Furuno 525TID-TMD User Manual

INSTALLATION INSTRUCTIONSOWNER’S GUIDE &

Transom Mount, 1kW, Depth Transducer

with Release Bracket

Models: TM258, TM260, TM270W

WARNING: Always wear safety goggles and a dust

mask when installing to avoid personal injury.

CAUTION: Never pull, carry, or hold the transducer by

the cable as this may sever internal connections.

17-299-02 rev. 01 01/09

CAUTION: Do not strike the transducer to release it.

When mounted on the bracket, remove the transducer

by removing the locking pin and hinge pin.

CAUTION: Never use solvents. Cleaners, fuel,

sealants, paint, and other products may contain strong

solvents, such as acetone, which attack many

plastics, greatly reducing their strength.

IMPORTANT: Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

Applications

• Recommended for outboard and inboard/outboard sport fishing

powerboats, 8m (25') and up

• Not recommended for inboard powerboats

• Not recommended for stepped hulls

• Adjusts to transom angles from 3° –21°

• Bracket protects the transducer from frontal impact only

Record the information found on the cable tag for future reference.

Part No.________________ Date___________ Frequency________ kHz

TM260

with shims

in operational position

Mounting Location

General Guidelines

CAUTION: Do not mount the transducer in an area of turbulence

or bubbles: near water intake or discharge openings; behind

strakes, struts, fittings, or hull irregularities.

CAUTION: Avoid mounting the transducer where the boat may be

supported during trailering, launching, hauling, or storage.

• For best performance, the transducer must be in contact with aeration-free and turbulence-free water. To identify an area of smooth

water, observe the flow off the transom while the boat is underway.

• Allow headroom space above the bracket for it to release and

rotate the transducer upward.

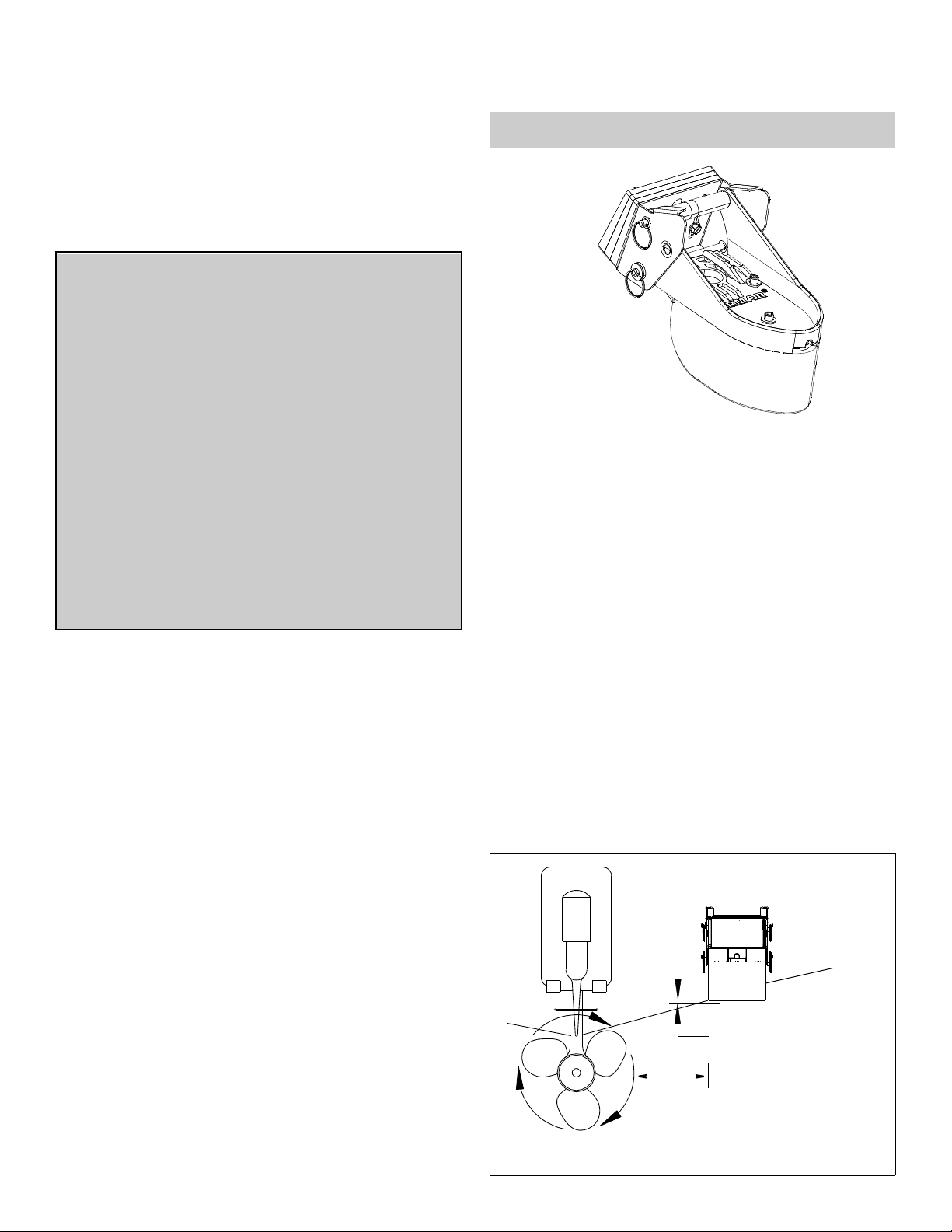

• Mounting on the side of the transom where the propeller blades

are moving downward is preferred (see Figure 1).

• Mount the transducer as close to the centerline (keel) of the

boat as possible to ensure the transducer’s face remains in the

water when the boat is turning. However, keep in mind that it

should be a minimum of 15 cm (6") beyond the swing radius of

the propeller, so the water passing over the transducer does not

cause a flow disturbance to the propeller.

Tools & Materials

Safety goggles

Dust mask

Angle finder

Masking tape (some installations)

Pencil

Electric drill

Drill bits:

Bracket holes 5mm, #4, or 7/32"

Transom hole (optional) 18mm, 11/16", or 3/4"

21mm or 13/16" (

Cable clamp holes 3mm or 1/8"

Marine sealant (suitable for below waterline)

Socket wrench

Straight edge

Small screwdriver

Grommets (some installations)

Cable ties

Water-based anti-fouling paint (mandatory in salt water)

Furuno, Raymarine only)

NOTE: Starboard

side of hull where

propeller blades are

moving downward

is prefered.

hull projection

0–3mm (0–1/8")

15cm (6")

minimum beyond

swing radius

Figure 1. Mounting location on single drive boat

Copyright © 2009 Airmar Technol ogy Corp.

parallel to

waterline

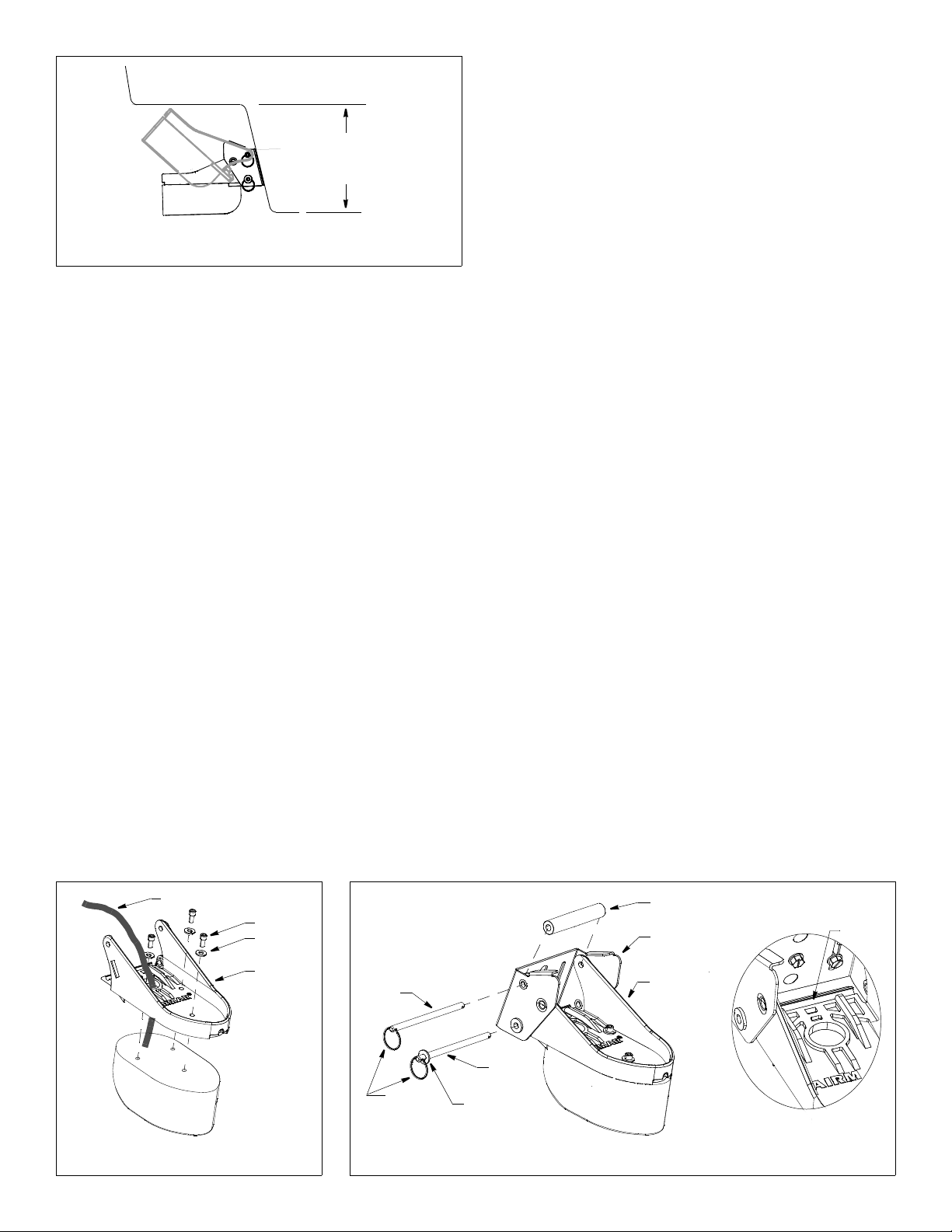

Compensating for Transom Angle

CAUTION: Do not position the leading edge of the transducer

deeper in the water than the trailing edge to avoid aeration.

headroom

TM258: 244mm (9-3/4")

TM260: 260mm (10-1/4")

TM270W: 260mm (10-1/4")

Figure 2. Headroom required on stepped transom

Copyright © 2009 Airmar Technology Corp.

Type of Boat

• Single drive—Mount a minimum of 15cm (6") beyond the

swing radius of the propeller (see Figure 1).

• Twin drive—Mount between the drives a minimum of 15cm

(6") beyond the swing radius of the propeller.

• Trim tabs—Mount inside the trim tab, space permitting.

• Stepped transom—Mount the transducer on the lowest step

being sure there is enough headroom for the bracket to release

(see Figure 2).

Installation

WARNING: Always wear safety goggles and a dust mask.

Assembling the Transducer & Bracket

1. Thread the cable through the large hole in the transducer

support (see Figure 3).

2. Fasten the support to the transducer using the three socket-

head-cap screws and washers supplied. Tighten the screws

with the 3/16" Allen wrench supplied.

3. Attach a safety ring to one end of each pin (see Figure 4).

4. While holding the transducer assembly against the bracket, insert

a pin through the upper hole in the bracket and the support.

Slide the spacer onto the pin and push it through the remaining

hole in the support and the bracket. Attach a second safety ring.

This pin will function as a hinge when the transducer is released.

5. Slide a washer onto the remaining pin. Push it through the lower

hole in the bracket, slide it along the channel in the support, and

through the second hole in the bracket. Slide the second washer

onto the free end of the pin and attach the second safety ring.

This will function as the locking pin to hold the transducer in the

operational position when underway.

For the best performance, the transducer beam must be aimed

straight at the bottom (see Figure 5). Since the transom of most

boats is angled, the bracket must compensate for it. Measure the

transom angle of the boat with an angle finder.

Standard transom (12° transom angle)—The bracket is

designed for a standard 12° transom angle. No shim is needed for

this installation. If your boat is capable of speeds above 20kn

(28MPH), install the bracket with one 3° shim, taper down. This

will ensure that the transducer is in contact with the water at high

speeds.

Shims—The bracket is supplied with three shims; each one has a

3° angle. Up to three shims can be combined for a maximum of 9°.

The shims are designed to mate together. Two bosses on the face fit

into recesses in the back of another shim or the holes in the bracket.

•Transom angles greater than 12°—Add the appropriate num-

ber of shims with the taper up to the 12° bracket angle.

• Transom angles less than 12°—To reduce the bracket’s 12°

angle, group the appropriate number of shims with the taper

down.

If you are unsure about using the shim(s), experiment with the

them by following the instructions “Mounting & Adjusting the

Bracket.”

Hole Drilling

1. At the selected mounting location, position the assembly so the

transducer projects 3mm (1/8") below the bottom edge of the

transom (see Figure 1). Be sure any shim(s) is in place. (You

may want to tape the shim(s) to the bracket temporarily.) With

the transducer in the operational position, mark the bottom

corners of the bracket.

2. Remove the transducer assembly from the bracket by removing

the locking pin and the hinge pin (see Figure 4). Hold the

bracket with any shim(s) in place against the transom at the

marked location. Draw an “X” at 12mm (1/2") from the top and

the bottom of each slot (see Figure 6).

3. Using a 5mm, #4, or 7/32" drill bit, drill the four holes.

Fiberglass hull—Minimize surface cracking by running the drill in

reverse until the gelcoat is penetrated.

cable

transducer

Figure 3. Assembling the transducer

Copyright © 2009 Airmar Technology Corp.

2

screw (3)

washer (3)

support

hinge

pin

safety

ring (4)

spacer

bracket

support

locking

pin

washer (2)

Figure 4. Attaching the transducer to the bracket

Copyright © 2009 Airmar Technol ogy Corp.

transducer

detail

channel

Loading...

Loading...