Page 1

or

or

or

or

INSTALLATION INSTRUCTION SUPPLEMENT

IMPORTANT

Use these instructions along with your sensor installation instructions.

These instructions supersede all other instructions where they differ.

17-276-01 rev. 02 7/01

WARNING

Installation of the anti-rotation bolt is mandatory!

Failure to install the anti-rotation bolt ma y result in the fairing rotating while the

boat is underway. The effect ma y be violent movement and loss of steering. This

could result in serious injury or death to passengers and/or damage to the boat or

other property .

High Speed Fairing

For Sensor Models: B45, B46, B256, B260,

B744V, SS505, SS544V

Caution

electrolytic corrosion will occur.

Tools and Materials Needed

Identify Y our Model

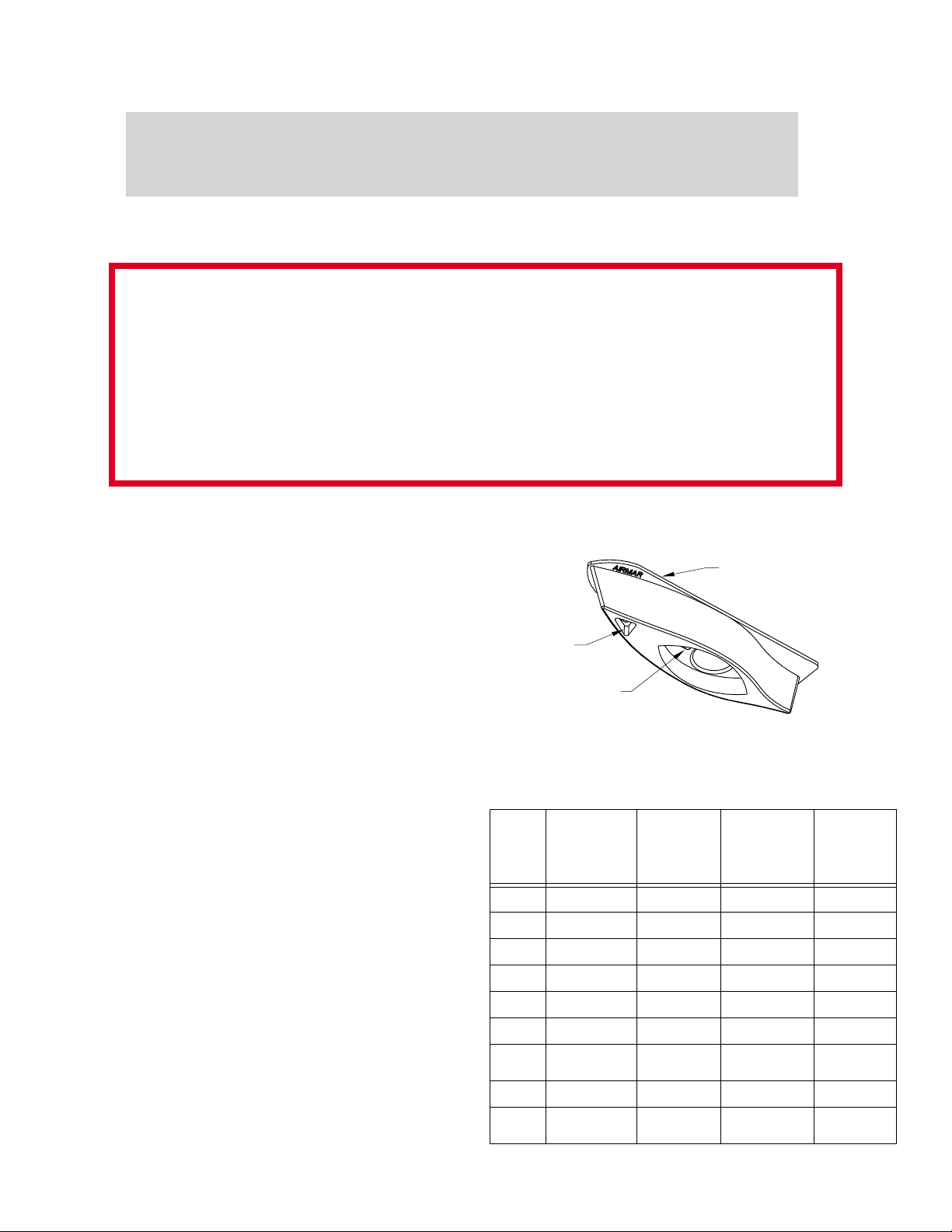

The model # appears in the recess of the fairing (see Figure 1).

: Ne ver install a bronz e housing in a metal hull because

Digital level or bubble level & protractor

or

Band saw

hand saw

Safety goggles

Dust mask

Rasp

or

power tool

Electric drill

Drill bits, hole saw(s) (see Specifications Table 1)

or

Pilot hole 3mm

1/8"

Sandpaper

File (installation in metal hull)

Mild household detergent

or

weak solvent (alcohol)

Marine sealant (3M # 5200)

Slip-joint pliers

Mallet

For installation in a cored fiberglass hull, additional tools and

materials are needed (see page 4).

cutting

guide

triangular

recess for

anti-rotation bolt

model

number

Figure 1. High-Speed Fairing—B744V Shown

Specifications T able 1

Max. Hull

Sensor

Model

B45 50mm (2") 35mm (1-3/8") 22mm or 7/8" 10mm or 3/8"

B46 40mm (1-5/8") 35mm (1-3/8") 22mm

B256 45mm (1-3/4") 38mm (1-1/2") 30mm

B260 45mm (1-3/4") 74mm (2-7/8") 33mm

B744V 19mm (3/4") 32mm (1-1/4") 51mm

SS505 56mm (2-1/4") 32mm (1-1/4") 22mm

SS505

in metal hull

SS544V 19mm (3/4") 32mm (1-1/4") 51mm

SS544V

in metal hull

Thickness

(measured

perpendicular

to water surface)

56mm (2-1/4") 32mm (1-1/4") 25mm or 1" 10mm or 3/8"

19mm (3/4") 32mm (1-1/4") 54mm or 2-1/8" 10mm or 3/8"

Min. Fairing

Thickness

Drill Bit for

Sensor

or

7/8" 10mm or 3/8"

or

1-3/16" 13mm or 1/2"

1-5/16" 13mm or 1/2"

2" 10mm or 3/8"

7/8" 10mm or 3/8"

2" 10mm or 3/8"

The min. hull thickness for all sensor models is 6mm (1/4").

Drill Bit for

Anti-rotation

Bolt

Page 2

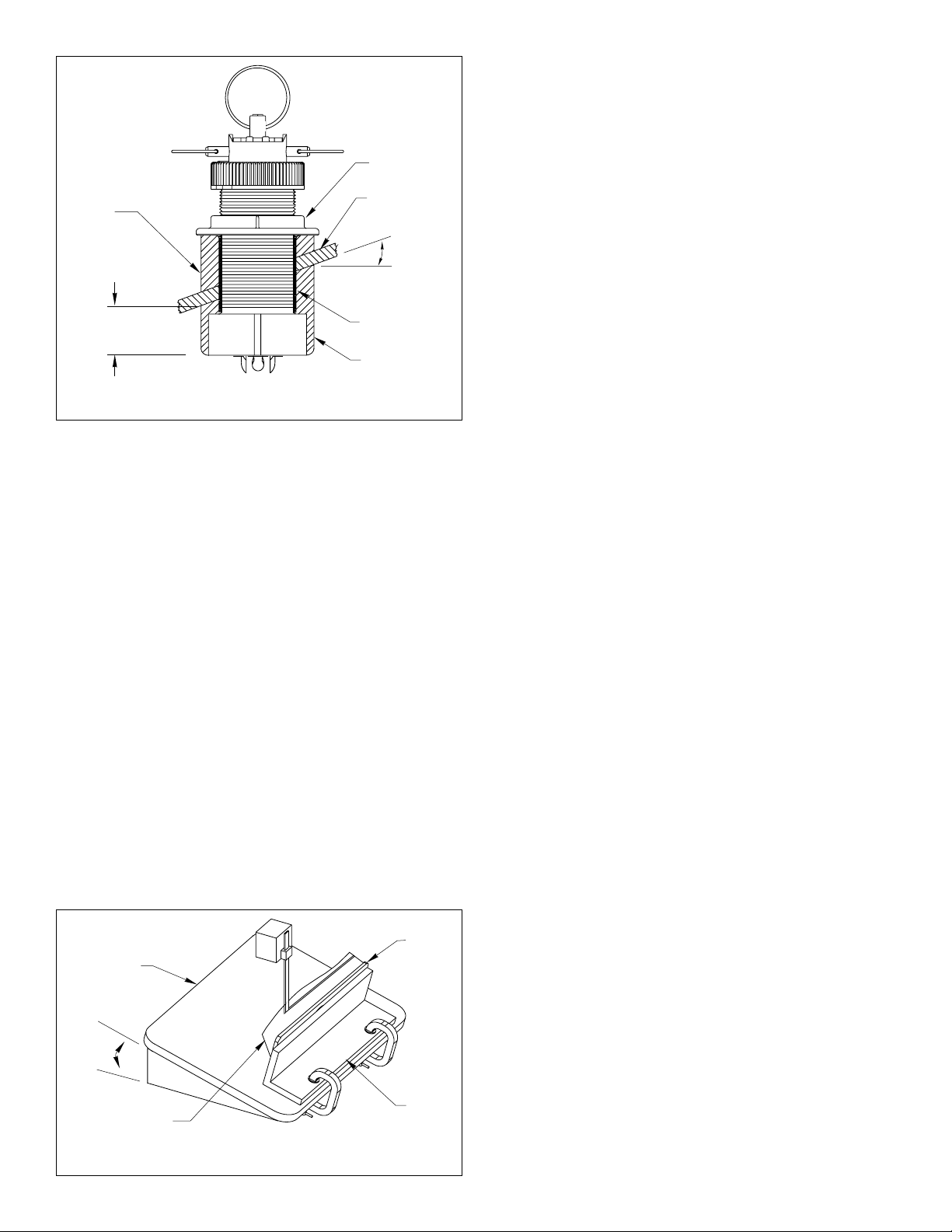

aft view

hull nut

backing

block

min. fairing

thickness

hull

slope of hull

deadrise

angle

parallel to

water surface

isolation

sleeve

fairing

Figure 2. SS544V with isolation sleeve

Cutting the Fairing

1.Measure the deadrise angle of the hull at the selected mounting

location using a digital level, or b ubble level and protractor (see

Figure 2).

2.Tilt the band saw table to the measured angle and secure the

cutting fence (see Figure 3).

Note : Be sure to orient the fairing on the band saw so the angle

cut matches the intended side of the hull and not the mirror

image.

3.Place the fairing on the table so the cutting guide rests against

the fence. The end with the triangular recess will be pointing

toward you for installation on the port side of the boat or

pointing away from you for installation on the starboard side.

Note : The end of the fairing with the triangular recess always

points forward toward the bow when installed.

4.There is a minimum thickness for the fairing at its thinnest

dimension (see Figure 2 and Specifications Table 1).

Warning : Always wear safety goggles and a dust mask.

5.Recheck steps 1 through 4; then cut the fairing.

6.Shape the fairing to the hull as precisely as possible with a rasp

or power tool.

7.Use the remaining section of the fairing as the backing block.

cutting

guide

band saw

table

Installation

Cored Fiberglass Hull —Follow separate instructions on page 4.

Caution : Never use solvents. Cleaners, fuel, paint, sealants, and

other products may contain strong solvent, such as acetone,

which attack plastics greatly reducing their strength.

Notice : Never pull, carry, or hold the sensor by the cable as this

may sever internal connections.

Drilling a Hole for the Sensor

Warning : Always wear safety goggles and a dust mask.

1.Drill a 3mm or 1/8" pilot hole perpendicular to the waterline from

inside the hull (see Figure 2). If there is a rib, strut or other hull

irregularity near the selected mounting location, drill from the

outside. (If the pilot hole is drilled in the wrong location, drill a

second hole in a better location. Apply masking tape to the

outside of the hull over the incorrect hole and fill it with epoxy.)

2.Using the appropriate size drill bit or hole saw, cut a hole from

outside the hull (see Specification Table 1).

3.Sand and clean the area around the hole, inside and outside, to

ensure that the sealant will adhere properly to the hull. If there

is any petroleum residue inside the hull, remove it with either

mild household detergent or a weak solvent (alcohol) before

sanding.

Metal hull —Remove all burrs with a file and sandpaper.

Drilling a Hole for the Anti-rotation Bolt

Dry fit the sensor to locate the hole for the anti-rotation bolt.

1.

B45, B46, B256, B260, SS505 —Remove the hull nut from the

sensor (see Figure 2).

2.Thread the sensor cable through the large hole in the fairing

and through the mounting hole in the hull. Seat the sensor

firmly in the recess in the fairing (see Figure 4).

Note : The sensor must be flush with the fairing. If it is recessed

more than 0.5mm (1/64") inside the fairing, you may carefully

file or sand the fairing flush with the sensor.

Warning : Always wear safety goggles and a dust mask.

3.Attach the appropriate size drill bit to your drill (see

Specifications Table 1). Slide the sensor’s stem with the fairing

in place into the mounting hole. (

the fairing is pointing forward to ward the bow

assembly in place and using the bolt hole in the fairing as your

guide, drill a hole through the hull for the anti-rotation bolt.

4.Remove the assembly and cable from the mounting hole.

5.Sand and clean the area around the hole, inside and outside, to

ensure that the sealant will adhere properly to the hull. If there

is any petroleum residue inside the hull, remove it with either

mild household detergent or a weak solvent (alcohol) before

sanding.

Metal hull —Remove any burrs around both holes with a file

and sandpaper.

Be sure the triangular recess in

.) While holding the

deadrise

2

angle

bow end

for installation

on port side

Figure 3. Cutting the fairing

cutting

fence

Bedding the Sensor

1.Remove the sensor from the fairing.

2.

Stainless steel sensor in metal hull only —Slide the

appropriate size isolation sleeve over the cable and onto the

stem of the sensor as far down as possible (see Figure 2).

sure

the top of the isolation sleeve will be below the top of the

backing block to prevent the sleeving from interfering with

tightening the hull nut.

Caution : To prevent electrolytic corrosion, never allow direct

contact between a stainless steel sensor and a metal hull!

Be

Page 3

WARNING

Installation of the anti-rotation bolt is mandatory!

Failure to install the anti-rotation bolt ma y result in the fairing rotating while the boat is

underway. The effect ma y be violent movement and loss of steering. This could result

in serious injury or death to passengers and/or damage to the boat or other property .

3.Apply a 2mm (1/16") thick layer of marine sealant to the sides of

the sensor that will contact the fairing and up the stem

6mm (1/4") higher than the combined thickness of the fairing,

hull, backing block, and hull nut. This will ensure there is marine

sealant in the threads to seal the hull and hold the hull nut

securely in place (see Figure 4).

Stainless steel sensor in metal hull —Apply the marine

sealant to the outside of the sleeving instead of the stem itself.

4.Thread the sensor cable through the fairing and seat the sensor

firmly within the recess in the fairing.

5.Apply a 2mm (1/16") thick layer of marine sealant to the surface

of the fairing that will contact the hull.

Bedding the Anti-rotation Bolt and Installing

1.From outside the hull, thread the cable through the mounting

hole. Push the stem of the sensor (with the fairing in place) into

the mounting hole using a twisting motion to squeeze out excess

sealant (see Figure 4).

Caution : Never strike the sensor.

2.From inside the hull, slide the backing block onto the sensor

cable and stem seating the backing bloc k firmly against the hull.

Screw the hull nut in place and tighten it with slip-joint pliers.

Wood hull —Allow for the wood to swell.

Fiberglass hull — Do not over-tighten and crush the hull.

Stainless steel sensor in metal hull — Be sure the top of the

isolation sleeve is below the top of the backing block to prevent

the sleeving from interfering with tightening the hull nut.

3.Apply a 2mm (1/16") thick layer of marine sealant to the antirotation bolt, 6mm (1/4") higher than the combined thickness of

the fairing, hull, backing bloc k, washer, and nut. This will ensure

that there is marine sealant on the threads to seal the hull and

hold the nut securely in place (see Figure 4).

4.Apply a 2mm (1/16") thick layer of marine sealant to one side of

the nut.

5.Push the bolt through the fairing and into the hull.

6.From inside the hull, slide the w asher onto the bolt. Slide the nut

onto the bolt with the

Screw the nut in place and tighten it with slip-joint pliers.

Wood hull —Allow for the wood to swell.

Fiberglass hull — Do not over-tighten and crush the hull.

7.Apply marine sealant to the

Push the plug into the triangular recess in the fairing.

triangular plug fits one way only. Be sure

plug is exposed, matching the curve on the outside of the

fairing. Tap it into place with a mallet.

Note : For smooth water flow over the transducer, be sure that

the external surface of the installed triangular plug is FLUSH

with the external curved surface of the fairing.

8.Proceed with the installation instructions that came with your

sensor beginning with “Installing” step #4.

sealant side facing the backing block .

FLAT side of the triangular plug.

The

the curved side of the

marine

sealant

detail

⇐

BOW

anti-rotation

hull

Figure 4. Bedding and installing the anti-rotation bolt—B744V shown

bolt

nut &

washer

triangular plug

with curved

surface facing

outward

marine sealant

hull nut

backing

block

fairing

3

Page 4

or

or

or

or

or

or

Installation in a Cored Fiberglass Hull

The core (wood or foam) must be cut and sealed carefully. The core

must be protected from water seepage, and the hull must be

reinforced to prevent it from crushing under the hull nut allowing the

sensor to become loose.

Additional Tools and Materials Needed

Drill bit(s), hole saw(s) (see Specifications Table 2)

Cylinder

Wax

Tape

Casting epoxy

Preparing a Cored Fiberglass Hull

Warning : Always wear safety goggles and a dust mask.

1.Drill a 3mm or 1/8" pilot hole from inside the hull (see Figure 5). If

there is a rib, strut, or other hull irregularity near the selected

mounting location, drill from the outside. If the hole is drilled in the

wrong location, drill a second hole in a better location. Apply

masking tape to the outside of the hull over the incorrect hole and

fill it with epoxy.

2.Using the appropriate size drill bit or hole saw cut a hole from

outside the hull through the

Table 2).

Be sure to hold the drill plumb, so the hole will be

perpendicular to the water surface.

Specifications T able 2

Model

B45 22mm or 7/8" 35mm or 1-3/8" 10mm or 3/8" 19mm or 3/4"

B46 22mm

B256 30mm

B260 33mm

B744V 51mm

SS505 22mm

SS544V 51mm

Drill Bit for

Sensor

(outer skin)

7/8" 35mm or 1-3/8" 10mm or 3/8" 19mm or 3/4"

1-3/16" 40mm or 1-5/8" 13mm or 1/2" 25mm or 1"

1-5/16" 44mm or 1-3/4" 13mm or 1/2" 25mm or 1"

2" 60mm or 2-3/8" 10mm or 3/8" 19mm or 3/4"

7/8" 35mm or 1-3/8" 10mm or 3/8" 19mm or 3/4"

2" 60mm or 2-3/8" 10mm or 3/8" 19mm or 3/4"

outer skin only (see Specification

Min. Size

Drill Bit for

Sensor

(inner cored

hull)

Drill Bit for

Anti-rotation

Bolt

(outer skin)

Anti-rotation Bolt

(inner cored hull)

Min. Size

Drill Bit for

Dimension equal to

pour in

casting

epoxy

hull

the thickness of the

hull’s outer skin to

ensure adequate

clearance

solid or hollow

cylinder

inner skin

core

outer skin

Figure 5. Preparing a cored fiberglass hull

3.Using the appropriate size drill bit or hole saw cut through the

inner skin and most of the core from inside the hull keeping

the drill perpendicular to the hull (see Specification Table 2).

The core material can be very soft. Apply only light pressure

to the hole saw after cutting through the inner skin to avoid

accidentally cutting the outer skin.

Caution : The optimal interior hole diameter is affected by the

hull’s thickness and deadrise angle. It must be large enough

in diameter to allow the core to be completely sealed.

4.Remove the plug of core material, so the inside of the outer

skin and the inner core of the hull is fully exposed. Sand and

clean the inner skin, core, and the outer skin around the hole.

5.Coat a hollow or solid cylinder of the correct diameter with

wax and tape it in place. Fill the gap between the cylinder and

hull with casting epoxy. After the epoxy has set, remove the

cylinder.

Caution : Always completely seal the hull to prevent water

seepage into the core.

6.Sand and clean the area around the hole, inside and outside,

to ensure that the sealant will adhere properly to the hull. If

there is any petroleum residue inside the hull, remove it with

either mild household detergent or a weak solvent, such as

alcohol, before sanding.

7.Follow the same procedure to prepare the hull for the antirotation bolt (“Preparing a Cored Fiberglass Hull”, steps 2

through 6).

8.Proceed with the installation beginning with "Bedding the

Sensor" on page 2.

AIRMAR

TECHNOLOGY CORPORATION

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

■

www.airmar.com

4

Loading...

Loading...