Page 1

"

"

New

• THRU-HULL • Depth • Speed • Temperature

B744V, B744VL,SS544V, B66V, B66VL

50 kHz,120 kHz, 120 kHz Dual Beam,

150 kHz, 170 kHz, 200 kHz, 235 kHz,

50/200 kHz Dual Frequency,

SECTION 1

50 kHz & 200 kHz Dual Frequency

Introduction

U.S. Patent No. 4,898,029

U.S. Patent No. 5,186,050

Canadian Patent No. 1,313,775

Australian Patent No. 605,281

Japanese Patent No. 1851014

Airmar TRIDUCER

rate a revolutionary self-closing valve to minimize water flow into the boat when the

paddlewheel insert is removed. “Gushers” are

eliminated with this simple to maintain valve.

Fins provide on either side of the paddlewheel

for more accurate speed measurement in

cross-flow conditions.

Combined with our fairing, installation is

made simple. Made of urethane, the fairing

will never swell or rot, and the unique cutting

guide allows safer, more accurate cutting with

a band saw. High speed fairings are provided

with a corrosion resistant bolt to secure the

fairing and prevent rotation.

SS544V

multisensors incorpo-

B66V

B66VL

B744V

The Latest Evolution in TRIDUCER

Multisensor Technology

Self-closing valve ...checks water flow when paddlewheel insert is removed

New B744V and long stem B744VL offer flush mounting in streamlined fairings

and accommodate ceramics up to 44 mm (1.75

popular 50/200 kHz model

SS544 includes a streamlined fairing and is designed specifically for isolated

mounting to steel and aluminum hulls. It accommodates ceramics up to 44 mm

(1.75

New streamlined fairings for B744V, B744VL, and SS544V provide much impr oved

echosounding at speeds above 20 knots and greatly reduce drag

Versatile B66V and long stem B66VL mounts frequencies varying from 50 kHz to

200 kHz including dual beam 120 kHz and dual element 50 kHz & 200 kHz

Optional

correlation technology

Specifications

• Hall-effect device senses paddlewheel rotation

• Unitary paddlewheel bearing assures exact alignment and minimal

rotational friction

• Corrosion-proof shaft for long life in saltwater

• Alignment key for easy speed/temperature assembly removal and

insertion in difficult access locations

• Replaceable valve assembly

• Polished paddlewheel shaft for quick start up

• Surge and reverse polarity protection

• Shielded cable to minimize noise pick-up and emission

• Designed to meet CE requirements

• Dual O-rings for superior sealing

• Retaining pin and safety chain secures paddlewheel and plug inserts

• Installation requires a 51mm (2") diameter hole

• Fairing is supplied standard with SS544V

• Blanking plug included

• Standard cable length: 10 m (33')

• W eight:

B744V 2.5 kg (5.5 lb.)

B744VL 2.6 kg (6.4 lb.)

SS544V 3.1 kg (6.8 lb..)

B66V 2.7 kg (6.0 lb.)

B66VL 3.1 kg (6.8 lb.)

) in diameter including the

) in diameter

paddlewheel-less speed/temperature sensor uses echo

AIRMAR

TECHNOLOGY CORPORATION

m 12

2000 #17-1205

Options

• Two wire speed sensor circuit

• Thermistor or semiconductor temperature sensor

• Urethane fairing

B744V, B744VL: High speed #33-353-01

B66V, B66VL: Standard #33-029

• Pulse division circuitry or other pulse rates

• CS4500 correlation speed/temperature insert

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

Page 2

New • THRU-HULL MOUNT • Depth • Speed • Temperature

Applications

• Fiberglass or wood hulls only

Notes

• Replaces B44, B50, B55, and B56 models

• For Parts and Accessories see pages p2 through p4

Single Connector/

Dual Connector Systems

The piezoceramic element, speed, and temperature circuitry are all within the bronze housing. The removable

paddlewheel insert contains no circuitry. The magnetic

field sensor to measure speed is mounted in the housing in

close proximity to the rotating paddlewheel. A single connector system is generally used when depth, speed, and

temperature will be processed in a single instrument or

when two instruments are within 1m (40") of each other.

When depth and speed/temperature functions will be processed in separate instruments, our cable can be split and

two connectors can be applied.

All signals are transmitted via a multi-conductor cable

with a high quality thermoplastic rubber jacket for

improved resistance to cutting, pinching, and degradation

from petroleum distillates. C144 cable is used in single

element TRIDUCER multisensors. Dual element multisensors use C145 cable.

Hull Thickness Limits

Model Minimum Maximum

B744V with fairing

without fairing

B744VL with fairing

without fairing

SS544V with fairing

B66V with fairing

without fairing

B66VL with fairing

without fairing

— 26 mm (1")

6 mm (1⁄4") 72 mm (2 7⁄8")

6 mm (1⁄4") 87 mm (3 3⁄4")

35 mm (1 3⁄8") 133 mm (5 1⁄4")

—

— 25 mm (1”)

6 mm (1⁄4") 70 mm (2 3⁄4")

30 mm (1 1⁄8") 87 mm (3 3⁄4")

70 mm (2 3⁄4") 133 mm (5 1⁄4")

14 mm (

1

⁄2")

Speed

The TRIDUCER multisensor provides accurate speed measurement

over the widest boat speed range of any thru-hull paddlewheel

transducer.

The combination of a hydrodynamic paddlewheel and paddlewheel ca vity, housing and fairing projection through the boundary layer and fins

on either side of the paddlewheel gives an unmatched linearity.

Specifications1

Speed range

Linearity Refer to

Pulse rate (B744V,B744VL,SS544V)

Pulse rate (B66V, B66VL)

Supply voltage 5–25 VDC

Supply current: “OFF”

Circuitry: standard

Unicurve® type thermistor 10,000 ohms

1. Refer to “Sensor Design Fundementals” for more detailed information.

2. Requires correction for non-linearity below 3 knots (3MPH).

3. ppnm = pulses per natical mile.

2

“ON”

optional

1–44 knots (1–50 MPH)

Airmar Technical Data Catalog

3

19,000 ppnm

21,500 ppnm

21,500 ppnm

21,500 ppnm

2.3 mA

8 mA at 5 VDC

3 wire format

2 wire format

(5.7 Hz/knot) with high speed fairing

3

(6.0 Hz/knot) without fairing

3

(6.0 Hz/knot) with standard fairing

3

(6.0 Hz/knot) without fairing

Temperature

Various temperature sensing devices can be

incorporated in the housing including thermistor and semiconductor types. See the

“Temperature” section for more detailed

information including thermal time constants.

Shielding

Inside the TRIDUCER multisensor housing,

shielding is used to eliminate interference

between the speed and depth sensors. A

shielded cable and separately shielded speed

and temperature conductors are used to prevent mutual interference. The bronze housing

also functions as a shield. Refer to wiring diagram beginning on p 35 for shielding details.

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

AIRMAR

TECHNOLOGY CORPORATION

2000 #17-1205

m 13

Page 3

New • THRU-HULL • Depth • Speed • Temperature

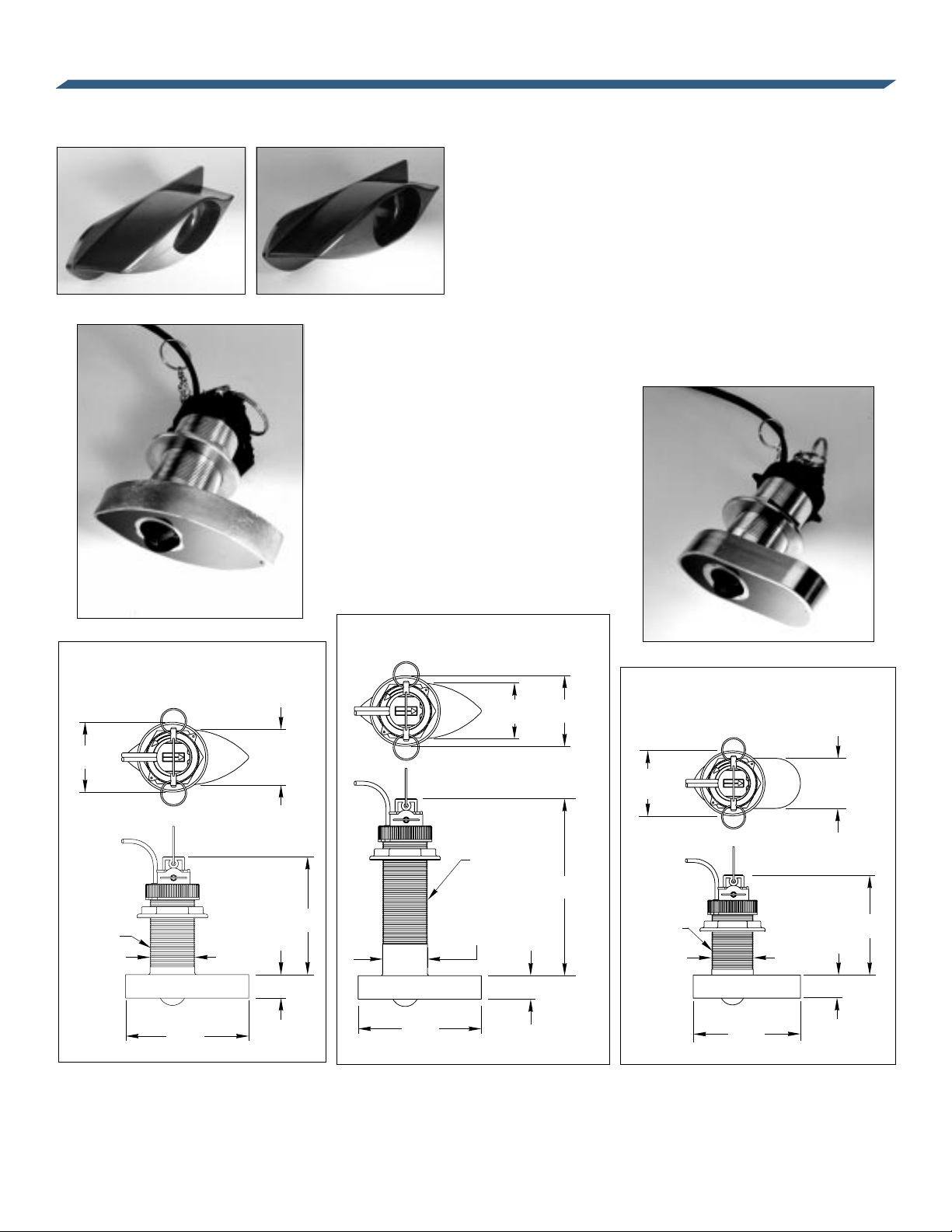

B744V, B744VL

High-speed

Fairing

SECTION 1

Introduction

SS544V

High-speed

Fairing

B744V

SS544V

B744VL top and side view

B744V top and side view

∅ 79 mm

[3.13”]

2”-12 un

threads

140 mm

[5.50"]

∅ 51 mm

[2.00”]

64 mm

[2.50"]

27 mm

[1.05"]

134 mm

[5.27"]

140 mm

[5.50"]

2”-12 un

threads

∅ 51 mm

[2.00”]

64 mm

[2.50"]

[1.05"]

27 mm

∅ 79 mm

[3.13”]

201 mm

[7.91"]

SS544V top and side view

∅ 79 mm

[3.13”]

2”-12 un

threads

130 mm

[5.11"]

∅ 51 mm

[2.00”]

60 mm

[2.38"]

28 mm

[1.11"]

121 mm

[4.77"]

AIRMAR

TECHNOLOGY CORPORATION

m 14

2000 #17-1205

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

Page 4

New • THRU-HULL MOUNT • Depth • Speed • Temperature

B66V, B66VL

B66VL

Standard Fairing

Paddlewheel

insert and

blanking

plug

102 mm

[4.03"]

B66V

B66V top and side view

∅ 79 mm

[3.13"]

7 mm

[0.28"]

174 mm

[6.83"]

2"-12 UN

threads

∅ 51 mm

[2.00"]

∅ 84 mm

[3.29"]

133 mm

[5.24"]

30 mm

[1.20"]

140 mm

[5.53"]

B66VL top and side view

∅ 79 mm

[3.13"]

45 mm

[1.78"]

174 mm

[6.83"]

2"-12 UN

threads

∅ 51 mm

[2.00"]

∅ 84 mm

[3.29"]

171 mm

[6.74"]

30 mm

[1.20"]

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

AIRMAR

TECHNOLOGY CORPORATION

2000 #17-1205

m 15

Page 5

New • THRU-HULL MOUNT • Depth • Speed • Temperature

TRIDUCER® Multisensor

• Self-closing valve assembly

• Improved speed measurement accuracy

• Same stem diameter and thread pitch as earlier housing

SECTION 1

Introduction

• Optional urethane fairing—impact resistant, keyed to

housings, with unique cutting guide

Front view

Side view

valve opened

fins

Improved speed accuracy

Fins straighten water flow onto

the paddlewheel improving accuracy

at low speeds and in cross-flow

conditions

Detail

double O-ring seal

valve closed

quick wetting acoustic window

AIRMAR

TECHNOLOGY CORPORATION

m 16

2000 #17-1205

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

Page 6

New • THRU-HULL MOUNT • Depth • Speed • Temperature

B744V

Exploded View

paddlewheel insert

O-rings, 2 required

paddlewheel

upper sleeve

pull ring

cap nut

safety chain assembly

retaining pin

pull rings, 3 required

paddlewheel shaft

spring

valve

spring pin

high speed fairing

cutting guide

housing

field replaceable

valve assembly

hull nut

anti-rotation nut

anti-rotation washer

anti-rotation bolt

bolt cover

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

AIRMAR

TECHNOLOGY CORPORATION

2000 #17-1205

m 17

Page 7

New • THRU-HULL MOUNT • Depth • Speed • Temperature

FREQUENCY AVAILABILITY by HOUSING TYPE

SECTION 1

Introduction

Ceramic

Designation

50 kHz – C 46°

120 kHz – B 16°

120 kHz – C 12°

120 kHz – M

(dual beam)

150 kHz – A 19°

170 kHz – A 12°

200 kHz – G 8°

200 kHz – Hlq 8°

200 kHz – U 11°

235 kHz – B 11°

235 kHz – D 7°

50/200 kHz – A

(dual frequency)

50 kHz – C & 200 kHz – B

(dual frequency)

Beam Width

@–3dB

35° & 14°

45° & 12°

46° & 13°

Housing

B744V B744VL SS544V B66V B66VL

••

•••

••

••

•••

••

••

••

•••

•••

••

•••

••

Frequency1 – Airmar Piezoceramic Designator

Element Material3/ Diameter (mm)

Beam Width at –3 dB

Q (fr/∆ f @ –3 dB)

Rated RMS Power (W)

Voltage Responses: Transmit/Receive5 (dB)

Figure of Merit (Insertion Loss)6 (dB)

Balanced Impedance7: Resistance, Rp (ohm)

Series Impedance [R – jX]8 (ohm)

Acoustic Window Material

Note: See page m 1 for footnotes.

* Unbalanced Impedance

4

Capacitance, C p (pF)

AIRMAR

TECHNOLOGY CORPORATION

m 18

2000 #17-1205

PERFORMANCE DATA

2

50 kHz – C 120 kHz – B 120 kHz – C 120 kHz – M Dual Beam

PZT/L/ 51 PZT/37 PZT/51 PZT/L/19 PZT/L/55

46° 16° 12° 35° 14°

18 21 21 9 15

600 300 600 100 600

156/–175 161/–181 166/–174 152/–188 167/–180

–27 –25 –18 –37 –16

12

280

0 860 1,510 2,200* 4,100*

280 – j0 250 – j40 150 – j20 300 – j310 110 – j50

Urethane Urethane Urethane Urethane Urethane

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

260 150 615* 150*

Page 8

New • THRU-HULL MOUNT • Depth • Speed • Temperature

Frequency1 – Airmar Piezoceramic Designator

Element Material3/Diameter (mm)

Beam Width at –3 dB

Q (fr/∆ f @ –3 dB)

Rated RMS Power (W)

Voltage Responses: Transmit/Receive5 (dB)

Figure of Merit (Insertion Loss)6 (dB)

Balanced Impedance7: Resistance, Rp (ohm)

Series Impedance [R – jX]8 (ohm)

Acoustic Window Material

Note: See page m 1 for footnotes.

*Unbalanced Impedance

4

Capacitance, C p (pF)

PERFORMANCE DATA

2

150 kHz – A 170 kHz – A 200 kHz – G

PZT/27 PZT/51 BT/51 PZT/51 BT/38

19° 12° 8° 8° 11°

23 25 29 7 22

200 500 600 600 375

160/–185 172/–184 167/–182 163/–182 164/–185

–27 –17 –16 –19 –22

400

550 0 1,120 1,200 1,930*

380 – j80 70 – j0 290 – j150 325 – j420 300 – j250

Urethane Urethane Urethane Urethane Urethane

70

12

370 865 510*

200 kHz – Hlq

11

200 kHz – U

PERFORMANCE DATA

Frequency1 – Airmar Piezoceramic Designator

Element Material3/Diameter (mm) PZT/36 BT/51

Beam Width at –3 dB 11° 7°

Q (fr/∆ f @ –3 dB)

Rated RMS Power (W) 350 600

Voltage Responses: Transmit/Receive5 (dB) 165 /–186 169/–185

Figure of Merit (Insertion Loss)6 (dB) –21 –16

Balanced Impedance7: Resistance, Rp (ohm)

Series Impedance [R – jX]8 (ohm) 330 – j70 220 – j180

Acoustic Window Material Urethane

Note: See page m1 for footnotes.

4

Capacitance, C p (pF)

2

235 kHz – B 235 kHz – D

25 16

350 370

410 1,440

Urethane Urethane Urethane Urethane

50/200kHz – A 50 kHz – C & 200 kHz – B

PZT/44

45° 12° 46° 13°

28 31

600 600

155/–174 164/–184

–31 –21

190 410

720 720

175 – j40 360 – j130

PZT/ L / 51

18

600

156/–175

–27

12

280

0

280 – j0

162/–187

450 – j160

BT/28

22

250

–26

510

560

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613 USA

Tel (603) 673-9570 • Fax (603) 673-4624 • e-mail: sales@airmar.com

AIRMAR

TECHNOLOGY CORPORATION

2000 #17-1205

m 19

Loading...

Loading...