Page 1

TFT PORTABLE DVB-T/DVD PLAYER

SUNSTECH PLF-77TD

SERVICE MANUAL

2006- PRINTED IN

R598MB

CAUTION: Before servicing the chassis, read the “IMPORTANT SERVICE SAFETY INFORMATION” section on

page 2 of this manual.

SPECIFICATIONS

l GENERAL SPECIFICATION

l 7” ACTIVE- MATRIX TFT TYPE.

l DVD, VCD, CD, CD-R, CD-RW, MP3, DIVX, HDCD

SUPPORTS.

l USB FUNCTION

l 16:9 / 4:3 PICTURE SELECT.

l HIGH BRIGHTENNESS.

l HIGH CONTRAST.

l WITH LOGO OPENING SCREEN.

l SLOW MOTION ½, 1/4, 1/8, 1/16

l F.B / F.F x2, x4, x8, x16 SPEED.

l ANGLE MENU.

l 20 TRACK PROGRAM FOR CD PLAYING.

l ZOOM x 2, 3, 4.

l REMOTE CONTROL.

l S. VIDEO OUTPUT (for Ext. TV Monitor)

l HEADPHONE OUT x 1.

l AUDIO OUTPUT 0.5W x 2/8 ohm.

l LONG BATTERY TIME OF OVER 2 HRS.

l DIMENSION :

212(L) x 170(W) x 4 30(H) mm(excluding battery)

l AC POWER SOURCE:

ADAPTER: 230V

l DC POWER SOURCE: BATTERY PACK: 7.2V

l FEATURES FOR DVB-T TUNER (FREE ON AIR)

l FREQUENCY RANGE :

VHF CH5 – CH12 (174MHZ – 230MHZ)

UHF CH21 - CH69 (470MHZ – 862MHZ)

l 1,000 PROGRAMMABLE FAVORITE CHANNELS

l 9 PICTURES FOR PROGRAM AUTO -SCAN

l EPG FUNCTION SUPPORT (TELE-TEXT OPTION)

l PROGRAM LIST WITH PROGRAM PREVIEW AFTER

TUNER POWER ON

l OSD TRANSPARENT ADJUSTMENT.

l FULL FUNCTION REMOTE CONTROL

CONTENTS

IMPORTANT SERVICE SAFETY INFORMATION................2

DISASSEMBLY FOR REPAIR .................................................3

WIRING DIAGRAM…………… ………………………....……4

BLOCK DIAGRAM....................................................................5

CIRCUIT DESCRIPTION .............................……………...6~14

PARTS LIST ..........................................…………............ 1 5~28

EXPLODED VIEW (CABINET) ............................................. 29

EXPLODED VIEW (DVB-T).................................................. 30

SCHEMATIC DIAGRAMS.................. ...............................31~39

PRINTED CIRCUIT BOARDS.......................................... 4 0~57

Note: Follows a policy of continuous advancements in development. For this reason specifications may be changed without notice.

Page 2

1. SAFETY PRECAUTIONS

Before returning a unit to the customer, always make a safety check

of the entire unit, including, but not limited to the following items:

a. Be sure that no built -in protective devices are defective and/or have

been defeated during servicing.

(1) Protective shields are provided to protect to protect both the

technician and the customer. Correctly replace all missing protective

shields including any removed for servicing convenience.

(2) When reinstalling the chassis and/or other assemblies in the

cabinet, be sure to put back in place all protective devices, including, but

not limited to, nonmetallic control knobs, insulating fishpapers,

adjustment and compartment covers/shields and isolation resistor

capacitor networks. Do not operate this unit of permit it to be operated

without all protective devices correctly installed and functioning.

b. Be sure that there are no cabinet openings through which an adult

or child might be able to insert their fingers and contact a hazardous

voltage. Such openings include, but are not limited to, excessively wide

cabinet ventilation slots, and an improperly fitted and/or incorrectly

secured cabinet back cover.

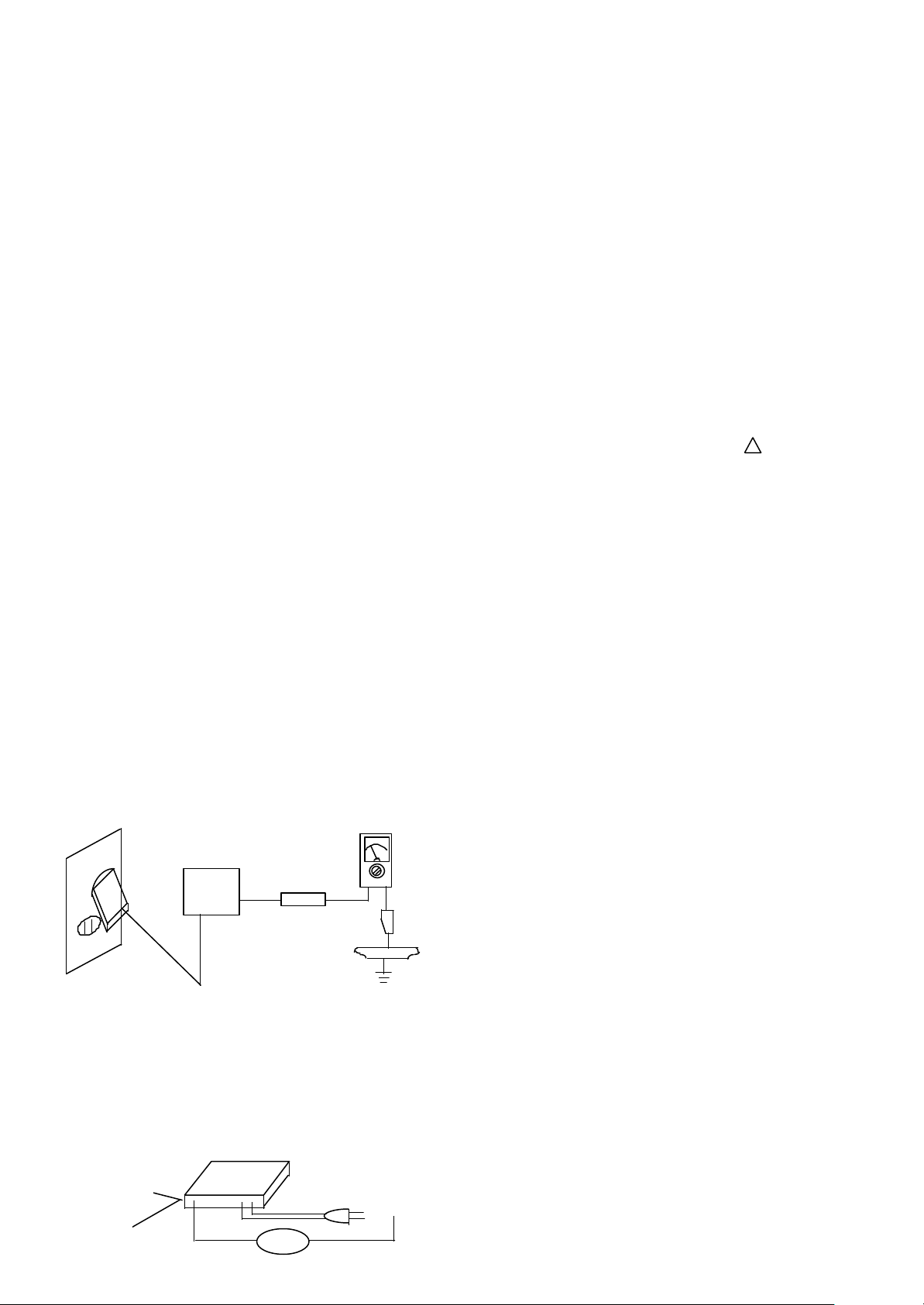

c. Leakage Current Hot Check - With the unit completely

reassembled, plug the AC line cord directly into a AC outlet. (Do not

use an isolation transformer during this test.) Use a leakage current

tester or a metering system that complies with American National

Standards institute (ANSI) C101.1 “Leakage Current for Appliances”

and Underwriters Laboratories (UL) 1410, (50.7). With the unit AC

switch first in the ON position and then in the OFF position, measure

from a known earth ground (metal water pipe, conduit, etc.) to all

exposed metal parts of the unit (antennas, handle bracket, metal cabinet,

screwheads, metallic overlays, control shaft, ect.), especially any

exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 milliamp. Reverse the unit

power cord plug in the outlet and repeat test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED

HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT

MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO

THE CUSTOMER.

AC LEAKAGE TEST

d. Insulation Resistance Test Cold Check

(1) Unplug the power supply cord and connect a jumper wire

between the two prongs of the plug.

(2) Turn on the power switch of the unit.

(3) Measure the resistance with an ohmmeter between the jumpered

AC plug and each exposed metallic cabinet part on the unit, such as

screwheads, antenna, control shaft, handle brackets, etc. When the

exposed metallic part has a return path to the chassis, the reading

ANTENNA

TERMINAL

2

EXPOSED

IMPORTANT SERVICE SAFETY INFORMATION

(READING

SHOULD

NOT BE

ABOVE

0.5mA)

EARTH

GROUND

METAL

PART

DEVICE

UNDER

TEST

TEST ALL EXPOSED

METAL SURFACES

2-WIRE CORD ALSO

TEST WITH PLUG

REVERSED (USING AC

ADAPTER PLUG A

REQUIRED)

OHMMETER

OM

LEAKAGE

CURRENT

TESTER

should be between 1 and 5.2 Megohm. When there is no return path to

the chassis, the reading must be “infinite”. If it is not within the limits

specified, there is the possibility of a shock hazard, and the unit must

be repaired and rechecked before it is returned to the customer.

2. PRODUCT SAFETY NOTICE

Some electrical and mechanical parts have special safety related

characteristics which are often not evident from visual inspection, nor

can be protection they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage, etc. Parts that have

special safety characteristics are identified by a ¡I on schematic and

parts list. Use of a substitute replacement that does not have the same

safety characteristics as the recommended replacement part might create

shock, fire, and/or other hazards. Product Safety is under review

continuously and new instructions are issued whenever appropriate.

3. SERVICING PRECAUTIONS

CAUTION: Before servicing the unit covered by this service manual

and its supplements, read and follow the SAFETY PRECAUTIONS on

this page. NOTE: If unforeseen circumstances create a conflict between

the following servicing precautions and any of the safety precautions,

always follow the safety precautions. Remember: Safety First.

General Servicing Precautions.

a. Always unplug the unit’s AC power cord from the AC power

source before:

(1) removing or reinstalling any component, circuit board, module, or

any other unit assembly.

(2) disconnecting or reconnecting any unit electrical plug or other

electrical connection.

(3) connecting a test substitute in parallel whit an electrolytic

capacitor in the unit.

Caution: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an explosion hazard.

b. Do not defeat any plug/socket B+ voltage interlocks with which

the unit covered by this service manual might be equipped.

c. Do not apply AC power to this unit and/or any of its electrical

assemblies unless all solid-state device heat sinks are correctly installed.

d. Always connect a test unit ground lead to the unit chassis ground

before connecting the test unit positive lead. Always remove the test

instrument’s ground lead last.

4. LASER PRECAUTIONS

WARNING!

1. When servicing (in case it is necessary to confirm Laser Beam

Emission), be sure not to place your eyes any closer than 1 ft or 30cm

from the surface of the Object Lens on the Optical Pickup Block.

HANDLING THE LASER PICKUP

2. Laser diodes are extremely susceptible to damage from static

electricity. Even if a static discharge does not ruin the diode, it can

shorten its life or cause it to work improperly. When replacing the

pickup, use a conductive mat on the floor and desk and wear a wrist

Page 3

band connected to ground through a 1M ohm resistor to protect the

laser diode from static damage. If the lens should get dusty, blow off the

OF PROCEDURES HEREIN MAY RESULT IN HAZARDOUS

dust carefully from the object.

3. There are no adjustable parts in the pickup assembly. If it is

defective, replace the whole pickup assembly.

CAUTION:

USE OF CONTROLS, ADJUSTMENTS OR PERFORMANCE

RADIATION EXPOSURE.

DANGER:

IF INTERLOCK FAILS OR IS DEFEATED, THE LASER LIGHT

IS ABLE TO FUNCTION. THE LASER IS INVISIBLE, AVOID

DIRECT EXPOSURE TO BEAM.

3

Page 4

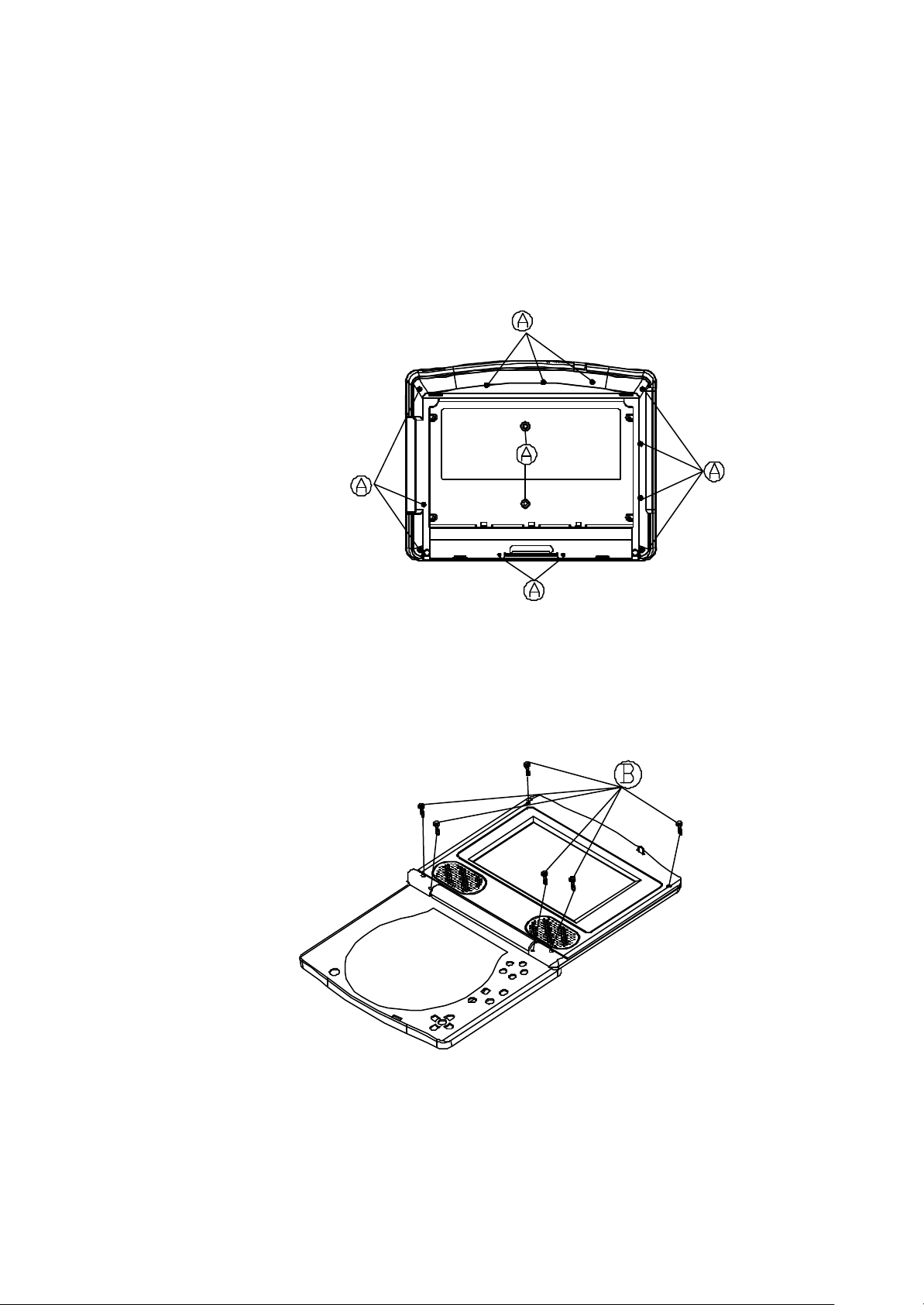

DISASSEMBLY FOR REPAIR

TO DISASSEMBLY THE BOTTOM METAL CABINET

1. Remove the 14 screws (A) from bottom metal cabinet.

TO REMOVE THE INNER PANEL

2. Remove the 6 screws (B) from the inner panel and out panel.

4

Page 5

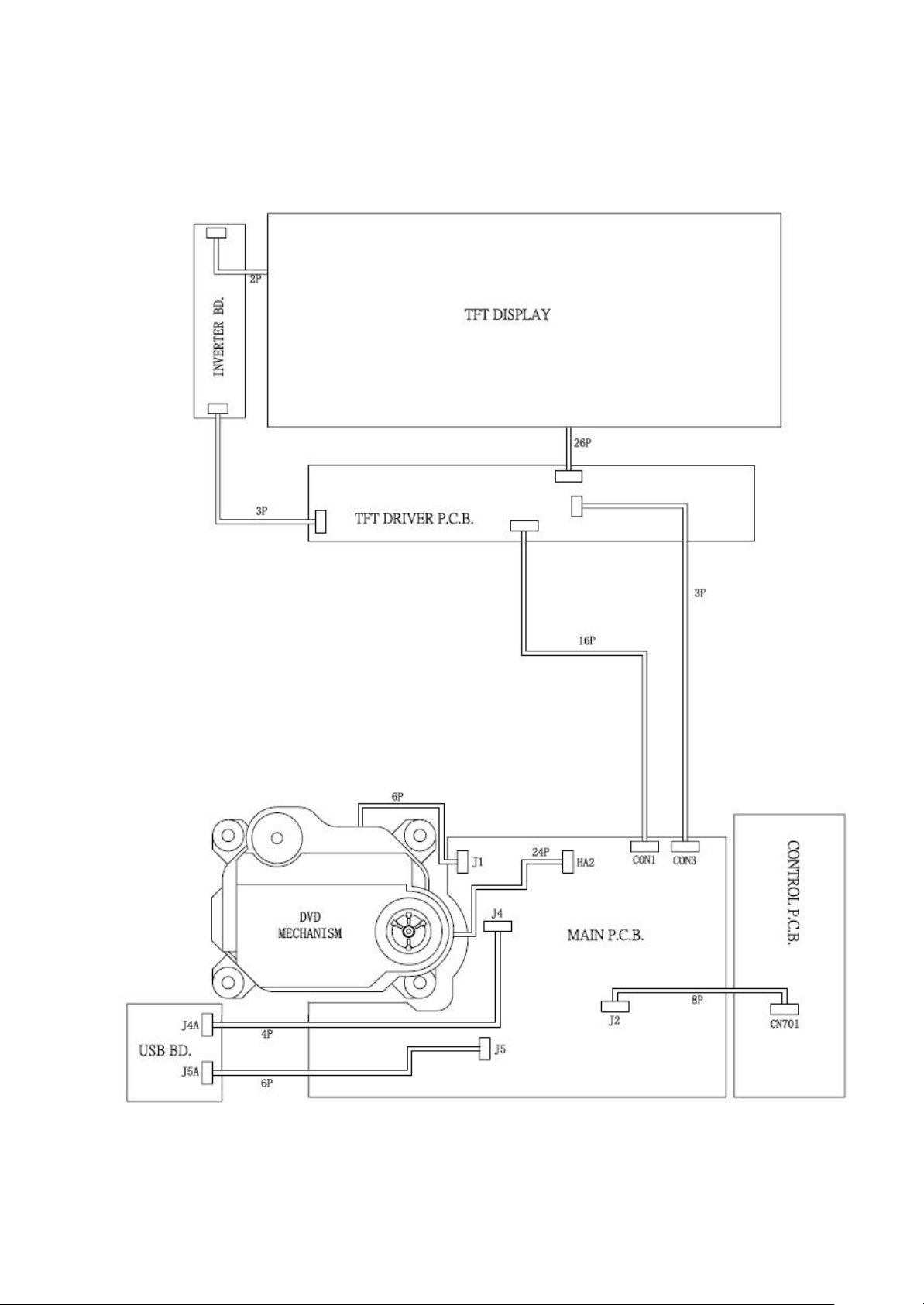

WIRING DIAGRAM

5

Page 6

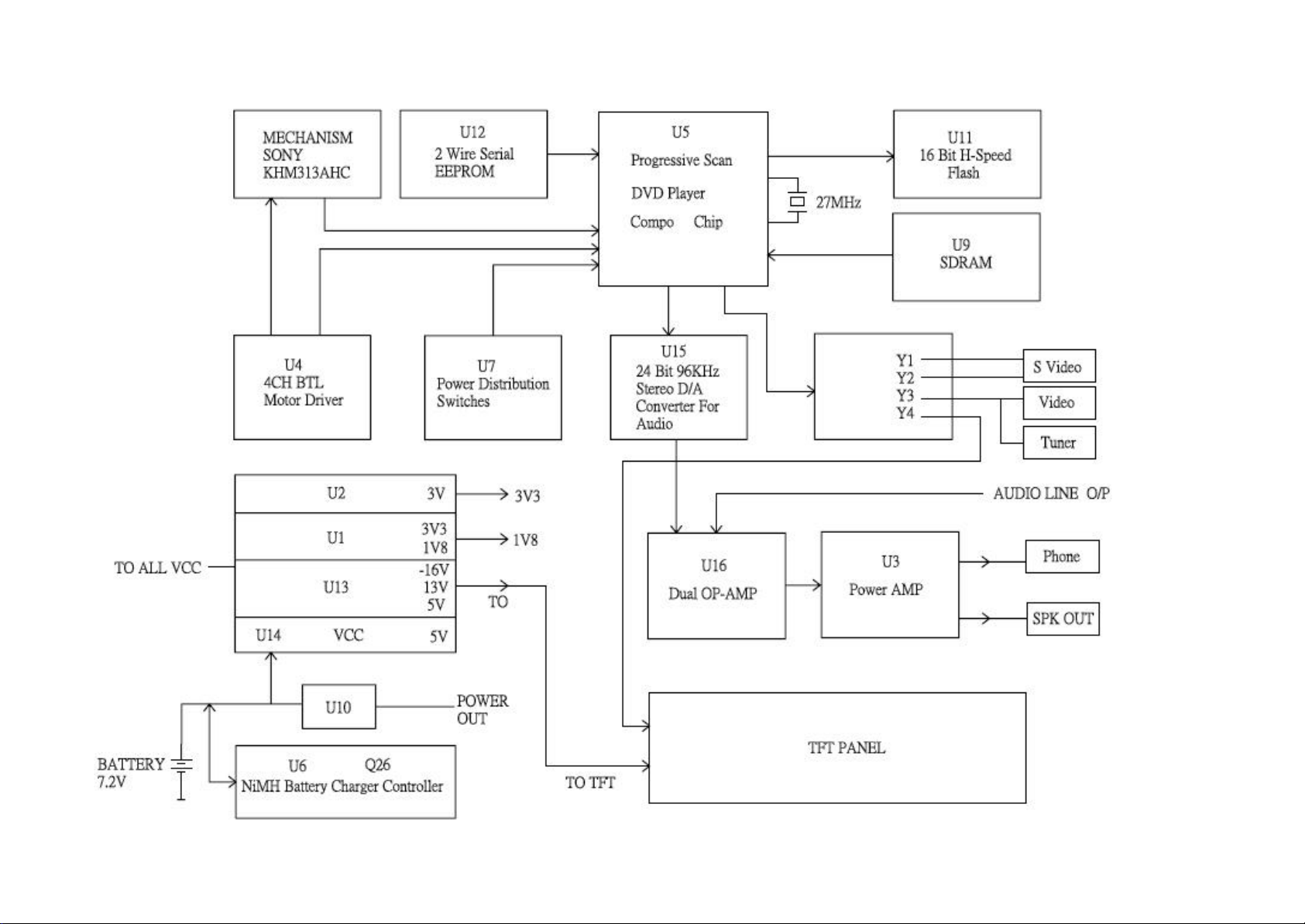

BLOCK DIAGRAM

Page 7

CIRCUIT DESCRIPTION

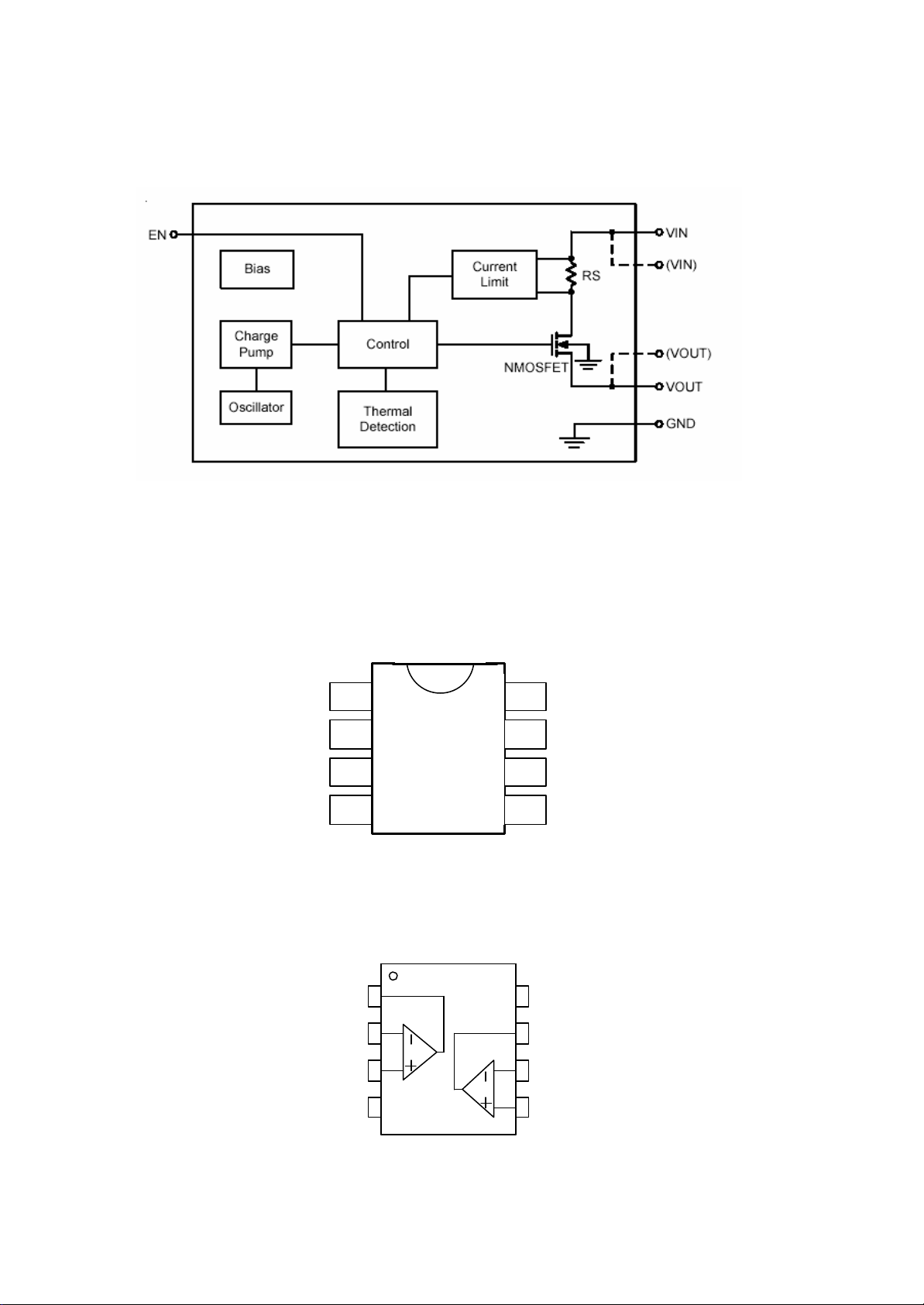

100m? Power Distribution Switches: RT9701CB (U7)

NiMH BATTERY CHARGER CONTROLLER: LS2964S (U6)

Timer

LED

OSC

1

2

3

8

7

6

VDD

PWM

Vdet

GND

4

5

Idet

DUAL OPERATIONAL AMPLIFIER: RC4558D (U7,16)

A OUTPUT

1

8

V +

A -INPUT

A +INPUT

V -

2

3

4

7

B OUTPUT

6

B -INPUT

5

B +INPUT

6

Page 8

CIRCUIT DESCRIPTION

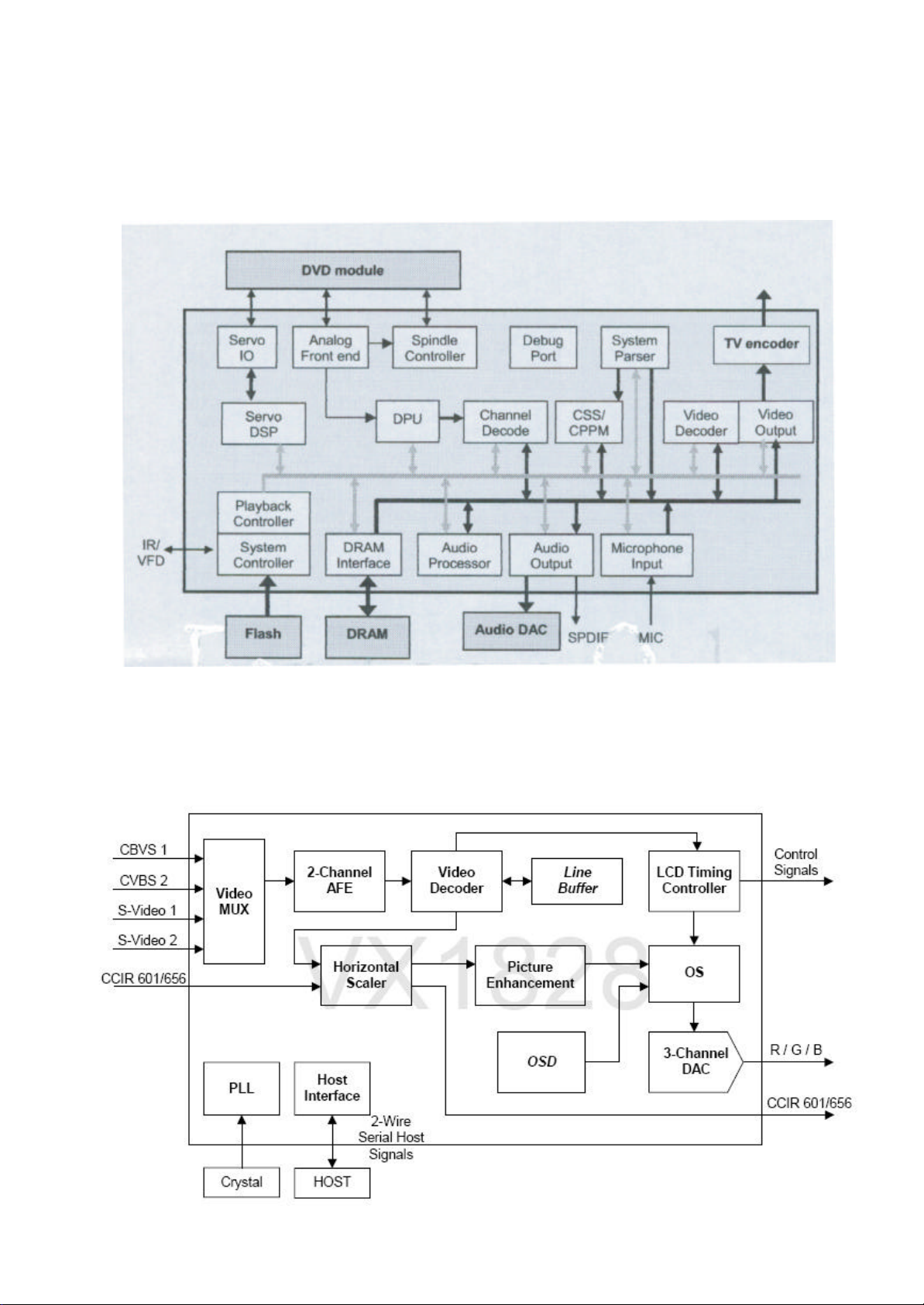

PROGRESSIVE SCAN DVD PLAYER COMBO CHIP: MT1389DE/B-L (U5)

VIDEO PROCESSOR FOR MIDDLE SIZE LCD PANEL: VX1828 (U1)

7

Page 9

CIRCUIT DESCRIPTION

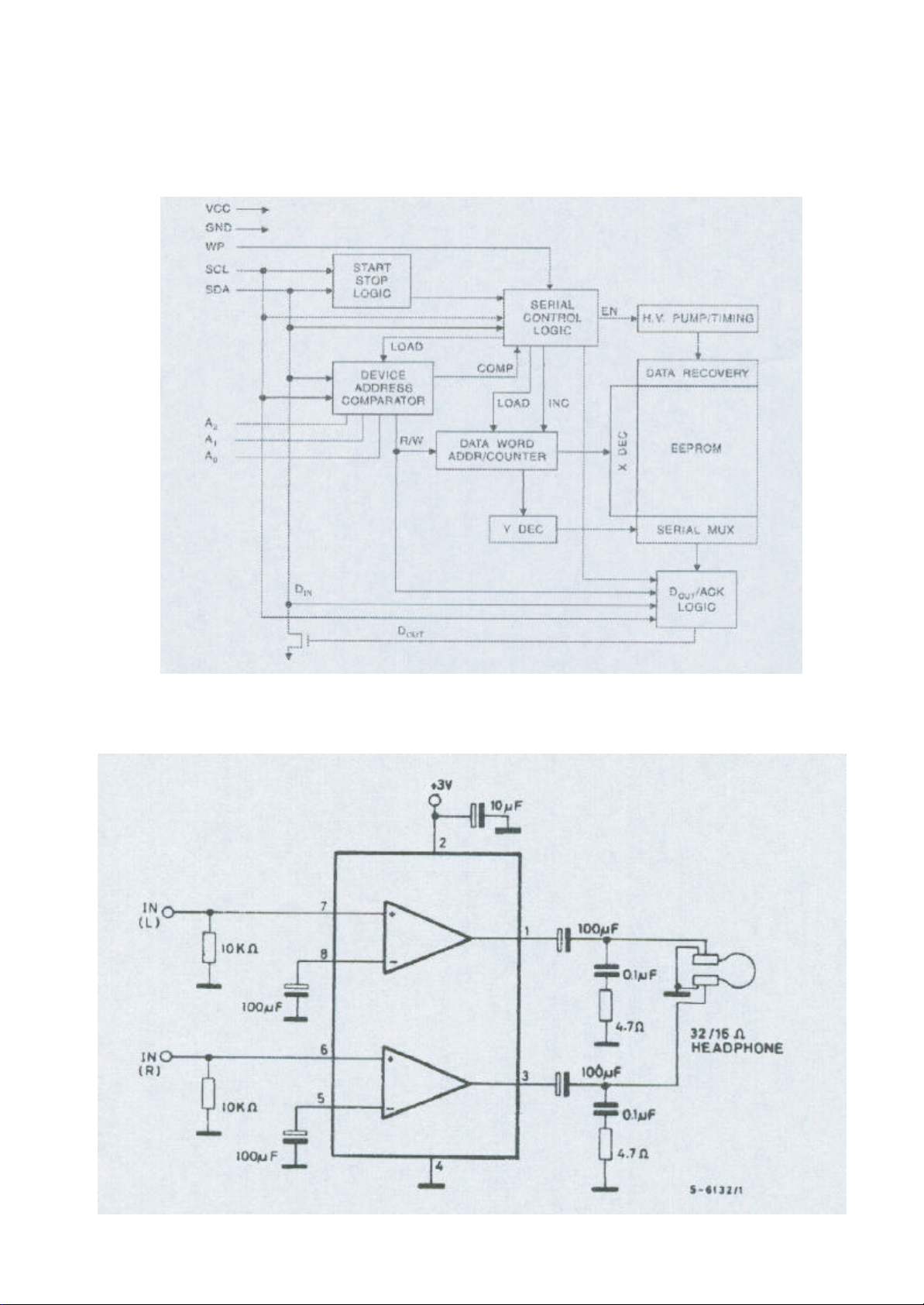

2-WIRE SERIAL EEPROM: AT24C02BN-10SU-1.8 (U6,U12)

DUAL LOW-VOLTAGE POWER AMPLIFIER: NJM2073M (U3)

8

Page 10

CIRCUIT DESCRIPTION

24-BIT, 96 KHZ STEREO D/A CONVERTER FOR AUDIO: CS4340 (U15)

DUAL COMPARATORS: LM393DR (U10)

SINGLE-SUPPLY DUAL HIGH CURRENT OPERATIONAL AMPLIFIER: NJM3414AM-TE1(U3)

9

Page 11

CIRCUIT DESCRIPTION

4-CHANNEL BTL MOTOR DRIVER FOR CD-ROM: AT5654H (U4)

300/500MA LOW DROPOUT LINEAR VOLTAGE REGULATOR: RP1101-19CXL( U1), RP110233CGL (Q2)

10

Page 12

CIRCUIT DESCRIPTION

8M/16M-BIT CMOS SINGLE VOLTAGE 3V ONLY HIGH SPEED FLASH: AT49BV163A-70TU

(U11) , S29AL008D70TFI020 (U4)

DIGITAL TV STB BACKEND PROCESSOR: CT212T (U3)

11

Page 13

CIRCUIT DESCRIPTION

2 BANKS X 512K X 16 BIT SYNCHRONOUS DRAM : K4S641632H-UC75 TSOP-54 (U1,U9)

INFRARED REMOTE CONTROL TRANSMITTER : SC6122-001 (IC1)

KI

KI

KI

KI

KI

REM

V

DD

SEL

OSCO

OSCI

V

2

3

4

5

6

7

SS

1

2

3

4

5

6KI

7

8

9

10

12 13

24

23

22

21

20

18

17

16

15

1411

KI

KI

CCS

KI/O

KI/O

KI/O19

KI/O

KI/O

KI/O

KI/O

KI/O

LMP

1

0

0

1

2

3

4

5

6

7

12

Page 14

CIRCUIT DESCRIPTION

2A STEP DOWN DC TO DC CONVERTER: MP9141ES-LF-Z (U8, 9)

10-pin, 24-Bit, 192 kHz Stereo D/A Converter: CS4345 (U5)

13

Page 15

CIRCUIT DESCRIPTION

25V STEP-UP CONVERTER IC: MP1522ET (U1)

DIGITAL TV STB BACKEND PROCESSOR: B1117N-ADJ (U10)

14

Page 16

N405M REMOTE CONTROL P.C.B.

20% 25V

1

5

Ref. No Parts No. Description QTY

2772M-STD-31 2772MB 120-230V VDE APP. STD

ASSY

059-05202-100-

102

HS-R598MB-GY-

410

001-04050-710

IC 1 002-06122-330 IC SC6122-001 (SILAN) SOP-24

Q1 003-24081-140 CHIP TRANSISTOR 2SC4081(RS)-

004-01122-600 INFRARED EMI TTING DIODES

R1 005-52109-301 CHIP RESISTOR 1 OHM +-5%

C2,3 006-72181-250 CERAMIC CHIP CAP 180 PF +-5%

C1 009-10476C510 ELECT CAP 47 UF +80%-20% 10V

X1 028-00455-011 CERAMIC FILTER ZTB455E

041-04051-002 N405 HANDSET BATTERY

041-04052-002 N405 HANDSET BATTERY

104-04050-0956 N405M H/S BOTTOM CAB.

111-04050-0956 N405M H/S BATTERY DOOR

125-04050-004 M593MB H/S

FOR HENDSET 144-11405-402 SCREW 1.4 X 5 KB 7

SW.ADAPTOR(SPEC

LIN)VDE:EN60065;W/M.I.C

SW0901500-W02(GP)

100~240V;TUV/CE;ROHS

R598MB H/S CHASSIS

W/COSMETIC ASSY(ROHS)

L.GY.MN C7-0 "SUNSTECH PLF77TD" (48 KEY)

(48 KEY) (ROHS)

(SMT) (ROHS)

TLB (ROHM) (ROHS)

EL-1L2 (ROHS)

(1608) (ROHS)

50V (1608) (ROHS) NPO

(ROHS) (PIN LENGTH 9MM)

(MEC) (2 PINS) (ROHS)

PLATE (+) (ROHS)

SPRING (-) (ROHS)

(L.GREY MN7-0) (ROHS)

(L.GREY MN7-0) (ROHS)

MEM.SW.PLATE(ROHS)W/RED

032C/ SIL.8001C/GN.375C

2X/SIL.GY.8403C/WH.SK.

Ref. No Parts No. Description QTY

1

R519MB -SIL-

1

127-04625-1974 R519MB POWER KNOB

127-04627-1974 R519MB PANEL OPEN KNOB

1

128-05180-0974 R519MB BUTTON 'A'

1

1

1

1

1

2

1

1

1

1

1

1

1

128-05181-0974 R519MB BUTTON 'B' (UP/DOWN)

128-05182-0974 R519MB BUTTON

128-05183-0974 R519MB BUTTON 'D' (SKIP

128-05184-0974

128-05185-0974 R519MB BUTTON 'F' (PLAY)

128-05189-0974 R519MB DISC.OPEN BUTTON

129-05180-000 M518 DOOR BRACKET;ROHS 2

129-05189-000 M518 DISC DOOR OPEN

M462-CAR-

001-35000-400 3500MC CAR BAT SUPPLY P.C.B.

D1-4 004-05401-300 RECTIFIER IN-5401 (ROHS) 4

R1 005-10152-314 RESISTOR 1.5 K +-5% 1/4W

C1 006-10203-550 CERAMIC CAP 0.02 UF +80%-20%

C2 009-10107-525 ELECT CAP 100 UF +80%-

D10 019-12000-110 L.E.D. DIAMETER 3MM(RED)

031-02600-040- JUMPER WIRE AWG22UL 60MM 1

KNOB

ADAPTOR-09

(D=2.5MM) ;ROHS

R519MB SILVER KNOB VERSION

ASSY(ROHS)

(SP.SIL.SS9-1/ABS) (ROHS)

(SP.SIL.SS9-1/ABS) (ROHS)

(LEFT/RIGHT) (ROHS)

(SP.SIL.SS9-1)

(ROHS) (SP.SIL.SS9-1)

'C'(SETUP/DIS./TITLE/MENU)

(SP.SIL.SS9-1) (ROHS)

F.F./F.R.) (SP.SIL.SS9-1) (ROHS)

R519MB BUTTON 'E' (STOP/PAUSE)

(SP.SIL.SS9-1) (ROHS)

(SP.SIL.SS9-1) (ROHS)

(SP.SIL.SS9-1) (ROHS)

BRACKET;ROHS

R598MB CAR ADAPTOR ASSY

(OUTPUT DC 9V,1.2A)

(ROHS)

(ROHS)

50V (ROHS)

(ROHS)

SEL-2110R (ROHS)

1

1

1

1

1

1

1

PARTS LIST

1

1

1

1

1

1

1

1

1

1

Page 17

300

1

6

Ref. No Parts No. Description QTY

001 RED (ROHS)

031-10500-100-

001

043-20192-

050-05020-201 2A/250V GLASS FUSE 5X20 FAST

101-97030-010 9703 CAR ADAPTOR FRONT

102-97030-010 9703 CAR ADAPTOR REAR

105-97030-010 9703 CAR ADAPTOR CAP

133-97031-311 GT9839 (9703) CAR ADAPTOR

133-97035-304 9703 CAR ADAPTOR SPRING

133-97036-352 9703 CAR ADAPTOR PLUG

FOR CAR ADAPTOR

FRONT CABINET

20MM X 1(D5) 202-10005-002 TINNED CCS WIRE (DIA.

R572M-DVD-

MAIN PCB (J1) TO

LOADER

037-45251-245 24P FILM CABLE 5+250+5 UL

FOR LOADER 145-69912-100 PVC WASHER W/HOLE (L=9MM

160-00313-001 DVD MECHANISM SONY

144-12608-111 SCREW 2.6 X 8 RT (BLACK)

LOADER

025-10006-149 6P J.WIRE #30UL 100MM (2P

JUMPER WIRE AWG22UL 50MM

BLACK(ONE SIDE 4MM,ONE

SIDE 10MM) (ROHS)

T409 DC CORD 75"#20 WH/BLK

(2P)W/BUSHING &DC PLUG

(Y001-D19102C458505Q)(Y.C.)

(ROHS)

ACTING;ROHS BUSSMANN/S500

UR/VDE/SEMKO/IMQ/BSI APP.

CABINET (BLACK) (ROHS)

CABINET (BLACK) (ROHS)

(BLACK) (ROHS)

SPRING PLATE T=1.0MM (ROHS)

T=0.4MM (ROHS)

(GENERAL TECHNIC) (ROHS)

(ROHS)

0.0000

0.5MM);ROHS (TIN PLATE WIRE

W/STEEL)

R572M LOADER (SONY

KHM313AHC) SUBASS'Y

2MM) JST;ROHS

(P=0.5MM) (ROHS)

W=6.5MM T=1MM DIA.=3.3MM)

(ROHS)

KHM313AHC (ROHS) (SLIM

1

1

1

1

1

1

1

1

1

4

65

1

1

1

2

1

Ref. No Parts No. Description QTY

TYPE/BALL CLAW)

161-03102-001 KHM-310 INSULATOR

(IIR,HARDNESS=40 DEG)

(SILICON RUBBER) ;ROHS

M519M-

CASING -02

029-02808-202-

001

FOR LCD GROUNDING 039-30005-000 SOLIDING LUG 5.5MM (DIA.

041-04621-002 M462 BATTERY CONTACT

041-04622-002 M462 BATTERY CONTACT

041-04623-002 M462 BATTERY PLATE SPRING

049-00706-009 TFT DISPLAY AT070TN07 V.A

129-04629-010 M462 BATTERY CONTACT

129-04629-110 M462 BATTERY CONTACT

129-04629-210 M462 DISC DOOR OPEN SWTICH

130-04624-110 M462 DISPLAY ADAPTOR RING

133-04099-302 T409 HOOK SPRING (ROHS) 1

133-04621-115 M462 METAL PLATE (D) (IRON)

133-04623-115 M462 METAL BRACKET (A)

133-04623-125 M462 METAL BRACKET (B)

FOR CD DOOR SW. X 1 133-04624-306 M462 SW. SPRING (ROHS) 2

M519M CASING ASSY (W/04900706-007) (ROHS)

28MM SPEAKER 8 OHM

NOR.:0.5W;MAX.:1W BLK

CLOTH ON BACK (SMDC

NO.:DS28-39) (ROHS)

1.7MM) ;ROHS

PLATE (+);ROHS

PLATE (-);ROHS

(+/-);ROHS

(INNOLUX);ROHS (7" TFT-LCD

MODULE W/O LED DRIVER BD.)

BRACKET (L)

(BLACK/POM) ;ROHS

BRACKET (R)

(BLACK/POM) ;ROHS

ADAPTOR (BLACK/POM) ;ROHS

(BLACK/POM) (ROHS)

(T=1.5 MM) (ROHS)

(IRON) (T=1.5 MM) (ROHS)

(IRON) (T=1.5 MM) (ROHS)

4

1

2

1

1

1

2

1

1

1

1

1

1

1

1

Page 18

RUBBER 6 X 10 X 12MM (W/TWO

090)

(SP.MATT.BLACK)

1

7

Ref. No Parts No. Description QTY

FOR TFT SW. X 1

133-04625-360 M462 METAL PIN(A)

(STEEL)(DIA.=6 MM) (ROHS)

FOR BATTERY LOCK 133-04626-103 M462 METAL PLATE (A) (IRON)

(T=0.3 MM) (ROHS)

FOR BOTTOM CAB. 133-04629-305 M462 BATTERY PLATE SPRING

FOR BOTTOM CAB. (ROHS)

FOR MAIN P.C.B.

GROUNDING X 1

FOR CONTROL P.C.B.

GROUNDING X 1

FOR P.C.B. GROUNDING 133-04629-305-

133-05189-305-

133-05589-306 R558 CD DOOR SPRING

FOR BOTTOM CAB. 136-10015-480 RUBBER FOOT (DIA.4.8X1.5) MM

FOR BOTTOM CAB. 136-10020-480 RUBBER FOOT (DIA.4.8X2)MM

FOR BOTTOM BATTERY

CAB. USE

FOR BATTERY USE 136-10530-100 RUBBER 10 X 5 X 3MM (W/ONE

FOR 7" TFT USE 136-10540-100 RUBBER (10*5*4)MM W/ONE

FOR BATTERY SET 136-11501-200 RUBBER 20 X 15 X 1.5MM

FOR BATTERY SET 136-21060-120

FOR 24P FLAT WIRE ON

LOADER

FOR TFT FRONT CAB. 136-80020-040 PANEL RUBBER FOOT

138-04624-010 M462 DISC DOOR HOOK

FOR TFT FRONT CAB. 144-11405-201 SCREW 1.4X5 TB SILVER;ROHS 2

144-11706-402 SCREW 1.7X6 KB;ROHS 12

133-04629-303 M462 P.C.B. SPRING (B) (STEEL

T=0.3)MM(ROHS)

M462 P.C.B. SPRING (A) (STEEL)

002

001

136-10510-050 RUBBER 5 X 5 X 1MM (W/ONE

136-21503-200 RUBBER 15 X 2.5 X

(DIA.=0.5) (ROHS)

M518M DOOR BRACKET SPRING

(DIA.=0.5MM) (ROHS)

(T=0.6MM) (STEEL) (ROHS)

W/ONE SIDE TAPE (ROHS)

W/ONE SIDE TAPE (ROHS)

SIDE TAPE) (ROHS)

SIDE TAPE) (ROHS)

SIDE TAPE (ROHS)

(W/ONE SIDE TAPE) (ROHS)

SIDE TAPE) (ROHS)

20MM(W/TWO SIDE TAPE)

(ROHS)

(DIA.3.6X2.2)MM (GREY) (ROHS)

(BLACK/POM) ;ROHS

1

1

2

2

1

1

1

1

1

2

4

2

4

1

1

2

1

Ref. No Parts No. Description QTY

FOR BATTERY CAB. 144-11706-412 SCREW 1.7X6 KB (BLAC K) ;ROHS 3

FOR TFT SPRING USE 144-12004-511 SCREW 2X4 CWB (BLACK)

HARDEN (D=5MM

T=0.5MM)(E6D8011-0) ;ROHS

FOR DOOR BRACKET 144-12006-300 SCREW 2*6 PWT (A);ROHS 1

FOR HINGE SHAFT 144-12606-111 SCREW 2.6X6 RT (BLACK) ;ROHS 1

FOR DISPLAY 144-21702-201 SCREW 1.7X2 BM;ROHS 1

144-52005-122 SCREW 2X5 STR (TB)

SILVER;ROHS

FOR BOTTOM CAB. 144-52008-112 SCREW 2X8 STR (TB)

BLACK;ROHS

FOR BOTTOM CAB. 144-52010-112 SCREW 2*10 STR (TB) BLACK

(SFBPN20100SM) (ROHS)

145-24620-000 M462 METAL WASHER (A)

(IRON) (T=1.0 MM) (ROHS)

FOR TFT FRONT CAB.

FOR TOP CAB. X 1

M593MB-

103-05930-001 M593MB BATTERY CASY TOP

104-05930-001 M593MB BATTERY CASE

117-05930-0618 M593MB SENSOR FRONT COVER

117-05931-0618 M593MB SENSOR REAR COVER

FOR TUNER-KEY P.C.B. 125-04092-003 T409 X'FORMER PC CUT SHEET

129-05933-010 M593MB SENSOR HOLDER

129-05939-010 M593MB BATTERY BACKET

130-55268-040 M526MB BATTERY LOCKER 1

146-50409-001 T409 MAGNET (NDFEB)

X 1

BATT-ASSY-02

20X3.5X5MM "SMDC" (ROHS)

R598MB DVD BATTERY PACK

CHASSIS ASSY (W/998-00000-

(ROHS)

(BLACK/ABS)

W/SIL.877C SK. ;ROHS

BOTTOM (BLACK/ABS) (ROHS)

LENS (DARK SMOKY

801691/ABS) (ROHS)

LENS (DARK SMOKY

801691/ABS) (ROHS)

(35X22X0.5)MM(ROHS)

(BLACK/ABS) (ROHS)

(BLACK/ABS) (ROHS)

10

2

6

2

7

2

1

1

1

1

1

1

1

1

Page 19

FOR CD DOOR BRACKET

1

8

PARTS LIST

Ref. No Parts No. Description QTY

(BLK./ABS) (SP.MATT.BLK.)

(ROHS)

133-04629-306-

001

133-05939-306 M593MB SENSOR SPRING

144-11704-411 SCREW 1.7X4 KT (BLACK) ;ROHS 2

FOR SENSOR COVER 144-51407-110 SCREW 1.4*7 STR (TA)

FOR BOTTOM CAB. 144-52005-112 SCREW 2X5 STR (TB) BLACK

FOR BOTTOM CAB. 144-52010-112 SCREW 2X10 STR (TB) BLACK

FOR BOTTOM CAB. 144-52012-112 SCREW 2*12 STR (TB)

998-00000-090 EPT NI-MH RECH.BATT. 7.2V

R598MB-C-0410 R598MB DVD "SUNSTECH"

103-05180-902 R598MB TOP CAB(INJ.GY.MN7-

104-04623-903 M526MB BOTTOM

108-04622-9410 M526 INNER P."SUNSTECH"

108-05180-9410 R598 OUTER

113-05180-004 R598 DVD DOOR

M462 BATTERY HOOK SPRING

(BLACK/STEEL) (DIA.=0.6MM)

(ROHS)

(DIA.:0.6MM) (ROHS)

BLACK;ROHS

(SFBPN205R0SM) ;ROHS

(SFBPN20100SM) ;ROHS

BLACK;ROHS

1500MAH (ROHS) EPT50AA150H6S;2P 120MM

WIRE+JST-XHP-2P

COSMETIC ASSY SPRAY

MATT.BLACK COLOR (ROHS)

0/ABS) (EMI.SP. SIL.SS9-1)

W/D.GY.433C/ENTER(W/USB)RO

HS

CAB.(INJ.BLK./ABS) (W/USB)

ROHS (EMI SP.MATT.BLK.)

W/SIL.877C/AV IN/OUT

(INJ.L.GY.MN7-0) (EMI SP.SIL.SS91/MATT.BK.)426C SK;ROHS

PANEL"SUNSTECH"(INJ.GY.MN7

-0/ ABS)(EMI.SP.SIL.SS9-

1)W/D.GY.433C (ROHS)

(INJ.GY./ABS#PA-777D)

Ref. No Parts No. Description QTY

ROHS(SP.SIL.SS9-1)

W/D.GY.433C(DIVX/DVBT)SK.

1

1

2

3

2

3

2

1

1

1

1

1

1

117-04620-0931 M462 SENSOR LENS (SEMI -

TRANS.WHITE/PMMA) ;ROHS

117-04621-0931 M462 LED LENS (SEMI -

TRANS.WHITE/PMMA) ;ROHS

130-04624-1887 M518MB DISPLAY SWITCH

ADAPTOR (L.GREY MNC7-

0/POM);ROHS

FOR FRONT CAB X 2

X 2

FOR BOTTOM CAB. X 2

FOR ME TAL PLATE X 1

FOR TFT RING X 1

180-04624-010 M462 METAL BOTTOM

R598MB-P-0410 R598MB DVD "SUNSTECH PLF-

015-80593-001 M593 DVB-T ANTENNA TQJ-V/U -

043-26102-541 1P RCA CABLE #26UL 1M (2 SIDE

043-26102-542 2P RCA CABLE #26UL 1M (2P

FOR BATTERY BOTTOM 136-70010-100 RUBBER FOOT (DIA.10X1)MM

998-00000-093 BATTERY CR2025 3V

MI-M598MB-

MI-04620-100-15 R598MB (MI) DVD MAIN 1

144-12005-401 SCREW 2X5 KT;ROHS 4

144-12005-411 SCREW 2X5 KT (BLACK) ;ROHS 4

CABINET (BLACK) ;ROHS

77TD" PACKING TO GERMANY

(ROHS)

BT4 (BOBOTO) VHF174-

230/UHF470-862MHZ;ROHS

RCA PLUG) YELLOW (Y001-

D100U182549B) (YIP

CHUN) ;ROHS

SIDE RCA PLUG) WHITE/RED

(Y001-D10025622637A49B)

(Y.C.) ;ROHS

NITTO 500 TAPE MATERIAL:

PORON #HH48C;ROHS

(YUFENG);(ROHS)

R598MB (MI) DVD

001

MAIN/CONT/TUNER BD. ASSY

(W/LINE SELECT) (ROHS)

1

1

1

1

1

1

1

1

2

1

1

Page 20

3P #30UL D.SHIELD WIRE 220MM

4P #28UL D.SHIELD WIRE 200MM

19

Ref. No Parts No. Description QTY

BD.CHASSIS ASSY (W/LINE

SELECT SWITCH)(FOR

KHM313AHC)

Q37 003-03906-100 TRANSISTOR 2N3906

(MOTOROLA) (PNP TO-92)

Q45 003-08050-393 TRANSISTOR 8050C (KEC) 1

R200 005-10121-314 RESISTOR 120 OHM +-5% 1/4W

(ROHS)

CE14 009-10477-510 ELECT CAP 470 UF +80%-20% 10V

(ROHS)

CE3,7,9,10,19,46,63,70,71,77

97,98,103, 105,107

CE1,11,12,26,45,47,83,85,86,

89,90

CE2,4,5 009-30107-416 ELECT CAP 100UF +-20% 16V (SS

CE62,73 009-30227-410 ELECT CAP 220 UF +-20% 10V (SS

CE52,57 009-30475-450 ELECT CAP 4.7 UF +-20% 50V (SS

CE8,16,17,18,21,22,58 009-30476-410 ELECT CAP 47 UF +-20% 10V (SS

CE6,87,88 009-30476-416 ELECT CAP 47 UF +-20% 16V (SS

CE13,20,23,25,125,126 009-69107-406 ELECT CAP 100 UF +-20% 6.3V

CE24 009-80107-410-

VOL1 010-20103-161 ROTARY VOL. R1016G21B1-A10K

L40,41 015-00003-101 CHOCK COIL 2 3/4 T NO.:R0157-

L32,34,37,38 015-00011-001 TOROID COIL R142-880928 11T

L19 015-00100-506 CHOKE COIL 10 UH DIA.6

L18 015-00150-106 CHOKE COIL 15 UH DIA.6 1

009-30106-425 ELECT CAP 10 UF +-20% 25V (SS

4X7) (ROHS)

009-30107-410 ELECT CAP 100 UF +-20% 10V (SS

5X7) (ROHS)

6.3X7) (ROHS)

6.3X7) (ROHS)

4X7) (ROHS)

4X7) (ROHS)

5X7) (ROHS)

(SM 5X5) (ROHS)

ELECT CAP 100 UF +-20% 10V

C02

(CEC) LF TAPING 5MM

(K101MBPN0507O) 5*7 (ROHS)

(DOUBLE) 10KA (SAME

PROPIT) ;ROHS

CB33-858688 (ROHS)

(COILS) (ROHS)

(RADIAL TYPE) (CW65-100K)

(ZHONGSHAN) ;ROHS

15

11

Ref. No Parts No. Description QTY

(RADIAL TYPE) (CW65-150K)

(ZHONGSHAN) ;ROHS

L30 015-00331-106 CHOCK COIL 330 UH (CW45-

1

L1,4,15,17 015-00470-106 CHOKE COIL 47 UH DIA.6

1

D25 019-12000-304 LED 3MM (RED) 304H (EVER

1

D22,23 019-15000-340 L.E.D. DIAMETER 3MM (GREEN)

SW1 020-12203-151 SWITCH SK-22D03-VG3 (NS)

S1 020-14204-112 SWITCH SK-42D01EG4 (SEE-

3

S5,6 020-31100-061 DETECTOR SWITCH SPPB512300

2

J9 021-23505-101 STEREO JACK EJS-3-0935B

2

J10 021-23505-106 STEREO JACK ST-35072-02 (SEE-

7

J8 021-23505-107 ST.P/H JACK ST-3531HW

3

6

1

1

2

4

1

J6 021-23506-105 STEREO JACK ST-3531HY (SEE-

J7 021-34503-101 DC JACK 3PINS (DC-014)

MAIN PCB (CON3) TO

TFT PCB (YC)

MAIN PCB (J4) TO USB

BD. J4A

MAIN PCB (J5) TO USB

BD. J5A

MAIN PCB (CON1) TO

TFT PCB (XS03)

J4A 025-20004-109 4P WAFER H-TYPE (1.5MM

025-10003-148

025-10004-154

025-10006-155 6P #28UL J.WIRE 150MM (2P

025-10016-009 16P UL J.WIRE #32*16 230MM (2P

331K) (RADIAL TYPE) ;ROHS

(RADIAL TYPE) (CW65-470K)

(ZHONGSHAN) ;ROHS

CHANNEL) (ROHS)

L-34GDLK KINGBRIGHT(ROHS)

(SEIKO) ;ROHS

PLUS) ;ROHS

(ALPS) ;ROHS

(DAIICHI) BLACK(ROHS)

PLUS) BLACK(ROHS)

(WHITE) (5 PINS) (SEE-PLUS)

(ROHS)

PLUS) YELLOW (ROHS)

SEIKO;ROHS

(2P 1.25MM) JS-1146-03*2

(KARSON 920-333-00) ; ROHS

(2P 1.5MM) (ROHS)

1.5MM) JST (WHITE) ;ROHS

1MM) JST SHR-16V -S-B*2

(HOUSING +/-);ROHS

PITCH) JST(ROHS)

1

4

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

Page 21

JUMPER WIRE AWG22UL 150MM

JUMPER WIRE AWG22UL 240MM

JUMPER WIRE AWG26UL 150MM

8P F.WIRE #28UL/2561 120MM (1P

Ref. No Parts No. Description QTY

J4 025-20004-214 4P WAFER V-TYPE (1.5MM

PITCH) (ROHS)

J1 025-20006-102 6P WAFER H-TYPE (2MM PITCH)

JST(ROHS)

J5A 025-20006-108 6P WAFER H-TYPE (1.5MM

PITCH) JST(ROHS)

J5 025-20006-208 6P WAFER V -TYPE (1.5MM

PITCH) W150V06T00(ROHS)

L35 027-00000-004 FERRITE BEAT CORE (RH-

3.5X6X1.0) (COILS NO.: 707866)

AXIAL TYPE (ROHS)

BATT.PLATE SPRING(+)

TO MAIN BD.BATT(+)

BATT.PLATE SPRING(-)

TO MAIN BD BATT(-)

FOR 7" DISPLAY 032-10151-040-

DISPLAY PCB (R+) TO RSPEAKER (+)

DISPLAY PCB(L+) TO

SPEAKER(+)

DISPLAY PCB(L -/R-) TO

SPEAKER(-)

USB1 046-80400-004 M560 USB CONNECTOR 4P USB

Y1 052-27000-000 CRYSTAL: 27MHZ AT -49 TYPE

J3 061-06038-001 INFRARED REMOTE DETECTOR

5MM * 1 CE15 202-10005-002 TINNED CCS WIRE (DIA.

20

MI-04620-700 M462MB (MI) DVD CONT.BD.

001-05180-700 M518MB CONTROL P.C.B.

CONTOR PCB (CN701) 025-10008-090

031-02151-040-

001

031-10241-040-

001

001

033-03700-030-

001

033-04700-030-

001

033-10700-030-

001

RED(ROHS)

BLACK(ROHS)

BLACK(ROHS)

JUMPER WIRE AWG28UL 70MM

ORANGE(ROHS)

JUMPER WIRE AWG28UL 70MM

YELLOW(ROHS)

JUMPER WIRE AWG28UL 70MM

BLACK(ROHS)

AF 90 (WHITE)G -AUASW204GX

(ALRIGHT) ROHS

(MEC) +-50PPM;ROHS

FM-6038LM(ROHS)

0.0000

0.5MM);ROHS(TIN PLATE WIRE

W/STEEL)

CHASSIS ASSY

(T=1MM) (138*35)MM (ROHS)

1.27MM) JS-1146-08 (KARSON

1

1

1

1

1

1

1

1

1

1

2

1

1

1

38

1

1

1

Ref. No Parts No. Description QTY

920-336-00) ;ROHS

048-10006-002 6MM CONNECTION PLATE

(200G) (W/LEAD) (ROHS)

MI-05930-100-02 M593 (MI) DVB-T TUNER BOARD

CHASSIS ASSY (ROHS)

EC10 009-30105-450 ELECT CAP 1 UF +-20% 50V (SS

4X7) (ROHS)

EC11,12,18,19,29,30 009-30106-425 ELECT CAP 10 UF +-20% 25V (SS

4X7) (ROHS)

EC1,2,3,4,8,13,14,15,16,17,22

,25

EC20,24 009-30107-416 ELECT CAP 100UF +-20% 16V (SS

EC32 009-30226-416 ELECT CAP 22 UF +-20% 16V (SS

EC27 009-30227-410 ELECT CAP 220 UF +-20% 10V (SS

EC21,23,26,28 009-30227-416 ELECT CAP 220 UF +-20% 16V (SS

EC31 009-30335-450 ELECT CAP 3.3 UF +-20% 50V (SS

EC5,6,7,9 009-30476-410 ELECT CAP 47 UF +-20% 10V (SS

LED1 019-35000-113 LED 2X5MM L -113GDLK (GREEN)

FOR J12 025-10002-204 2P J.WIRE #20UL 220MM (1P

025-10004-168 4P RAC CABLE 400MM (2P

J10,11,12 025-20002-204 2P WAFER V -TYPE (2.5MM

J3 025-20004-202 4P WAFER V -TYPE (2MM PITCH)

J2 025-20008-203 8P WAFER V -TYPE (2MM PITCH)

FOR DVB-T TUNER PCB

(RED) & BATT (+) *1

FOR DVB-T TUNER PCB

009-30107-410 ELECT CAP 100 UF +-20% 10V (SS

5X7) (ROHS)

6.3X7) (ROHS)

4X7) (ROHS)

6.3X7) (ROHS)

6.3X7) (ROHS)

4X7) (ROHS)

4X7) (ROHS)

KINGBRIGHT(ROHS)

2.5MM) JST (RED/BLACK);ROHS

2MM)JSY A2001H-4P (3.5MM

PLUG*2 MOND & ST.+4P

R/W/GND/Y) ;ROHS

PITCH) JST(ROHS)

JST (ROHS) (B4B-PH-K-S)

JST(ROHS)

027-13060-080 TOROID CORE

(12.70*6.35*7.90)MM (COILS

NO.:M191206079CL5) (ROHS)

14

1

1

6

12

2

1

1

4

1

4

1

1

1

3

1

1

2

Page 22

JUMPER WIRE AWG22UL 220MM

JUMPER WIRE AWG22UL 150MM

2

1

Ref. No Parts No. Description QTY

(BLK) & BATT (-) *1

DVB-T TUNER PCB TO

BATT (+)

DVB-T TUNER PCB TO

BATTERY (-)

031-02221-040-

001

031-10151-040-

001

RED(ROHS)

BLACK(ROHS)

XTAL1 052-27000-000 CRYSTAL: 27MHZ AT -49 TYPE

(MEC) +-50PPM;ROHS

U2 061-00404-002 DVB-T TUNER DNOS404PH104A

(SAMSUNG) (HORIZONTAL

MOUNT TYPE/DIN-JACK);ROHS

30MM*5 (FOR SHIELD

PLATE TO GND)

202-10005-002 TINNED CCS WIRE (DIA.

0.5MM);ROHS (TIN PLATE WIRE

W/STEEL)

MI-05930-700-01 M593 (MI) DVB CONTROL

P.C.B.CHASSIS ASSY

001-05930-700 M593 CONTROL P.C.B. (94HB)

(22*40*1.6)MM "CHEERTEK"

T212(ROHS)

R1,2 005-10100-306 RESISTOR 10 OHM +-5%

1/16W(ROHS)

C1 009-30107-410 ELECT CAP 100 UF +-20% 10V (SS

5X7) (ROHS)

SW1 020-22204-106 SWITCH SS-22F04 (2P2T) (SEE-

SPLUS) (ROHS)

K1,2 020-31100-058 TACT SWITCH TC -00104C-00

(SEE-PLUG) (ROHS)

FOR INFRARED REMOTE 025-10003-066C 3P J.WIRE #26UL 120MM (1P

2MM) JST

CONTROL PCB (CN1) TO

DVB-T TUNER PCB(J2)

025-10008-019 8P FLAT WIRE 190MM (1 PLUG

2MM) JST;ROHS

061-00138-003 INFRARED REMOTE CONTROL

RECEIVER MODULE HT138BS

(MOBICON) 38KHZ;ROHS

135-05932-201 M593 COPPER SHEET-02

(80*78*0.1)MM;ROHS (1 SIDE

W/TAPE & COATING PAPER)

MI-10550-710-01 R519MB (MI) TFT DRIVER

BD.CHASSIS ASSY ROHS

CE15,16,17,18 009-30106-425 ELECT CAP 10 UF +-20% 25V (SS

4X7) (ROHS)

1

1

1

1

0.0004

14

1

1

2

1

1

2

1

1

1

1

1

4

Ref. No Parts No. Description QTY

FOR TFT DRIVER BD. J5 025-10003-180 3P J.WIRE #28UL 60MM (2P

1.25MM)

JST(RED/WHITE/BLACK) (ROHS)

X1 052-20000-001 CRYSTAL: 20MHZ AT -49 TYPE

(EMC) +-50PPM;ROHS

SMT-R598MB-

001

R598MB (SMT)

MAIN/DRIVER/TUNER BD.

ASSY(W/LINE SELECT) (ROHS)

SMT-04620-100-

15

R598MB (SMT) DVD MAIN

BD.CHASSIS ASSY (W/LINE

SELECT SWITCH)(FOR

KHM313AHC)

001-04620-100 M462 MAIN/PWR/USB

P.C.B.(FR4) (T=1MM)

(113*146)MM (R.6) (ROHS)

U10 002-00393-110 IC LM393DR (T.I.) SMT

SOP08;ROHS

U1 002-01101-002-

170

IC RP1101-19CXL (RICH POWER)

1.9V/300MA SOT-89(L TYPE)SMT;ROHS

U2,13,14 002-01380-000-

101

IC AT1380HP (AIMTRON) SMT

TSSOP8;ROHS

U5 002-01389-854 IC MT1389DE (MEDIATEK) SMT

(5.1 CH/WMA/DIVX/USB) ; ROHS

U3 002-02073-180 IC NJM2073M (JRC) ;ROHS 1

U12 002-02402-451 IC AT24C02A-10SC-207 (SO-8)

(ATMEL) (EEPROM) (ROHS)

U6 002-02964-001-

163

IC LS2964S (LINKAS) SOP-8

(SMT) NIMH BATTERY

CHARGER CONTROLLER IC

(ROHS)

U15 002-04340-410 IC CS4340 (CRYSTAL) (ROHS) 1

U6 002-04558-110 IC RC4558D (T.I.) (SOP08)

SMT(ROHS)

U4 002-05654-101 IC AT5654H (AIMTRON) (SMT)

(ROHS)

U7 002-09701-920 IC RT9701CB (RICHTEK) SMT

SOT25(ROHS)

U9 002-46416-061 IC K4S641632H-UC75 TSOP-54 1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

Page 23

STE179.1B

2

2

Ref. No Parts No. Description QTY

(SAMSUNG) 64M SDRAM IC

(133MHZ) (ROHS)

U11 002-49163-450 IC AT49BV163A-70TU (ATMEL)

TSOP-48 16M FLASH MEMORY

IC (SMT) LEAD FREE(ROHS)

Q7,22,25,27 003-20323-140 CHIP TRANSISTOR DTC323TU

(UMT3) ROHM (ROHS)

Q4,5,30 003-21132-149 CHIP TRANSISTOR 2SB1132R

(MPT3) (ROHM) (ROHS)

Q1,2 003-23018-140 CHIP TRANSISTOR 2SK3018,SOT-

23 (ROHM) (ROHS)

Q9,16 003-23065-140 CHIP TRANSISTOR 2SK3065

(ROHM) SMALL SWITCHING

(60V,2A) (ROHS)

Q29 003-23400-001-

137

Q10,26 003-23401-001-

137

Q3,6,8,11,12,15,17,18,19,

20,21,23,24,32,34,35,36

Q14,28,31,33 003-23906-001-

Q13 003-27002-100 CHIP TRANSISTOR 2N7002LT1

D15 004-80051-401 SW.DIODES RB051L-40 (ROHM)

Z1,5 004-80056-215 ZENER DIODE UDZ5.6B (ROHM)

Z6 004-80075-215 ZENER DIDOE UDZ7.5B (ROHM)

Z7 004-80091-215 ZENER DIODE UDZS9.1B-TRB

Z3 004-80110-215 ZENER DIODE UDZS11B-TRB

Z4 004-80120-215 ZENER DIODE UDZS12B-TRB

Z2 004-80130-215 ZENER DIODE UDZS13B-TRB 1

003-23904-001-

114

114

CHIP TRANSISTOR AO3400

(ALPHA & OMEGA) SOT-23

(ROHS)

CHIP TRANSISTOR AO3401

(ALPHA & OMEGA) SOT-23

(ROHS)

CHIP TRANSISTOR NPN

FMMT3904 (HSMC) (ROHS)

CHIP TRANSISTOR PNP

FMMT3906 (HSMC) (ROHS)

SOT-23(MOTOROLA) (ROHS)

SMT(ROHS)

5.6V 0.2W SMT(ROHS)

7.5V 0.2W SMT (ROHS)

(ROHM)9.1V 0.2W UDZ(SMT) (ROHS)

(ROHM) 11V 0.2W SMT (ROHS)

(ROHM) 12V 0.2W SMT(ROHS)

17

Ref. No Parts No. Description QTY

(ROHM) 13V 0.2W SMT(ROHS)

D27 004-80154-400 SW. DIODE 1SR154-400-TRB

1

D4,10,11 004-80160-401 SCHOTTKY DIODE RB160L-60

4

3

2

2

1

2

4

1

1

2

1

1

1

1

D19 004-80202-400 SW. DIODE DAN202K (ROHM)

D1,2,5,6,8,12,13 004-80217-400 DIODE DAN 217 (ROHM)

D3,9,14,16,18,20,21 004-80355-400 SW. DIODE 1SS355-TRB (ROHM)

D17 004-80520-401 SW. DIODES RB520S-30 (ROHM)

R100 005-50471-301 CHIP RESISTOR 470 OHM (2012)

R26,27,28,29,31,61,62,67,99,

102,159, 188,L7,D7

R74,81,83,87,90,91,92,154,164 005-52100-301 CHIP RESISTOR 10 OHM +-5%

R114,120,185,195 005-52101-301 CHIP RESISTOR 100 OHM +-5%

R4,5,6,24,33,40,48,109, 116,

122,197,199

R16,32,35,54,126,129,149,

155,165,168,189

R22,42,43,44,45,59 005-52109-301 CHIP RESISTOR 1 OHM +-5%

R2,34,50,52,58,68,69,72,

73,76,77,78, 79,82,84,93,

94,95,106,115,119,127,

130,146,150,152,167,173,

174,196

R20,63,64,176,177,178,179 005-52121-301 CHIP RESISTOR 120 OHM +-5%

R158 005-52123-301 CHIP RESISTOR 12 K +-5% (1608)

R14,46,49,183,187 005-52153-301 CHIP RESISTOR 15 K +-5% (1608)

R17,19 005-52154-301 CHIP RESISTOR 150 K +-5% (1608) 2

005-52000-301 CHIP RESISTOR 0 OHM +-5%

005-52102-301 CHIP RESISTOR 1 K +-5% (1608)

005-52104-301 CHIP RESISTOR 100 K +-5% (1608)

005-52103-301 CHIP RESISTOR 10 K +-5% (1608)

(ROHM) SMT(ROHS)

(ROHM) SMT(ROHS)

SMT (SMD3) SC-59 (DAN202K-

TLB) (ROHS)

SMT(ROHS)

SMT(ROHS)

SMT(ROHS)

(MCR10EZHJ471) (ROHS)

(1608) (ROHS)

(1608) (MCR03EZHJ100) (ROHS)

(1608) (MCR03EZHJ101) (ROHS)

(MCH03EZHJ102)

(ROHS)

(1608) (ROHS)

(ROHS)

(1608) (ROHS)

(MCR03EZHJ123) (ROHS)

(ROHS)

1

3

1

7

7

1

1

14

9

4

12

11

6

30

7

1

5

Page 24

2

3

Ref. No Parts No. Description QTY

(ROHS)

R47,184 005-52183-301 CHIP RESISTOR 18 K +-5% (1608)

(ROHS)

R125,128 005-52184-301 CHIP RESISTOR 180 K +-5% (1608)

(ROHS)

R60,98,153 005-52202-301 CHIP RESISTOR 2 K +-5% (1608)

(ROHS)

R51,53,56,104,117,121 005-52203-301 CHIP RESISTOR 20 K +-5% (1608)

(ROHS)

R145 005-52220-301 CHIP RESISTOR 22 OHM +-5%

(1608) (ROHS)

R13,23 005-52221-301 CHIP RESISTOR 220 OHM +-5%

(1608) (MCR03EZHJ221) (ROHS)

R30,148 005-52222-301 CHIP RESISTOR 2.2 K +-5% (1608)

(MCH03EZHJ222) (ROHS)

R162 005-52224-301 CHIP RESISTOR 220 K +-5% (1608)

(MCR03EZHJ224) (ROHS)

R75,80,89 005-52302-301 CHIP RESISTOR 3 K +-5% (1608)

(MCH03EZHJ302) (ROHS)

R7,137,141,190 005-52330-301 CHIP RESITOR 33 OHM +-5%

(1608) (ROHS)

R65,66 005-52331-301 CHIP RESISTOR 330 OHM +-5%

(1608) (ROHS)

R37 005-52334-301 CHIP RESISTOR 330 K +-5% (1608)

(MCR03EZHJ334) (ROHS)

R70,85,96 005-52391-301 CHIP RESISTOR 390 OHM +-5%

(1608) (ROHS)

R136,142 005-52393-301 CHIP RESISTOR 39 K +-5% (1608)

(MCR03EZHJ393) (ROHS)

R186 005-52470-301 CHIP RESISTOR 47 OHM +-5%

(1608) (MCR03EZHJ470) (ROHS)

R9,103,139,163 005-52471-301 CHIP RESISTOR 470 OHM +-5%

(1608) (ROHS)

R8,88,105,124,151,157, 166 005-52472-301 CHIP RESISTOR 4.7 K +-5% (1608)

(ROHS)

R101,107,108,143,144,175,18

2,193

005-52473-301 CHIP RESISTOR 47 K +-5% (1608)

(ROHS)

R12,39,41,111,113,138, 161 005-52479-301 CHIP RESISTOR 4.7 OHM +-5%

(1608) (ROHS)

R131,132 005-52512-301 CHIP RESISTOR 5.1 K +-5% (1608) 2

Ref. No Parts No. Description QTY

(ROHS)

2

R25 005-52561-301 CHIP RESISTOR 560 OHM +-5%

1

(1608) (ROHS)

2

R55,123,147 005-52562-301 CHIP RESISTOR 5.6K +-5% (1608)

3

(ROHS)

3

R71,86,97 005-52563-301 CHIP RESISTOR 56 K +-5% (1608)

3

(MCR03EZHJ563) (ROHS)

6

R172 005-52564-301 CHIP RESISTOR 560 K +-5% (1608)

1

(ROHS)

1

R191 005-52680-301 CHIP RESISTOR 68 OHM +-5%

1

(1608) (ROHS)

2

R10,15 005-52684-301 CHIP RESISTOR 680 K +-5% (1608)

2

(ROHS)

2

R1,156,160 005-52689-301 CHIP RESISTOR 6.8 OHM +-5%

3

(1608) (ROHS)

1

R180,181 005-52750-301 CHIP RESISTOR 75 OHM +-5%

2

(1608) (ROHS)

3

R3 005-52754-301 CHIP RESISTOR 750 K +-5% (1608)

1

(ROHS)

4

R11,21,38 005-52820-301 CHIP RESISTOR 82 OHM +-5%

3

(1608) (ROHS)

2

R110,118,133,135,140 005-52822-301 CHIP RESISTER 8.2 K +-5% (1608)

5

(ROHS)

1

R134 005-52912-301 CHIP RESISTOR 9.1 K +-5% (1608)

1

(ROHS)

3

2

1

4

7

8

7

RN1,2,3 005-53103-301 CHIP RESISTOR (MULTPLE) 10 K

+-5% (1608) X 4 (RCML08W103JB)

ARRAY (ROHS)

R57 005-54278-301 CHIP RESISTOR 0.27 OHM+ -5%

(5025) (ROHS)

CB4,14,29,33 006-72100-250 CERAMIC CHIP CAP 10 PF +-5%

50V (1608) (ROHS) NPO

C22,72,137,155,CB27,32 006-72101-250 CERAMIC CHIP CAP 100 PF +-5%

50V (1608) (ROHS) NPO

C15,16,23,24,25,26,27,81,95,

127,154

006-72105-410 CERAMIC CHIP CAP 1 UF +-20%

10V (1608) (ROHS) Y5V

C6 006-72102-350 CERAMIC CHIP CAP 0.001 UF +-

10% 50V (1608) (ROHS) X7R

C19 006-72103-350 CERAMIC CHIP CAP 0.01 UF +-

3

1

4

6

11

1

1

10% 50V(1608) (ROHS) X7R

Page 25

2

4

Ref. No Parts No. Description QTY

(MCH185CN103KK)

C5,20,66,68,76,78,92,94 006-72105-416 CERAMIC CHIP CAP 1 UF +-%20

16V (1608) (ROHS) Y5V

C49,50,51,54,56,58,60 006-72105-435 CERAMIC CHIP CAP 1 UF +-20%

35V (1608) (ROHS) Y5V

C7,8,12,13,21,29,30,33,34,35,

36,39,43,45, 46,48,61,

64,69,71,73,74,77,79,82,91,93

, 96,102,104,108,111,

112,113,114,115,116, 117,

118,119,120,121,138,139,

140,142,143, 145,162,

CB1,3,15,16,18,19,20,21,

22,23,25,28,46, 47,48,49,

50,51,52,53,60

C41,42 006-72151-250 CERAMIC CHIP CAP 150 PF +-5%

C53 006-72152-350 CERAMIC CHIP CAP 0.0015 UF +-

C40 006-72153-350 CERAMIC CHIP CAP 0.015 UF +-

C28 006-72180-250 CERAMIC CHIP CAP 18 PF +-5%

C4 006-72200-250 CERAMIC CHIP CAP 20 PF +-5%

CB9,24,31 006-72220-250 CERAMIC CHIP CAP 22 PF +-5%

C101,106,CB17,30,34 006-72221-250 CERAMIC CHIP CAP 220 PF +-5%

C3,47,52,55,57,62,63,67, 70,

149

C10,11 006-72270-250 CERAMIC CHIP CAP 27 PF +-5%

C32,65,75 006-72271-250 CERAMIC CHIP CAP 270 PF +-5%

C84 006-72330-250 CERAMIC CHIP CAP 33 PF +-5%

CB37,38 006-72331-250 CERAMIC CHIP CAP 330 PF +-5%

C141,144 006-72332-350 CERAMIC CHIP CAP 0.0033 UF +- 2

006-72104-525 CERAMIC CHIP CAP 0.1 UF +80%-

20% 25V (1608) (MCH182F104ZK)

(ROHS) Y5V

50V (1608) (ROHS) NPO

10% 50V (1608) (ROHS) X7R

10% 50V (1608) (ROHS) X7R

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

006-72222-350 CERAMIC CHIP CAP 0.0022 UF +-

10% 50V (1608) (ROHS) X7R

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

70

10

Ref. No Parts No. Description QTY

10% 50V(1608) (ROHS) X7R

8

7

2

1

1

1

1

3

5

2

3

1

2

C14,80,83 006-72333-325 CERAMIC CHIP CAP 0.033 UF +-

10% 25V(1608) (ROHS) X7R

(MCH182C333KK)

C1 006-72391-250 CERAMIC CHIP CAP 390 PF +-5%

50V(1608) (ROHS) NPO

CB30 006-72392-350 CERAMIC CHIP CAP 0.0039UF +-

10% 50V (1608) (ROHS) Y5V

CB2,7 006-72470-250 CERAMIC CHIP CAP 47 PF +-5%

50V (1608) (ROHS) NPO

C99,100 006-72472-250 CERAMIC CHIP CAP 0.0047 UF +-

5% 50V (1608) (ROHS) NPO

C17,18 006-72473-350 CERAMIC CHIP CAP 0.047 UF +-

10% 50V(1608) (ROHS) X7R

L2,3,11,13 015-00018-901 CHIP INDUCTOR 1.8 UH (0805)

(COILS) CCSP0805FIR8J;ROHS

L21,22 015-00100-904 CHIP INDUCTOR 10 UH (CCSP

0805F 10RJ) (COILS) ;ROHS

L4 015-00220-916 CHIP INDUCTOR 22UH

(SMT)(EBL2012-220K,M) ;ROHS

CON1 025-20016-503 16P HEADE R D-TYPE WAFER

(1MM PITCH) (NO:990-775-00)

(ROHS)

CON3 025-23003-101 3P WAFER H-TYPE (1.25MM

PITCH) KARSON 990-777-00

(SMT) (ROHS)

J2 025-23008-101 8P WAFER H-TYPE (1.25MM

PITCH) KARSON 990-778-00

(SMT) (ROHS)

HA2 025-50024-205 24P ZIF CONN.V -TYPE (0.5MM

PITCH) SMT (CF2024 IVORO)

(ROHS)

L5,6,8,9,10,12,14,16,20,23,24,

25,26, 27,28,29

FUSE1 050-42410-201 2A/125V (SMT) FUSE (2410)

S3 065-00012-001 RELAY ME12-S-5 (5V) (MASSUSE)

027-01121-002 CHIP FERRITE BEAD

BK2125HM121 (TAI) (ROHS)

SLOW BLOW BEL/TYPE SST2

UL/CE/CSA(ROHS)

(ROHS)

3

1

1

2

2

2

4

2

1

1

1

1

1

16

1

1

Page 26

2

5

Ref. No Parts No. Description QTY

SMT-10550-710-

01

001-10550-710 I1055 7" TFT DRIVER PCB (4

U2 002-01102-001-

170

U1 002-01828-001-

209

U3 002-03414-180 IC NJM3414AM-TE1 (NJRC)

Q1,2,3 003-23904-001-

114

R41,L4,5 005-52000-301 CHIP RESISTOR 0 OHM +-5%

R46 005-52102-301 CHIP RESISTOR 1 K +-5% (1608)

R2,45,47 005-52103-301 CHIP RESISTOR 10 K +-5% (1608)

R34,35,36 005-52104-301 CHIP RESISTOR 100 K +-5% (1608)

R8 005-52105-301 CHIP RESISTOR 1 M +-5% (1608)

R38,44 005-52153-301 CHIP RESISTOR 15 K +-5% (1608)

R43 005-52201-301 CHIP RESISTOR 200 OHM +-5%

R18,23,28 005-52223-301 CHIP RESISTOR 22 K +-5% (1608)

R19,24,29 005-52271-301 CHIP RESISTOR 270 OHM +-5%

R39 005-52330-301 CHIP RESITOR 33 OHM +-5%

R1,3,4,9,10,13,14,15,16,21,26

,31

R32,33,37 005-52332-301 CHIP RESISTOR 3.3 K +-5% (1608)

R11,12 005-52622-301 CHIP RESISTOR 6.2K +-5% (1608) 2

005-52331-301 CHIP RESISTOR 330 OHM +-5%

R519MB (SMT) TFT DRIVER

BD.CHASSIS ASSY (ROHS)

LAYER) (94V0) (121*23*1)MM

(ROHS)(R.2)

IC RP1102-33CGL(RICH POWER)

3.3V/500MA SOT-223 (L TYPE)SMT;ROHS

IC VX1828 (VXIS) 100-PIN LQFP

(SMT)

(SMT);ROHS

CHIP TRANSISTOR NPN

FMMT3904 (HSMC) (ROHS)

(1608) (ROHS)

(ROHS)

(ROHS)

(ROHS)

(MCR03EZHJ105) (ROHS)

(ROHS)

(1608) (ROHS)

(ROHS)

(1608) (ROHS)

(1608) (ROHS)

12

(1608) (ROHS)

(MCR03EZHJ332) (ROHS)

Ref. No Parts No. Description QTY

1

R20,25,30 005-52683-301 CHIP RESISTOR 68 K +-5% (1608)

1

R6,7,17,22,27 005-52750-301 CHIP RESISTOR 75 OHM +-5%

1

1

1

3

3

1

3

3

1

2

1

3

1

1

3

C1,2,3,6,7,9,10,13,18,19,

20,21,22,23, 25,26,28,29,

30,31,32,33,34,35,36,37,38,39

,40,42,44,46,47,48,49,

50,51,52

C4,5,8,12 006-72220-250 CERAMIC CHIP CAP 22 PF +-5%

C24 006-72330-250 CERAMIC CHIP CAP 33 PF +-5%

C11 006-72473-350 CERAMIC CHIP CAP 0.047 UF +-

C27 006-72820-250 CERAMIC CHIP CAP 82 PF +-5%

VR1 012-18473-101 CHIP SEMI -FIXED EVM3Y-SX30-

L2 015-00100-904 CHIP INDUCTOR 10 UH (CCSP

J4 025-20016-503 16P HEADER D-TYPE WAFER

J6 025-20026-102 26P CONNECTOR H-TYPE

J1,5 025-23003-101 3P WAFER H-TYPE (1.25MM

L1,3,6,7,9,10,11 027-01121-002 CHIP FERRITE BEAD

CE6,7,8,11,12,13,14 047-11106-410-

CE5,10 047-11107-406-

006-72104-525 CERAMIC CHIP CAP 0.1 UF +80%-

E01

K02

(ROHS)

(MCR03EZHJ683) (ROHS)

(1608) (ROHS)

20% 25V(1608) (ROHS) Y5V

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

10% 50V(1608) (ROHS) X7R

50V (1608) (ROHS) NPO

BQ4 B47KB (H-TYPE) (3 PINS)

(PANASONIC);ROHS

0805F 10RJ) (COILS);ROHS

(1MM PITCH) (NO:990-775-00)

(ROHS)

SMT(0.5MM PITCH) W/FLIP

LOOK (LOW CONTACT)(ROHS)

PITCH) KARSON 990-777-00

(SMT) (ROHS)

BK2125HM121 (TAI) (ROHS)

TANTALUM CHIP CAP 10 UF +-

20% 10V (ELAN) (SK6-1A106M-

RC) (3.2X1.6X1.6/CASE A) ;ROHS

TANTALUM CHIP CAP 100UF +-

20% 6.3V KEMET

T491B107M006AS;3.5*2.8*1.9/CA

3

5

38

4

1

1

1

1

1

1

1

2

7

7

2

Page 27

(167*60*1)MM

2

6

Ref. No Parts No. Description QTY

SE B;ROHS

CE1,4,9 047-11476-406-

K01

TANTALUM CHIP CAP 47 UF +20% 6.3V(ROHS) 3.2*1.6*1.6/CASE

A;KEMET;T491A476M006AS

SMT-76000-400 R600MB 7" INVERTER BOARD

CHASSIS ASSY(IC MP1522ET)

001-76000-400 R600 INVERTER P.C.B. (2 LAYER)

(FR4) (50*12*1)MM (ROHS)

U1 002-01522-001-

167

IC MP1522ET (MPS) SOT23-5

(SMT) 25V STEP-UP CONVERTER

IC (ROHS)

D1 004-80051-402 CHIP SHOTTKY BARRIER DIODE

RSX051VA-30(ROHM) ROHS

D2 004-80355-400 SW. DIODE 1SS355-TRB (ROHM)

SMT (ROHS)

R5 005-52100-301 CHIP RESISTOR 10 OHM +-5%

(1608) (ROHS)

R1 005-52104-301 CHIP RESISTOR 100 K +-5% (1608)

(ROHS)

R4 005-52120-301 CHIP RESISTOR 12 OHM +-5%

(1608) (ROHS)

R7 005-52272-301 CHIP RESISTOR 2.7 K +-5% (1608)

(MCR03EZHJ272) (ROHS)

R2 005-52561-301 CHIP RESISTOR 560 OHM +-5%

(1608) (ROHS)

R3 005-52562-301 CHIP RESISTOR 5.6K +-5% (1608)

(ROHS)

L1 015-00150-901 CHIP INDUCTOR 15 UH

(DRH4D28-150M) COILS(ROHS)

C1,5 006-72104-525 CERAMIC CHIP CAP 0.1 UF +80%-

20% 25V(1608) (ROHS) Y5V

L2 015-00220-910 CHIP INDUCTOR 22 UH

(DRH4D28-220M) COILS (ROHS)

J2 025-20002-114 2P WAFER H-TYPE (3.5MM

PITCH) JST (ROHS) 3502P0210T

(LANDWIN)

J1 025-23003-101 3P WAFER H-TYPE (1.25MM

PITCH) KARSON 990-777-00

(SMT) (ROHS)

L3 027-01121-002 CHIP FERRITE BEAD 1

Ref. No Parts No. Description QTY

BK2125HM121 (TAI) (ROHS)

3

C2 047-11106-425 TANTALUM CHIP CAP 10 UF +-

1

20% 25V(6X3.2/CASE C);ROHS

C3 047-11475-425-E TANTALUM CHIP CAP 4.7 UF +-

1

20% 25V(ELNA) (SK6-1E475M-RB)

1

(3.4X2.8X1.9/CASE B);ROHS

1

C4 047-11476-416-E TANTALUM CHIP CAP 47 UF +-

1

20% 16V (ELNA) (SK6-1C476M-

1

SMT-05930-100-

02

1

001-05930-100 M593 DVB-T TUNER P.C.B. (4

RC)(6.0X3.2X2.5/CASE C);ROHS

R598 (SMT)DVB-T TUNER

BOARD CHASSIS ASSY (ROHS)

1

1

LAYER); R.1;ROHS

1

U3 002-00212-001-

1

183

"CHEERTEK" CT212 VER 1.52

IC CT212T (CHEERTEK) QFP-208

(SMT);ROHS DIGITAL TV STB

1

BACKEND PROCESSOR

1

1

1

1

U10 002-01117-005-

112

IC B1117N-ADJ (BAY LINEAR)

SMT SOT-223 (ADJUSTABLE)

VOLTAGE REGULATOR IC; ROHS

U6 002-02402-452 IC AT24C02BN-10SU-1.8 (SO-8)

(ATMEL) (EEPROM)(ROHS)

U5 002-04345-410 IC CS4345-CZZ (CRYSTAL)

TSSOP-10 (SMT) 24-BIT,192 KHZ

1

1

1

ST. D/A CONVERTER IC;ROHS

1

U7 002-04558-110 IC RC4558D (T.I.) (SOP08)

1

SMT;ROHS

1

2

1

U8,9 002-09141-001-

167

U4 002-29008-001-

184

IC MP9141ES-LF-Z (MPS) SOIC8

SMT 1.8A STEP-DOWN DC TO

DC CONVERTER (ROHS)

IC S29AL008D70TFI020

(SPANSION) TSOP48 8M FLASH

2

1

MEMORY IC (SMT) ;ROHS

1

U1 002-46416-061 IC K4S641632H-UC75 TSOP-54

1

(SAMSUNG) 64M SDRAM IC

(133MHZ) (ROHS)

1

Q1 003-20807-640 CHIP TRANSISTOR PNP BC807-25

1

SOT-23 (FAIRCHILD) (ROHS)

Q3,10,12 003-20847-242 CHIP TRANSISTOR NPN BC847B

3

SOT-23 (PHILIPS) (ROHS)

Page 28

PARTS LIST

2

7

Ref. No Parts No. Description QTY

Q11 003-20857-242 CHIP TRANSISTOR PNP BC857B

SOT-23 (PHILIPS) (ROHS)

Q2,4,5,9 003-23904-001-

114

Q6,7,8 003-23906-001-

114

D6 004-80051-215 ZENER DIODE UDZS5.1B (ROHM)

D8 004-80154-400 SW. DIODE 1SR154-400-TRB

D7,9 004-80160-401 SCHOTTKY DIODE RB160L-60

D1,2,3,4,5 004-84148-400 SW. DIODE LL4148 (GOOD

FB98 005-50000-301 CHIP RESISTOR O OHM +-5%

R79 005-50150-301 CHIP RESISTOR 15 OHM +-5%

R24,55,83 005-52000-301 CHIP RESISTOR 0 OHM +-5%

R9,73,74,75 005-52101-301 CHIP RESISTOR 100 OHM +-5%

R39,43,50,52,57,66 005-52102-301 CHIP RESISTOR 1 K +-5% (1608)

R1,2,3,11,17,20,25,37,41,

44,46,49,51,58,63,64,67,68,72

,84

R56 005-52104-301 CHIP RESISTOR 100 K +-5% (1608)

R34 005-52105-301 CHIP RESISTOR 1 M +-5% (1608)

R69 005-52153-301 CHIP RESISTOR 15 K +-5% (1608)

R60 005-52182-301 CHIP RESISTOR 1.8 K +-5% (1608)

R36,48 005-52203-301 CHIP RESISTOR 20 K +-5% (1608)

R71 005-52221-301 CHIP RESISTOR 220 OHM +-5%

005-52103-301 CHIP RESISTOR 10 K +-5% (1608)

CHIP TRANSISTOR NPN

FMMT3904 (HSMC) (ROHS)

CHIP TRANSISTOR PNP

FMMT3906 (HSMC) (ROHS)

5.1V (0.2W) UDZS5R1(B)-TRB

(SMT) (ROHS)

(ROHM) SMT(ROHS)

(ROHM) SMT(ROHS)

EXCEL) SMT(ROHS)

(2012) (MCR10EZHJ000) (ROHS)

(2012) (ROHS)

(1608) (ROHS)

(1608) (ROHS)

(ROHS)

(ROHS)

(ROHS)

(MCR03EZHJ105) (ROHS)

(ROHS)

(ROHS)

(ROHS)

(1608) (MCR03EZHJ221) (ROHS)

1

4

3

1

1

2

5

1

1

3

4

6

20

1

1

1

1

2

1

Ref. No Parts No. Description QTY

R61,70,80 005-52222-301 CHIP RESISTOR 2.2 K +-5% (1608)

(ROHS)

R53 005-52223-301 CHIP RESISTOR 22 K +-5% (1608)

(ROHS)

R28 005-52229-301 CHIP RESISTOR 2.2 OHM +-5%

(1608) (ROHS)

R29,47 005-52243-301 CHIP RESISTOR 24 K +-5% (1608)

(MCR03EZHJ243) (ROHS)

R65 005-52303-301 CHIP RESISTOR 30 K +-5% (1608)

(ROHS)

R5,8,10,18,19,22,23,31,32,35,

38,40,42

R6,77 005-52333-301 CHIP RESISTOR 33 K +-5% (1608)

R27 005-52431-301 CHIP RESISTOR 430 OHM +-5%

R54 005-52471-301 CHIP RESISTOR 470 OHM +-5%

R4,7,12,13,14,15,16,30,33,62,

76,78,82

R59 005-52473-301 CHIP RESISTOR 47 K +-5% (1608)

R45 005-52479-301 CHIP RESISTOR 4.7 OHM +-5%

R26 005-52820-301 CHIP RESISTOR 82 OHM +-5%

R81 005-52822-301 CHIP RESISTER 8.2 K +-5% (1608)

RN1,RNM1,RNM2,RNM3 005-53330-301 CHIP RESISTOR (MULTPLE) 33

C21 006-72100-250 CERAMIC CHIP CAP 10 PF +-5%

C22,23 006-72101-250 CERAMIC CHIP CAP 100 PF +-5%

C13,15,17 006-72102-250 CERAMIC CHIP CAP 0.001 UF +-

C64,70 006-72103-250 CERAMIC CHIP CAP 0.01 UF+-5%

C20 006-72105-435 CERAMIC CHIP CAP 1 UF +-20%

005-52330-301 CHIP RESITOR 33 OHM +-5%

(1608) (ROHS)

(ROHS)

(1608) (ROHS)

(1608) (ROHS)

005-52472-301 CHIP RESISTOR 4.7 K +-5% (1608)

(ROHS)

(ROHS)

(1608) (ROHS)

(1608) (ROHS)

(ROHS)

OHM +-5% (1608) X 4(ROHS)

50V (1608) (ROHS) NPO

50V (1608) (ROHS) NPO

5% 50V(1608) (ROHS) NPO

50V (1608) (ROHS) NPO

35V (1608) (ROHS) Y5V

3

1

1

2

1

13

2

1

1

13

1

1

1

1

4

1

2

3

2

1

Page 29

10%

PARTS LIST

2

8

Ref. No Parts No. Description QTY

C31,61 006-72121-250 CERAMIC CHIP CAP 120 PF +-5%

50V (1608) (ROHS) NPO

C1,2,3,4,5,6,8,9,10,11,12,14,1

6,25,26,27,28,29,30,38,39,40,

41,42,43,44,45,46,4748,49,50,

51,52,53,54,55,5657,58,59,60,

65,68,69,71,7475,76,

CX1,CX2

BC1,BC2

C19,24,32,33 006-72220-250 CERAMIC CHIP CAP 22 PF +-5%

C72 006-72273-350 CERAMIC CHIP CAP 0.027 UF +-

C35,63 006-72470-250 CERAMIC CHIP CAP 47 PF +-5%

C66 006-72473-350 CERAMIC CHIP CAP 0.047 UF +-

C34,62 006-72821-250 CERAMIC CHIP CAP 820 PF +-5%

L5 015-00010-900 CHIP INDUCTOR 1UH (SMT)

L1,2,3,4,FB79,91,100,101,134

,139

L6,7 015-00221-901 CHIP INDUCTOR 220 UH (SMT)

FB1,4,11,13,15,17,18 027-01094-001 CHIP BEADS BK2125 HS750-T +-

FB62,63,64 027-01121-002 CHIP FERRITE BEAD

FB2,3,5,6,8,9,10,14 027-01601-003 CHIP BEAD BLM21A601SPT

006-72104-350 CERAMIC CHIP CAP 0.1 UF +-

50V (1608) (ROHS) X7R

50V (1608) (ROHS) NPO

10% 50V (1608) (ROHS) X7R

50V (1608) (ROHS) NPO

10% 50V (1608) (ROHS) X7R

50V (1608) (ROHS) NPO

(EBL2012-1R0K,M) (ROHS)

015-00220-916 CHIP INDUCTOR 22UH

(SMT)(EBL2012-220K,M) (ROHS)

(DA75NP) (COILS)

(7.0*7.8*5.3)MM (ROHS)

25% (2125) TAPE & REEL "TAIYO

YUDEN" (VTL1094-A-T) (ROHS)

BK2125HM121 (TAI) (ROHS)

(2125) (MURATA) TAPE REEL

(ROHS)

2

53

4

1

2

1

2

1

10

2

7

3

8

Loading...

Loading...