Page 1

Page 2

HYDRAULIC LINEAR ACTUATOR

LA11

TABLE OF CONTENTS

1. GENERAL INFORMATION ............................................... p. 01

2. TECHNICAL SPECIFICATIONS and APPLICATION ........ p. 02

3. DESCRIPTION ................................................................. p. 03

3.1 General

3.2 Pump Unit (HRP11)

3.3 Reservoir/Bypass Assembly

3.4 Steering Cylinder

4. INSTALLATION ................................................................. p. 05

4.1 Mechanical

4.2 Hydraulic

4.3 Electrical

5. NOTES ............................................................................. p. 07

6. DRAWINGS ..................................................................... p. 08

6.1 LA11 — Assembly Schematic

6.2 LA11 — System Connection Schematic

i

Page 3

1. GENERAL INFORMATION

The Accu-Steer LA11 unit is a hydraulic linear actuator designed

to interface an autopilot system with a mechanical steering systems such as wire, cable or chain drives. A hydraulic linear actuator consists of a hydraulic drive unit (containing a pump unit,

bypass valve and reservoir assembly), a steering cylinder and the

interconnecting hoses.

One end of the cylinder is xed and the other end is connected to

a tiller arm or the mechanical quadrant, which is connected to a

rudder shaft. With this connection to a tiller arm the linear movement of the cylinder is changed to rotary movement, which turns

the rudder and steers the vessel.

During normal mechanical steering, the hydraulic steering cylinder

strokes to port and starboard as the vessel is steered manually.

The oil in both sides of the cylinder ows back and forth through

a normally open bypass valve located in the linear actuator drive

unit. The steering cylinder is connected to the drive assembly with

two hoses (port and starboard). When the autopilot is switched into

the operating mode, the bypass valve is electrically closed. The

autopilot then drives the reversing hydraulic pump which in turn

operates the steering cylinder. See section 3 of this manual for a

more in depth description.

When the autopilot is operating, the cylinder with be turning the

rudder. The mechanical steering will be back-driven during this

time. The vessel’s steering wheel will be turning as the autopilot

makes corrections.

The Accu-Steer HRP11 is the reversing pump unit used in the LA11

linear actuator. The output ow rate of the pumpset determines the

speed of the steering cylinder. The HRP11 pump outputs 1.0 cu

in/sec or 16.4 cc/sec.

The BA150 X 9 is a balanced steering cylinder, which means the

volume of oil on both sides of the cylinder is equal. The volume of

this steering cylinder is 13 cu in (215 cc) of oil.

p01

Page 4

2. TECHNICAL SPECIFICATIONS and APPLICATION

Model Number LA11-12 LA11-24

Voltage 12 VDC 24 VDC

Output/Sec 1 cu in/sec 1.0 cu in/sec

Average Motor Amp 3-6 2-4

Solenoid Valve Amp 1.5 AMPS .75 AMP

Weight 15 lbs (7 kgs) 15 lbs (7 kgs)

The output of the hydraulic reversing pump is 1.0 cu in/sec. The

volume of the steering cylinder is approximately 13.1 cu in (215 cubic centimeters). The rudder speed will be approximately 13 seconds hard over to hard over (HOH).

The rudder speed, hard over to hard over (HOH), is determined

by dividing the volume (cu in) of the cylinder by the output of the

pumpset (cu in/sec).

The steering cylinder is capable of approximately 785 lbs of thrust

based on an output of 500 psi from the pump. The force or torque

applied to the rudder through the rudder shaft is dependent of the

distance between the center of the rudder shaft and the position

of the tiller bolt.

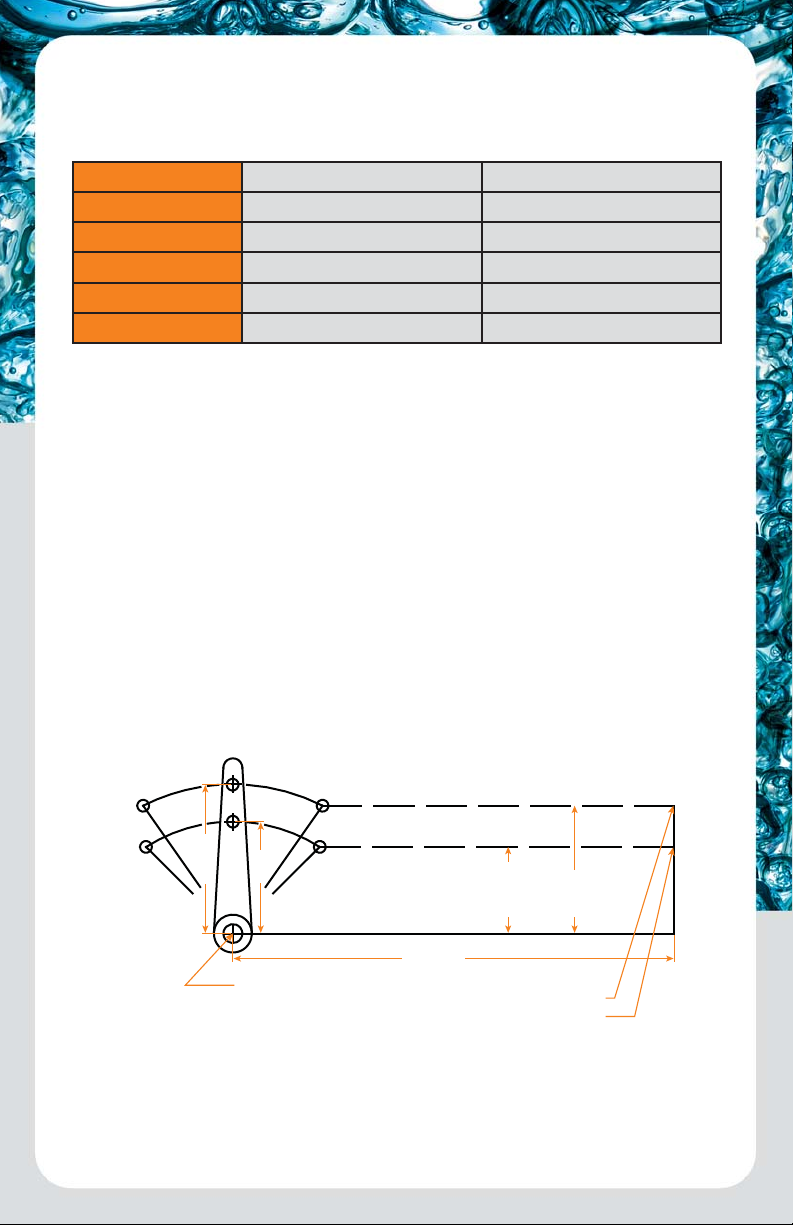

Figure 2 CYLINDER SCHEMATIC

35°

PORT

45°

PORT

7.875"

TILLER ARM

RUDDER SHAFT

6.0"

35°

PORT

45°

PORT

4.5625"

23.25"

35° TRUNNION CENTER

45° TRUNNION CENTER

6.75"

Distance (rudder shaft to tiller bolt): 6” = 4,710 in/lb; 7” = 5,495 in/lb;

8” = 6,280 in/lb; 9” = 7,065 in/lb. The torque required to turn the rudder

can be calculated or obtained from the vessel’s builder.

p02

Page 5

3. DESCRIPTION OF OPERATION

3.1 GENERAL

The Accu-Steer LA11 is a complete linear actuator drive unit.

It consists of a reversing gerotor gear pump, hydraulic lock

valves, suction make-up check valves, a valve housing manifold, an electric permanent magnet motor, an electric solenoid

bypass valve and an oil reservoir.

Figure 3.1 HYDRAULIC SCHEMATIC

STARBOARD PORT

79

5

“A”

2

DC

MOTOR

10

8

43

1

6

“B”

During normal mechanical steering the cylinder is stroked both

ways as driven by the mechanical steering system. The oil in

the cylinder is bypass through the normally open (NO) solenoid

valve (10). When the autopilot becomes active it closes the

solenoid valve (clutch/bypass or switched power output). The

autopilot then drives the hydraulic reversing pump (2).

p03

Page 6

The HRP (Hydraulic Reversing Pumpset) operates as follows:

As the motor (1) rotates CCW, oil from the gear pump (2) is

pumped towards output “A”. This oil passes through the check

valve (5) and goes to the line output (7). The oil pushes the cylinder in the port direction. The pressure at output “A” ensures

the check valve (3) stays closed and manually opens check

valve (6). Opening check valve (6) allows the returning oil from

the steering cylinder to ow back to the pump. If the pressure

at the pump suction “B” is less than the weight of the oil in the

reservoir (8) then the oil in the reservoir will pass by the check

valve (4). This prevents cavitation due to any air that may be

in the steering line. When the pump stops turning all springloaded check valves return to the normally closed position.

When the motor (1) rotates (CW) the reverse movement of the

oil and valves takes place.

3.2 PUMP UNIT (HRP11)

The electric motor has the following features:

t Ignition protected (UL 1500 and SAE-1171)

t Ball bearing shaft supports both ends

t Cushioned foot mounts for quiet operation

t Opposite end shaft mount for tachometer/encoder

The valve block is an aluminum block, precision machined to

house the valves, direct the oil and serve as the endplate for

the gear pump. The output check valves are part of what is

called a lockvalve assembly.

The lockvalve assembly consists of two output check valves

and a lockvalve spool. In the non-running position the spring

operated check valves remain closed, isolating the pump from

the steering system. The spring action of the check valves

holds the lockvalve spool in the mid-closed position.

3.3 RESERVOIR/BYPASS ASSEMBLY

The reservoir unit is machined out of solid aluminum and pro-

vides approximately 11.5 cu in of oil for oil make-up. The solenoid bypass valve is located in the same aluminum housing.

It is a normally open valve and switches to the closed position

when energized by the autopilot. The valve returns to the normally open position when the autopilot is switched into the

standby mode or if there was a loss of power to the autopilot.

p04

Page 7

Oil passages are machined as large as possible to minimize

any restrictions which may effect manual steering.

3.4 STEERING CYLINDER

The brass steering cylinder is engineered and manufactured

for heavy duty marine usage and is suitable for commercial

and pleasure boat applications. The cylinder has a 1-1/2” bore

and a 9” stroke. The trunnion mount (xed end) and the ball

joint allow for about 10 degrees of articulation. The cylinder is

shipped full of oil and is also equipped with bleed ttings.

4. INSTALLATION

4.1 MECHANICAL

The linear actuator drive unit must be mounted on a horizontal

shelf or bracket with a solid foundation. The unit can be bolted

or screwed down with the motor feet and the foot bracket.

The mounting brackets are tted with anti-vibration mounts

to maintain the quiet operation of the pumpset. The drive unit

should be mounted above the steering cylinder if possible to

assist in the system bleeding.

Proper cylinder installation is the key to the successful op-

eration of the linear actuator. An incorrectly installed cylinder

is subject to rapid seal and bearing wear and non-repairable

damage. Minimum side loading of the cylinder rod and maximum cylinder performance can be achieved as follows.

An imaginary line drawn through the tiller arm hole at both hard

over positions will create the cylinder center line, see Figure

4.1. The distance between X and Y must be less than 9” so

that the cylinder doesn’t act as an end stop for the rudder.

Figure 4.1 CYLINDER SCHEMATIC

CENTER LINE FOR CYLINDER MOUNT

XY

TILLER ARM SHOWN IN THE HARD

OVER AND MIDSHIP POSITIONS

p05

Page 8

In a new installation, mechanical stops can be installed after

the cylinder. For retro-t applications, use Figure 4.1 as a reference to ensure the ends of the cylinder travel are outside the

stops. Mount cylinder with the ttings in the up direction.

4.2 HYDRAULIC

The unit is shipped full of oil with a sealed plug in the top of the

reservoir cover. A vented breather cap is supplied with the unit.

The vented cap must be installed in place of the plug after the

drive unit has been mounted. The oil in the LA11 is standard

hydraulic oil (ISO-32).

If the hydraulic lines are removed during installation, be sure to

cap them to minimize the loss of oil. Located on the top of the

valve/reservoir block is a small bleed tting. This tting can be

used add oil to the port and starboard lines or bleed air from

the system. If the cylinder is mounted properly, the cylinder

can be manually stroked and the air will collect at the bleed

tting. Be sure to re-install this plug before using the LA11 as

it is part of the steering line.

The oil reservoir should be maintained at least 3/4 full. During

bleeding and lling this level should be maintained.

It is not critical to identify which of the steering lines is port

or starboard as most new autopilots will determine the pump

direction and program the drive outputs to suit. For older autopilots the motor leads can be reversed to change the pumps

direction.

4.3 ELECTRICAL

The motor is a permanent magnet style motor, ignition pro-

tected, built to conform to UL-1500 and SAE-1171 standards.

Two leads connect to the autopilot pump driver junction box

(processor), the direction of the pumpset can be reversed by

simply reversing the polarity of these two leads.

The solenoid valve is connected to the autopilot junction box.

It is usually referred to as clutch/bypass or switched power.

The polarity of the solenoid valve does not matter.

To test the operation of the LA11 pumpset, touch the two leads

from the motor to the supply voltage (12 VDC or 24 VDC) to jog

the motor in one direction and then reverse the leads to jog the

pumpset in the other direction. Do not to perform this opera-

tion where any combustible fumes exist.

p06

Page 9

5. NOTES

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

....................................................................................................................

p07

Page 10

6. DRAWINGS

6.1 LA11 ASSEMBLY SCHEMATIC

FILLER

CAP

6.375”

5.25”

MOTOR

LEADS

BYPASS VALVE

SOLENOID LEADS

SIDE VIEW

VALVE

BYPASS

8”

3.5”

MOTOR

LEADS

FILLER

CAP

BYPASS VALVE

SOLENOID LEADS

TOP VIEW

BYPASS

VALVE

p08

Page 11

6.2 LA11 SYSTEM CONNECTION SCHEMATIC

INTERCONNECT HOSES (3 FEET)

BA150 X 9

STEERING CYLINDER

RUDDER SHAFT

p09

TOP

VIEW

FILLER

CAP

MOTOR

LEADS

BYPASS

VALVE

SOLENOID LEADS

BYPASS VALVE

Page 12

Loading...

Loading...