Page 1

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080474401**00080474401*

*00080474401**00080474401*

*OME72360R10**OME72360R10*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. OME-72360OME-72360

Printed in JapanPrinted in Japan

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION :AUG.AUG. 19921992

R1R1 :: FEB.FEB. 12,200312,2003

(( DAMIDAMI ))

DS-30DS-30

* 0 0 0 8 0 4 7 4 4 0 1 ** 0 0 0 8 0 4 7 4 4 0 1 *

*OME72360R10**OME72360R10*

* O M E 7 2 3 6 0 R 1 ** O M E 7 2 3 6 0 R 1 *

Page 3

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

Immediately turn off the power at the

switchboard if water leaks into the

equipment or an object is dropped into

the equipment.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Do not place liquid-filled containers on

the top of the equipment.

Fire or electrical shock can result if the

liquid spills into the equipment.

Do not disassemble or modify the

equipment.

CAUTION

Do not use the equipment for other than

its intended purpose.

Improper use of the equipment can result

in personal injury or equipment damage.

Turn off the equipment immediately if

you feel it is abnormal.

Turn off the power from the switchboard if

the equipment is emitting strange noises

or becomes excessively hot. Contact your

dealer for advice.

The useable ambient temperature range

is 15°C

Do not use the equipment out of the

above temperature range.

Do not place objects around the

equipment.

Overheating may result.

to

55°C.

Fire, electrical shock or serious injury can

result.

Keep the equipment away from rain

and water splash.

Fire or electrical shock can result if the

rain or water gets into the equipment.

Do not operate the equipment with wet

hands.

Electrical shock can result.

Keep heater away from equipment.

A heater can melt the equipment's power

cord, which can cause fire or electrical

shock.

Use the proper fuse.

Fuse rating is shown on the equipment.

Use of a wrong fuse can result in damage

to the equipment.

Do not power the equipment when the

transducer is in air.

The transducer may become damaged.

Handle all units carefully.

Damage can lead to corrosion.

Do not use chemical cleaners such as

alcohol, acetone and benzine to clean

the equipment.

Chemical cleaners can remove paint and

markings. Use only a soft, dry cloth. For

stubborn dirt, use a soft cloth moistened

with water-diluted mild detergent.

When dry docked remove marine life

from the transducer.

Remove marine life to maintain good

sensitivity.

Do not paint the transducer face.

Further, handle the transducer with

care.

Paint will affect equipment performance.

Page 4

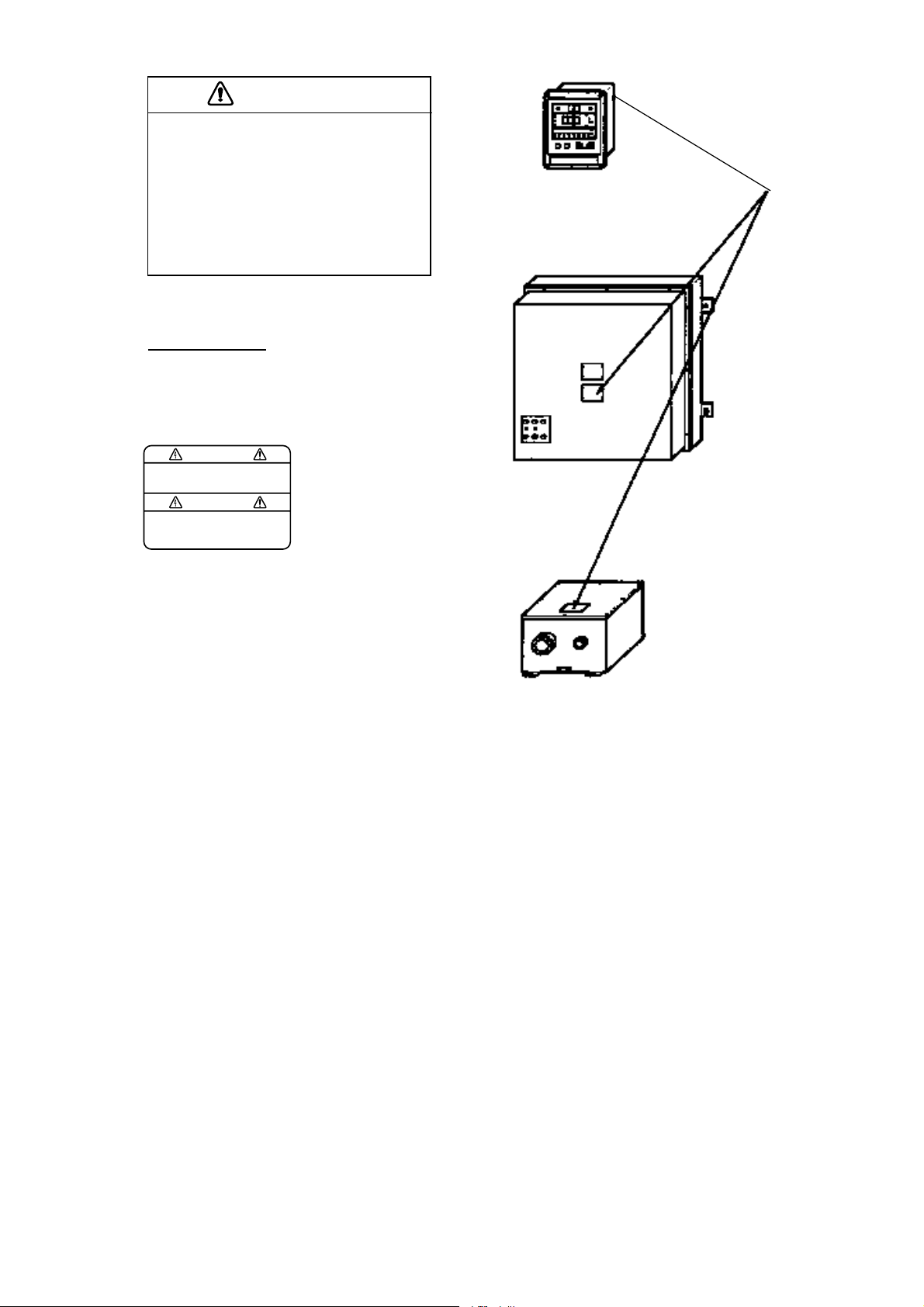

CAUTION

If the optional rate gyro is installed,

turn on the power when the ship is dead

in water or running straight.

The heading generated by the rate gyro

is used as reference, therefore turning on

the equipment while the ship is turning will

result in large heading errror.

WARNING LABEL

A warning label is attached to the

units shown right. Do not remove the

labels. If a label is missing or is illegible,

contacta FURUNO dealer or agent about

replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label (1)

Type: 86-003-1011

Code No.: 100-236-230

MAIN DISPLAY UNIT

DS-500

Warning

label

PROCESSOR UNIT

DS-510, DS-511

TRANSCEIVER UNIT

DS-520

ii

iiiiiiiiiiiiiiiiiiiiiiiiii

Page 5

Page 6

Page 7

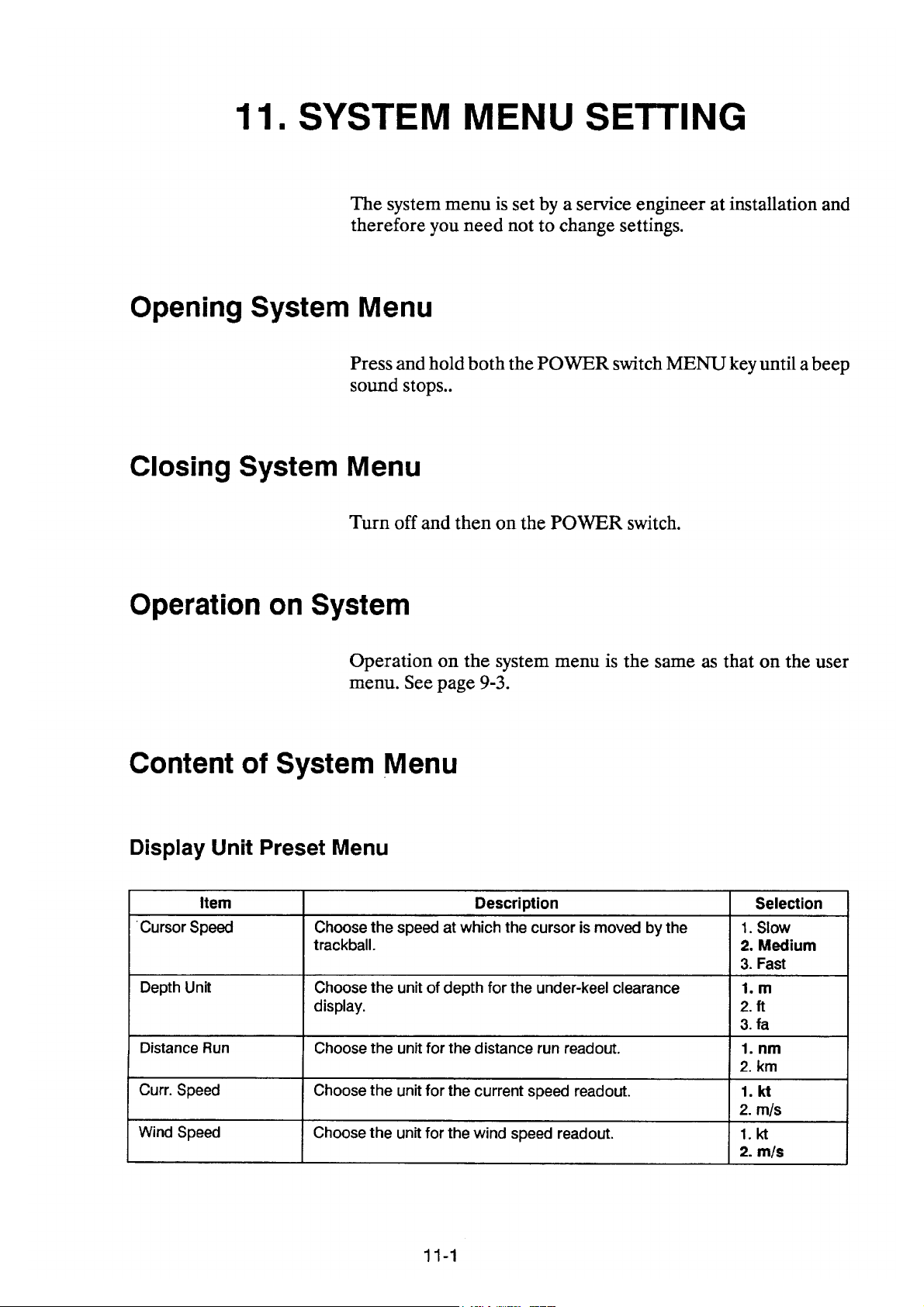

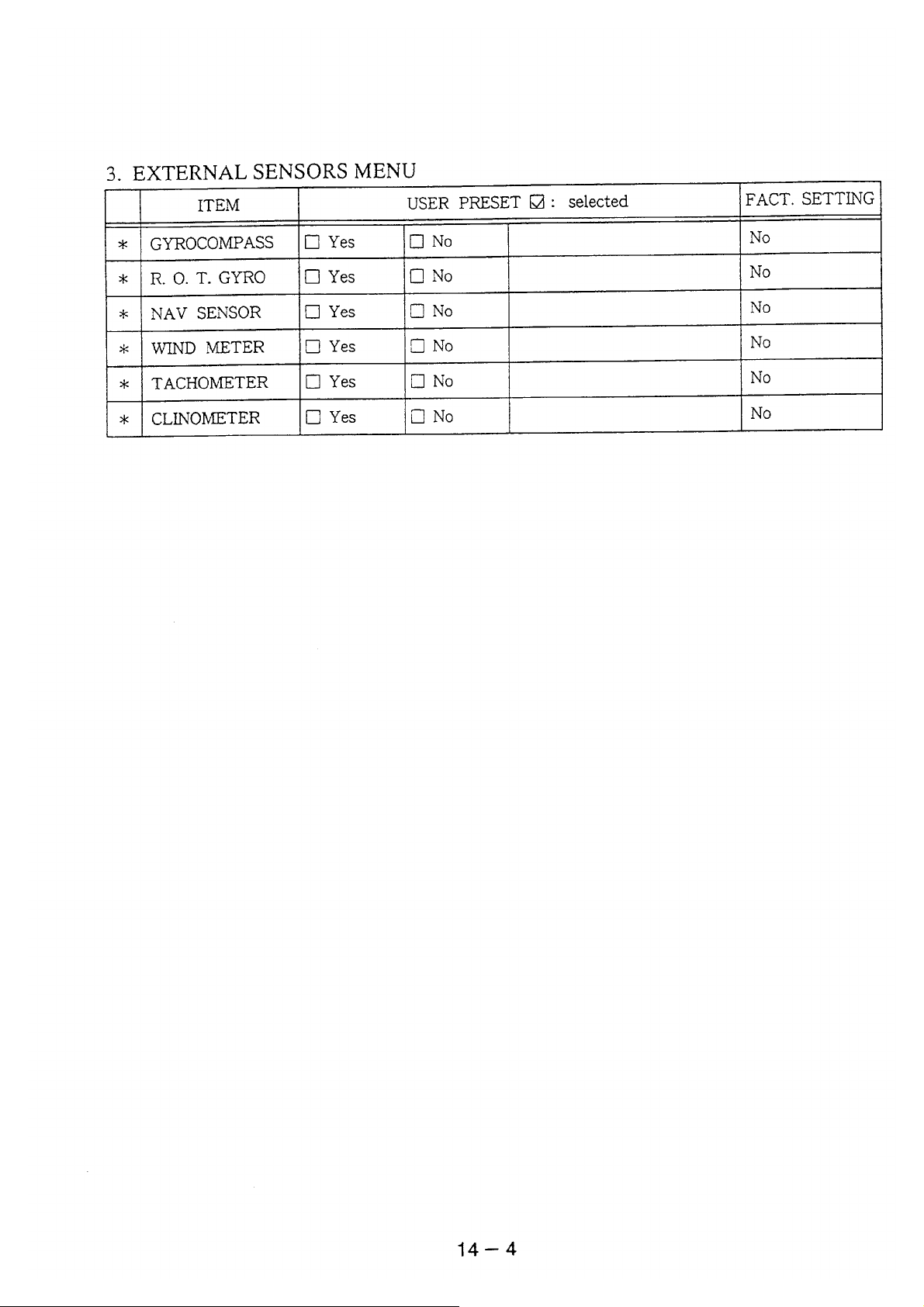

11. SYSTEM MENU SETTING .....................................................................................11-1

Opening System Menu ........................................................................................................................ 11-1

Closing System Menu .......................................................................................................................... 11-1

Operation on System Menu ................................................................................................................. 11-1

Content of System Menu ..................................................................................................................... 11-1

Display Unit Preset Menu ................................................................................................................ 11-2

Display Test Menu ........................................................................................................................... 11-2

Ship Data Menu ............................................................................................................................... 11-2

External Sensor Menu ..................................................................................................................... 11-3

12. REPLACEMENT OF SENSOR IN RATE-OF-TURN GYRO (OPTION) ..............................12-1

13. SPECIFICATIONS OF DOPPLER SONAR DS-30.............................................................13-1

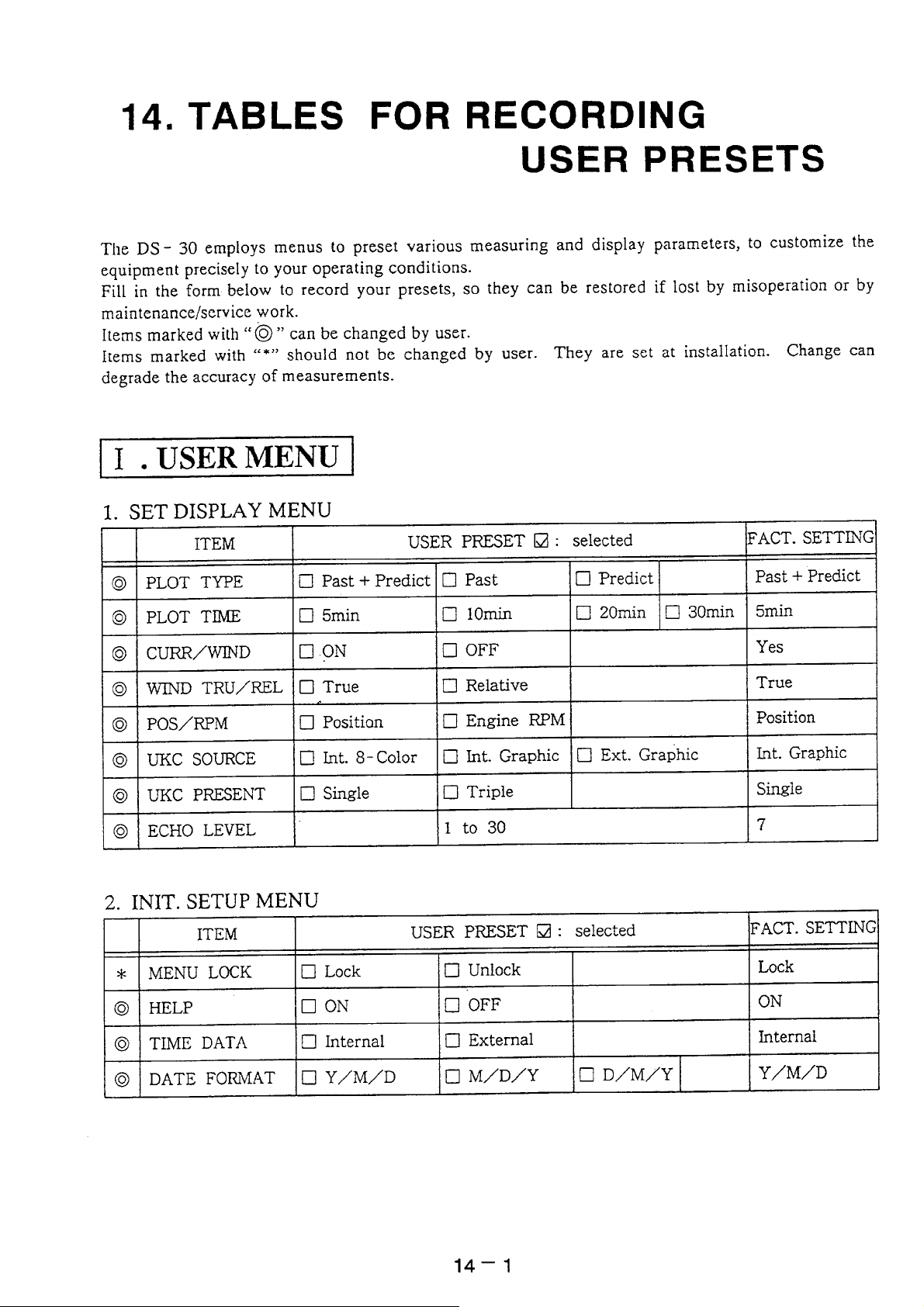

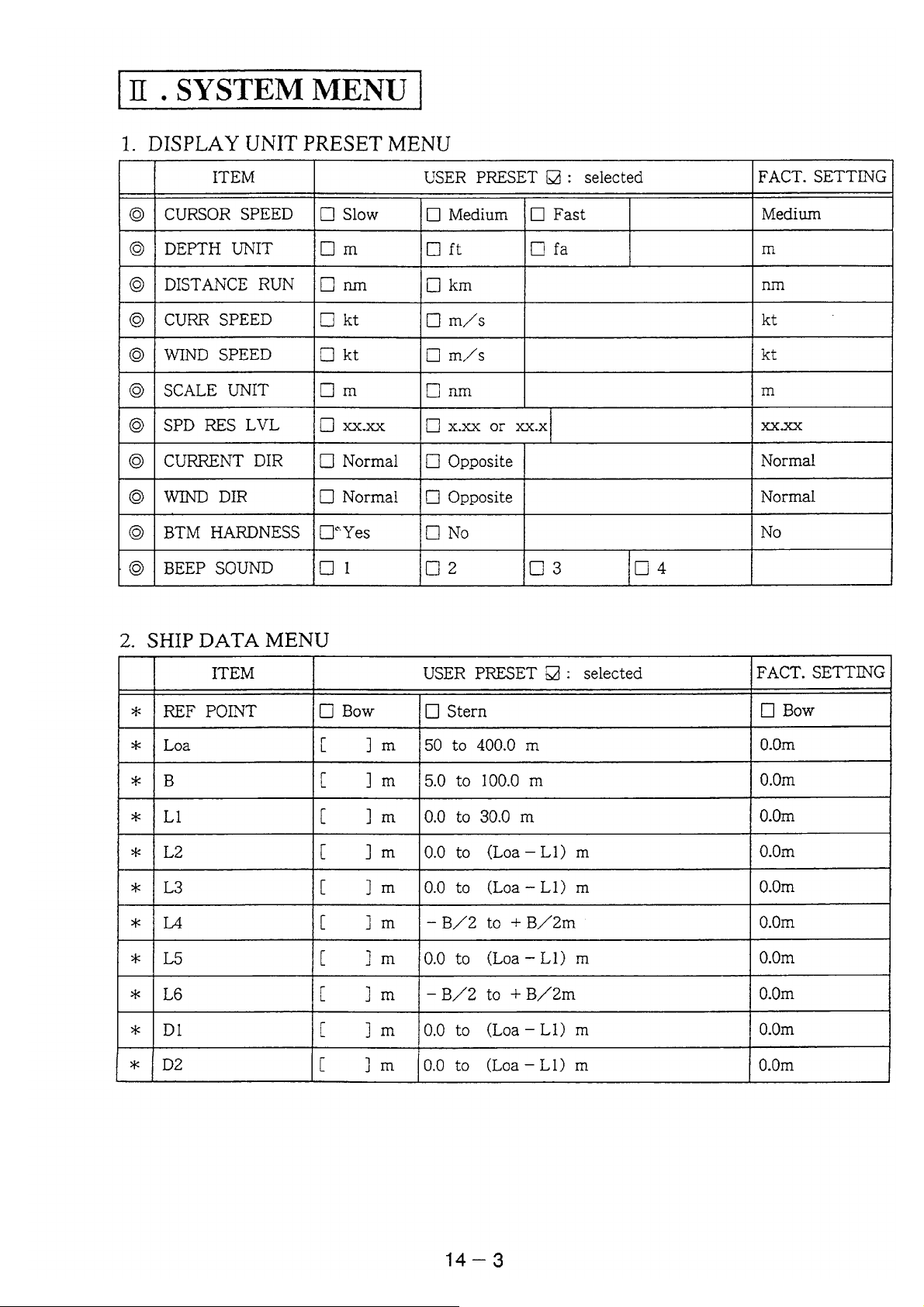

14. TABLES FOR RECORDING USER PRESETS..................................................................14-1

15. DIGITAL INTERFACE (IEC 61162-1 EDITION 2)...............................................................15-1

16. PROGRAM NUMBER ........................................................................................................16-1

Declaration of Conformity

v

Page 8

1. GENERAL

The DS-30 is a highly–advanced, precision Doppler Sonar which incorporates FURUNO’s long

established ultrasonic technology.

It provides accurate displays of ship’s speed over a wide range from dead slow to maximum.

Speeds are detected relative to the ground or water both fore-aft and athwarthship. This feature

allows precise docking of mammoth tankers to oil loading/unloading facilities, as well as safe

navigation in narrow channels or straits.

Features

1) High measuring accuracy of ± (0.2% + 0.01 mm/sec) or better for low longitudinal speed, even in

shallow waters with under keep clearance as little as 1 meter, enables close control of speed and

safe berthing and anchoring operations.

2) Ground tracking up to 200 m provides accurate ship’s ground speed in most coastal waters.

3) Single hull unit composition with employment of the rate-of-turn gyro economizes installation

and maintenance costs. (Most other doppler sonars use two hull units: one each for measuring

ship’s transverse speed at the fore and the stern.

4) Rate-of-turn gyro uses optical fibers instead of moving parts, providing high reliability.

5) Logically arranged presentations of information on the color LCD for instant recognition of

ship’s motion and speed together with under-keel clearance, current and wind conditions.

6) GPS navigator connection provides ship’s ground speed at all times.

7) Conforms to the following standards: IMO A.824(19), as amended by MSC.96(72), IMO

A.694(17), IEC 61023, IEC 60945 (3

rd

edition), IEC 61162-1 (2nd edition)

1-1

Page 9

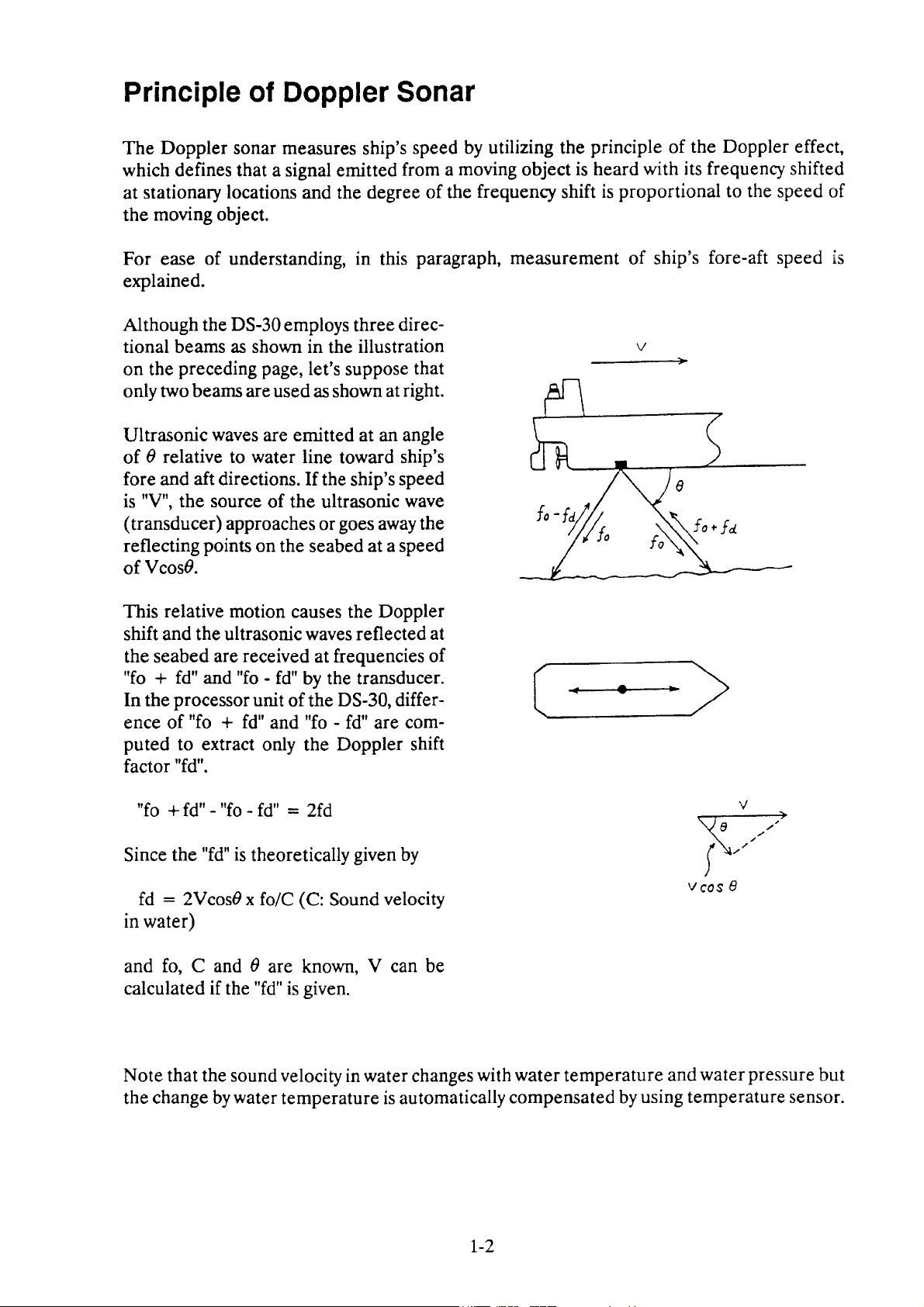

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

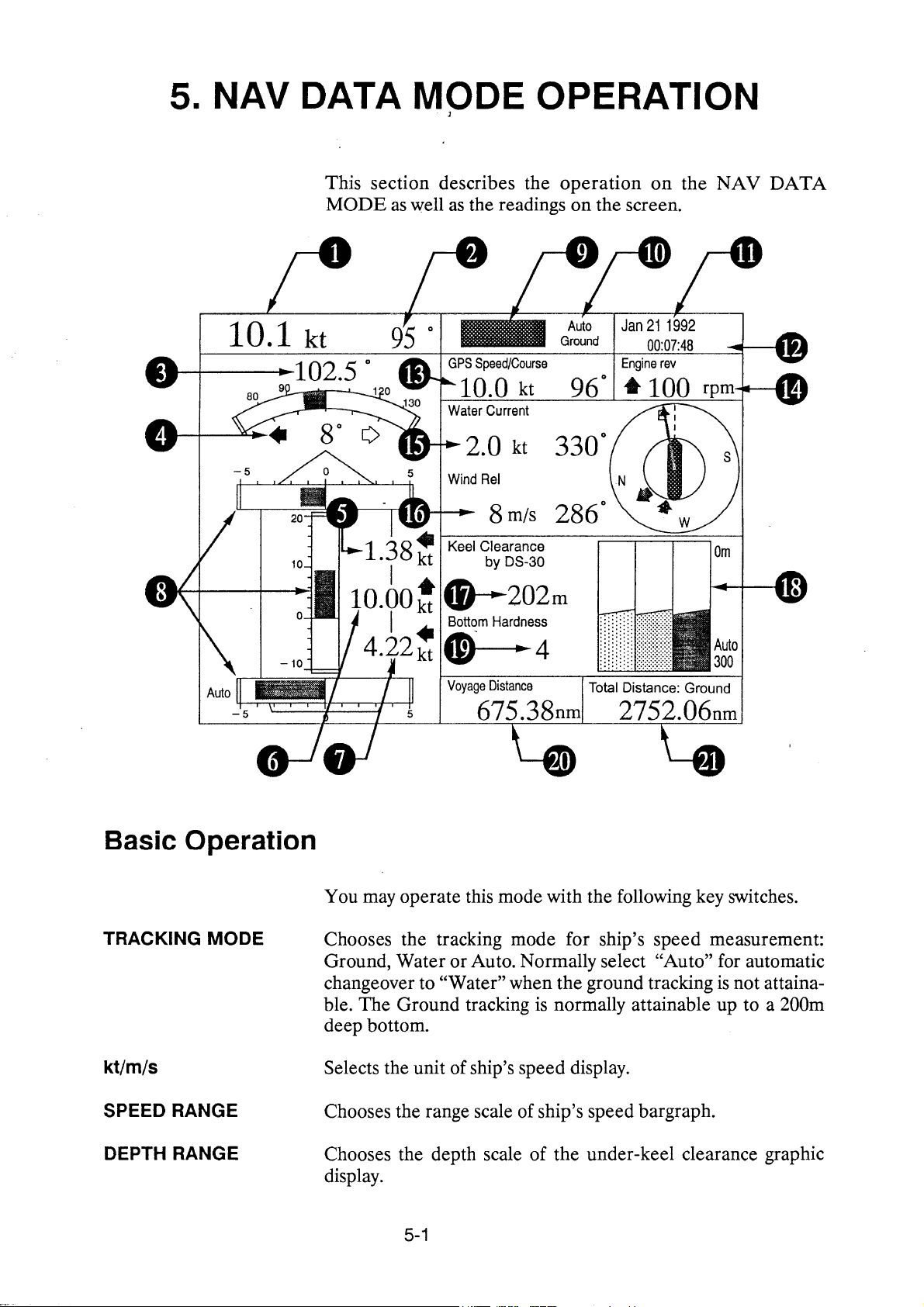

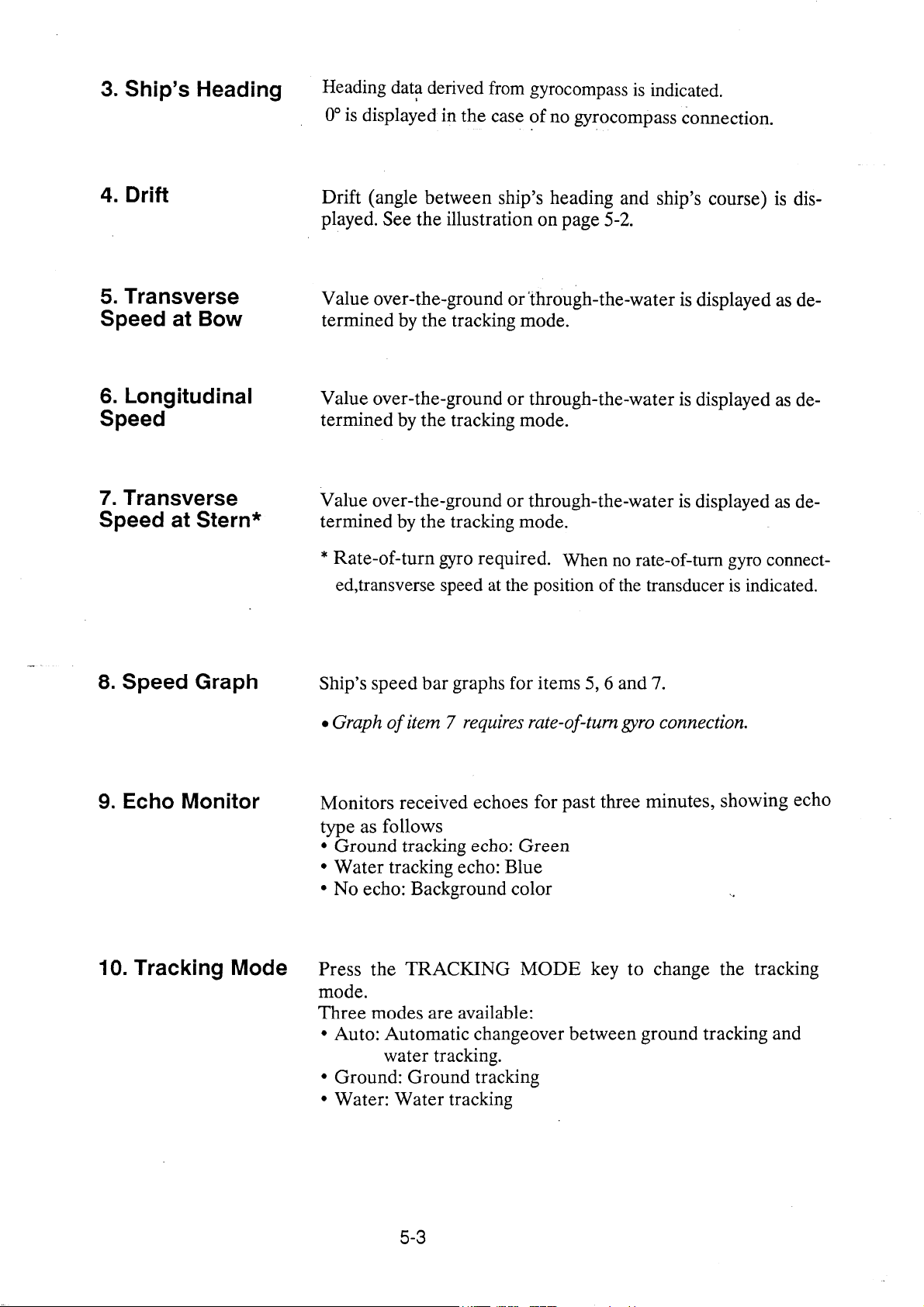

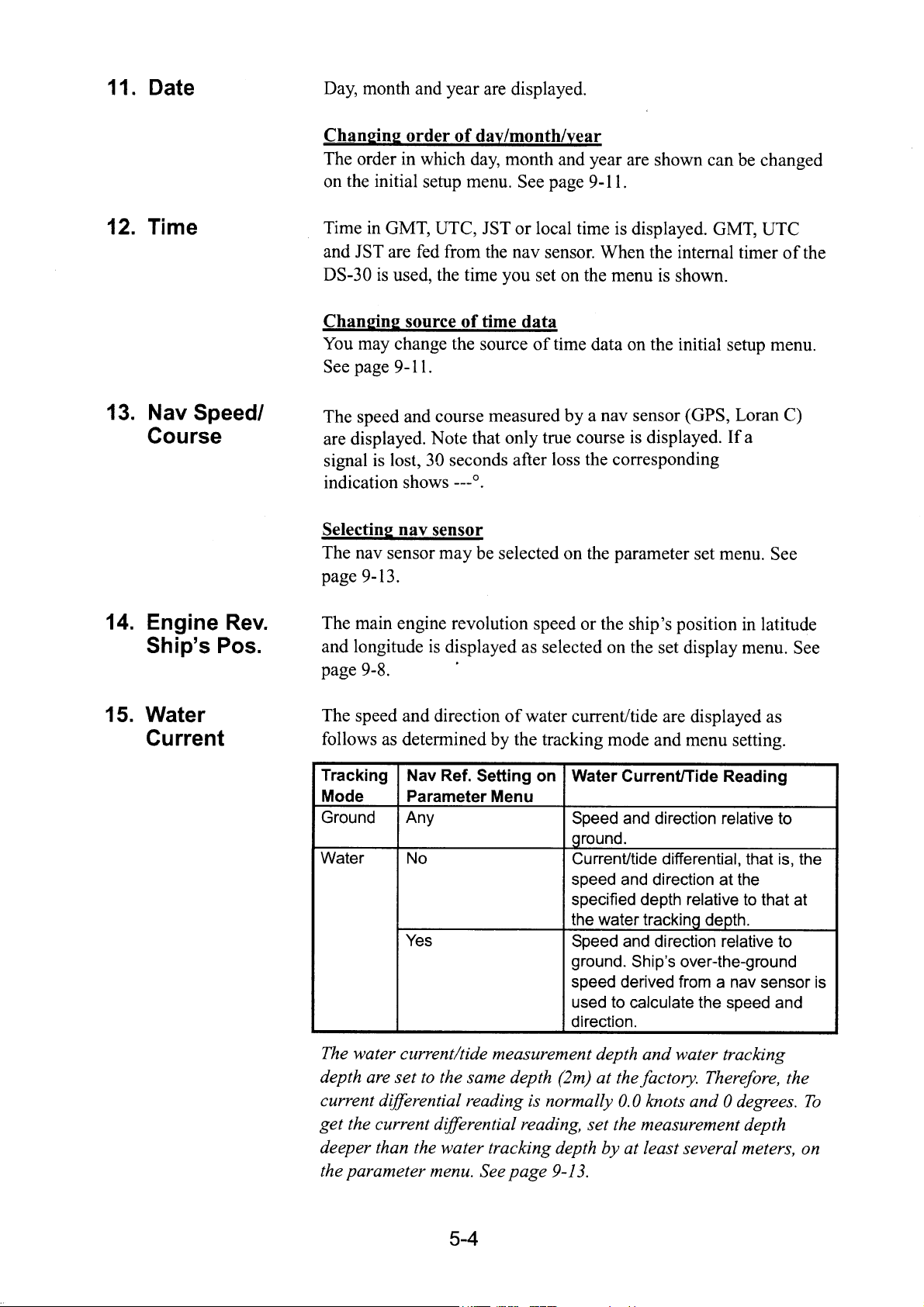

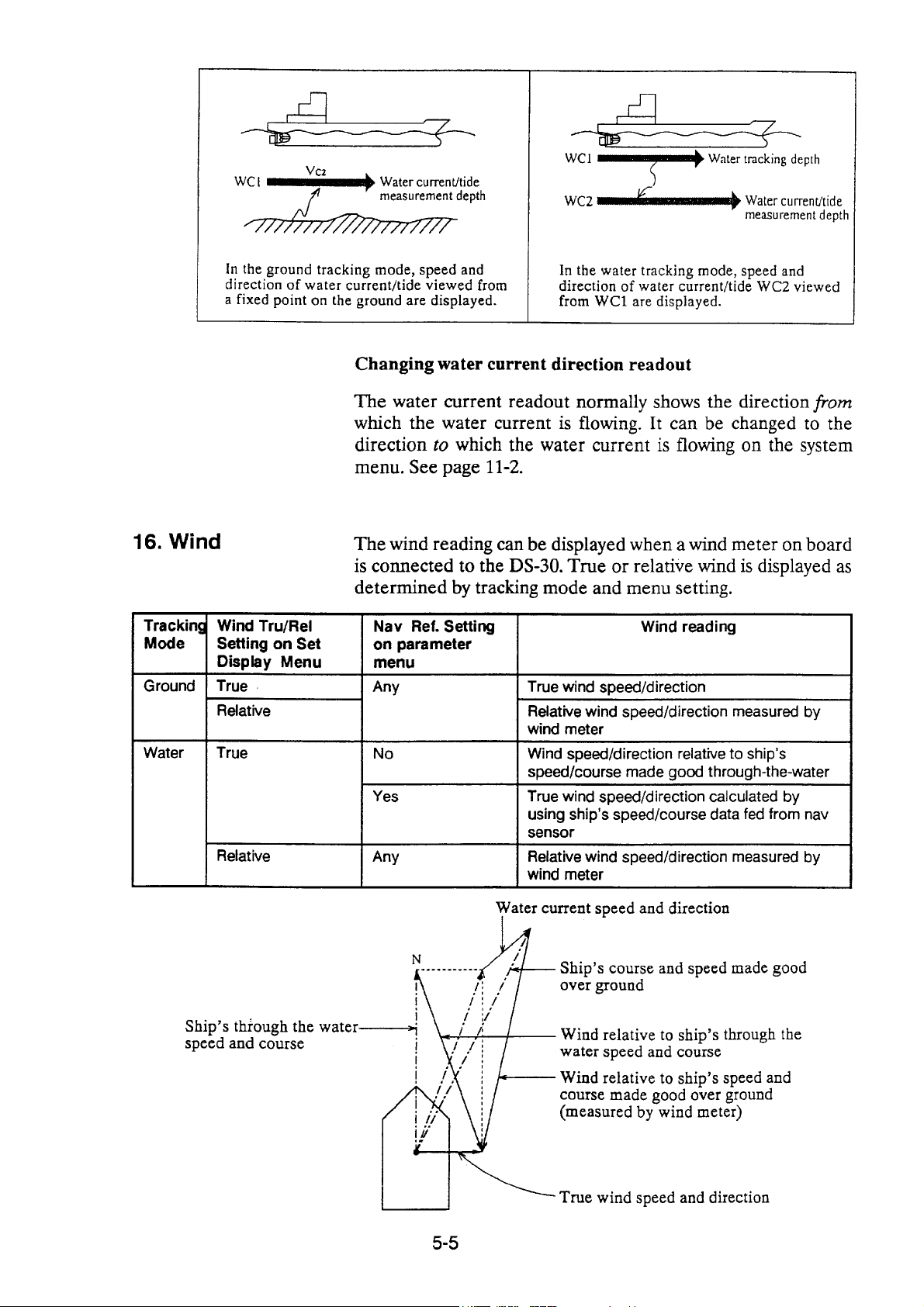

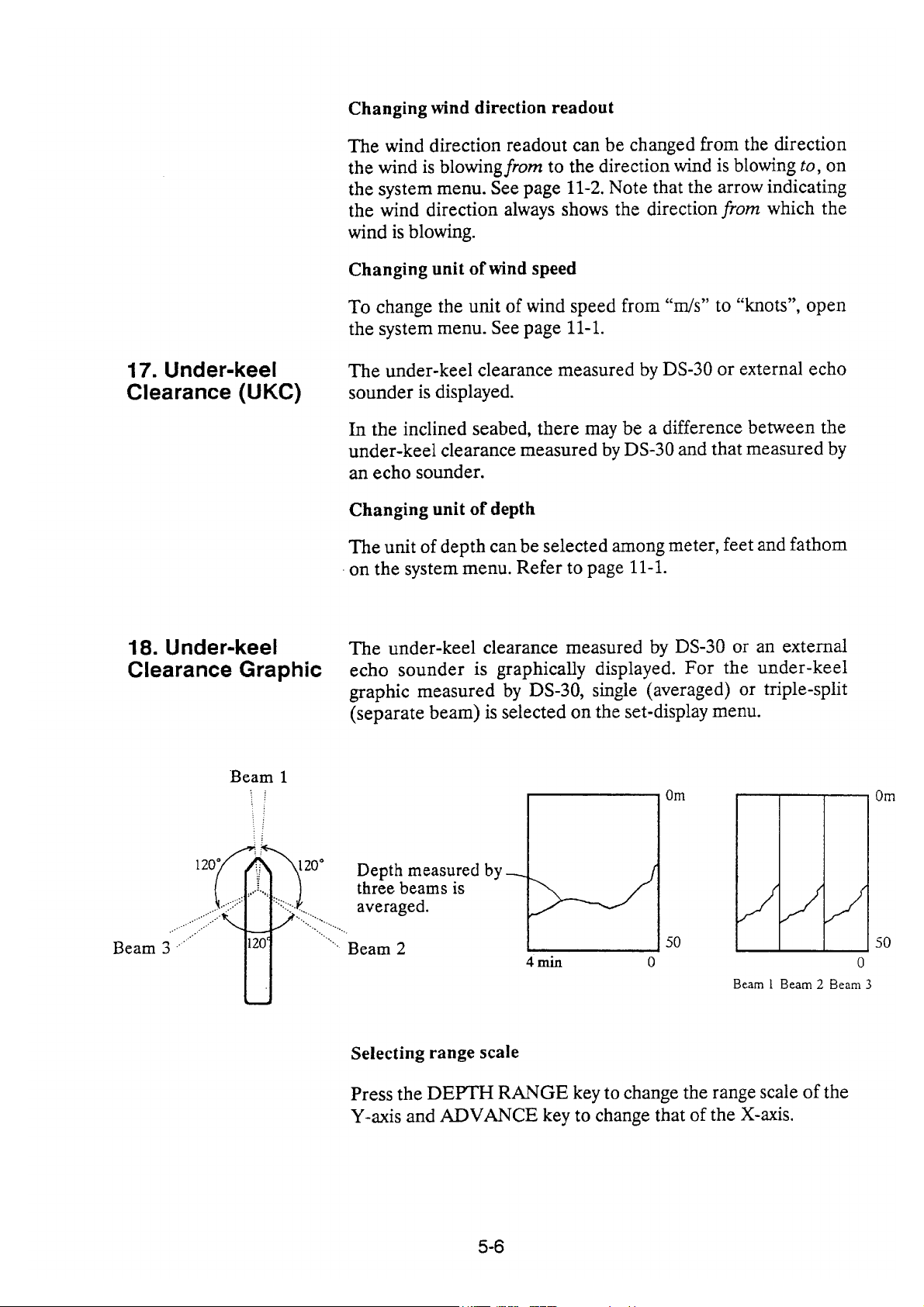

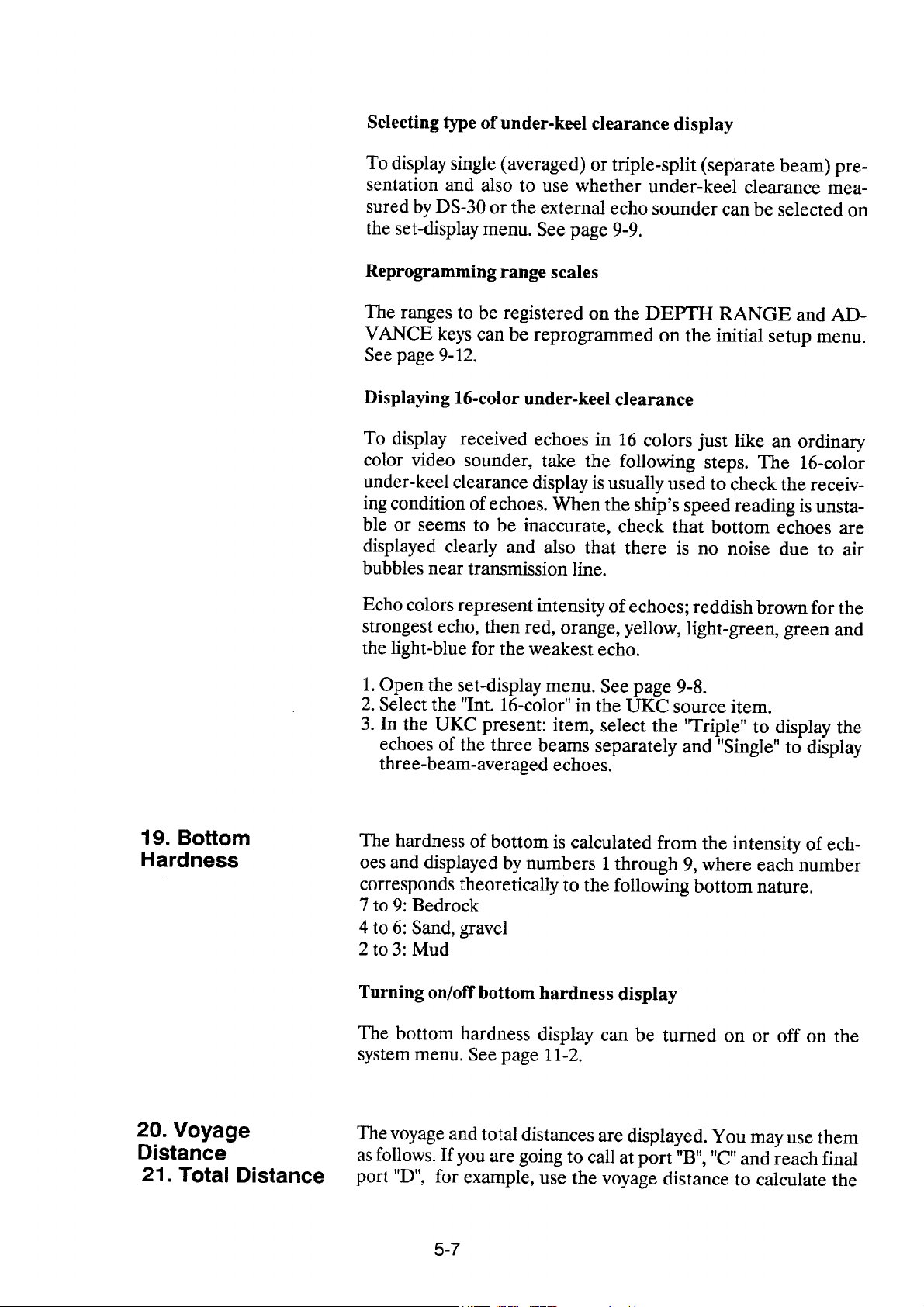

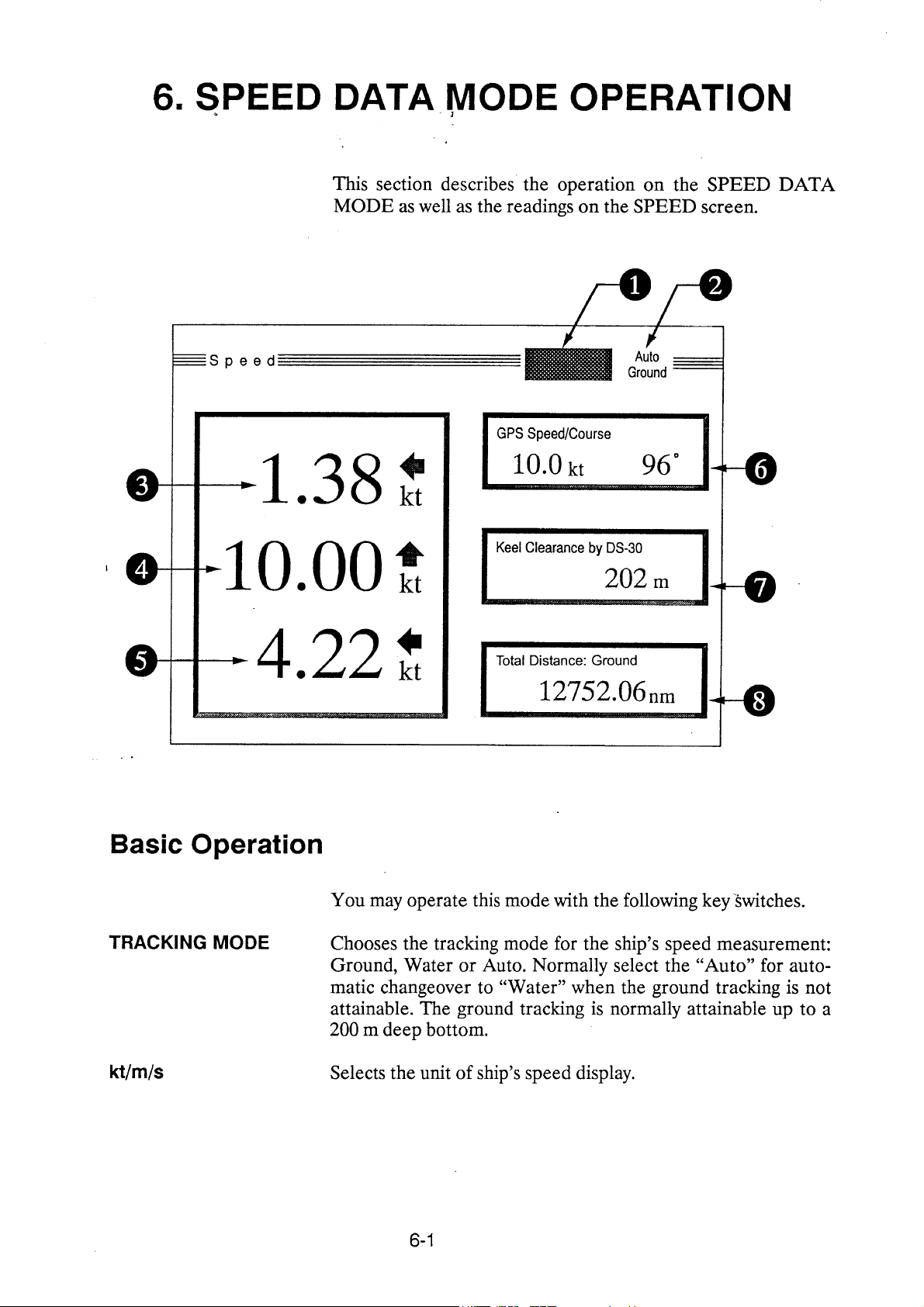

Interpreting Readings and Advanced Operation

In this section, the number beside each header corresponds to the

same number in the illustration of the SPEED DATA MODE screen

on the preceding page. If there is an operation related to a headed

item, the operating procedure is shown.

1. Echo Monitor

2. Tracking Mode

3. Transverse at

Speed at Bow

4. Longitudinal

Speed

5. Transverse

speed at Stern

6. Nav Speed/

Course

7. Under-keel

Clearance

(UKC)

Monitors received echoes for the past two minutes, showing echo

type as follows.

Three modes are available:

• Ground tracking echo (green)

• Water tracking echo (blue)

• No echo (background color)

Press the TRACKING MODE key to change the tracking mode.

• Auto: Automatic changeover between ground tracking and water

tracking.

• Ground: Ground tracking

• Water: Water tracking

Value over-the-ground or through-the-water is displayed as

determined by the tracking mode.

Value over-the-ground or through-the-water is displayed as

determined by the tracking mode.

Value over-the-ground or through-the-water is displayed as

determined by the tracking mode

The speed and course measured by a nav sensor (GPS, Loran C)

are displayed. Note that only true course is displayed. If the speed

or course signal is lost the respective indication is erased 30

seconds later.

Selecting nav sensor

The nav sensor may be selected on the parameter set menu. See

page 9-13.

The under-keel clearance measured by the DS-30 or external

sounder is displayed.

6-2

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

13. SPECIFICATIONS OF

DOPPLER SONAR DS-30

1. Measurement Range

a. Ship's Speed Bow:

Fore-aft: -10.00 to + 40.00 knots

Port-stbd: -9.99 to + 9.99 knots

Stern with optional Laser gyro:

Port-stbd: -9.99 to + 9.99 knots

b. Speed Measurement Depth

Ground tracking:1 to 200m below hull bottom

Water tracking: 3 to 25m below hull bottom

(Above figures will changed depending on installation conditions

and surrounding water conditions. The measuring accuracy will

be reduced for the depth shallower than 30 m.)

c. Current Direction: 360 degrees (Relative or True with gyro signal input)

Speed: 0.0 to + 9.9 knots

d. Current Measurement Depth

2 to 100m below hull bottom (clearance of more than 8m required)

2. Accuracy

a. Ship's Speed ±0.2% or ±0.01 m/sec for low ship's speed ground tracking.

±1.0% or ±0.1 knots for water tracking mode and high ship's

speed ground tracking (clearance of more than 30m).

~ ±1.0% or ±0.04 m/sec for port-stbd at stern (ship's length 400 m).

[Influence of ship 's inclination and vibration excepted.]

b. Sea Depth (clearance) : ±1.0% or ±0.1m

(at 1500 m/sec of sound velocity and by converting inclined

beams to vertical, without consideration of temperature error.)

c. Distance Signal ±1.0% or ±0.1 nm

d. Current Speed ±2.0% or ±0.2 kt

NOTE 1: The speed error which results from variation of sound velocity by water temperature is

automatically compensated by water temperature measured with temperature sensor mounted on the

transducer: The salinity does not affect accuracy.

NOTE 2: Ship’s static inclination (trim and heel) degrades accuracy by 100(cosθ-1)%

(where θ = angle of inclination). The error caused by this inclination can be corrected by entering trim

and heel angles (-12.5° to + 12.5°) on the OFFSET DATA menu.

NOTE 3: Ship 's rolling/pitching degrades accuracy by 0.2% for ±5° rolling/pitching and 0.65% for ±10°.

The error is 1% when it is 11.5%.

13 – 1

Page 62

3. Display

a. Display Unit 10-inch color LCD

b. Digital Display Unit Wide angle numeric LCD

4. Transmission Frequency

440 kHz

5. Input/Output Si g nal

a. Input/Output Serial signal: 2 ports

b. Input Heading from gyro via Converter AD-100: 1 port

Keying pulse from onboard echo sounding equipment for

minimizing interference: 2 ports

DC signal for wind/speed direction: 1 port

DC voltage signal for main engine revolution: 1 port

c. Output Ship speed (for digital indicator): 3 ports

for distribution box: 1 port

Distance signal: for distribution box: 1 port

for contact closure signal: 8 ports

(200 pulses/nm, forward data only, 30V, 0.2A max.)

for TTL signal (400 p/nm, forward data only): 1 port

Alarm signal: contact signal (30V, 2A max): 1 port

Keying pulse: 1 port

d. IEC 61162-1 2nd edition Input signal: ZDA, GLL,VTG, DBT, RMA, RMC,

format signal HCC*, HDM*, DBK*

Output signal: VDR, VHW, VTG, VLW, VBW, ROT, VCD*

* = Available in NMEA sentence

6. Power Supply

Ship’s Mains 100, 110, 120, 200, 220 or 240 VAC

1ф, 50/60 Hz, 300 VA or less (average), 400 VA or less (peak

value)

7. Environmental Conditions

a. Temperature -15

b. Humidity 95% (at 40°C) max.

(Display unit should be installed indoors)

13 – 2

°C to +55°C

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

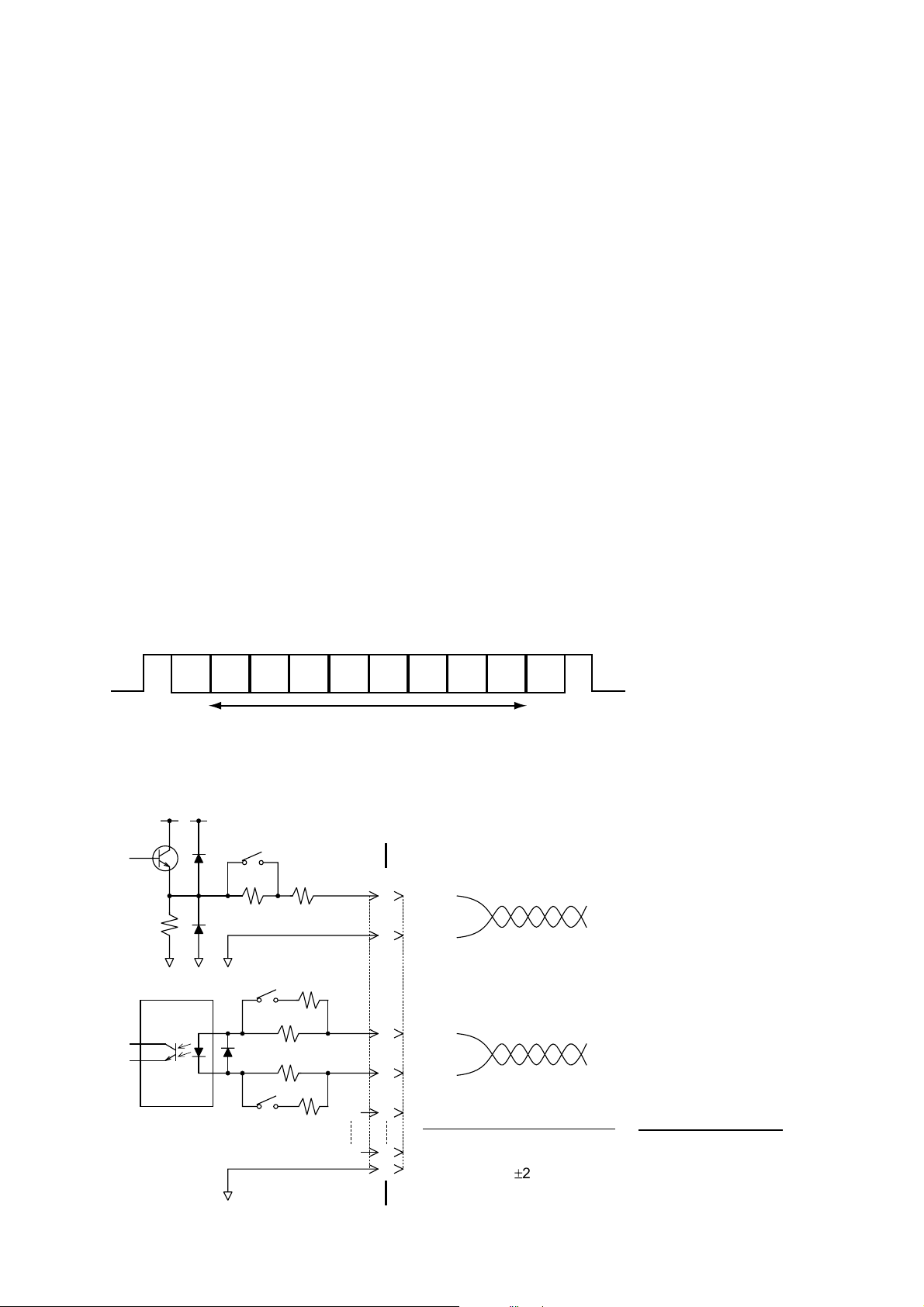

15. DIGITAL INTERFACE

(IEC 61162-1EDITION 2)

Output sentences of channel 1, 2 (NMEA/CIF 1, NMEA/CIF 2)

VDR, VHW, VTG, VLW (talker VD), VBW, ROT

Input sentences of channel 1, 2 (NMEA/CIF 1, NMEA/CIF 2)

ZDA, GLL, VTG, DBT, RMA, RMC

Transmission interval

1 s for any sentence

Data transmission

Data is transmitted in serial asynchronous form in accordance with the standard referenced in 2.1 of

IEC 61162-1. The first bit is a start bit and is followed by data bits, least-significant-bit as illustrated

below.

The following parameters are used:

Baud rate: 4800

Data bits: 8 (D7 = 0), parity none

Stop bits: 1

D0 D1 D2 D3 D4 D5 D6 D7

Start

bit

Data bits

Stop

bit

Schematic diagram

CIF: ON

5V

470 ohm

IEC 61162-1 (NMEA 0183) OFF

5V

J2/J3

180 ohm

47 ohm

SRCN6A16/10S

66P3318

1

TXD-A

2

TXD-B

SRCN6A16/10P

CO-0.2X5P

MAX. 25mA

22 ohm

47 ohm

RXD-A

3

47 ohm

4

RXD-B

NC

NC

5

Load requirements as listener

Isolation: Optocoupler

9

Input Impedance: 30 ohms

10

Max. Voltage: ±2.5V

Threshold: 4 mA

22 ohm

15-1

Output drive capability

Max. 25 mA

Page 70

Data sentences (input)

DBT – Depth below transducer

$--DBT,x.x,f,x.x,M,x.x,F*hh<CR><LF>

| | | | | | |

| | | | | | +--------- 4

| | | | +--+----------- 3

| | +--+----------------- 2

+--+----------------------- 1

1. Water depth, feet

2. Water depth, m

3. Water depth, fathoms

4. Checksum

GLL – Geographic position, latitude and longitude

$--GLL,llll.lll,a,yyyyy.yyy,a,hhmmss.ss,A,a*hh<CR><LF>

| | | | | | | |

| | | | | | | +------- 6

| | | | | | +--------- 5

| | | | | +----------- 4

| | | | +---------------- 3

| | +------+----------------------- 2

+---+----------------------------------- 1

1. Latitude, N/S

2. Longitude, E/W

3. UTC of position

4. Status: A=data valid, V=data invalid

5. Mode indicator(see note)

6. Checksum

NOTE Positioning system Mode indicator:

A = Autonomous

D = Differential

E = Estimated (dead reckoning)

M = Manual input

S = Simulator

N = Data not valid

The Mode indicator field supplements the Status field. The Status field shall be

set to V=invalid for all values of Operating Mode except for A=Autonomous and

D=Differential. The positioning system Mode indicator and Status field shall not

be null fields.

MWD – Wind direction and speed

$--MWD,x.x,T,x.x,M,x.x,N,x.x,M*hh<CR><LF>

| | | | | | | | |

| | | | | | | | +--- 5

| | | | | | +--+----- 4

| | | | +--+----------- 3

| | +--+----------------- 2

+--+----------------------- 1

1. Wind direction, 0 to 359 true

2. Wind direction, 0 to 359 Magnetic

3. Wind speed, knots

4. Wind speed, m/s

5. Checksum

15-2

Page 71

MTW - Water temperature

$--MTW,x.x,C*hh<CR><LF>

| | |

| | +--------- 2

+---+----------- 1

1. Temperature, degrees C

2. Checksum

RMA - Recommended minimum specific LORAN-C data

$--RMA,A,llll.lll,a,yyyyy.yy,a,x.x,x.x,x.x,x.x,x.x,a,a*hh<CR><LF>

| | | | | | | | | | | | |

| | | | | | | | | | | | +------- 10

| | | | | | | | | | | +--------- 9

| | | | | | | | | +---+----------- 8

| | | | | | | | +------------------ 7

| | | | | | | +---------------------- 6

| | | | | | +-------------------------- 5

| | | | | +------------------------------ 4

| | | +----+--------------------------------- 3

| +---+-------------------------------------------- 2

+------------------------------------------------------- 1

1. Status: A=data valid, V=blink, cycle or SNR warning

2. Latitude, degrees N/S

3. Longitude, degrees E/W

4. Time difference A, microseconds

5. Time difference B, microseconds

6. Speed over ground, knots

7. Course over ground, degrees true

8. Magnetic variation(see note 1),degree E/W

9. Mode indicator(see note 2)

10. Checksum

NOTE 1 - Easterly variation(E) subtracts from true course

Westerly variation(W) adds to true course

NOTE 2 Positioning system Mode indicator:

A = Autonomous

D = Differential

E = Estimated (dead reckoning)

M = Manual input

S = Simulator

N = Data not valid

The Mode indicator field supplements the Status field. The Status field

shall be set to V=invalid for all values of Operating Mode except for

A=Autonomous and D=Differential. The positioning system Mode indicator

and Status field shall not be null fields.

15-3

Page 72

RMC - Recommended minimum specific GPS/TR ANSI T data

$--RMC,hhmmss.ss,A,llll.lll,a,yyyyy.yyy,a,x.x,x.x,xxxxxx,x.x,a,a*hh<CR><LF>

| | | | | | | | | | | | |

| | | | | | | | | | | | +--- 10

| | | | | | | | | | | +----- 9

| | | | | | | | | +--+------- 8

| | | | | | | | +--------------- 7

| | | | | | | +--------------------- 6

| | | | | | +------------------------- 5

| | | | +---+---------------------------- 4

| | +---+---------------------------------------- 3

| +--------------------------------------------------- 2

+---------------------------------------------------------- 1

1. UTC of position fix

2. Status: A=data valid, V=navigation receiver warning

3. Latitude, N/S

4. Longitude, E/W

5. Speed over ground, knots

6. Course over ground, degrees true

7. Date: dd/mm/yy

8. magnetic variation, degrees E/W

9. Mode indicator(see note)

10. Checksum

NOTE Positioning system Mode indicator:

A = Autonomous

D = Differential

E = Estimated (dead reckoning)

M = Manual input

S = Simulator

N = Data not valid

The Mode indicator field supplements the Status field. The Status field

shall be set to V=invalid for all values of Operating Mode except for

A=Autonomous and D=Differential. The positioning system Mode indicator

and Status field shall not be null fields.

15-4

Page 73

VTG – Course over ground and ground speed

$--VTG,x.x,T,x.x,M,x.x,N,x.x,K,a*hh<CR><LF>

| | | | | | | | | |

| | | | | | | | | +------- 6

| | | | | | | | +--------- 5

| | | | | | +--+----------- 4

| | | | +--+----------------- 3

| | +--+----------------------- 2

+--+----------------------------- 1

1. Course over ground, degrees true

2. Course over ground, degrees magnetic

3. Speed over ground, knots

4. Speed over ground, km/h

5. Mode indicator(see note)

6. Checksum

NOTE Positioning system Mode indicator:

A = Autonomous

D = Differential

E = Estimated (dead reckoning)

M = Manual input

S = Simulator

N = Data not valid

The positioning system Mode indicator field shall not be a null field.

ZDA – Date and time

$--ZDA,hhmmss.ss,xx,xx,xxxx,xx,xx*hh<CR><LF>

| | | | | | |

| | | | | | +--------- 7

| | | | | +----------- 6

| | | | +-------------- 5

| | | +------------------ 4

| | +---------------------- 3

| +------------------------- 2

+--------------------------------- 1

1. UTC

2. Day, 01 to 31(UTC)

3. Month, 01 to 12(UTC)

4. Year(UTC)

5. Local zone hours, 00h to +-13h

6. Local zone minutes, 00 to +59

as local hours

7. Checksum

15-5

Page 74

Data sentences (output)

VBW- Dual ground/water speed

$--VBW,x.x,x.x,A,x.x,x.x,A,x.x,A,x.x,A*hh<CR><LF>

| | | | | | | | | | |

| | | | | | | | | | +--- 11

| | | | | | | | | +----- 10

| | | | | | | | +-------- 9

| | | | | | | +----------- 8

| | | | | | +-------------- 7

| | | | | +----------------- 6

| | | | +-------------------- 5

| | | +------------------------ 4

| | +--------------------------- 3

| +------------------------------ 2

+---------------------------------- 1

1. Longitudial water speed, knots

2. Transverse water speed, knots

3. Status: water speed, A=data valid V=data invalid

4. Longitudial ground speed, knots

5. Transverse ground speed, knots

6. Status: ground speed, A=data valid V=data invalid

7. Stern transverse water speed, knots

8. Status: stern water speed, A=data valid V=data invalid

9. Stern transverse ground speed, knots

10. Status: stern ground speed, A=data valid V=data invalid

11. Checksum

VDR - Set and drift

$--VDR,x.x,T,x.x,M,x.x,N*hh<CR><LF>

| | | | | | |

| | | | | | +--------- 4

| | | | +--+----------- 3

| | +--+----------------- 2

+--+----------------------- 1

1. Direction, degrees true

2. Direction, degrees magnetic

3. Current speed, knots

4. Checksum

VHW - Water speed and heading

$--VHW,x.x,T,x.x,M,x.x,N,x.x,K*hh<CR><LF>

| | | | | | | | |

| | | | | | | | +--------- 5

| | | | | | +--+----------- 4

| | | | +--+----------------- 3

| | +--+----------------------- 2

+--+----------------------------- 1

1. Heading, degrees true

2. Heading, degrees magnetic

3. Speed, knots

4. Speed, km/h

5. Checksum

15-6

Page 75

VLW - Distance travelled through the water

$--VLW,x.x,N,x.x,N*hh<CR><LF>

| | | | |

| | | | +--------- 3

| | +--+----------- 2

+--+----------------- 1

1. Total cumulative distance, nautical miles

2. Distance since reset, nautical miles

3. Checksum

VTG - Course over ground and ground speed

$--VTG,x.x,T,x.x,M,x.x,N,x.x,K,a*hh<CR><LF>

| | | | | | | | | |

| | | | | | | | | +------- 6

| | | | | | | | +--------- 5

| | | | | | +--+----------- 4

| | | | +--+----------------- 3

| | +--+----------------------- 2

+--+----------------------------- 1

1. Course over ground, degrees true

2. Course over ground, degrees magnetic

3. Speed over ground, knots

4. Speed over ground, km/h

5. Mode indicator(see note)

6. Checksum

NOTE Positioning system Mode indicator:

A = Autonomous

D = Differential

E = Estimated (dead reckoning)

M = Manual input

S = Simulator

N = Data not valid

The positioning system Mode indicator field shall not be a null field.

ROT – Rate of turn

$--ROT,x.x,A*hh<CR><LF>

| | |

| | +--- 3

| +----- 2

+-------- 1

1. Rate of turn, deg/min, "-"=bow turns to port

2. Status: A=data valid, V=data invalid

3. Checksum

15-7

Page 76

16. PROGRAM NUMBER

Pub No., Reason for Modification,

Date

OME-72360-R

Modified to conform to IEC 61162-1

Edition 2

2002/4

Software (Prog. No.)

DS-300

CP board 665-0100-007

DS-310

CP board 665-0110-008

FT board 665-0120-100

KL board 665-0130-100

IF board 665-0140-010

DS-320

CP board 665-0160-102

16-1

Page 77

Loading...

Loading...