Page 1

OPERATOR'S MANUAL

REMOTE DISPLAY

MODEL

RD-20

www.furuno.co.jp

Page 2

Page 3

IMPORTANT NOTICES

General

• This manual has been authored with simplified grammar, to meet the needs of international users.

• The operator of this equipment must read and follow the descriptions in this manual. Wrong operation or maintenance can cancel the warranty or cause injury.

• Do not copy any part of this manual without written permission from FURUNO.

• If this manual is lost or worn, contact your dealer about replacement.

• The contents of this manual and equipment specifications can change without notice.

• The example screens (or illustrations) shown in this manual can be different from the screens

you see on your display. The screens you see depend on your system configuration and equipment settings.

• Save this manual for future reference.

• Any modification of the equipment (including software) by persons not authorized by FURUNO

will cancel the warranty.

• All brand and product names are trademarks, registered trademarks or service marks of their

respective holders.

How to discard this product

Discard this product according to local regulations for the disposal of industrial waste. For disposal

in the USA, see the homepage of the Electronics Industries Alliance (http://www.eiae.org/) for the

correct method of disposal.

How to discard a used battery

Some FURUNO products have a battery(ies). To see if your product has a battery(ies), see the

chapter on Maintenance. Follow the instructions below if a battery(ies) is used.

In the European Union

The crossed-out trash can symbol indicates that all types of batteries

must not be discarded in standard trash, or at a trash site. Take the

used batteries to a battery collection site according to your national

legislation and the Batteries Directive 2006/66/EU.

In the USA

The Mobius loop symbol (three chasing arrows) indicates that Ni-Cd

and lead-acid rechargeable batteries must be recycled. Take the used

batteries to a battery collection site according to local laws.

Ni-Cd Pb

In the other countries

Cd

There are no international standards for the battery recycle symbol. The number of symbols can

increase when the other countries make their own recycle symbols in the future.

i

Page 4

SAFETY INSTRUCTIONS

Indicates a condition that can cause death or serious

WARNING

CAUTION

Safety Instructions for the Operator Safety Instructions for the Installer

injury if not avoided.

Indicates a condition that can cause minor or moderate

injury if not avoided.

WARNING

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious

injury can occur.

Turn off the power immediately if

water leaks into the equipment or

smoke or fire is coming from the

equipment.

Failure to turn off the equipment can

cause fire or electrical shock.

Contact a FURUNO agent for service.

Keep heater away from the

equipment.

Heat can change the equipment

shape and meltthe power cord, which

can cause fire or electrical shock.

WARNING

Turn off the power at the

switchboard before you install

the equipment.

Fire or electrical shock can occur if

the power is left on.

Be sure that the power supply is

compatible with the voltage rating

of the equipment.

Connection of an incorrect power

supply can cause fire or equipment

damage. The voltage rating of the

equipment appears on the label

above the power connector.

CAUTION

Ground the equipment to

prevent mutual interference.

CAUTION

Do not use the equipment for other

than its intended purpose.

Improper use of the equipment can

affect performance and void the

warranty.

Observe the following compass

safe distances to prevent

interference to a magnetic

compass:

Model

RD-20

RD-501 1.30 m 0.85 m

RD-502 1.00 m 0.65 m

Standard

compass

1.25 m 0.80 m

Steering

compass

ii

Page 5

TABLE OF CONTENTS

FOREWORD................................................................................................................ iv

SYSTEM CONFIGURATION........................................................................................ v

1. OPERATION.......................................................................................................... 1

1.1 Controls ......................................................................................................................1

1.2 How to Turn the Power On and Off............................................................................3

1.3 How to Adjust Display Brilliance................................................................................. 3

1.4 How to Select a Screen.............................................................................................. 4

1.5 How to Select the Units of Measurement ...................................................................8

1.6 How to Select the Display Mode.................................................................................8

1.7 How to Set the User Menu ....................................................................................... 10

2. MAINTENANCE, TROUBLESHOOTING................................................ ............ 12

2.1 Maintenance .............................................................................................................12

2.2 Life of the Parts ........................................................................................................13

2.3 Error Screens ...........................................................................................................13

2.4 Diagnostic Test.........................................................................................................13

2.5 Simulation Mode....................................................................................................... 15

2.6 Parts Location and Parts List.................................................................................... 16

3. INSTALLATION................................................................................................... 18

3.1 Equipment List..........................................................................................................18

3.2 Installation of Remote Display..................................................................................18

3.3 Installation of Remote Controller and Dimmer Controller.........................................20

3.4 Wiring .......................................................................................................................21

3.5 Adjustments..............................................................................................................26

3.6 JIS Cable Guide ....................................................................................................... 29

SPECIFICATIONS.................................................................................................. SP-1

PACKING LISTS .......................................................................................................A-1

OUTLINE DRAWINGS ..............................................................................................D-1

INTERCONNECTION DIAGRAM..............................................................................S-1

iii

Page 6

FOREWORD

A Word to the Owner of the RD-20 Remote Display

Congratulations on your choice of the FURUNO RD-20 Remote Display. We are confident you will

see why the FURUNO name has become synonymous with quality and reliability.

For over 60 years FURUNO Electric Company has enjoyed an enviable reputation for innovative

and dependable marine electronics equipment. This dedication to excellence is furthered by our

extensive global network of agents and dealers.

Your equipment is designed and constructed to meet the rigorous demands of the marine environment. However, no machine can perform its intended function unless properly installed and

maintained. Please carefully read and follow the operation and maintenance procedures set forth

in this manual.

We would appreciate feedback from you, the end-user, about whether we are achieving our purposes.

Thank you for considering and purchasing FURUNO equipment.

Features

The main features of the RD-20 are as shown below.

• Compact remote display features easy-to-view display with red LED.

• The navigation data in digital format with connection of various sensors.

• The size conforms to DIN (Deutsche Industrie Normen) standards, so there is uniformity among

the remote displays of other makers.

• Daisy chain connection is available for connecting a total of 10 RD-20s.

• When you connect multiple RD-20s, their display brilliances can be adjusted together.

Program Number

Program Number Initial Version

RD-20

Starter 2651003-01.xx Aug. 2009

Booter 2651004-01.xx Aug. 2009

Main 2651005-01.xx Aug. 2009

RD-501, RD-502

2651009-01.xx Aug. 2009

xx: minor change

iv

Page 7

SYSTEM CONFIGURATION

r

Single remote display

Remote display

RD-20

UNIT

MODE

RD-20

BRILL

FURUNO

PWR

DISP

12-24 VDC

NMEA0183

sensor signal

Remote controller

Environmental category:

Protected from weather: RD-20, RD-501, RD-502

FURUNO

DISP UNIT

MODE

REMOTE CONTROLLER

RD-501

RD-501

FURUNO

DAY

NT

BRILL

DIMMER CONTROLLER

RD-502

Dimmer controlle

RD-502

v

Page 8

SYSTEM CONFIGURATION

Multiple remote displays (daisy chain connection)

Pattern 1: Sensor signal and dimmer controller are commonly used. A total of 10 RD-20s

can be connected.

RD-20: A (main)

FURUNO

PWR

DISP

12-24 VDC

NMEA0183

sensor signal

RD-20

UNIT

MODE

BRILL

RD-20: B (sub) RD-20: C (sub) RD-20: D (main) RD-20: E (sub)

12-24 VDC

RD-501

FURUNO

DISP UNIT

MODE

REMOTE CONTROLLER

RD-501

RD-502: a

FURUNO

DAY

NT

BRILL

DIMMER CONTROLLER

RD-502

FURUNO

PWR

DISP

RD-20

UNIT

MODE

BRILL

FURUNO

PWR

DISP

RD-20

UNIT

MODE

BRILL

12-24 VDC

RD-501

FURUNO

DISP UNIT

REMOTE CONTROLLER

RD-501

MODE

DISP UNIT

Brilliance for RD-20 A, B and C are

controlled by RD-502 a.

Brilliance for RD-20 D and E are

controlled by RD-502 b.

12-24 VDC 12-24 VDC

RD-501

FURUNO

MODE

REMOTE CONTROLLER

RD-501

FURUNO

PWR

DISP

UNIT

MODE

RD-20

BRILL

RD-501

FURUNO

DISP UNIT

REMOTE CONTROLLER

RD-501

RD-502: b

FURUNO

DAY

NT

DIMMER CONTROLLER

RD-502

MODE

BRILL

FURUNO

PWR

DISP

RD-20

UNIT

MODE

BRILL

RD-501

FURUNO

DISP UNIT

MODE

REMOTE CONTROLLER

RD-501

Pattern 2: Dimmer controller is commonly used. A total of 10 RD-20s can be connected.

RD-20: main

FURUNO

PWR

DISP

12-24 VDC

NMEA0183

sensor signal

RD-20

UNIT

MODE

BRILL

RD-501

FURUNO

DISP UNIT

REMOTE CONTROLLER

RD-20: sub RD-20: sub RD-20: sub RD-20: sub

FURUNO

PWR

12-24 VDC

MODE

RD-501

RD-20

UNIT

DISP

MODE

BRILL

NMEA0183

sensor signal

FURUNO

PWR

DISP

12-24 VDC

RD-20

UNIT

MODE

BRILL

12-24 VDC 12-24 VDC

NMEA0183

sensor signal

RD-20

FURUNO

PWR

UNIT

DISP

MODE

NMEA0183

sensor signal

BRILL

RD-20

FURUNO

PWR

UNIT

DISP

MODE

NMEA0183

sensor signal

BRILL

RD-502

FURUNO

DAY

NT

BRILL

DIMMER CONTROLLER

RD-502

Note: When turning off the power for a RD-20 in the daisy chain connection, the RD-20s which

are connected after that RD-20 can receive neither the sensor signal nor the brilliance signal.

vi

Page 9

1. OPERATION

1.1 Controls

Remote display RD-20

RD-20

PWR DISP UNIT

2 3

1

No. Control Description

1 PWR Turn on/off the power.

2 DISP Switch the screen.

3 UNIT Select the units of measurement for the current screen.

4 MODE Select the mode for the current screen.

5 T, ST: Decrease the display brilliance.

S: Increase the display brilliance.

(See section 1.3 for details.)

How to remove the hard cover

MODE

4

5

Press here with thumb and

pull cover forward.

1

Page 10

1. OPERATION

Remote controller RD-501

2

1

DISP

REMOTE CONTROLLER

UNIT

RD-501

MODE

3

No. Control Description

1 DISP Switch the screen.

2 UNIT Select the units of measurement for the current screen.

3 MODE Select the mode for the current screen.

Dimmer controller RD-502

2

1

DAY

NT

BRILL

DIMMER CONTROLLER

RD-502

No. Control Description

1 DAY/NT Switch the display brilliance between daytime use and nighttime use.

2 T, ST: Decrease the display brilliance.

S: Increase the display brilliance.

2

Page 11

1. OPERATION

1.2 How to Turn the Power On and Off

Press the PWR key to turn on the power.

The start-up screen appears, showing all LED dots and 7-segments. Then, the model name, and

then the results of the ROM and RAM check, OK or NG (No Good), are shown. After the self-tests

are completed, the last-used display appears.

FURUNO

RD-20

8.8.8.8

LED test for dots

and 7-segments

Note: If all dots and 7-segments do not light, or if NG appears as the ROM and RAM check result,

contact your dealer.

To turn off the power, press the PWR key.

.

Model name

ROM

RAM

ROM/RAM test

OK

OK

1.3 How to Adjust Display Brilliance

To adjust the display brilliance, press T, S, or DAY/NT key. The setting range is 0 to 9. "0" is off

and "9" is the brightest.

Operation with main RD-20

The main RD-20 simultaneously controls the display brilliance of the main RD-20 and the sub

RD-20s.

• Controls with T key: Decrease the display brilliance.

• Controls with S key: Increase the display brilliance.

Operation with sub RD-20

When you want to individually adjust the display brilliance for each sub RD-20, do as follows:

• Controls with T key: Decrease the display brilliance. (The variation is smaller than that of the

main RD-20 and RD-502 connected to the main RD-20.)

• Controls with S key: Increase the display brilliance. (The variation is smaller than that of the

main RD-20 and RD-502 connected to the main RD-20.)

Operation with RD-502

The RD-502 simultaneously controls the display brilliance of the main RD-20 and the sub RD-20s.

• Controls with T key: Decrease the display brilliance.

• Controls with S key: Increase the display brilliance.

• Controls with the DAY/NT key: The display brilliance changes as shown in the table below with

every press of the key.

Current setting Setting after key operation Current setting Setting after key operation

00 59

15 62

26 73

37 84

48 95

3

Page 12

1. OPERATION

1.4 How to Select a Screen

Screen

The screen for the RD-20 changes as follows with the DISP key. When you start the RD-20, the

last-used screen appears. Availability of data depends on your system configuration.

Display mode

(AUTO, SOG, STW, GPS)

Direction of ship’s movement

(AFT or : After, FWD or : Forward)

Distance run

Display mode

(AUTO, SOG, STW, GPS)

“A” means AUTO mode.

Distance run

Display mode

(AUTO, SOG, STW, GPS)

“A” means AUTO mode.

Direction of ship’s turn

(S or : Starboard, P or : Port,

No indication: When 0.0 deg/min)

SOG

AFT

AUTO

kn

25.9

Speed (default)

DISP key

23456.7

SOG

N

M

kn

A

25.9

Distance since reset

DISP key

234567.8

SOG

N

M

kn

A

25.9

Total distance

DISP key

ROT

P

deg

/

min

10.6

Rate of turn

DISP key

AUTO appears when display

mode is “AUTO”.

Direction of ship’s movement

( : After, : Forward)

Speed

Underline for total distance screen

Direction of ship’s movement

( : After, : Forward)

Speed

Display mode

(No indication: True,

MAG: Magnetic)

Display mode

(No indication: True,

MAG: Magnetic)

Course over the ground

Display mode

(AUTO, DBK, DBT, DBS)

HDG

MAG

deg

135.4

Heading

DISP key

COG

MAG

deg

132.9

DISP key

DEPTH

DBK

A

m

198.5

Depth

DISP key (cotinued on next page)

“A” means AUTO mode.

4

Page 13

(Continued from previous page)

1. OPERATION

Direction of ship’s turn

(STBD or : Starboard side,

PORT or : Port side,

No indication: When 0.0 or 180.0 deg)

Direction of ship’s turn

(STBD or : Starboard side,

PORT or : Port side,

No indication: When 0.0 or 180.0 deg)

Display mode

(ENGINE or SHAFT)

Direction of ship’s movement

(AH or

: Ahead, AS or -: Astern)

+

Engine/Shaft revolution or Propeller pitch (Select in the user menu.)

Display mode

(T: Theoretical,

R: Relative)

Display mode

(T: Theoretical, PORT: The wind

blows from the port (relative),

STBD: The wind blows from the

starboard (relative), No indication:

When 0.0 or 180.0 deg)

RUDDER

STBD

9.4

Rudder angle

ORDER

STBD

9.4

Rudder angle order

ENGINE

+

3

RPM

150

or

WIND

T

3.1

Wind speed and direction

WIND

T

84.5

Wind direction

P

deg

DISP key

P

deg

DISP key

PITCH

+

DISP key

SPD

kn

DISP key

DIR

deg

DISP key

Current rudder position

(S: STBD (starboard),

P : PORT,

No indication: SINGLE)

Current rudder position

(S: STBD (starboard),

P : PORT,

No indication: SINGLE)

2

%

Number of engine, shaft

or propeller (When 0 is

selected, no indication.)

36

Theoretical: Theoretical

or calculated wind. Wind

direction relative to the

ship’s bow, wind speed

as if the ship is stationary.

Relative: Relative or

apparent wind. Wind

direction relative to the

ship’s bow, wind speed

relative to a moving vessel.

WATER

TEMP

°

C

41.0

Water temperature

DISP key

Go to the Speed screen.

Note: Settings are saved six seconds after you change settings. If you turn off the power right after

you change settings, the last settings are not saved.

5

Page 14

1. OPERATION

List of terms

The following table shows the terms used in the RD-20.

Term Meaning

% Percent

°C Degree(s) Celsius

°F Degree(s) Fahrenheit

1AXIS 1-axis

7-SEG 7-Segment

38.4k 38.4Kbps

4.8k 4.8Kbps

A, AUTO Automatic

AFT After

AH Ahead

ALL All

ARROWS Arrows

AS Astern

AVE Average

BACK Back

BAUD-RATE Baud rate

BOOTER Booter

BRILL Brilliance

CAL Calibration

CH1 Serial Input port, “Channel 1” (RD1A, RD1B)

CH2 Serial Input/Output port, “Channel 2” (RD2A, RD2B, TD2A, TD2B)

ChkSUM Check Sum

CLEAR Clear

COG Course Over the Ground

DATA Data

DAY Daytime

DBK Depth Below Keel

DBS Depth Below Surface

DBT Depth Below Transducer

deg/min degree/minute

DEPTH Depth

DIMMER Dimmer

DIR Direction

DISP Display

DOT Dot-Matrix

ENGINE Engine

ft feet

FWD Forward

GPS Global Positioning System

HDG Heading

KEY Key

km/h Kilometer/hour

kn knot

LED Light Emitting Diode

LOOP Loop

MAG Magnetic: The bearing measured with magnetic north as the reference direction.

MAIN Main

6

Page 15

1. OPERATION

Term Meaning

MENU Menu

mph Miles per hour

m/s Meter/second

NG No Good

NM Nautical Mile

No. Number

NO No

NT Night

OFF Off

OFFSET Offset

OK OK

ON On

ORDER Rudder Angle Order

OUT Output

PITCH Propeller Pitch

P, PORT Port/Port Side

PWR Power

R Relative: Relative or apparent wind. The wind direction relative to the ship’s bow

and the wind speed relative to the moving vessel.

RAM Random Access Memory

RANK Rank of Dot-Matrix LED

ROM Read Only Memory

ROT Rate of Turn

RPM Revolutions Per Minute

RUDDER Rudder/Rudder Angle

SAVE Save

SELECT Select

SET Set

SHAFT Shaft

SIM Simulation

SINGLE Single

S-OUT Sensor Out

SPEED, SPD Speed

SOG Speed Over the Ground

STARTER Starter

STW Speed Through the Water

S, STBD Starboard/Starboard Side

SUB Sub

SYS System

T Theoretical: Theoretical or calculated wind. The wind direction relative to the

ship’s bow and the wind speed as if the ship is stationary.

TEMP Temperature

TEST Test

TEXT Text

TIME Time

UNIT Unit

VECTOR Vector

WATER Water

WIND Wind

YES Yes

7

Page 16

1. OPERATION

1.5 How to Select the Units of Measurement

You can select the units of measurement for speed, distance, depth, wind speed and water temperature.

1. Press the DISP key to display the screen which you want to change the units of measurement.

2. Press the UNIT key to select the unit desired.

• Speed: kn (default), m/s, km/h

• Depth: ft (default), m, fm

• Wind speed: kn (default), m/s, km/h, mph

• Water temperature: °C (default), °F

• Distance: The combinations of the units for distance and speed are as follows:

Distance Speed Remarks

NM kn Default

NM m/s

km m/s

km kn

1.6 How to Select the Display Mode

1. Press the DISP key to display the screen which you want to change the display mode.

2. Press the MODE key to select the display mode desired.

• Speed: AUTO (default), SOG, STW, GPS

In the [AUTO] mode, speed data is displayed in order of priority, SOG, STW and GPS. The

SOG has the highest and GPS has the lowest priority. That is, when SOG, STW and GPS

data are input, the SOG data is displayed. "AUTO" appears at the upper-right corner of the

screen when the [AUTO] mode is active.

Display mode

(SOG: Speed over the ground,

STW: Speed through the water,

GPS: Speed data from the GPS)

SOG/STW: The speed data from the doppler sonar, doppler log, speed log, etc.

GPS: The data from the navigation equipment not described above (mainly, SOG data from

a GPS navigator)

SOG

AUTO

AFT

10.8

kn

“AUTO” indication

• Distance: AUTO (default), SOG, STW, GPS

In the [AUTO] mode, the highest priority data is SOG and the lowest is GPS. "A" appears

after the display mode when the [AUTO] mode is active.

N

M

kn

A

“A” means AUTO mode.

Display mode

234567.8

SOG

25.9

8

Page 17

1. OPERATION

• Heading: True (default, display indication: none), Magnetic (display indication: "MAG")

HDG

Display mode

(No indication: True,

MAG: Magnetic)

• Course over the ground: True (default, display indication: none), Magnetic (display indication: "MAG")

Display mode

(No indication: True,

MAG: Magnetic)

• Depth: AUTO (default), DBK, DBT, DBS

In the [AUTO] mode, the highest priority data is DBK and the lowest is DBS. "A" appears

after the display mode when the [AUTO] mode is active.

MAG

135.4

COG

MAG

30.9

deg

deg

Display mode

(DBK: Depth below keel,

DBT: Depth below transducer,

DBS: Depth below surface)

• Engine/shaft revolution: Select [ENGINE] or [SHAFT] from the user menu. The screen

shows "ENGINE" or "SHAFT" depending on your selection.

Display mode

(ENGINE or SHAFT)

DEPTH

DBK

A

ft

198.5

ENGINE

+

3

RPM

“A” means AUTO mode.

Revolution per minute

150

• Propeller pitch: Select [PITCH] from the user menu. "PITCH" appears on the screen.

Display mode

PITCH

+

2

%

36

• Wind speed: Theoretical (default, display indication: "T"), Relative (display indication: "R")

Display mode

(T: Theoretical,

R: Relative)

WIND

T

SPD

kn

3.1

• Wind direction: Theoretical (default, display indication: "T"), Relative (When the wind blows

from the port, "PORT" is displayed. When the wind blows from the starboard, "STBD" is displayed. When the wind direction is 0.0 or 180.0 degrees, there is no indication of "PORT"

nor "STBD".)

Display mode

(T: Theoretical,

PORT/STBD/no indication: Relative)

WIND

T

84.5

DIR

deg

9

Page 18

1. OPERATION

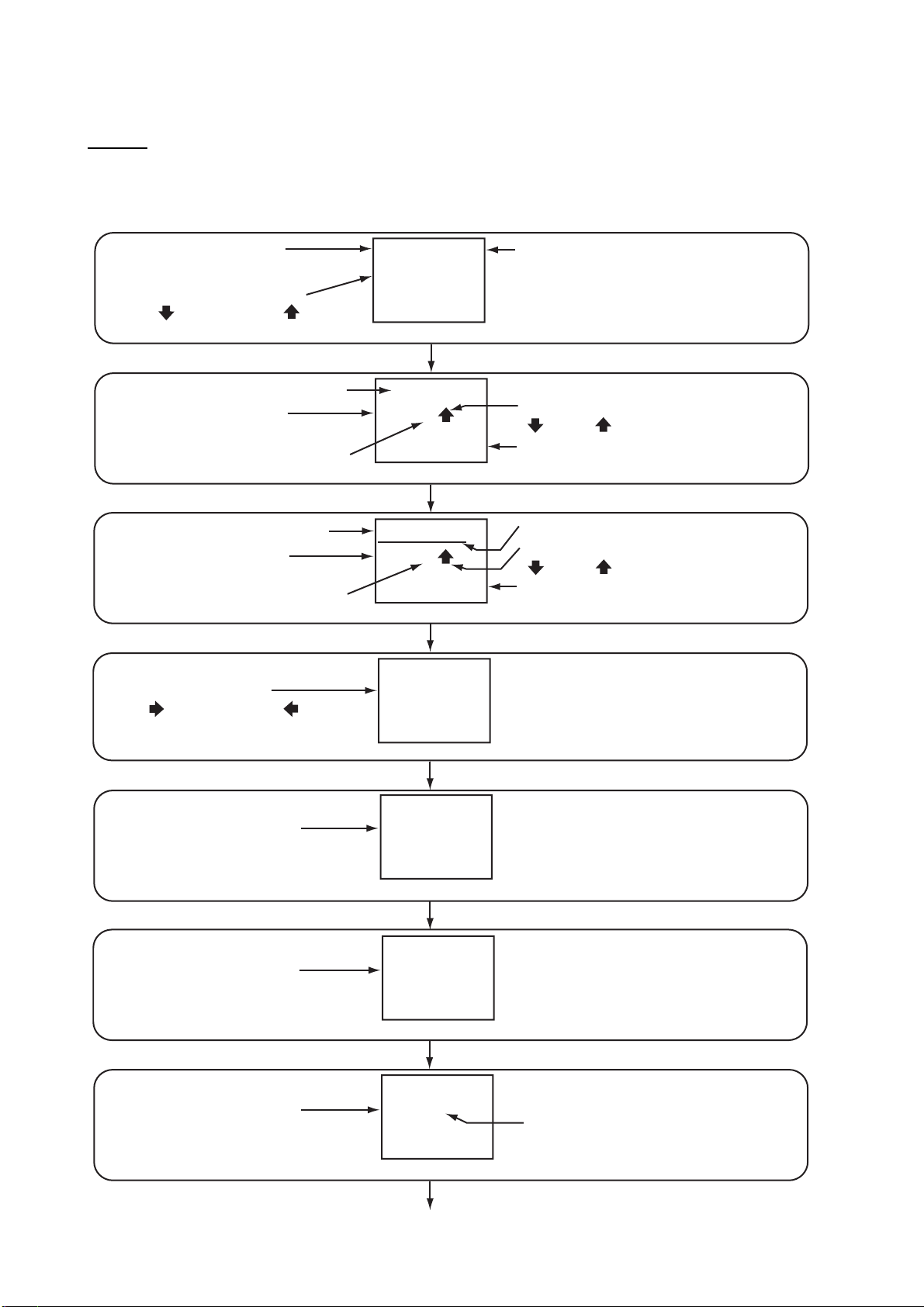

1.7 How to Set the User Menu

The user menu lets you adjust the RD-20 to meet your needs.

No. Menu Description Setting Default

1 KEY LED BRILL Set the brilliance for key LED. 1 to 8 8

2 RPM SET ENGINE

(or SHAFT, PITCH)

3 RPM SET No. Select the number of engine, shaft, or

4 WIND AVE TIME Set the wind averaging time to smooth

5 RUDDER SINGLE (or

STBD, PORT)

6 Direction ARROWS

(or TEXT)

7 DOT LED CAL If there is a difference between the dot8 7-SEG LED CAL -3 to 3 0

Select the engine-related data to show

from [ENGINE], [SHAFT], or [PITCH].

propeller.

wind data. The longer the setting, the

more the data is smoothed. To find the

momentary wind direction and speed, select the shorter time.

Select the mounting location of the rudder from [SINGLE], [STBD] (starboard),

or [PORT].

Select the indication of direction from

[ARROWS] or [TEXT] for speed, ROT

(rate of turn), rudder and engine/shaft/

pitch.

matrix LED brilliance and the 7-segment

LED brilliance, adjust the DOT LED CAL

or 7-SEG LED CAL so that both brilliances are the same. -3 is the darkest and 3

is the brightest.

ENGINE,

SHAFT,

PITCH

0 to 9 0

0, 1, 2, 3,

5, 10 min

SINGLE,

STBD,

PORT

ARROWS,

TEXT

-3 to 3 0

ENGINE

1 min

SINGLE

ARROWS

Setting procedures

1. While you hold down the DISP key, press the PWR key to turn on the power.

2. Press the MODE key or the UNIT key to select the screen desired.

3. Press T or S key to set the value then press the MODE key to save the data and go to the

next screen.

4. After you set all options, the screen for saving data appears. Press the MODE key to save the

data. The equipment restarts.

Note: The user menu is inoperative on the RD-501 and RD-502.

10

Page 19

1. OPERATION

KEY

BRILL

LED

1

Set the brilliance for key LED

using

or key

8

UNIT key

2

Select an item to display among [ENGINE], [SHAFT], or [PITCH].

RPM

SET

ENGINE

key key

RPM

SHAFT

key

UNIT key

RPM

No.

UNIT key

WIND

TIME

UNIT key

5

Select the mounting location of rudder.

RUDDER

SINGLE

key key

RUDDER

STBD

key

UNIT key

6

Select the indication of direction.

Direction

ARROWS

UNIT key

key

key

MODE key

SET

MODE key

SET

0

MODE key

AVE

1

MODE key

MODE key

Direction

TEXT

MODE key

RPM

SET

PITCH

3

Select the number of

engine, shaft or propeller

using

or key

4

Set the wind average

processing time (min)

using

or key

RUDDER

PORT

.

.

.

Dot-matrix

Segment

DOT

LED

CAL

0

UNIT key

7-SEG

CAL

MODE key

LED

0

UNIT key

SAVE DATA

YES

The equipment restarts.

MODE key

MODE

MODE key

11

7

Adjust the dot-matrix

LED brilliance using

or key

8

Adjust the 7-segment

LED brilliance using

or key

Confirmation for

saving data

.

.

Page 20

2. MAINTENANCE, TROUBLESHOOTING

NOTICE

Do not apply paint, anti-corrosive

sealant or contact spray to coating

or plastic parts of the equipment.

Those items contain organic solvents

that can damage coating and plastic

parts, especially plastic connectors.

2.1 Maintenance

Check the following points regularly to maintain performance:

• Check that connections on the rear panel are firmly tightened and free of dust.

• Check that the ground system is free of rust and the ground wire is tightly fastened.

• Remove dust or dirt from the cabinet with a soft, dry cloth. For stubborn dirt, you can use water-

diluted mild detergent. Clean the cabinet with a dry cloth after you use detergent. Do not use

solvents like thinner, acetone or benzene to clean the unit. They can remove paint and indications.

12

Page 21

2. MAINTENANCE, TROUBLESHOOTING

2.2 Life of the Parts

Fuse replacement

The fuse in the remote display protects the equipment from overcurrent and equipment fault. If the

fuse blows, find the cause before you replace the fuse. Use the correct fuse. A wrong fuse can

damage the equipment. See the outline drawings about the location of the fuse.

WARNING

Use the correct fuse.

A wrong fuse can damage the equipment

and cause fire.

Type Code No. Remarks

FGMB 125V 2A PBF 000-157-479-10 12-24 VDC

LED life

The life of the LED is approximately 46,000 hours. The actual number of hours depends on ambient temperature and humidity. The consumption current depends on the number of lighting

LEDs and the LED brilliance.

2.3 Error Screens

When the NMEA sentences are not input or are timed out, the RD-20 displays the following error

screens.

RUDDER

---

Example: Rudder

angle

P

deg

-

.

SPEEDAUTO

kn

--.-

Example: Speed

in [AUTO] mode

DEPTH

DBK

---

Example: Depth

in not [AUTO]

mode

ft

-

.

------

GPS

A

--.-

Example: Total

distance in

[AUTO] mode

N

-

.

M

kn

2.4 Diagnostic Test

The diagnostic test checks the system for correct operation. There are two types of diagnostic

tests; automatic test and key test.

Automatic test

1. While you hold down the UNIT key, press the PWR key to turn on the power.

2. Press the MODE key. The automatic test starts. To stop the test, press the PWR key.

Note: You can extend the display time for a screen by three seconds. Momentarily press any

key (except the PWR key) at the desired screen during the test. You can do this procedure up

to 10 times, that is you can extend the display time to a maximum of 30 seconds.

13

Page 22

2. MAINTENANCE, TROUBLESHOOTING

While holding down the UNIT key,

press the PWR key to turn on the power.

SELECT

Start screen for

automatic test

MODE key (Automatic test starts.)

AUTO

FURUNO

Model name

LED test

pattern 1

RD-20

8.8.8.8

LED test

pattern 2

8.8.8.8

ROM/RAM test

ROM

RAM

OK

OK

LOOPBACK

Serial loopback

test for CH2*

Serial loopback

test for CH1*

*: When loopback test

is OK, “OK” appears.

When loopback test is

NG, there is no indication.

CH2

LOOPBACK

CH1

RD-502

2651009-

.

**: When connecting

RD-501 or RD-502,

program number and

version number are

displayed.

xx.xx

RD-501

2651009-

.

xx.xx

RD-502 program

version**

RD-501 program

version**

MAIN

2651005-

Main program

version

xx.xx

STARTER

Starter program

version

2651003-

xx.xx

xx: Program version number

Test results

• Model name: The model name "RD-20" is displayed.

• LED test (pattern 1 and 2): Check that all LED segments light.

• ROM, RAM: The results of the ROM/RAM test are displayed as OK or NG (No Good). If any NG

is displayed, contact your dealer for instruction.

• Program version (starter, booter, main, RD-501, RD-502): The program version numbers are

displayed.

• Serial loopback test (CH1 and CH2), for field serviceman: A test jumper is required for this test.

The result of the loopback test is displayed as OK or no indication (test not done).

Key test

1. While you hold down the UNIT key, press the PWR key to turn on the power.

2. Press T key once to display the key test screen.

Note: You can not use the T key of the RD-502 at this screen.

BOOTER

2651004-

xx.xx

Booter program

version

14

Page 23

2. MAINTENANCE, TROUBLESHOOTING

3. Press the MODE key.

4. Press each key except the PWR key. You can test up to 10 keys. The key name for the key

pressed and the number of keys remaining to test are displayed. When the count is 0, the start

screen for the key test appears. When testing more than 10 keys, repeat steps 3 and 4.

While holding down the UNIT key,

press the PWR key to turn on the power.

SELECT

Start screen for

automatic test

AUTO

key

SELECT

Start screen for

key test

KEYTEST

MODE key

KEYTEST

10

Any key (for example,

KEYTEST

DISP

5. To stop the test, press the PWR key.

Note: For the remote controller and dimmer controller, "-R" is displayed after the key name except

the DAY/NT key.

2.5 Simulation Mode

The simulation mode, which shows internally generated navigation data, is provided to acquaint

you with the features of the RD-20. "SIM" appears and flashes at the upper-right corner of the

screen when the simulation mode is turned on.

SOG

AFT

DISP key)

9

Any key

SIM

kn

The indication

“SIM” appears.

KEY TEST

UNIT

0

(for example,

UNIT key)

10.8

1. While you hold down the UNIT key, press the PWR key to turn on the power.

2. Press T key twice. The screen for simulation appears.

Note: You can not use the T key of the RD-502 at this screen.

3. Press the MODE key to start the simulation mode.

4. To stop the simulation mode, press the PWR key to turn off the power.

15

Page 24

2. MAINTENANCE, TROUBLESHOOTING

2.6 Parts Location and Parts List

Parts Location

RD-20

26P0009

RD-501/502

Rear side

26P0009

26P0008

Cover opened

RD-501: 26P0012A

RD-502: 26P0012B

Cover opened

16

Page 25

Parts List

2. MAINTENANCE, TROUBLESHOOTING

ELECTRICAL PARTS

PRINTED CIRCUIT BOARD Code No.

26P0008, PNL

26P0009, MAIN

ELECTRICAL PARTS

PRINTED CIRCUIT BOARD Code No.

26P0012A, RMT

ELECTRICAL PARTS

Model

Unit Remote display RD-20

-

-

Model

Unit Remote controller RD-501

-

Model

Unit Dimmer controller RD-502

RD-20

RD-501

RD-502

PRINTED CIRCUIT BOARD Code No.

26P0012B, RMT

-

17

Page 26

3. INSTALLATION

3.1 Equipment List

Standard supply

Name Type Code No. Qty Remarks

Remote Display RD-20 - 1

Installation Materials CP26-01001* 001-076-460-00 1

Accessories FP26-00301* 001-076-470-00 1

Spare Parts SP26-00101* 001-076-450-00 1

Optional supply

Name Type Code No. Remarks

Remote Controller RD-501 - Including CP26-01101*

Dimmer Controller RD-502 - Including CP26-01201*

Hanger OP26-1* 000-016-195-00

*: See the Packing lists.

3.2 Installation of Remote Display

Mounting considerations

The remote display can be installed on a desktop, on the overhead, or flush mounted in a panel.

When you select a mounting location, keep in mind the following points:

• The nominal viewing distance for the display unit is 2.0 m. Select a suitable mounting location

considering that distance.

• Locate the unit away from exhaust pipes and vents.

• Locate the unit out of direct sunlight.

• Select an installation location that is well ventilated.

• Mount the unit where shock and vibration are minimal.

• Locate the unit away from equipment which generates the electromagnetic fields like a motor

or generator.

• Allow enough maintenance space at the sides and rear of the unit. Leave enough slack in cables to facilitate maintenance and servicing.

• Observe the compass safe distances (see page ii) to prevent interference to a magnetic compass.

18

Page 27

3. INSTALLATION

Flush mounting

1. Make a cutout in the mounting location (132 mm (width) x 120 mm (height)).

2. Make four pilot holes for self-tapping screws (diameter: 3 mm) in the location indicated in the

illustration below.

3. Insert the sponge to the remote display from the rear side.

4. Set the remote display to the cutout and fasten the remote display with four self-tapping

screws (M3x15).

5. Set a cosmetic cap to each fixing screw on the front panel. (See “How to set the cosmetic cap”

on page 20.)

131 ± 0.5 (5.16”)

132 ± 1.0 (5.20”)

131 ± 0.5 (5.16”)

Pilot hole for

self-tapping screw

144 (5.67”)

131 ± 0.5 (5.16”)

144 (5.67”)

131 ± 0.5 (5.16”)

120 ± 1.0 (4.72”)

Fixing hole (4-φ4)

for self-tapping screw

12 (0.47”)

74 (2.91”)

104 (4.09”)

Note: If it is more convenient to connect cables before you install the remote display, first connect the cables referring to the section 3.4.

Desktop or overhead mounting

You can mount the remote display on a desktop or on the overhead using the optional hanger

(Type: OP26-1, Code No.: 000-016-195-00).

1. Insert the hanger mounting plate to the remote display from the rear and fasten the hanger

mounting plate from the front of the remote display with four binding head screws (M3x12).

2. Fix the bottom of the hanger to the mounting location with four self-tapping screws (4x16).

3. Insert a washer to each knob (right and left) and fix the knobs to the remote display loosely.

4. Slip the screw parts of the knobs to the slit of the hanger and set the remote display to the

hanger.

5. Tighten the knobs to fasten the hanger to the remote display.

6. Set a cosmetic cap to each fixing screw on the front panel. (See “How to set the cosmetic cap”

on page 20.)

Washer

Binding

head screw

Knob

Hanger mounting plate

Hanger

19

Page 28

3. INSTALLATION

How to set the cosmetic cap

Set a cosmetic cap to each fixing screw on the front panel as shown below.

Set cosmetic cap to hole so cap is flush with panel.

3.3 Installation of Remote Controller and Dimmer Controller

The optional remote controller RD-501 and dimmer controller RD-502 can be flush mounted in a

panel. The size and the mounting procedure are shared by RD-501 and RD-502. For the mounting

location, refer to the mounting considerations for the remote display in section 3.2.

Flush mounting

1. Make a cutout in the mounting location (88 mm (width) x 76 mm (height)).

2. Make four holes of φ4 in the location indicated in the illustration below.

3. Set the remote controller or dimmer controller to the cutout. Insert four binding head screws

(M3x12) from the front side then fasten the unit with four sets of flat washers, spring washers

and hexagonal nuts from the rear side.

88 ± 1.0 (3.46”)

DISP

UNIT

MODE

86 ± 0.5 (3.39”)

76 ± 1.0 (2.99”)

86 ± 0.5 (3.39”)

Fixing hole (4-φ4)

REMOTE CONTROLLER

RD-501

Note: If it is more convenient to connect cables before you install the remote controller or dimmer controller, first connect the cables referring to the section 3.4.

20

Page 29

3.4 Wiring

Interconnection

Refer to the interconnection diagram (page S-1) to connect cables.

Single remote display

Remote display RD-20

12 11 10

9 8 7 6 5 4 3 2 1

12-24 VDC

Sensor signal

+

11

-

12

DPYC-1.5

TTYCS-1 (max. 100 m)

3. INSTALLATION

4

φ

Ground

terminal

Dimmer controller

RD-502

9 8 7 6 5 4 3 2 1

Signal

TD2A

TD2B

Vin

GND

RD-502 RD-501

1 6

2 7

3 8

4 9

TTYCS-4

RD1A

RD1B

Remote controller

RD-501

9 8 7 6 5 4 3 2 1

Signal

RD2A

RD2B

Vout

GND

7

8

Signal

Vin

GND

TD2A

TD2B

4

φ

TTYCS-4

RD-501 RD-20

3 1

4 2

1 3

2 4

IV-1.25sq

To ground terminal

on hull

Signal

Vout

GND

RD2A

RD2B

21

Page 30

3. INSTALLATION

RD-501

RD-502: a

RD-20: A

(Dimmer main)

12-24 VDC

NMEA0183 sensor signal

12-24 VDC

RD-501

RD-20: B

(Dimmer sub)

RD-20: C

(Dimmer sub)

RD-20: D

(Dimmer main)

RD-20: E

(Dimmer sub)

12-24 VDC

RD-501

Multiple remote displays (daisy chain connection)

Pattern 1: Sensor signal and dimmer controller are commonly used. A total of 10 RD-20s

can be connected in a daisy chain. A maximum of nine sub RD-20s can be connected.

NMEA0183 sensor signal

NMEA0183 sensor signal

12-24 VDC

12-24 VDC

RD-20: A

RD-20: A

(Dimmer main)

(Dimmer main)

RD-20

FURUNO

PWR

UNIT

DISP

MODE

BRILL

RD-501

RD-501

FURUNO

DISP UNIT

MODE

REMOTE CONTROLLER

RD-501

RD-502: a

DAY

NT

DIMMER CONTROLLER

RD-502: a

FURUNO

BRILL

RD-502

RD-20: B

RD-20: B

(Dimmer sub)

(Dimmer sub)

RD-20

FURUNO

PWR

UNIT

DISP

MODE

BRILL

12-24 VDC

12-24 VDC

RD-501

RD-501

FURUNO

DISP UNIT

REMOTE CONTROLLER

RD-501

MODE

RD-20: C

RD-20: C

(Dimmer sub)

(Dimmer sub)

RD-20

FURUNO

PWR

UNIT

DISP

MODE

12-24 VDC

12-24 VDC

FURUNO

DISP UNIT

REMOTE CONTROLLER

RD-501

Brilliance for RD-20 A, B and C is

controlled by RD-502 a.

BRILL

RD-501

RD-501

MODE

RD-20: E

RD-20: D

RD-20: D

(Dimmer main)

(Dimmer main)

RD-20

FURUNO

PWR

UNIT

DISP

MODE

BRILL

12-24 VDC 12-24 VDC

RD-20: E

(Dimmer sub)

(Dimmer sub)

RD-20

FURUNO

PWR

UNIT

DISP

MODE

RD-501

FURUNO

DISP UNIT

REMOTE CONTROLLER

RD-501

MODE

FURUNO

DISP UNIT

REMOTE CONTROLLER

RD-501

RD-502: b

FURUNO

DAY

NT

DIMMER CONTROLLER

RD-502

Brilliance for RD-20 D

BRILL

and E is controlled by

RD-502 b.

BRILL

RD-501

MODE

DC

Sensor

Remote display RD-20

(Dimmer main)

12 11 10

9 8 7 6 5 4 3 2 1

FURUNO

DAY

RD-502

NT

BRILL

DIMMER CONTROLLER

RD-502

Signal

TD2A

TD2B

12 11 10

DC

TTYCS-1 (max. 30 m)

FURUNO

DISP UNIT

MODE

REMOTE CONTROLLER

RD-501

RD-501

RD-20 (main) RD-20 (sub)

5 7

6 8

Remote display RD-20

(Dimmer sub)

9 8 7 6 5 4 3 2 1

FURUNO

DISP UNIT

MODE

REMOTE CONTROLLER

RD-501

Signal

RD1A

RD1B

RD-501

22

Page 31

3. INSTALLATION

Pattern 2: Dimmer controller is commonly used. A total of 10 RD-20s can be connected in

a daisy chain. A maximum of nine sub RD-20s can be connected.

DC

Sensor

FURUNO

DAY

NT

DIMMER CONTROLLER

RD-502

Remote display RD-20

(Dimmer main)

1 2 11 10

9 8 7 6 5 4 3 2 1

FURUNO

BRILL

RD-502

DISP UNIT

REMOTE CONTROLLER

RD-501

RD-501

MODE

DC

Sensor

TTYCS-1

Remote display RD-20

(Dimmer sub)

1 2 11 10

9 8 7 6 5 4 3 2 1

Signal

TD2A

TD2B

RD-20 (main) RD-20 (sub)

5 3

6 4

Sensor

Remote display RD-20

(Dimmer sub)

1 2 11 10

9 8 7 6 5 4 3 2 1

DC

TTYCS-1

Signal

RD2A

RD2B

Note: When you turn off the power for a RD-20 in the daisy chain connection, the RD-20s which

are connected after that RD-20 can receive neither the sensor signal nor the brilliance signal.

Connection of each unit

Process each cable referring to the illustrations below and on the next page. The cables shown

are JIS (Japanese Industrial Standard) cables. For the equivalent cables, see section 3.6.

Fabrication of RD-20 power cable DPYC-1.5

RD-20

120

7

Fabrication of sensor signal cable TTYCS-1

RD-20

110

7

Arbitrary

length

Sheath

Vinyl tape

Arbitrary

length

Sheath

Armor

Armor

M4

Shield

90

Vinyl tape

23

Page 32

3. INSTALLATION

r

Fabrication of cable TTYCS-4 between RD-20 and RD-501/5 02

RD-20

x2

M4

Arbitrary

110

7

Shield

70

length

Sheath

Vinyl tape

Armor

RD-501/502

7

x2

M4

50

Shield

65

Arbitrary

length

Sheath

Vinyl tape

Fabrication of cable TTYCS-4 between RD-501 and RD-502

RD-501

7

x2

M4

110

Shield

75

Arbitrary

length

Sheath

Vinyl tape

Armor

RD-502

7

x2

M4

50

Shield

65

Arbitrary

length

Sheath

Vinyl tape

Fabrication of cable TTYCS-1 between RD-20s in daisy chain conn ection

Armor

Armor

RD-20

M4

110

7

Shield

75

Arbitrary

length

Sheath

Vinyl tape

Armor

Connection

Remove the WAGO connector from each unit and connect each cable core to the WAGO connector. See the interconnection diagram (page S-1). The terminal opener is attached inside the remote display at the location shown in the figure below.

WAGO connecto

Terminal opener

Ground terminal

Cable entrance

Remote display, rear panel

24

Page 33

How to connect wires to WAGO connector

Press downward.

Terminal opener

Wire

Twist

Procedure

1. Twist the cores.

2. Press the terminal opener downward.

3. Insert the wire to hole.

4. Remove the terminal opener.

5. Pull the wire to confirm that it is secure.

WAGO connector

3. INSTALLATION

Attach the WAGO connectors (with cables). Bind the sheaths of cables to the fixture with the cable

ties.

25

Page 34

3. INSTALLATION

3.5 Adjustments

After wiring each unit, initialize each remote display as follows:

1. While you hold down the MODE key, press the PWR key to turn on the power.

SYS MENU

NO

Note: If you press the MODE key with this screen shown, the equipment restarts.

2. Press T key to select the screen for [YES].

SYS MENU

YES

3. Press the MODE key. The screen for speed appears.

4. Press T or S key to change the setting.

MODE

MODE

5. Press the MODE key to go to the next screen. Use T or S key to change the setting.

6. Repeat step 5 to set all menus. You can use the UNIT key to return to the previous screen.

7. After you set all menus, press the MODE key with the screen for [ALL CLEAR]. The equipment

restarts.

Note: The system menu is inoperative on the RD-501 and RD-502.

26

Page 35

MODE key + PWR key

3. INSTALLATION

The equipment

restarts.

MODE key

SYS MENU

NO

UNIT key

Default

SPEED

1 AXIS

UNIT key

Default

DIMMER

MAIN

UNIT key

Default

NoChkSUM

Disable

UNIT key

Default

BAUD

-

CH1 4.8k

BAUD

-

CH2 4.8k

MODE

MODE key

MODE key

RATE

UNIT key

RATE

key

key

MODE key

key

key

key

key

key

key

MODE key

key

key

MODE key

key

key

SYS MENU

YES

MODE

SPEED

VECTOR

DIMMER

SUB

NoChkSUM

Enable

BAUD

-

RATE

CH1 38.4k

Default

BAUD

-

RATE

CH2 38.4k

Select [YES] to start

the system menu.

1

Set the speed

([1 AXIS] or [VECTOR]).

2

Select [MAIN] or [SUB].

3

Select whether to

receive the nonchecksum data

or not.

4

Select the baud rate of

CH1 input data and CH2

input/output data.

UNIT key

Default

MODE key

key

S - OUT

ON

UNIT key

DOT

RANK

LED

key

MODE key

Press or key to

set the value. The

setting range is 1 to 3.

1

UNIT key

ALL CLEAR

NO

After saving the settings,

the equipment restarts.

MODE key

MODE

MODE key

key

key

5

Select whether to

S - OUT

OFF

ALL CLEAR

YES

The equipment restarts

with the default settings.

MODE

MODE key

share the sensor

signal or not in

the daisy chain.

6

Set the rank for

LED brilliance.

7

Select whether to

clear settings (restore

default settings) or

not.

27

Page 36

3. INSTALLATION

No. Menu Description Default

1 SPEED • [1 AXIS]: Display FWD/AFT speed.

Forward: FWD (↑), After: AFT (↓)

• [VECTOR]: Do not display the direction of the ship’s movement.

Note: The [VECTOR] speed consists of forward/after speed of

the ship and the influence of tidal current/wind. Requires multiaxis speed data.

2 DIMMER • [MAIN]: Set the unit which is connected to the dimmer con-

troller in the daisy chain connection as the main unit.

• [SUB]: Set the unit which is not connected to the dimmer

controller in the daisy chain connection as a sub unit.

3 NoChkSUM • [Enable]: Receive NMEA0183 sentences with and without

checksums.

• [Disable]: Do not receive NMEA0183 sentences that do not

have checksums.

4 BAUD-RATE • [CH1/2 4.8k]: Select if the CH1 input data or CH2 input/out-

put data is 4.8 Kbps.

• [CH1/2 38.4k]: Select if the CH1 input data or CH2 input/output data is 38.4 Kbps.

5 S-OUT • [ON]: Share the sensor signal in the daisy chain (pattern 1 in

the system configuration).

• [OFF]: Do not share the sensor signal in the daisy chain (pattern 2 in the system configuration).

[1 AXIS]

[MAIN]

[Disable]

[CH1 4.8k],

[CH2 38.4k]

[ON]

6DOT LED

RANK

7 ALL CLEAR • [NO]: Do not clear the settings. Select [NO] and press the

Set the rank for LED brilliance in order to even out the brilliance

of the remote displays in the daisy chain connection. Press T

or S key to set the value. The setting range is 1 to 3. [3] is the

highest ranking.

MODE key. After saving the above setting, the equipment

restarts.

• [YES]: Clear the settings. Select [YES] and press the MODE

key. The equipment restarts with the default settings.

When clearing the settings for RD-20, the following items are

restored to default.

• Settings for the data display (screen mode), display mode,

unit of measurement, direction of the ship, display brilliance

• Settings for the user menu

• Settings for the system menu except the rank for LED brilliance

-

[NO]

28

Page 37

3. INSTALLATION

3.6 JIS Cable Guide

Cables listed in the manual are usually shown as Japanese Industrial Standard (JIS). Use the following guide to locate an

equivalent cable locally.

JIS cable names may have up to 6 alphabetical characters, followed by a dash and a numerical value (example: DPYC-2.5).

For core types D and T, the numerical designation indicates the cross-sectional Area (mm

For core types M and TT, the numerical designation indicates the number of core wires in the cable.

2

) of the core wire(s) in the cable.

2. Insulation Type 1. Core Type

Double core power line

D

Triple core power line

T

1mm Multi core

M

0.75mm twisted pair communications (1Q = quad cable)

TT

4. Armor Type

C

Steel

PY

Ethylene Propylene

5. Shielding Type 6. Core Sheath

Corrosive resistant

YS

1 2 3 4 5 6

DPYCYS - 1.5 EX:

Designation type Core Area (mm )

2

3. Sheath Type

Vinyl

All cores in one sheath

Individually sheathed cores

-S

1 2 3 4

MPYC - 5

Designation type

DPYC

TPYC

MPYC-5

# of cores

TTYCS-4

The following reference table lists gives the measurements of JIS cables commonly used with Furuno products:

Core Cable

Type Area Diameter

Diameter

Type Area Diameter

Core Cable

Diameter

DPYC-1.5 1.5mm

DPYC-2.5 2.5mm

DPYCY-2.5

DPYCYS-1.5

DPYCYS-2.5

MPYC-2

MPYC-4

MPYC-7

MPYCY-12

MPYCY-19

TTYCS-1

TTYCS-1Q

TTYCS-4

TTYCYS-1

2.5mm

1.5mm

2.5mm

1mm

1mm

1mm

1mm

0.75mm

0.75mm 1.11mm

0.75mm 1.11mm

0.75mm 1.11mm

2

1.56mm 11.7mm

2

2.01mm

2

2.01mm 14.8mm

2

1.56mm 14.6mm

2

2.01mm 15.5mm

2

1.29mm 10.0mm

2

1.29mm

2

1.29mm 13.2mm

2

1.29mm 19.0mm

2

1.29mm

2

1.11mm 10.1mm

2

2

2

12.8mm

11.2mm

22.0mm1mm

11.3mm

16.3mm

21.1mm

TPYCY-1.5

TPYCY-2.5

TPYCY-4

TPYCYS-1.5

1.5mm

2.5mm

4mm

1.5mm

2

1.56mm 14.5mm

2

2.01mm 15.5mm

2

2.55mm 16.9mm

2

1.56mm 15.2mm

29

Page 38

FURUNO

RD-20

SPECIFICATIONS OF REMOTE DISPLAY

RD-20

1 REMOTE DISPLAY

1.1 Display type Segment LED and dot matrix (red)

1.2 Brilliance 10 steps (includes ‘OFF’)

1.3 Data indication Ship’s speed, Course, Heading, Distance, Depth, Rate of turn,

Wind direction/speed, Rudder angle, Engine/ shaft RPM,

Propeller pitch, Water temperature

1.4 Remote control Remote controller (option) required

1.5 Remote dimmer Dimmer controller (option) required

1.6 Interface

Remote control Serial, 1 port, 38,400 bps,

5 VDC output (for remote/dimmer controller)

Sensor Input: 1 port, NMEA0183 Ver1.5/2.0/3.0

Daisy chain (for RD-20) Output: 1 port, 38,400 bps

1.7 Data sentences DBK, DBS, DBT, DPT, HDG, HDT, HDM, HTC, HTD, MTW, MWV,

RPM, RMC, ROT, RSA, VBW, VHW, VLW, VTG, VWT, VWR

2 REMOTE CONTROLLER (OPTION)

2.1 Control button DISP, UNIT, MODE

2.2 Interface Serial, Input: 1 port, Output: 1 port, 38,400 bps

5 VDC input (supplied from remote display)

5 VDC output (for dimmer controller)

3 DIMMER CONTROLLER (OPTION)

3.1 Control button DAY/NT, BRILL (▲/▼)

3.2 Interface Serial, Output: 1 port, 38,400 bps

5 VDC input (supplied from remote display)

4 POWER SUPPLY

4.1 Remote display 12-24 VDC: 0.6-0.3 A (includes controller source)

5 ENVIRONMENTAL CONDITION

5.1 Ambient temperature

Remote display -25°C to +55°C

Remote/Dimmer controller -15°C to +55°C

5.2 Relative humidity 95% at 40°C

5.3 Degree of protection IP22, IP56 (optional waterproof box required)

5.4 Vibration IEC 60945

6 UNIT COLOR

N2.5

SP - 1 E4454S01E

Page 39

工事材料表

,

A-1

INSTALLATION MATERIALS

番 号

NO.

1

2

3

4

5

名 称

NAME

Fマウントスポンジ

FLUSH MOUNTING SPONGE

+バインドタッピン1シュ

TAPPING SCREW

コンベックス

CABLE TIE

圧着端子

CRIMP-ON LUG

圧着端子

CRIMP-ON LUG

REMOTE DISPLAY

RD-20

略 図

OUTLINE

CODE NO.

TYPE

型名/規格

DESCRIPTIONS

26-004-1201-0

CODE NO.

3X16 SUS304

CODE NO.

CV-150B

CODE NO.

FV2-4

CODE NO.

FV5.5-4(LF)

CODE NO.

001-076-460-00

CP26-01001

100-350-750-10

000-171-996-10

000-167-183-10

000-157-247-10

000-166-744-10

数量

Q'TY

1

4

9

3

1

26AB-X-9401

用途/備考

REMARKS

-1

1/1

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF THE UPPER PRODUCT.

QUALITY IS THE SAME.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

FURUNO ELECTRIC CO .

LTD.

26AB-X-9401

Page 40

付属品表

,

A-2

ACCESSORIES

番 号

NO.

1

2

名 称

フィルタークリーナー

LCD CLEANING CLOTH

ネジキャップ

CAP

NAME

REMOTE DISPLAY

RD-20

略 図

OUTLINE

CODE NO.

TYPE

型名/規格

DESCRIPTIONS

02-155-1082-1

CODE NO.

26-004-1255-1

CODE NO.

001-076-470-00

FP26-00301

100-332-651-10

100-353-651-10

数量

Q'TY

1

4

26AB-X-9501

用途/備考

REMARKS

-1

1/1

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF THE UPPER PRODUCT.

QUALITY IS THE SAME.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

FURUNO ELECTRIC CO .

LTD.

26AB-X-9501

Page 41

SHIP NO.

A-3

CODE NO.

TYPE

SPARE PARTS LIST FOR U S E

REMOTE DISPLAY

RD-20/RD-50,DS-600

001-076-450-00

SP26-00101

26AB-X-9301

BOX NO. P

SETS PER

VESSEL

-1

1/1

ITEM

NO.

1

NAME OF

PART

ヒューズ

GLASS TUBE

FUSE

OUTLINE

DWG. NO.

OR

TYPE NO.

FGMB 125V 2A

PBF

QUANTITY REMARKS/CODE NO.

WORKING

PER

PER

SET

SPARE

VES

2

000-157-479-10

MFR'S NAME

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品

質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF

THE UPPER PRODUCT. QUALITY IS THE SAME.

FURUNO ELECTRIC CO.,LTD.

DWG NO.

26AB-X-9301

1/1

Page 42

工事材料表

,

A-4

INSTALLATION MATERIALS

番 号

NO.

1

2

3

4

5

6

7

名 称

NAME

コンベックス

CABLE TIE

圧着端子

CRIMP-ON LUG

圧着端子

CRIMP-ON LUG

六角ナット 1シュ

HEXAGONAL NUT

ミガキ丸平座金

FLAT WASHER

バネ座金

SPRING WASHER

+バインドコネジ

BINDING HEAD SCREW

REMOTE CONTROLLER

RD-501

略 図

OUTLINE

CODE NO.

TYPE

型名/規格

DESCRIPTIONS

CV-150B

CODE NO.

FV2-4

CODE NO.

FV5.5-4(LF)

CODE NO.

M3 SUS304

CODE NO.

M3 SUS304

CODE NO.

M3 SUS304

CODE NO.

M3X12 SUS304

CODE NO.

001-076-990-00

CP26-01101

000-167-183-10

000-157-247-10

000-166-744-10

000-167-477-10

000-167-453-10

000-167-404-10

000-171-998-10

数量

Q'TY

4

1

2

4

4

4

4

26AC-X-9401

用途/備考

REMARKS

-1

1/1

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF THE UPPER PRODUCT.

QUALITY IS THE SAME.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

FURUNO ELECTRIC CO .

LTD.

26AC-X-9401

Page 43

工事材料表

,

A-5

INSTALLATION MATERIALS

番 号

NO.

1

2

3

4

5

6

7

名 称

NAME

コンベックス

CABLE TIE

圧着端子

CRIMP-ON LUG

圧着端子

CRIMP-ON LUG

六角ナット 1シュ

HEXAGONAL NUT

ミガキ丸平座金

FLAT WASHER

バネ座金

SPRING WASHER

+バインドコネジ

BINDING HEAD SCREW

DIMMER CONTROLLER

RD-502

略 図

OUTLINE

CODE NO.

TYPE

型名/規格

DESCRIPTIONS

CV-150B

CODE NO.

FV2-4

CODE NO.

FV5.5-4(LF)

CODE NO.

M3 SUS304

CODE NO.

M3 SUS304

CODE NO.

M3 SUS304

CODE NO.

M3X12 SUS304

CODE NO.

001-077-000-00

CP26-01201

000-167-183-10

000-157-247-10

000-166-744-10

000-167-477-10

000-167-453-10

000-167-404-10

000-171-998-10

数量

Q'TY

2

1

1

4

4

4

4

26AC-X-9402

用途/備考

REMARKS

-1

1/1

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF THE UPPER PRODUCT.

QUALITY IS THE SAME.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

FURUNO ELECTRIC CO .

LTD.

26AC-X-9402

Page 44

REMOTE DISPLAY

A-6

CODE NO.

TYPE

000-016-195-00

OP26-1

-0 26AB-X-9402

1/1

明細書

DESCRIPTION

番 号

NO.

+トラスタッピンネジ 1シュ

1

SELF-TAPPING SCREW

+バインドコネジ

2

BINDING HEAD SCREW

ハンガー組品

3

HANGER ASSY.

名 称

NAME

RD-20

略 図

OUTLINE

型名/規格

DESCRIPTIONS

4X16 SUS304

CODE

NO.

M3X12 SUS304

CODE

NO.

OP26-1-1

CODE

NO.

000-162-605-10

000-171-998-10

001-076-490-00

数量

Q'TY

4

4

1

用途/備考

REMARKS

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりませ

ん。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF THE UPPER

PRODUCT. QUALITY IS THE SAME.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

FURUNO ELECTRIC CO .,LTD.

26AB-X-9402

Page 45

9/Jun/09R.Esumi

D-1

Page 46

9/Jun/09R.Esumi

D-2

Page 47

9/Jun/09R.Esumi

D-3

Page 48

9/Jun/09R.Esumi

D-4

Page 49

1

S-1

23

1) NMEAデータを共有する場合 TO USE NMEA DATA JOINTLY

リモートディスプレイ

REMOTE DISPLAY

RD-20

A

IV-1.25sq.

12-24VDC

NMEA0183

RD-20

*3

RD1A

RD1B

12

*1

DPYC-1.5 *1

TTYCS-1 *1

7

8

Vout

GND

RD2A

RD2B

TD2A

TD2B

RD1A

RD1B

DC_H

DC_C

NC

NC

P

1

2

3

4

5

6

7

8

9

10

11

12

TTYCS-1

P

P

P

P

*1

B

TTYCS-4

*1

1

MAX.30m

(W/O RD-501)

*1

TTYCS-4

TD2A

2

TD2B

3

Vin

4 GND

5NC

6

RD2A

7

RD2B

8

Vout

9 GND

TD2A

1

TD2B

2

Vin

3

4 GND

9

リモート操作部

REMOTE

CONTROLLER

9

RD-501

*2

IV-1.25sq.

調光器

DIMMER

9

CONTROLLER

RD-502

IV-1.25sq.

*1

*2

*1

2) 調光制御のみを共有する場合 TO USE DIMMER CONTROL ONLY JOINTLY

リモートディスプレイ

REMOTE DISPLAY

RD-20

12

C

*1

IV-1.25sq.

Vout

GND

RD2A

RD2B

TD2A

TD2B

RD1A

RD1B

DC_H

DC_C

1

P

2

3

P

4

5

P

6

7

P

8

9

NC

10

NC

11

12

TTYCS-4

*1

TTYCS-1

DPYC-1.5

同上

DITTO

*1

NMEA0183

*1

12-24VDC

RD-20

注記

D

*1)造船所手配。

*2)オプション。

*3)メニューより設定変更が必要。

NOTE

*1: SHIPYARD SUPPLY.

*2: OPTION.

*3: CHANGE SETTING FROM MENU.

DRAWN

31/Jul/09

CHECKED

31/Jul/09

APPROVED

SCALE

DWG.No. REF.No.

4/Sep/09R.Esumi

C4454-C01- B 26-004-0001-1

T.YAMASAKI

T.TAKENO

MASS

kg

RD2A

RD2B

TD2A

TD2B

RD1A

RD1B

DC_H

DC_C

P

P

P

TTYCS-1 *1

TTYCS-1 *1

TTYCS-1 *1

DPYC-1.5 *1

RD-20

NMEA0183

12-24VDC

TITLE

名称

RD-20

リモートディスプレイ

3

4

5

6

7

8

11

12

相互結線図

NAME

REMOTE DISPLAY

INTERCONNECTION DIAGRAM

Page 50

Page 51

Page 52

Thepaperusedinthismanual

9‑52Ashihara‑cho,

Fax:

A:OCT

2009

.

B:FEB.25,2010

Pub.No.

(

)

*

00017201211

**00017201211

*

Nishinomiya,662‑8580,JAPAN

Telephone: +81‑(0)798‑65‑2111

+81‑(0)798‑65‑4200

iselementalchlorinefree.

・FURUNOAuthorizedDistributor/Dealer

Allrightsreserved.

YOTA

RD‑20

PrintedinJapan

OME‑44540‑B

*00017201211**00017201211*

*00017201211*

Loading...

Loading...