Page 1

Multi Air Conditioning System

for Buildings

VRF (FREELY SELECTABLE MULTI TYPE SYSTEM)

SERVICE MANUAL

CONFIDENTIAL

Page 2

Multi Air Conditioning System

for Buildings

VRF (FREELY SELECTABLE MULTI TYPE SYSTEM)

SERVICE MANUAL

– 2 –

Page 3

CONTENTS

1. OUTLINE OF SYSTEM

1-1

MODEL CONSTRUCTION

1-2

SYSTEM CONSTRUCTION CONDITIONS

1-2-1

1-2-2

1-3

(1)

(2)

REFRIGERANT PIPING

SYSTEM WIRING

ADDRESS SETTING

KINDS OF ADDRESS AND SETTING RANGE

EXAMPLES OF SYSTEM SETTING

................................................................................................

................................................................................................

2. TEST RUN ADJUSTMENT

CHECK ITEMS BEFORE TEST RUN

2-1

2-2

2-2-2

OUTDOOR PC BOARD2-2-1

TEST OPERATION USING REMOTE CONTROLLER

TEST RUN CONTROL2-3

................................................................................................TEST RUN METHOD

3. REFRIGERANT PIPE SYSTEM DIAGRAM

COOLING ONLY / HEAT PUMP TYPE3-1

3-2

4. FUNCTION OF PRINTED CIRCUIT BOARD

PCB LAYOUTS4-1

MICROPROCESSOR BLOCK DIAGRAM4-2

MICROPROCESSOR FUNCTION LIST4-3

FUNCTION AND SETTING OF EACH SWITCH4-4

INDOOR UNIT

OUTDOOR UNIT

REMOTE CONTROLLER

..........................................................................................................

..........................................................................................................

.......................................................................................................

5. OUTDOOR UNIT OPERATION CONTROL

5-1

COMPRESSOR OPERATION CONTROL

5-1-1

5-1-2

5-1-3

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

OPERATION STOP CONDITION

COMPRESSOR OUTPUT PATTERN

3 MINUTES RESTART PREVENTION ( 3 MIN ST )

HEAT EXCHANGER CAPACITY CONTROL

OUTDOOR FAN MOTOR CONTROL

EXPANSION VALVE 1/2 CONTROL

FOUR-WAY VALVE 1 CONTROL

CIRCULATING SAVE AMOUNT CONTROL

SOLENOID VALVE 2 CONTROL

FOUR-WAY VALVE 5 CONTROL

DEFROSTING CONTROL

OIL RETURN CONTROL

OIL RECOVERY CONTROL

PROTECTION FUNCTION

PUMP DOWN CONTROL

......................................................................................

......................................................................................

......................................................................

....................................................................

......................................................................................

...........................................................................................

....................................................................

.........................................................................................HEAT RECOVERY TYPE

.................................................................

....................................................................

........................................................................................ 36

......................................................................

.................................................................

......................................................................

.........................................................................

...........................................................................

..............................................................................

...........................................................................

........................................................................................

......................................................................................

.................................................................................

...................................................................................

......................................................................................

– 3 –

.............................................................

.......................................................

.......................................

.......................................................

...............................................................

..........................................

.......................................................5-1-4 COMPRESSOR RECOVERY OPERATION

............................................................

............................................................

12

13

13

15

19

20

20

20

22

23

24

25

26

28

30

30

34

43

43

43

43

44

45

46

48

49

5

51

52

53

54

55

56

57

5

7

7

0

Page 4

6. INDOOR UNIT OPERATION

6-1 TIMER CONTROL

6-2 FAN CONTROL

6-2-1

6-3

6-3-3

6-3-4

6-3-5

6-5

6-6

6-7

"AUTO" POSITION .............................................................................................

"LOW" "MED" AND "HIGH" POSITION6-2-2

MASTER CONTROL

OPERATION MODE CONTROL ...........................................................................

"COOL" POSITION

"HEAT" POSITION

"FAN" POSITION

LOUVER CONTROL6-4

ELECTRONIC EXPANSION VALVE CONTROL

AUTO RESTART

DRAIN PUMP OPERATION

..................................................................................................... 59

..........................................................................................................

..................................................................................................

..............................................................................................."AUTO" POSITION6-3-2

...............................................................................................

...............................................................................................

.................................................................................................

.................................................................................................

......................................................................................................

....................................................................................

7. WIRING DIAGRAM

INDOOR UNIT

OUTDOOR UNIT

............................................................................................................

.........................................................................................................

8. TROUBLESHOOTING

8-1

INDOOR UNIT

8-1-1

8-1-2

8-2-1 NORMAL OPERATING DISPLAY

8-4

8-5-1 CHARACTERISTICS OF THERMISTOR

8-5-3 ELECTRIC EXPANSION VALVE

NORMAL OPERATION DISPLAY

ABNORMAL OPERATION DISPLAY

OUTDOOR UNIT8-2

ABNORMAL OPERATION DISPLAY8-2-2

REMOTE CONTROL UNIT8-3

ERROR CODE & TROUBLESHOOTING

INDOOR UNIT TROUBLESHOOTING 91...................................................................

OUTDOOR UNIT TROUBLESHOOTING 96................................................................

CENTRAL REMOTE CONTROLLER TROUBLESHOOTING .................................

OTHERS8-5

PRESSURE SENSOR8-5-2

RB UNIT (HEAT RECOVERY TYPE ONLY)8-5-4

OTHERS8-5-5

............................................................................................................

.......................................................................................................

.......................................................................................

...................................................................................................................

.........................................................................................

..............................................................................................................

.................................................................

........................................................................

....................................................................

........................................................................

...................................................................

................................................................

.......................................................TROUBLESHOOTING (NO ERROR CODE)8-4-1

..............................................................

........................................................................

........................................................

1

64

64

64

65

656-3-1

65

69

69

70

71

74......................................................

74

74

75

83

84

84

85

88

88

89

90

91

091

141

24

241

261

261

261

261

9. IN USE OF THE NEW REFRIGERANT R407C

10. DISASSEMBLY ILLUSTRATION

11. PARTS LIST

................................................................................................................

..........................................................................

– 4 –

...................................................

291

341

731

Page 5

1. OUTLINE OF SYSTEM

1-1 MODEL CONSTRUCTION

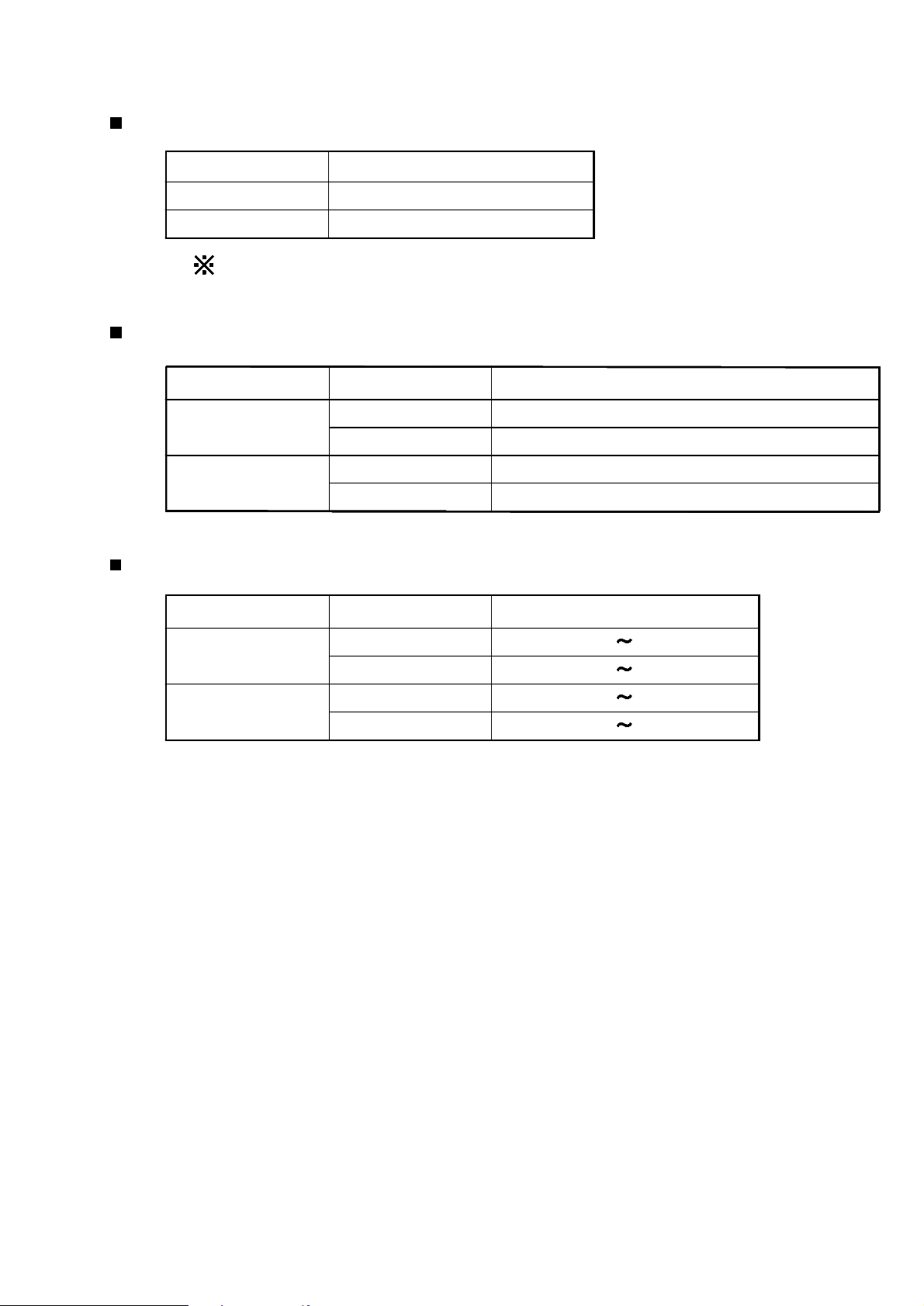

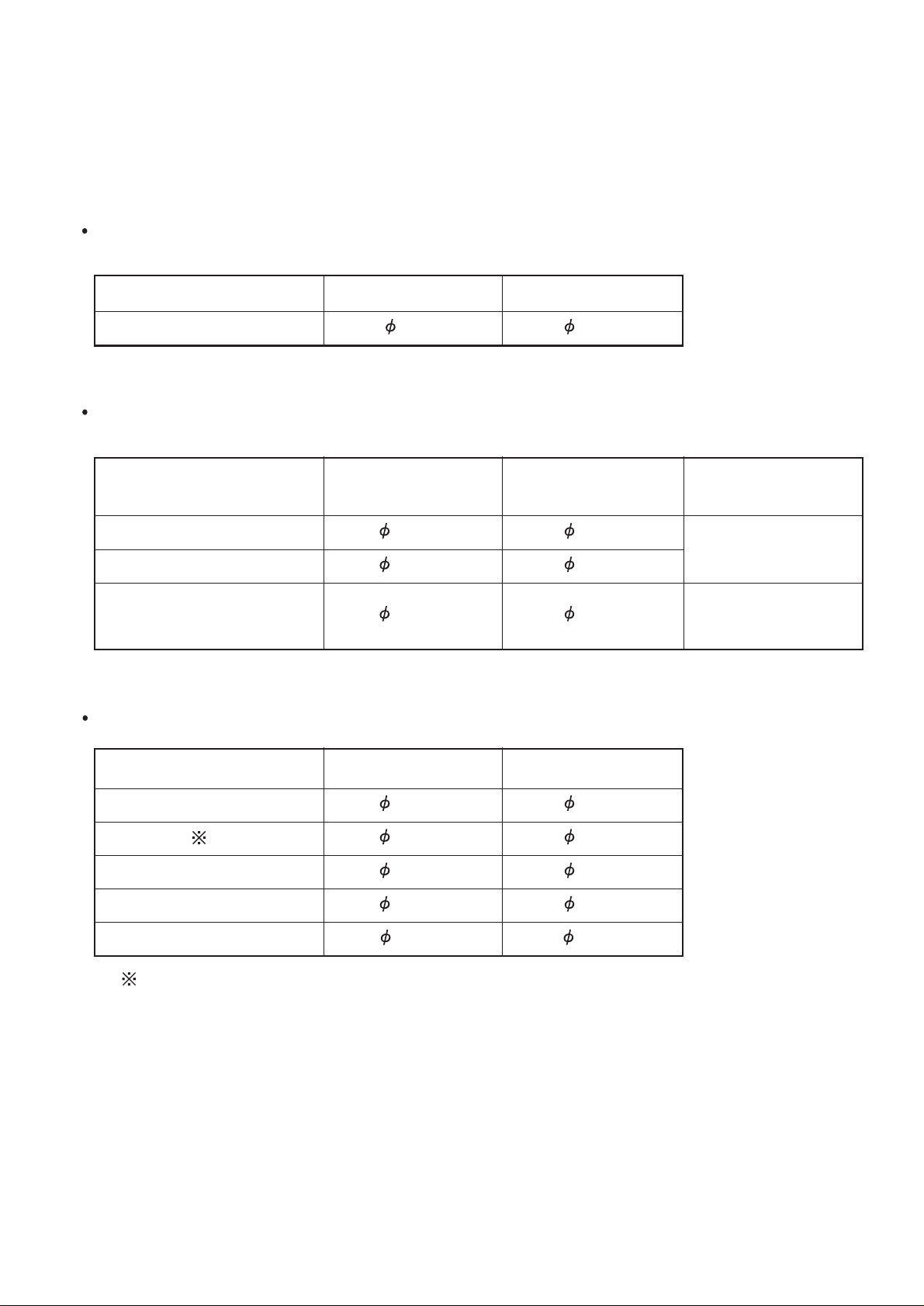

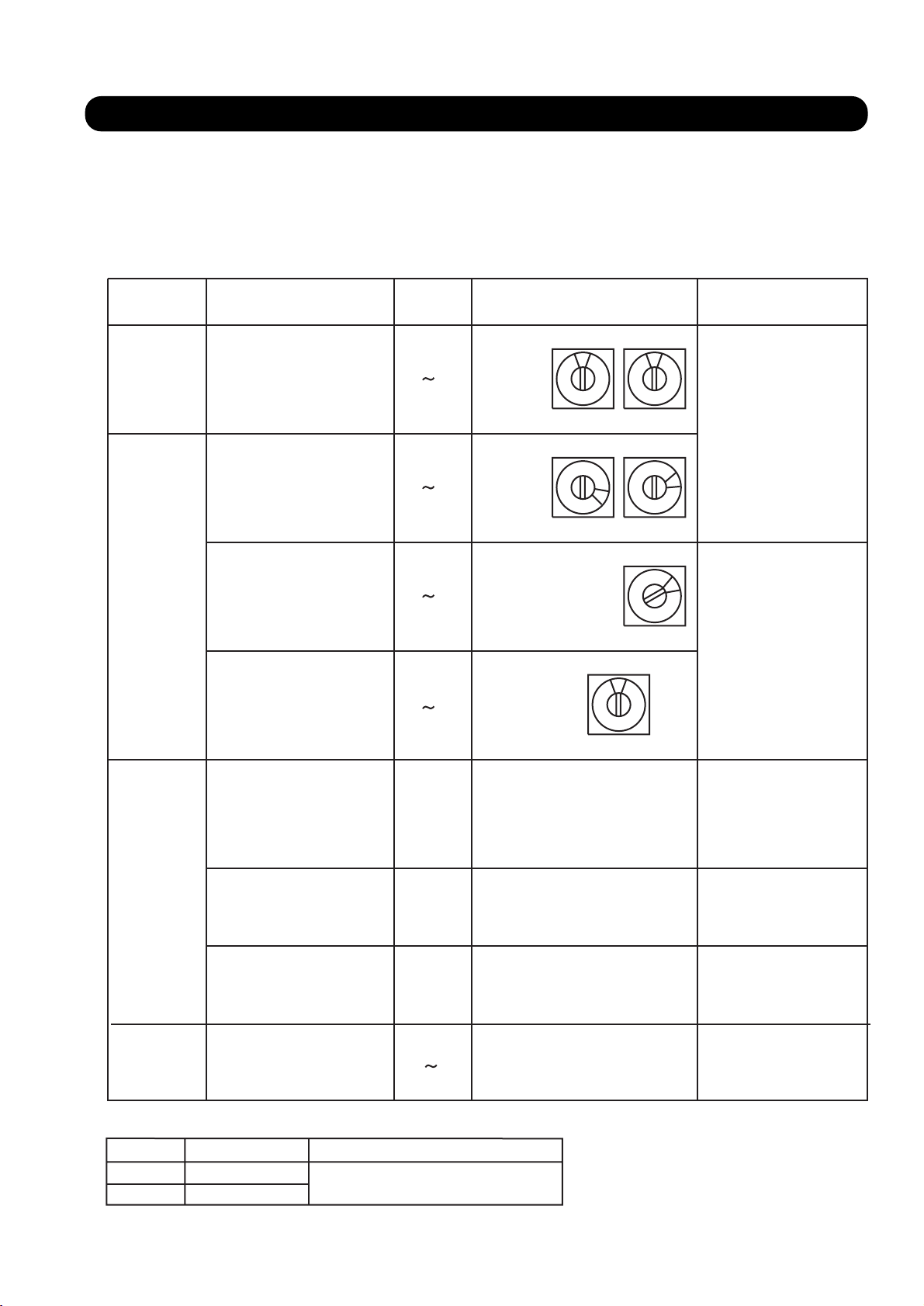

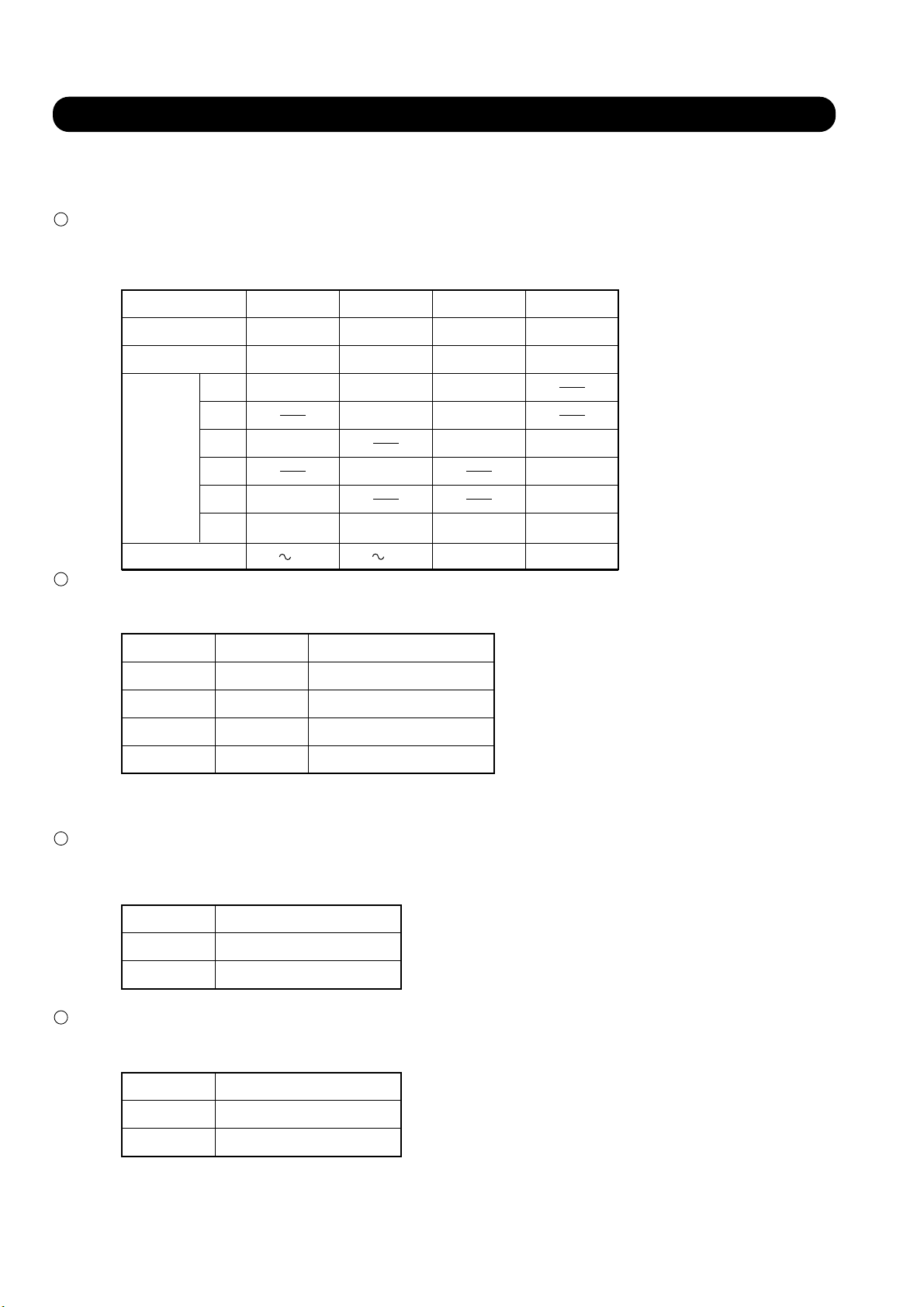

■ OUTDOOR UNITS

TYPE

COOLING ONLY

HEAT PUMP

HEAT RECOVERY

POWER SOURCE

3 PHASE 4 LINE

380 415V 50Hz

380 415V 50Hz

380 415V 50Hz

CAPACITY RANGE

28.0 kW

28.0 kW

28.0 kW

Compact size

1,380

1,300

Serial installation possible

650

■ INDOOR UNITS

10 types, 39 models ranging from 2.15kW to

17.0kW.

Type

Capacity

kw Model code

14.1

(17.0)

12.7

10.5

8.8

6.8

(7.05)

5.3

(5.7)

4.05

3.6

2.8

2.15

54

(60)

45

36

30

24

(25)

18

(20)

14

12

Ceiling/

Floor

9

7

Ceiling

(High Static

Pressure)

Cassette

(compact)

: 2002

CassetteDuctDuctDuct Duct

Wall

mounted

Wall

mounted

– 5 –

Page 6

UTR-BP54A Less than 60

UTR-BP90A More than 61 or more

UTR-BP54R Less than 60

UTR-BP90R More than 61 or more

Model Max. connectable indoor units

UTF-Y90A4A 4

UTF-Y54A1A 1

Type Model Total model code of connectable indoor unit

Heat pump

Heat recovery

UTR-HD906A 3 6

UTR-HD908A 7 8

UTR-HD906R 3 6

UTR-HD908R 7 8

Type Model

Connectable indoor units

Cooling only

Heat pump

Heat recovery

RB (REFRIGERANT BRANCH) UNIT

SEPARATION TUBE

Above units are required during heat recovery operation.

HEADER

Cooling only

– 6 –

Page 7

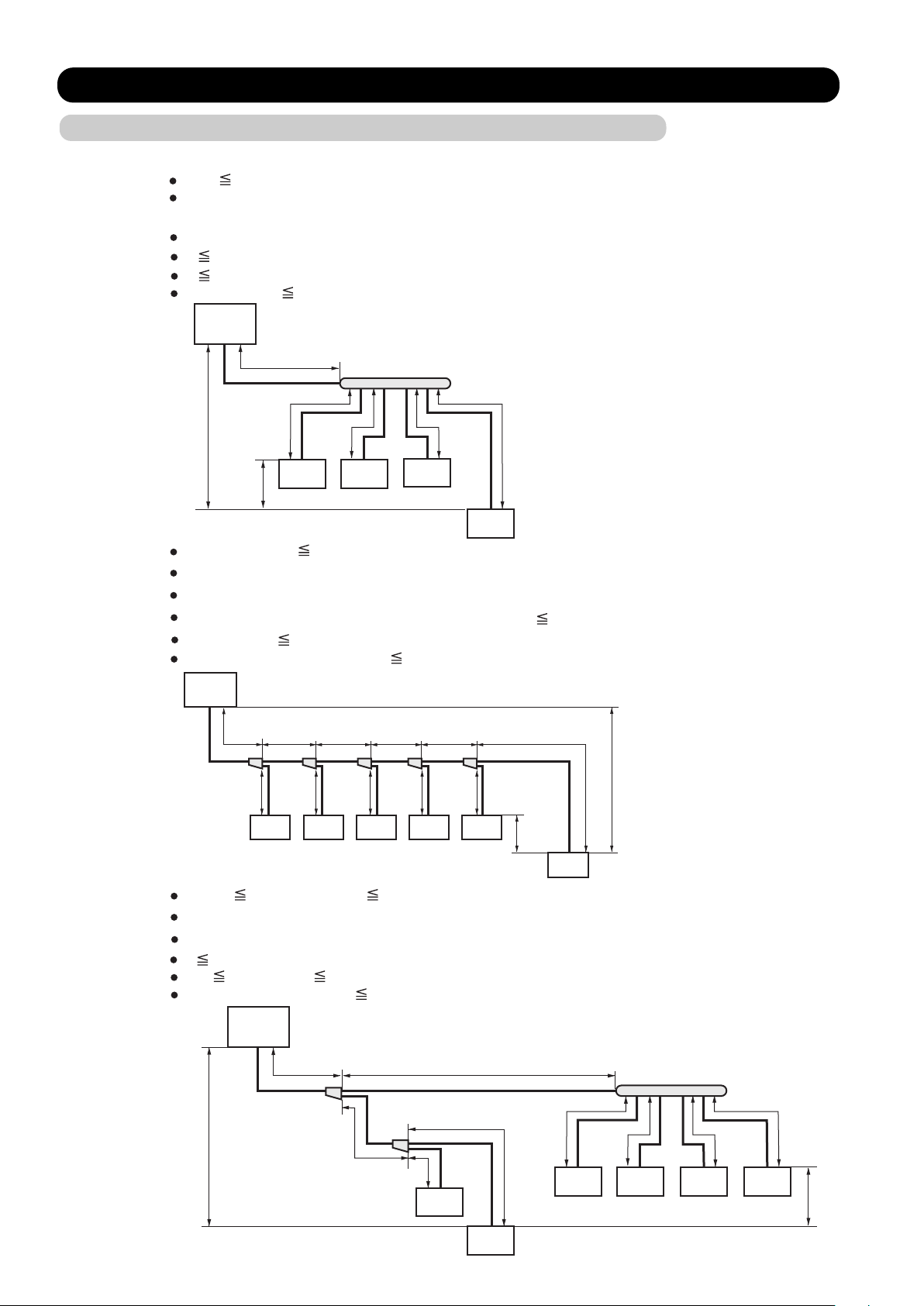

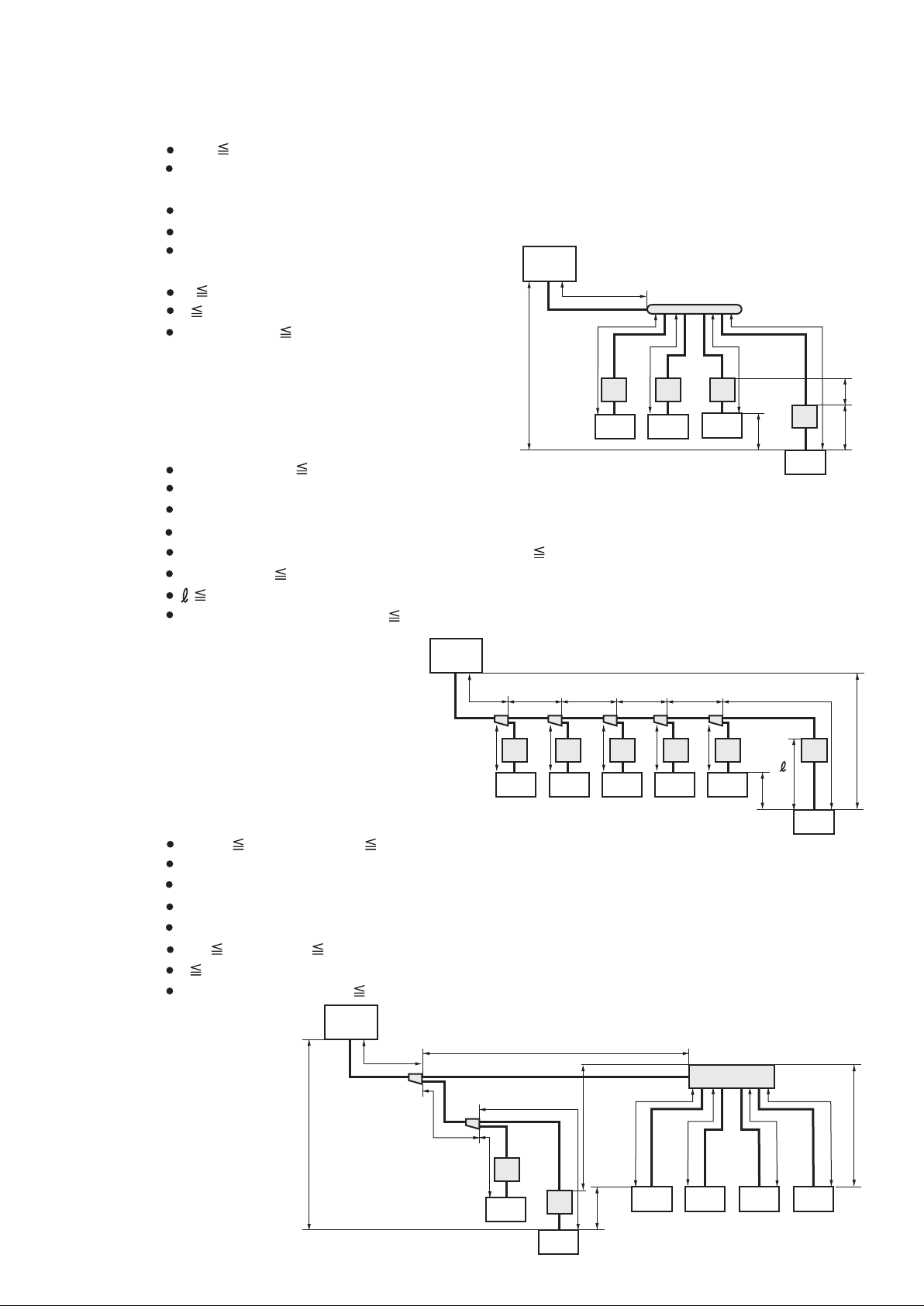

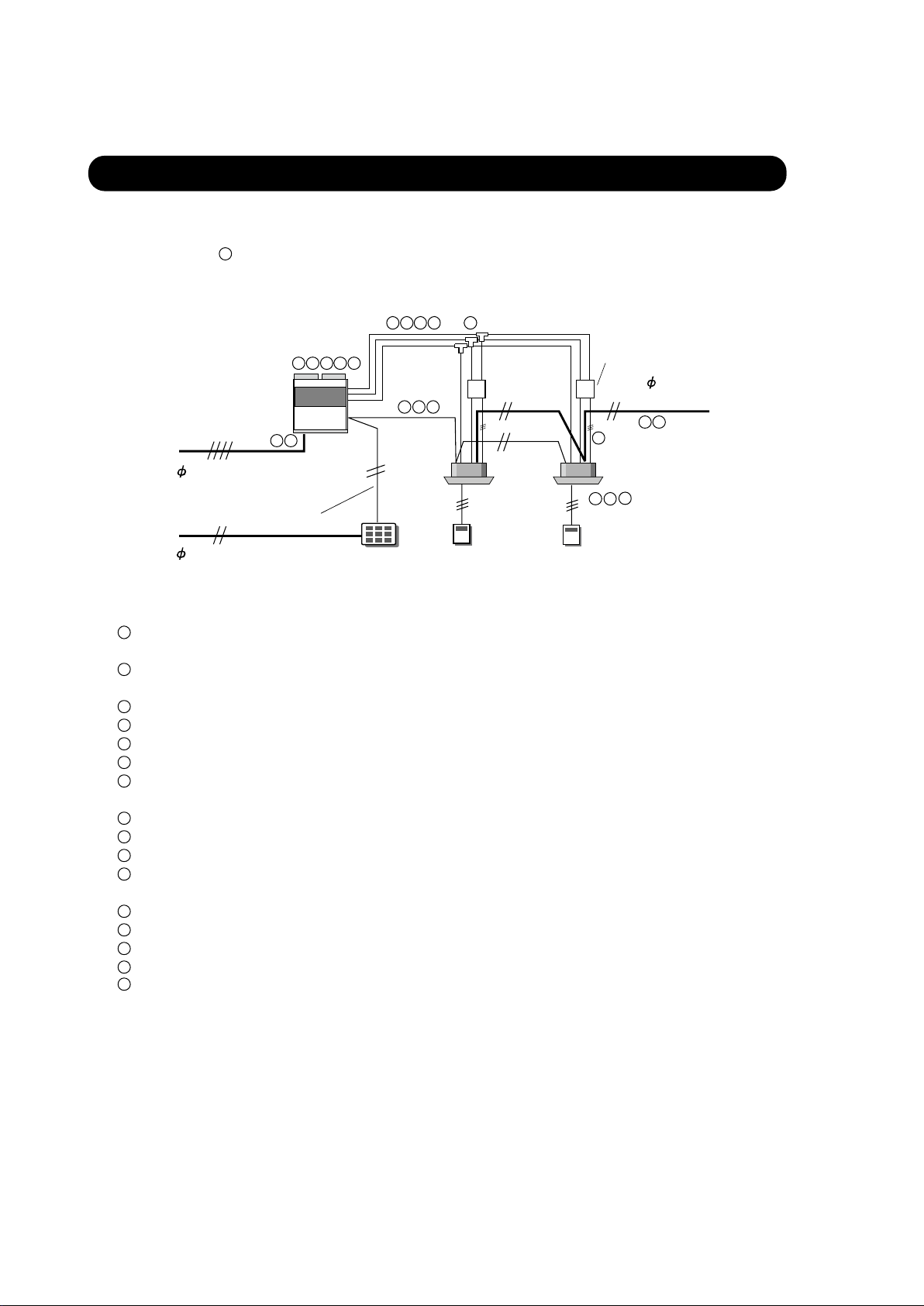

■

1-2 SYSTEM CONSTRUCTION CONDITIONS

1-2-1 REFRIGERANT PIPING

COOLING ONLY / HEAT PUMP MODEL

a+e 100m (actual pipe length)

Difference in height between outdoor unit and indoor units (H1) maximum 50m.

(For the outdoor unit stated below:maximum 40m)

Difference in height between adjacent indoor units (H2) maximum 15m.

e 40m (actual pipe length)

a 70m (actual pipe length)

a+b+c+d+e 200m (total pipe length)

Outdoor

unit

a

H1

H2

Indoor

unit

Indoor

unit

Indoor

unit

dcb

Indoor

unit

e

a+b+c+d+e+f 100m (actual pipe length)

Difference in height between outdoor unit and indoor units (H1) maximum 50m.

Difference in height between adjacent indoor units (H2) maximum 15m.

From outdoor unit to first separation tube a 70m (actual pipe length)

b+c+d+e+f 40m (actual pipe length)

a+b+c+d+e+f+g+h+i+j+k 200m (total pipe length)

Outdoor

unit

a

bcde

g h i j k

Indoor

unit

Indoor

unit

Indoor

unit

Indoor

unit

Indoor

unit

H2

Indoor

unit

H1

f

a+g+i 100m a+b+f 100m (actual pipe length)

Difference in height between outdoor unit and indoor units (H1) maximum 50m.

Difference in height between adjacent indoor units (H2) maximum 15m.

a 70m (actual pipe length)

g+i 40m b+f 40m (actual pipe length)

a+b+c+d+e+f+g+h+i 200m (total pipe length)

Outdoor

unit

h

Indoor

unit

b

– 7 –

Indoor

unit

Indoor

unit

f

H2

edc

i

Indoor

unit

Indoor

unit

Indoor

unit

H1

a

g

Page 8

PIPE SIZE

COOLING ONLY / HEAT PUMP MODEL

Pipe size connected to outdoor unit.

Model Gas Pipe Liquid Pipe

AO 90 28.58 12.7

Between two adjacent refrigerant branch kits.

(unit : mm)

(unit : mm)

Total model code of

Gas Pipe Liquid Pipe Separation Kit

indoor unit

Less than 30 15.88 9.53

UTR-BP54A

31 or more to 60 19.05 9.53

61 or more 28.58 12.7 UTR-BP90A

Connection pipe size of indoor unit.

(unit : mm)

Model code of indoor unit Gas Pipe Liquid Pipe

7, 9 9.53 6.35

12, 14

( )

18

12.7 6.35

18, 20, 24, 25 15.88 6.35

30

15.88

9.53

36, 45, 54, 60 19.05 9.53

Cassette(compact) only

– 8 –

Page 9

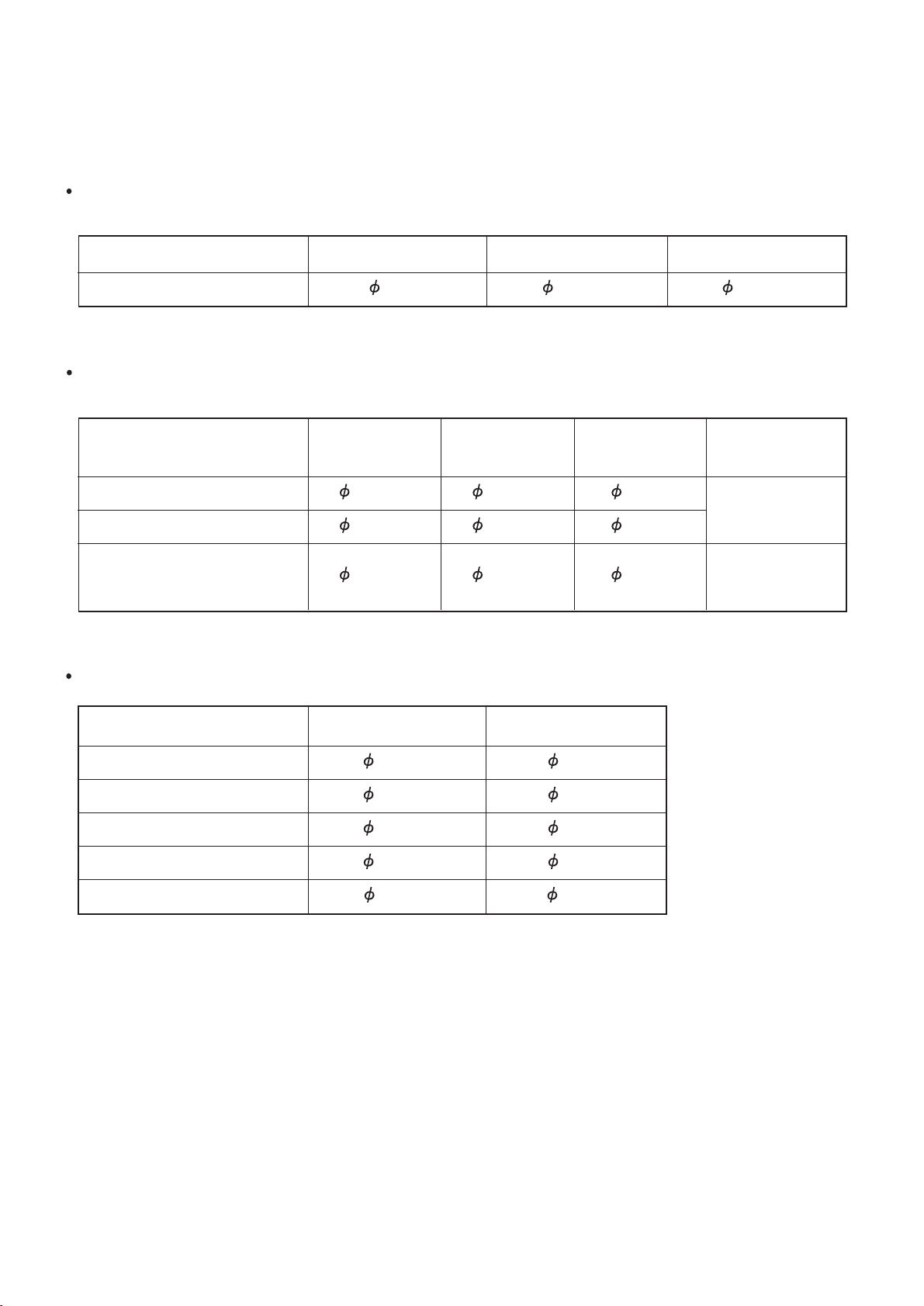

■

HEAT RECOVERY MODEL

a+e 100m (actual pipe length)

Difference in height between outdoor unit and indoor units (H1) maximum 50m.

(For the outdoor unit stated below : maximum 40m)

Difference in height between adjacent indoor units (H2) maximum 15m.

Difference in height between RB unit and RB unit (H3) 15m or less.

Difference in height between

RB unit and indoor unit (H4) 5m or less

e

40m (actual pipe length)

f

10m (actual pipe length)

a+b+c+d+e 200m (total pipe length)

.

Outdoor

unit

a

H1

a+b+c+d+e+f 100m (actual pipe length)

b

RB

unit

Indoor

unit

c

Indoor

RB

unit

unit

RB

unit

Indoor

unit

d

RB

unit

H2

Indoor

unit

Difference in height between outdoor unit and indoor units (H1) maximum 50m.

Difference in height between adjacent indoor units (H2) maximum 15m.

Difference in height between RB unit and indoor unit (H3) 5m or less.

From outdoor unit to first separation tube a 70m (actual pipe length)

b+c+d+e+f 40m (actual pipe length)

10m (actual pipe length)

a+b+c+d+e+f+g+h+i+j+k 200m (total pipe length)

Outdoor

unit

a

bcde

g h i j k

RB

unit

Indoor

unit

RB

unit

Indoor

unit

RB

unit

Indoor

unit

RB

unit

Indoor

unit

RB

unit

Indoor

unit

H3

H2

Indoor

a+g+i 100m a+b+f 100m (actual pipe length)

Difference in height between outdoor unit and indoor units (H1) maximum 50m.

Difference in height between adjacent indoor units (H2) maximum 15m.

Difference in height between RB unit and RB unit (H3) 15m or less.

Difference in height between RB unit and indoor unit (H4) 5m or less.

g+i 40m b+f 40m (actual pipe length)

j 10m (actual pipe length)

a+b+c+d+e+f+g+h+i 200m (total pipe length)

Outdoor

unit

a

b

RB unit

4 brunch

RB

unit

unit

e

H3

H4, f

H1

f

H1

g

edc

RB

unit

Indoor

unit

H3

i

H2

Indoor

unit

Indoor

unit

Indoor

unit

Indoor

unit

– 9 –

h

RB

unit

Indoor

unit

H4

f

j

Page 10

HEAT RECOVERY MODEL

Pipe size connected to outdoor unit.

(unit : mm)

Model Suction Gas Pipe

Discharge Gas Pipe

Liquid Pipe

AO 90 28.58 19.05 12.7

Between two adjacent refrigerant branch kits.

Total model code of Suction Discharge

Liquid Pipe

Separation Kit

indoor unit Gas Pipe Gas Pipe

Less than 30 15.88 12.7 9.53

UTR-BP54R

31 or more to 60 19.05 15.88 9.53

61 or more 28.58 19.05 12.7 UTR-BP90R

Connection pipe size of indoor unit.

(unit : mm)

(unit : mm)

Model code of indoor unit

Gas Pipe Liquid Pipe

7, 9 9.53 6.35

12, 14 12.7 6.35

18, 20, 24, 25 15.88 6.35

30

15.88

9.53

36, 45, 54, 60 19.05 9.53

– 10 –

Page 11

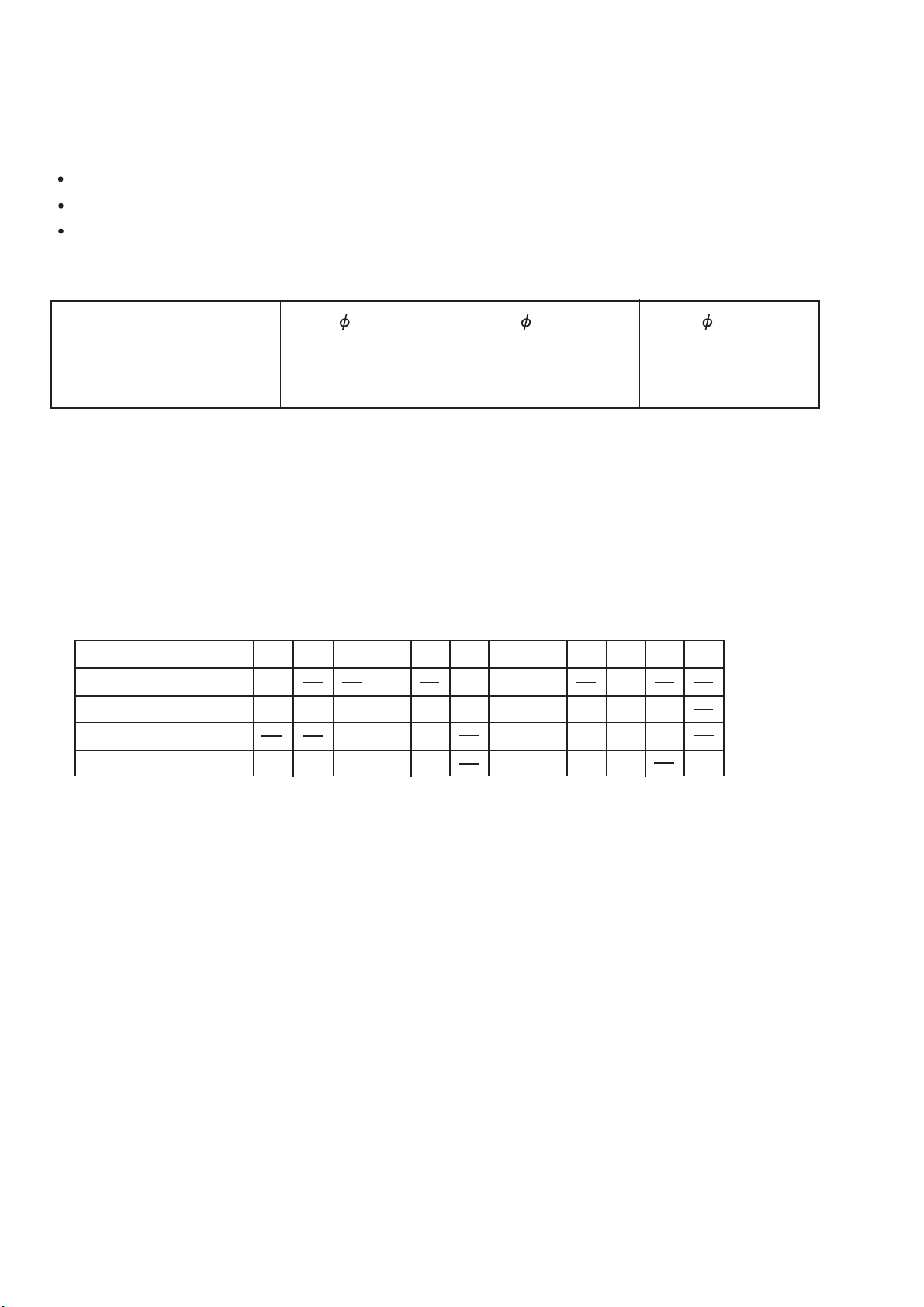

ADDITIONAL CHARGE

Up to a pipe length of 7.5 m, charging with additional refrigerant is not necessary.

If the pipe length exceeds 7.5 m, charging with refrigerant is necessary.

Charge with additional refrigerant in the amounts shown in the table below.

(1) Pipe length

Liquid pipe (mm) 12.7 9.53 6.35

Additional refrigerant

0.1 0.05 0.03

(R407C) (kg/m)

(2) System type

It is necessary to add refrigerant to all connected Indoor unit.

Add refrigerant to the corresponding type as shown in the Table for every connected Indoor unit to the

refrigerant system.

Example : When AR30 x2 and AU18 x2 are connected to the refrigerant system.

" Additional charge of system type" is 1.0(kg)x2 +0.65(kg)x2=3.3(kg)

Model / Model code

AS

AU

AB

AR

0.65

0.4

7 9

0.65120.65

0.4

0.65

0.45

14

0.9

0.65

0.65

0.45

18

0.65

0.65

0.7

ADDITIONAL CHARGE = (1) + (2)

20

0.9

0.8

24/25

0.9

0.9

0.8

0.8

1.0

1.0

1.0

1.0

30

36

45

54

1.5

1.5

1.0

2.0

amount of refrigerant (kg)

1.0

2.0

1.5

1.0

60

2.0

– 11 –

Page 12

1-2-2 SYSTEM WIRING

Use

Outdoor

2

unit

Indoor

Power supply

cable (mm )

unit

Transmission

cable (mm )

2

Wired remote control

cable (mm )

1,2

3

4 10m cable attached.

2

The grounding wire is not included in this cable.

Always ground the unit.

Do not bundle the transmission cable with other wires.

Transmission cable between each unit : 200m max

Each unit means indoor unit,outdoor unit,central remote controller,

and signal amplifier.

Total wiring length:maximum 2000m.

However,when wiring exceeds 500m in length,

a signal amplifier (option) is required.

Use the shielded wire specified and always ground(however,one side only).

If not,transmit-receive with a transmission line is not

only impossible normally,but malfunction may occur.

Use the shielded cable in accordance with standards

in the country.

Wiring length of a remote controller group shall be

within 500m.

Size

Maximum H07RN-F or

Minimum equivalent

Maximum H07RN-F or

Minimum equivalent

Maximum

8.0

6.0

2.5

1.5

1.25

Wire type Remarks

Shield cord

(LONWORKS

Minimum

Maximum Sheathed vinyl

Minimum cord cable

0.75

1.25

0.75

compatible part)

3 4 wire 50Hz

380-415V

1 2 wire 50Hz

220-240V

Non-polar

2-core

Polar 3-core

1

2

3

4

Fuse

capacity

per one outdoor unit

5

per one refrigerant system.

6

Model Field fuse

Outdoor

unit

Indoor

unit

40A

20A

5

6

– 12 –

Leakage breaker

40A 100mA 0.1sec or less

20A 40mA 0.1sec or less

Page 13

1-3 ADDRESS SETTING

This system is needed to set the address for the indoor unit, outdoor

unit and remote controller and central remote controller.

(1) KINDS OF ADDRESS AND SETTING RANGE

UNIT SETTING

Outdoor

unit

Refrigerant

circuit address

Refrigerant

circuit address

Indoor

unit

Indoor unit address

Remote controller

address

SETTING

RANGE

0 99

0 99

0 15

0 15

TYPE OF SWITCH REMARKS

Setting

example

0

Setting

example

63

Setting

example

2

Setting

example

0

0

SW 9 SW 8

6

SW 8 SW 7

0

Show next page

3

2

SW 5

0

Remote controller

switch 1

Remote

controller

Number of indoor

unit connection

Remote controller

switch 2

Central

remote

Central remote

controller address

controller

INDOOR UNIT CONTROL METHOD

DSW1-4

OFF

ON

METHOD

Master

Slave

Allocate remote

by order from the

ON/OFF

ON/OFF

ON/OFF

combination

0 15

REMARKS

control addresses

master unit

SW 9

DIP SW1-1

DIP SW1-2

DIP SW1-4

Initial setting

Terminator

Number of indoor unit

OFFON: 1 unit

: multiple unit

Shown below

– 13 –

Page 14

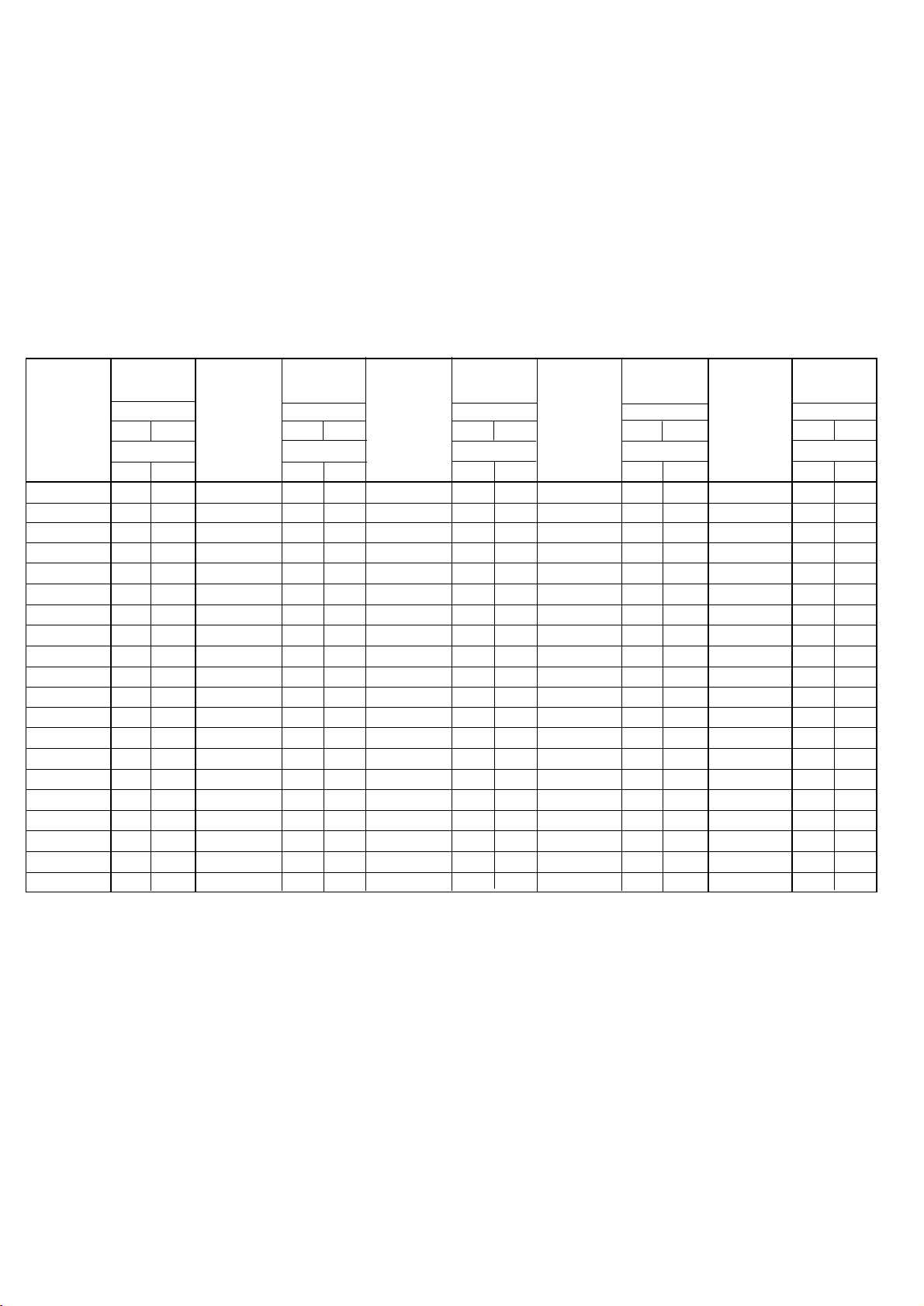

Refrigerant circuit address conversion table

Outdoor unit

Rotary switch (SW 8)- - - Factory setting "0"

Rotary switch (SW 9)- - - Factory setting "0"

Indoor Unit

Rotary switch (SW 7)- - - Factory setting "0"

Rotary switch (SW 8)- - - Factory setting "0"

In case of multiple refrigerant system,set SW 8 and SW 9 Indoor unit SW7 and SW8 as shown

in the table for each refrigerant system.

Do not use a nonexistent switch setting combination.

Example : When SW 9 is set to "1" and SW 8 is set to "14" the refrigerant circuit address will be "30".

Refrigerant

circuit

address

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Rotary

Switch setting

OUTDOOR UNIT

SW9

Refrigerant

circuit

address

SW8

INDOOR UNIT

SW7

SW8

0

0

1

0

2

0

3

0

0

4

5

0

0

6

0

7

0

8

0

9

0

10

0

11

0

12

0

13

0

14

0

15

0

1

1

1

2

1

3

1

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Rotary

Switch setting

OUTDOOR UNIT

SW9

Refrigerant

circuit

address

SW8

INDOOR UNIT

SW8

SW7

4

1

5

1

6

1

1

7

8

1

9

1

1

10

1

11

1

12

1

13

1

14

1

15

0

2

1

2

2

2

2

3

2

4

2

5

2

6

2

7

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

Rotary

Switch setting

OUTDOOR UNIT

SW9

Refrigerant

circuit

address

SW8

INDOOR UNIT

SW8

SW7

2

8

2

9

2

10

2

11

2

12

2

13

2

14

2

15

3

0

1

3

2

3

3

3

3

4

5

3

6

3

3

7

3

8

3

9

10

3

3

11

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

Rotary

Switch setting

OUTDOOR UNIT

SW9

Refrigerant

circuit

address

SW8

INDOOR UNIT

SW7

SW8

3

12

3

13

3

14

3

15

0

4

1

4

2

4

3

4

4

4

5

4

6

4

7

4

8

4

9

4

10

4

11

4

12

4

13

4

14

4

15

4

90

91

92

93

94

95

96

97

98

99

80

81

82

83

84

85

86

87

88

89

Rotary

Switch setting

OUTDOOR UNIT

SW9

SW8

INDOOR UNIT

SW7

SW8

0

5

1

5

2

5

3

5

4

5

5

5

6

5

7

5

8

5

9

5

10

5

11

5

12

5

13

5

14

5

5

15

6

0

6

1

2

6

6

3

– 14 –

Page 15

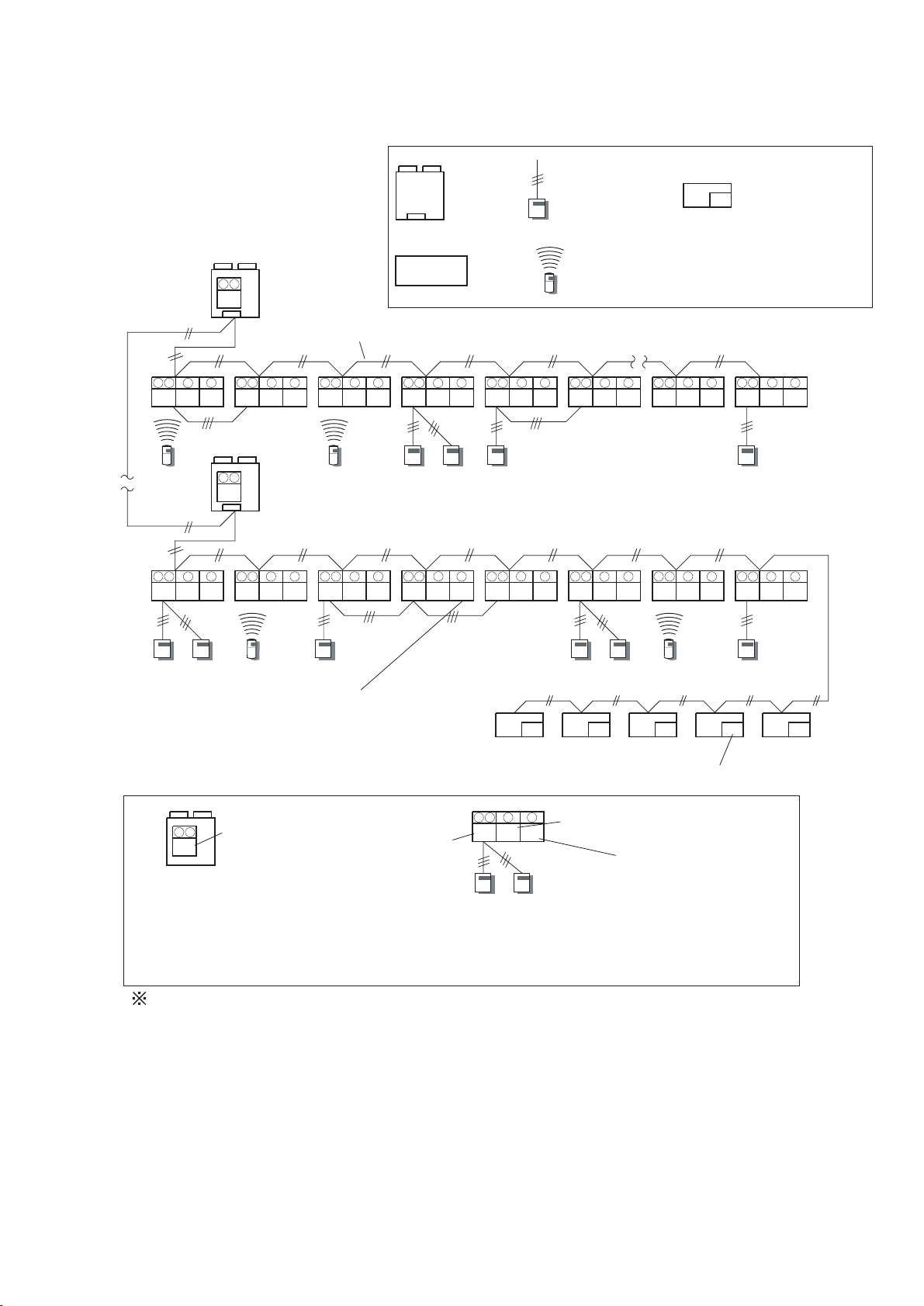

(2) SETTING EXAMPLE

Outdoor unit

9 8

Outdoor

unit

Indoor

unit

0

Wired remote

controller

Wireless remote

controller

Transmission line

(Non-polar 2 core)

8 7

5

0

9 8 7

5

1

9 8 7

5

2

9 8 7

9 8 7 5 9 8 7 5 9 8 7

5

3

4

0 0 0 0 0 00 1 0 0 0 1

5

2 (Max.16 Numbers)

9 8

63

8 7

63 0 163 0263 0363 1463 2563 0 63636 0

5

0

9 8 7

5

9 8 7

5

OFF ONDIP SW1-1

OFF ONDIP SW1-4

9 8 7

5

9 8 7

5

9 8 7

5

9 8 7

00

5

9 8 7

14

5

0 0

0 15 0

9 8 7

Central remote

controller

5

9

5

9

7

0

3

OFF ONDIP SW1-1

OFF ONDIP SW1-4

9 8

63

Refrigeration

circuit address

Rotary-sw9,8

Instructions for setting up the address

1 The refrigerant system address of the indoor and outdoor units can be set to optional numbers

in the range of 0 and 99.

2 Address of the indoor unit can be set to optional numbers in the range of 0 to 15.

3 Set address of the remote controller in the order of 0,1,2,...15.(Blank is impossible)

4 Address of the central remote controller can be set to optional numbers in the range of 0 to 15.

ONDIP SW1-1

Number of the unit

in the group

Refrigeration

circuit address

Rotary-sw8,7

DIP SW1-1 Remote controller address1

DIP SW1-2 Number of indoor unit connection

DIP SW1-4 Remote controller address2

00 01 02 03 04

Central Remote controller (Max.16)

Central remote controller address

5

8 7

63 0

9

6

Indoor unit address

Rotary-sw5

Remote controller address

Rotary-sw9

– 15 –

Page 16

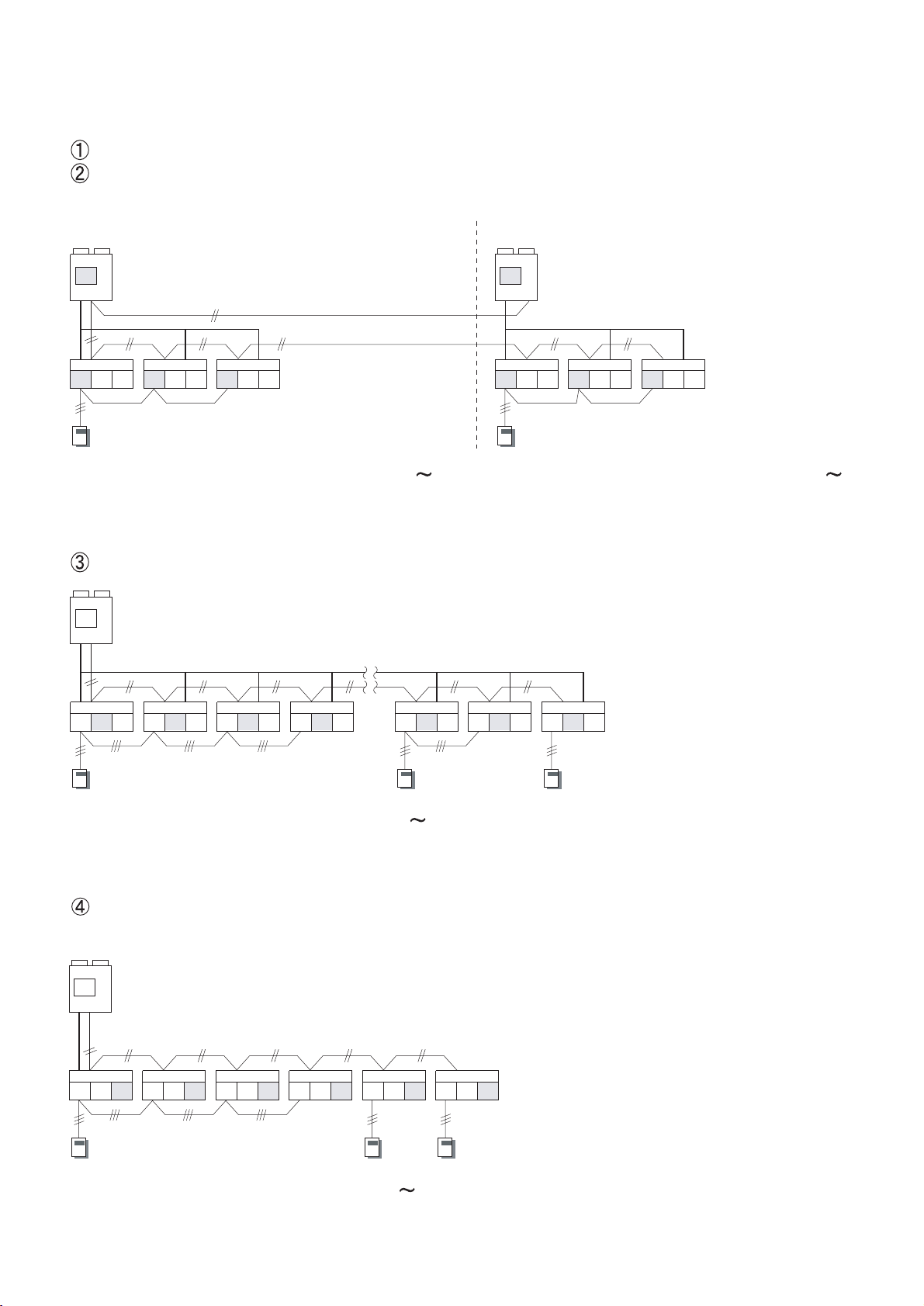

Refrigerant circuit address (Outdoor unit)

Refrigerant circuit address (Indoor unit)

Refrigerant circuit 1 Refrigerant circuit 2

1

00 01 02

1 1 10 1 2 2 2 20 1 2

Outdoor unit PCB (Address setting No.0

99) 99)

Setting by rotary SW8,9

2

00 01 02

Indoor unit PCB (Address setting No.0

Setting by rotary SW7,8

Indoor unit address

0

00 0 01 1 02 2 13 0 14 1 15 003

0 0 0 0 0 0 0

Indoor unit PCB (Address setting No. 0

15)

Setting by rotary SW5

Remote controller address

(Indoor unit)

0

00 0 01 1 02 2 0 03 3 0 04 0 0 05 0

0

Indoor unit PCB (Address setting No.0

0 0

15)

Setting by rotary SW9

– 16 –

Page 17

Remote controller switch 1

[Master] [Slave]

OFF

ON

Remote controller unit PCB

Setting by DIP SW 1-1

No. indoor unit connection

ON OFF

ON

Remote controller PCB

124

Setting by DIP SW 1-2

– 17 –

Page 18

Remote controller switch 2

(Remote controller)

[Master] [Slave]

Remote controller unit PCB

Setting by DIP SW 1-4

Central remote controller address

[Master] [Slave]

00

01

02

03

Central remote controller (Max.16)

Set central remote controller address first,to conduct the initial setting of it.

– 18 –

Page 19

Outdoor

unit

3 4W 50Hz 380 - 415V

1 50Hz

220 - 240V

Transmission line

Indoor

unit

1

13

7 8

4

7

8

1

9

14 15 16

10 11

12

2

3 5 6

13

14

Central

remote controller

Wired

remote controller

RB unit

Before test running, check the following items.

Note: RB unit ( ) is for the heat recovery type.

Is the selection of the outdoor unit and the indoor unit correct?

(Maximum operating indoor unit, total capacity of the indoor unit)

Is the piping length correct?

(Ex. Maximum piping length : 100m)

Is the separate selected correct?

Doesn't gas leak?

Is the refrigerant flow correct?

Are the power supplies connected?

1

2

(Power supply for the indoor unit and outdoor unit is separated.)

Is the spec. for the power supply cable correct?

Is the RB unit cable connected?

Is the length of the transmission line under the limit?

Is the spec. for the transmission cable correct?

(non-polar 2-core, 0.75-1.25mm )

Is the transmission cable connected to all units?

2

Are the addresses set? (Ex. Refrigerant circuit address, indoor unit address, remote controller address, etc.)

Have the all settings done on the PCB?

Is the refrigerant valve opened?

Is the power supplied to crank case heater for 12 hours before winter operation?

3

4

5

6

7

8

9

10

Is the diameter of the pipe selected correct?

11

12

13

14

15

2-1 CHECK ITEMS BEFORE TEST RUNNING

9

2. TEST RUN

1 50Hz 220 - 240V

16

– 19 –

Page 20

2-2 TEST RUNNING METHOD

Supply power to the crankcase heater for 12 hours prior to the start of operation in the winter.

The following is the procedure for the test operation.

2-2-1 OUTDOOR PC BOARD

If the test operation is to be done for cooling operation, set DIP switch (SW-1-1) to on. If the test operation is to be done for heating,

set DIP switch (SW1-2) to on.

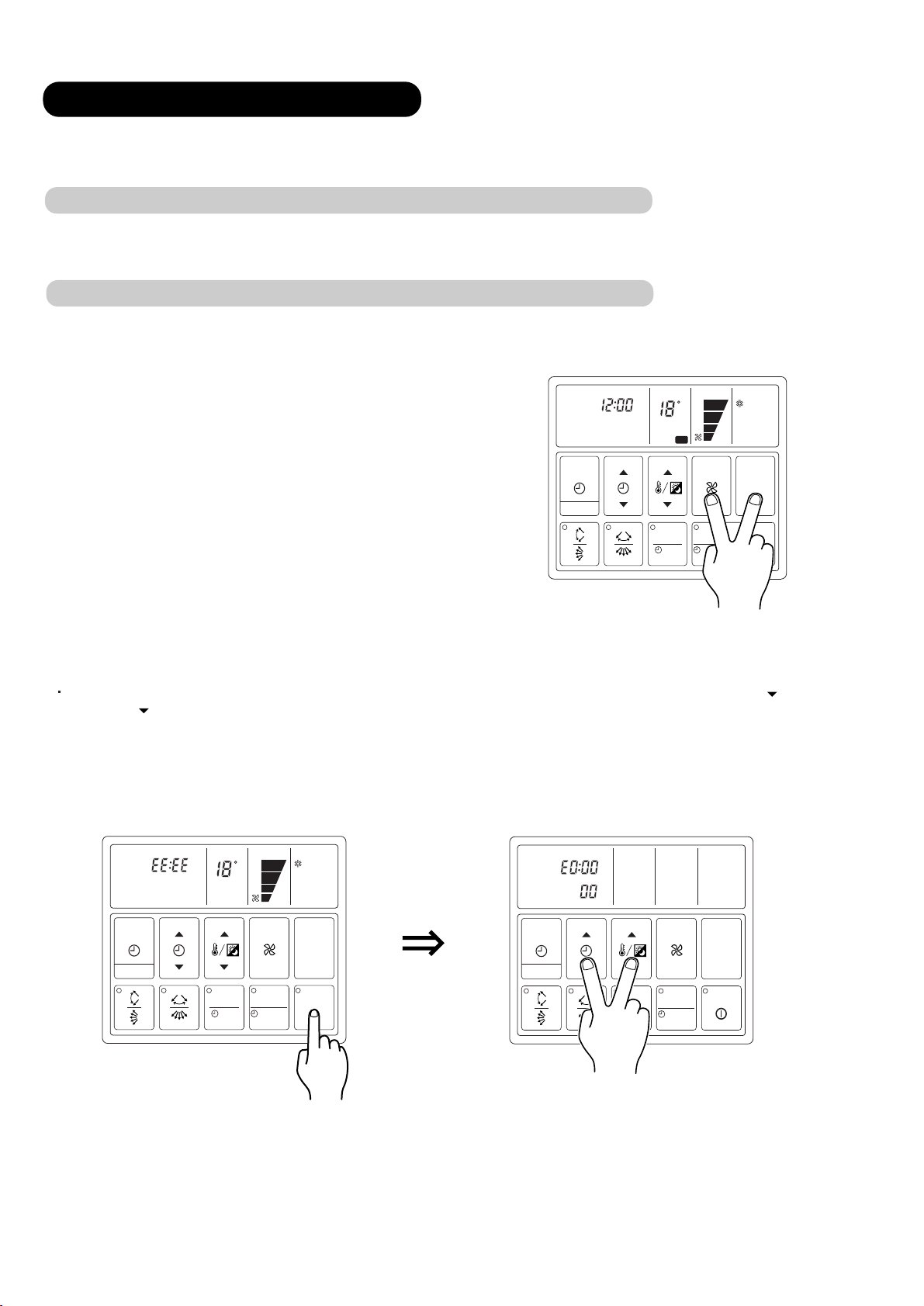

2-2-2 TEST OPERATION USING REMOTE CONTROLLER

(1) Standard wired remote controller

For test running, when the remote controller FAN CONTROL

button and MASTER CONTROL button are pressed simulta-

neously for more than three seconds when the air conditioner is

not running, the air conditioner starts and TEST is displayed on

the remote controller display.

However, the SET TEMP./DAY setting button does not function,

but all other buttons, displays, and protection functions operate.

CLOCK

NON STOP

SET TIME

TIMER

MODE

CLOCK ADJUST

TEST

TEMP./DAY

C

CONTROL

FAN

COOL

MASTER

CONTROL

When EE : EE blinks at the current time display, there

DAY button ( ) are pressed

simultaneously for more than three seconds, the self

be displayed at the current time display. In addition,

lights, press the START/STOP button and after

CLOCK

NON STOP

SET TIME

TIMER

MODE

CLOCK ADJUST

TEMP./DAY

C

CONTROL

FAN

COOL

MASTER

CONTROL

operation lamp goes off, perform the same operation.

ZONE

ENERG

SET

D

is an error inside the air conditioner. If the SET TIME

diagnosis check will start and the error

the remote controller address will be displayed below.

TIMER

MODE

CLOCK ADJUST

SET TIME

TEMP./DAY

FAN

CONTROL

MASTER

CONTROL

OP

SET

button ( ) and SET TEMP.

contents will

When the oper

ation

lamp

Stop operation

ZONE

SET

START/STOP

ENERGY SAVE

DAY OFF

– 20 –

ZONE

SET

SET

START/STOP

ENERGY SAVE

DAY OFF

Page 21

Error Code

Error contents

Error Code

Error contents

No error

Model information abnormal

Power supply frequency abnormal

EEPROM access error

EEPROM elimination error

Room temperature thermistor error

Indoor unit heat exchange thermistor

(middle) error

Indoor unit heat exchange thermistor

(inlet) error

Indoor unit heat exchange

(exit) error

thermistor

To stop test running, press the START/STOP button.

For the operation method, refer to the operating manual and perform operation check.

Check that there are no abnormal sounds or vibration sounds during test running.

(2) Standard wireless remote controller

Press the remote control unit test run button while the air condi tioner is running.

Blower temperature thermistor error

Drain abnormal

Room temperature abnormal

Indoor unit fan error

Communication error

Node setting error

Parallel communication error

Outdoor unit error

Remote control unit

At the end of test running, press the remote control unit start-

stop button.

Operation can be checked by lighting and flashing of the display

section OPERATION and TIMER lamps.

Perform judgment in accordance with the following.

Test running

When the air conditioner is run by pressing the remote control

unit test run button, the OPERATION and TIMER lamps flash

slowly at the same time.

START

STOP

A B C D

START/STOP button

TEST RUN button

– 21 –

Page 22

– 22 –

1) When the test run signal is transmitted from the standard wired remote controller, the wireless remote controller

and the central remote controller.

(1) In the test running status, operated in accordance with the setting of each switch besides the room temperature

switch. The room temperature adjustment does not funtion, and then the electric expansion valve is controlled

with maximum flow.

(2) De-frosting and de-icing prevention has priority over item(1).

(3) After 60 minutes passes, the test run stops.

2) When the test run signal is transmitted from the outdoor unit.

(1) Whether state of the indoor unit operates or stops, test run will be made in accordance with the operation

mode of the indoor unit , which belongs to the same refrigerant system.

(2) Test running initialization is shown below.

Air Flow Hi Hi

RoomTemperature Indication 18 30

Vertical Air Direction Panel

Horizontal Air Direction Panel

Swing

Operating Mode Cooling Heating

Initialized position Initialized position

Front Front

OFF

OFF

2-3 TEST RUN CONTROL

Page 23

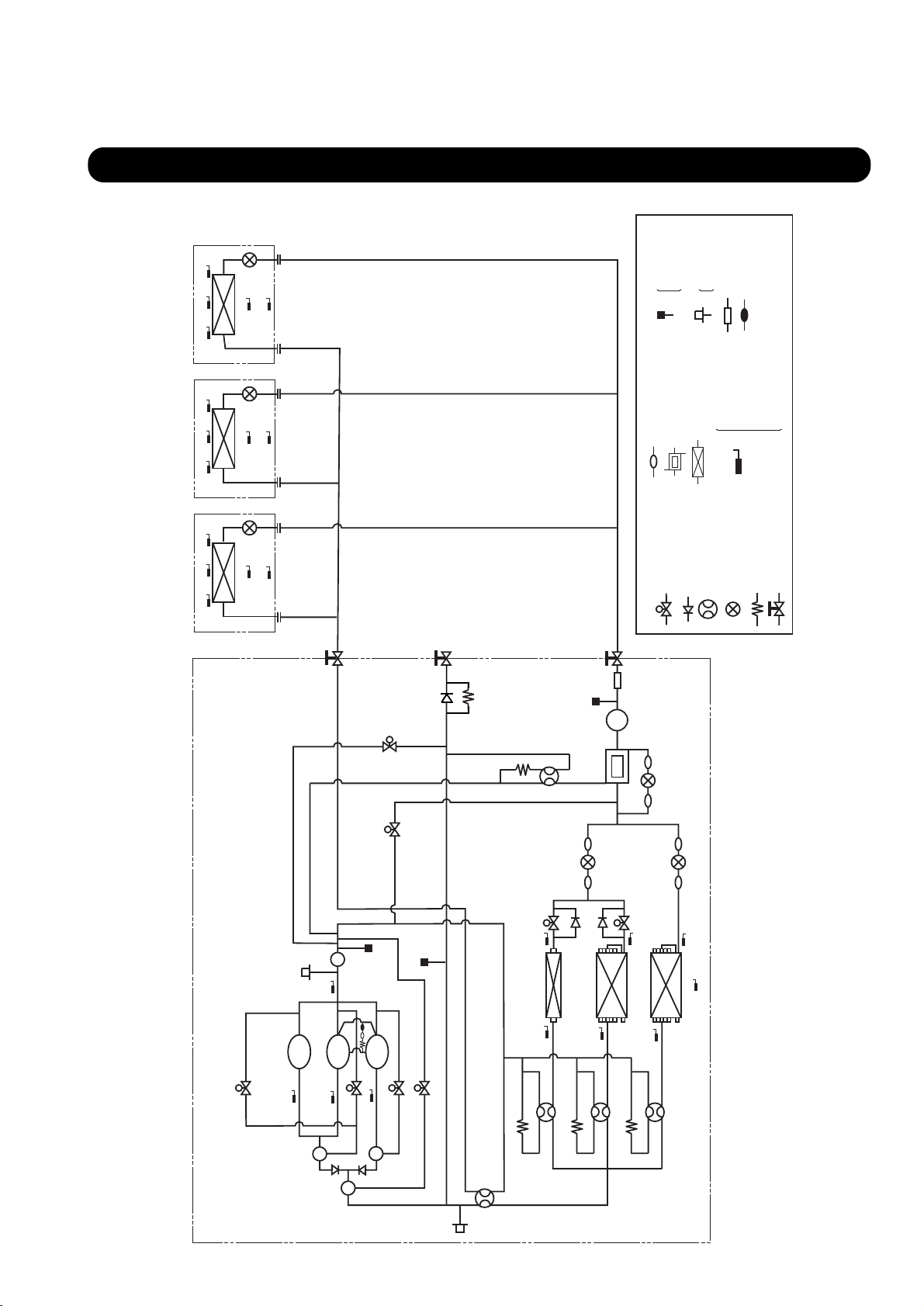

3.REFRIGERANT PIPE SYSTEM DIAGRAM

3-1 COOLING ONLY / HEAT PUMP TYPE

THOA

THHO THHM THHI

THOA

THHO THHM THHI

THOA

THHO THHM THHI

INDOOR UNIT A INDOOR UNIT B INDOOR UNIT C

EEV

EEV

EEV

HP:High pressure

MP:Middle pressure

LP:Low pressure

HP:High pressure

LP:Low pressure

:Oil sensor

:Dryer

:Pressure switch

THIATHIA THIA

:H.E. middle thermistor

:Outlet air thermistor

:H.E. outlet thermistor

:H.E. inlet thermistor

D

OA

HM

HO

Hi

BV1

SV2

BV2

4WV5

:Discharge thermistor

TH

:Heat exchanger

:Thermistor

:4-way valve

:Check valve

TH

:Expansion valve

:Strainer :Pressure sensor

:Power accumulation unit

:Solenoid valve

BV3

MP

TANK

RECEIVER

THs:Suction thermistor

TH

TH

TH

THR:Room temp thermistor

:Capillary tube

THo:Outdoor temp thermistor

THIA:Indoor Room temp thermistor

:Ball valve

OUTDOOR UNIT

SV3

EEV3

SV1

EEV1

SV7

LP

LP

CCUMU

A

LATEOR

THS

HP

THHO1

H.E.1

THHI1

COMP.1

COMP.2

COMP.3

SV4

THD1

THD2

OIL

SEPARATER

OIL

SEPARATER

THD3

SV6

SV5

4WV2

OIL

SEPARATER

4WV1

HP

SV8

THHO2

H.E.2

THHI2

4WV3

EEV2

THHO3

THO

H.E.3

THHI3

4WV4

– 23 –

Page 24

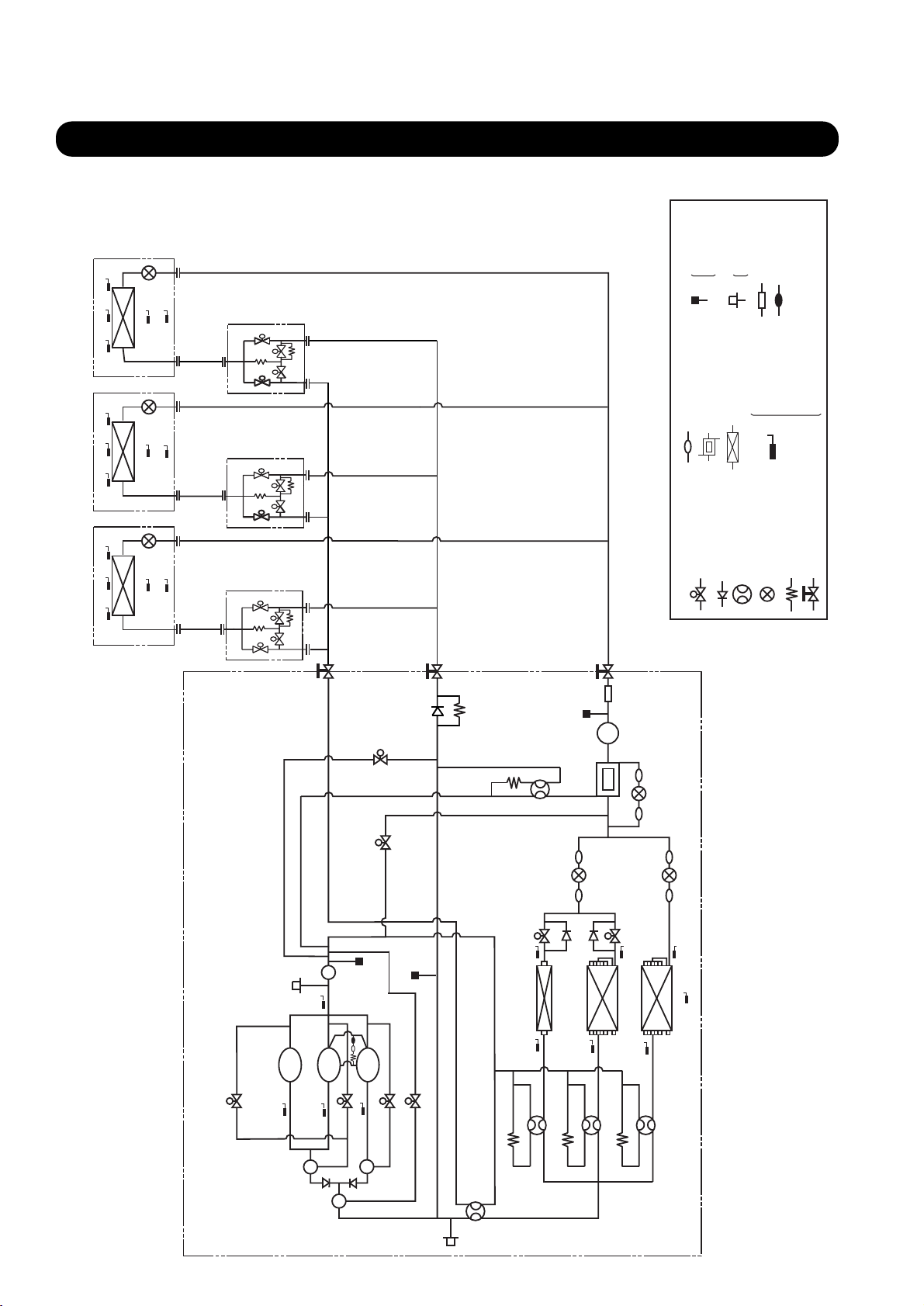

3-2 HEAT RECOVERY TYPE

EEV

THIA

THOA

THHO THHM THHI

EEV

THOA

THIA

THHO THHM THHI

R.B UNIT

R.B UNIT

SVD

SVB2

SVB1

SVs

SVD

SVB2

SVB1

SVs

HP:High pressure

MP:Middle pressure

LP:Low pressure

:Pressure switch

:Strainer :Pressure sensor

:Power accumulation unit

:Heat exchanger

HP:High pressure

LP:Low pressure

:Oil sensor

:Dryer

:H.E. middle thermistor

:H.E. outlet thermistor

:H.E. inlet thermistor

:Discharge thermistor

D

Hi

HO

HM

TH

TH

TH

TH

:Thermistor

:Outlet air thermistor

OA

THs:Suction thermistor

TH

THo:Outdoor temp thermistor

THR:Room temp thermistor

THIA:Indoor Room temp thermistor

THOA

THHO THHM THHI

INDOOR UNIT A INDOOR UNIT B INDOOR UNIT C

EEV

:Solenoid valve

:4-way valve

:Check valve

:Expansion valve

:Capillary tube

:Ball valve

THIA

SVD

R.B UNIT

SVB2

SVB1

SVs

4WV5

H.E.1

BV3

MP

TANK

RECEIVER

EEV3

EEV1

SV8

THHO2

H.E.2

EEV2

THHO3

H.E.3

THO

SV2

SV1

BV2

SV7

HO1

T

HP

BV1

LP

LP

CCUMU

A

LATEOR

THS

OUTDOOR UNIT

SV3

THHI1

COMP.1

COMP.2

COMP.3

SV4

THD1

THD2

OIL

SEPARATER

OIL

SEPARATER

THD3

SV6

SV5

4WV2

OIL

SEPARATER

4WV1

HP

THHI2

4WV3

THHI3

4WV4

– 24 –

Page 25

4. FUNCTION OF PRINTED CIRCUIT BOARD

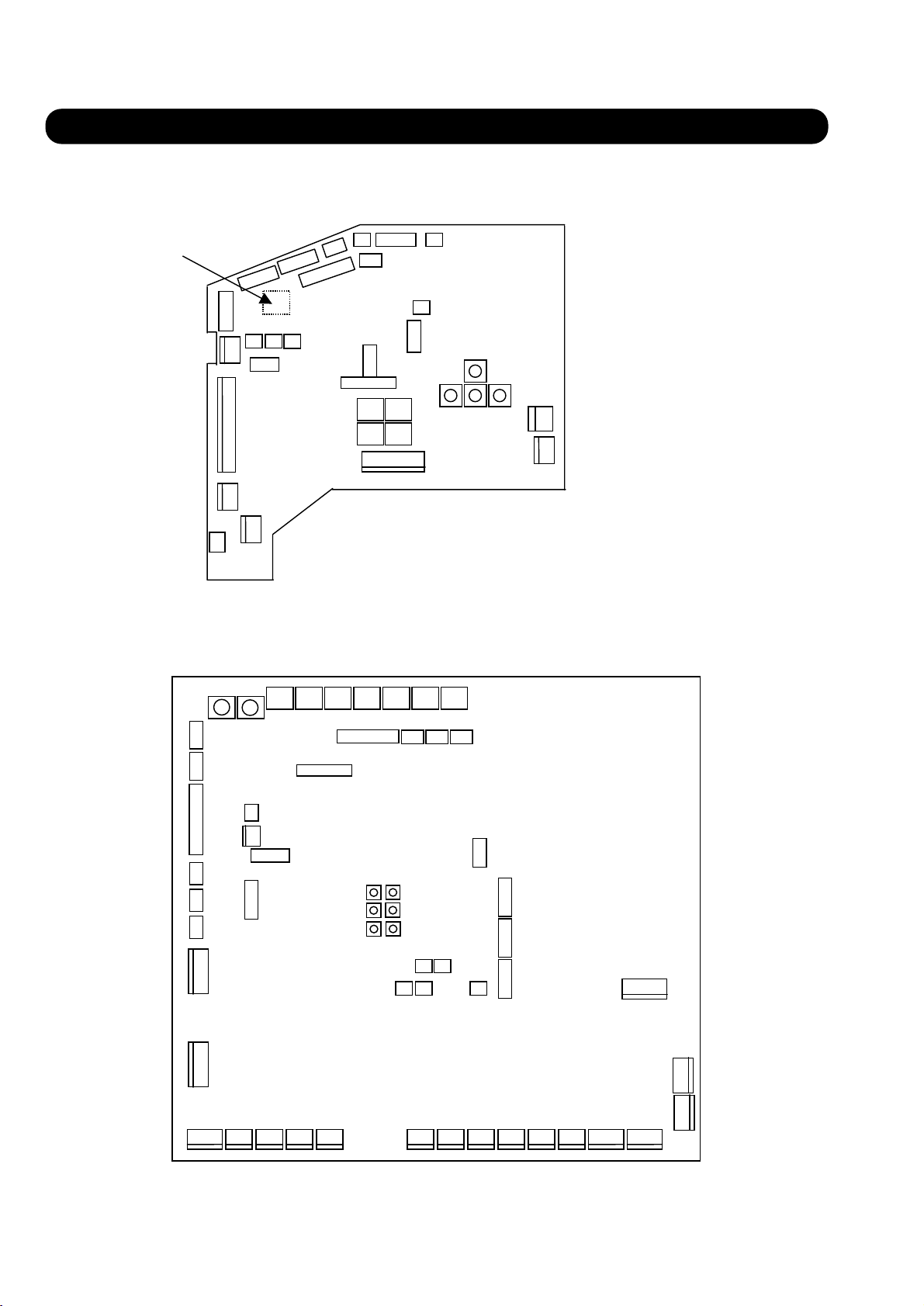

4-1 PCB LAYOUTS

■

INDOOR UNIT CONTROL CIRCUIT BOARD

CN19 CN20 CN21

CN15

JM1-3

CN10

CN16

CN4

CN11

CN23

CN14

CN18

CN13 CN8

CN22

CN12

CN24

CN26

SW2

SW1

CN17

CN25

SW4

SW3

CN6

SW5

SW9SW7SW8

CN2

CN1

CN3

SW10

■

OUTDOOR UNIT CONTROL CIRCUIT BOARD

CN52

CN53

CN45

CN24

CN25

CN26

CN4

SW9 SW8

CN5

SW6SW7 SW5 SW4 SW3 SW2 SW1

CN27 CN3 4

CN51

CN2

CN22

CN44

CN28

LED4

LED5

LED6

EXT.

INPUT1

CN33

LED1

LED2

LED3

CN43 CN42

EXT.

INPUT2

CN32

CN48CN49CN50

CN35

CN29

CN30

CN31

CN1

CN3

CN21

CN20

CN19

CN18

CN17

CN14

CN12 CN10 CN8

CN13 CN11 CN9 CN7

– 25 –

CN5

CN6

Page 26

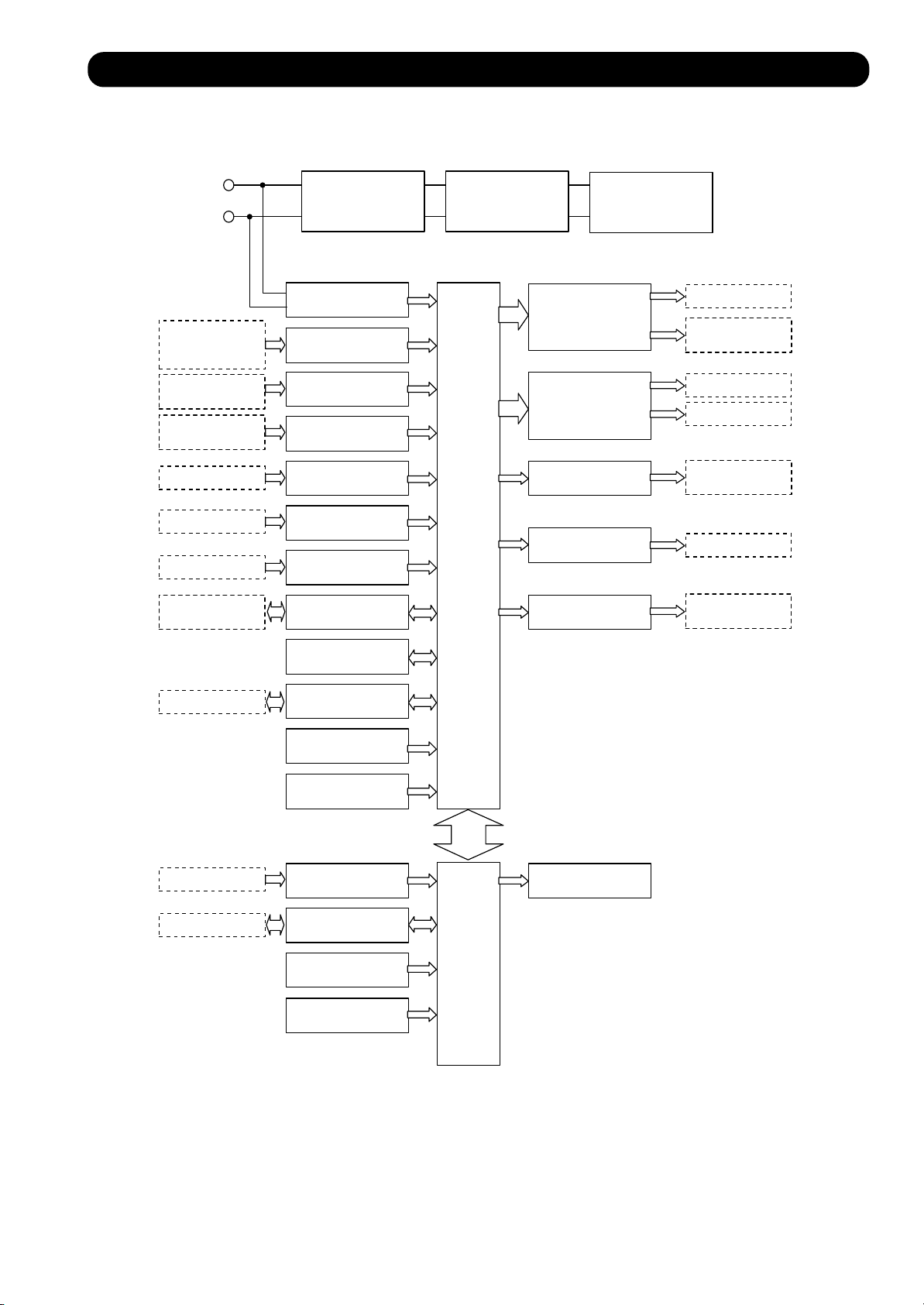

4-2 MICROPROCESSOR BLOCK DIAGRAM

INDOOR UNIT

■

Power supply

ROOM THERMISTER(CN19)

PIPE INLET/IMEDIATE

/OUTLET THERMISTER(CN20)

OUTLET THERMISTER(CN21)

FAN FEEDBACK

DIP SW(SW1-4)

ROTARY SW(SW5,7,9)

FLOAT SW(CN15)

COMMUNICATION

PWB.(CN26)

(CN16)

TEST(CN18)

(CN24)

FILTER CIRCUIT

POWER DETECTION

CIRCUIT

TEMPERATURE

DETECTION CIRCUIT

FAN ROTATION

READ CIRCUIT

SWITCH

READ CIRCUIT

FLOAT SWITCH

INPUT CIRCUIT

TEST INPUT

CIRCUIT

EXTERNAL INPUT

CIRCUIT

COMMUNICATION

CIRCUIT

RECTIFICATION

SMOOTHING

CIRCUIT

MICROPROCESSOR

DC-DC CONVERTER

5V,12V,14V

ACTUATOR

DRIVE CIRCUIT

SP MOTOR

DRIVE CIRCUIT

INDICATOR

DISPLAY OUTPUT

EXTERNAL OUTPUT

AUXILIARY

HEATER OUTPUT

FAN MOTER(CN4)

DRAIN PUMP(CN5)

SV(CN6)

LOUVER(CN10,CN11)

EEV(CN14)

INDICATOR

DISPLAY(CN13)

(CN22)

AUXILIARY

HEATER(CN12)

(CN24)

Wired remote

controller(CN17)

(CN25)

EEPROM

FLASH WRITE

CIRCUIT

RESET CIRCUIT

OSCILLATOR

CIRCUIT

WIRED REMOTE

CONTROLLER

READ CIRCUIT

FLASH WRITE

CIRCUIT

RESET CIRCUIT

OSCILLATOR

CIRCUIT

COMMUNICATION

BUZZER OUTPUT

MICROPROCESSOR

– 26 –

Page 27

OUTDOOR UNIT

■

Power supply

SUCTION/

OUTDOOR/

DISCHARGE

TEMP. 1-3(CN27)

PRESSURE

SENSOR(CN32-34)

DIP SW(SW1-7)

ROTARY SW(SW8,9)

TEST(CN35)

COMMUNICATION

PWB.(CN51)

(CN44)

FILTER CIRCUIT

POWER DETECTION

CIRCUIT

TEMPERATURE

DETECTION CIRCUIT

PRESSURE

DETECTION CIRCUIT

SWITCH

READ CIRCUIT

TEST INPUT

CIRCUIT

COMMUNICATION

CIRCUIT

EEPROM

FLASH WRITE

CIRCUIT

RECTIFICATION

SMOOTHING

CIRCUIT

MICROPROCESSOR

DC-DC CONVERTER

5V,12V,14V

ST MOTOR

DRIVE CIRCUIT

EEV (CN29-31)

WIRED REMOTE

CONTROLLER(CN17)

OIL SENSOR

SW(CN52,53)

PRESSURE

SW(CN49,50)

(CN49,50)

(CN28)

RESET CIRCUIT

OSCILLATOR

CIRCUIT

POWER DETECTION

CIRCUIT

TEMPERATURE

DETECTION CIRCUIT

OIL SENSOR

READ CIRCUIT

PRESSURE SWITCH

READ CIRCUIT

EXTERNAL

INPUT CIRCUIT

FLASH WRITE

CIRCUIT

RESET CIRCUIT

OSCILLATOR

CIRCUIT

COMMUNICATION

ACTUATOR

DRIVE CIRCUIT

LED OUTPUT

EXTERNAL OUTPUT

COMPRESSOR

(CN24-26)

FAN MOTOR(CN3,4)

4WYV(CN17-21)

SV(CN7-16)

BASE HEATER(CN5)

COMPRESSOR

(CN24-26)

LED(LED1-6)

(CN28)

MICROPROCESSOR

– 27 –

Page 28

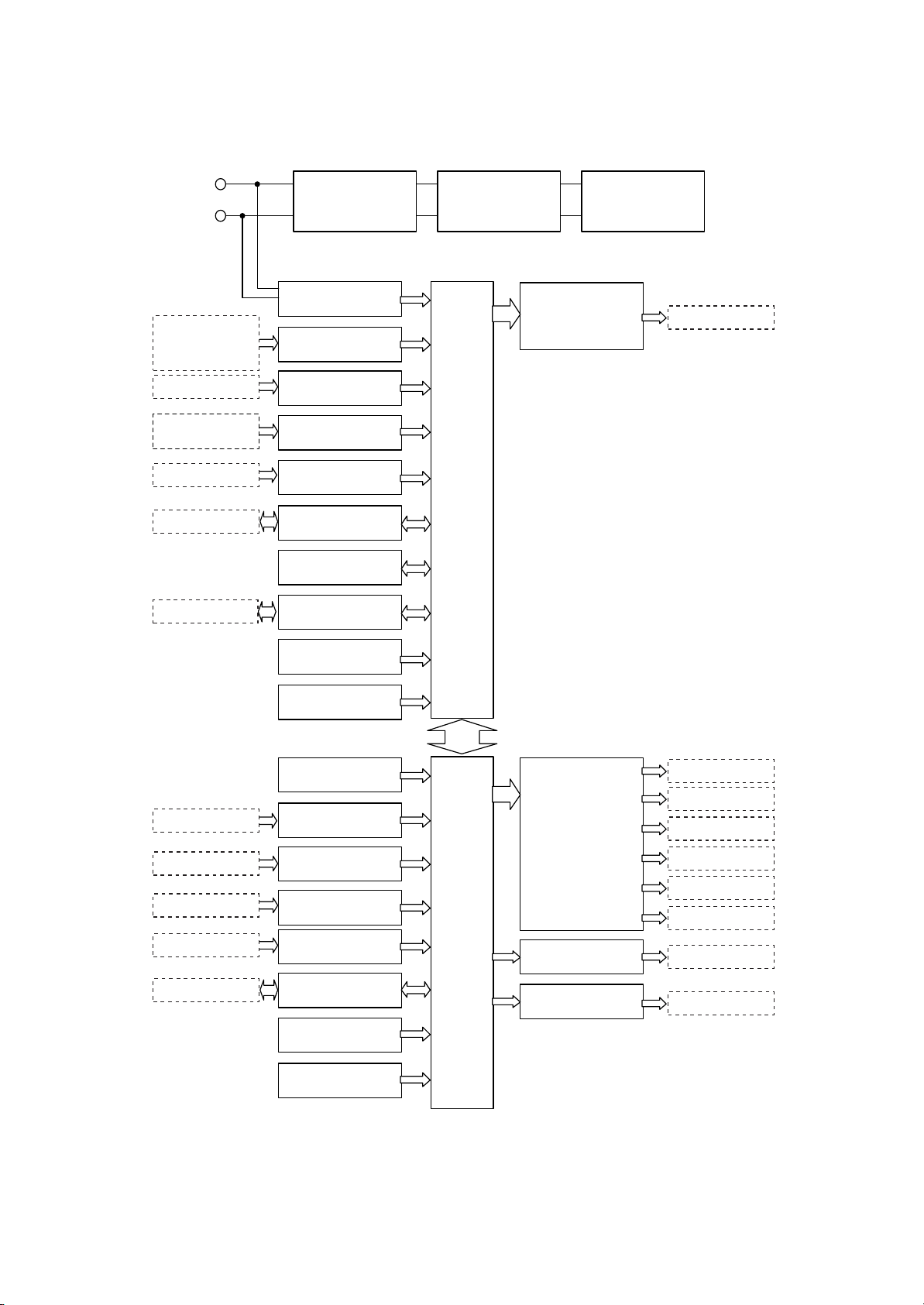

4-3 MICROPROCESSOR FUNCTION LIST

■ INDOOR UNIT

INDOOR UNIT TYPE

60,000

54,000

45,000

36,000

30,000

CAPACITY

(BTU/h)

24,000(25,000)

20,000

18,000

14,000

12,000

9,000

7,000

CN1 ACIN

CN2 TH FUSE

CN3 FAN CAPA

CN4 FAN MOTOR

CN5 DRAIN PUMP

CN6 S. VALVE

CN8 NETWORK

CN10 SP-M(U.D)

CN11 SP-M(R,L)

CN12

HEATER

CN13 DISPLAY

CN14 E.E.VALVE

CN15 FLOAT SW

CN16

CN17

FAN FEEDBACK

WIRED REMOTE

CONTROLLER

CN18 TEST

CN19 R.TH

CN20 P.TH

CN21 S.TH

CN22

CN23

EXT.OUTPUT

EXT.INPUT

CN24 FLASH(MAIN)

CN25 FLASH(SUB)

CN26 COMMUNICATE

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

SW9

SW10

FUNCTION 1

FUNCTION 2

FUNCTION 3

FUNCTION 4

INDOOR UNIT

ADDRESS 1

INDOOR UNIT

ADDRESS 2

REFRIGERANT

ADDRESS 1

REFRIGERANT

ADDRESS 2

REMOTE CONT-

ROLLER ADDRESS

MANUAL AUTO

Large

Ceiling

Universal

Compact

Cassette

Large

Cassette

Compact

Duct

Low

Duct

High

Static

Pressure

Duct

Static

Pressure

25 25

Wall

Mounted

– 28 –

Page 29

■ OUTDOOR UNIT

OUTDOOR UNIT TYPE

CN1 AC IN

CN2 NET

CN3 FAN.1

CN4 FAN.2

CN5 BASE HEATER

CN6 CRANK CASE HEATER

CN7 S.V.1

CN8 S.V.2

CN9 S.V.3

CN10 S.V.4

CN11 S.V.5

CN12 S.V.6

CN13 S.V.7

CN14 S.V.8

CN17 4WV.1

CN18 4WV.2

CN19 4WV.3

CN20 4WV.4

CN21 4WV.5

CN22 TERMINATOR

CN24 COMP.1

CN25 COMP.2

CN26 COMP.3

CN27 TH.1

CN28 FLASH W/R S

CN29 E.E.V.1

CN30 E.E.V.2

CN31 E.E.V.3

CN32 P.SEN-L

CN33 P.SEN-M

CN34 P.SEN-H

CN35 TEST

CN42 P.SW-H

CN43 P.SW-L

CN44 FLASH W/R M

CN45 TH.2

CN48 EXT.OUTPUT

CN49 EXT.INPUT2

CN50 EXT.INPUT1

CN51 COMMUNICATION

PWB.

CN52 OIL LV-HI

CN53 OIL LV-LO

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

SW9

FUNCTION 1

FUNCTION 1

FUNCTION 1

FUNCTION 1

FUNCTION 1

FUNCTION 1

FUNCTION 1

REFRIGERANT

ADDRESS 1

REFRIGERANT

ADDRESS 2

AOY90TPAMF

– 29 –

Page 30

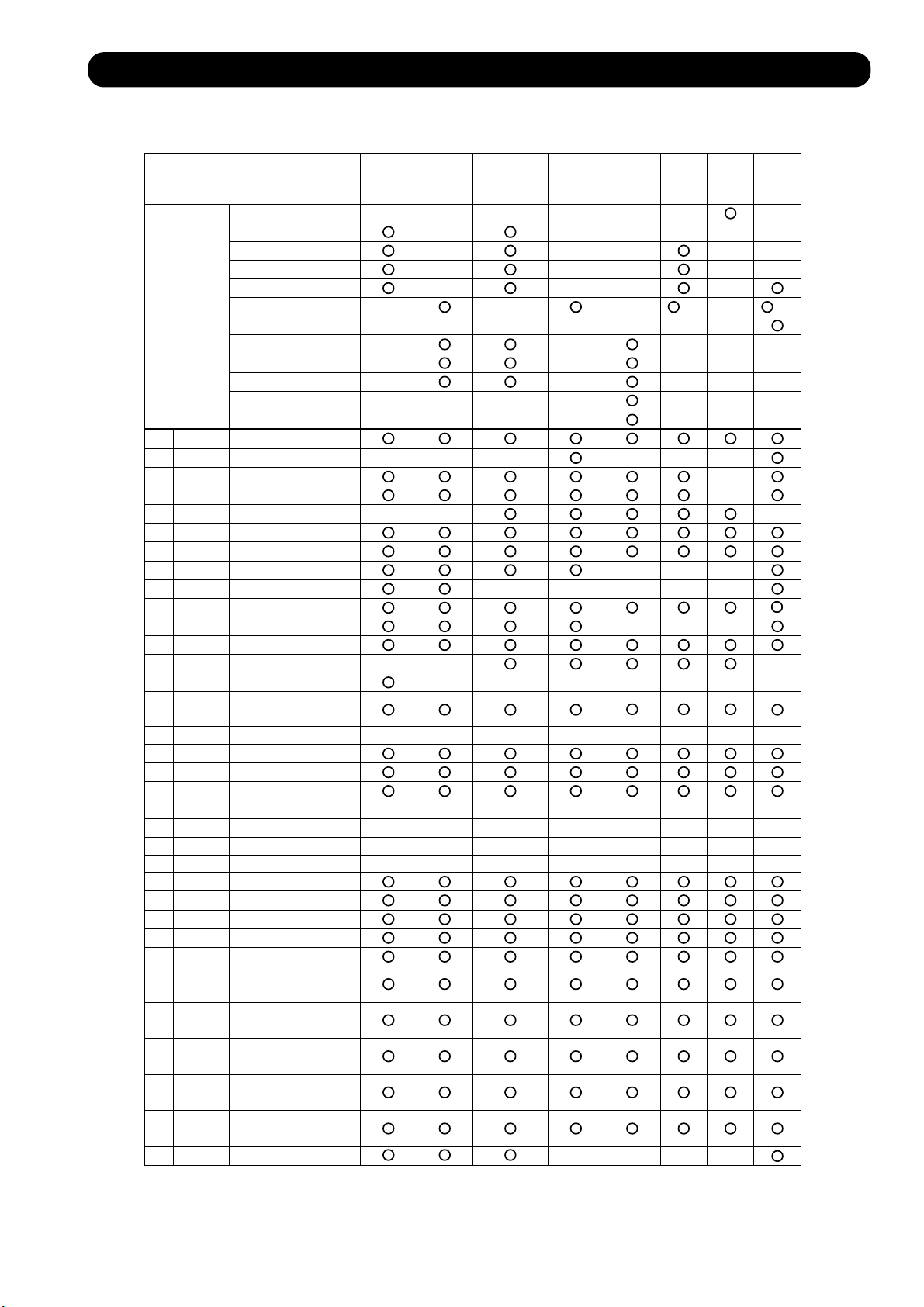

4-4 FUNCTION AND SETTING OF EACH SWITCH

■ INDOOR UNIT

1. DIP SWITCH 1

1

Ceiling height setting.

Changeover the fan speed of the indoor fan phase control according to ceiling height (cassette type).

Details of rotation is according to DIP SW3 setting.

CEILING HEIGHT SETTING 1,2

Standard High ceiling 1 Low ceiling

SW1-1

SW1-2

(2)

NOTCH

Ceiling height

Room temp correct coefficient of heating.

2

Decide room temp correct coefficient value of heating.

ROOM TEMP. CORRECT COEFFICIENT OF HEATING

SW1-3

OFF

ON OFF - 2 deg

(3)

(4)

(5)

(6)

OFF

OFF OFF

HIGH(1)

MED

LOW LOW

S-LOW S-LOW S-LOW S-LOW

2.5 3.0m

SW1-4

OFF

ON

3.0 3.5m

Coefficient value

High ceiling 2

ON

HIGH HIGH

MED MED

+ 2 deg

0 degOFF

OFF

ON ON

LOW

more than

3.5m

ON

HIGH

MEDLOW

less than

2.5m

+ 4 degON ON

2. DIP SWITCH 2

Room temp. correct coefficient of cooling.

1

Decide room temp correct coefficient value of cooling.

ROOM TEMP CORRECT COEFFICIENT OF COOLING

SW2-1

OFF

ON + 2 deg

2

Zone control switch.

Decide the indoor unit for zone control use and not for zone control.

ZONE CONTROL SWITCH

SW2-2

OFF

ON

Coefficient value

0 deg

Switch control

Validity

Invalidity

Ð 12Ð

– 30 –

Page 31

3

Filter check validity/invalidity.

Filter check is set with Dip SW 2-3.

FILTER CLEANING FUNCTION

SW2-3

Filter check

OFF

ON

4

Auto restart validity/invalidity.

Invalidity

Validity

Auto restart is set with Dip SW2-4. But,when a LCD wired remote controller

is connected, auto restart is set to "validity" regardless of the indoor unit setting.

AUTO RESTART SETTING

SW2-4

OFF

ON

Auto restart

Invalidity

Validity

3. DIP SWITCH 3

Indoor unit for speed switch.

1

This switch has eight kinds of rotation table, and can select fan speed corresponding to each model.

INDOOR UNIT FAN SPEED TABLE

Table No.

SW3-2

SW3-3 OFF

0 1 3

OFF

ONSW3-1

OFF OFF

OFF

OFF OFF

2 4 75

OFF

ON ON

ON

OFF

OFF

ON

ON

OFF

ON

6

OFF

ON

ON

ON

ON

ON

INDOOR FAN MOTOR SPEED (LARGE CEILING)

Table No.

Models

Hi

Me

Lo

S-Lo

0 1 3

AB30

Not used

750

600

500 500

2 4 75

AB36

1000850

900

750

Not used Not used Not used

AB45

1100

1000

850

500

Rotating speed of the indoor fan motor is the same for Cooling / Fan / Heating.

6

AB54

1250

1150

1000

500

Ð 12Ð

– 31 –

Page 32

INDOOR FAN MOTOR SPEED (CASSETTE)

Table No.

Models

(1)

(2)

(3)

(4)

(5)

(6)

Models

(1)

(2)

(3)

(4)

(5)

0

AU54

680

630

580 550

550 500

500 470

300 300

4

AU30

500

470

430

390

360

AU45

620

580

Not used

1 2

AU36

580

550

500

470

420

300

5 6

AU25

460

430

390

350

320

3

Not used

7Table No.

AU20

420

390

350

310

280

(6)

*

2

Not used (SW3-4).

Rotating speed of the indoor fan motor is the same for Cooling/Fan/Heating.

300

4. DIP SWITCH 4

Indoor unit model switch.

1

Indoor unit model (capacity data) is set with SW4-1 4.

INDOOR UNIT MODEL SWITCH

Capacity

Type

SW4-1

SW4-2 OFF

SW4-3

90

OFF

ON

ON

60

ON

ON

OFF

ON

54

OFF

ON

OFF

ON

45

ON

OFF

OFF

ON

36

OFF

OFF

OFF

ON

30

ON

ON

ON

OFF

25

OFF

ON

ON

OFF

20

ON

OFF

ON

OFF

300

OFF

OFF

OFF

18

ON

14

ON

ON

OFF

OFF

12

OFF

ON

OFF

OFF

250

9

ON

OFF

OFF

OFF

7

OFF

OFF

OFF

OFFSW4-4

Ð 12Ð

– 32 –

Page 33

5. JUMPER

Custom code selection of the remote controller.

1

Custom code of the infrared signal is set with jumper lead combinations which are shown below.Once set, other infrared

signal is not accepted.

REMOTE CONTROLLER CUSTOM CODE SELECTION

JP1 JP2

Custom code

2

Not used (JP3)

Connect

Disconnect

Connect

Disconnect

Connect

Connect

Disconnect

Disconnect

Type A (Primary setting)

Type B

Type C

Type D

Ð 12Ð

– 33 –

Page 34

■ OUTDOOR UNIT

1. DIP SWITCH 1

1

Test run.

Test run(forced operation) and normal operation are set with SW1-1.2 on the PCB.

The cooling/heating operation mode on the test run is set.

TEST RUN SW

SW1-2 SW1-1 Test Run Remarks

OFF OFF Normal operation

OFF ON Cooling test run

ON OFF Heating test run

ON ON Normal operation

Pump down operation.

2

Pump down operation is set with SW1-3 on the PCB.

(OFF-ON)and (operated continuously

more than 1 min. with ON state)

(OFF-ON)and (operated continuously

more than 1 min. with ON state)

( Initial setting)

PUMP DOWN SW

SW1-3 Pump down operation Remarks

OFF Release

ON Operate

Forced defrost operation.

3

Defrosting is started forcedly with SW1-4 on the PCB.

FORCED DEFROST SW

SW1-4 Forced defrost Remarks

OFF Release

ON Operate

(OFF-ON)and (operated continuously

more than 1 min. with ON state)

(OFF-ON)and (operated continuously

more than 1 min. with ON state)

( Initial setting)

( Initial setting)

2. DIP SWITCH 2

Night operation fan mode.

1

The night operation fan mode ON/OFF is set with SW2-1 thermistor

detects the temperature less than 30 C and the outdoor unit operation mode is cooling.

NIGHT OPERATION FAN MODE SW

SW2-1

OFF

ON Operate

Snow falling protection fan mode SW.

2

When the compressor is stopped,snow falling protection fan mode is set with SW2-2.

SNOW FALLING PROTECTION FAN MODE SW

SW2-2

OFF

ON Operate

Night operation fan mode

Release

Snow falling protection fan mode

Release

( Initial setting)

( Initial setting)

– 34 –

Page 35

Expansion valve initialize.

3

The pulse of the expansion valve is initialized with SW2-3.

EXPANSION VALVE INITIALIZATION SW

SW2-3

OFF

ON Operate

Forced oil recovery operation.

4

Forced oil recovery operation started with SW2-4.

Expansion Valve Initialization

Operation

Release

( Initial setting )

Remarks

FORCED OIL RECOVERY SW

SW2-4

OFF

ON

Forced Oil Recovery

Release

Operate

3. DIP SWITCH3 SETTING IS FORBIDDEN

4. DIP SETTING IS FORBIDDEN

5. DIP SWITCH5

SW5-1 and SW5-2 setting are forbidden.1

2

Base heater validity/invalidity.

The base heater setting is performed with SW5-3.

BASE HEATER SETTING SW

SW5-3

OFF

ON Invalidity

Base Heater Setting SW

Validity

6. DIP SWITCH6 SETTING IS FORBIDDEN

( Initial setting )

Remarks

(OFF-ON)+(ON continues for 1 minute)

( Initial setting )

Remarks

7. DIP SWITCH7

System type switch 1,2.

1

Model change in Heat recovery / Heat pump type / Cooling only type are made with SW7-1,2.

SYSTEM TYPE SWITCH 1/2

SW7-1 Model selectionSW7-2

OFF

OFF

ON

ON

OFF

ON

OFF

ON

Heat Pump

Cooling Only

Heat Recovery

Cannot Set

( Initial setting )

Remarks

8. External input terminal 1/2

When the cooling or heating mode is selected, the priority circuit is set.

With CN49 and CN50.

EXTERNAL INPUT TERMINAL 1/2

Terminal

External input

terminal 1CN50

External input

terminal 2CN49

Conditions

R.C.

External input

Cool

Heat

Setting

OPEN

SHORT

OPEN

SHORT

Remarks

– 35 –

Page 36

■ WIRED REMOTE CONTROLLER

1. DIP SWITCH 1

1

Remote controller address 1

FINAL REMOTE CONTROLLER SWITCH

SW1-1

Terminator

OFF

ON YES

2

Indoor unit connection.

This is switched according to No. of connected indoor unit.

No. INDOOR UNIT CONNECTION SWITCH

SW1-2

OFF

ON Multiple unit connection

Remote controller address1,2.

3

Used for setting of the remote controller address. Set the addresses by ordering MASTER SLAVE

without any space.

REMOTE CONTROLLER ADDRESS 1,2 SWITCH

SW1-3 SW1-4

OFF

OFF ON Slave

Number of indoor unit

One unit connection

OFF Master

NO

Method

SW1-5 and SW1-6 setting are forbidden.4

2. DIP SWITCH 2

Cooling only / heat pump.

1

Switching cooling only / heat pump is set with SW2-1.

COOLING ONLY / HEAT PUMP SWITCH

SW2-1

OFF

ON Cooling only

2

Auto change over validity / invalidity.

Auto change over validity / invalidity is set with SW2-2.

AUTO CHANGEOVER SWITCHING

SW2-2

OFF

ON Validity

Operation system

Heat pump

Auto restart

Invalidity

Ð 12Ð

– 36 –

Page 37

3

SW2-3 setting is forbidden.

4

Maintenance.

Used for indication of the refrigerant system, indoor unit address and error history.

MAINTENANCE SWITCH

SW2-4

Mode

OFF

ON Maintenance mode

5

SW2-5 setting is forbidden.

6

Battery backup switch.

When installing, turn the SW2-6 ON.

Normal mode

Ð 12Ð

– 37 –

Page 38

■ CENTRAL REMOTE CONTROLLER

1. DIP-SW2

DIP SW2-1 2-2 setting forbidden.

1

DIP SW 2-1 OFF

DIP SW 2-2 OFF

DIP SW2-3 setting.

2

Filter check sign indication or not when filter check comes from indoor unit.

( Factory setting)

SW2-3

Filter check sign indication

OFF

ON Display

DIP SW2-4 setting.

3

C / F switch

Temperature display is centigratde( ) / Fahrenheit( )

SW2-4

OFF

ON

DIP SW2-5 setting

4

For validity / invalidity the wired and wireless remote controller operation prohibit function.

SW2-5

OFF

ON Invalidity

DIP SW2-6 2-7 setting forbidden.

5

Non-Display

C

( Factory setting)

C / F

C

F

( Factory setting)

RC operation prohibit function

Validity

F

DIP SW 2-6 OFF

DIP SW 2-7 OFF

DIP SW2-8 setting.

6

SRAM Battery ON / OFF

When installing the control remote controller, this switch must be set to ON.

(factory setting:OFF)

( Factory setting)

SW2-8

OFF

ON

At the time of shipment,the battery is turned off to avoid electricity consumption.

Be sure to set this switch to ON.

7

SW42 Initial setting button

This switch is used when initializing the central remote controller.

SRAM Battery

OFF

ON

– 38 –

Page 39

WIRED REMOTE CONTROLLER

■

Display panel

TURE OF CONTROLLER

FEA

Four kinds of timer setup (OFF/ ON1/ ON2/ WEEKLY) are

possible.

NON STOP

OFFON

TIMER

WEEKLY

12

TIMER

MODE

CLOCK ADJUST

CLOCK

TIMER

NEXT DAY

SET TIME

OFF

ON

ON

OFF

CENTRAL

DAY OFF

DEFROST

TEMP./DAY

ZONE

SET

C

F

DAY

TEST

FAN

CONTROL

ENERGY SAVE

DAY OFF

AUTOAUTO

COOL

DRY

FAN

HEAT

ANTI FREEZE

MASTER

CONTROL

START/STOP

Equipped with weekly timer as standard function.

(2 times Start/Stop per day for a week)

By failure,the error code is displayed. The error history

can be displayed,which is convenient for maintenance.

2 remote controllers can be connected.

Up to 16 indoor units can be simultaneously controlled.

Anti freeze, saving operation and zone control are possible.

Favorite timer ( ON 2 )

■

FUNCTIONS

15

Display

CLOCK

14

13

12

11

10

9

8

7

NON STOP

OFFON

TIMER

WEEKLY

12

NON STOP

OFFON

TIMER

WEEKLY

12

TIMER

MODE

CLOCK ADJUST

19

CLOCK

TIMER

NEXT DAY

CENTRAL

OFF

ON

TIMER

ON

DAY OFF

OFF

DEFROST

NEXT DAY

SET TIME

TEMP./DAY

ZONE

SET

20 21 22 23

CENTRAL

OFF

ON

ON

DAY OFF

OFF

DEFROST

DAY

TEST

DAY

F

C

FAN

CONTROL

ENERGY SAVE

DAY OFF

C

F

TEST

AUTOAUTO

COOL

DRY

FAN

HEAT

ANTI FREEZE

MASTER

CONTROL

START/STOP

AUTOAUTO

COOL

DRY

FAN

HEAT

ANTI FREEZE

2426 252728

16

17

18

1

START/STOP button

Pressed to start and stop operation

2

Operation lamp

Lights during operation and when the timer is on.

3

Energy save button

Turns the energy efficient mode on and off.

4

Day off button

Temporary cancellation of one day timer.

5

Energy save lamp

Lights up when the unit is in the energy save mode.

6

1

2

3

4

5

6

Zone button

Use to turn the zone control on and off.

7

Set button

Sets the date, hour, minute and on-off time.

8

Zone lamp

Lights up when the unit is in the zone control mode.

9

Horizontal air flow direction and swing button

Push for two seconds and change swing mode.

10

Horizontal swing lamp

Push for two seconds and change swing mode.

11

Vertical air flow direction and swing button

Push for two seconds and change swing mode.

12

Vertical swing lamp

13

Clock adjust button

Timer mode button

14

Changes the timer mode (NON STOP, OFF TIMER,

ON TIMER, WEEKLY TIMER).

15

Set time button

Sets the current time and on-off time.

16

Temp./Day button

Sets the indoor temperature / days.

17

Fan control button

Selects the fan speed (AUTO, LOW, MED, HIGH).

18

Master control button

Selects the operating mode(AUTO, HEAT, FAN, COOL, DRY).

Clock display

19

20

Central control display

21

Set temperature / Day display

Fan speed display

22

Master control display

23

24

Anti freeze display

25

Day off display

Test display

26

27

Defrost display

28

Timer mode display

– 39 –

Page 40

WIRELESS REMOTE CONTROLLER

■

TURE OF CONTROLLER

FEA

C

L

O

C

K

TIM

ER

S

L

E

O

N

AM

O

F

H

M

PM

T

IM

E

R

R

E

S

E

O

F

F

O

N

E

N

E

R

G

Y

S

A

V

E

A

U

T

O

A

U

C

C

O

O

L

H

IG

D

R

Y

M

E

LO

FA

N

H

E

A

T

A B C D

A B C D

■

FUNCTIONS

Display

3

2

1

9

10

11

Display panel

15

CLOCK

16

AM

PM

OFF

AUTO

COOL

DRY

FA

HEAT

E

P

F

T

T

O

H

D

W

C

L

O

C

K

AM

PM

O

F

F

AUTO

C

O

O

L

DR

Y

FA

N

H

E

A

T

ON

ENERGY SAVE

N

Four kinds of timer setup (ON/OFF/PROGRAM/SLEEP)

are possible.

Up to 16 indoor units can be simultaneously controlled.

Both wired and wireless remote controller can be used jointly.

TIMER

S

L

E

E

P

O

N

O

F

F

H

M

T

IM

E

R

R

E

S

E

T

O

N

ENERGY SAVE

AUTO

C

H

IG

H

M

ED

L

O

W

12

13

A B C D

TIMER

14

SLEEP

ON

HM

OFF

TIMER RESET

AUTO

C

HIGH

MED

LOW

18

19

20

1

5

64

START/STOP button

Pressed to start and stop operation

2

Set temp./Set time buttons

Sets the indoor temp./Sets the current time and on-off time

3

Master control button

Selects the operating mode(AUTO, HEAT, FAN, COOL, DRY).

4

Sleep timer button

Press to select sleep timer.

5

Signal transmitter

6

7

Timer button

Press to select the timer mode.(OFF TIMER,ON TIMER,

.

PROGRAM TIMER,TIMER RESET)

7

Fan control button

8

Selects the fan speed (AUTO, LOW, MED, HIGH).

8

Battery compartment lid

9

Air flow direction button

Use to set the desired air flow direction & SWING

function.

10

Energy save button

Turns the energy efficient mode on and off.

11

Code change (Slide Switch)

Switching the remote control unit code.(Max.4 units)

12

Time adjust button

Set the current time.

13

Test run button

This button is used when testing the air conditioner

after installation.

14

ACL button

This button is used when replacing batteries.

15

Transmit indicator

Clock display

16

17

Master control display

18

Timer mode display

Fan speed display

19

20

Set temperature display

Timer set indicator

21

22

Temperature set indicator

17

21

22

– 40 –

Page 41

CENTRAL REMOTE CONTROLLER

SETTINGMONITOR MEMORY

ERROR

SUN SATFRITHU

WED

TUE

MON

AM

CLOCK

PM

ADDRESSADDRESS

AM

NON STOP

PM

ON

OFF

TIMER

AM

12

PM

WEEKLYWEEKLY

■

FEATURE OF CONTROLLER

NEXT DAYNEXT DAY

0

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19

20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

1

ONON

OFFOFF

40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

2

60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79

OFFOFF

3

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

x100

ALL/GROUP

SELECT

TEST

CENTRAL CONTROL

ALL

X

100

Up to 400 indoor units/64 groups can be controlled with one central remote controller.

Up to 16 central remote controllers can be connected in one system.

Central remote controller can control by all/group/individual.

By setting the central remote controller, it is possible to lock the function of the standard

controllers. Items of selections are all functions, timer mode, disabling all functions for

certain hour, operating mode, temperature setting, reset filter, and On/Off.

Weekly timer is equipped as standard function. (2 times On/Off per day for one week).

Setting contents of central remote controller are all memorized, so that each indoor unit can

be operated in the memorized condition even if the operating conditions are changed later on.

Error code is displayed when it occurs.

The history of failure can also be displayed, which is convenient for maintenance.

FILTER

ZONE

ON OFF

ALL

OFFON

TEMP

F

C

ENERGY

SAVE

ON OFF

LOUVER

OPERATION

ON

OFF

AUTO

AUTO

COOL

DRY

FAN

HEAT

FIXED

ANTI

FREEZE

ON OFF

DEFROST

Examples of error:

1. Communication/micro computer error

2. Abnormal heat exchanger thermistor

3. Float switch operating

4. Abnormal outdoor unit thermistor

5. Abnormal discharge temperature

6. Abnormal oil sensor

7. Excessive indoor units connected

8. Abnormal indoor fan

■

FUNCTION

32

31

30

29

28

27

26

25

24

SUN SATFRITHU

MON

CLOCK

ADDRESSADDRESS

NON STOPNON STOP

OFF

TIMER

12

WEEKLYWEEKLY

CLOCK

ADJUST

TIMER

MODE

TIMER

COPY

9. Abnormal room temperature thermistor

10. Abnormal air blow temperature thermistor

11. 3 phase reverse polarity connection

12. Abnormal pressure

13. Abnormal refrigerant pressure sensor

14. Duplicated indoor unit address

15. Duplicated outdoor unit address

Display

133

SETTINGMONITOR MEMORY

ERROR

TEST

SET

CHECK

CENTRAL CONTROL

ALL

TEST

WED

TUE

AM

PM

AM

PM

ON

AM

PM

DAY

DAY OFF

NEXT DAYNEXT DAY

0

0000 0101 0202 0303 0404 0505 0606 0707 0808 0909 1010 1111 1212 1313 1414 1515 1616 1717 1818 1919

2020 2121 2222 2323 2424 2525 2626 2727 2828 2929 3030 3131 3232 3333 3434 3535 3636 3737 3838 3939

1

ONON

OFFOFF

4040 4141 4242 4343 4444 4545 4646 4747 4848 4949 5050 5151 5252 5353 5454 5555 5656 5757 5858 5959

2

6060 6161 6262 6363 6464 6565 6666 6767 6868 6969 7070 7171 7272 7373 7474 7575 7676 7777 7878 7979

OFFOFF

3

8080 8181 8282 8383 8484 8585 8686 8787 8888 8989 9090 9191 9292 9393 9494 9595 9696 9797 9898 9999

x100

ALL/GROUP

SELECT

X

100

TIME

TIMER

DELETE

TIMER

SET

MEMORY

OPERATION

MEMORY

SETTING

CENTRAL

CONTROL

GROUP

SETTING

BACK

DELETE

ZONE

FILTER

RESET

FILTER

ZONE

ON OFF

ALL

OFFON

ENERGY

SAVE

ON OFF

TEMP

F

C

ENERGY

SAVE

ON OFF

LOUVER

OPERATION

ON

OFF

TEMP.

AUTO

FAN

CONTROL

AUTO

COOL

DRY

FAN

HEAT

FIXED

ANTI

FREEZE

ON OFF

DEFROST

MASTER

CONTROL

ANTI

FREEZE

2

3

4

5

6

7

8

9

20

21

2223

19

18

1617

15

14

13

12

11 10

– 41 –

Page 42

1

All ON/OFF button

2

All ON/OFF LED

3

Back button

4

Zone button

5

Energy save button

6

Fan control button

7

Master control button

8

Anti freeze button

9

Horizontal Air flow direction and swing button

10

Vertical Air flow direction and swing button

11

Temp button

12

ON/OFF button

13

Filter reset button

14

Delete button

15

Test button

16

Set button

17

Set LED

18

Check button

19

Group setting button

20

Memory setting button

21

Timer set button

22

Time button

23

Day off button

24

Timer copy button

25

Timer mode button

26

Clock adjust button

27

Day button

28

Timer delete button

29

Memory operation button

30

Central button

31

All/Group button

32

Select 100 button

33

Select button

Change over the zone.

Starting energy save operation.

Setting of indoor temperature.

ON/OFF setting by groups.

Delete of setting.

Transmission of all changed setting details.

Blinks when transmission is necessary.

Confirmation of address setting and error code.

Setting of group of some remote controller group connected to the central remote controller.

Memory the setting contents of all.

Setting of dates, hours, minutes and on-off time.

Setting of on-off time.

Temporary cancellation of one day timer.

Copying the timer condition (the day before).

Changeover the timer mode (NON STOP, OFF, ON1, ON2, WEEKLY).

Operating the memorized condition.

Forbid some operation of the individual remote controller.

Changeover of control unit (ALL GROUP R.C.GROUP).

Remote controller group indication by hundreds.

Change to remote controller and group number.

Display panel

SUN SATFRITHU

TUE

MON

AM

52

CLOCK

PM

ADDRESSADDRESS

AM

NON STOPNON STOP

PM

ON

OFF

TIMER

AM

12

PM

WEEKLYWEEKLY

51

34

Day of the week display

35

Status display

36

Transmit indicator display

37

Central control display

38

Filter reset display

39

Zone display

WED

NEXT DAY

50

ERROR

36

TEST

CENTRAL CONTROL

ALL

3534

SETTINGMONITOR MEMORY

0

0000 0101 0202 0303 0404 0505 0606 0707 0808 0909 1010 1111 1212 1313 1414 1515 1616 1717 1818 1919

2020 2121 2222 2323 2424 2525 2626 2727 2828 2929 3030 3131 3232 3333 3434 3535 3636 3737 3838 3939

1

ONON

OFFOFF

4040 4141 4242 4343 4444 4545 4646 4747 4848 4949 5050 5151 5252 5353 5454 5555 5656 5757 5858 5959

2

6060 6161 6262 6363 6464 6565 6666 6767 6868 6969 7070 7171 7272 7373 7474 7575 7676 7777 7878 7979

OFFOFF

3

8080 8181 8282 8383 8484 8585 8686 8787 8888 8989 9090 9191 9292 9393 9494 9595 9696 9797 9898 9999

x100x100

49 48

40

Temperature display

41

Energy save display

42

Fan control display

43

Master control display

44

Fixed cooling or heating

operation display

45

46

47

48

49

50

– 42 –

38

FILTER

ZONE

ON OFF

40

39

TEMP

ENERGY

SAVE

ON OFF

OPERATION

ON

OFF

37

Anti freeze display

Defrost display

Air flow direction display

ON/OFF display

Group control display

ON/OFF time display

F

C

LOUVER

43

4241

AUTO

AUTO

COOL

DRY

FAN

HEAT

FIXED

ANTI

FREEZE

ON OFF

DEFROST

47

46

51

Timer mode display

52

Clock and address

display

44

45

Page 43

5. OUTDOOR UNIT OPERATION CONTROL

5-1 COMPRESSOR OPERATION CONTROL

5-1-1 OPERATION STOP CONDITION

Compressor operation condition

When cooling requirement capacity or heating requirement capacity from either of the indoor units in the same

refrigerant system is input, the compressor operates.

But in the following case, the compressor operates in accordance with operation of each mode.

During 3 minute restart prevention operation

During compressor recovery operation

During deicing operation

Failure ( except for a part )

Defrosting

4-way valve 1 restart switching

Oil recovery

Under expansion valve initialization

At protective operation

Central discharge temperature protection

High pressure protection

Compressor stop condition

When all the indoor units in no "cooling requirement capacity" or "heating requirement capacity ",

are stopped.

But, in the following case, the compressor operates in accordance with operation of each mode.

all the compressors

Defrosting

Oil recovery

5-1-2 COMPRESSOR OUTPUT PATTERN

The output pattern of a compressor is defined as shown below.

Compressor output pattern

OUTPUT PATTERN

Step 0

Step 1

Step 2