Page 1

SERVICE MANUAL

Main Section

I Specifications

I Adjustment Procedures

I Troubleshooting

I Schematic Diagrams

I CBA’s

I Exploded Views

I Parts List

Plasma Display Module Section

I Disassembly Procedures

I Troubleshooting

I Exploded Views

I Parts List

PLASMA DISPLAY

F42PDME

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and described in this service manual are effective methods of performing service

operations. Some of these service special tools should be used when and

as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk of

personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is impo rtant to understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Funai

could not possibly know, evaluate and advice the service trade of all conceivable ways in which service might be done or of the possible hazardous

consequences of each way. Consequently, Funai has not undertaken any

such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not recommended by Funai must first use all precautions thoroughly so that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

Page 3

MAIN SECTION

PLASMA DISPLAY

F42PDME

Main Section

I Specifications

I Adjustment Procedures

I Troubleshooting

I Schematic Diagrams

I CBA’s

I Exploded Views

I Parts List

TABLE OF CONTENTS

Specifications............................................................................................... 1-1-1

Important Safety Precautions....................................................................... 1-2-1

Standard Notes for Servicing....................................................................... 1-3-1

Basic Setup and Operating Guide............................................................... 1-4-1

Cabinet Disassembly Instructions................................................................ 1-5-1

Electrical Adjustment Instructions................................................................ 1-6-1

Troubleshooting........................................................................................... 1-7-1

Block Diagrams............................................................................................ 1-8-1

Schematic Diagrams / CBA’s and Test Points............................................. 1-9-1

Waveforms................................................................................................. 1-10-1

Wiring Diagram....................................... ................................. .................. 1-11-1

IC Pin Functions......................................................................................... 1-12-1

Lead Identifications.................................................................................... 1-13-1

Cabinet Exploded Views............................................................................ 1-14-1

Packing Exploded Views............................................................................ 1-14-3

Mechanical Parts List................................................................................. 1-15-1

Electrical Parts List .................................................................................... 1-16-1

Page 4

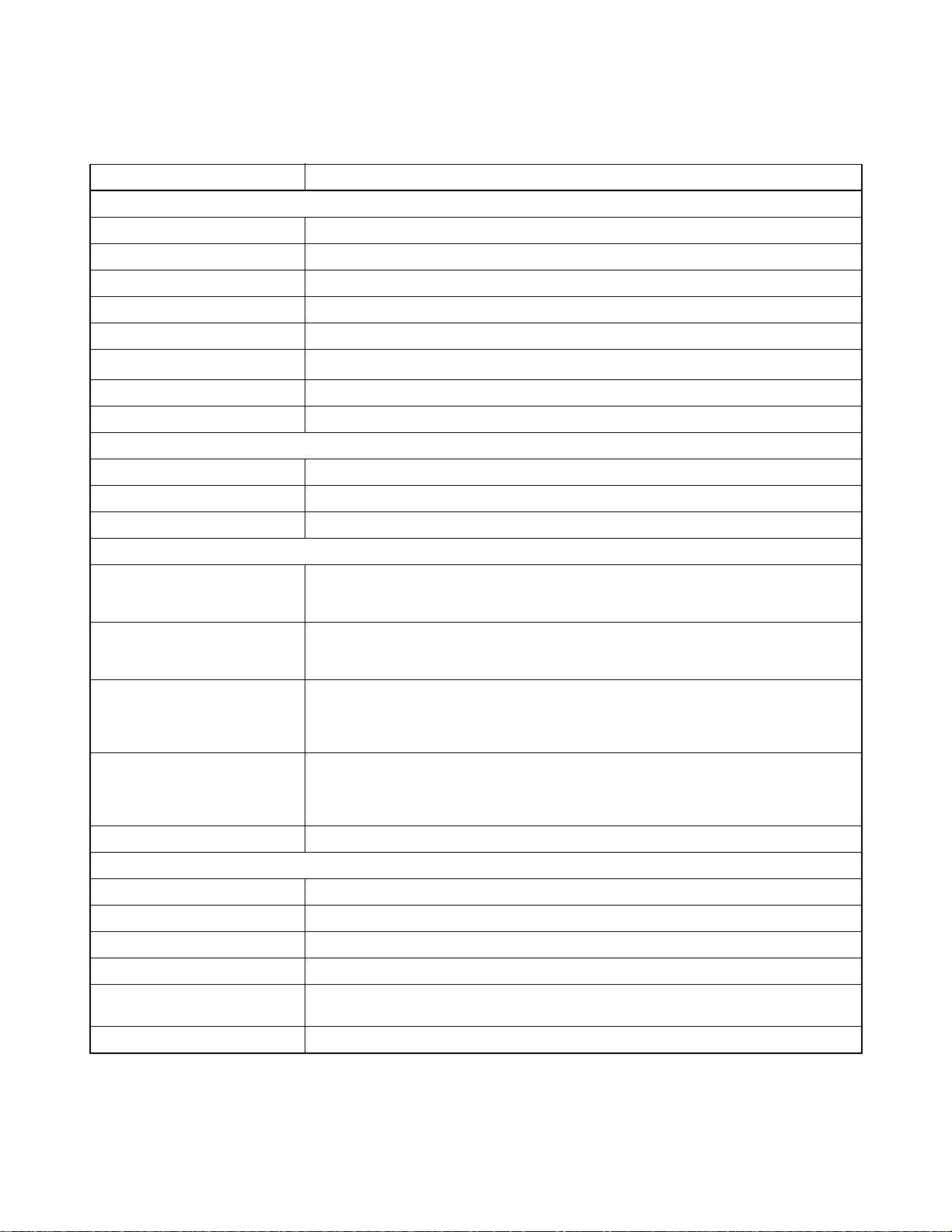

SPECIFICATIONS

Description Condition

Display Features

Screen Size 920.1 (W) x 518.4 (H) mm, 42 in. Wide VGA panel

Pixel Resolution 852 (H) x 480 (V)

Output Colors 16.7 million

Screen Aspect Ratio 16:9

Contrast Ratio 1000:1

Brightness

Comb Filter Type 3-Dimensional Y/C Separation

Available Input Format 720p/1080i/480p/480i (720p/1080i/480p: Component 2 only)

Sound Output 5W + 5W, 10% THD

Speaker 3 in Round Type x 4

Audio IN 0.5Vrms

470 cd/m

2

(PEAK)

Audio Features

Connectors

Component AV Input (1) SD component video/Y, Cb, Cr, (RCA x 3) - rear

Component AV Input (2) HD component video/Y, Pb, Pr, (RCA x 3) - rear

Composite AV Input (1)

S-Video (1)

Composite AV Input (2)

S-Video (2)

Analog Audio output audio L/R (RCA x 2) - rear

Power In 120V ±10%, 60Hz/AC

Power Consumption 350 W (standby-condition 1.3W)

Operation Temperature 41F - 104F (5°C - 40°C)

Humidity Under 80%

Dimension 1314 (W) x 692 (H) x 149.5 (D) mm

audio L/R (RCA x 2) - rear

Y: 1.0Vp-p (75 Ohm), Cb/Cr: 0.7Vp-p (75 Ohm)

audio L/R (RCA x 2) - rear

Y: 1.0Vp-p (75 Ohm), Pb/Pr: 0.7Vp-p (75 Ohm)

Composite video (RCA x 1) - rear, 1.0Vp-p (75 Ohm)

S-Video (4 pin DIN) - rear

audio L/R (RCA x 2) - rear

Y: 1.0Vp-p (75 Ohm), C: 0.286Vp-p (75 Ohm)

Composite video (RCA x 1) - rear, 1.0Vp-p (75 Ohm)

S-Video (4 pin DIN) - rear

audio L/R (RCA x 2) - rear

Y: 1.0Vp-p (75 Ohm), C: 0.286Vp-p (75 Ohm)

General

1314 (W) x 789 (H) x 393 (D) mm (Incl. Stand)

Weight 112.46 lbs (51 kg)

Note:

Nominal specificati ons represen t the design specificatio ns. All units sh ould be able to approximat e these. Som e

will exceed and so me may drop slightly below thes e specifications. Limit specific ations represent the absolut e

worst condition that still might be considered acceptable. In no case should a unit fail to meet limit specifications.

1-1-1 L0605SP

Page 5

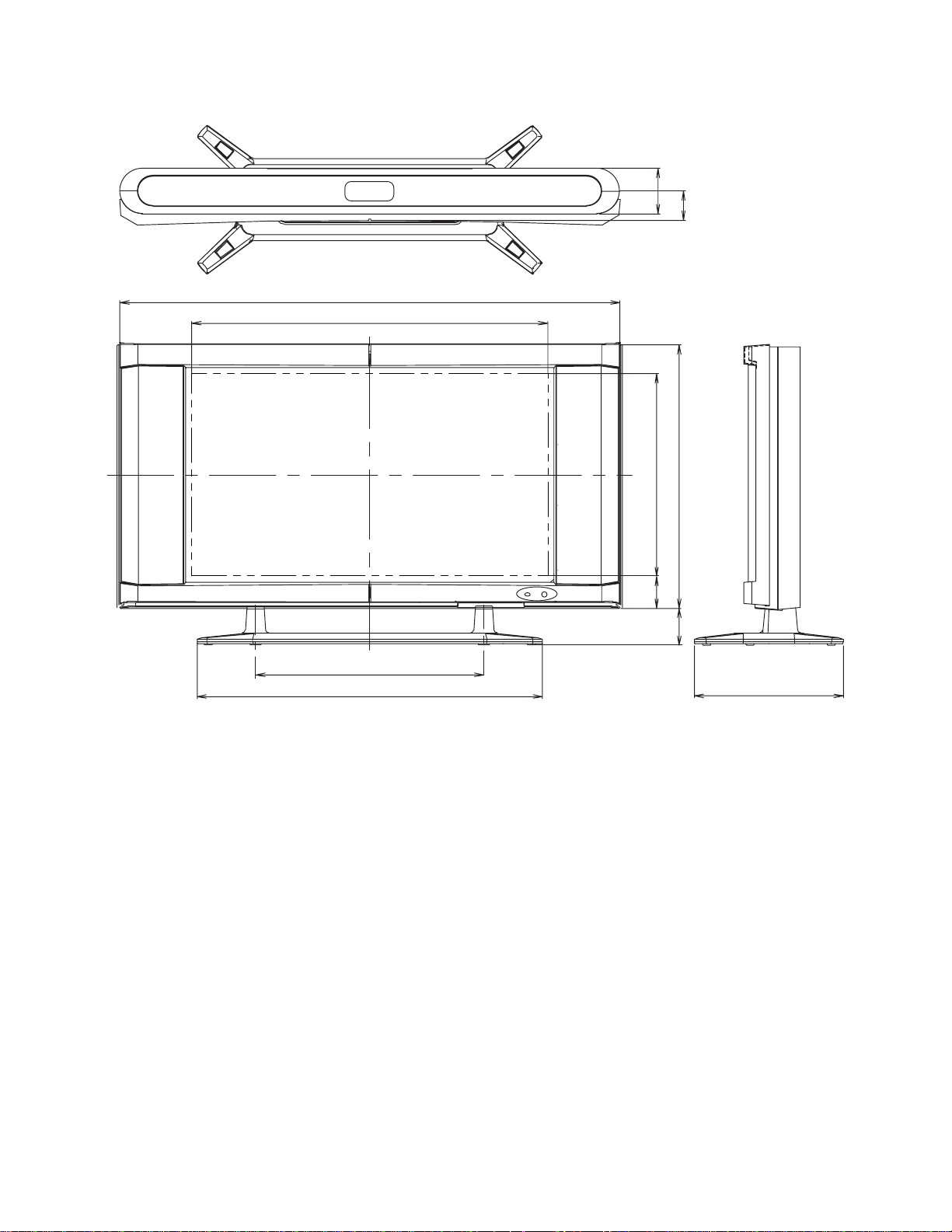

DIMENSIONS

1314

920.1

120

518.483.6

77

692

600

907.47

97

393

1-1-2 L0605SP

Page 6

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the fact ory, our products are stri ctly insp ected for recogni zed pr oduct sa fety and elec trical

codes of the countries in which they are to be sold. Howev er, in order to ma intain such c ompliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions fo r M onitor C ircuit

1. Before returning an instrum ent t o the c ustom -

er, always make a safety check of the entire instru-

ment, including, but not limited to, the following

items:

a. Be sure that no built-in protec tive devic es are de -

fective and have b een defeated during servicing.

(1) Protective shields are provided on this chassis

to protect both the technician an d the customer.

Correctly replace all missing protective shields, including any removed for servicing convenience. (2)

When reinstalling the chassis and/or other assembly in the cabinet, be su re to put back in p lace all

protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpapers,

adjustment and compartment cove rs/shields, and

isolation resistor/capacitor networks. Do not oper-

ate this instrument or permit it to be operated

without all protective devices correctly installed and functioning. Servicers who defeat

safety features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to, (1) excessively wide cabinet ventilation slots, and (2) an improperly fitted and/or incorrectly secured cabinet

back cover.

c. Leakage Current Cold Check - With the instru-

ment AC plug removed from any AC s ource, con nect an electrical jumper across the two AC plug

prongs. Place the in strument AC swi tch in the on

position. Connect one lead of an oh mmeter to the

AC plug prongs tied together and touch the other

ohmmeter lead in tu rn to each exposed metallic

cabinet part. If the measured resistance is less

than 1.0 megohm or greater than 5.2 megohm, an

abnormality exists that must be corrected before

the instrument is returned to the customer. Repeat

this test with the instrument AC switch in the off position.

d. Leakage Current Hot Check - With the instru-

ment completely reassembled, plug the AC line

cord directly into a 120V AC outlet. (Do not use an

isolation transformer d uring thi s test.) Use a leakage current tester or a metering system that complies with American National Standards Institute

(ANSI) C101.1 Leakage Current for Appliances.

With the instrument AC switc h first in the on posi tion and then in the o ff position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle br ackets, metal cabi net, screw

heads, metallic overlay s, control shafts, etc.), es pecially any exposed metal parts that offer an electrical return path to the chassis. Any current

measured must not exceed 0.75 milli-ampere. Reverse the instrument power cord plug in the outlet

and repeat the test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO

THE CUSTOMER OR BEFORE CONNECTING

THE ANTENNA OR AC CES SORI ES.

2. Read and comply with all caution and safety-related notes on or insid e the cabi net, or on the chassis,

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of th is mon itor. Design alterations and additions, including,

but not limited to circuit mod ifications and the addition of items such as auxiliary audio and/or video

output connections, might a lter the sa fety charac teristics of this receiver and create a hazard to the

user. Any design alterations or additions will void

the manufacturer's warrant y and may make you,

the servicer, responsible for personal injury or

property damage resulting therefrom.

4. Hot Chassis Warning -

a. Some monitor chassi s are electrically connected

directly to one conductor of the AC power cord and

maybe safety-servi ced without an isolati on transformer only if the AC power plug is inserted so that

the chassis is con nec ted to the ground side of the

AC power source . To confirm that the A C power

plug is inserted correctly, with an AC voltmeter,

measure between the chas sis and a known ear th

ground. If a voltage read ing in excess of 1.0V is

obtained, remove and reinsert t he AC power plug

in the opposite polarity and again measure the

voltage potential between the chassis and a

known earth ground.

1-2-1 L0604IMP

Page 7

b. Some monitor chassis normally have 85V

AC(RMS) between chassi s and earth ground regardless of the AC p lug pol arity. This chass is can

be safety-serviced only with an isolation transformer inserted in the p ower lin e betwee n the r ecei ver

and the AC power so urce, for both p erso nnel a nd

test equipment protection.

c. Some monitor chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not isolated from

the AC power line. The two ground systems are

electrically separated by insulation material that

must not be defeated or altered.

5. Observe orig inal lead dre ss. Take extra ca re to assure correct lead dress in the following areas:a.

near sharp edges,b. near thermally hot parts-be

sure that leads and components do not touch thermally hot parts,c. th e AC supply,d. high voltage,

and,e. antenna wiring. Always inspect in all ar eas

for pinched, out of plac e, or frayed wiring. Ch eck

AC power cord for damage.

6. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or wiring that meet origina l specifications. Additionally,

determine the cause of ov erheating and/or damage and, if necessary, take corrective action to remove any potential safety hazard.

7 Product Safety Notice - Some electrical and me-

chanical parts have sp ecial safety -relate d char acteristics which are often not evident from visual

inspection, nor can the protection they give necessarily be obtain ed by replac ing them wi th components rated for higher voltage, wattage, etc.. Parts

that have special safet y characte ristic s are ide ntified by a ( # ) on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety charac teristics as the recommend ed

replacement part might crea te shock, fire, and/or

other hazards. The product's safety is under review continuously and new instructions are issued

whenever appropriate . Prior to shipme nt from the

factory, our produc ts are strict ly ins pected to con firm they comply with the recognized product safety and electrical code s of the countries in which

they are to be sold. However , in order to maintai n

such compliance, it is equally important to implement the following precautions when a set is being

serviced.

General Caution of Plasma Display

1. Since the Panel module and front filter are made of

glass, sufficient care shall be taken when handling

the broken module and filter in order to avoid injury.

2. If necessary to replace Panel module, this work

must be started after the panel module and the

AC/DC Power supply becomes sufficiently cool.

3. Special care must be taken with the display area to

avoid damaging its surface.

4. The Panel Module sha ll not be touched wit h bare

hands to protect its surface from stains.

5. It is recommended to use clean soft gloves during

the replacing work of the Panel module in order to

protect, not only the display area of the panel module but also the serviceman.

6. The Chip Tube of the panel module (located upper

left of the back of the panel modu le) and flexible

cables connecting Pane l glasses to the drive circuitry Printed Wiring Boards (P.W.B.) are very

weak, so sufficient c are must be taken t o prevent

breaking or cutting any of these. I f the Chip Tube

breaks the panel mo dul e wi ll ne ve r w ork, re pla ce ment for a new plasma panel module will be needed.

7. Signal, power supply P.W.B.’s and PDP driving circuits P.W.B.’s are assembled o n the rear side of

the PDP module, take special care with this fragile

circuitry; particularly, Flexible Printed Circuits

bonded to surrounding edges of the glass panel.

They are not strong enough to withstand harsh

outer mechanical forces. Avoid tou ching th e flexible printed circuits by not only your hands, but also

tools, chassis, or any oth er obj ec t. E xtre me bend ing of the connectors must be avoided too. In case

the flexible printed c ircuits are damage d, the corresponding addres sed portions of the screen will

not be lit and exchange of a glass panel will be required.

1-2-2 L0604IMP

Page 8

PDP Module Handling

Precautions during Servicing

When there is need to rep lace a brok en PDP m odule

which is the displaying device from the Plasma display

unit, consider the following:

1. When carrying the PDP module, two persons

should stand at both shorter-edge sides of the

glass-panel and transport it with their palms. Avoid

touching the Flexible Prin ted Circuits or the chip

tube on the corner of the glass-panel. Handle only

by the surface of the glass panel.

2. When carrying PDP module, watch surrounding

objects, such as tables, and also do not carry it

alone since it may be dangerous and it will be damaged due to excessive stress to the module (glasspanel).

3. Please do not stand the m odule with the edge of

the glass-panel on the table since this might result

in damage to the glass-pa nel and /or flex ible printed circuits due to exces sive stress to the modul e

(glass-panel).

A. Parts identified by th e ( # ) symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations applying to spurious radiati on. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especiall y:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before solder ing.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. Also check areas surrounding repaired locations.

I. Use care that foreign objects (screws, solder drop-

lets, etc.) do not remain inside the set.

J. When connecting or disconnecting the internal

connectors, first, discon nect the AC plug from the

AC supply outlet.

1-2-3 L0604IMP

Page 9

Safety Check after Servicing

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts and wires have been returned to original positions. Afterwards, perform th e fol lo wing tes ts and c on firm the specified values in orde r to verify comp liance

with safety standards.

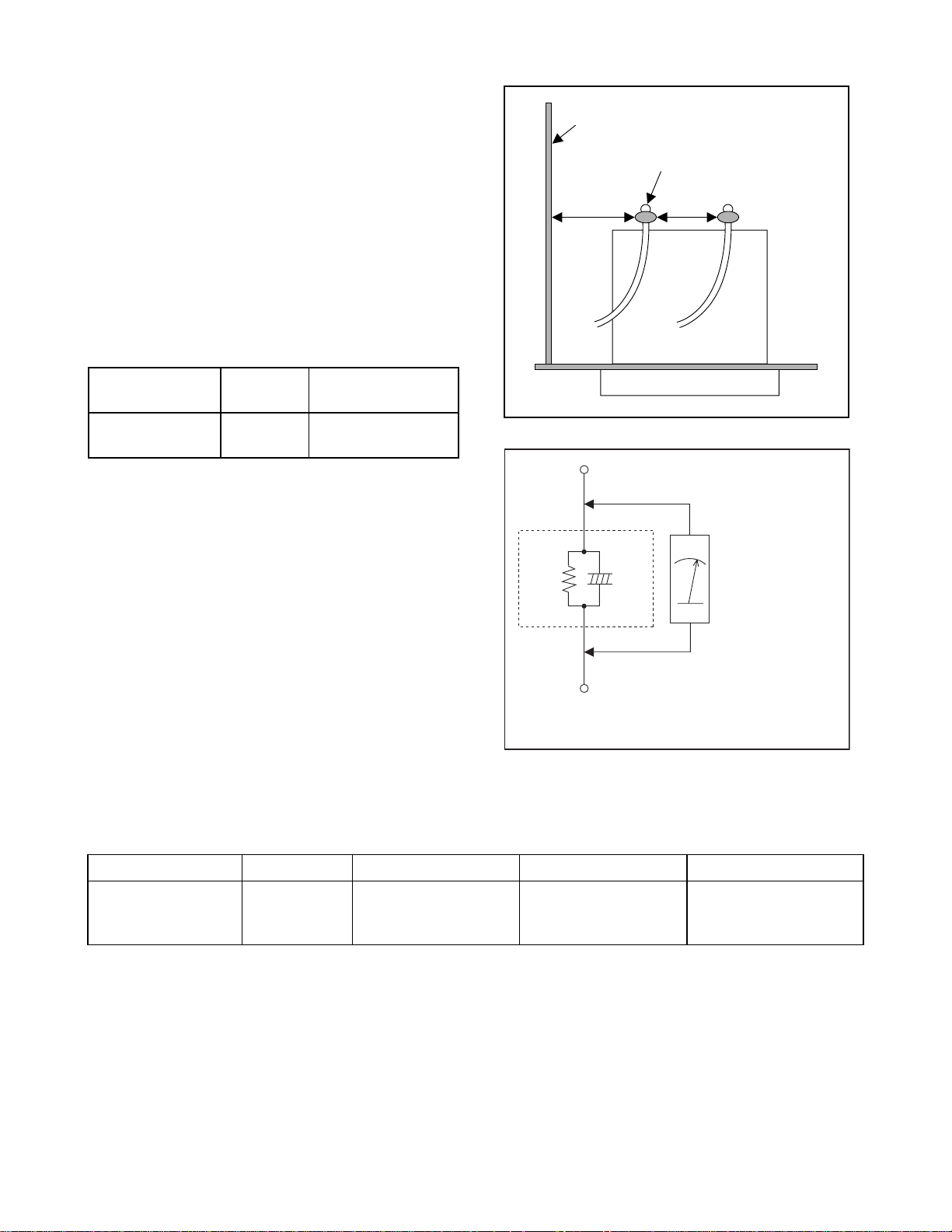

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance d istance (d) a nd (d') betwee n soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

T able 1 : Ratings for selected area

AC Line Voltage Region

110 to 130 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

USA or

CANADA

Clearance

Distance (d) (d')

≥ 3.2 mm

(0.126 inches)

2. Leakage Current Test

Confirm the specified (or lower) leakage current between B (any two parts or contacts, between any part

or contact and either pole of the power cord plug

prongs) and ext ernally exposed access ible parts (RF

terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone

jacks, etc.) is lower than or equal to the spec ified value in the table below.

Measuring Method: (Power ON)

Insert load Z between B (any two parts or contacts,

between any part or contact and either pole of the

power cord plug prongs) and exposed accessible

parts. Use an AC voltmeter to measure across both

terminals of load Z. See Fig. 2 and following table.

Z

1.5kΩ

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

Exposed Accessible Metal Part

AC Voltmeter

0.15µF

One of Power Cord

B

Plug Prongs

(High Impedance)

Fig. 1

Fig. 2

Table 2: Leakage current ratings for selected areas

AC Line Voltage Region Load Z Leakage Current (i) Earth Ground (B) to:

0.15µF CAP. & 1.5kΩ

110 to 130 V USA

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

RES. connected in

parallel

1-2-4 L0604IMP

i≤0.75mA peaks

Exposed accessible

parts

Page 10

STANDARD NOTES FOR SERVICING

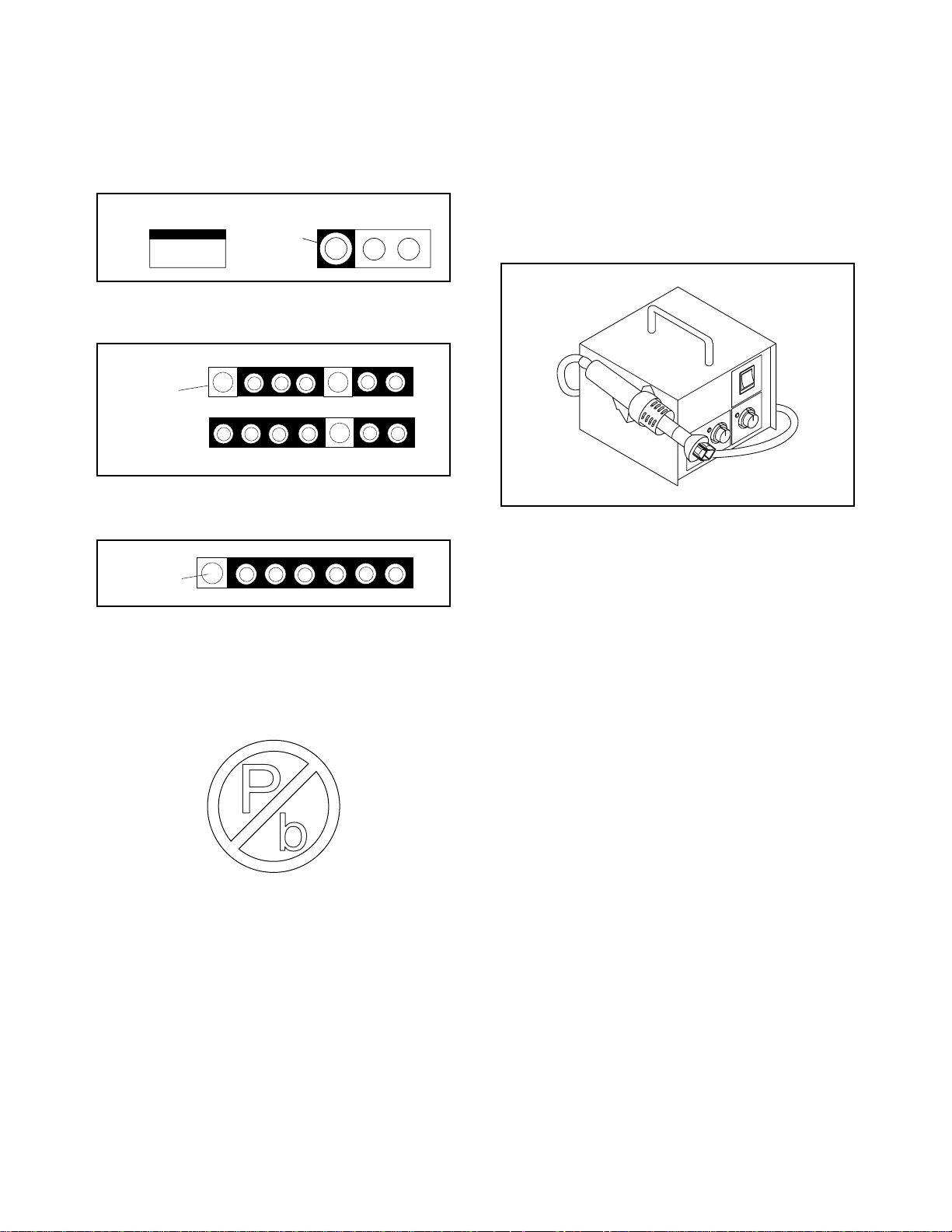

Circuit Board Indications

a. The output pin of the 3 pin Regulator ICs is indicat-

ed as shown.

Top Vie w

Out

b. For other ICs, pin 1 a nd ever y fifth pin are in dic at -

ed as shown.

Pin 1

c. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

Pb free mark will be found on PCBs which use Pb

free solder. (Refer to figure.) For PCBs with Pb

free mark, be sure to use Pb free solder. For PCBs

without Pb free mark, use standard solder.

Pb free mark

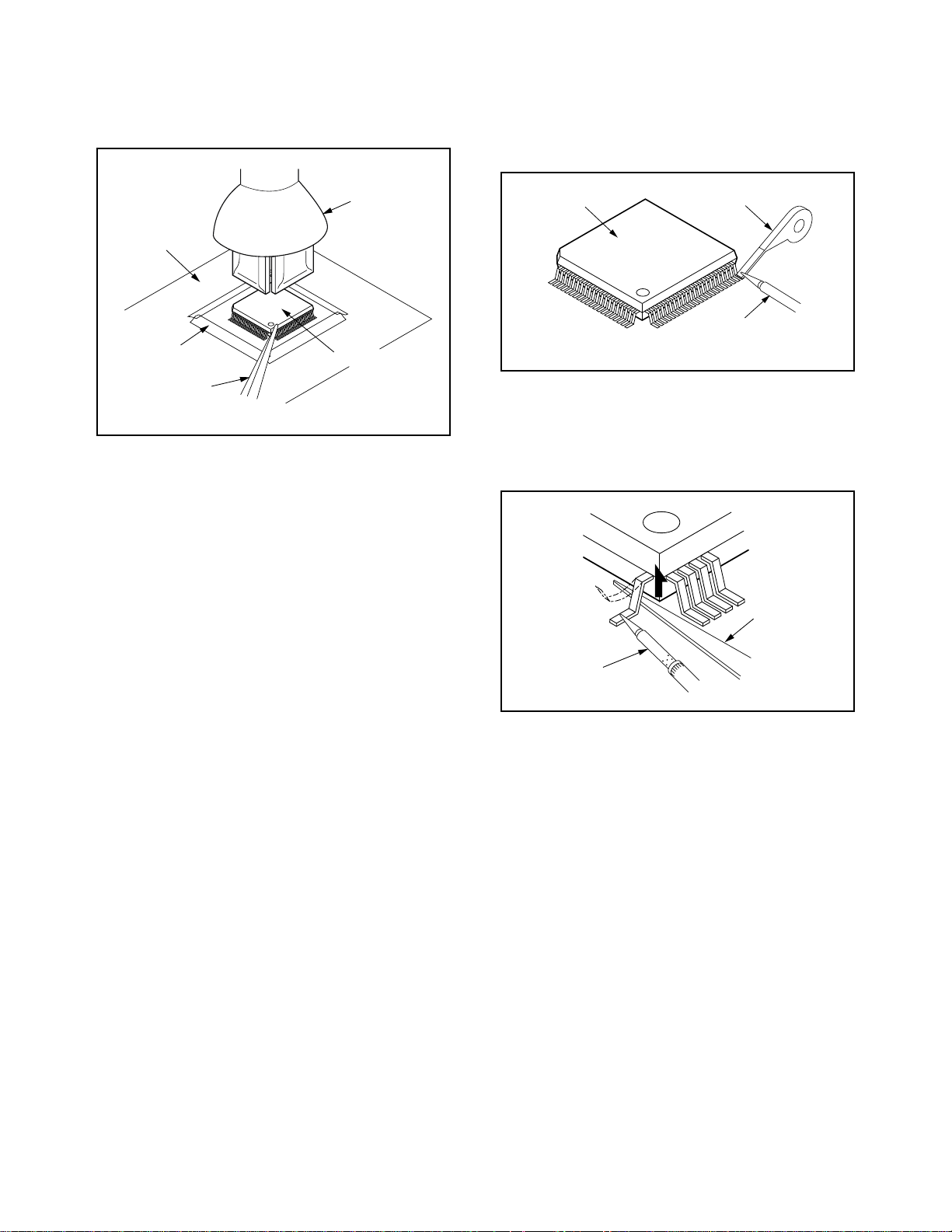

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

(1) Prepare the hot-air flat pack-IC desoldering ma-

chine, then apply hot air to the Flat Pack-IC (about

5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

(2) Rem ove the flat pack-IC with tweezers while ap-

plying the hot air.

(3) B ottom of the flat pack-I C is fixed wi th glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Caution:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering ma-

chine, whose shape matches that of the Flat Pack-

IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protec t other par ts from

damage. (F ig. S-1-2)

1-3-1 L14STA2

Page 11

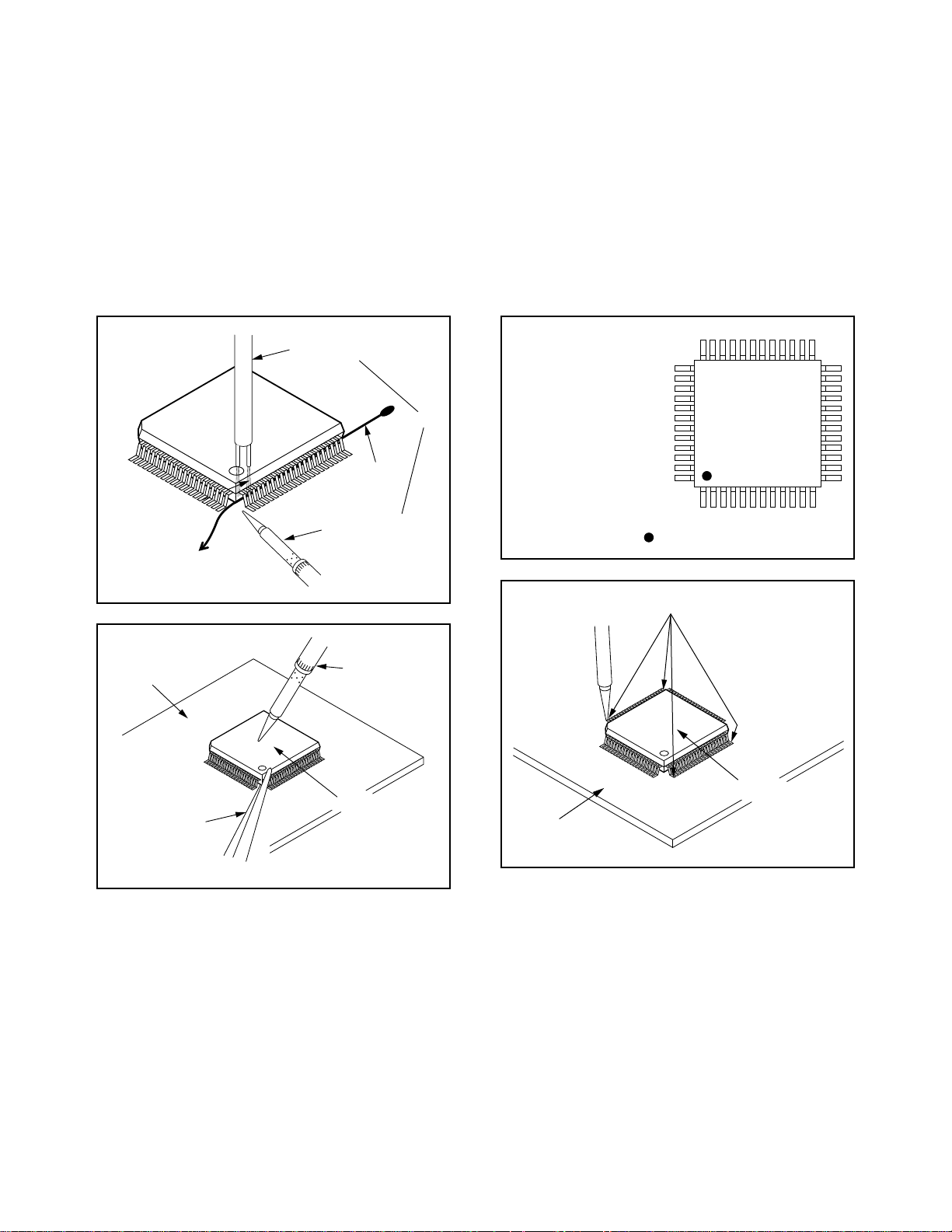

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to bre ak or d ama ge the f oil of each

pin or the solder l ands under the IC when remov ing it.

With Soldering Iron:

(1) Us ing desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applie d to al l pins o f th e flat pac k-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

(2) Li ft each lead of the flat pack-IC upward one by

one, using a sharp pin or wi re to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering machine.(Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

(3) B ottom of the flat pack-I C is fixed wi th glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

With Iron Wire:

(1) Us ing desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applie d to al l pins o f th e flat pac k-IC,

you can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads fr om the CBA contact pads as shown in Fig. S-1-5.

Fig. S-1-4

1-3-2 L14STA2

Page 12

(4) Bottom of the flat pack -IC is fixe d with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Note:

When using a soldering iron, care must be taken to

ensure that the flat pack-IC is not being held by

glue. When the flat pack-IC i s removed from the

CBA, handle it gently because it may be damaged

if force is applied.

2. Installation

(1) Us ing desoldering braid, remove the solder from

the foil of each pin of the fla t pack-IC o n the CBA

so you can install a replacement flat pack-IC more

easily.

(2) T he "I" mark on the flat pac k-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

pre- solder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

(3) Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

To Solid

Mounting Point

CBA

Tweezers

Hot Air Blower

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Presolder

CBA

Fig. S-1-7

Flat Pack-IC

Fig. S-1-6

Fig. S-1-8

1-3-3 L14STA2

Page 13

Instructions for Handling

Semiconductors

Electrostatic breakdown of the semiconductors may

occur due to a poten tial differen ce caused b y electrostatic charge during unpacking or repair work.

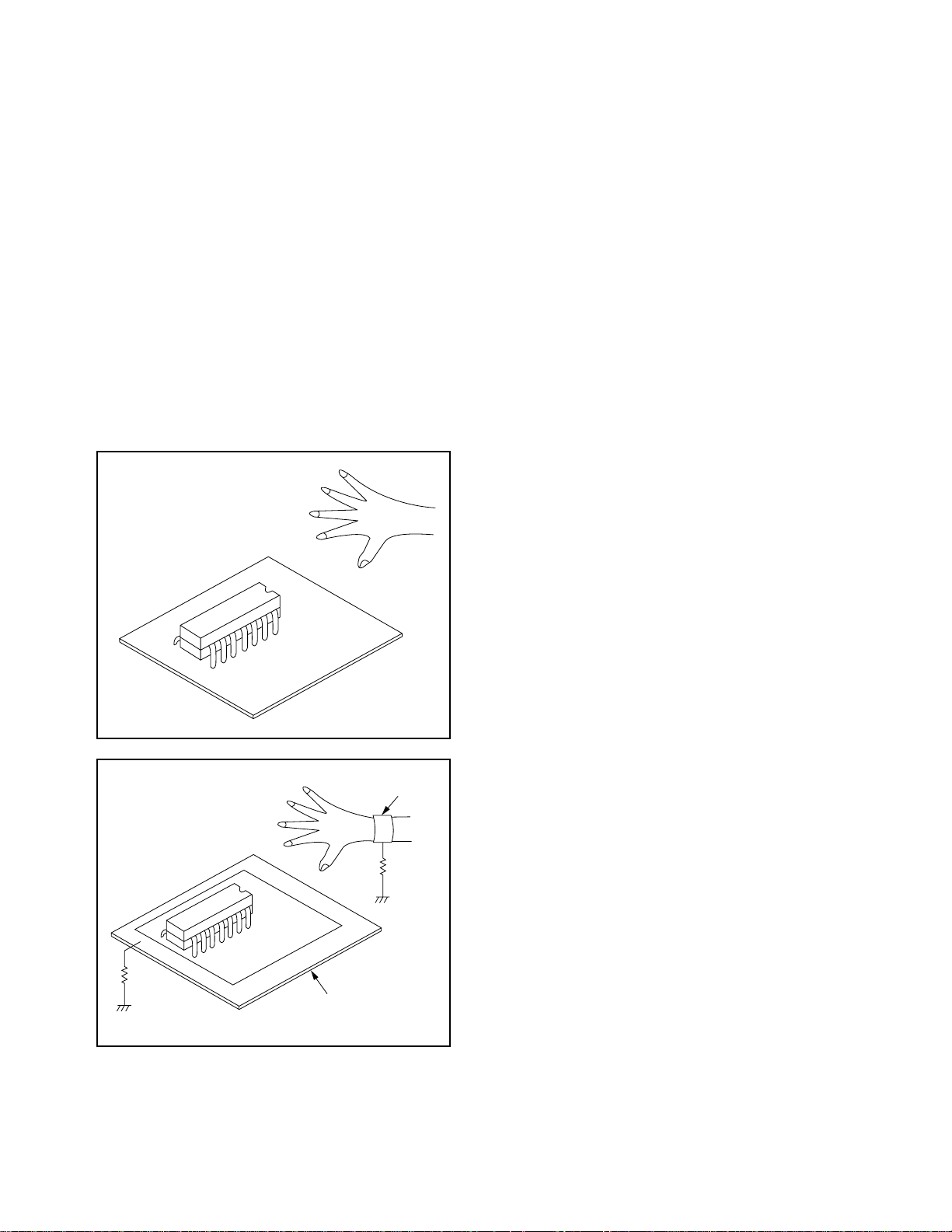

1. Ground for Human Body

Be sure to wear a grounding band (1M Ω) that is prop erly grounded to remove any static electricity that may

be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the workbench or

other surface, where the semiconductors are to be

placed. Becaus e the static elec tricity cha rge on cloth ing will not esc ape throug h the body grounding ban d,

be careful to avoid contacting semiconductors with

your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-3-4 L14STA2

Page 14

1

2

3

4

5

6

7

r

r

-

M

3

3

S-VIDEO

VIDEO

L

R

S-VIDEOVIDEO

LR

L

R

VIDEO1

S-VIDEO1

VIDEO2

S-VIDEO2

AUDIO

AUDIO OUT

AC IN

AUDIO

Pr

L

Y

Pb

R

Cr

L

Y

Cb

R

COMPONENT1

COMPONENT2

Input Terminals

6 7 8 9

INPUT SELECTVOLUME

POWER

AC IN

S-VIDEO

VIDEO

L

R

L

R

AUDIO

AUDIO OUT

AUDIO

Pr

L

Y

Pb

R

Cr

L

Y

Cb

R

COMPONENT1

COMPONENT2

VIDEO1

S-VIDEO1

VIDEO2

S-VIDEO2

S-VIDEOVIDEO

LR

2

1

4

Infrared Sensor

5

INPUT SELECTVOLUME

POWER

INPUT SELECTVOLUME

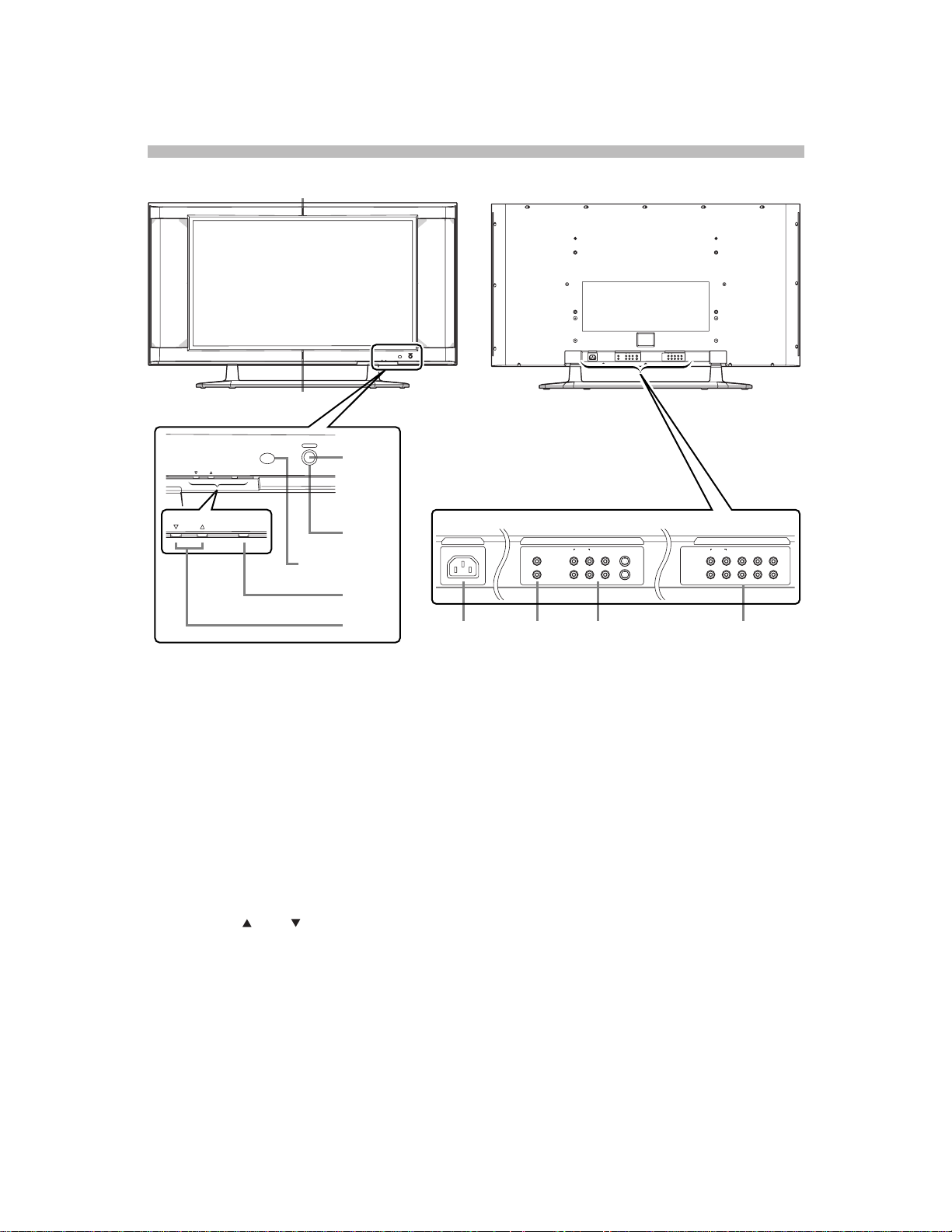

BASIC SETUP AND OPERATING GUIDE

AIN UNIT

Front Rear

POWER button: Turns the power ON or in

STANDBY.

POWER indicator: Lights up (Blue) when

the power is in the standby mode. Lights up

(Green) when the power is ON.

STANDBY indicator: Lights up when the

power is in the standby mode. Disappears

when the power is ON.

8

AUDIO/VIDEO/S-VIDEO: Input terminals fo

an audio and video signal. You can select

either VIDEO or S-VIDEO.

9

COMPONENT: Input terminals for a compo

nent signal. You can make a Y-Cb-Cr interlaced connection to component 1 or Y-Pb-P

progressive or interlaced connection to com

ponent 2.

INPUT SELECT button: Selects input terminals.

VOLUME (up) / (down) button:

Increases or decreases the volume.

AC IN terminal: Connect the supplied

power cable for a standard AC outlet.

AUDIO OUT: Output terminals for audio.

1-4-1 L0605IB

Page 15

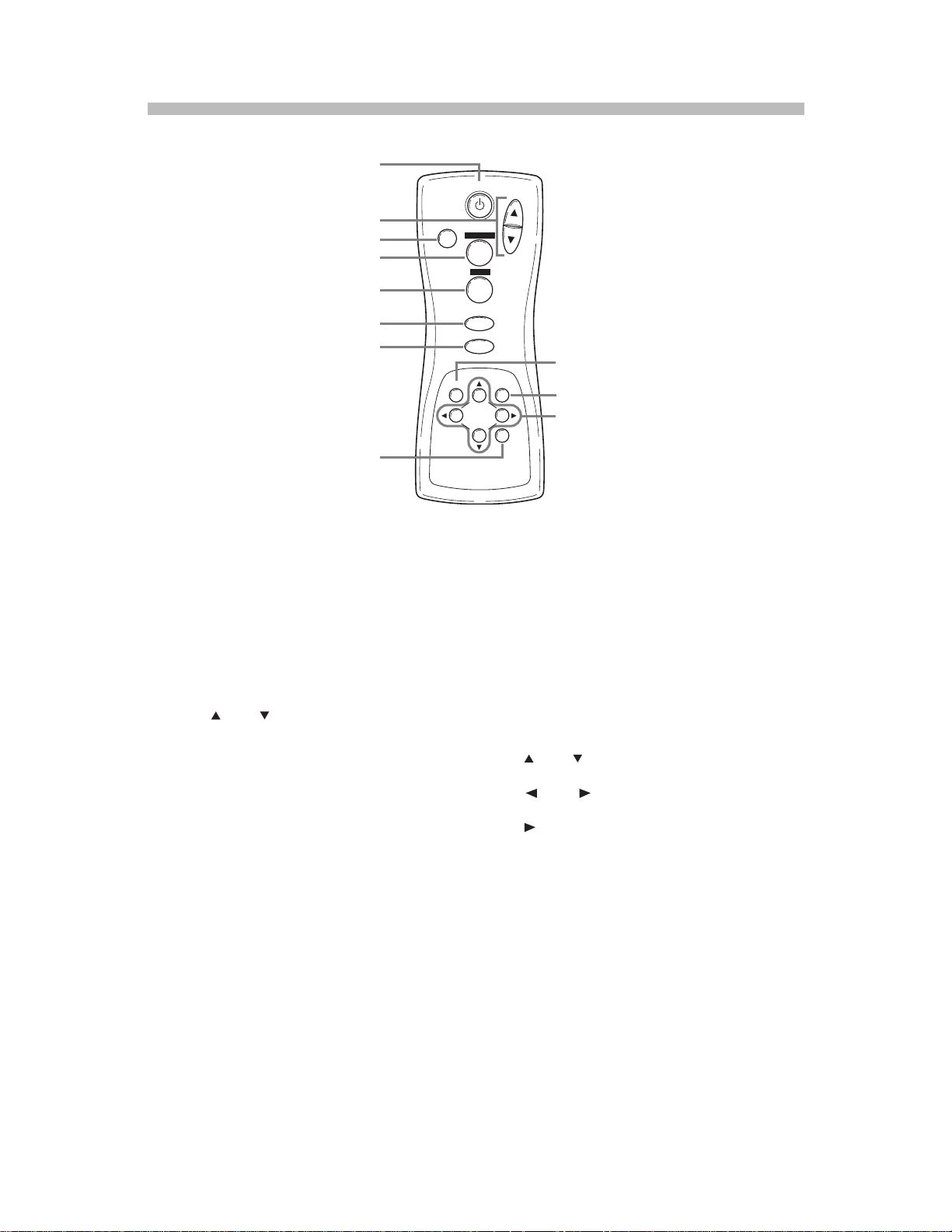

R

1

2

3

4

5

6

7

8

POWER

INPUT SELECT

DISPLAY

MENU

PREVIOUS

SLEEP

VOL

MUTE

SCREEN MODE

STILL

1

2

3

4

5

6

7

8

9

10

11

EMOTE CONTROL

POWER button: Turns the main power ON

or in STANDBY.

VOL (up) / (down) button: Increases or

decreases the volume.

MUTE button: Turns the audio off or on.

SCREEN MODE button: Selects aspect

ratios available for the screen.

STILL button: Pauses the image shown on

the screen.

INPUT SELECT button: Selects input termi-

nals.

DISPLAY button: Displays the name of the

selected input terminal on the screen.

SLEEP button: Sets the sleep timer.

9 MENU button: Accesses the setup menu,

allowing you to access various settings.

10

PREVIOUS button: Moves up one level in

the setup menu.

11

(up) / (down) button: Selects the vari-

ous modes in the setup menu.

(left) / (right) button: Selects and

adjusts levels for the various settings.

(enter) button: Also used as the enter

button.

1-4-2 L0605IB

Page 16

CABINET DISASSEMBLY INSTRUCTIONS

e

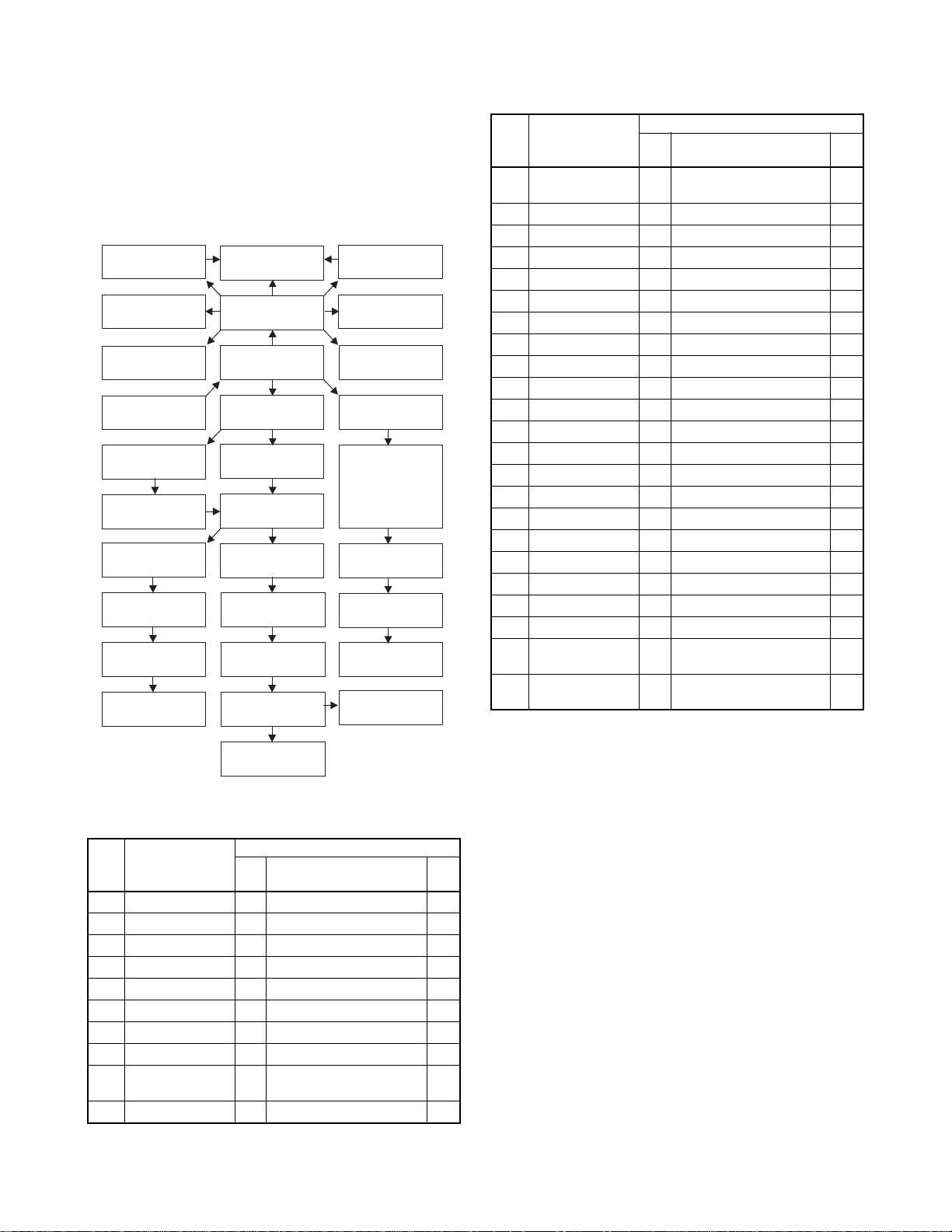

r

1. Disassembly Flowchart

This flowchart indicate s the disassem bly steps for the

cabinet parts, and the CBA in order to g ain access to

item(s) to be servic ed. Wh en rea ssemb ling, fol low th e

steps in reverse order. Bend, route and dress the

cables as they were.

[22] Filter

Holder(L)(s)

[11] LED A CBA

and LED B CBA

[13] Decoration

Panel

[1] Back Cabinet

[6] Analog CBA

[7] Filter CBA

[25] Stand Unit

[26] Stand

Cover

[27] Stand(s)

[28] Stand Base

[24] Optical

Filter

[9] Front Cabinet

Assembly

[2] Rear Cabinet

[3] PCB Shield

Plate

[5] Digital CBA

[8] PCB Holder

[21] Jack Cover

[29] Chassis

Bracket(s)

[30] Panel

Spacer(s)

[31] SP Holder

Plate(s)

[32] Plasma

Display Module

2. Disassembly Method

Step/

Loc.

No.

1 Back Cabinet 1 17(S-1), 5(S-2) 1

2 Rear Cabinet 2 22(S-3) 2

3 PCB Shield Plate 3 12(S-4), CLN8 3

4 Speaker Cover(s) 3 14(S-5) 4

5 Digital CBA 4 4(S-6), 3(S-7) 5

6 Analog CBA 4 4(S-8), 4(S-9) 6

7 Filter CBA 4 2(S-10), Two connectors 7

8 PCB Holder 4 4(S-11) 8

9

10 Brand Plate 5 2(S-13) 10

Part

Front Cabinet

Assembly

Fig. NoRemove/*unlock/release/

unplug/unclamp/desolder

5 14(S-12) 9

[23] Filter

Holder(S)(s)

[12] Switch CBA

[10] Brand Plat

[4] Speaker

Cover(s)

[14] Speaker-1

[15] Speaker-2

[16] Speaker-3

[17] Speaker-4

[18] Speaker

Spacer(s)

[19] Speaker

Holder(L)

[20] Speaker

Holder(R)

[33] Panel Holde

Assembly

Removal

Note

Step/

Loc.

No.

11

12 Switch CBA 5 3(S-14) 11

13 Decoration Panel 6 20(S-15), 2(S-16) 12

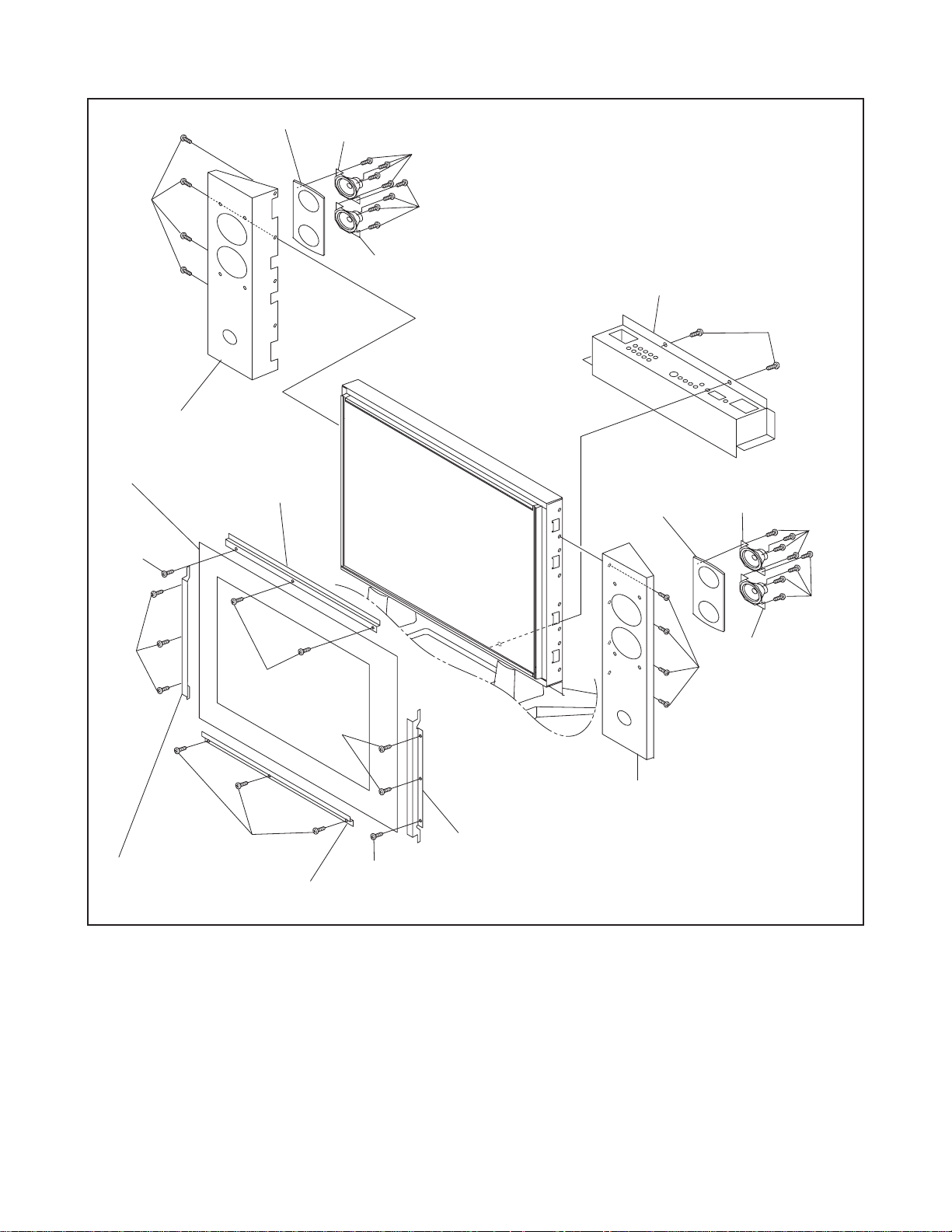

14 Speaker-1 7 2(S-17) 13

15 Speaker-2 7 2(S-18) 14

16 Speaker-3 7 2(S-19) 15

17 Speaker-4 7 2(S-20) 16

18 Speaker Spacer(s) 7 ---------- 19 Speaker Holder(L) 7 4(S-21) 17

20 Speaker Holder(R) 7 4(S-22) 18

21 Jack Cover 7 2(S-23) 19

22 Filter Holder(L)(s) 7 6(S-24) 20

23 Filter Holder(S)(s) 7 6(S-25) 21

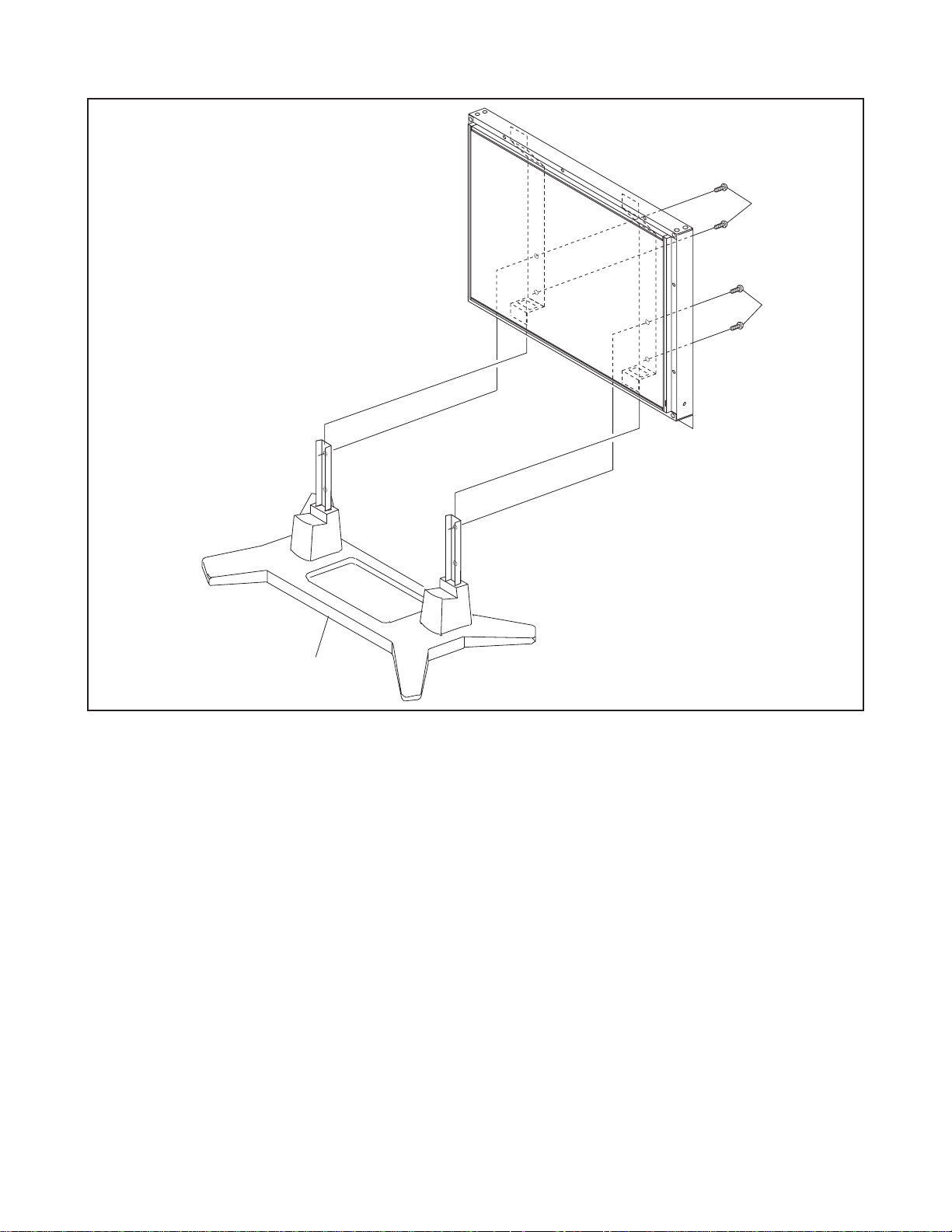

24 Optical Filter 7 ---------- 25 Stand Unit 8 4(S-26) 22

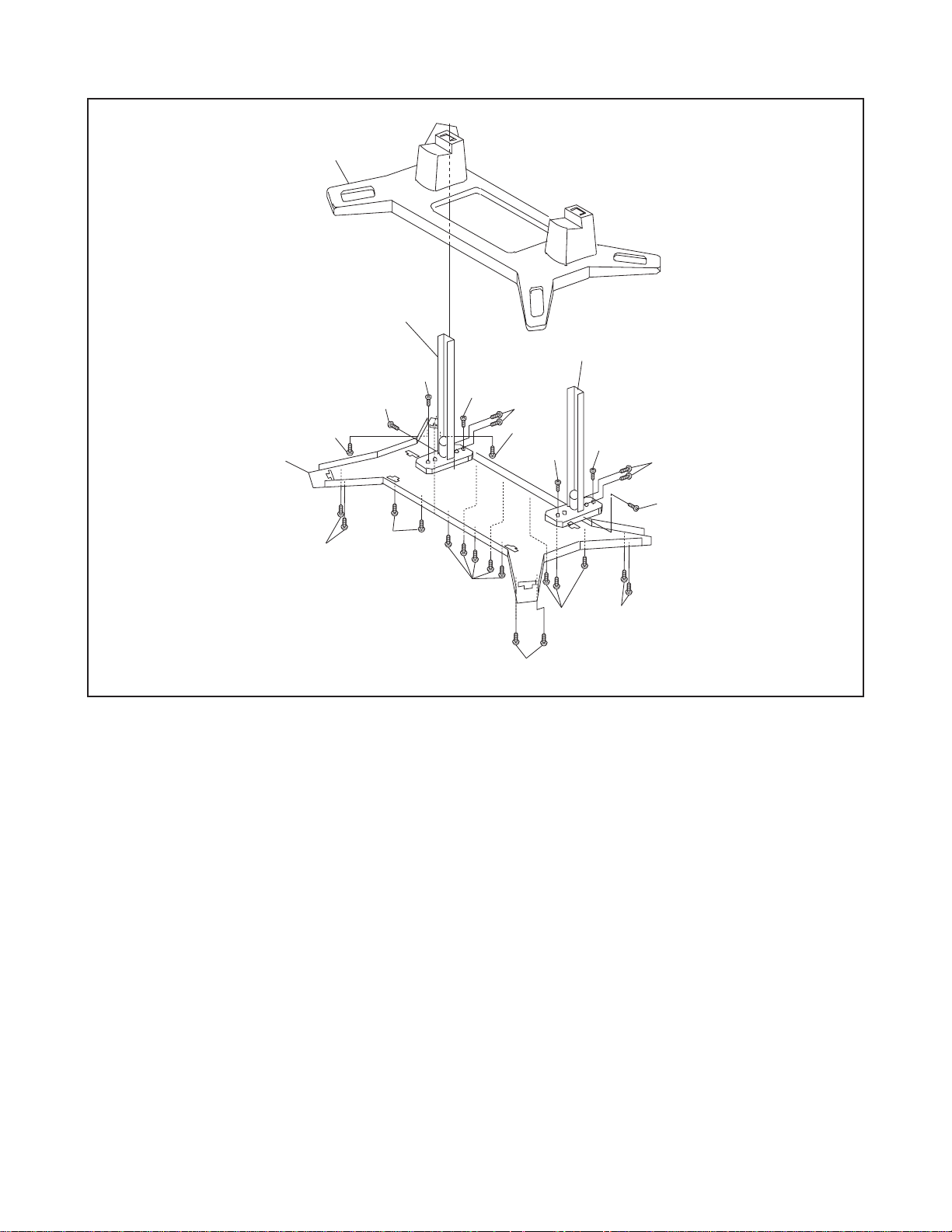

26 Stand Cover 9 8(S-27), 10(S-28) 23

27 Stand(s) 9 4(S-29), 6(S-30) 24

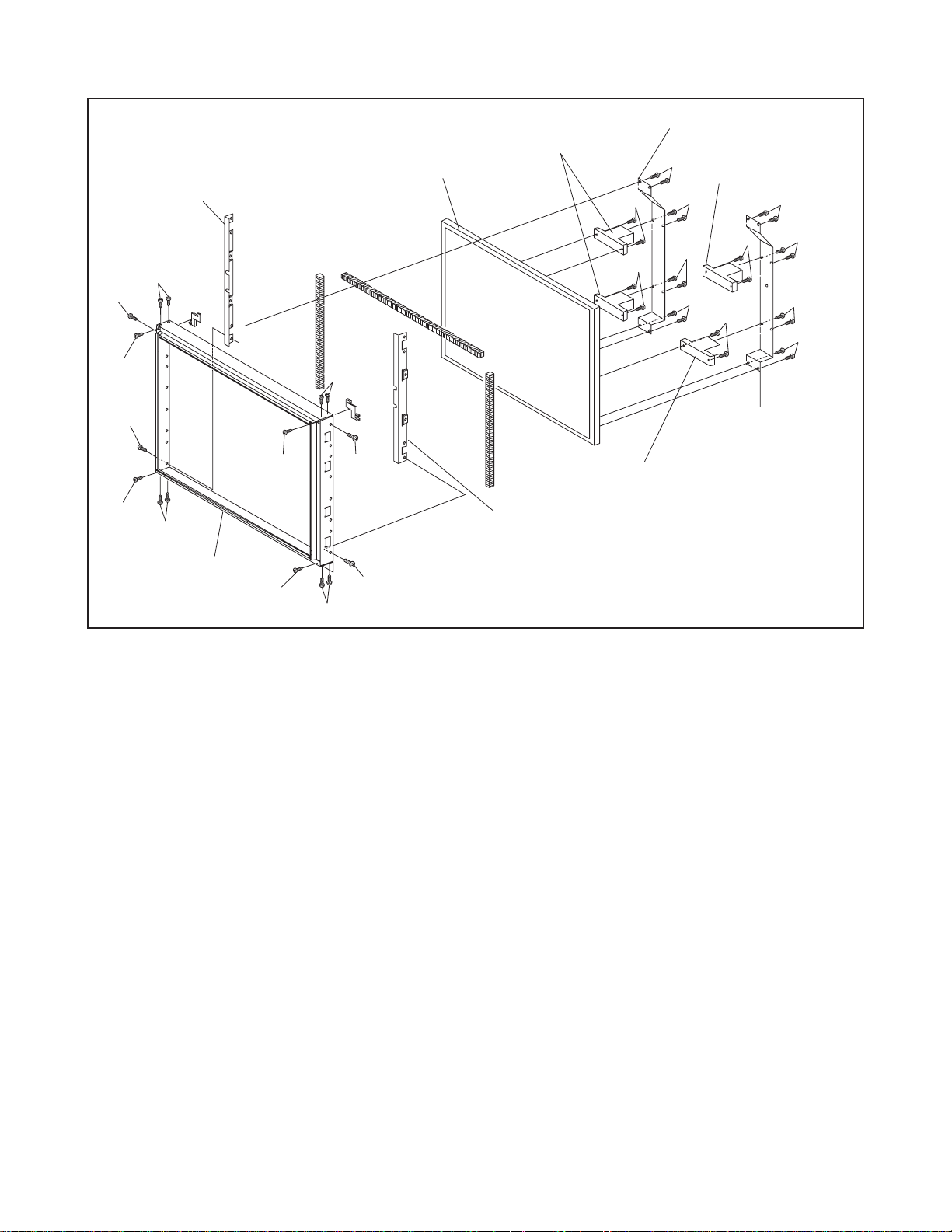

28 Stand Base 9 ---------- 29 Chassis Bracket(s) 10 8(S-31), 8(S-32) 25

30 Panel Spacer(s) 10 8(S-33) 26

31 SP Holder Plate(s) 10 4(S-34) 27

32

33

Part

LED A CBA and

LED B CBA

Plasma Display

Module

Panel Holder

Assembly

Fig. NoRemove/*unlock/release/

unplug/unclamp/desolder

5 ---------- -

10 12(S-35) 28

10 ---------- -

Removal

Note

↓↓ ↓ ↓ ↓

(1) (2) (3) (4) (5)

Note:

(1) O rder of steps i n procedu re. When reass embling,

follow the steps i n reverse or der. These n umbers

are also used as the Identification (location) No. of

parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of part to be removed, unhooked, un-

locked, released, unplugged, unclamped, o r des-

oldered.

S=Screw, P=Spring, L=Locking Tab, CN=Con-

nector, *=Unhook, Unlock, Release, Unplug, or

Desolder

2(S-2) = two Screws (S-2)

(5) Refer to the following "Reference Notes in the

Table.

1-5-1 L0605DC

Page 17

Reference Notes in the Table

Caution:

Refer to "General Caution of Plasma Display" and

"PDP Module Handling" of "IMPORTANT SAFETY

PRECAUTIONS" section not to injure and/or break the

Plasma Display Module.

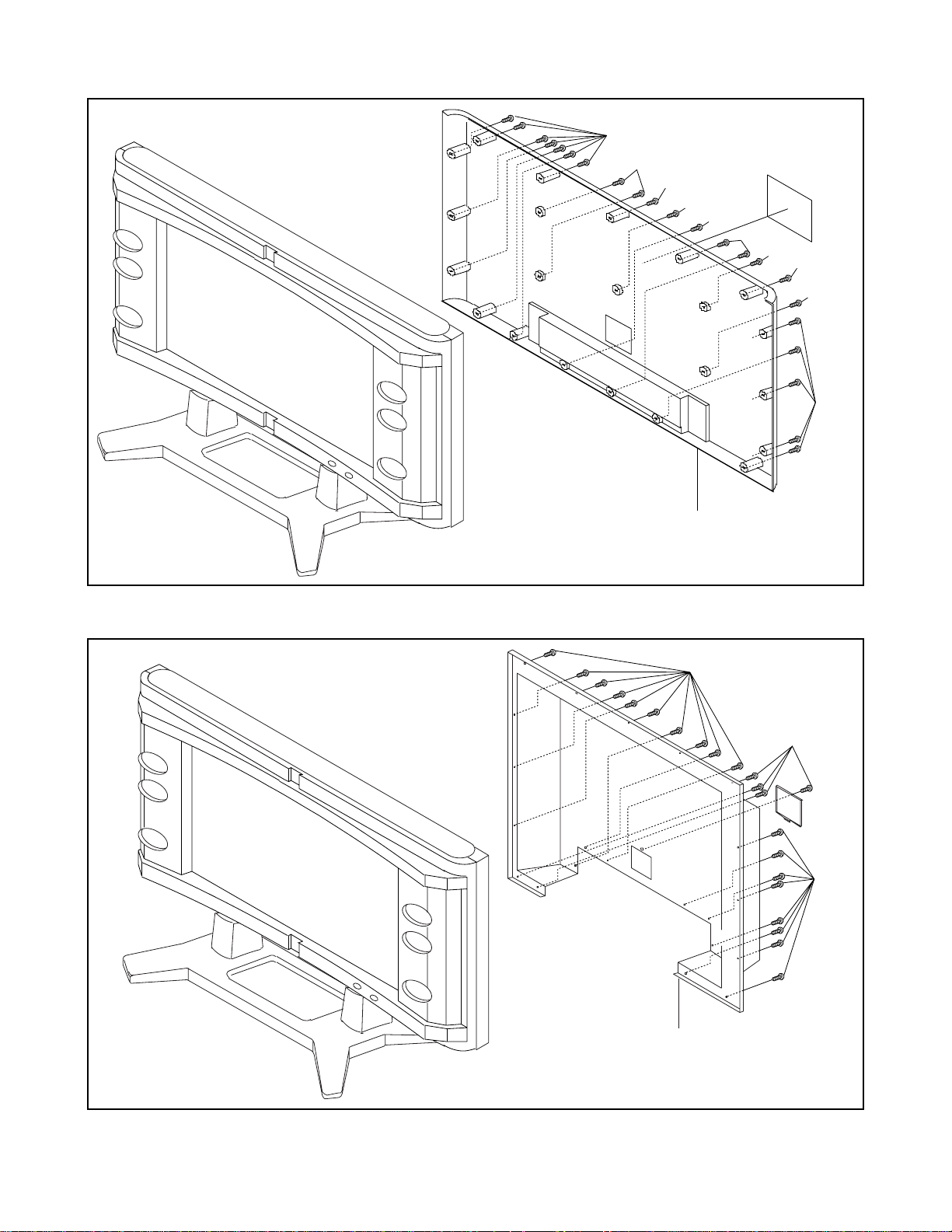

1. Removal of the Back Cabinet. Remove screws

17(S-1) and 5(S-2).

2. Removal of the Rear Cabinet. Remove screws

22(S-3).

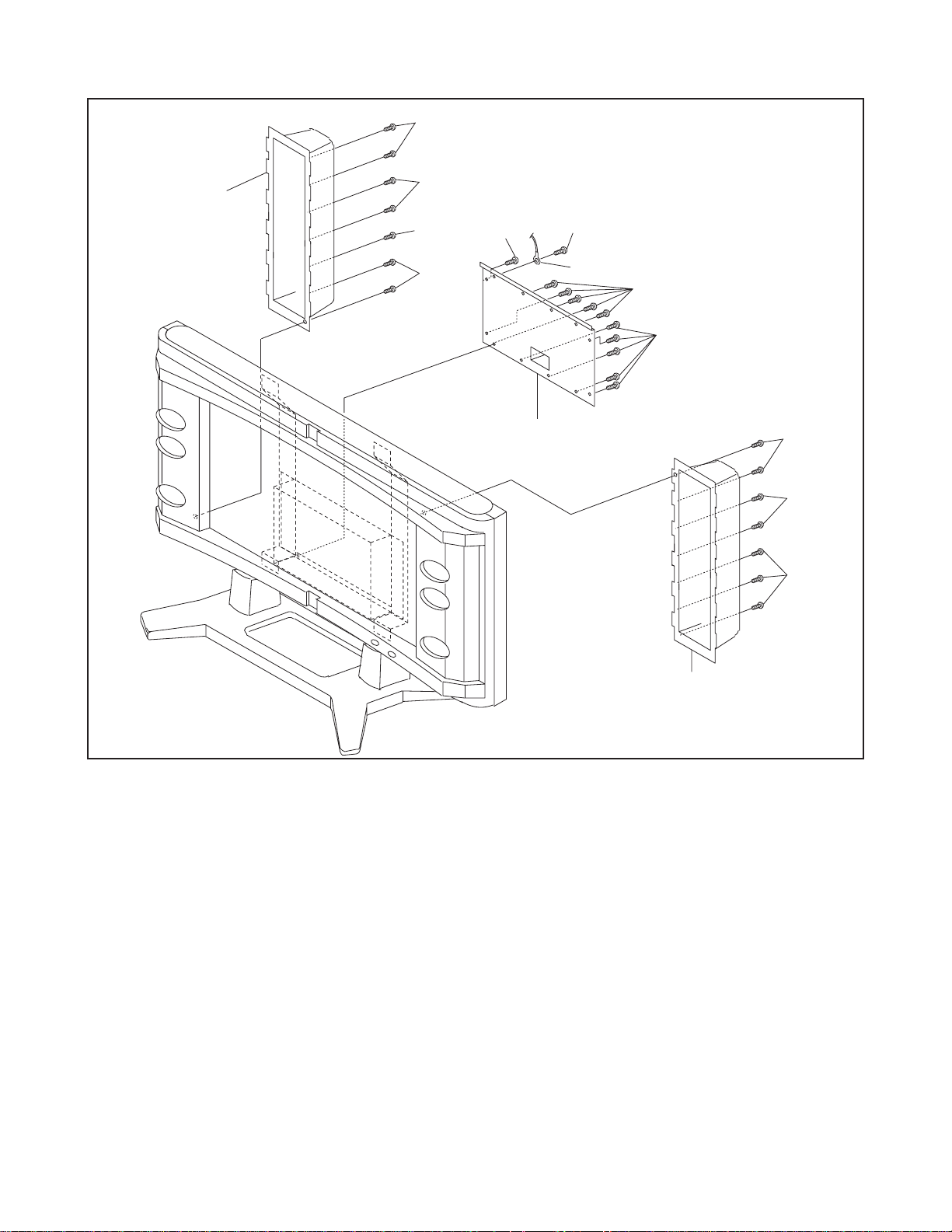

3. Removal of the P CB Shiel d Plate . Remo ve screw s

12(S-4) and wire assembly CLN8.

4. Removal of the Speaker Cover(s). Remove screws

14(S-5).

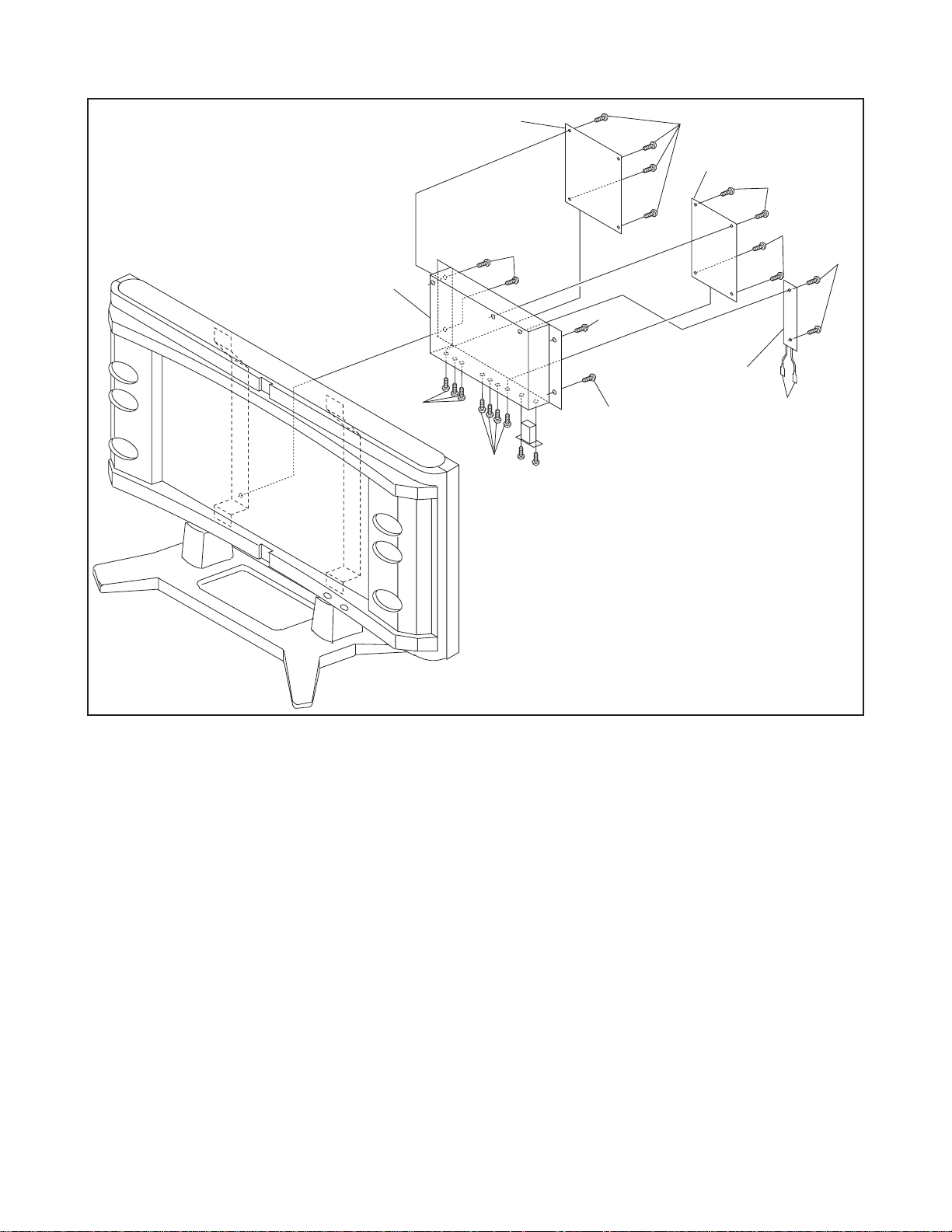

5. Removal of the Digital CBA. Disconnect connectors *CN1701, *CN1702, *CN1 703, *CN1704, and

*CN1709, and remove screws 4(S-6) and 3(S-7).

6. Removal of the An alog CBA. Disconnect connectors *CN201, *CN203, *CN204, *C N501, *CN502,

*CN701, *CN801, and *CN802, and remove

screws 4(S-8) and 4(S-9).

7. Removal of the Filter CBA. Disconnect connecto r

*CN801, and remove two connectors, then remove

screws 2(S-10).

8. Removal of the PCB Ho lder. Remove screws 4(S-

11).

9. Removal of the Front Cabinet Assembly. Remove

screws 14(S-12).

10.Removal of th e Brand Plate. Remov e screws 2(S-

13).

11. Re moval of the Switch CBA. Re move screws 3(S-

14) and disconnect connector *CN751.

12.Removal of th e Decorati on Pane l. Remov e screws

20(S-15) and 2(S-16).

13.Removal of the Speaker-1. Remove screws 8(S-

17).

14.Removal of the Speaker-2. Remove screws 8(S-

18).

15.Removal of the Speaker-3. Remove screws 8(S-

19).

16.Removal of the Speaker-4. Remove screws 8(S-

20).

17.Removal of the Speaker Holder(L). Remove

screws 4(S-21).

18.Removal of the Speaker Holder(R). Remove

screws 4(S-22).

19.Remov al of the Jack Cove r. Remove scre ws 2(S-

23).

20.Removal of the Filter Holder(L)(s). Remove screws

6(S-24).

21.Removal of the Filter Holder(S)(s). Remove screws

6(S-25).

22.Removal of the Stand Unit. Remove screws 4(S-

26).

23.Removal o f the Stand Cover. Remove screws 8(S-

27) and 10(S-28).

24.Removal of the Stand(s). Remove screw s 4(S-29)

and 6(S-30).

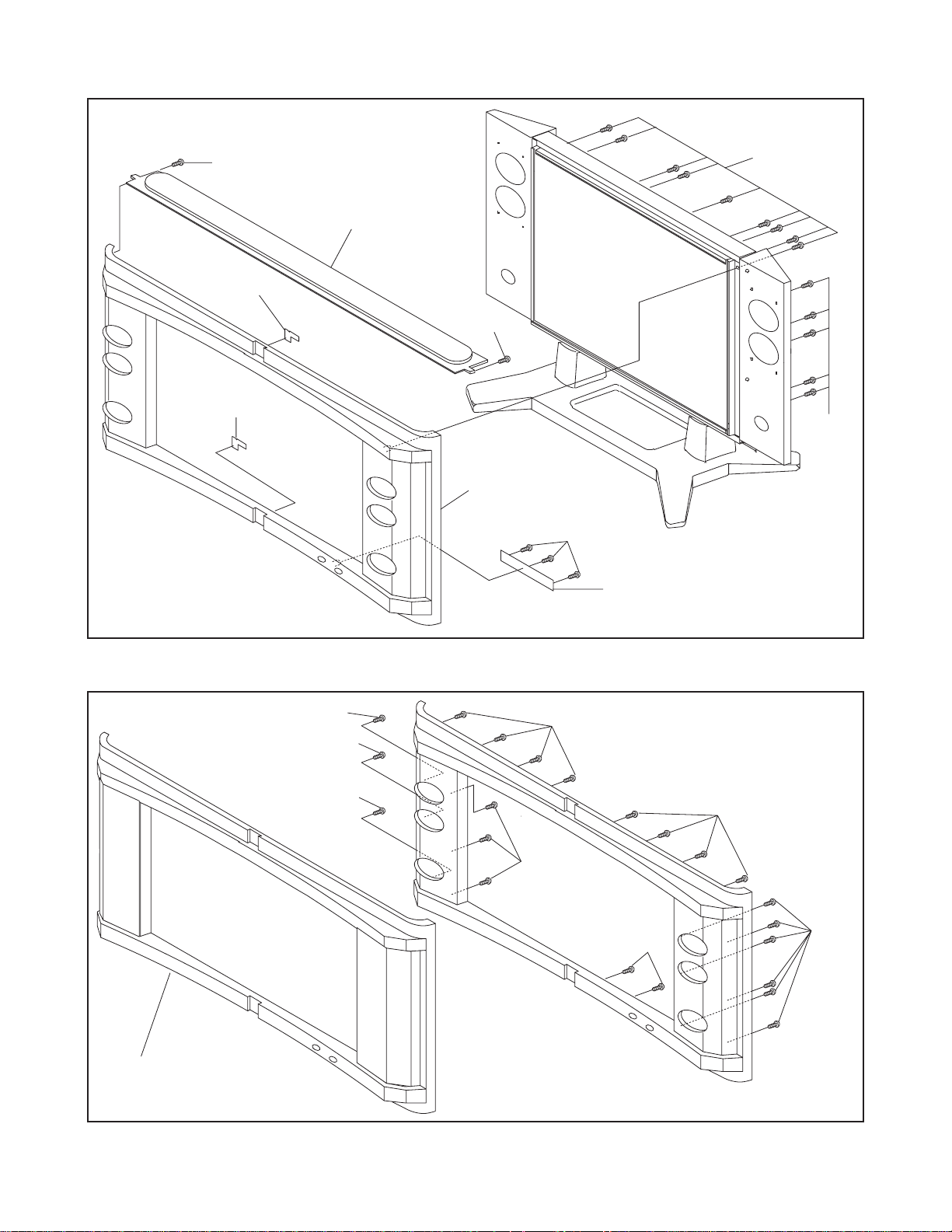

25.Removal of the Chassis Bracket. Remove screws

8(S-31) and 8(S-32).

26.Removal of the Panel Spacer(s). Remove screws

8(S-33).

27.Removal of the SP Holder Plate(s). Remove

screws 8(S-34).

28.Removal of the Plasma Display Module. Remove

screws 12(S-35).

1-5-2 L0605DC

Page 18

(S-1)

(S-2)

(S-1)

(S-2)

(S-1)

(S-1)

(S-2)

(S-1)

(S-2)

(S-1)

[1] Back Cabinet

Fig. 1

(S-3)

(S-3)

[2] Rear Cabinet

(S-3)

Fig. 2

1-5-3 L0605DC

Page 19

(S-5)

[4] Speaker

Cover

(S-5)

(S-5)

(S-5)

(S-4)

(S-4)

CLN8

[3] PCB Shield Plate

(S-4)

(S-4)

(S-5)

(S-5)

(S-5)

[4] Speaker Cover

Fig. 3

1-5-4 L0605DC

Page 20

[8] PCB Holder

)

[5] Digital CBA

(S-11)

(S-6)

[6] Analog CBA

(S-8)

(S-8)

(S-10

(S-11)

[7] Filter CBA

(S-7)

(S-9)

(S-11)

Connectors

(to AC Inlet)

Fig. 4

1-5-5 L0605DC

Page 21

(S-13)

)

[11] LED

A CBA

[11] LED B CBA

(S-12)

[10] Brand Plate

(S-13)

(S-12)

[9] Front Cabinet

Assembly

(S-14)

[12] Switch CBA

[13] Decoration Panel

(S-15)

(S-15)

(S-15)

Fig. 5

(S-15)

(S-15)

(S-15)

(S-15

(S-16)

Fig. 6

1-5-6 L0605DC

Page 22

[18] Speaker Spacer

[14] Speaker-1

(S-17)

(S-21)

[19] Speaker Holder(L)

[24] Optical Filter

[22] Filter Holder(L)

(S-24)

(S-25)

(S-24)

(S-18)

[15] Speaker-2

[21] Jack Cover

[18] Speaker

Spacer

(S-22)

(S-23)

[16] Speaker-3

(S-19)

(S-20)

[17] Speaker-4

(S-24)

[23] Filter Holder(R)

(S-25)

[20] Speaker Holder(R)

[23] Filter Holder(R)

(S-25)

[22] Filter Holder(L)

Fig. 7

1-5-7 L0605DC

Page 23

(S-26)

(S-26)

[25] Stand Unit

Fig. 8

1-5-8 L0605DC

Page 24

[26] Stand Cover

[28] Stand Base

[27] Stand

(S-27)

(S-29)

(S-30)

(S-29)

(S-30)

(S-27)

(S-29)

[27] Stand

(S-29)

(S-30)

(S-30)

(S-27)

(S-28)

(S-28)

(S-27)

(S-28)

(S-27)

Fig. 9

1-5-9 L0605DC

Page 25

[31] SP Holder Plate

r

[32] Plasma Display

Module

[30] Panel Spacer

(S-33)

[29] Chassis Bracket

(S-31)

(S-32)

[30] Panel Space

(S-31)

(S-35)

(S-34)

(S-35)

(S-34)

(S-35)

(S-35)

[33] Panel Holder

Assembly

(S-35)

(S-35)

(S-35)

(S-35)

(S-34)

(S-34)

(S-33)

[30] Panel Spacer

[31] SP Holder Plate

(S-33)

(S-32)

(S-31)

(S-33)

(S-32)

(S-32)

(S-31)

[29] Chassis Bracket

Fig. 10

1-5-10 L0605DC

Page 26

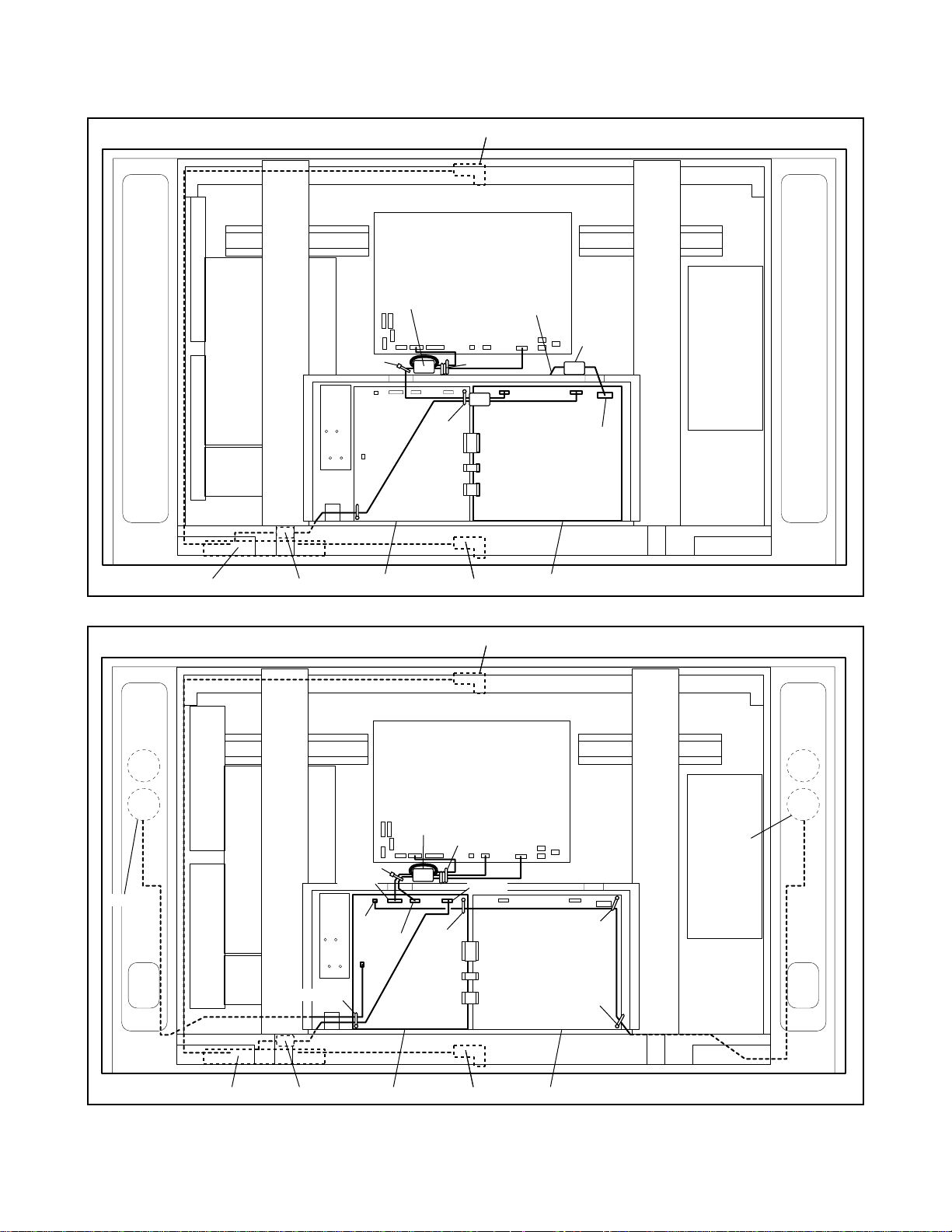

Plasma Display Cable Wiring Diagram

Cables on the Digital CBA

Switch CBA Ferrite core (FC2)

Clamper

Ferrite

core (FC1)

Analog CBA

Clamper

CN203

CN201

CN701

LED CBA

Clamper

Ferrite

core (FC6)

CN1703

CN1702

CN1701

LED CBA

to P31

CN1704

Ferrite

core (FC3)

CN1706

CN1709

Digital CBA

Fig. 11

Cables on the Analog CBA

Speaker

Clamper

Clamper

CN501

CN802

CN801

CN502

Ferrite

core (FC1)

Clamper

CN203

CN201

CN701

LED CBA

Clamper

CN204

CN1703

CN1702

CN1701

Speaker

Clamper

Clamper

Switch CBA Ferrite core (FC2)

Digital CBAAnalog CBA LED CBA

Fig. 12

1-5-11 L0605DC

Page 27

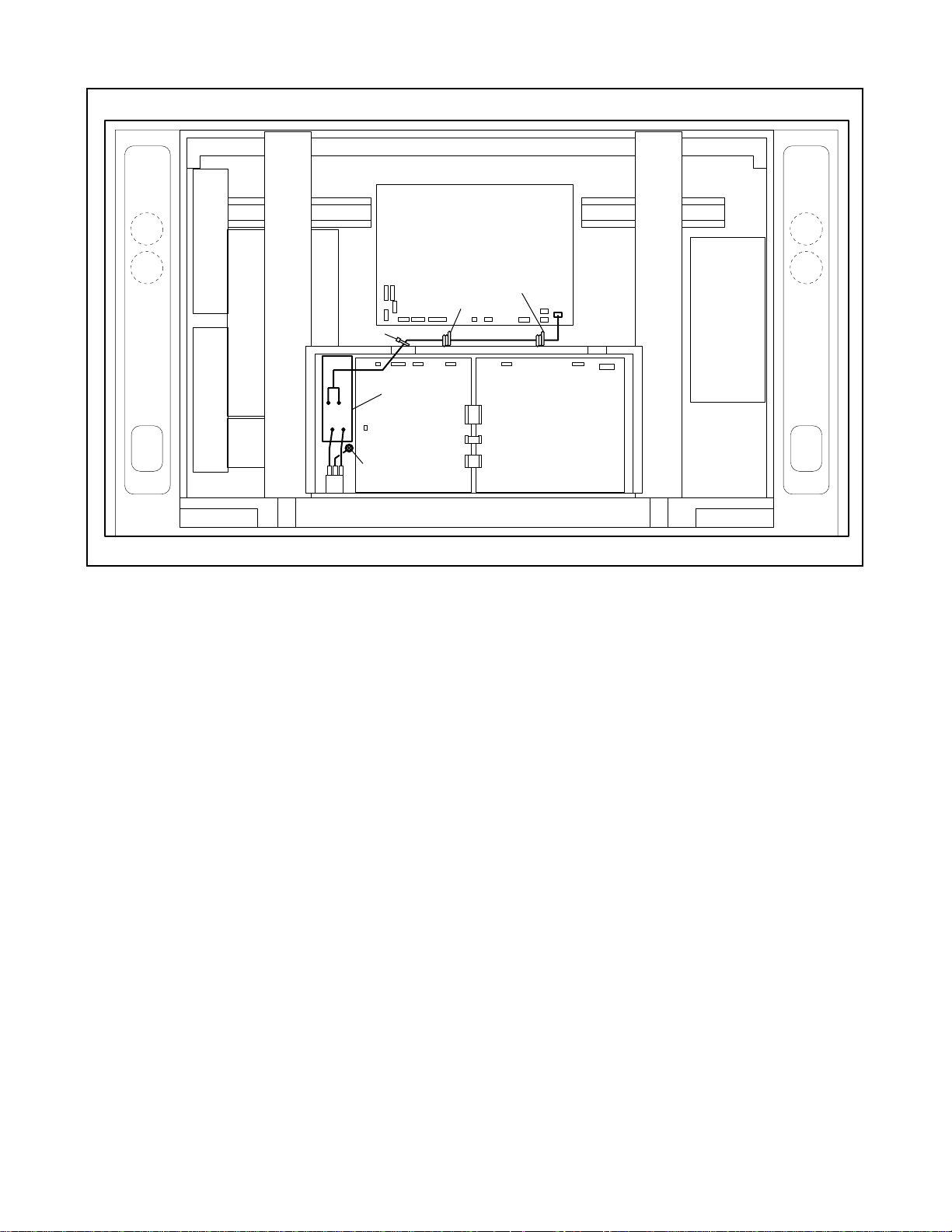

Cables on the Filter CBA

Clamper

Earth

Filter CBA

Clamper

Clamper

CN801

Fig. 13

1-5-12 L0605DC

Page 28

ELECTRICAL ADJUSTMENT INSTRUCTIONS

Fig. 2

3

General Note:

"CBA" is abbreviation for "Circuit Board Assembly."

NOTE:

Electrical adjustm ent s ar e r equ ired after replacing

circuit components a nd certain mechanic al parts.

It is important to perform these adjustm ents only

after all repairs and replacements have been completed.

Also, do not attempt these adjustments unless the

proper equipment is available.

Test Equipment Required

1. NTSC Pattern Gen erat or ( Col or Bar W/W hit e Wi ndow, Red Color, Gray Scale)

2. Plastic Tip Driver

3. Remote control unit: Part No. N0105UD, N0108UD,

N0127UD or N0132 UD

4. Color Analyzer

How to make service remote control

unit:

1. Prepare normal remote control unit. (Part No.

N0105UD, N0108UD, N0127UD or N0132UD) Remove 3 Screws from the back lid. (Fig. 1-1)

2. Add J1 (Jumper Wire) to the r emote cont rol CBA.

(Fig. 1-2)

SCREW

REMOTE CONTROL UNIT

J 1

Fig. 1-1

How to set up the service mode:

Service mode:

1. To turn the power on, pre ss "POWER" button on the

normal remote control unit or the unit.

2. Use the service remote control unit.

3. Press "SLEEP" button on the service remote control unit. Fig. 2 appears on the screen.

MAIN UCOM Ver.

SUB UCOM Ver.

MEMORY SIZE

CHKSUM

4. Confirm the following

a. Version of main micro

computer --- PZ1_US_LF_Ver1.29 (or 1.31)

b. Version of sub micro computer --- K746_015

c. Memory size --- 32

d. FLASH DATA Check- S um (pr es s "0" butto n on

the service remote control unit) --- D2F7h (or

E170h)

Initial setting:

1. To turn the power on, pre ss "POWER" button on the

normal remote control unit or the unit.

2. Enter the service mode.

3. To reset to factory setting, press "DIS PLAY" button on the service remote control unit.

- "INITIALIZE" (red) appears on the screen as

shown in Fig. 3.

: PZ1_US_LF_Ver1.29 (or 1.31)

: K746_015

: 32

: Push 0 key

REMOTE CONTROL CBA

Fig. 1-2

MAIN UCOM Ver.

SUB UCOM Ver.

MEMORY SIZE

CHKSUM

: ********

: ********

: 32

: ****

INITIALIZE

Fig.

- Aft er few second s (compl eti on initi aliz ation) , col-

or of "INITIALIZE" will change green.

1-6-1 L0605EA

Page 29

1. Auto Calibration (Black & White)

Fig. 4

1. Operate the unit more than 20 minutes.

2. Input black raster signal from only Component AV Input (2) video/Y jack (green). Do not input any signal

to Component AV Input (2) vide o/Pb or Pr jack.

3. Enter the service mode.

4. To enter the Auto Calibration (Black) adjustment

mode, press "2" button on the servi ce rem ote con trol unit. If no sign al, "No signal" appears on the

screen.

5. To start auto adjustment, press "CH o" button on

the service remote control unit.

6. Input white raster signal (100% or 110%) from only

Component AV Input (2) vide o/Y jack (green). Do not

input any signal to Co mponent AV Input (2 ) video/Pb

or Pr jack.

7. To enter the Auto Calibration (White) adjustment

mode, press "3" button on the servi ce rem ote con trol unit. If no sign al, "No signal" appears on the

screen.

8. To start auto adjustment, press "CH o" button on

the service remote control unit.

9. Upon completion, wait for at le ast 5 seco nds.

10. Unpl ug AC cord and plug it in AC outlet again to reset

then enter the ser vi ce m ode a gai n.

11. Conf irm that both the "Black Calibration : Complete"

and "White Calibration : Complete" are dis played

on the screen as shown in F ig. 4. If "Yet" is displayed instead of "Complete", repeat above steps.

MAIN UCOM Ver.

SUB UCOM Ver.

MEMORY SIZE

CHKSUM

Black Calibration : Complete

White Calibration : Complete

: ********

: ********

: 32

: Push 0 key

2. White Balance Adjustment

Purpose: To mi x r ed , gr ee n an d bl ue bea ms co rre ctly

for pure white.

Symptom of Misadjustment: White becomes blui sh

or reddish.

Test

Point

Screen

Notes:

- Use service remote control unit.

- This adjustment should be per formed in both Com ponent 2 mode and Video 1 mode. Adjustment in

Component 2 mode should be performed after completion of ADC calibration adjustment.

1. Operate the unit more than 20 minutes.

2. Inp ut the gray scale pattern signal ( 5 scales) from

Component AV Input (2 ) vid eo/Y j ack.

3. Set the color analyzer to the CHROMA mode and

after zero point calibration, for high light adjustment, bring the optical receptor to the 2nd scale as

shown below.

Adj.

Point

CH o / p

buttons

Mode Input

Video 1 &

Component 2

M. EQ. Spec.

Pattern Generator,

Color analyzer

Figure

Color Analyzer

Gray scale

pattern signal

(5 scales)

See below

Fig. 5

2nd gray scale

Fig. 6

4. Enter the Service mode.

1-6-2 L0605EA

Page 30

5. Enter the component adjustment mode, press

W

Fig. 8

r

"VOL p" button once on the service remote control

unit.

6. Press "4" button on the serv ice rem ote cont rol uni t

for Red adjustment. Press "6" button on the service

remote control unit for Blue adjustment.

7. In each color mode, press "CH o / p" b utton to adjust the values of color.

8. Adjust Red an d Bl u e colo r s o tha t t he t em p er at ur e

becomes 9200°K-5MPCD (x: 288 / y: 288) ±3%.

9. For low light adjustment, bring the optical receptor

to the 4th scale as shown below.

4th gray scale

3. Sub-Brightness Adjustment

Purpose: To get proper brigh tnes s .

Symptom of Misadjustment: If Sub-Brightness is

incorrect, proper brightness cannot be obtained by

adjusting the Brightness Control.

Adj. Point Mode Input

CH o / p buttons

M. EQ. Spec.

Pattern Generator See below

Video 1 &

Component 2

Figure

IQW

Fig. 7

10. Press "1" button on the servic e remote control unit

for Red adjustment. Press "3" button on the service

remote control unit for Blue adjustment.

11. In each color mode, press "CH o / p" b utton to adjust the values of color.

12. Adjust Re d and Bl u e co lo r s o t ha t th e t em p er at ur e

becomes 9200°K-5MPCD (x: 288 / y: 288) ±3%.

13. Check adjustment value in high light adjustment

again. If adjustment value is not within specification, repeat steps 2-8.

14. To enter the adjustment mode in the Composite

mode (Video 1 mode), pr ess "VO L p" button once

on the service remote control unit.

15. Input the gray scale pattern signa l (5 scales) from

Composite AV Input (1) video jack (Video 1).

16. Adjust in the same way ab ove.

hite

Notes:

- IQW Setup level --- 7.5 IRE

- Use service remote control unit.

- This adjustment should be per formed in both Com ponent 2 mode and Video 1 mode. Adjustment in

Component 2 mode should be performed after completion of ADC calibration adjustment.

1. Enter the Service mode. Then input IQW signal

from Component AV Input (2) video.

2. Press "VOL p" button on the service remote control

unit.

3. Press "7" on the service remote control unit.

4. Press "CH o / p" buttons so that the bar is just vis-

ible. (Refer to Fig. 8.)

5. Input IQW signal from Composite AV Input (1) vid-

eo jack (Video 1).

6. To adjust in Composite mode (Video 1 m ode), re-

peat steps 2 - 4.

7. Turn the power off and on again, using the ma in

power button on the TV unit.

Black

This ba

just

visible

1-6-3 L0605EA

Page 31

FLOW CHART NO.1

The power cannot be turned on.

TROUBLESHOOTING

Is the fuse normal?

Yes

Are Pins (1,2,5,8,9,11) on CN501 are shorted?

No

Is the +4.5V voltage outputted between Pin (11)

and GND?

Yes

After reconnecting CLN6 to CN501, does the

voltage between each pin and GND become

following value during turning the power on?

CN501 Pins (1,2) P-ON+6.5V

CN501 Pins (8,9) P-ON+21V

No

No

Yes

No

Remove CLN6 connecting to CN501 and check

Pins (1,2,5,8,9,11) on CLN6 are shorted.

Not shorted Shorted

Yes

After replacing fuse,

does it break when

turning the power on ?

No

Check each line of power supply on the Analog

CBA and service it if defective.

Replace the Plasma Display Module.

Replace the Plasma

Display Module.

Yes

Is the +3.3V voltage outputted to the emitter of

Q503?

Yes

Is the "H" signal inputted into Pin (2) on CN502?

Yes

Replace the Plasma Display Module.

No

No

Check Q503, D503 and the periphery circuit,

and service it if defective.

Replace IC205.

1-7-1 L0605TR

Page 32

FLOW CHART NO. 2

Video signal is not outputted normally.

F

Input video signal.

Is the video signal outputted to each pins on the

CN701 of the Analog CBA?

(If the video signal is not outputted when signal

is inputted to component 1, 2 jack on the rear,

replace the Digital CBA.)

When inputting video signal to Video 1 S-VIDEO

jack...

CN701 Pin (10) VIDEO1-Y

CN701 Pin (12) VIDEO1-C

When inputting video signal to Video 1 composite

jack...

CN701 Pin (8) VIDEO1

When inputting video signal to Video 2 S-VIDEO

jack...

CN701 Pin (4) VIDEO2-Y

CN701 Pin (6) VIDEO2-C

When inputting video signal to Video 2 composite

jack...

CN701 Pin (2) VIDEO2

Are serial data signal outputted to TP2037 and

TP2038 on the Digital CBA?

Yes

No

No

No

No

No

Check lines between Pins (10, 12) on CN701

and JK701, and service it if defective.

Check lines between Pin (8) on CN701 and

JK702, and service it if defective.

Check lines between Pins (4, 6) on CN701 and

JK701, and service it if defective.

Check lines between Pin (2) on CN701 and

JK702, and service it if defective.

Replace the Digital CBA.

Yes

Replace the Plasma Display Module.

LOW CHART NO. 3

Audio is not outputted from speakers normally.

Input audio signal.

Is audio signal inputted to each pins on IC202

and IC203?

[****] is the check point on the componet side.

When inputting to Video 1 jack...

IC203 Pin (13) [J165] AUDIO1(L)

IC202 Pin (13) [J135] AUDIO1(R)

When inputting to Video 2 jack...

IC203 Pin (14) [J166] AUDIO2(L)

IC202 Pin (14) [J129] AUDIO2(R)

When inputting to component 1 jack...

IC203 Pin (15) [CN201 Pin (1)] AUDIO3(L)

IC202 Pin (15) [CN201 Pin (2)] AUDIO3(R)

When inputting to component 2 jack...

IC203 Pin (12) [CN201 Pin (4)] AUDIO4(L)

IC202 Pin (12) [CN201 Pin (5)] AUDIO4(R)

No

No

No

No

Check lines between Pin (13) on IC203 and

JK702, between Pin (13) on IC202 and JK702,

and service it if defective.

Check lines between Pin (14) on IC203 and

JK702, between Pin (14) on IC202 and JK702

and service it if defective.

Replace the Digital CBA.

Replace the Digital CBA.

(continued to "A" on next page)

1-7-2 L0605TR

Page 33

.

.

A

Yes

Is input switching signal inputted to each pins on

IC202 and IC203?

[****] is the check point on the componet side.

Pin (9)

[Q205-C]

Video 1

Video 2

Component 1

Component 2

Is audio signal outputted to each pins on IC202

and IC203?

[****] is the check point on the componet side.

IC203 Pin (3) [J148] L-CH

IC202 Pin (3) [J142] R-CH

Is audio signal inputted to each pins on IC801?

IC801 Pin (5) L-CH

IC801 Pin (2) R-CH

Is audio signal outputted to each pins on IC801?

IC801 Pin (7) L-CH

IC801 Pin (12) R-CH

L

L

L

L

Pin (10)

[Q204-C]

Yes

Yes

Yes

Yes

Pin (11)

[Q203-C]

L

L

H

H

L

H

L

H

No

No

No

No

Check lines between each pins on IC203 and

each pins on IC205, between each pins on IC202

and each pins on IC205 and service it if defective

Pin (9) on IC202,IC203 Pin (30) on IC205

Pin (10) on IC202,IC203 Pin (29) on IC205

Pin (11) on IC202,IC203 Pin (28) on IC205

Check +6.5 V line and service it if defective.

No

Is +6.5V signal inputted to Pin (16) on IC202

and Pin (16) on IC203?

Yes

Replace IC202 or IC203.

Check lines between each pins on IC203 and

each pins on IC801, between each pins on IC202

and each pins on IC801 and service it if defective

Pin (3) on IC203 Pin (5) on IC801

Pin (3) on IC202 Pin (2) on IC801

Check +21 V line and service it if defective.

No

Is +21V signal inputted to Pin (10) on IC801?

Yes

Is the "L" pulse supplied to the base of Q801?

Yes

Replace IC801. Replace IC205.

No

Is each audio signal inputted to Pin (1) on

CN801 and Pin (1) on CN802?

CN802 Pin (1) L-CH

CN801 Pin (1) R-CH

Yes

Replace Speaker (SP801 or SP802).

No

Check lines between Pin (1) on CN801 and each

pins on IC801, between Pin (1) on CN802 and

each pins on IC801 and service it if defective.

Pin (7) on IC801 Pin (1) on CN802

Pin (12) on IC801 Pin (1) on CN801

1-7-3 L0605TR

Page 34

.

.

FLOW CHART NO. 4

Audio is not outputted from audio output terminal normally.

Input audio signal.

Is audio signal inputted to each pins on IC202

and IC203?

[****] is the check point on the componet side.

When inputting to Video 1 jack...

IC203 Pin (13) [J165] AUDIO1(L)

IC202 Pin (13) [J135] AUDIO1(R)

When inputting to Video 2 jack...

IC203 Pin (14) [J166] AUDIO2(L)

IC202 Pin (14) [J129] AUDIO2(R)

When inputting to component 1 jack...

IC203 Pin (15) [CN201 Pin (1)] AUDIO3(L)

IC202 Pin (15) [CN201 Pin (2)] AUDIO3(R)

When inputting to component 2 jack...

IC203 Pin (12) [CN201 Pin (4)] AUDIO4(L)

IC202 Pin (12) [CN201 Pin (5)] AUDIO4(R)

Is input switching signal inputted to each pins on

IC202 and IC203?

[****] is the check point on the componet side.

Video 1

Video 2

Component 1

Component 2

Is audio signal outputted to each pins on IC202

and IC203?

[****] is the check point on the componet side.

IC203 Pin (3) [J148] L-CH

IC202 Pin (3) [J142] R-CH

Is audio signal outputted to the collector of Q707

(L-CH) and the collector of Q708 (R-CH)?

Is the "L" pulse supplied to the base of Q711 and

the base of Q712?

Check lines between Q707 and JK703, between

Q708 and JK703 and service it if defective.

Pin (9)

[Q205-C]

L

L

L

L

Yes

Pin (10)

[Q204-C]

Yes

Yes

Yes

Yes

No

No

No

No

Pin (11)

[Q203-C]

L

L

H

H

L

H

L

H

No

No

No

No

Check lines between Pin (13) on IC203 and

JK702, between Pin (13) on IC202 and JK702,

and service it if defective.

Check lines between Pin (14) on IC203 and

JK702, between Pin (14) on IC202 and JK702

and service it if defective.

Replace the Digital CBA.

Replace the Digital CBA.

Check lines between each pins on IC203 and

each pins on IC205, between each pins on IC202

and each pins on IC205 and service it if defective

Pin (9) on IC202,IC203 Pin (30) on IC205

Pin (10) on IC202,IC203 Pin (29) on IC205

Pin (11) on IC202,IC203 Pin (28) on IC205

Check +6.5 V line and service it if defective.

No

Is +6.5V signal inputted to Pin (16) on IC202

and Pin (16) on IC203?

Yes

Replace IC202 or IC203.

Check Q707, Q708 and the periphery circuit, and

service it if defective.

Is the "L" pulse supplied to the base of Q710?

Yes

Check Q709 and the periphery

circuit, and service it if

defective.

No

Replace IC205

1-7-4 L0605TR

Page 35

BLOCK DIAGRAMS

111

1

System Control Block Diagram

REMOTE

POWER-SW

P-ON-H

BLOCK DIAGRAM

Q206

Q207

P-ON-H

56

4

39

+3.3V

BUFFER

Q271

IC205

TO

+3.3V

(PDP MICROCONTROLLER)

POWER SUPPLY

Q272

RXD

15

TXD

14

RESET-18138P-OFF-RQ54P-OFF-H

55

A-MUTE

32

Q295

A-OUT-MUTE

313029

VOLUME

A-OUT-MUTE

TO AUDIO

AUDIO-SW0

AUDIO-SW1

AUDIO-SW2

28

AUDIO-SW0

AUDIO-SW1

AUDIO-SW2

BLOCK DIAGRAM

IC201

(MEMORY)

SCL

48

6

SCL

SDA

47

5

SDA

D1908,

D1909

POWER

D1910,

D1911

STANDBY

+3.3V

+3.3V

CN1904

STANDBY-LED

11MCU+3.3V

22

CN1910

D1903, D1904

STANDBY

CN1905CN1911

11MCU+3.3V

D1905, D1906

CN204

POWER-KEY

POWER-LED

STANDBY-LED

66

44REMOTE

22

33

CN1901

REMOTE

SENSOR

RV1901

SW1908

Q1902

+3.3V

POWER

KEY

CN1902

22KEY-IN1

CN1706

V16

KEY-IN1

SWITCH

33KEY-IN2

44KEY-IN3

Y16

W16

KEY-IN2

KEY-IN3

SWITCH CBA

+3.3V

Q1901

STANDBY-LED

22

STANDBY

CN203

CN1703

RESET

SW1401

KEY-IN-POW

12

12KEY-IN-POW

T17

KEY-IN-POW

8 RXD

16TXD

V12

TXD

7 TXD

17RXD

Y12

RXD

10 REMOTE

14REMOTE

V11

REMOTE

4 RESET-181

14 P-OFF-RQ

20RESET-181

10P-OFF-RQ

Y11

W14

RESET

P-OFF-RQ

15 P-OFF-H

16 VOLUME

9P-OFF-H

8VOLUME

Y15

P-OFF-H

VOLUME-MUTE

13

11

VOLUME-MUTE

VOLUME

CONTROL

Q1401

V15

VOLUME

TO DIGITAL

SIGNAL PROCESS 1

SCL

W13

SCL

BLOCK DIAGRAM

SDA

V13

SDA

TO VIDEO

SCL

BLOCK DIAGRAM

SDA

RESET

Y14

RESET

SCL

TO DIGITAL

SIGNAL PROCESS 2

SDA

I2C-READY

Y13

I2C-READY

BLOCK DIAGRAM

PANEL-ON

IC1404

(MEMORY)

SCL

6

TO POWER SUPPLY

BLOCK DIAGRAM

SDA

PANEL-ON

5

DIGITAL CBA UNIT ANALOG CBA

W19

PANEL-ON

LED-A CBA

LED-B CBA

IC1401

(DIAPLAY CONTROLLER)

1-8-1

L0605BLS

Page 36

Video Block Diagram

VIDEO SIGNAL

95

VUV[0]

97

98

VUV[1]

VUV[2]

VUV[0~7]

100

101

VUV[3]

VUV[4]

103

104

VUV[5]

VUV[6]

OUTPUT

FORMATTER

106

VUV[7]

TO DIGITAL

SIGNAL

PROCESS 1

BLOCK

67656462615958

VY[0]

VY[1]

VY[2]

DIAGRAM

VY[0~7]

VY[3]

VY[4]

VY[5]

VY[6]

56

VY[7]

PVCLK

HD

718687

VD

SERIAL

I/F

83

82

33~40

TO SYSTEM

CONTROL

BLOCK

SDA

SCL

DIAGRAM

RESET

DCLK

127

DPEN

128

DHS

129

DFBK

130

TO DIGITAL

SIGNAL

PROCESS 2

BLOCK

DIAGRAM

DVS

131

168 166

82

SERIAL

RESET

142

I/F

GRE[0~7]

139~136

~

GRE[0]

133~152

GRE[7]

GGE[0~7]

146~160

~

GGE[0]

OUTPUT

MULTIPLEXER

ITU-R656

DIGITAL

VIDEO

143

GGE[7]

FORMATTER

GBE[0~7]

~

~

GBE[0]

153

GBE[7]

ADC

INPUT

SELECT

IC1101 (VIDEO DECODER)

137

139

135

145

88VIDEO1

214VIDEO2

412VIDEO2-Y

10 6VIDEO1-Y

WF12

R738

PICTURE

/TONE

DIGITAL

SIGNAL

141

610VIDEO2-C

12 4VIDEO1-C

WF13

R746

CONTROL

PROCESS

ADC

INPUT

149

153

SELECT

151

ADC

159

DATA

COLOR

SPACE

CONTROL

21 22 24 25 27 28 30 31

FRAME DELAY

MEMORY CONTROL

1~4 6~9 11~19

ADRESS

ANALOG CBA

IC1102 (SDRAM)

WF6

R1774

IC1301 (VIDEO DECODER)

WF7

R1776

43

WF8

R1778

WF9

R1773

44

DATA

MULTIPLEXER

VIDEO

DECODER

ADC

WF10

R1775

51

35

WF11

R1777

DIGITAL CBA UNIT

BUFFER

JK702 Q706 CN701 CN1701

VIDEO1

IN

Q703

BUFFER

VIDEO2

IN

BUFFER

BUFFER

Q705

Q704

2

1

3 4

JK701

YC

S-VIDEO1

IN

BUFFER

Q702

2

1

3 4

YC

Q701

S-VIDEO2

IN

BUFFER

1-8-2

BUFFER

BUFFER

BUFFER

BUFFER

Q1701

Q1703

BUFFER

Q1705

Q1702

JK1704

Q1706

Q1704

VIDEO3-YINVIDEO3-CbINVIDEO3-CrINVIDEO4-YINVIDEO4-PbINVIDEO4-Pr

BUFFER

IN

L0605BLV

Page 37

Digital Signal Process 1 Block Diagram

TO DIGITAL

SIGNAL

PROCESS 2

BLOCK

DIAGRAM

VCLK

VIDEO SIGNAL

VVC

VHS

DB[0~7]

139

145~149

~

DB[6]

DB[0]

H-SYNC

/V-SYNC

TIMING

COLOR

SCALE

CONVERTER

UPSCALER

DEINTERLACER

PRIMARY

PICTURE

148

DB[7]

DG[0~7]

156~157

~

DG[0]

DG[7]

FILM-MODE

DETECTION

~

DR[0]

DR[0~7]

2

159

~

DR[2]~DR[3]

MEMORY

CONTROLLER

~

6

136

137

138

DR[7]

DISPLAY

TIMING

33~46 54~69

DATA

ADRESS

IC1202 (SDRAM)

DIGITAL CBA UNIT

IC1201 (DIGITAL SIGNAL PROCESS)

MOTION

~

VUV[0]

~

109

VUV[0~7]

&

DETECT

VIDEO

INPUT

VUV[7]

116

NOISE

REDUCTION

~

VY[0]

VY[7]

~

95

102

VY[0~7]

TO VIDEO

BLOCK

DIAGRAM

105

PVCLK

VD

107

HD

108

1-8-3

SERIAL

I/F

125 126

SCL

SDA

TO SYSTEM

CONTROL

BLOCK

DIAGRAM

L0605BLD1

Page 38

Digital Signal Process 2 Block Diagram

PDM501

PLASMA DISPLY

MODULE

30 30RA-

IC1405 (LVDS I/F)

50

V19

2

Y20

CN1709

515254

R16

U19

~

DRE[0]

48

R18

DRE[7]

29 29RA+

47

55

W20

56

V20

3

U20

28 28RB-

27 27RB+

46

45

810467

T19

T20

R19

R20

M18

~

DGE[0]

25 25RC-

42

TLL

PARALLEL

111214

P18

DGE[7]

24 24RC+

41

TO SERIAL

CONVERTER

P19

P20

21 21RD-

38

16181519202223

M17

N20

20 20RD+

37

M20

WF4

L17

~

DBE[0]

TP2037

K17

M19

DBE[7]

23 23RCLK-

40

PLL

L19

22 22RCLK+

39

24

L20

WF3

WF5

TP2038

27

R1421

D18

28

R1420

C20

30

N19

31

R1419

J17

WF2WF1

22SLE

I2C-READY

33SCLK

SCL

TO SYSTEM CONTROL

44SD ATA

SDA

BLOCK DIAGRAM

55DISPEN

PANEL-ON

DIGITAL CBA UNIT

IC1401 (DIGITAL SIGNAL PROCESS / DISPLAY CONTROL)

DISPLAY

TIMING

DISPLAY PORT

COLOR MATRIX

/ GAMMA CORRECTION

/ CLTs / COLOR

SPACE EXPANDER

MEMORY

DIGTAL

SIGNAL

PROCESS

VIDEO PORT

SYNC DECODER

/ AUTO IMAGE

OPTIMIZER

/ COLOR SPACE

CONVERTER / HDCP

~

VB[0]

VB[7]

~

~

L1

L4

M1

M3

~

VG[0]

VG[7]

~

J1

N1

~

J4

K1

K3

H1

~

VR[0]

VR[7]

~

G1

G3

F2

F1

E2

H2

F3

E1

E3

H3

~

GRE[0]

~

C1

C3

B1

D2

GRE[7]

D3

GRAPHIC PORT

F4

E4

A7A8B7

I / F

SYNC DECODER

/ AUTO IMAGE

OPTIMIZER

/ COLOR SPACE

CONVERTER / HDCP

~

GGE[0]

GGE[7]

B8

B11

B12

C8

C11

A15

DATA BU S

IC1403

(FRASH MEMORY)

ADDRESS BUS

~

GBE[0]

GBE[7]

~

A17

A19

A20

B16

~

B9

A9

A10

A11

C10

B18

DB[0~7]

DG[0~7]

TO DIGITAL

SIGNAL

PROCESS 1

BLOCK

DIAGRAM

DR[0~7]

VCLK

VVC

VHS

1-8-4

GRE[0~7]

GGE[0~7]

TO VIDEO

BLOCK

DIAGRAM

GBE[0~7]

DCLK

DPEN

DHS

DFBK

DVS

L0605BLD2

Page 39

Audio Block Diagram

SP803

SPEAKER

1 SP-L

CN802

7

AMP

(AUDIO AMP)

5

L-CH

2 SP-GND

WF14

SP804

AUDIO SIGNAL

SPEAKER

L-CH

IC801

SP802

1 SP-R

CN801

AMP

2 12

SPEAKER

R-CH

2 SP-GND

SP801

VOLUME

CTL

SPEAKER

R-CH

6

Q831

Q801

TO POWER SUPPLY

BLOCK DIAGRAM

AC-DET

TO SYSTEM

CONTROL

BLOCK DIAGRAM

VOLUME

JK703

Q707

AUDIO(L)

AMP

OUT

Q708

AUDIO(R)

OUT

AMP

Q712

Q711

+5V

Q709

Q710

IC203

(INPUT SELECT)

13

151412

3

109 11

SW CTL

IC202

(INPUT SELECT)

13

151412

3

109 11

SW CTL

Q205

Q204

Q203

ANALOG CBA

AUDIO-SW0

AUDIO-SW1

AUDIO-SW2

A-OUT-MUTE

TO SYSTEM

CONTROL

BLOCK

CN201

91AUDIO3(L)

CN1702

82AUDIO3(R)

64AUDIO4(L)

55AUDIO4(R)

DIAGRAM

JK702

AUDIO1(L)

IN

AUDIO1(R)

IN

AUDIO2(L)INAUDIO2(R)

IN

1-8-5

JK1703

AUDIO3(L)

IN

AUDIO3(R)INAUDIO4(R)

AUDIO4(L)

IN

IN

DIGTAL CBA UNIT

L0605BLA

Page 40

Power Supply Block Diagram

P-ON+5V

P-ON+5V

21

20

CN203

P-ON+5V

P-ON+6.5V(2)

P-ON+21V

MCU+3.3V

TO SYSTEM CONTROL

BLOCK DIAGRAM

TO AUDIO

P-ON-H

AC-DET

BLOCK DIAGRAM

P-ON+5V

4

CN1703

P-ON+5V

3

P-ON+5V

IC1201

IC1202

IC1401

IC1402

IC1301

IC1403

IC1101

TO SYSTEM CONTROL

BLOCK DIAGRAM

PANEL-ON

+5V REGULATOR

+3.3V REGULATOR

Q503

Q501

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ONLY WITH SAME TYPE 8 A, 250V FUSE.

128

9

CAUTION:

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE 8A, 250V.

8A 250V

P-ON+6.5V(1)

P-ON+6.5V(2)

128

CN9003

3

(PLASMA DISPLAY MODULE)

PDM501

CN8001 CN501CN601

AC120V

WHITE 1

AC120V

BLACK

11

P-ON+21V

P-ON+21V

AL+4.5V

9

11

CN502CN9002

P-ON-H

2 2

AC-DET

5 5

ANALOG CBA

+2.5V REGULATOR

POWER

SUPPLY

CIRCUIT

IC1508

CN1704CN9001

D+4.6V

1 1

+3.3V REGULATOR

IC1509

5

D+4.6V

PANEL-ON

2 2

5

+1.5V REGULATOR

IC1502

+3.3V REGULATOR

IC1510

+1.8V REGULATOR

IC1501

IC1503

+1.8V REGULATOR

+3.3V REGULATOR

IC1507

+3.3V REGULATOR

IC1506

+3.3V REGULATOR

IC1505

IC1504

DIGITAL CBA UNIT

+1.5V REGULATOR

FILTER CBA

HOT

8A/125V

F601

8A/125V

CN603

HOT CIRCUIT. BE CAREFUL.

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

AC601

CLN601

AC CORD

CLN602

GND

FRAME

1-8-6

L0605BLP

Page 41

SCHEMATIC DIAGRAMS / CBA'S AND TEST POINTS

Standard Notes

Many electrical and mechanical parts in this chassis have special characteristics. These characteristics often

pass unnoticed and the protection afforded by them cannot necessarily be obtained by using replacement components rated for highe r vo ltage, wattage, etc. Replacemen t parts th at hav e t hese s pe ci al s afet y ch ar acter isti cs are

identified in this man ual and its supplements; electrical comp onents having such features are ide ntified by the

mark " # " in the schematic diagram and the parts list. Before replacing any of these components, read the parts

list in this manual carefully. The use of substitute replacement parts that do not have the same safety characteristics as specified in the parts list may create shock, fire, or other hazards.

Note:

1. Do not use the part number shown on these drawi ngs for ordering. The correct part number is sho wn in the

parts list, and may be slightly different or amended since these drawings were prepared.

2. All resistance values are indicated in ohms (K=10

3. Resistor wattages are 1/4W or 1/6W unless otherwise specified.

4. All capacitance values are indicated in µF (P=10

5. All voltages are DC voltages unless otherwise specified.

Note of Capacitors:

ML --- Mylar Cap. PP --- Metallized Film Cap. SC --- Semiconductor Cap. L --- Low Leakage type

3

, M=106).

-6

µF).

Temperature Characteristics of Capacitors are noted with the following:

B --- ±10% CH --- 0±60ppm/°C CSL --- +350~-1000ppm/°C

Tolerance of Capacitors are noted with the following:

Z --- +80~-20%

Note of Resistors:

CEM --- Cement Res. MTL --- Metal Res. F --- Fuse Res.

Capacitors and transistors are represented by the following symbols.

CBA Symbols

(Top View) (Bottom View)

+

(Bottom View)

Transistor or Digital Transistor

E C B

(Top View)

NPN Transistor

Electrolytic Capacitor

(Top View)

PNP Transistor

Schematic Diagram Symbols

Digital Transistor

E C B

(Top View)

E C B

NPN Digital Transistor

E C B

(Top View)

PNP Digital Transistor

E C B

1-9-1 L0604SC

Page 42

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

lts

THE FOLLOWING PAGES:

1. CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME

TYPE_A,_V FUSE.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE_A,_V.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, first check to see that all components in the power supply circuit are not defective

before you connect the AC plug to the AC power supply. Otherwise it may cause some components in the power supply circuit to fail.

3. Note:

(1) Do not use the part number sh own on the dra wings for orde ring. The correc t part number i s shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

(2) To maintain ori ginal func tion and reli ability of repaired u nits, use only origin al replacem ent parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications on the schem at ics are as shown be low:

Plug the TV power cord into a standard AC outlet.:

231

Voltage

5.0

(3.0)

5.0

Indicates that the voltage

is not consistent here.

Power on mode

Unit: Vo

5. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to area "D3".

2. "1-B1" means that line number "1" goes to area "B1".

6. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

3

AREA D3

2

1

ABCD

AREA B1

1-D3

1-B1

1-9-2 L0604SC

Page 43

Digital 1/5 Schematic Diagram

DIGITAL 1/5

Ref No. Position

IC1301

B-1

IC1401(1/4)

F-3

IC1501

A-1

CN1702 A-4

ICS

CONNECTOR

*1 Note:

1. The order of pins shown are different from that of IC1401 itself.

2. Some pins are not shown because they are not used.

3. IC1401 is shown as IC1401(1/4) through IC1401(4/4) in Digital Schematic Diagram section.

Video Signal

Audio Signal

A4

A3

B4

B3

C4

C3

D4

D3

E4

E3

F4

F3

A2

A1

B2

B1

1-9-3 1-9-4

C2

C1

D2

D1

E2

E1

F2

F1

L0605SCD1

Page 44

Digital 2/5 Schematic Diagram

DIGITAL 2/5

Ref No. Position

IC1101

I-2

IC1502

G-1

IC1503

I-1

IC1504

H-1

IC1505

H-1

IC1506

J-1

IC1507

K-1

Q1101

K-4

Q1102

K-2

Q1701

H-3

Q1702

H-3

Q1703

H-2

Q1704

H-2

Q1705

H-2

Q1706

H-1

CN1701 G-4

ICS

TRANSISTORS

CONNECTOR

Video Signal

G4

G3

H4

H3

I4

I3

J4

J3

K4

K3

L4

L3

G2

G1

H2

H1

1-9-5 1-9-6

I2

I1

J2

J1

K2

K1

L2

L1

L0605SCD2

Page 45

Digital 3/5 Schematic Diagram

DIGITAL 3/5

Ref No. Position

IC1201

N-2

IC1202

Q-3

IC1401(2/4)

M-3

IC1508

M-1

IC1509

N-1

CN1402

R-1

CN1703

R-3

CN1704 R-1

ICS

CONNECTORS

*1 Note:

1. The order of pins shown are different from that of IC1401 itself.

2. Some pins are not shown because they are not used.

3. IC1401 is shown as IC1401(1/4) through IC1401(4/4) in Digital Schematic Diagram section.

Video Signal

M4

M3

N4

N3

O4

O3

P4 Q4 R4

P3

Q3

R3

M2

M1

N2

N1

1-9-7 1-9-8

O2

O1

P2

P1

Q2

Q1

R2

R1

L0605SCD3

Page 46

Digital 4/5 Schematic Diagram

DIGITAL 4/5

Ref No. Position

IC1401(3/4)

T-4

IC1404

S-2

IC1405

V-3

IC1510

S-3

CN1709 X-3

ICS

CONNECTOR

*1 Note:

1. The order of pins shown are different from that of IC1401 itself.

2. Some pins are not shown because they are not used.

3. IC1401 is shown as IC1401(1/4) through IC1401(4/4) in Digital Schematic Diagram section.

Video Signal

S4

S3

T4

T3

U4

U3

V4

V3

W4

W3

X4

X3

S2

S1

1-9-9

T2

T1