Page 1

UTY-TTRX

INSTALLATION MANUAL

THERMOSTAT CONVERTOR

For authorized service personnel only.

MANUEL D’INSTALLATION

CONVERTISSEUR DE THERMOSTAT

Pour le personnel agréé uniquement.

MANUAL DE INSTALACIÓN

CONVERTIDOR DE TERMOSTATO

Únicamente para personal de servicio autorizado.

EnglishEspañol

Français

[Original instructions]

PART NO. 9374707225

Page 2

INSTALLATION MANUAL

PART NO. 9374707225

THERMOSTAT CONVERTOR

Contents

1. SAFETY PRECAUTIONS ……………………………………………… 1

2. MAIN UNIT AND ACCESSORIES …………………………………… 1

3. ELECTRICAL REQUIREMENT ………………………………………… 1

4. SELECTING AN INSTALLATION LOCATION ………………………2

4. 1. Dimensions ………………………………………………………2

4. 2. Specifi cations …………………………………………………… 2

5. WIRING …………………………………………………………………… 2

5. 1. Wiring method …………………………………………………… 3

5. 2. Unit wiring …………………………………………………………4

6. INSTALLING THE THERMOSTAT CONVERTOR ……………………4

6. 1. Connecting the cables …………………………………………… 4

7. CONNECTION OF REMOTE CONTROLLER CABLE ……………… 5

8. CIRCUIT BOARD SETTING ……………………………………………6

9. TURNING ON THE POWER …………………………………………… 7

10. LED DISPLAY …………………………………………………………… 7

10. 1. Normal code ……………………………………………………… 7

10. 2. Error code ………………………………………………………… 7

11. USAGE …………………………………………………………………… 7

1. SAFETY PRECAUTIONS

▪ The “SAFETY PRECAUTIONS” indicated in this manual contain impor-

tant information pertaining to your safety. Be sure to observe them.

▪ Request the user to keep this manual on hand for future use, such as

for relocating or repairing the unit.

This mark indicates procedures which, if improp-

WARNING

Perform electrical work by an authorized service personnel in accordance

with this manual and the electrical wiring regulations or implementation

regulations of the country. Also do not install this product by yourself.

Improper electric work will cause electric shock or a fi re.

Perform installation work in accordance with this manual. Request an

authorized service personnel to perform installation work. Do not install

this product by yourself. Improper installation will cause injury, electric

shock, fi re, etc.

In the event of a malfunction (burning smell, etc.), immediately stop

operation, turn off the electrical breaker, and consult authorized service

personnel.

Do not install the unit in the following areas:

▪ Do not install the unit near a source of heat, steam or fl ammable gas.

▪ Area fi lled with mineral oil or containing a large amount of splashed oil

or steam, such as a kitchen. It will deteriorate plastic parts, causing the

parts to fail or the unit to leak water.

▪ Area that generates substances that adversely affect the equipment,

such as sulfuric gas, chlorine gas, acid or alkali. It will cause the copper

pipes and brazed joints to corrode, which can cause refrigerant leakage.

▪ Area containing equipment that generates electromagnetic interfer-

ence. It will cause the control system to malfunction, preventing the unit

from operating normally.

▪ Area that can cause combustible gas to leak, contains suspended

carbon fi bers or fl ammable dust, or volatile infl ammables such as paint

thinner or gasoline. If gas leaks and settles around the unit, it can

cause a fi re.

▪ Install the unit in a well-ventilated place avoiding rains and direct sun-

light.

Do not operate this product when your hands are wet. Touching the unit

with wet hands will cause an electric shock.

If children may approach the unit, take preventive measures so that they

cannot reach the unit.

erly performed, might lead to the death or serious

injury of the user.

This mark indicates procedures which, if improp-

CAUTION

Pay abundant care when transporting this product because it is a precision device. Improper transportation will cause trouble.

Do not touch the switches with sharp objects. Doing so will cause injury,

trouble, or electric shock.

Do not expose this product directly to water. Doing so will cause trouble,

electric shock, or heating.

Do not set vessels containing a liquid on this product. Doing so will cause

heating, fi re, or electric shock.

Dispose of the packing materials safely. Tear and dispose of the plastic

packing bags so that children cannot play with them. There is the danger

of suffocation if children play with the original plastic bags.

NOTES:

This product is manufactured to metric units and tolerances.

United States customary units are provided for reference only. In cases

where exact dimensions and tolerances are required, always refer to

metric units.

erly performed, might possibly result in personal

harm to the user or damage to property.

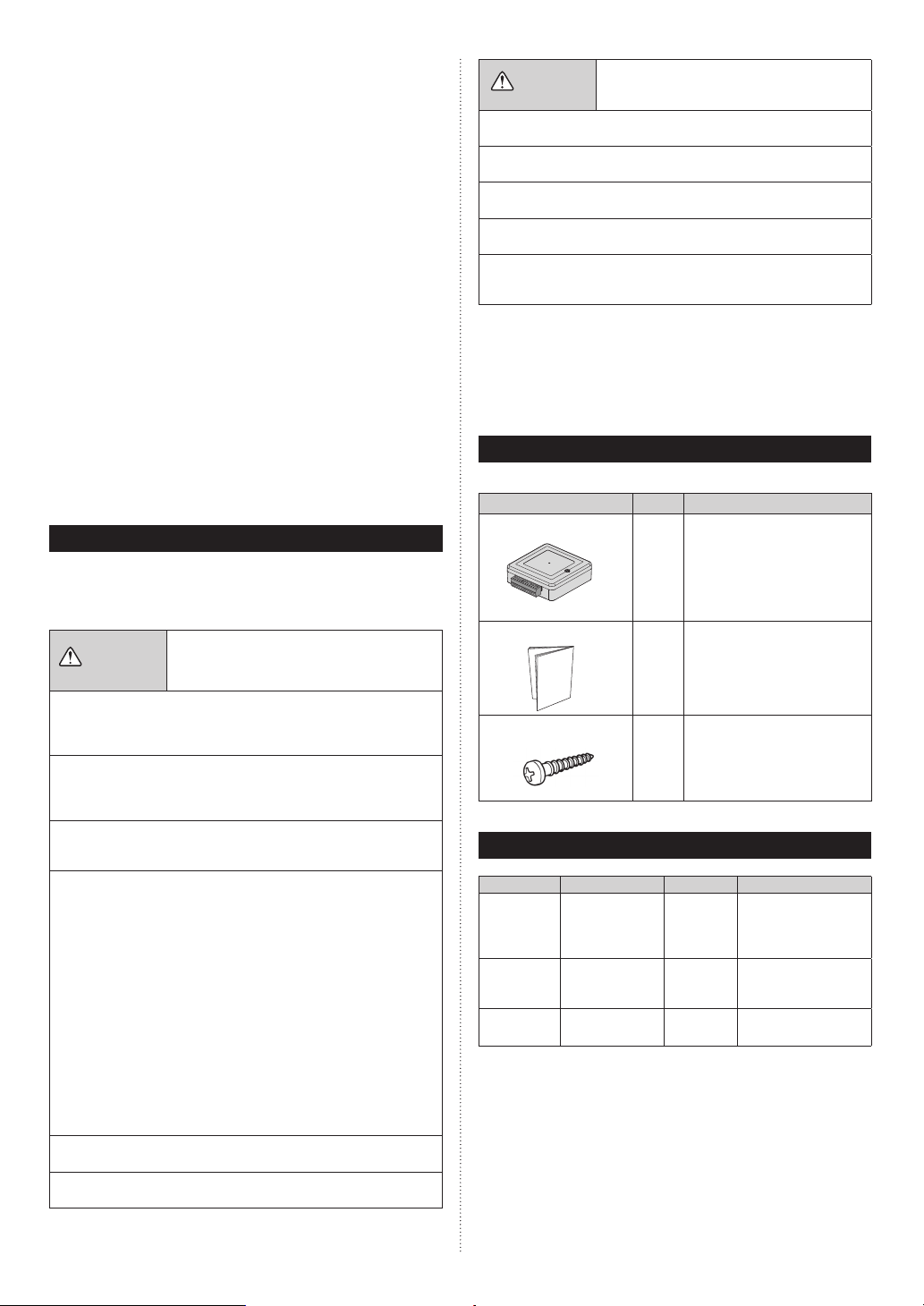

2. MAIN UNIT AND ACCESSORIES

The following installation parts are supplied. Use them as required.

Name and Shape Q’ty Application

Thermostat convertor

Installation manual

Screw (M4 x 16 mm)

This product

1

This manual

1

For mounting this product

2

3. ELECTRICAL REQUIREMENT

Use Size Cable type Remarks

Remote controller cable

(2-wire type)

Remote controller cable

(3-wire type)

Thermostat

wires

*: Use shielded cable in accordance with local rules for remote controller

cable.

16~22AWG

(0.33 to 1.25 mm

22AWG

2

(0.33 mm

18AWG

2

(0.82 mm

2

)

)

)

Sheathed

PVC cable*

Sheathed

PVC cable*

Sheathed

PVC cable*

Non-polar 2 core,

twisted pair

Maximum cable length:

1,640 ft (500m)

Polar 3core

Maximum cable

length: 82 ft (25m)

Maximum cable

length: 164 ft (50m)

En-1

Page 3

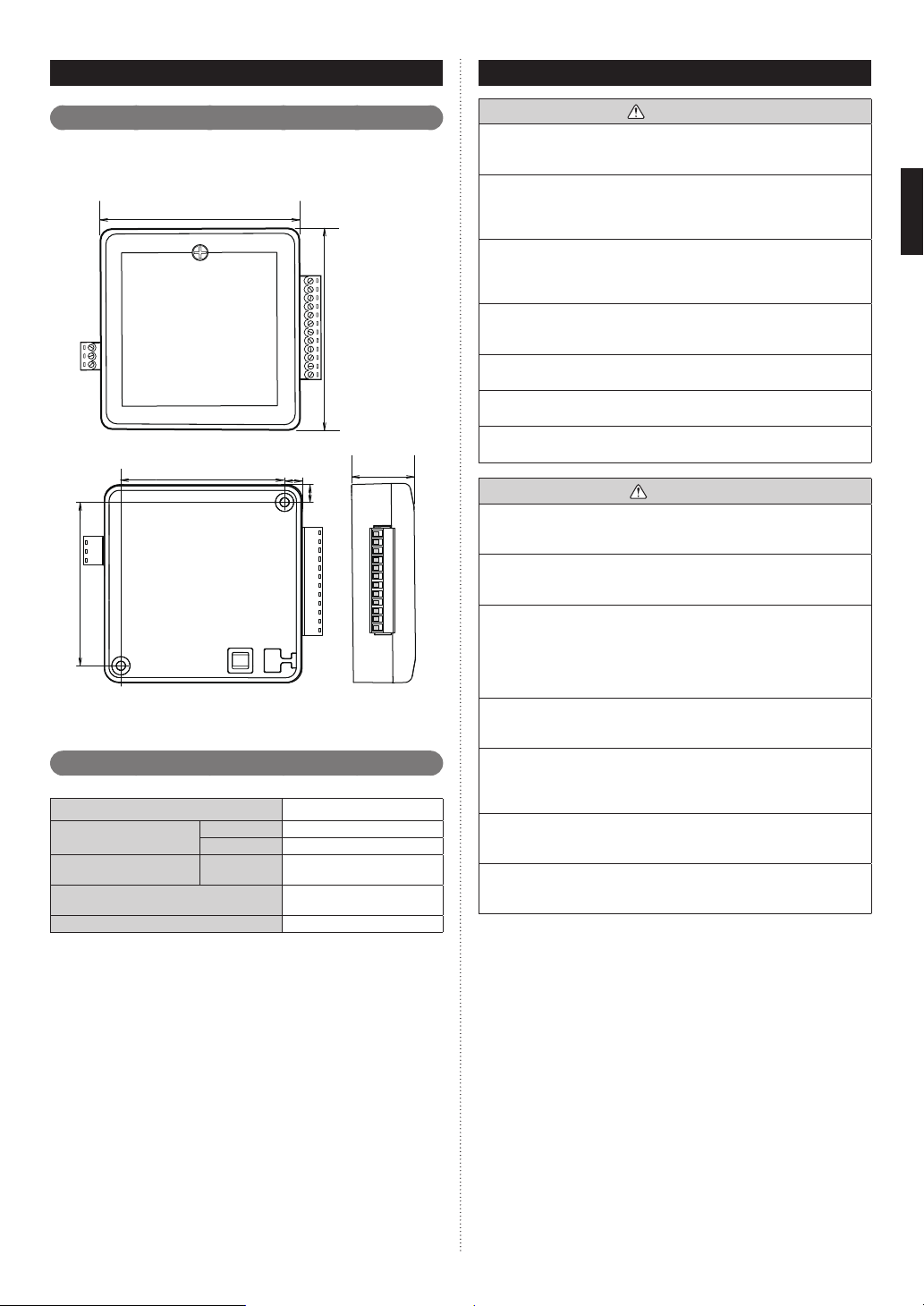

4.

SELECTING AN INSTALLATION LOCATION

Dimensions

4. 1.

This product is comprised of a body and cover.

3-7/16 (86.7)

2-7/8 (72.7)

Set the bottom side to a fl at place.

Specifi cations

4. 2.

Power consumption (W)

Temperature °F (°C)

Humidity (%) Packaged

Dimensions

H x W x D in (mm)

Weight oz. (g)

Upper side

2-7/8 (72.7)

Bottom side

Operating

Packaged

1/4 (7)

1/4

(7)

0.6

32–114 (0–46)

14–140 (-10–60)

0–95 (RH);

No condensation

1-1/16 × 3-7/16 × 3-7/16

(27 × 86.7 × 86.7)

4 (100)

Unit :in (mm)

3-7/16 (86.7)

1-1/16

(27)

5. WIRING

WARNING

Before starting installation work, turn off the power of this product and

the connection destination. Do not turn on the power again until installation is completed. Otherwise, it will cause electric shock or fi re.

Use the accessories or specifi ed connection cable. Do not modify power

supply cable and connection cables other than those specifi ed, do not

use extension cables, and do not use independent branch wiring. It may

cause electric shock or fi re.

Install the connection cables securely to the terminal block. Confi rm that

external force of the cable is not applied to the terminal block. Use the

specifi ed cables. If intermediate connection or insertion fi xing are imper-

fect, it will cause electric shock, fi re, etc.

When connecting the connection cable, route the cables so that the

cover of this product is securely fi xed. If the cover is imperfectly fi xed, it

may cause fi re or overheating of the terminals.

Perform earth (ground) work positively. Do not connect the earth (ground)

cable to a telephone cable, water pipe, or conductor rod.

Perform all wiring works so that the user does not touch the wiring.

Otherwise it will cause injury or electric shock.

If any cable is damaged, do not repair or modify it yourself. Improper

work will cause electric shock or fi re.

CAUTION

Do not bind the remote controller cable and the external input cable

together with or parallel to the power supply cable of the indoor and

outdoor units. It may cause erroneous operation.

When performing wiring work, be careful not to damage the cable or

injure yourself. Also, connect the connectors securely. Loose connectors

will cause trouble, heating, fi re, or electric shock.

Install the indoor unit, outdoor unit, power supply cable, transmission

cable and remote control cable at least 40 in (1 m) away from a television

or radio.

The purpose of this is to prevent TV reception interference or radio noise.

(Even if they are installed more than 40 in (1 m) apart, you could still

receive noise under some signal conditions.)

Perform wiring so that water does not enter this product along the external wiring. Always install a trap to the wiring or take other countermeasures. Otherwise it will cause trouble or electric shock or fi re.

Confi rm the name of each unit and name of each terminal block of the

unit and connect the wiring in accordance with the directions given in the

manual so that there is no incorrect wiring. Incorrect wiring will damage

the electric parts and cause smoke and fi re.

When installing the connection cables near a source of electromagnetic

waves, use shielded cable.

Otherwise, a breakdown or malfunction could result.

The terminal screws and earth (ground) screws have different shapes.

Be sure to install the screws in the correct locations. If the screws are

installed in the wrong locations, the circuit board could be damaged.

En-2

Page 4

5. 1.

Wiring method

Indoor unit

(VRF/single/multi)

Remote controller cable

Max. 16 units

Case 2: Single-stage Cooling and Heating

(Example:Remote controller for 2-wire type)

Thermostat

controller

This product

Thermostat

Controller

The connection example of thermostat convertor and thermostat controller is

shown below.

The connection method is different depending on the type of thermostat controller. Connect them according to the following Cases.

For remote controller cable, 2 kinds of type, which are 2-wire type and 3-wire

type are available depending on the device to be connected.

(1) All wiring shown should be performed with 18 AWG thermostat wire.

(2) Terminals to thermostat controller on this product support 20-30VAC.

(3) High/medium/low fan signals are optional, and may not be available on

all thermostat models.

(4) W2 and Y2 signals are optional, and may be omitted for single-stage

thermostats. In addition, if Y2 and W2 are used, turn ON the DIP switches

SET3-1.

Thermostat

Case 1: Two-stage Cooling and Heating

(Example:Remote controller for 3-wire type)

Thermostat

24 VAC

controller

cable

Indoor unit

Max.

16 units

24 VAC

24 VAC

Transformer*

208/230 VAC

Thermostat convertor

(Locally purchased)

Indoor unit

Max.

16 units

Case 3: Single-stage Cooling and Heating with Dedicated Fan

Speed Relays(Example:Remote controller for 2-wire

type)

Thermostat

controller

Thermostat convertor

24 VAC

Transformer*

208/230 VAC

* Install the transformer, as necessary, per building code and manufacturer’s

installation instructions. Maximum Power: 5.0VA

(Locally purchased)

24 VAC

24 VAC

Transformer*

208/230 VAC

Fan

(Locally purchased)

Thermostat convertor

Indoor unit

Max.

16 units

En-3

Page 5

The names of terminal connected to thermostat have the following meanings.

TC Common (In) from transformer

C Common to thermostat controller

TR Power supply from transformer

R Power supply to thermostat controller

G3 Airfl ow High

G2 Airfl ow Medium

G1 Airfl ow Low

Y2 Cooling Stage 2

Y1 Cooling Stage 1

W2 Heating Stage 2

W1 Heating Stage 1

G Fan

NOTES:

Up to 16 indoor units may be controlled with a single

・

ler, Multiple indoor units connected to convertor operate by the same

operating setting.

Two or more types of VRF1 system, VRF2 system, single model or

・

multi systems cannot be mixed together.

Unit wiring

5. 2.

thermostat

control-

5. 2. 1 Thermostat cable and Remote controller cable

Thermostat cable

1-5/16 in

(33 mm)

1/4 in

(7 mm)

Remote controller cable

9/16 in

For 2-wire type

For 3-wire type

1/4 in

(7 mm)

1/4 in

(7 mm)

(15 mm)

No polarity

9/16 in

(15 mm)

Y2:White

Y3:Black

Y1:Re d

6.

INSTALLING THE THERMOSTAT CONVERTOR

WARNING

Always use the accessories and specifi ed installation work parts. Check

the state of the installation parts. Not using the specifi ed parts will cause

units to fall off, electric shock, fi re, etc.

Install at a place that can withstand the weight of the unit and install

positively so that the unit will not topple or fall.

When installing this product, make sure that there are no children

nearby.

Otherwise, injury or electric shock could result.

CAUTION

Do not set the DIP switch of this product except as specifi ed in this instal-

lation manual or the instruction manual supplied with the air conditioner.

Setting the switches other than specifi ed will cause an accident or

trouble.

Use an insulated screwdriver to set the DIP switches.

Before opening the cover of this product, completely discharge static

electricity charged on your body. Otherwise, failure or malfunction could

result.

Do not touch the circuit board and circuit board parts directly with your

hands.

Otherwise, injury or electric shock could result.

Tightening the mounting screws too tight will damage the body of this

product.

• When using the indoor unit without Fan mode, do not

connect G (Fan), G1, G2, and G3 signals. Otherwise air

conditioner might operate incorrectly.

• If the air conditioner system is a heat pump type, please

select “ Priority on Administrative Indoor Unit” in the setting

of priority mode by PUSH SWITCH of outdoor unit (refer to

installation manual of outdoor unit). Furthermore, please

complete “Administrative Indoor Unit Setting” for indoor unit

which is connected to this Thermostat Convertor by using

the wired remote controller (refer to installation manual of

remote controller.)

NOTES:

When this product is used, do not use the remote controller because

indoor unit is controlled centrally by thermostat controller.

However, the remote controller connecting is temporarily required for the

initial setting. During the initial setting by remote controller do not connect Thermostat Convertor to indoor unit.

After when all initial setting is completed, disconnect the wired remote

controller. Then connect Thermostat Converter to indoor unit at fi rst time.

WARNING

Tighten the terminal screws to the specifi ed torques, otherwise,

abnormal overheating may be occurred and possibly cause heavy

damage inside the unit.

Tightening torque

M2 screw

Remote controller / Y1, Y2, Y3

Thermostat input /

Y1, Y2, G1, G2, G3, R, TR, C, TC

To peel the sheath from the cables, use a dedicated tool that will not

damage the conductor of the cable.

When installing a screw on the terminal block, do not cut the cable

by overtightening the screw. On the other hand, a loosen screw can

cause faulty contact, which will lead to a communication failure.

G, W1, W2,

CAUTION

1.9 to 2.2 lbf·in

(0.22 to 0.25 N·m)

(2.2 to 2.5 kgf·cm)

Connecting the cables

6. 1.

(1) For thermostat cable, use the single wire of 18AWG thermostat wire.

(2) Power-supply voltage of thermostat (TC, TR) is 20 to 30VAC.

(3) Insert the cable to the connected terminal and fi x with screw using

screw driver.

(4) For remote controller cable, 2 kinds of 2 kinds of type, which are

2-wire type and 3-wire type are available depending on the device to

be connected.

(5) The number of connected thermostat cable is different the type of

thermostat controller.

(6) For details of connection method, refer to Case 1 to Case 3 of “5.

Wiring”.

En-4

Page 6

7.

CONNECTION OF REMOTE CONTROLLER CABLE

CAUTION

When connecting the remote controller cable to the indoor unit, do not

connect it to the outdoor unit or the power terminal block. It may cause a

failure.

When connecting Indoor unit and

thermostat convertor with the Remote

controller cable, the following items

should be considered.

Remote controller cable

This product

There are 2 methods to connect the remote controller cable to the indoor

unit. One is the connection using connecting cable contained by indoor

unit, and the other is the connection the remote controller cable is connected to the exclusive terminal block of the indoor unit.

Exclusive terminal block for remote controller connection method is different depending on each model. Modify the remote controller cable as per

below description and connect it.

(For the details, refer to the installation manual of the indoor unit to be

used.)

(1)

When connecting to the connector

Indoor unit

Red

White

Black

Case 1: For non-polar 2-wire

Use a tool to cut off the terminal on the end of the remote controller cable,

and then remove the insulation from the cut end of the cable as shown

in Fig. 1. Connect the remote controller cable and connecting cable as

shown in Fig. 2. Be sure to insulate between the cables.

Fig.1 Fig.2

13/16 in

(20 mm)

Remote controller

cable (Non-polar)

Insulated

connection

White

Red

Connecting cable

(The number of terminal

is different depending

Black

on the model.)

Cut and

insulate

Case 2: For polar 3-wire

Modify the cable as per below methods.

Use a tool to cut off the terminal on the end of the remote controller

cable, and then remove the insulation from the cut end of the cable as

shown in Fig. 1.

Connect the remote controller cable and connecting cable as shown in

Fig. 2.

Be sure to insulate between the cables.

Fig. 1 Fig. 2

13/16 in

(20 mm)

Remote

controller cable

Insert it to the connector.

Connecting cable

Remote controller cable

When the board has the 2WIRE/3WIRE DIP switch on it, set it to

3WIRE.

For how to set, see “Case 1: For non-polar 2-wire”.

(2)

When connecting to the exclusive terminal block

Connect the end of remote controller cable directly to the exclusive

terminal block.

If there is the 2WIRE/3WIRE switch on the PC board of the indoor unit,

set it to match the connection method of the connected remote controller cable.

Example) Connection of non-polar 2-wire

Functional earthing

(If necessary)

Remote controller

cable

* Layout of terminal block and

Terminal block

PC board is varies, depending

on the type of indoor unit.

Red

White

Red

White

Insulated connection

Black

Connector

Set to “2WIRE” the

DIP switch (SW1)

Connector

Black

Indoor unit

PCB

PCB

Terminal block

to outdoor unit /

power supply

Connecting

cable

Indoor unit

PC board

Insert it to the connector. Set to “2WIRE” the DIP switch (SW1) on the

PC board of the indoor unit.

Set to “2WIRE” the

DIP switch (SW1)

Connect to earth

(ground) screw

Remote controller

cable (Non-polar)

* Layout of Connector and PC

board is varies, depending on

the type of indoor unit.

Functional earthing

(If necessary)

Connecting cable

Connector

(adapter)

Indoor unit

PC board

Connector CNC01

(onboard)

SW1

Indoor unit

PC board

En-5

Page 7

8. CIRCUIT BOARD SETTING

Remove the cover of main unit by the following procedure to perform the

initial setting.

Tightening torque

M3 screw

When the cover is removed, the circuit board appears.

The circuit board has DIP switches and LEDs as shown below.

4.4 to 5.3 lbf·in

(0.5 to 0.6 N·m)

(5 to 6 kgf·cm)

Heating setting temperature

SW

SET3-3

OFF

OFF ON 81 (27) Pattern2

ON OFF 75 (24) Pattern3

ON ON 70 (21) Pattern4

SW

SET3-4

OFF

Heating Stage 1 setting

temperature

°F (°C)

86 (30) Pattern1

(: Factory setting)

(3)-2 Two-stage setting

Cooling setting temperature

Cooling Stage 1 setting

SW

SET3-2

OFF

ON 72 (22) 68 (20) Pattern2

temperature

°F (°C)

68 (20) 64 (18) Pattern1

Cooling Stage 2 setting

temperature

°F (°C)

(: Factory setting)

Heating setting temperature

Heating Stage 1

SW

SET3-3

OFF

OFF ON 77 (25) 82 (28) Pattern2

ON OFF 75 (23) 79 (26) Pattern3

ON ON 70 (21) 75 (24) Pattern4

SW

SET3-4

OFF

setting

temperature

°F (°C)

81 (27) 86 (30) Pattern1

NOTES:

These are the limit temperature for cooling and heating.

Energy saving performance is improved in the order from Cooling Pattern 1 to 2 and Heating Pattern 1 to 4.

Heating Stage 2

setting

temperature

°F (°C)

(: Factory setting)

Remarks

Remarks

Remarks

(4) Delay off setting

Perform the initial setting using 3 DIP switches (SET 1 to 3)

on the circuit board.

Delay OFF:

Delay OFF is the function to operate continuously after reaching to the

setting temperature of thermostat.

This function may make the air conditioning effi cient.

(1) 2WIRE/3WIRE setting (SET1)

Remote controller 2WIRE/3WIRE switching SW

“Factory setting : 2WIRE”

Set the Delay OFF time by SW SET 2-3 and SW SET 2-4.

(5) Fan setting (G signal)

Set matched with the connection method of the remote controller cable to be connected.

(2) Single-stage or Two-stage setting

SW

SET3-1

OFF

ON Temperature setting: Two-stage

Temperature setting: Single-stage

Contents

(: Factory setting)

(3) Temperature setting

(3)-1 Single-stage setting

Cooling setting temperature

SW

SET3-2

OFF

ON 68 (20) Pattern2

Cooling Stage 1 setting

temperature

°F (°C)

64 (18) Pattern1

Remarks

(: Factory setting)

SW

SET2-3

OFF

OFF ON 5 minutes

ON OFF 10 minutes

ON ON 20 minutes

SW

SET2-1

OFF

OFF ON High

ON OFF Med.

ON ON Low

SW

SET2-4

OFF

SW

SET2-2

OFF

Delay off time

0 minutes

Indoor unit airfl ow

Auto

(: Factory setting)

(: Factory setting)

En-6

Page 8

9. TURNING ON THE POWER

(1) Check this product wiring and switch settings on the circuit board.

(2) Check the wiring and switch settings for the VRF system or multi

system or single model. For the wiring and switch settings method,

refer to the installation instruction sheet of each unit.

(3) Turn on the power for the VRF system etc.

(4) Power will be supplied from the indoor unit to this product.

▪ This product will be initialized and the power turned on.

LED1 (green) and LED2 (orange) will fl ashing.

▪ After initial setting is completed, operation will be restarted auto-

matically.

LED1 (green) lights.

▪ This product does not operate during initialization.

* An error code will appear on LED in the event of a malfunction.

10. LED DISPLAY

Normal code

10. 1.

Normal indications

LE

D1

LE

D2

(green)

(orange)

Display mode : On

: Off

: 1s ON / 1s OFF

LED3

(red)

LE

(blue)

Normal contents

D4

During initialization (during

initialization sequence)

Normally operating

11. USAGE

• For the usage and installation of thermostat controller,

refer to the operating manual and installation manual of

thermostat controller.

Error code

10. 2.

Error indications

LE

D1

LE

D2

(orange)

(n) (n) Thermostat convertor error

(n) (n) Indoor unit error

(red)

(green)

LED3

LE

D4

(blue)

Error contents

Display mode : On

: Off

: 0.5s ON / 0.5s OFF

: 0.1s ON / 0.1s OFF

( ) : Number of flashing

En-7

Page 9

Loading...

Loading...