Page 1

DOPPLER SPEED LOG

Marine Speed and Distance Measuring Equipment (SDME)

DS-80

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080889601**00080889601*

*00080889601**00080889601*

*OME72470M10**OME72470M10*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. OME-72470OME-72470

Printed in JapanPrinted in Japan

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION : FEB.FEB. 20002000

M1M1 :: FEB.FEB. 12,200312,2003

(( DAMIDAMI ))

DS-80DS-80

* 0 0 0 8 0 8 8 9 6 0 1 ** 0 0 0 8 0 8 8 9 6 0 1 *

*OME72470M10**OME72470M10*

* O M E 7 2 4 7 0 M 1 ** O M E 7 2 4 7 0 M 1 *

Page 3

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

Immediately turn off the power at the

switchboard if water leaks into the

equipment or an object is dropped into

the equipment.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Do not place liquid-filled containers on

the top of the equipment.

Fire or electrical shock can result if the

liquid spills into the equipment.

Do not disassemble or modify the

equipment.

CAUTION

Do not use the equipment for other than

its intended purpose.

Improper use of the equipment can result

in personal injury or equipment damage.

Turn off the equipment immediately if

you feel it is abnormal.

Turn off the power from the switchboard if

the equipment is emitting strange noises

or becomes excessively hot. Contact your

dealer for advice.

The useable ambient temperature range

is 15

°

C to 55°C.

Do not use the equipment out of the

above temperature range.

Do not place objects around the

equipment.

Overheating may result.

Fire, electrical shock or serious injury can

result.

Keep the equipment away from rain

and water splash.

Fire or electrical shock can result if the

rain or water gets into the equipment.

Do not operate the equipment with wet

hands.

Electrical shock can result.

Keep heater away from equipment.

A heater can melt the equipment's power

cord, which can cause fire or electrical

shock.

Use the proper fuse.

Fuse rating is shown on the equipment.

Use of a wrong fuse can result in damage

to the equipment.

Do not power the equipment when the

transducer is in air.

The transducer may become damaged.

Handle all units carefully.

Damage can lead to corrosion.

Do not use chemical cleaners such as

alcohol, acetone and benzine to clean

the equipment.

Chemical cleaners can remove paint and

markings. Use only a soft, dry cloth. For

stubborn dirt, use a soft cloth moistened

with water-diluted mild detergent.

When dry docked remove marine life

from the transducer.

Remove marine life to maintain good

sensitivity.

Do not paint the transducer face.

Further, handle the transducer with

care.

Paint will affect equipment performance.

i

Page 4

WARNING LABEL

A warning label is attached to the

Distributor, Transceiver and Terminal

Box. Do not remove the labels. If a

label is missing or is illegible, contact

a FURUNO dealer or agent about

replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label (1)

Type: 86-003-1011-0

Code No.: 100-236-230

RECORD OF MODIFICATIONS IN THIS OPERATOR’S MANUAL

Pub No. Software (Prog. No.)

Publicized for submission to type

test BSH

Apr/2000

Publicized for submission to type

test BSH

June/2000

03I-02J-02K

(DS-800, DS-801,

DS-810)

6550100003I (DS-800)

6550110003J (DS-801)

6550120003K

(DS-810)

Modified to conform to IEC

61162-1 Edition 2

2002/4

DS-800: 6550100004

DS-801: 6550110003

DS-810: 6550120003

Outline of changes in

Operator’s Manual

ii

Page 5

TABLE OF CONTENTS

SPECIFICATIONS .......................SP-1

FOREWORD...................................... 1

SYSTEM CONFIGURATION............. 2

PRINCIPLE OF OPERATION............ 3

REMARKS ON USAGE..................... 4

1 OPERATION OF DISPLAY UNIT . 5

1.1 Controls........................................... 5

1.2 Turning the Power On/Off................ 5

1.3 Adjusting Contrast, Panel Dimmer... 6

1.4 Selecting a Display.......................... 6

1.5 Main Menu Operation...................... 7

1.6 Distance Run Operation.................. 7

1.7 System Setting ................................ 9

1.8 Demonstration Mode...................... 11

2 OPERATION OF OPTIONAL

EQUIPMENT ..............................12

2.1 Digital Indicator DS-830, Distance

Indicator DS-840............................12

3 MAINTENANCE,

TROUBLESHOOTING................14

3.1 Maintenance.................................. 14

3.2 Troubleshooting ............................. 15

3.3 Diagnostics, Checking

Program Number ...........................16

4 DIGITAL INTERFACE

(IEC 61162-1 Edition 2)..............17

4.1 I/O Sentences ................................ 17

4.2 Sentence Description..................... 20

5 PARTS LOCATION AND

PARTS LIST................................23

Parts Location......................................23

Parts List..............................................25

CALIBRATION SHEET....................29

MENU OVERVIEW..........................30

INDEX..................................... Index-1

Declaration of conformity

iii

Page 6

This page is intentionally left blank .

Page 7

SPECIFICATIONS OF THE DOPPLER SPEED LOG

DS-80

1. GENERAL

(1) Speed Range Fore-Aft: -10.0 to +40 knots through-the-water

(2) Distance Run 0.00 to 999,999.99 nautical miles through-the-water

(3) Working Depth Water depth greater than 3 m beneath the keel.

(4) Worki ng Frequency 1 .0 MHz

(5) Speed Accuracy 1.0% or 0.1 knots whichever is the greater

(6) Distance Accuracy 1.0% or 0.1 nm whichever is the greater

Note : Accuracy is subject to shallow water effects, to the effect of wind , current and tide, and

sensor location. Any ultrasonic equipment having the same frequency may interfere with

speed measurement. The Doppler Log transducer should be installed apart from the

transducers of such kind of equipment.

2. DISPLAY UNIT

(1) Display Character size 15 or 21 mm H on monochrome LCD

(2) Indication

Ship’s speed Fore: c**.* knots (+40.0 kt ma x.)

Aft: d**.* knots (-10.0 kt max.)

Distance run ******.** nm

(3) Other Function Diagnostic check

3. DIGITAL INTERFACE

(1) Serial Signal

Output: 2 ports; VBW, VLW in IEC 61162-1 (NMEA 0183 Ver 2.0)

Input: 1 port; IEC 61162 (NMEA 0183 Ver 2.0)

(2) Analog Signal Speed signal for Analog display: 2 port

-3.3 mA to 10 mA/ -10 kt to +30 kt

Analog curr e nt ou tp ut: 1 por t

4 mA to 20 mA/ -10 kt to 30 kt

Analog voltage output: 1 port

-3.3 V to 10 V/ -10 kt to 30 kt

(3) Distance run output 2 ports; Contact closure each 0.005 nm, forward speed,

30 VDC: 0.4 A

(4) System Check signal 1 port, 30 VDC: 0.2 A, default: closed

SP - 1

Page 8

4. POWER SUPPLY

(1) System Sourc e 100/110 /1 15/200/220/ 23 0 VAC : 1.5 / 0. 7 A max ., 1 phase, 50-60 Hz

5. ENVIRONMENTAL CONDITION (IEC 60945)

(1) Ambient Temperature -15°C to +55°C (units for protected area)

Analog display: 0°C to +50°C

(2) Relative Humidity 95% at 40°C

(3) Vibration IEC 60945 adopted

(4) Category o f Equipment

Display Unit/Distance indicator/Transceiver Unit:

For protected area

Transducer: For submerged use, 600 kPa x 12 h

Distributor/Terminal box: For protected area

6. COATING COLOR

(1) Display Unit Cover: Munsell 2.5GY5/1.5 (light gray), Panel: N3.0 (gray)

(2) Distribution Box Munsell 2.5GY5/1.5 (light gray)

(3) Transceiver Unit Munsell 2.5GY5/1.5 (light gray)

(4) Terminal Box Munsell 2.5GY5/1.5 (light gray)

(5) Analog Display Munsell 2.5GY5/1.5 (light gray)

7. COMPASS SAFE DISTANCE

(1) Display Unit/Digital Indicator/Digital Distance Indicator

Stan dard: 0.50 m, St eering: 0.40 m

(2) Transceiver Unit Standard: 2.05 m, Steering: 1.40 m

(3) Distribution Box Standard: 3.1 0 m, Steering: 2.10 m

(4) Terminal Box Standard: 0.6 5 m, Steering: 0.45 m

SAFETY PREC AUTION

- There is no unit gi vi n g ris e to a dose rate > 0.5 mrem/h at 50 mm.

- There is no harmful radiation from the screen.

- All units of this equipment comply with EMC requirements in IEC 60945, as required by IMO

Res. A.813 (19).

SP - 2

Page 9

FOREWORD

Foreword

Thank you for purchasing the FURUNO

DS-80 Doppler Speed Log. We are

confident you will discover why FURUNO

has become synonymous with quality and

reliability.

Dedicated in the design and manufacture of

marine electronics equipment for half a

century, FURUNO Electr ic Company has

gained an unrivaled reputation as a world

leader in the industry. This is the result of

our technical excellence as well as our

worldwide distribution and service network.

Please carefully read and follow the safet y

information and operating and maintenance

instructions set forth in this manual bef ore

attempting to operate the equipment and

conduct any maintenance. Your Doppler

speed log will perform to the utmost of its

ability only if it is operated and maintained

in accordance with the correct procedures.

This equipment is designed, produced and

documented by FURUNO Electric Co., Ltd. ,

complying with ISO 9001 standards as

certified by the Lloyd’s Register of Quality

Assurance System.

Features

The FURUNO DS-80 displays ship’s speed

relative to water, using the Doppler

principle; ship’s speed is measured by

detecting the Doppler shift frequency f r om

the signal returned from the watermass.

The output is interfaced with ARPA, AIS,

and other shipborne equipm ent in IEC

61162-1 format.

The main features of the DS-80 are

• Simple operation. In most cases all that

is required to display ship’s speed is to

turn on the equipment.

• Pair-beam system effectively reduces

error caused by pitching. The transducer

assembly symmetrically emits two sonic

beams, one fore and the other aft. By

averaging the Doppler shift in both

directions accurate speed data is

available under rough sea conditions.

• Speed and distance information on the

adjustable-contrast LCD display.

• Analog display, digital Indicator and

digital distance indicator display

optionally available.

• Conforms to the following standards: IMO

A.824(19), as amended by MSC.97(72),

IMO A.694(17), IEC 61023, IEC 60945

rd

(3

edition), IEC 61162-1 (2nd edition)..

1

Page 10

TERMINAL BOX

DS-802

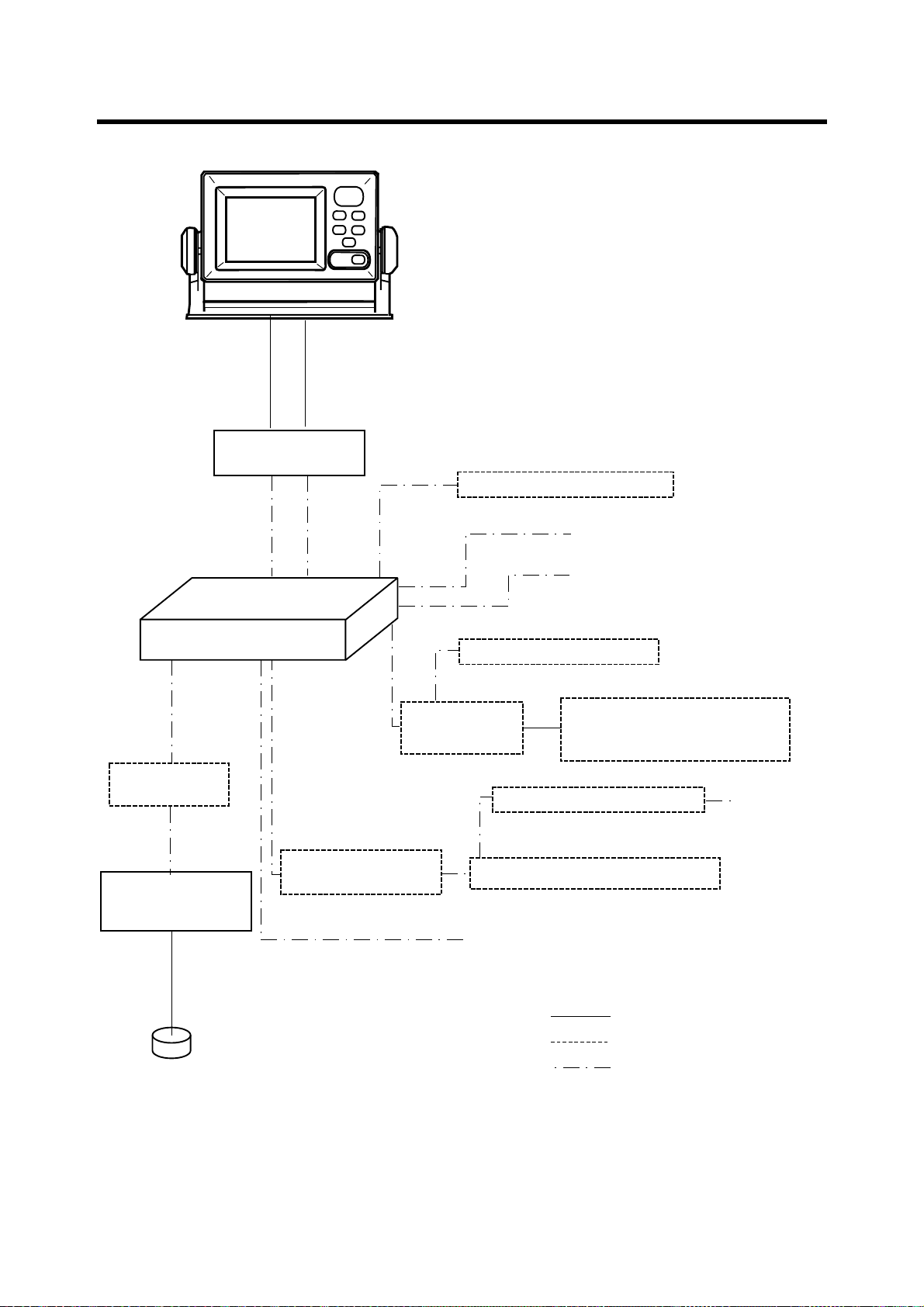

SYSTEM CONFIGURATION

DISPLAY UNIT

DS-800

DIMMER MF-22L-1/MF-22L-2

IEC 61162-1 Input

DISTRIBUTION BOX

JUNCTION BOX

CI-630

TRANSCEIVER

UNIT DS-810

TRANSDUCER

DS-801

RANGE SWITCH BOX

DS-389

DS-820

DIMMER MF22L-1/MF22-2

TERMINAL BOX

DS-802

DIMMER MF-22L-1/MF-22-2

ANALOG DISPLAY UNIT MF-22A-1

SHIP'S MAINS

115/230 V AC

Power ON SW Signal

Distance Run Signal

IEC 61162-1 Output

DIGITAL INDICATOR DS-830

DISTANCE INDICATOR DS-840

115/230 V AC

: STANDARD SUPPLY

: OPTIONAL SUPPLY

: LOCAL SUPPLY

2

Page 11

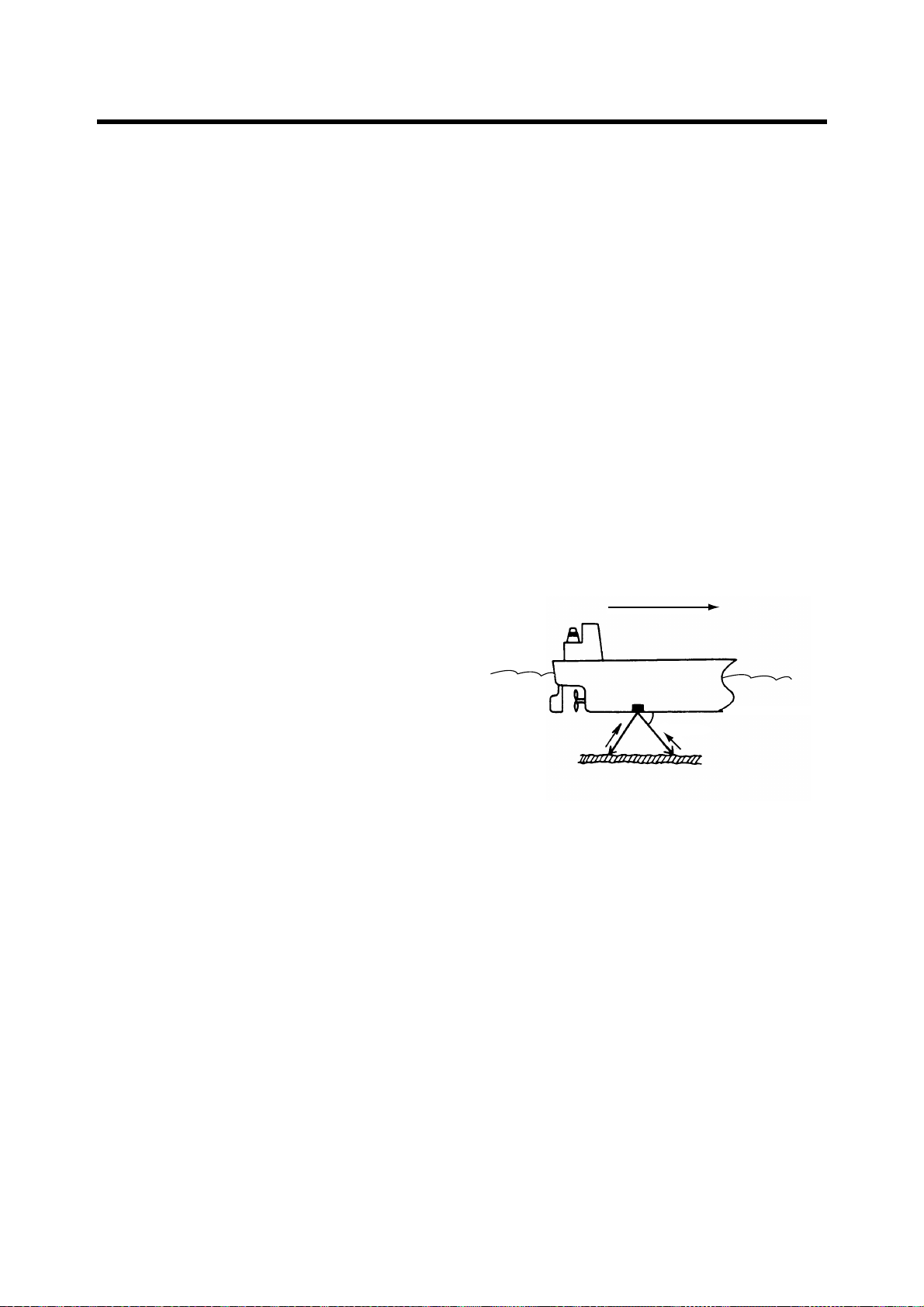

PRINCIPLE OF OPERATION

The Doppler speed log measures ship's

speed by using the Doppler Effect, which is

observed as a frequency shift resulting from

relative motion between a transmitter and

receiver or reflector of acoustic or electromagnetic energy . A common example of the

Doppler Effect is a train. When a train is

approaching, the whistle has a higher pit ch

than normal. You can hear the change in

pitch as the train passes.

The DS-80 has a pair-beam, one directed in

the fore direction and the other in the aft

direction, which emits ultrasonic waves at

an angle of θ to the waterline towards ship’s

fore and aft directions. The frequency of the

received signal is then compared with that

of the transmitted frequency to measure

doppler shift to calculate ship’s speed.

The relative motion causes the Doppler shift

and the ultrasonic waves reflected at t he

watermass (plankton or any underwater

r

objects) are received at the frequency of f

fo + fd where fd is the number of frequency

shifts counted at the receiver circuit. To

calculate ship’s speed, the following formula

is used.

V = fd/fo • c/2sinθ

c: Underwater velocity

Note that the sound velocity in water

changes with water temperature and water

pressure but the DS-80 readout is

automatically compensated for change by

using a temperature sensor.

=

V

f

o

θ

WATERMASS

fr = fo + f

SEA

SURFACE

d

3

Page 12

REMARKS ON USAGE

Remarks on Usage

The DS-80 measures ship’s speed by

detecting the Doppler shift f r equency of the

echo reflected by a watermass (water layer

containing plankton and other microorganisms) located within the measuring

area, which is usually about 2 m. In some

instances, however, no signal is returned

because of too few plankton in the sensing

depths. This phenomenon can occur in

particular areas in particular seasons. The

probable cause is the plankton are lying in

deep water because an ice-melted cold

water mass covers the sea surface. Similar

cases may also occur in a freshwater lake.

Under these circumstances the DS-80 will

not show the correct ship’s speed.

Conditions Affecting the Accuracy

(with ref to IMO A.824/3.3)

The Doppler speed log DS-80 is designed for

reliable and accurate performance through

The accuracy will not be affected by:

- water temperature (sound velocity)

•

salinity

•

pitch/roll ±10°

•

Beware of Transducer Location

The transducer may be damaged if it hits

the dry dock blocks. Take the following

measures to prevent damage to the

transducer.

1. Before delivering the ship, draw up a

suitable docking plan taking into

account the dimensions and location of

the transducer. Store the plans onboard

the ship.

2. Place the dry dock blocks according to

the plan.

3. Have a diver check the position

between the transducer and the blocks

before removing the water. Confirm that

the transducer will not touch the blocks.

FURUNO’s long experience and advanced

technology. It operates on the best choice of

system frequency and power output. As far as

the sonic energy is used, the performance

(accuracy) may be reduced or even lost

under:

rough weather (may be sea state 6 or

•

severer)

improper location of sensor, e.g., too close

•

to the propeller, thrusters, drain tubes, echo

sounder transducer

depth under the keel if less than 3 m

•

4

Page 13

1.1 Controls

1 OPERATION OF DISPLAY UNIT

Omnipad

Selects items, options

on menus.

Opens/closes the menu.

Selects display; speed

plus distance or speed.

MENU

DISP

DS-80

1.2 Turning the Power On/Off

1.2.1 Power on

Press the [POWER] switch to turn on the

equipment. The last-used display appears.

The example below shows the speed and

distance run.

SPEED STW

Speed

10.0

DISTANCE

kt

ENT

DIM

Registers options on menus.

Adjusts panel illumination.

Adjusts LCD contrast.

*

PWR

1.2.2 Power off

Press the [POWER] switch to turn the

power off.

Note:

Keep the DS-80 energized

continuously unless it fails. Turning off the

DS-80 may cause an inconvenience in

associated equipment, such as a radar.

Turns power on/off.

12.50

nm

Note:

STW means Speed Thro ugh Water. Thi s

indication flashes when transduc er temperatur e,

which can be monitored on the TEST display

(see page 16), is abnormal. This means speed

accuracy is less than stated in the

specifications.

Distance

Run

5

Page 14

1.3 Adjusting Contrast, Panel

1.4 Selecting a Display

Dimmer

1.3.1 Contrast

1. Press the [*] key to open the contrast

adjustment dialog box.

CONTRAST (0~63)

41

EXIT: [ENT]

2. Press the Omnipad at or to adjust

the contrast. The setting range is 0 to 63

and the default setting is 48.

3. Press the [ENT] key.

Note:

The contrast is automatically set to

default (48) when the power is turned on.

1.3.2 Panel dimmer

Press the [DISP] key to select display

desired. Each time the key is pressed the

display shows speed and distance run or

speed alone as below.

Direction

: Fore

: Aft

SPEED STW

Speed

10.0

DISTANCE

12.50

nm

[DISP] key

to switch

SPEED STW

kt

Distance

Run

1. Press the [DIM] key to show the dimmer

adjustment dialog box.

DIMMER (1~8)

7

EXIT: [ENT]

2. Press the Omnipad at or to adjust

the dimmer. The setting range is 1 to 8

and the default setting is 4.

3. Press the [ENT] key to conclude.

Note:

The [DIM] key is inoperative when

dimmer is controlled externally.

10.0

kt

Arrow indicates direction:

•

fore;

The distance run indication shows the

•

total distance run in forward speed only.

The distance run is backed up when the

•

power is turned off.

Note:

because of air bubbles, etc.

When speed error occurs, the speed

indication freezes, and “KT” is highlighted

and blinks. If speed error continues more

than 30 seconds, the speed indication

changes to **.*.

, aft.

Speed error may occur in rough seas

indicates

6

Page 15

1.5 Main Menu Operation

Functions of the DS-80 are selected

through the menu.

5. Press the [MENU] key twice to close the

menu. (Some menus require only a

single pressing of the [MENU] key.)

1. Press the [MENU] key to open the

menu.

MENU

DISTANCE RUN DISPLAY

DEMO

SYSTEM MENU

SYSTEM MENU2

2. Press the Omnipad at

or

to select

a menu item (current selection is

highlighted) and press the [ENT] key.

For example, when DISTANCE RUN

DISPLAY is selected the following

display appears. Distance run is a form

of contact closure, 200 pulses/nm. To

select IEC 61162 sentence, see

paragraph 1.6.1.

To enter numerical data

Some menus require input of numeric data.

This is done with the Omnipad.

1. Select the digit or sign (+ or -) to change

with

or on the Omnipad. (The

cursor shows the digit or sign selected.)

2. Enter a figure at each digit by hitting the

Omnipad at

. The example

or

below shows the DISTANCE RUN

DISPLAY menu, where you may adjust

the distance run indication for SET.

DISTANCE RUN DISPLAY

DATA DISPLAY

CONTACT CLOSURE

RESET OFF

SET

Cursor

000000.00nm

SET

ENT

DISTANCE RUN DISPLAY

DATA DISPLAY

CONTACT CLOSURE

RESET OFF

SET

0.00nm

SET

ENT

3. Press the Omnipad at

or

the menu item desired and press the

[ENT] key. For example select RESET.

DISTANCE RUN DISPLAY

DATA DISPLAY

CONTACT CLOSURE

RESET OFF

SET

4. Press the Omnipad at

OFF

ON

or

the menu option desired and press the

[ENT] key.

to select

to select

3. Press the [ENT] key to conclude.

1.6 Distance Run Operation

The operator may adjust and reset the

distance run indication and select display

method.

1.6.1 Selecting display method

The default setting provides for independent

display and adjustment of the distance run

indication on all displays (display un it,

Digital Indicator, distance indicator).

To show the same distance run indication

on all displays do the following:

1. Press the [MENU] key to open the

menu.

7

Page 16

MENU

DISTANCE RUN DISPLAY

DEMO

SYSTEM MENU

SYSTEM MENU2

2. Press the Omnipad at

to select

DISTANCE RUN DISPLAY and press

the [ENT] key.

The cursor circumscribes the leftmost

digit of the distance run figure.

DISTANCE RUN DISPLAY

DATA DISPLAY

CONTACT CLOSURE

RESET OFF

SET

Cursor

000000.00nm

ENT

SET

DISTANCE RUN DISPLAY

DATA DISPLAY

CONTACT CLOSURE

RESET OFF

SET

0.00nm

SET

ENT

3. Select DATA DISPLAY and press the

[ENT] key.

DISTANCE RUN DISPLAY

DATA DISPLAY

CONTACT CLOSURE

RESET OFF

IEC61162(VLW)

SET

CONTACT CLOSURE

0.00 nm

SET

4. Press

ENT

to select IEC 61162(VLW)

and press the [ENT] key.

5. Press the [MENU] key twice to close the

menu.

4. Press the Omnipad at or to select

the digit to change.

5. Press the Omnipad at

or

to

change value. The setting range is 0.00

nm to 999999.99 nm.

6. Press the [ENT] key followed by

pressing the [MENU] key twice to

conclude your selection and close the

menu.

1.6.3 Resetting distance run to zero

Distance run can be reset to zero when the

menu item DATA DISPLAY is selected to

CONTACT CLO S URE. It may also be reset

to zero only at the display unit when IEC

61162(VLW) is selected.

1. Press the [MENU] key to open the

menu.

1.6.2 Adjusting distance run

Distance run can be changed when the

menu item DATA DISPLAY is selected to

CONTACT CLO S URE. It may also be

changed only at the display unit when IEC

61162(VLW) is selected. .

1. Press the [MENU] key to open the

menu.

2. Use

DISPLAY and press the [ENT] key.

3. Select SET and press the [ENT] key.

to select DISTANCE RUN

2. Press the Omnipad at

to select

DISTANCE RUN DISPLAY and press

the [ENT] key.

3. Select RESET and press the [ENT] key.

DISTANCE RUN DISPLAY

DATA DISPLAY

CONTACT CLOSURE

RESET OFF

SET

OFF

ON

4. Press the Omnipad at to select ON.

8

Page 17

5. Press the [ENT] key to finish and press

the [MENU] key twice to close the

menu.

3. Select averaging time period desired

among 15, 30, 45 and 60 seconds.

4. Press the [ENT] key.

The distance run indication reads 0.00.

1.7 System Setting

The system setting provides the

fundamental parameters for intended

performance of the DS-80.

1.7.1 Displaying the system menu

1. Press the [MENU] key to open the

menu.

2. Select SYSTEM MENU and press the

[ENT] key.

SYSTEM MENU

SHIP SPEED AVG 15 SEC

SPEED OFFSET +0.0%

TRACK DEPTH 2.0 m

XDR OFFSET +00˚

SPD DATA SELECT

DOPPLER

ENT: SET

1.7.2 Ship speed average

5. Press the [MENU] key twice to close the

menu.

1.7.3 Speed offset (calibration)

Calibration of any speed log is necessary

through the sea trials during the

commissioning tests. Fill in the calibration

sheet which is on page 25 of this manual.

Us the resultant data to calculate speed

offset and enter it as below. The setting

range is -25.0% to +25.0%.

1. Open the SYSTEM MENU.

2. Select SPEED OFFSET and press the

[ENT] key.

SYSTEM MENU

SHIP SPEED AVG 30 SEC

SPEED OFFSET +0.0%

TRACK DEPTH 2.0 m

XDR OFFSET +00˚

SPD DATA SELECT

DOPPLER

ENT: SET

Wind and currents affect ship’s speed, and

speed data is averaged over the time period

set on this menu. Increase the speed

averaging period if the speed reading is

unstable.

1. Open the SYSTEM MENU.

2. Select SHIP SPEED AVG and press the

[ENT] key.

15 SEC

30 SEC

45 SEC

60 SEC

3. Select the digit to change with or

and change the value with

or

on

the Omnipad.

4. Press the [ENT] key.

5. Press the [MENU] key twice to close the

menu.

1.7.4 Tracking depth

Doppler shift measuring depth in the DS-80

is 2 m at default. If the speed readout is

unstable due to air bubbles near the ship’s

hull, increase or decrease the track depth to

stabilize the readout. The sett ing range is

1.0 m to 9.9 m.

1. Open the SYSTEM MENU.

9

Page 18

SYSTEM MENU

1.7.6 Speed data selection

SHIP SPEED AVG 30 SEC

SPEED OFFSET +0.0%

TRACK DEPTH 2.0 m

XDR OFFSET +00˚

SPD DATA SELECT

DOPPLER

ENT: SET

2. Select TRACK DEPTH and press the

[ENT] key.

SYSTEM MENU

SHIP SPEED AVG 30 SEC

SPEED OFFSET +0.0%

TRACK DEPTH 2.0 m

XDR OFFSET +00˚

SPD DATA SELECT

DOPPLER

ENT: SET

3. Select the digit to change or and

change the value with

or

on the

Omnipad.

4. Press the [ENT] key.

5. Press the [MENU] key twice to close the

menu.

When the DS-80 fails to work as an SDME,

the display unit can be used as a monitor

display tool for a GPS speed or other

equipment measuring the ship’s speed.

1. Open the SYSTEM MENU.

2. Select SPD DATA SELECT and press

the [ENT] key.

GPS

DOPPLER

AUTO

3. Select the option GPS and press the

[ENT] key.

4. Press the [MENU] key twice to close the

menu.

See the illustration below for speed display

information. If the speed displayed is

unstable perform the check described in

paragraph 3.2.

GPS-measured

speed

1.7.5 Transducer offset

Sets the deviation angle of the transducer’s

orientation with reference to the ship’s

longitudinal axis. This is done at installation;

no user adjustment is necessary.

SPEED STW

DISTANCE

nm

Doppler speed

10.0

12.50

kt kt

SPEED GPS

DISTANCE

nm

GPS speed

10.0

12.50

"AUTO" position indicates a Doppler speed

(SDME) but if the DS-80 fails, a GPS speed

will be indicated.

Note 1:

If the log speed fails, the display

unit reads a GPS speed, but speed data will

not be output to other equipment.

Note 2

: Doppler speed is used to calculate

speed when both DOPPLER and GPS are

abnormal in AUTO.

10

Page 19

1.7.7 S ystem menu 2

The System Menu 2 contains the diagnostic

test and selection of dimmer control and

display language.

1. Press the [MENU] key to open the

menu.

2. Select SYSTEM MENU 2 and press the

[ENT] key.

SYSTEM MENU2

TEST

DIMMER INTERNAL

/LANG. ENGLISH

4. Select the digit to change with

to set. (The setting range

5. Use

or

or .

is

-10.0 to +40.0 kt, and the default set ting

is +10.0 kt.)

6. Press the [ENT] key.

7. Press the [ENT] key to open the DATA

DISPLA Y menu.

DEMO

SPEED

+10.0 kt

DATA DISPLAY OFF

ON

OFF

ENT: SET

ENT: SET

TEST :

Checks the equipment for proper

operation. For further details see Chapter 3.

DIMMER:

LANG.:

See paragraph 1.3.2.

Selects the language to use in

menus, English or Japanese.

1.8 Demonst ration Mode

The demonstration mode out puts the

Doppler speed signal to external equipment.

This checks if the signal is being correctly

output. )

1. Press the [MENU] key to open the

menu.

2. Select DEMO and press the [ENT] key.

8. Press

to select ON and press the

[ENT] key.

9. Press the [MENU] key twice to close the

menu.

The indication “DEMO” appears at the top

right-hand corner when the demo mode is

on. To turn off the demonstration display,

show the DEMO menu and set SPD to OFF.

SPEED DEMO

10.0

DISTANCE

Demonstration

mode "ON"

kt

DEMO

SPEED

+10.0 kt

DATA DISPLAY OFF

ENT: SET

3. Select SPEED and press the [ENT] key.

11

Page 20

2 OPERATION OF OPTIONAL

The Digital Indicator DS-830 and Distance

Indicator DS-840 have the same controls as

the display unit. This chapter explains the

features which are not shared with the

display unit.

EQUIPMENT

SPEED STW

10.0

DISTANCE

kt

12.50

DISTANCE INDICATOR nm

Speed

Distance

Run

2.1 Digital Indicator DS-830, Distance Indicator DS-840

2.1.1 Selecting a display

Press the [DISP] key to select the display

mode. Each time the key is pressed the

display shows speed plus distance run or

speed alone as below.

SPEED STW

Speed

DISTANCE

10.0

nm

SPEED INDICATOR

[DISP] key

to switch

SPEED STW

kt

12.50

Distance

Run

[DISP] key

to switch

DISTANCE

12.50

DISTANCE INDICATOR

Distance Indicator DS-84 0

2.1.2 Menu operation

1. Press the [MENU] key to show the

display below.

MENU

DISTANCE RUN DISPLAY

SYSTEM MENU2

nm

10.0

SPEED INDICATOR

Digital Indicator DS-830

kt

2. For details refer to the following:

DISTANCE RUN DISPLAY:

1.6.

SYSTEM MENU 2:

2.

2.1.3 Adjusting dimmer and

contrast

See paragraph 1.3.

See 1.7.7 System Menu

12

See paragraph

Page 21

ANALOG DISPLAY UNIT

CORRECTION DIAGRAM AT EXTREME TEMPERATURES

Doppler Speed Log DS-80

CORRECTION FACTOR FOR ANALOG DISPLAY MF-22A-1

Example:

If the analog speedometer reads 14.2 kt at a temperature of –15°C, the correct speed

through the water is 15 kt. Failure of correct ion in lo w temperature can result in a m aximum

error of –0.8 kt or 5.3% for 14.2 kt readout. IMO limit of ±2% is exceeded over 10.0 – 30.0 kt

reading but correction by this graph brings a correct measurement.

At +55°C, an error of +0.0 kt (+2.7%) occurs at a speed of 30 kt; no other point IMO limit of

±

2% is exceeded.

When the digital display and anal og display readouts are different, t ake precedence of the

digital readout. At temperatures 0°C to 50°C, the speedometer never exceeds the IMO

limits.

13

Page 22

3 MAINTENANCE, TROUBLESHOOTING

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

3.1 Maintenance

3.1.1 Preventive maintenance

Check the following points regularly to

maintain performance.

Check that the connectors on all units of

•

the system are firmly fastened and free of

rust. Clean if soiled or corroded.

Check that all ground wires are tightly

•

fastened.

Dust and dirt on the display unit including

•

the screen may be removed with a soft

cloth. Do not use chemical cleaners to

clean the display unit; they can remove

paint and markings.

3.1.2 Transducer maintenance

CAUTION

Do not paint the transducer.

Painting will affect performance.

3.1.3 Fuse replacement

Fuses in the units of the system protect the

electrical circuitry from burning by

overcurrent. If the equipment cannot be

energized check the fuse in the power

cable connected to the display unit. Locate

the cause before replacing the fuse.

Unit

Display

Unit

Distribution

Box

Transceiver

Unit

Rating,

Qty

1A,

2 pcs.

3A,

2 pcs.

1A,

2 pcs.

Type,

Code No.

FGMB 1A

125 VAC,

000-114-8

05

FGBO 3A

250 VAC

000-549021

FGBO 1A

250 VAC,

000-549019

Location

Fuse

holder in

power

cable

Inside

unit

Marine life (barnacles, etc.) adhering to the

transducer face will reduce sensitivity.

Periodically remove any marine life from

the transducer face with fine sandpaper or

a piece of wood.

CAUTION

Use the proper fuse.

Use of a wrong fuse can cause fire or

equipment damage and void the warranty.

14

Page 23

3.2 Troubleshooting

This section provides troubleshooting procedures. Advanced level troubleshooting should

be done by referring to the Service Manual (optional supply).

Problem Probable cause Remedy

General

Cannot turn on the

power.

Power is on but

Loosened power cable Fasten the power cable.

Blown fuse Replace the fuse.

Contrast too low. Press the [*] key several times.

nothing appears on

the screen.

Doppler speed indication

SPEED

DISTANCE

nm

SPEED

DISTANCE

nm

SPEED STW

DISTANCE

nm

STW

10.0

12.50

Last correct speed is displayed

(display freezes).

kt

Reverse video and blinking

STW

**. *

Speed shown as "**.*".

kt

12.50

10.0

flashing

STW

kt

12.50

GPS speed indication

SPEED GPS

DISTANCE

nm

**.*

12.50

Speed indication shown as "**.*".

kt

Ship’s speed cannot be calculated

because of air bubbles, etc. (Speed error :

30 seconds)

• Problem with the transducer or air

bubbles.

• Speed error continues more than 30

seconds.

• Temperature sensor is abnormal.

GPS data error.

SPEED

DISTANCE

nm

----

"GPS" is replaced with "----".

---

kt

12.50

If any abnormal speed indication continues

contact your dealer for advice.

• No GPS data for 30 seconds.

• GPS receiver disconnecte d.

15

Page 24

3.3 Diagnostics, Checking Program Number

The diagnostic facility checks the ROM,

RAM, SIO and displays program ID.

1. Press the [MENU] key to open the

menu.

2. Select SYSTEM MENU2 and press the

[ENT] key.

SYSTEM MENU2

TEST

DIMMER INTERNAL

/LANG. ENGLISH

control is operated within five seconds,

the equipment autom atically begins

checking the LCD.

Transducer temperature

Name of control operated

appears here.

TEST

No. of times test

consecutively

executed.

ROM : OK 12.3CX

RAM : OK

SIO : OK

PUSH KEY

(STOP: PWR OFF)

6550100003I

6550110003J

CNT: 006 6550120003K

6550100003I = Display Unit DS-800

6550110003J = Distribution Box DS-801

6550120003K = Transceiver Unit DS-810

X appears when

temperature

sensor is

abnormal

Control operated and indication

3. Press the [ENT] key. The following

display appears.

TEST START ?

(STOP: PWR OFF)

ARE YOU SURE ?

YES NO

4. Press the [ENT] key to start the test. In

a few moments the display should

changes as shown at the top of the

adjacent column.

The ROM, RAM and SIO (if special

connector is used) are checked for

proper operation and the results shown

as OK or NG (No Good). For NG,

contact your dealer for advice.

Control Indication

UP

DOWN

LEFT

RIGHT

MENU MENU

ENT ENT

DISP DISP

DIM DIM

* *

5. The equipment automatically checks

the LCD, displaying the following in

order.

<LCD CHECK>

ALL ON 2 SEC.

ALL OFF 3 SEC.

The program number also appears

here.

“PUSH KEY” is highlighted, prompting

you to check the controls. Operate any

control (except the [POW ER] switch)

within five seconds. The name of the

activated control appears on screen if it

is operating normally. Note that if no

6. The test repeats itself. To stop the test,

turn the power switch off and on again.

16

Page 25

4 DIGITAL INTERFACE (IEC 61162-1

Edition 2)

4.1 I/O Sentences

Input sentences of IEC61162_RX port

GGA, VTG

Output sentences of IEC61162_TX1, IEC61162_TX2 ports

VBW, VLW (Talker: VD)

Transmission interval

3 s for VBW; 1 s for VLW

Data transmission

Data is transmitted in serial asynchronous form in accordance with the standard referenced

in 2.1 of IEC 61162-1. The first bit is a start bit and is followed by data bits,

least-significant-bit as illustrated below.

The following parameters are used:

Baud rate: 4800

Data bits: 8 (D7 = 0), parity none

Stop bits: 1

D0 D1 D2 D3 D4 D5 D6 D7

Start

bit

Data bits

Stop

bit

17

Page 26

Schematic diagrams

IEC61162 RX port

DS-801

65P6010

11

12

.

.

.

.

<11<

<12<

.

.

TB3

F2047A-20P-B

IEC61162_RX_A

IEC61162_RX_B

Load requirements as listener

Isolation: Optocoupler

Input Impedance: 44 ohm s

Max. Voltage: ±2.6V

Threshold: 4 mA

IEC61162 TX1 po rt

JP6

ERJ_6GEY0R00V

JP7

ERJ_6GEY0R00V

R121 22Ω

R122 120Ω

R123 120 Ω

R124 22Ω

1

2

CR17 1SS181

PC400

U42

1

3

6

4

5

Output drive capability

Max. 20 mA

18

Page 27

IEC61162 TX2 po rt

DS-801

65P6010

9

10

.

.

.

.

.

.

.

.

TB3

F2047A-20P-B

IEC61162_TX2_A

IEC61162_TX2_B

Output drive capability

Max. 20 mA

<7<

<8<

R136

47

R135

47

Vcc

1

U43

SN75ALS191PS

8

7

2

4

19

Page 28

4.2 Sentence Description

GGA - Global positioning system (GPS) fix data

Time, position and fix related data for a GPS receiver.

Note: Item Only GPS quality indicat or and antenna altitude above/below are used.

20

Page 29

VTG - Course over ground and ground speed

The actual course and speed relative to the ground.

$--VTG,x.x,T,x.x,M,x.x,N,x.x,K,a*hh<CR><LF>

| | | | | | | | | |

| | | | | | | | | +------- 6

| | | | | | | | +--------- 5

| | | | | | +--+----------- 4

| | | | +--+----------------- 3

| | +--+----------------------- 2

+--+----------------------------- 1

1. Course over ground, degrees true

2. Course over ground, degrees magnetic

3. Speed over ground, knots

4. Speed over ground, km/h

5. Mode indicator(see note)

6. Checksum

NOTE Positioning system Mode indicator:

A = Autonomous

D = Differential

S = Simulator

N = Data not valid

The positioning system Mode indicator field shall not be a null field.

Note: Speed, course degrees magnetic and course degrees true not used.

21

Page 30

VBW - Dual ground/water speed

Water-referenced and ground-referenced speed data.

$--VBW,x.x,x.x,A,x.x,x.x,A,x.x,A,x.x,A*hh<CR><LF>

| | | | | | | | | | |

| | | | | | | | | | +--- 11

| | | | | | | | | +----- 10

| | | | | | | | +-------- 9

| | | | | | | +----------- 8

| | | | | | +-------------- 7

| | | | | +----------------- 6

| | | | +-------------------- 5

| | | +------------------------ 4

| | +--------------------------- 3

| +------------------------------ 2

+---------------------------------- 1

1. Longitudial water speed, knots

2. Transverse water speed, knots

3. Status: water speed, A=data valid V=data invalid

4. Longitudial ground speed, knots

5. Transverse ground speed, knots

6. Status: ground speed, A=data valid V=data invalid

7. Stern transverse water speed, knots

8. Status: stern water speed, A=data valid V=data invalid

9. Stern transverse ground speed, knots

10. Status: stern ground speed, A=data valid V=data invalid

11. Checksum

Notes

1. Longitudinal speed: “-” astern.

* Not used.

VLW - Distance travelled through the water

The distance travelled, relative to the water.

$--VLW,x.x,N,x.x,N*hh<CR><LF>

| | | | |

| | | | +--------- 3

| | +--+----------- 2

+--+----------------- 1

1. Total cumulative distance, nautical miles

2. Distance since reset, nautical miles

3. Checksum

22

Page 31

5 PARTS LOCATION AND PARTS LIST

Parts Location

Display unit DS-800

U10 (ROM)

Distribution box DS-801

ICP Board 65P6000, parts side

From right TB1, TB2, TB3

TB101

POWER

switch

JPW Board

Distribution Box DS-801, inside view

23

Page 32

Transceiver unit DS-810

TB1

KCP Board

TB101

POWER

Switch

Transceiver Unit DS-810, inside view

24

Page 33

Parts List

This equipment contains complex modules in which fault diagnosis and repair down to

component level are not practicable (IMO A.694(17)/8.3.1). Only some discrete components

are used. FURUNO ELECTRIC CO., LTD. believes identifying these components is of no

use for shipborne maintenance; theref ore, they are not listed in this manual. Major modules

can be located on parts location photos on the preceding page.

25

Page 34

Model DS-80

Y

Unit DISPLAY UNIT DS-800

ELECTRICAL PARTS LIST Ref.Dwg. C3441-K01-C

2000-01 Block.No.

SYMBOL TYPE CODE No. REMARKS SHIPPABLE

ASSEMBL

PRINTED CIRCUIT BOARD

65P6000, ICP 000-142-649 X

CABLE w/CONNECTOR

MJ-A7SPF-005-020 000-139-384 20S0251

MJ-A6SPF-003-020 000-142-658 65S1231

MJ-PH 6P 000-142-659 65S1227

MJ-PH 7P 000-142-660 65S1228

26

Page 35

Model DS-80

Y

Unit TRANSCEIVER DS-810

ELECTRICAL PARTS LIST Ref.Dwg. C7247-K02-A

2000-01 Block.No.

SYMBOL TYPE CODE No. REMARKS SHIPPABLE

ASSEMBL

PRINTED CIRCUIT BOARD

65P6020,KCP 002-889-570 X

POWER SUPPLY ASSEMBLY

DS-810 002-889-530 X

SWITCH

S1 S-331 000-474-214

VARISTOR

CR1 ERZV-20D471 000-136-287

TRANSFORMER

T1 65S1218 000-142-647

TERMINAL BOARD

TB101 F1003-20A-5725-6P 000-137-321

NOISE FILTER

XF1 ZGB2202-01U 000-132-968

CABLE w/CONNECTOR

66-045(2P) 002-889-550 VH CONNECTOR

65-046(6P) 002-889-560 VH CONNECTOR

27

Page 36

Model DS-80

Y

Unit DISTRIBUTOR DS-801

ELECTRICAL PARTS LIST Ref.Dwg. C7247-K03-A

2000-01 Block No.

SYMBOL TYPE CODE No. REMARKS SHIPPABLE

ASSEMBL

PRINTED CIRCUIT BOARD

65P6010,JPW 002-889-490

ASSEMBLY

DS-801 002-889-470 POWER SUPPLY

POWER SUPPLY ASSEMBLY

DS-801-100 002-889-410

DS-801-110 002-889-420

DS-801-115 002-889-430

DS-801-200 002-889-440

DS-801-220 002-889-450

DS-801-230 002-889-460

X

X

X

X

X

X

X

X

SWITCH

S1 S-331 000-474-214

VARISTOR

CR1 ERZV-20D471 000-136-287

TERMINAL BOARD

TB101 F1003-20A-2P 000-142-631

FUSE HOLDER

F1 FH-001AF 000-138-909

POWER SUPPLY

PD1 FAW-24-2R1 000-142-633

NOISE FILTER

XF1 ZAC2210-11 000-120-155

28

Page 37

CALIBRATION SHEET

SEA STATE

DS-80

Location of Transducer (m) from bow or frame No.

CALIBRATION SHEET FOR DS-80 DOPPLER SPEED LOG

DATE: TEST SITE SHIP'S LENGTH (M) DRAFT Fore Aft Mean (m)

SHIP'S NAME Ser. No. DOCKYARD TRIM (m)

.

29

Page 38

Default settings in bold italic.

[MENU] key

MENU OVERVIEW

DISTANCE RUN DISPLAY

DEMO

SYSTEM MENU

SYSTEM MENU2

DATA DISPLAY (

RESET (ON,

SET (0.0 nm-999999.99 nm,

SPEED (-10.0 to +40.0 kt,

DATA DISPLAY (

SHIP SPD AVG (15, 30, 45, 60 SEC)

SPEED OFFSET (-25.0% to +25.0%,

TRACK DEPTH (1.0 m to 9.9 m,

XDR OFFSET (-40˚ to +40˚,

SPD DATA SELECT (GPS,

TEST (Check of ROM, RAM, LCD, Key Panel)

DIMMER (

LANG. (

INTERNAL,

ENGLISH

CONTACT CLOSURE

OFF

)

0.00 nm

+10.0 kt

OFF

, ON)

0

˚)

DOPPLER

EXTERNAL)

, JAPANESE)

)

2 m

, IEC 61162-1(VLW))

)

0%

)

)

, AUTO)

30

Page 39

INDEX

C

Contrast.......................................................... 6

Control description.........................................5

D

Demonstration mode...................................... 9

Diagnostics...................................................14

Digital indicator.............................................12

Digital interface.............................................16

Digitial display ..............................................12

DIM key ..........................................................6

Dimmer........................................................... 6

Distance run

adjusting .....................................................9

display method............................................8

resetting to zero..........................................8

F

Fuse replacement.........................................13

P

Parts list ........................................................20

Parts location ................................................18

POWER switch ...............................................5

S

Ship's speed

averaging time.............................................9

offset..........................................................10

source........................................................11

System configuration......................................2

System menu..................................................9

System menu2..............................................11

T

Transducer

maintenance..............................................13

position offset............................................10

Troubleshooting............................................14

M

Maintenance................................................. 13

MENU key ......................................................7

Menu operation ..............................................7

Menu tree .....................................................24

U

UNIT key.........................................................7

W

Water tracking depth.....................................10

Index-1

Page 40

Loading...

Loading...