping screws

(supplied). See the outline drawing for mounting dimensions.

2. Screw the knobs into the display unit.

3. Set display unit to the hanger and tighten the knobs.

4. Run the ground wire between the ground terminal on the display unit and the

ship’s superstructure.

Fixing Screw

2-14

Desktop

Overhead

Display unit mounting methods

Page 29

2.4.2 Flush mounting

Two types of flush mounts are available. See the outline drawing at the back of

the manual for details.

Flush mount “F”

2. INSTALLATION

Flush mount “F” kit Type: OP20-29, Code No: 000-041- 405)

Name Type Code No. Qty

Cosmetic Panel 20-016-1051 100-251-370 1

Tapping Screw 5X20 000-802-840 4

Hex Bolt M6X12 000-862-127 2

Spring Washer M6 000-864-260 2

1. Make a cutout in mounting location. The dimensions are 183(W) x 92(H) mm.

2. Fasten the cosmetic panel to the display unit with hex bolts and flat washers.

3. Fasten the display unit to the mounting location with tapping screws.

Flush mount “S”

Flush mount “ S ” kit Type: OP20-17, Code No.: 000-040-720)

Name Type Code No. Qty

Flush Mount Fixture 20-007-2401 100-183-190 2

Wing Bolt M4X30 000-804-799 4

Wing Nut M4 000-863-306 4

Hex Bolt M6X12 000-862-127 2

Spring Washer M6 000-864-260 2

1. Make a cutout in the mounting location. The dimensions are 167(W) x 92(H)

mm.

2. Place the display unit in the cutout.

3. Fix the display unit to the two flush mount fixtures with hex bolts and spring

washers.

4. Screw the wing nut on the wing bolt.

5. Fix the display unit with the wing bolt and then tighten the wing nut.

Flush mount “S ”

2-15

Page 30

2. INSTALLATION

2.5 Wiring

This section covers general wiring. For further details see the interconnection

diagram at the back of this manual.

DISPLAY UNIT

SC-602

MJ-A7SPF0006-100,

10 m

SASATELLITE

TELLITE

COMP

COMP

ANTENNA UNIT

SC-1203F

*

ASS

ASS

PROCESSOR UNIT

SC-1201/SC-1201D

Note 1

Cable Tie

(Long life, temperature

resistant, local supply)

DGPS ANTENNA

GR-800-1-S

TNC-PS-3D (15 m)

12-24 VDC

TPPX6-3D2V-15M, 15 m

See Note 2.

MJ-A3SPF0013-035,

3.5 m

General w iring diagram

• The length of the cable between the display unit and processor unit is 10 m.

Connect it to the DISPLAY port on the processor unit.

• The antenna cable is 15 meters (standard) long. Connect the three coaxial

cables to the processor unit according to cable color as below. Incorrect

connection will result in wrong heading.

Antenna TPPX6-3D2V-15M

Port on

Processor Unit

Antenna Element 1 No color GPS ANT 1

Antenna Element 2 Yellow GPS ANT 2

Antenna Element 3 Red GPS ANT 3

2-16

Page 31

2. INSTALLATION

Note 1: Instead of TPPX6-3D2V, three Japan Industrial Standard coaxial cables

3D2V (local supply) or equivalent can be used as antenna cables.

3D2V

50

W

f

5.3 mm

Core

f

0.96 mm

Insulator T1.02 mm

Shield

Sheath

Sectional view of coaxial cable 3D2V

Note 2: The optional antenna cable set (CP20-01700 or CP20-01710, 3 sets)

allows you to extend the antenna cable to 30 m or 50 m. See the next

page for how to attach the connector.

2-17

Page 32

2. INSTALLATION

How to attach connector N-P-8DFB

Outer Sheath

Armor

Cover with heat-shrink tubing and heat.

Clamp Nut

Inner Sheath Shield

50

Gasket

(reddish

brown)

Trim shield here.

30

Clamp

Aluminum Foil

10

(Dimensions in millimeters.)

Cut off insulator and core by 10 mm.

Twist shield end.

Slip on clamp nut,

gasket and clamp as shown left.

Fold back shield over clamp and trim.

Cut aluminum foil at four places,

90 from one another.

Fold back aluminum foil onto shield

and trim.

Expose the insulator by 1 mm.

Expose the core by 5 mm.

Slip the pin onto the conductor.

Solder them together through the

hole on the pin.

Insert the pin into the shell.

Screw the clamp nut into the shell.

(Tighten by turning the clamp nut.

Do not tighten by turning the shell.)

Trim aluminum

tape foil here.

Clamp Nut

Solder through

the hole.

Insulator

1

5

Pin

Shell

How to att ac h c onnec tor N-P-8DFB

2-18

• Connect the DGPS antenna cable to the BEACON ANT port on the processor

unit. The standard cable is 15 m long. With the optional extension cable the

cable can be extended to 30 m or 60 m.

Page 33

2. INSTALLATION

2.6 Initial Settings

Follow the procedures in this section to enter initial settings.

NOTICE

Improper menu settings may stop output of

data and display the message "RATE

ERROR." Be sure to enter correct data.

2.6.1 Confirming satellite status; choosing mounting method

1. Turn on the processor unit and press the [MENU] key to show the menu.

MAIN MENU

SATELLITE

DGPS

I/O SETUP

INST MENU

ERASE

TRIP MENU

Main menu

2. Use the Omnipad (

ALARMS

MESSAGES

GPS SETUP

SYS SETUP

SOFT VER.

OTHERS

) to choose “INST MENU” and press the [ENT] key.

INSTALLATION SETUP

MOUNTING : FLOOR

DIRECTION : A

LANGUAGE : ENG

Installation setup menu

3. Confirm that “MOUNTING” is selected and press the [ENT] key.

4. Use the Omnipad to choose the mounting method: “FLOOR”, “WALL” or

“INVERT” as appropriate.

5. Press the [ENT] key.

6. Choose “DIRECTION” and press the [ENT] key.

7. Use the Omnipad to choose mounting direction (“A ”, “B ”, “C” or “D”) as

appropriate. Refer to section 2.3.1.

8. Press the [ENT] key.

9. Press the [SAT STATUS] key.

Satellites used for

measurement

"OK" displayed when

Satellites

being

tracked

SAT TRACKING STATUS

TIMER 5 '52" OK

NO. GOOD STATUS

GPS1 8 8 D3D

GPS2 7 7 D3D

GPS3 8 8 D3D

the "GOOD" column

shows that the number

of satellites acquired is

five or more.

"3D" shown when no

beacon receiver is used.

Satellite tracking status display

2-19

Page 34

2. INSTALLATION

When the system is turned on for the first time it is in the “cold start” state, which

means there is no satellite data (almanac data) stored. In this condition it takes

about 20 minutes to find heading, indicated by displaying “OK.” (Once almanac

data is stored it takes about five minutes to find heading.) The timer at the top

left corner of the screen shows time since power on. If OK is not displayed within

30 minutes after turning on the power, the antenna mounting location may not be

suitable. It is suspected that the number of

satellites in view is less than five due to

signal blockage. Clear the problem and

then check status on the status display.

If the heading error is between 5° and 10°,

loosen the nut at the center of the antenna

unit and adjust antenna orientation, while

watching the heading indication on the

display.

Antenna

Element

- Direction

Antenna

Element

3

PORT

Antenna

Element

1

BOW

2

Adjusting ant enna orient ation

+ Direction

2.6.2 Choosing heading source

Choose the source of heading data as below:

CAUTION

1. Never switch from internal to external

heading while the autopilot is in the

automatic mode. Change to the

manual mode before switching.

2. The data of external heading must

come from type-approved sensor,

in case of SOLAS vessel.

1. Press the [HDG SETUP] key.

HEADING SETUP

OFFSET : +000.0

(SERVICE ONLY)

HEADING : INT

INT HDG - - - . EXT HDG - - - . -

2. Use the Omnipad to choose HEADING.

3. Press the [ENT] key.

4. Choose INT or EXT as appropriate. Normally choose INT. If the GPS sensor

is not working and a heading sensor such as a gyrocompass is available,

choose EXT.

°

°

OFFSET : Heading offset. See service manual for instructions.

"SERVICE ONLY" means heading offset shown

for display only.

HEADING : Select heading source. Choose INT for normal use.

If a gyrocomapss is connected for primary means,

leaving this equipment as backup, choose EXT.

INT HDG : Bow heading. Includes offset.

EXT HDG : Heading fed from external equipment.

Heading set up menu

2-20

Page 35

Note: When switching from internal heading to external heading when using

an autopilot in the auto mode, set the autopilot in the manual mode

BEFORE switching, adjust heading at the autopilot and then switch to

the auto mode.

5. Press the [ENT] key.

6. Press the [DISP] key to close the menu.

2.6.3 Heading data format

1. Turn off the processor unit.

2. Unfasten four screws from the processor unit to remove the top cover.

3. Choose the heading format of the equipment connected to the ports HDG

OUT 1, HDG OUT 2 and HDG OUT 3 with the jumper wires on the circuit

board 20P8171, referring to the table below. The default setting for each port

is AD-10.

2. INSTALLATION

Jumper w ire and format on the circuit board 20P8171

Port Format Setting Remarks

1

2

3

AD-10 J11 < - > J13 HDG OUT

NMEA J11 < - > J12

AD-10 J14 < - > J16 HDG OUT

NMEA J14 < - > J15

AD-10 J17 < - > J19 HDG OUT

NMEA J 17 < - > J18

ANGULAR

RATE SENSOR

BEACON

HEAD1

NMEA and AD-10 are identified

on the circuit board. Choose

NMEA for IEC 61162-1

sentences.

NMEA

(IEC 61162)

AD-10

20P8171

HEAD3

AD-10

NMEA (IEC 61162)

NMEA (IEC 61162)

HEAD2

AD-10

Processor u nit, cover open ed, top view

2-21

Page 36

2. INSTALLATION

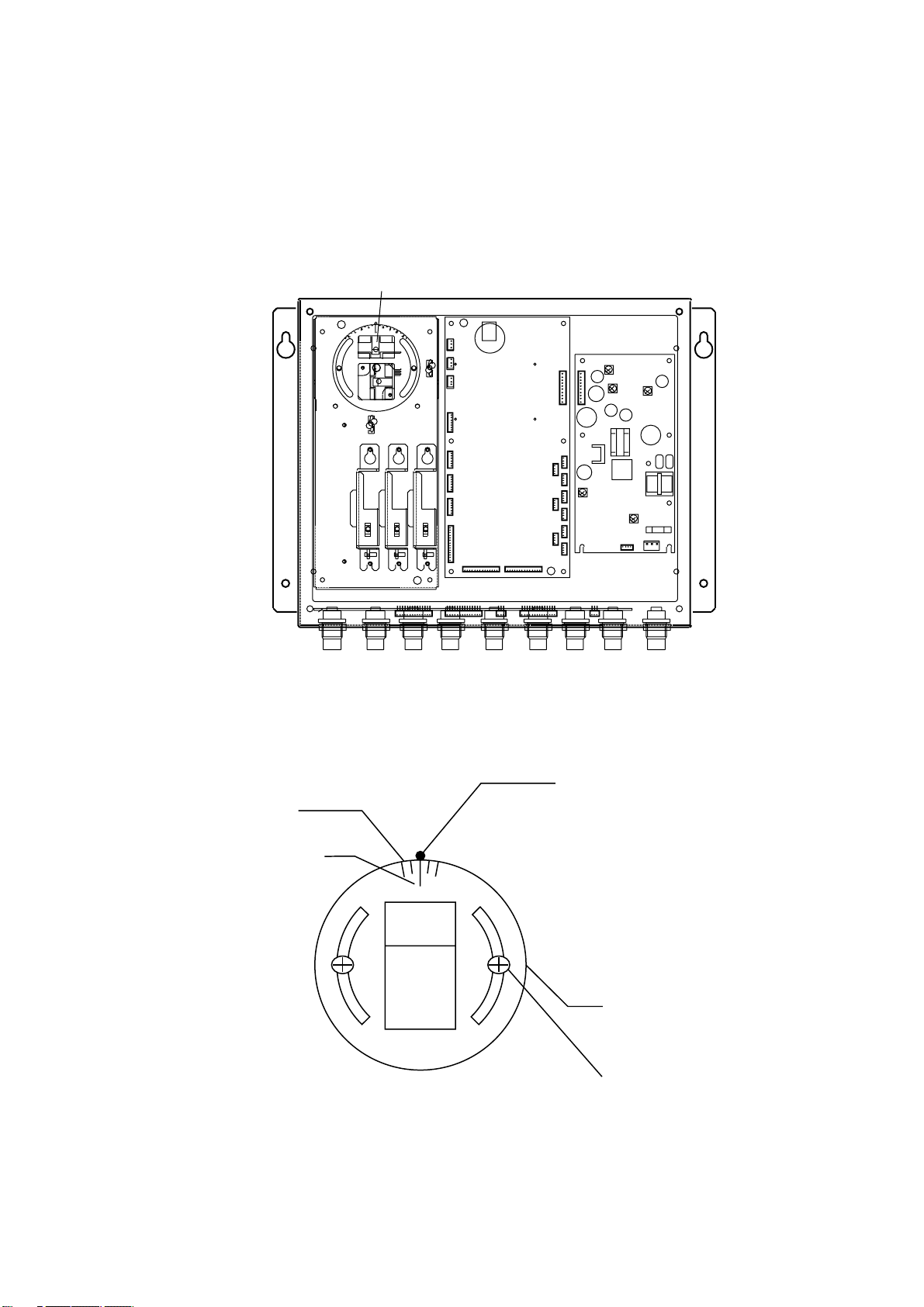

2.7 Connection of External Equipment

All external equipment are terminated on the rear panel of the processor unit.

Output: Plotter, Radar in

Input: External DGPS Beacon

Receiver in RTCM SC-104 Format

Cable: MJ-A7SPF0003-050 (option)

Output: Log Pulse.

Cable: MJ-A7SPF0003-050

(option)

NMEA 0183 (IEC 61162)

Cable: MJ-A6SPF0012-100 (option)

Output: Radar, Auto Pilot,

Plotter, Scanning Sonar,

Current Indicator in AD-10 Format,

NMEA 0183 (IEC 61162)

Cable: MJ-A6SPF0007-100 (Inst. Mat. 1)

MJ-A6SPF0012-100 (Option)

MJ-A6SPF0003--050 (Option)

BEACON

EXT

DISPLAY LOG/ALARM HDG IN NAV OUT

ANT GPS ANT

Input: Heading Sensor*, Gyrocompass* in

AD-10 Format, NMEA 0183 (IEC 61162)

Doppler Speed Log/Current Indicator

in NMEA0183 (IEC 61162)

Cable: MJ-A6SPF0003-100 (Option)

MJ-A6SPF0007-100 (Option)

MJ-A6SPF0012--050 (Option)

External heading input format and output sentence

AD-10: Header of IEC 61162 data sentence chosen on menu is output.

IEC 61162: When EXT data is output from this equipment, NMEA Header (Identifier) of the

external data is output as it is without changes.

1

2

3

1

2

HDG OUT

1243

Output: PC in NMEA 0183 (IEC 61162)

Cable: D-sub 9P

12-24 VDC

Output: PC in NMEA 0183 (IEC 61162)

Cable: D-sub 9P

* = The data of external heading must

come from type-approved sensor,

in case of SOLAS vessel.

Processor u nit, rear vi ew

2.8 Installing the DGPS Beacon Receiver Kit

The optional DGPS beacon receiver provides DGPS capability. The beacon

receiver assy. is installed in the processor unit. A DGPS antenna is necessary.

DGPS Beacon Receiver Kit

Type: GR-7001-K Code No. 000-041-738

Name Type Code No. Qty Remarks

Antenna GR-8 000-040-660 1

Hose Clamp SS7200N 000-570-239 2

Spring Washer M10 000-864-261 1

DGPS Receiver Assy. SC-601 004-377-860 1

Cable Assy. TNCBPJ(140) 000-143-748 1 w/toothed washer and nut

PH Connector 20-061(7-6P) 004-377-770 1

Pan Head Screw M3X8 000-881-404 4

DGPS Station List J49-80010 000-808-435 1

Whip Antenna

2-22

FAW-1.2 000-130-046 1.2 m

04S4176 000-112-845 1 2.6 m

Page 37

2. INSTALLATION

Procedure

1. Open the top cover processor unit.

2. Open the cover of the DGPS receiver assembly.

3. Connect the cable TNCBPJ(140) to J1 on the DGPS receiver assembly.

4. Remove the plug at the rear of the processor unit.

5. Pass the cable TNCBPJ(140) through the hole made at step 4 and fasten it

with the toothed washer and nut.

6. Fasten the DGPS receiver assembly at the location shown below.

Panhead Screw

M3X8, 2 pcs.

DGPS Receiver

Assembly

Cable Assembly

TNCBPJ(140)

J2

J1

Cover

Toothed Washer

Nut

Torque

1.37 0.98 Nm

Plug

Processor u nit, cover removed, top vi ew

7. Connect the 6P connector of the PH connector 20-061(7-6P) to J2 on the

DGPS receiver assy.

8. Connector the 7P connector of the PH connector 20-061(7-6P) to J10 on the

circuit board 20P8171.

2-23

Page 38

2. INSTALLATION

9. Fix the PH connector assy. with a clamp as shown in the illustration below.

J7

J8 (BLK)

9 (RED)

J3J1

Pass PH connector

through clamp

DGPS Receiver

Assy.

10. Close the top cover of the processor unit.

11. Mount the DGPS antenna and whip antenna, referring to section 2.2.

J10

20P8171

J6

J5 (BLK)

J2

J4 (RED)

Processor u nit, cover removed, top vi ew

20P8164

J4

J1

2-24

Page 39

3 OPERATION

3.1 Controls

MENU

ENT

DISP

DIM

HDG

SETUP

SATELLITE

SAT

STATUS

COMPASS

Omnipad: Selects menu items;

shifts cursor.

MENU key: Opens/closes menu.

ENT key: Terminates keyboard input.

DISP key: Selects display.

DIM key: Adjusts panel illumination,

display contrast.

HDG SETUP key: Sets up the equipment.

HOW TO REMOVE THE COVER

Press here and pull toward

you to remove cover.

SAT STATUS key: Shows status display

See illustration below for description.

Satellites used for

measurement

SAT TRACKING STATUS

Satellites

being

tracked

TIMER 5 '52" OK

NO. GOOD STATUS

GPS1 8 8 D3D

GPS2 7 7 D3D

GPS3 8 8 D3D

Display unit

CAUTION

Reduced accuracy may occur in case

of unfavorable satellite constellation,

worsened HDOP, etc.

Always confirm position against other

navigation devices to verify reliability.

"OK" displayed when

the "GOOD" column

shows that the number

of satellites acquired is

five or more.

"3D" shown when no

beacon receiver is used.

3-1

Page 40

3. OPERATION

3.2 Turning the Power On/Off

Use the power switch on the processor unit to turn the power on and off.

Processor unit

The display starts up with the last-used display.

Note 1: Turn on external equipment AFTER

heading data, to prevent heading output error.

Note 2: The display flashes when backup heading data is used.

POWER

Switch

the SC-120 is showing reliable

3.3 Panel Illumination, Display Contrast

1. Press the [DIM] key.

DIMMER (1-8)

4

CONTRAST (0-63)

45

EXIT: [ENT]

Dialog box for adjustment of panel illumination, display contrast

2. Press ▲ or ▼ on the Omnipad to adjust panel illumination.

3. Press ◄ or ► on the Omnipad to adjust display contrast.

4. Press the [ENT] key.

3-2

Page 41

3.4 Choosing a Display

Use the [DISP] key to show a display desired. Each press of the key changes

the display in the sequence shown in the paragraph below.

3.4.1 Description of displays

Heading display

The heading display shows heading, course, speed, date, time and

position-fixing method. The heading status mark changes in the sequence

shown below. The “final calculations” mark disappears after heading becomes

reliable, which is approximately 90 seconds after that mark appears.

3. OPERATION

Position-fixing status indications

2D 2D GPS position fix

3D 3D GPS position fix

D2D 2D DGPS position fix

D3D 3D DGPS position fix

SIM Simulation mode

Heading Status Mark

= Acquiring satellite

= Calculating heading

= Final calculations

When the data

of external sensor is input,

EXT (in reverse video) replaces

HDG on the Heading, Nav data,

Steering and Compass displays.

Nav data display

Date

Positionfixing

status

01 DEC 01

3D

HDG

SOG

Speed over

ground

(day/month/year)

832

.

kt

.00

COG

Course over

ground

Time

23:54:13

°

0

213

.4

Heading

°

Heading display

The nav data display shows position in latitude and longitude, course, speed,

date, time and position-fixing method.

HDG

00:00:00

’0.°0

’0.°0

728

N

E

.0

Position in

Latitude, Longitude

°

3D

SOG

01 DEC 01

00 00

00 00

kt

.00

Nav data display

3-3

Page 42

3. OPERATION

Steering display

The steering display mainly shows heading, in digital and analog form. The own

ship mark points to heading on the bearing scale.

07:54

°

0

.

Lubber’s mark

°

213

.4

Bearing

scale

3D

HDG

SOG

782

260250 270 280 290 300

kt

.00

COG

Steering display

Compass display

The compass display shows heading by compass direction, pitch and roll The

compass rose rotates with heading.

Pitching

Rolling

3D

23:24:01

0

HDG

+

0

PIT

+

0

ROL

.0

°

°

°

NW

W

N

NESW

ES

SE

Own ship symbol

Compass display

ROT (Rate-of-Turn) display

The ROT display provides digital and analog indications of rate of turn.

3D

2030 10 0 10 20 30

ROT

scale

ROT

PORT

ROT

221

.

STBD

°/min

ROT display

Set and Drift display, Distance Run display

Depending on the setting of DISTANCE DISP on the TRIP menu, the Set and

Drift display or the Distance Run display is shown. The Set and Drift display

requires the Doppler Speed Log DS-80 and it shows current direction and

speed.

3D

SOG

211

kt

STW

kt

CURRENT

.

222

36

2

2

.

.

°

.

8

.

2

5

kt

3D

SOG

211

kt

STW

kt

DISTANCE

.

222

2

.

.

54768

.

2

nm

Set and Drift display Speed and Distance Run display

Set and drift display, distance run display

3-4

Page 43

3.5 Alarms

The SC-120 can alert you with audio and visual alarms when GPS data and

DGPS data are lost. To set the alarm mode;

1. Press the [MENU] key to show the menu.

3. OPERATION

MAIN MENU

ALARMS

MESSAGES

GPS SETUP

SYS SETUP

SOFT VER.

OTHERS

SATELLITE

DGPS

I/O SETUP

INST MENU

ERASE

TRIP MENU

Main menu

2. Choose ALARMS and press the [ENT] key.

ALARMS

BUZZER : LONG

DGPS : OFF

HDG RESTORATION: MAN

HDG BACKUP: 5MIN

Alarm menu

3. Press the [ENT] key.

SHORT

LONG

CONSTANT

Alarm menu, GPS buzzer options

4. Use ▲ or ▼ on the Omnipad to choose buzzer type desired.

SHORT: Two short beeps

LONG: Three long beeps

CONSTANT: Continuous beep

5. Press the [ENT] key.

6. Select DGPS, HDG RESTORATION or HDG BACKUP as appropriate.

DGPS: Turns on/off DGPS alarm.

HDG RESTORATION: Choose how to restore GPS signal, automatically

or manually.

HDG BACKUP: Choose how long to wait before stopping output of

heading, when GPS signal is lost.

3-5

Page 44

3. OPERATION

7. Press the [ENT] key.

OFF

ON

DPGS options HDG RESTORATION options

Alarm menu, DGPS buzzer options

7. Select appropriate option. For HDG BACKUP, use ▲ or ▼ on the Omnipad to

set time, from 1 to 5 (minutes).

8. Press the [ENT] key.

9. Press the [DISP] key to close the menu.

3.6 Confirming Satellite Status

You can check the receiving condition of each antenna element as follows:

1. Press the [MENU] key to open the menu.

2. Choose SATELLITE and press the [ENT] key.

Positionfixing

status

North

DOP

MAN

AUTO

RX signal level

Horizontal bar extends

with signal strength.

Satellite whose signal

strength extends past

the first vertical line

is used for heading

calculation.

Elevation

angle 5

˚

Antenna

element

no.

3D

02

10

12

01

GPS1

Elevation

angle 45

08

N

07

06

04

05

Satellites shown in white on black are

˚

used for calculation of heading.

DOP

1. 5

01

02

- -

04

05

06

07

08

- -

10

- -

12

Satellite status display

3. Use ◄ or ► on the Omnipad to choose antenna element for which to confirm

receiving status

4. Press the [DISP] key to close the menu.

3-6

Page 45

3.7 GPS Setup

The GPS SETUP menu smooths position and course, averages speed, applies

position offset, and deactivates unhealthy satellites.

3.7.1 Displaying the GPS setup menu

1. Press the [MENU] key to open the menu.

2. Choose GPS SETUP and press the [ENT] key.

GPS SETUP

SMOOTH POS : 0SEC

SMOOTH S/C : 5SEC

LAT OFFSET : 0.000’N

LON OFFSET : 0.000’E

DISABLE SV :

GPS SETUP menu

3. OPERATION

3.7.2 GPS SETUP menu description

SMOOTH POS (Smoothing position)

When the DOP (Dilution of Precision, the index for position-fixing accuracy) or

receiving condition is unfavorable, the GPS fix may change randomly, even if the

vessel at anchor. This change can be smoothed by averaging a number of GPS

fixes. The setting range is from 0 (no smoothing) to 999 seconds. The setting

range is from 0 (no smoothing) to 999 seconds, and the default is 5 s, which is

good for rolling period o 5-8 s. The higher the setting the more smoothing.

However, too high a setting slows updating of position. “0” is the default setting;

increase the setting if the GPS fix fluctuates largely.

SMOOTH S/C (Smoothing speed/course)

Ship’s speed and course are directly measured by receiving GPS satellite

signals, independent of positions. The data varies with receiving conditions and

other factors. You can reduce this random variation by increasing the smoothing.

The higher the setting the more that speed and course are smoothed. If the

setting is too high, however, the follow-up to actual values gets slower. The

setting range is from 0 (no smoothing) to 999 seconds.

LAT/LON OFFSET (L/L position offset)

If GPS fixes are erroneous while at anchor, enter a position offset to compensate

for position error. Consult a nautical chart to determine latitude and longitude

differences between the chart and GPS display. Enter that value as the offset.

DISABLE SV (Disable satellite)

Every GPS satellite is broadcasting abnormal satellite number(s) in its Almanac,

which contains general orbital data about all GPS satellites. Using this

3-7

Page 46

3. OPERATION

informat ion, the GPS r ec eiver automatically eliminates any malfunctioning

satell ite from the GPS s atellite schedul e. However, the Almanac sometim es m ay

not contain this infor m ation. If y ou hear of an inoperativ e s atellite you ca n

disable it manually. Enter satellite number in two digits and press the [ENT] k ey.

To restore a satellite, ent er “00” .

3.8 Output Data

3.8.1 Heading

Heading data is output from the HDG OUT port on the processor unit, in IEC

61162-1 format. For fur ther details about input / output data ports see page A - 7.

1. Press the [ MENU] key to open the menu.

2. Choose I/O SETUP and pr es s the [ENT]

key to show the OUTPUT DATA SETUP

menu.

3. Press the [ E NT] key to show the HDG

OUT display.

HDT: True heading (require d for radar,

AIS, EC DIS, etc.)

HDM: Magnetic heading

VTG: Course over ground and ground

speed

ZDA: Time and date

GGA: Global pos itioning system (GPS)

fix data

ROT: Rate-of-turn data

VDR: Set and drift

4. Choose item desired and pr es s the [ENT]

key.

5. Choose ON or OFF as appropriate and

press the [ENT] key .

6. Press the [ DISP] key to close the menu.

Note 1: Some b oaters may w ant magnetic head ing when the boat is fitted wi th

only a magnetic compas s without correction of deviation and variat ion.

HDM is obtained in this equipment by adding the magnetic variat ion to

HDT automatical ly.

Note 2: VB W and VHW sentences m us t be inpu t at the HDG IN port to output

the VDR sente nc e.

OUTPUT DATA SETUP

HDG OUT ?

: HDT HDM VTG ZDA

NAV OUT ?

: VTG GGA ZDA GLL

VER :

NMEA

LOG PULSE

HDG TALKER ID: GP

OUTPUT DATA SETUP menu

HDT : ON

HDM : ON

VTG : ON

ZDA : ON

GGA : OFF

ROT : OFF

VDR : OFF

HDG OUT display

VER 2.0

: 200p/nm

HDG OUT

3-8

Page 47

3.8.2 Navigation data

Choose the data to output from the NAV OUT port as follows:

1. Press the [MENU] key.

2. Choose I/O SETUP and press the [ENT] key.

3. Choose “NAV OUT?” and press the [ENT] key.

VTG: Course over ground and ground speed

GGA: Global positioning system (GPS) fix data

ZDA: Time and date

ATT: True heading, pitching, rolling

GLL: Geographic position (latitude and longitude)

ROT: Rate-of-turn data

3. OPERATION

NAV OUT

VTG : ON

GGA : ON

ZDA : ON

ATT : OFF

GLL : ON

ROT : OFF

NAV OUT menu

4. Choose item desired and press the [ENT] key.

5. Choose ON or OFF as appropriate and press the [ENT] key.

6. Press the [DISP] key to close the menu.

3.8.3 Interface

Normally choose IEC for supplying heading information to AIS and radars. If you

are unsure of the version your equipment uses, try all three and choose the one

which successfully outputs data.

1. Press the [MENU] key to open the menu.

2. Choose I/O SETUP and press the [ENT] key.

3. Choose NMEA VER and press the [ENT] key.

OFF

ON

VER1.5

VER2.0

IEC

Format selection window

4. Choose VER 1.5 or VER 2.0 as appropriate and press the [ENT] key.

3-9

Page 48

3. OPERATION

3.8.4 Log pulse

This equipment provides SOG (speed over ground) in high accuracy. It converts

an SOG value to a closure signal and outputs at the rate of 200 or 400

pulses/nm.

1. Press the [MENU] key.

2. Choose I/O SETUP and press the [ENT] key.

3. Choose LOG PULSE and press the [ENT] key.

200p/nm

400p/nm

Log pulse rate selection window

4. Choose 200 p/nm or 400 p/nm as appropriate and press the [ENT] key.

5. Press the [DISP] key to close the menu.

3.8.5 Talker identifier mnemonics

Choose the heading talker ID for the output data sentence HDT and HDM as

follows:

1. Press the [MENU] key.

2. Choose I/O SETUP and press the [ENT] key.

3. Choose HDG TALKER and press the [ENT] key.

GP

HE

HN

HC

Heading talker selection window

4. Choose GP, HE, HN or HC as appropriate and press the [ENT] key. Choose

GP normally. If an external gyrocompass is to be used, choose HC.

GP: GPS Navigator

HE: North-seeking gyrocompass

HN: Non-north seeking gyrocompass

HC: Gyrocompass

5. Press the [DISP] key to close the menu.

3-10

Page 49

3.9 System Setup

3.9.1 Geodetic data

Your unit is preprogrammed to recognize most of the major chart systems of the

world. Although the WGS-84 system (default setting) is the GPS standard, other

categories of charts in other datum still exist. Match the GPS datum with the

chart system.

1. Press the [MENU] key to open the menu.

2. Choose SYS SETUP and press the [ENT] key.

DATUM : WGS84

UNITS : kt

TIME DIFF : +00:00

TIME DISP : 24 HOUR

TEST?

DEMO : OFF

EXCHANGE BATTERY?

3. OPERATION

SYSTEM SETUP

SYSTEM SETUP menu

3. Confirm that the cursor is selecting DATUM and press the [ENT] key.

4. Choose WGS84 (GPS standard), WGS72 or OTHER according to the

nautical chart you use and press the [ENT] key.

5. If you chose WGS72 or WGS84, press the [DISP] key to finish. For OTHER,

go to step 6.

6 Press the [ENT] key.

7. Use the Omnipad to enter chart number, referring to the geodetic chart list on

page A-2. Choose location with ◄ or ►; change value with ▲ or ▼.

8. Press the [ENT] key.

9. Press the [DISP] key to close the menu.

3-11

Page 50

3. OPERATION

3.9.2 Units of measurement

Distance/speed can be displayed in nautical miles/knots, kilometers/kilometers

per hour, or miles/miles per hour.

1. Press the [MENU] key to open the menu.

2. Choose SYS SETUP and press the [ENT] key.

3. Choose UNITS.

4. Press the [ENT] key.

5. Choose unit of measurement combination desired; kt, km/h, mi/h.

6. Press the [ENT] key.

7. Press the [DISP] key to close the menu.

3.9.3 Using local time

GPS uses UTC time. If you would rather use local time, enter the time difference

(range: -13:30 to +13:30) between local time and UTC.

1. Press the [MENU] key to open the menu.

2. Choose SYS SETUP and press the [ENT] key.

3. Choose TIME DIFF and press the [ENT] key.

4. Press ▲ or ▼ to display + or – as appropriate.

5. Enter time difference with the Omnipad. Choose digit with ◄ or ►; change

value with ▲ or ▼.

6. Press the [ENT] key.

7. Press the [DISP] key to close the menu.

3.9.4 Time format

Time can be displayed in 12 hour or 24 hour format.

1. Press the [MENU] key to open the menu.

2. Choose SYS SETUP and press the [ENT] key.

3. Choose TIME DISP and press the [ENT] key.

4. Choose 12HOUR or 24HOUR as appropriate and press the [ENT] key.

5. Press the [DISP] key to close the menu.

3-12

Page 51

3.9.5 Demonstration mode

The demonstration mode provides simulated operation of the equipment.

1. Press the [MENU] key to open the menu.

2. Choose SYS SETUP and press the [ENT] key.

3. Choose DEMO and press the [ENT] key.

4. Choose ON or OFF as appropriate and press the [ENT] key.

5. Press the [DISP] key to close the menu.

The indication SIM appears at the top of the screen when the demonstration

mode is active. When the demonstration mode is first made active,

SIMULATION MODE appears when the power is turned on and it is erased

when any key is pressed.

3.10 DGPS Setup

3. OPERATION

The internal type DGPS receiver is set at the factory for automatic reception. If

you want to set it manually or are using an external beacon receiver, follow the

procedure below. Note that DGPS increases position accuracy fix but it does not

affect heading accuracy.

3.10.1 Manual DGPS setup

1. Press the [MENU] key to open the menu.

2. Choose DGPS and press the [ENT] key.

See Note

DGPS

BEACON : INT

STATION : AUTO

RATE : 000 BPS

FREQ : 000.0 kHz

STATION = - - DGPS DATA = - - SIG. S: 55.2 dB SNR: 22.0 dB

DGPS menu

STATION: Shows GOOD or NG.

DGPS DATA: Shows GOOD or NG.

SIG. S = Signal Strength. A figure between 0 and 99 is shown.

The higher the figure the stronger the beacon signal.

SNR = Signal to Noise Ratio. A figure between 1 and 22 is shown.

When your boat is in the service area of a beacon station, SNR

should be 21 or 22. If the figure is below 18 the position will be

inaccurate. If this happens, check for radar interference, poor

ground and generator noise on own ship.

DGPS Data

3-13

Page 52

3. OPERATION

3. The cursor is on the BEACON field. Press the [ENT] key.

4. Choose appropriate option and press the [ENT] key.

OFF

INT

EXT

Beacon receiver selection window

INT: For internal DGPS beacon receiver.

EXT: For external DGPS beacon receiver

OFF: Disables DGPS function. When OFF is selected it takes about one

minute to find GPS position.

Note: When connecting a FURUNO external DGPS beacon receiver (such

as the GR-80) to the SC-120, turn the GR-80’s remote function on to

set up the beacon receiver with commands from the SC-120. Also set

the external DGPS beacon receiver as follows: Byte Format, 8-6; First

Bit, LSB; Parity Bit, None; Stop Bit, 1; Bit Rate, 8.

5. Press the [ENT] key.

6. Choose DGPS beacon station selection method: AUTO, MANUAL or LIST.

AUTO: Automatically searches for best DGPS beacon station.

MANUAL: Manually enter DGPS beacon station specifications in the RATE

and FREQ fields, referring to a DGPS beacon station list.

LIST: Lists five of the closest DGPS beacon stations, including

user-programmed stations.

7. Press the [ENT] key. If you selected AUTO, no further operation is required;

press the [DISP] key to close the menu. For MANUAL or LIST follow the

appropriate procedure below.

MANUAL

a) The cursor is now on the RATE field. Press the [ENT] key.

b) Choose the data rate of the DGPS beacon station to be used, among 50, 100

or 200 bps. Press the [ENT] key.

c) The cursor is now on the FREQ field. Press the [ENT] key.

d) Enter the transmission frequency of the DGPS beacon station to be used and

press the [ENT] key.

3-14

Page 53

LIST

a) The following display appears after pressing the [ENT] key at step 7.

STATION (NEAREST)

[EXIT] [USER]

310.0 29.1 nm 92

287.0 56.7 nm 134

292.0 160 nm 320

321.0 234 nm 134

302.0 426 nm 121 *

3. OPERATION

Beacon station

frequency

Range and bearing from own

ship to beacon station

(Reference only)

Beacon station display

b) Choose desired station with the Omnipad.

c) Press the [ENT] key.

8. Press the [DISP] key to close the menu.

3.10.2 Programming user beacon stations

The user may program 20 DGPS beacon stations from which to use in selection

of DGPS beacon station. Whenever a new station comes into operation, you can

add it to the list.

1. Press the [MENU] key to open the menu.

2. Choose DGPS and press the [ENT] key.

3. Choose STATION and press the [ENT] key.

4. Choose LIST and press the [ENT] key.

5. Choose USER and press the [ENT] key to show the STATION (USER)

display.

* = User-registered station

STATION (USER)

[EXIT] [NEW?] [CLR?]

01

02

03

04

05

06

STATION (USER) display

6. Choose “NEW?” and press the [ENT] key.

3-15

Page 54

3. OPERATION

NEW USER CHANNEL

FREQ : 310.0kHz

RATE : 200BPS

LAT : 37

LON : 133

EXIT? SAVE?

NEW USER CHANNEL display

Note: For steps 7-10 use the Omnipad to enter data. Choose location with

◄ or ►; change value with ▲ or ▼.

7. Press the [ENT] key, enter frequency of the station, and press the [ENT] key.

8. Press the [ENT] key, enter baud rate of the station, and press the [ENT] key.

9. Press the [ENT] key, enter latitude of the station, and press the [ENT] key.

10. Press the [ENT] key, enter longitude of the station, and press the [ENT] key.

11. Choose “SAVE?” and press the [ENT] key.

12. Press the [DISP] key to close the menu.

3.10.3 Editing user beacon stations

˚

59’N

˚

00’E

1. Press the [MENU] key to open the menu.

2. Choose DGPS and press the [ENT] key.

3. Choose STATION and press the [ENT] key.

4. Choose LIST and press the [ENT] key.

5. Choose USER and press the [ENT] key.

6. Choose a station from the list and press the [ENT] key. The display looks

something like the one below.

FREQ : 310.0kHz

RATE : 200BPS

LAT : 37

LON : 133

EXIT SAVE? ERASE?

˚

59’N

˚

00’E

Display for editing user channels

7. Choose item, press the [ENT] key, edit data, and press the [ENT] key.

8. Choose “SAVE?” and press the [ENT] key.

9. Press the [MENU] key twice to finish.

3-16

Page 55

3.10.4 Erasing individual user stations

1. Press the [MENU] key to open the menu.

2. Choose DGPS and press the [ENT] key.

3. Choose STATION and press the [ENT] key.

4. Choose LIST and press the [ENT] key.

5. Choose USER and press the [ENT] key.

6. Choose a channel from the list and press the [ENT] key.

7. Choose “ERASE?”.

8. Press the [ENT] key to erase channel selected.

3.10.5 Erasing all user beacon stations

1. Press the [MENU] key to open the menu.

2. Choose DGPS and press the [ENT] key.

3. Choose STATION and press the [ENT] key.

4. Choose LIST and press the [ENT] key.

5. Choose USER and press the [ENT] key.

6. Choose CLR? and press the [ENT] key. You are asked if it is all right to erase

all user channels.

3. OPERATION

ERASE ALL?

ARE YOU SURE?

YES NO

Prompt for erasure of all user channels

7. Choose YES and press the [ENT] key to erase all user channels.

3-17

Page 56

3. OPERATION

3.11 OTHERS Menu

The OTHERS menu chooses whether to output last-used heading data, and

smooths rate of turn (rate-of-turn meter required).

1. Press the [MENU] key to display the main menu.

MAIN MENU

ALARMS

MESSAGES

GPS SETUP

SYS SETUP

SOFT VER.