Page 1

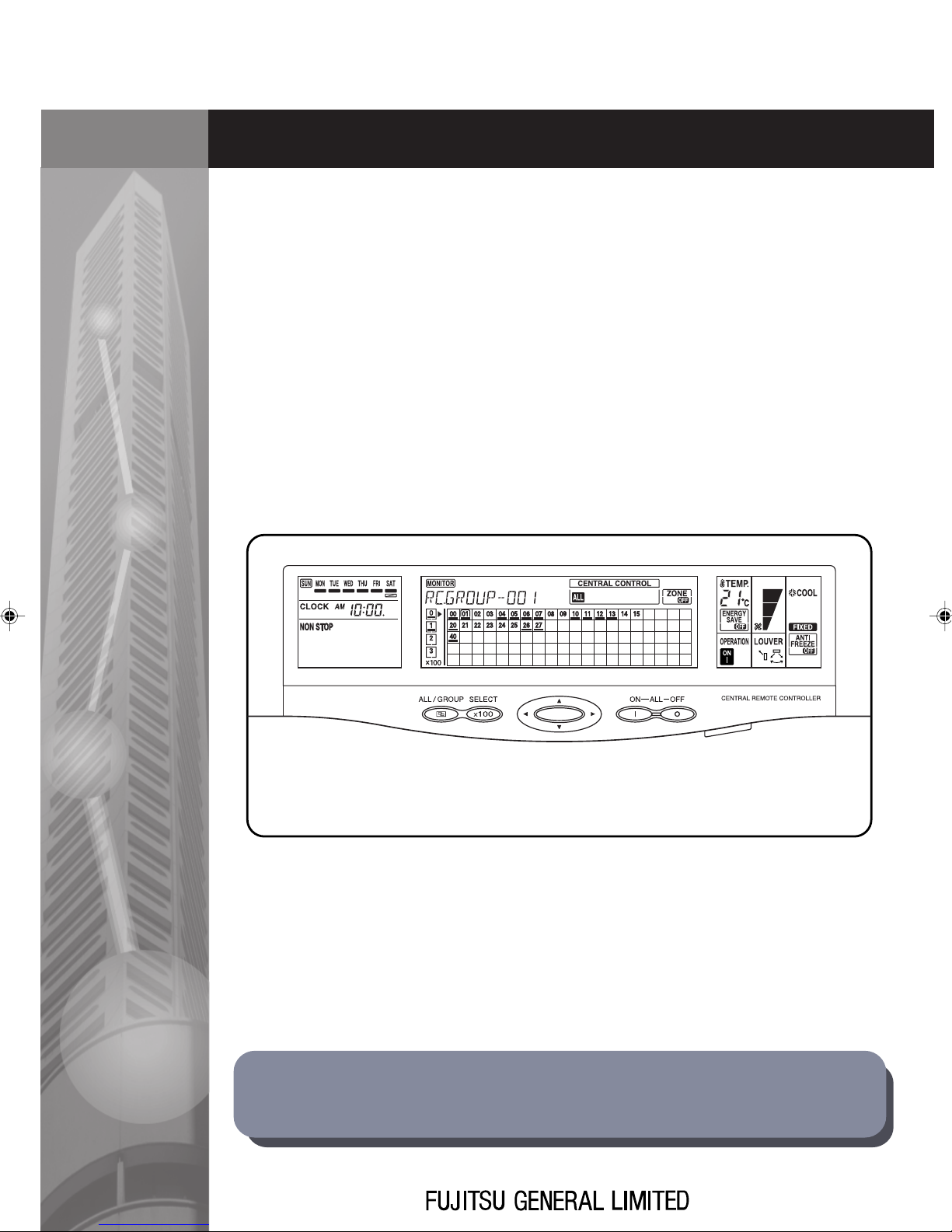

SETTING MANUAL

CENTRAL REMOTE CONTROLLER

UTB-YCA

UTB-GCA

Before using this controller, please read this [SETTING MANUAL]

to ensure correct operation. Keep this manual for future reference.

Page 2

Page 3

CONTENTS

1. SAFETY PRECAUTIONS.............................................................. 2

2. SYSTEM OUTLINE ....................................................................... 3

2-1. SYSTEM OUTLINE............................................................................. 3

2-2. EXPLANATION OF TERMS ................................................................ 5

2-3. NAMES AND FUNCTIONS OF THE PARTS ...................................... 8

2-4. PRECAUTIONS WHEN SETTING THE SYSTEM ............................ 10

2-4-1. Priority of remote controller setting ......................................................... 10

2-4-2. Group information store .......................................................................... 10

3. SETTING ..................................................................................... 11

3-1. FLOW OF INSTALLATION ................................................................ 11

3-2. SETTING OPERATION..................................................................... 13

3-2-1. Turn on power ......................................................................................... 13

3-2-2. Initial setting ............................................................................................ 13

3-2-3. Clock setting ........................................................................................... 24

3-2-4. Group information store .......................................................................... 26

3-2-5. Test operation ......................................................................................... 28

4. ERROR DISPLAY........................................................................ 30

4-1. ERROR MONITOR ........................................................................... 30

4-2. ERROR CODES ............................................................................... 32

4-3. ALL CLEAR SWITCH........................................................................ 33

5. SPECIFICATIONS ....................................................................... 34

5-1. SPECIFICATIONS............................................................................. 34

5-2. DIMENSIONS ................................................................................... 34

1

Page 4

1. SAFETY

PRECAUTIONS

1. SAFETY PRECAUTIONS

• Before using CENTRAL REMOTE CONTROLLER, read this “SAFETY PRECAUTIONS” thoroughly to ensure the correct operation.

• This section discribes the important safety information to operate CENTRAL REMOTE CONTROLLER.

• The meanings of “WARNING” and “CAUTION” are explained as follows.

This mark indicate procedures which, if improperly performed, are most

WARNING!

likely to result in the death of or serious injury to the user or service personnel.

CAUTION!

This mark indicates procedures, which might result in personal harm to

the user or damage to property if improperly performed.

WARNING!

• Do not attempt to install this controller by yourself.

• This controller contains no user-serviceable parts. Always consult authorized service personnel for repairs.

• When moving this controller, consult authorized service personnel for disconnection and

installation.

• If the problem (burning, smell, etc) occurs, turn off the electrical breaker immediately to

stop operation and then consult the authorized service personnel.

• If the power supply cord becomes damaged, contact your service representative for instruction.

CAUTION!

• Do not expose the controller directly to water.

• Do not operate the controller with wet hands.

• Do not touch the switches with sharp objects.

• Always turn off the electrical breaker whenever cleaning the controller, the air conditioner

or the air filter.

• Ensure that all electronic equipment is at least one meter away from the controller.

• Avoid installing the controller near a fireplace or other heating apparatus.

• When installing the controller, take precautions to prevent access to infants.

• Do not use inflammable gases near the controller.

• At the time of installation, always provide a breaker for electrical leakage.

• Always use fuses with the proper capacity and type.

2

Page 5

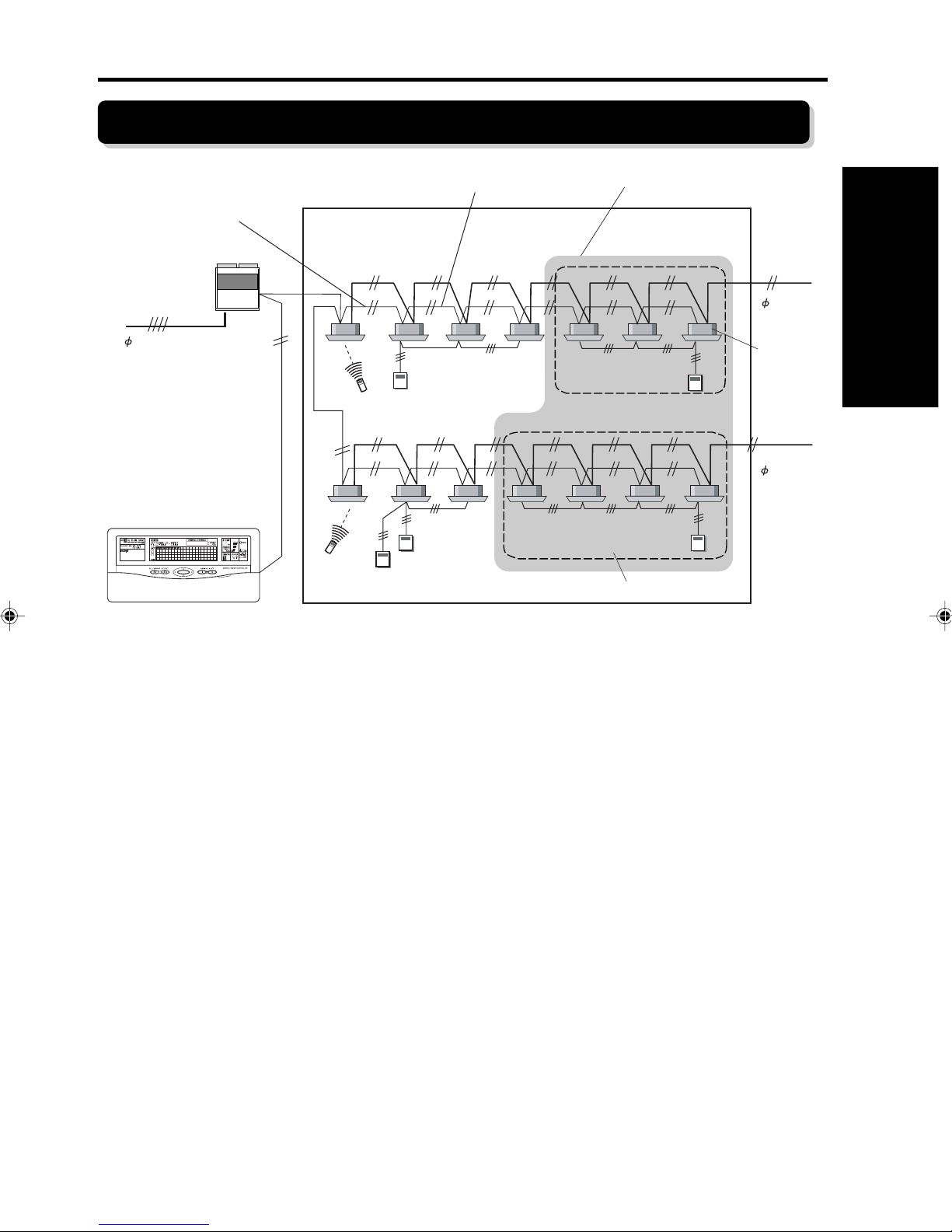

2. SYSTEM OUTLINE

2-1. SYSTEM OUTLINE

Transmission line

Refrigeration

system 1

3 4W 50Hz 380 - 415V

Centr

al remote

controller

Controller line

Group

1 50Hz

220 - 240V

Indoor unit

2. SYSTEM OUTLINE

1 50Hz

220 - 240V

Remote Controller Group

Please consult your sales representative when two or more central remote controllers need to be

installed in one system.

• What is the central remote controller?

The central remote controller allows all the stored remote controller groups (the indoor units) to

be controlled from a remote location.

(Refer to “2-3. EXPLANATION OF TERMS 1” for details about remote controller groups.)

• Three functions of the central remote controller

• CENTRAL CONTROL

The central control provides management of the remote controller groups (the indoor units).

This includes placing restrictions on the standard remote controllers or performing memory operation for easily reproducing operating conditions that have been saved.

• OPERATION CONTROL

The operation control provides a controlled operation (such as the to stop operation) of the stored

remote controller groups (the indoor units) in the same manner as the standard remote controller.

• TIMER CONTROL

The timer control allows the starting and stopping of stored remote controller groups and indoor

units through the timer functions in the central remote controller. These timer functions include:

the off timer, on timer 1, on timer 2 and weekly timer.

3

Page 6

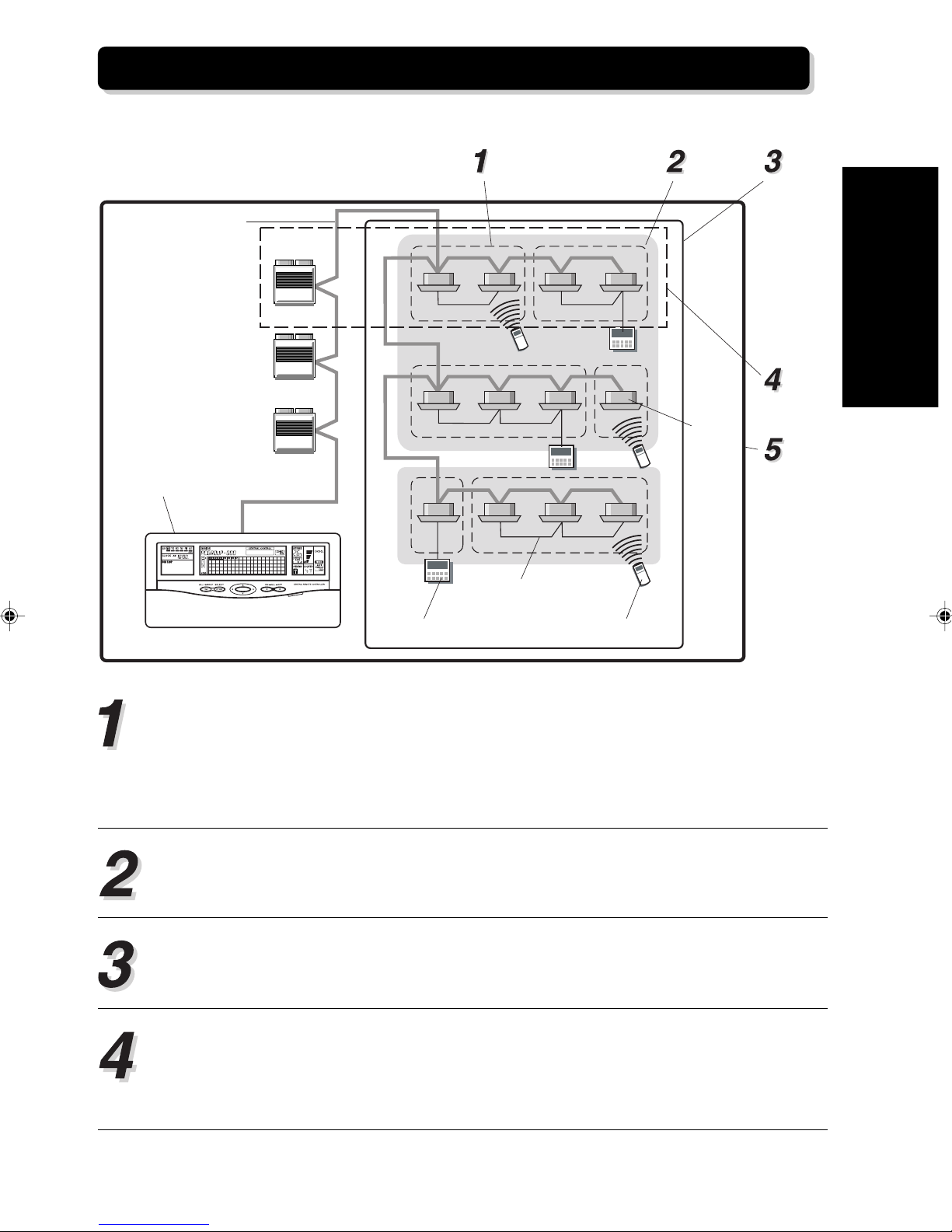

• Three control methods of the central remote controller

• Individual control

2. SYSTEM OUTLINE

Provides control for each respective remote controller group.

• Group control

Provides control for each group which is made up of single or multiple previously set remote

control groups.

(Refer to “2-3. EXPLANATION OF TERMS” for details about groups.)

• All control

Provides control for all remote control groups that haven been stored in the central remote controller.

4

Page 7

2-2. EXPLANATION OF TERMS

■Controller related items

Transmission line

Outdoor unit

Central remote

controller

Remote controller group Group

Controller line

Indoor

unit

All

Refrigerant

system

System

2. SYSTEM OUTLINE

Wired remote

controller

Wireress remote

controller

Remote Controller group:

This is the control unit of indoor units that have been connected with one controller line

as well as the control unit of a single indoor unit that has not been connected with any

controller line.

These two kinds of control units are the smallest unit controlled by central remote controller, and are called a remote control group.

Group:

This is a control unit comprised single or multiple remote control groups.

All:

This is a control unit of all remote control groups that have been stored in the central

remote controller.

Refrigerant system:

This is a system that is composed of indoor units, outdoor unit as well as those of

relevant control equipment. All of the units and the equipment are connected with pipes

with the same refrigerant.

5

Page 8

System:

This is all of the indoor units, outdoor unit as well as those of relev ant control equipment

2. SYSTEM OUTLINE

(central remote controllers, standard remote controllers) that are connected with the

same communication cable.

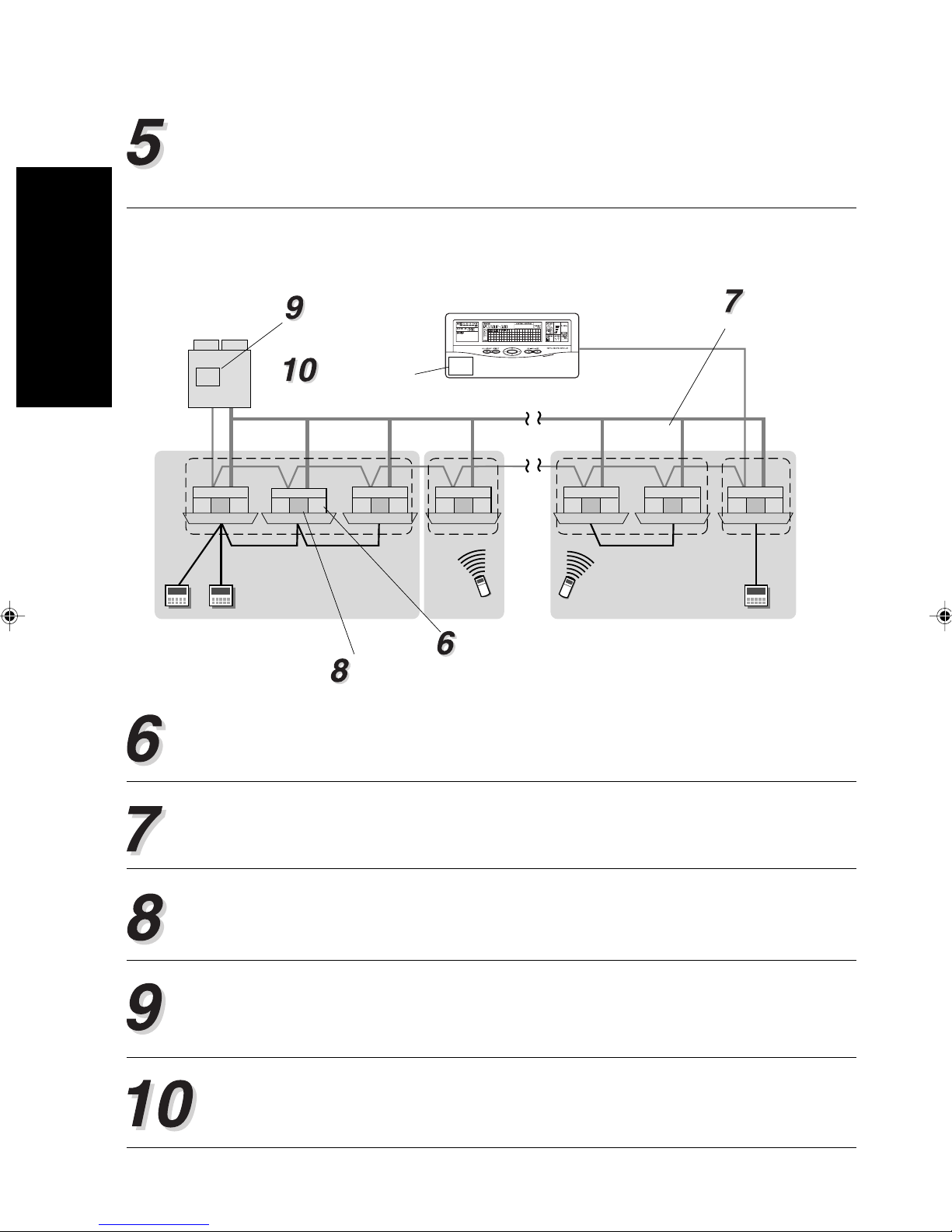

■Address related items

Group address

00

Refrigerant system

address

Central remote

controller address

0

01 2

00

00

0

00

01

1

00

02

2

00

03

0

Remote address

Indoor unit address

Remote controller address (0~15):

This is the ID individually assigned to the indoor units forming each remote control

group and is used for control.

00

13

0

00

14

1

00

15

0

Group number (0~63):

This is the ID individually assigned to each group and is used for control.

Indoor unit address (0~15):

This is the ID individually assigned to each indoor unit and is used for control.

Refrigerant system address (0~99):

This is the ID individually assigned to each refrigerant system and is used for control.

Central remote controller address (0~15):

This is the ID individually assigned to each central remote controller and is used for

control.

6

Page 9

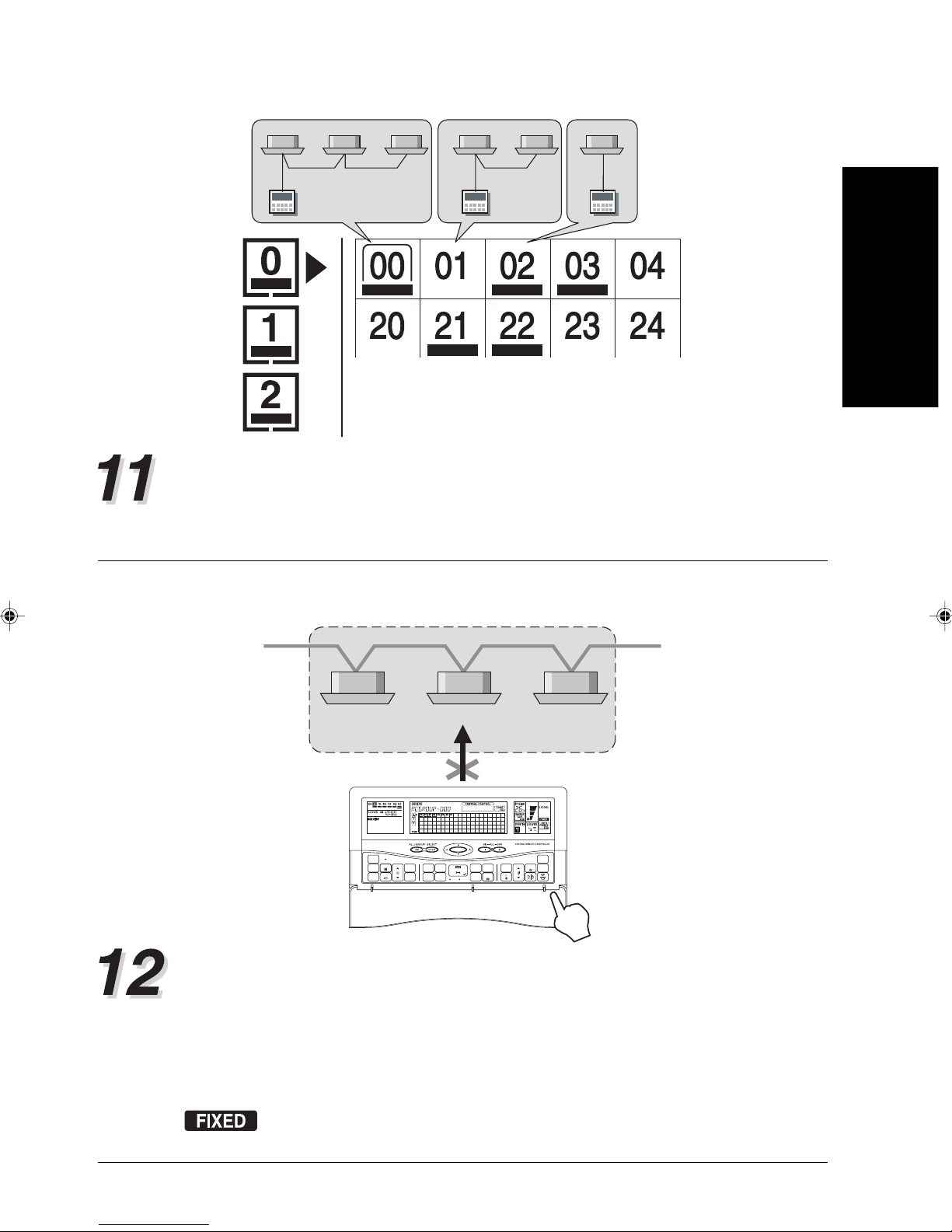

One central control number indicates

one remote control number.

Central control number (0~339):

These are the numbers by which the control of the indoor units is perf ormed.

Each number that appears on the LCD of the central remote controller is the number that

has been assigned individually to a remote control group to be controlled and has been

stored in the central remote controller . Ref er to the SETTING MANU AL f or specific details.

Heating priority setting

2. SYSTEM OUTLINE

HEAT

[FIXED]

CLOCK

ADJUST

TIMER

MODE

TIMER

COPY

Cooling / Heating priority:

ACL

DAY

TIME

DAY OFF

Cooling operation

HEAT

[FIXED]

TIMER

MEMORY

CENTRAL

CONTROL

OPERATION

DELETE

TIMER

MEMORY

GROUP

SETTING SETTING

SET

CHECK

ENERGY ANTI

BACK

ZONE

SET

SAVE

FILTER

ON OFF

RESET

DELETE

TEST

HEAT

[FIXED]

MASTER

CONTROL

FAN

TEMP.

CONTROL

FREEZE

When a HEAT PUMP TYPE oper ating system is used, the system can only be performed

in one of two operation modes (cooling / heating) for single refrigerant system. When an

indoor unit in the system first starts an heating operation, the system is then in “heating

priority”. This means the system will refuse a command for changing the operation mode.

On the other hand, when an indoor unit in the system first starts a cooling operation, the

system is then in “cooling priority”. The system will refuse to change to any other operation

mode, except f or the drying operation.

will appear on the LCD when the indoor units associated with the selected

central control number exists in cooling / heat pump type refrigerant system.

7

Page 10

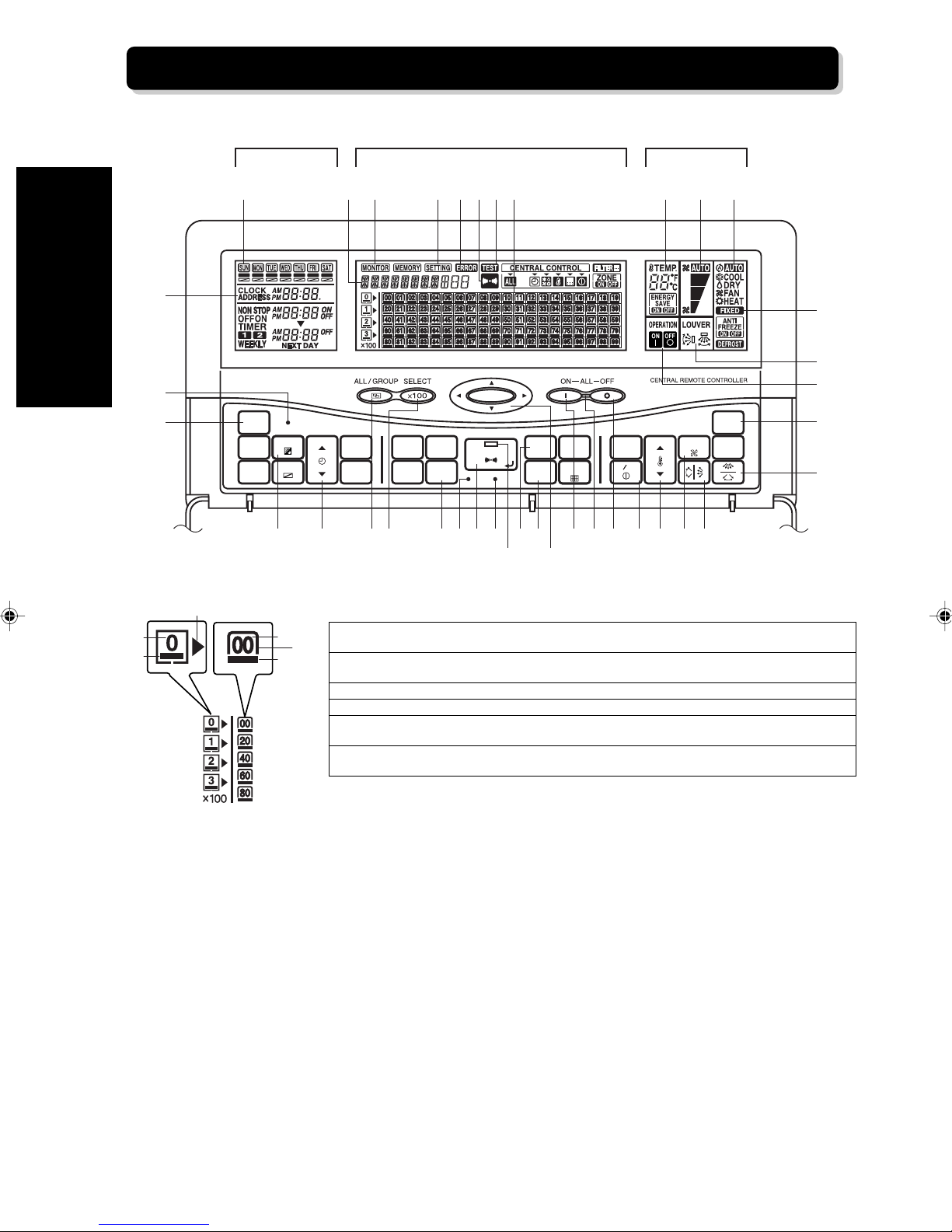

2-3. NAMES AND FUNCTIONS OF THE PARTS

2. SYSTEM OUTLINE

2

3

4

TIMER CONTROL

AREA

ACL

CLOCK

ADJUST

DAY

TIMER

MODE

TIMER

DAY OFF

COPY

OPERATION

CENTRAL CONTROL AREA

781 9 0 BC Q R S

TIMER

DELETE

TIMER

SET

MEMORY

OPERATION

MEMORY

SETTING

CENTRAL

CONTROL

GROUP

SETTING

A

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

DELIHF65 G K Y

CONTROL AREA

TEMP.TIME

ENERGY

SAVE

ON OFF

XWPON

FAN

CONTROL

Z

MASTER

CONTROL

ANTI

FREEZE

MJ

T

U

V

[

\

c

d

b

]

a

CENTRAL CONTROL NUMBER

] Visible numbers represent the central control numbers that have been stored. An error will

^

cause the relevant central control number to flash.

^ Cursor: To be used in order to select the central control number. It flashes when the filter need

to be cleaned or exchanged.

a Visible under lines distinguish the operating indoor units from all indoor units.

b Page cursor: To show the current page.

c Visible page numbers inform that there are some central control numbers in the page. An error

will cause the relevant page number to flash.

d Visible under lines inform that at least one indoor unit which is stored in this page is now

operating.

8

Page 11

TIMER CONTROL AREA

1 DAY OF THE WEEK DISPLAY

2 CLOCK AND ADDRESS DISPLAY

3 ALL CLEAR BUTTON

4 CLOCK ADJUST BUTTON

5 DAY BUTTON

6 TIME BUTTON

Displays the day of the week.

Shows the current time and address.

To delete all set value in the central remote controller.

To set the time.

To change the day.

To set ON/OFF time.

CENTRAL CONTROL AREA

7 STATUS DISPLAY

8 MONITOR DISPLAY

9 SETTING DISPLAY

0 ERROR DISPLAY

A TRANSMIT INDICATOR DISPLAY

B TEST DISPLAY

C GROUP CONTROL DISPLAY

D ALL / GROUP BUTTON

E SELECT

F GROUP SETTING BUTTON

G CHECK BUTTON

H SET BUTTON

I TEST BUTTON

J SET LED

K BACK BUTTON

L DELETE BUTTON

M SELECT BUTTON

N ALL ON BUTTON

O ALL OFF BUTTON

P ALL ON / OFF LED

××

×100 BUTTON

××

Displays the various kinds of information.

Comes on together with an individual status display.

Comes on during various setting.

Comes on or flashes when error is detected.

Flashes in the period of sending the new setting from the central remote controller to other

units.

Comes on during test operation.

Displays the stored central control number and the operating status of the currently

selected indoor units.

To change the control mode (individual / group / all).

To switch to the next screen of the central control numbers by 100.

To start the group setting.

To switch to error code display.

To confirm the new setting and to send signals to the indoor units whose settings need to

be changed.

To start test operation.

Lights up when the new setting has been made. It will go out when the newly set

information has been sent to the relevant indoor units.

To cancel the just made setting and to return to the previous screen.

To delete the set item.

To select the central control number in central control display.

To start the operation of all indoor units stored in the central remote controller.

To stop the operation of all indoor units stored in the central remote controller.

Flashes when error occurs. It will light up when an indoor unit is operating.

2. SYSTEM OUTLINE

OPERATION CONTROL AREA

Q TEMPERATURE DISPLAY

R FAN CONTROL DISPLAY

S MASTER CONTROL DISPLAY

T FIXED COOLING OR HEATING

DISPLAY

U AIRFLOW DIRECTION DISPLAY

V ON / OFF DISPLAY

W ON / OFF BUTTON

X TEMP. BUTTON

Y FAN CONTROL BUTTON

Z HORIZONTAL AIRFLOW DIRECTION

AND SWING BUTTON

[ MASTER CONTROL BUTTON

\ VERTICAL AIRFLOW DIRECTION AND

SWING BUTTON

Shows the set temperature.

Shows the set fan speed.

Shows the current operating mode.

Comes on when the indoor unit is set in the cooling and heat pump type refrigerant system.

Shows the method to control the airflow direction.

Shows the operating condition (ON / OFF) of the indoor units associated with the selected

central control number.

To turn the selected indoor units on and off.

To set room temperature.

To change the fan speed.

To set the angle or movement of up / down swing of the flaps.

To change the operating mode.

To set the angle or movement of right / left swing of the flaps.

9

Page 12

2-4. PRECAUTIONS WHEN SETTING THE SYSTEM

2-4-1. Priority of remote controller setting

2. SYSTEM OUTLINE

The most recent control transmission has priority. In other words, if two controllers (standard remote controller, central remote controller) send different control command to one indoor unit, it is

the last transmission that will have priority and be used by the indoor unit.

(Example) If the indoor unit is operating at a setting of 25 °C using a command from central remote

controller 1 and receives a command to operate at a setting of 20 °C from central remote controller

2, the indoor unit will operate at the setting of 20 °C.

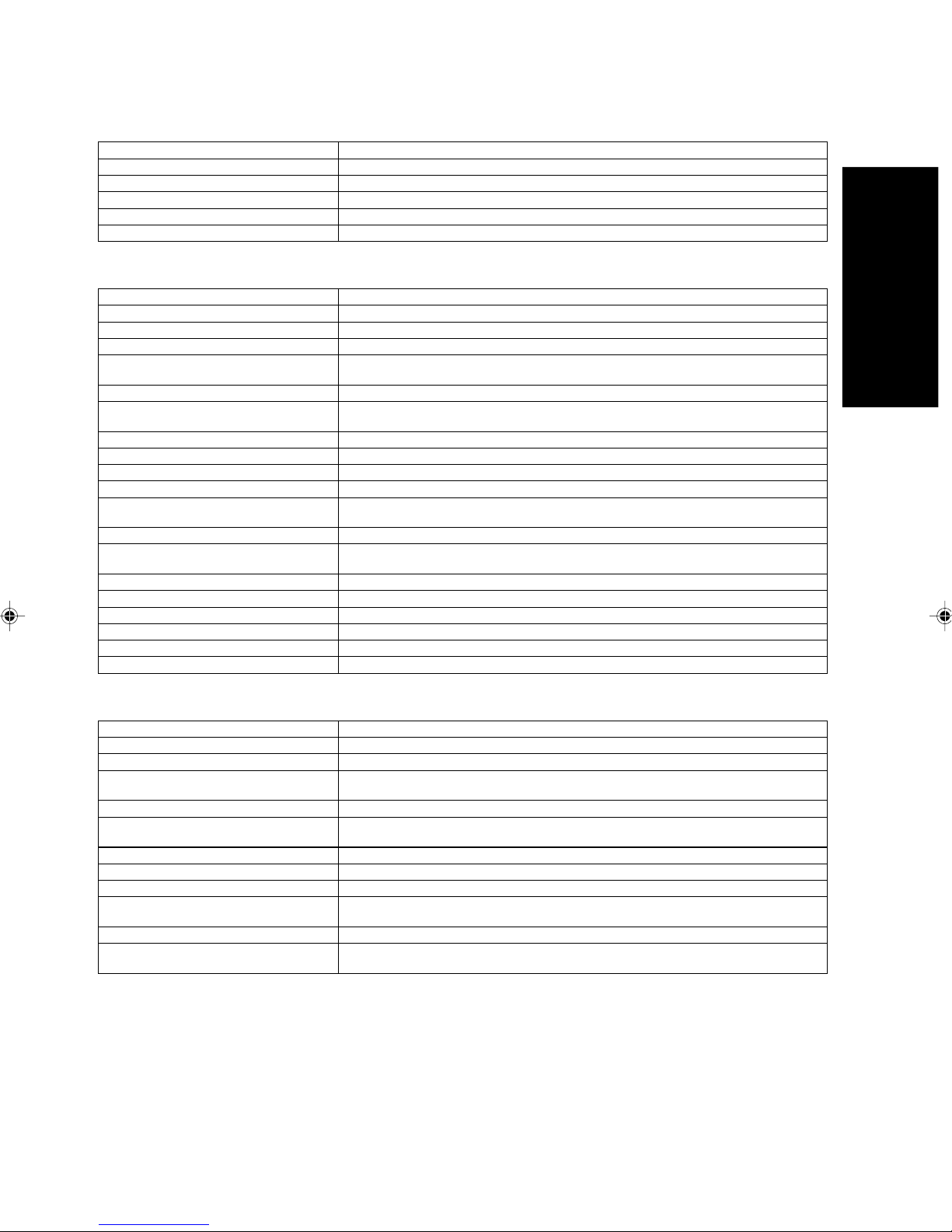

1

Central remote controller 1

TEMP.

Indoor unit

OFF

OFF

Setting of 25°C

Operating at 25°C

25°C

2

Central remote controller 2

Operating at 20°C

TEMP.

Setting of 20°C

20°C

This applies when performing separate operations from different controllers.

Central remote controller ⇔ Standard wired remote controller or Central remote controller 1 ⇔

Central remote controller 2.

2-4-2. Group information store

The following show the restrictions on group information store.

• A maximum of 64 groups can be formed in one system.

• A maximum of 64 remote control groups can be stored per group.

• Since the remote control group is the smallest control unit and can not be broken up, the

group must be made up with complete remote control groups.

The following show examples of group formation. There are some restrictions on operating

mode, on display for the following occasions.

• Group formed with the indoor units in two refrigerant systems.

When part of indoor units exist in cooling & heat pump type refrigerant system, certain operating

mode of the group can not be carried out even if the operating mode is shown on the LCD. In

addition, the operating mode is limited owing to cooling / heating priority setting.

• Overlapping groups.

The operating condition of the indoor units overlapped in the group is determined by the control

signal last sent to indoor units.

10

Refrigerant system 1

Refrigerant system 2

Page 13

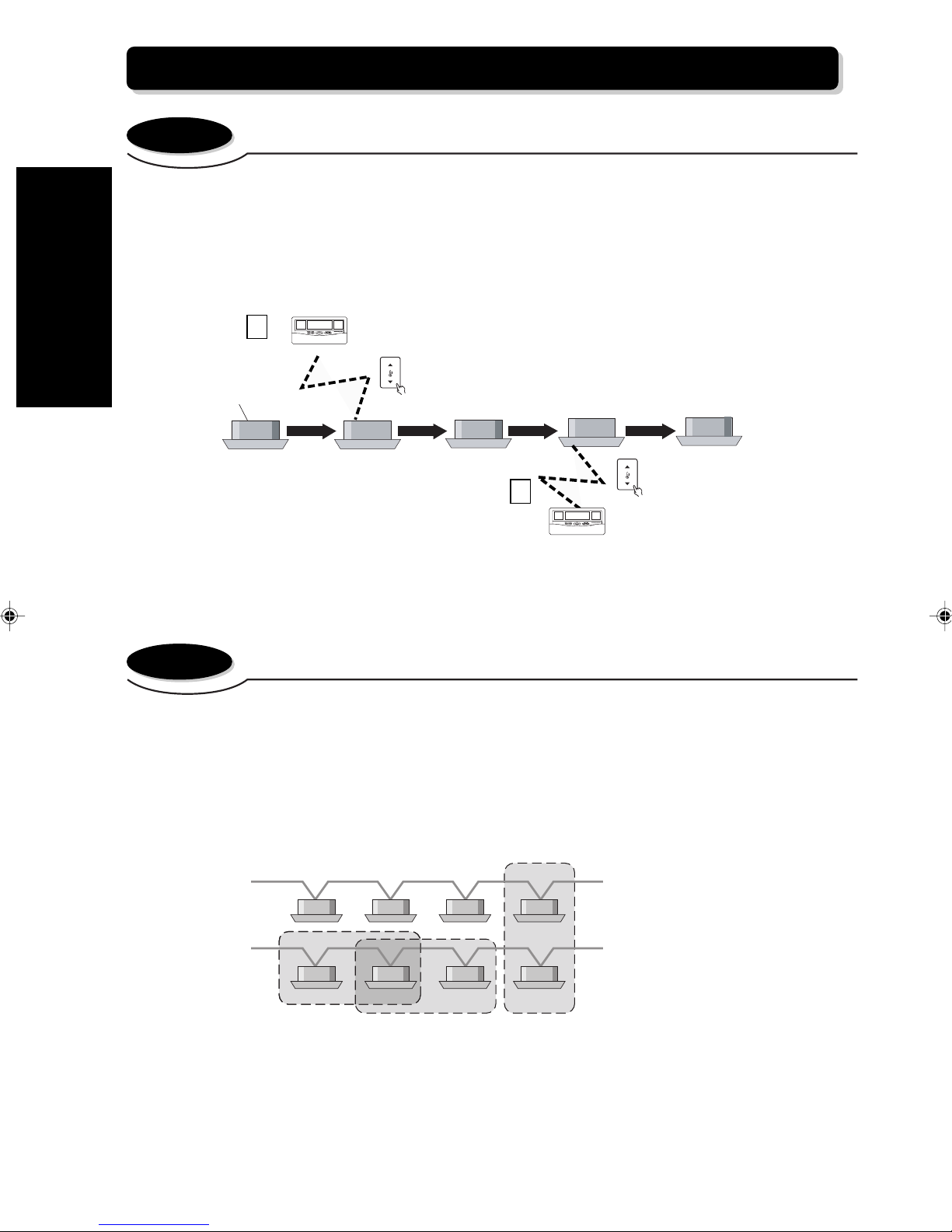

3. SETTING

3-1. FLOW OF INSTALLATION

The following is the flow of the installation of a central remote controller.

• INSTALLATION

INSTRUCTION SHEET

• SETTING MANUAL

DIP-SW setting • • • • Refer to “INSTALLATION

INSTRUCTION SHEET”.

Installation / Wiring • • • • Refer to“INSTALLATION

INSTRUCTION SHEET”.

Turn on power • • • • Refer to “3-2-1 Turn on

power”.

Initial setting • • • • Refer to “3-2-2 Initial

setting”.

Clock setting • • • • Refer to “3-2-3 Clock

setting”.

Group information store • • • • Refer to “3-2-4 Group

information store”.

3. BASIC OPERATION

Test operation • • • • Refer to “3-2-5 Test

operation”.

11

Page 14

3. BASIC OPERATION

Notes Setting control panel DIP SW2

No.

3 ★ Non-display Display For setting filter indicator

4 ★ °C display °F display For setting the unit for the temperature display

DIP SW2

[DIP SW2-3] For setting filter replacement indicator

• This is used to set whether or not the filter indicator will come on when it is time to clean the filter.

[DIP SW2-4] For setting the unit for the temperature display.

• This is used to set the temperature display to displa y either centigrade (°C) or Fahrenheit (°F).

[DIP SW2-5] For validity / invalidity the standard remote controller operation prohibit function.

• This is used for validity / invalidity the standard remote controller operation prohibit function.

[DIP SW2-8] For enabling / disabling the backup function.

• Performs the enabling / disabling of the backup function by the internal battery.

• When it is enabled, the various settings are saved using the internal battery if there is an interruption or stoppage of

the power supply.

• Always enable this function when installing the unit. (Note: It is disabled when shipped from the factory to prevent

consumption of the battery charge.)

• Do not change any other switches.

• Always turn off power breaker before changing the switch settings.

• Refer to “3-2-2. Initial setting” DIP-SW positions.

5 ★ Validity Invalidity For validity / invalidity the standard remote

8 ★ Disabled Enabled For enabling / disabling the backup function

Sw state

OFF ON

Details

controller operation prohibit function

(★ : Factory setting)

12

Page 15

Turn on power Initial setting Clock setting

Group information store

Test operation

3-2. SETTING OPERATION

3-2-1. Turn on power

Once the installation and wiring has been completed, use the following procedure to turn on the

power.

1. Turn on the power for all connected indoor units.

2. Turn on the power for all connected outdoor units.

3. Turn on the power for all connected central remote controllers.

Wait f or one min ute or more after turning on the power bef ore perf orming the initialization shown in

“3-2-2. Initial setting”.

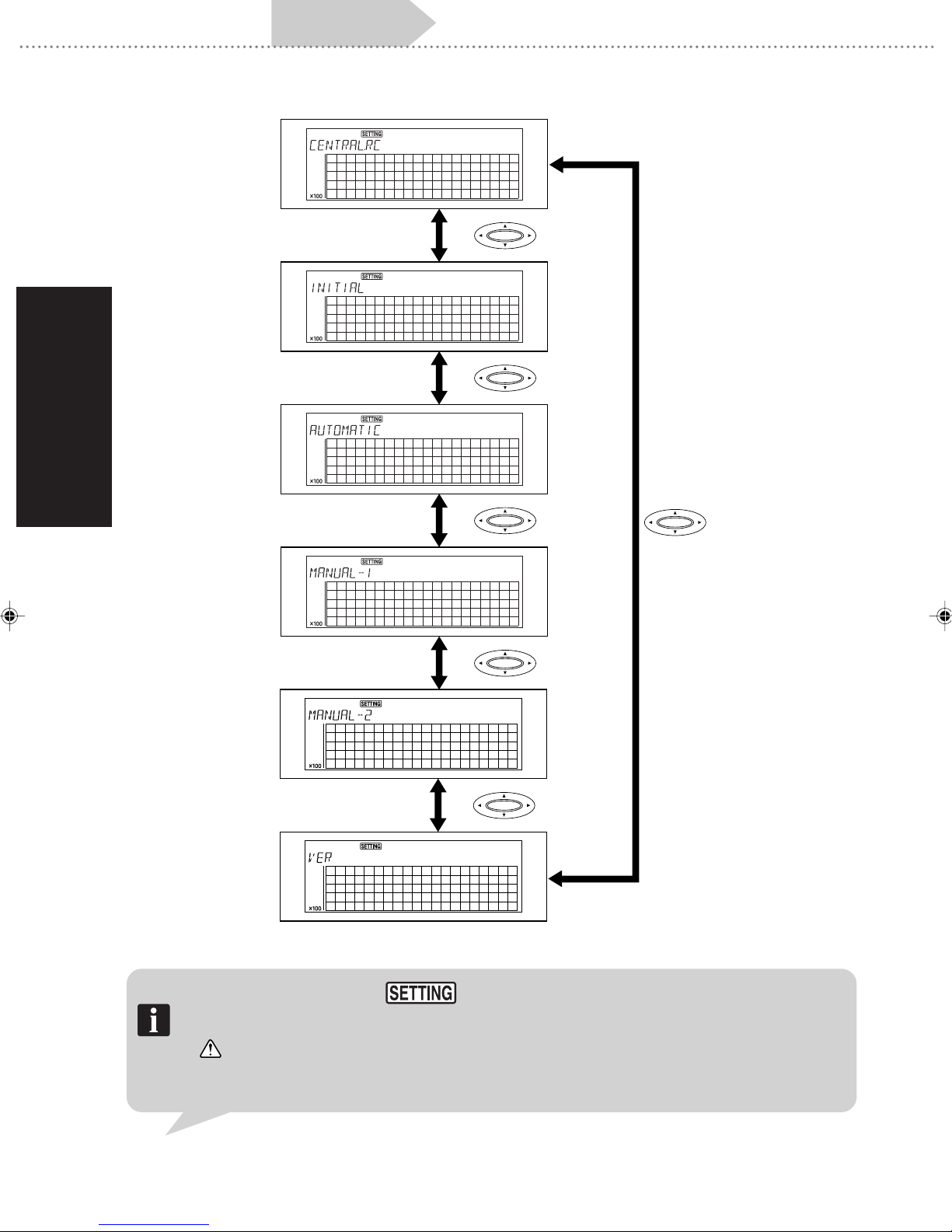

3-2-2. Initial setting

The initial settings are performed by the initial setting mode. This is the required setting mode when

performing operation using the central remote controller. Initial setting mode is started under the

following conditions .

• When the power for the central remote controller is turned on for the first time.

• When SW42 on the control circuit board is pressed.

3. BASIC OPERATION

DIP-SW. 2

SW. 42

How to remove the case top of the control

panel.

• Inser t a flap-tip screw driver and turning

it to remove the cover.

When the power is turned on for the central remote controller for the first time, initial setting mode

automatically starts so that the initial settings for the central remote controller can be performed.

These settings are performed using the following procedure.

1. Central remote controller address settings.

2. System information scanning

3. Storing the remote controller group to central control number.

• Automatic storing.

• Manual storing 1.

• Manual storing 2.

Press between each setting to change. (Refer to the next page.)

Once the settings have been completed, press SW42 on the control circuit board to end the

initial setting mode.

13

Page 16

3. BASIC OPERATION

Turn on power Initial setting Clock setting

Setting of central remote

controller address

System information

scanning

Group information store

Test operation

Automatic storing

Manual storing 1

Manual storing 2

XXXX.XX

Version display

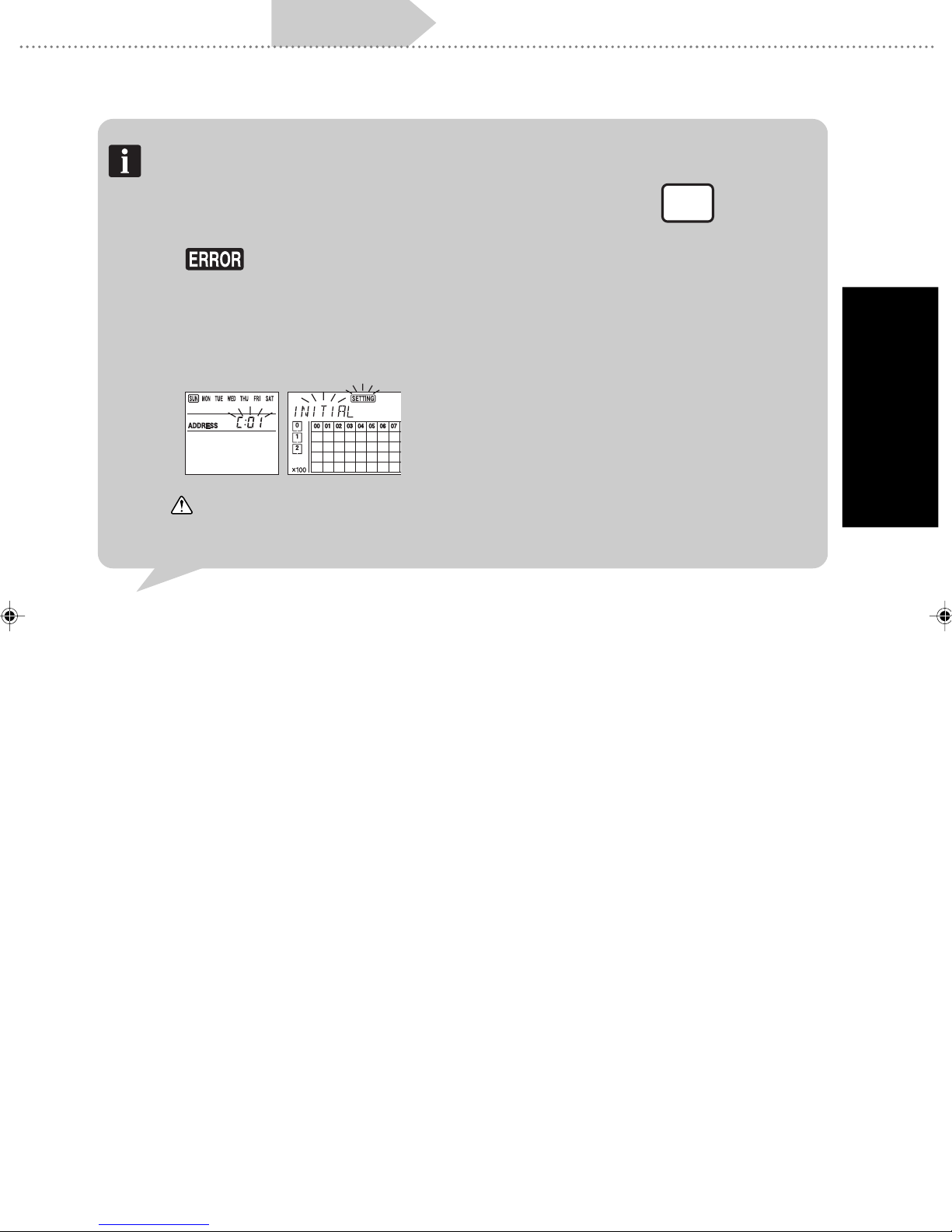

Note • When in initial setting mode, will light up.

• Unless “(2) System information scanning” or “(3) Indoor unit storing” have been completed, initial setting

mode will not end even if SW42 is pressed.

Always wait one minute or more after performing the operations for turning on the power shown in “32-1. Turn on power” before performing the initial settings. If initial settings are performed after the

power is turned on and before the outdoor and indoor unit system data has been created, an error will

occur.

14

Page 17

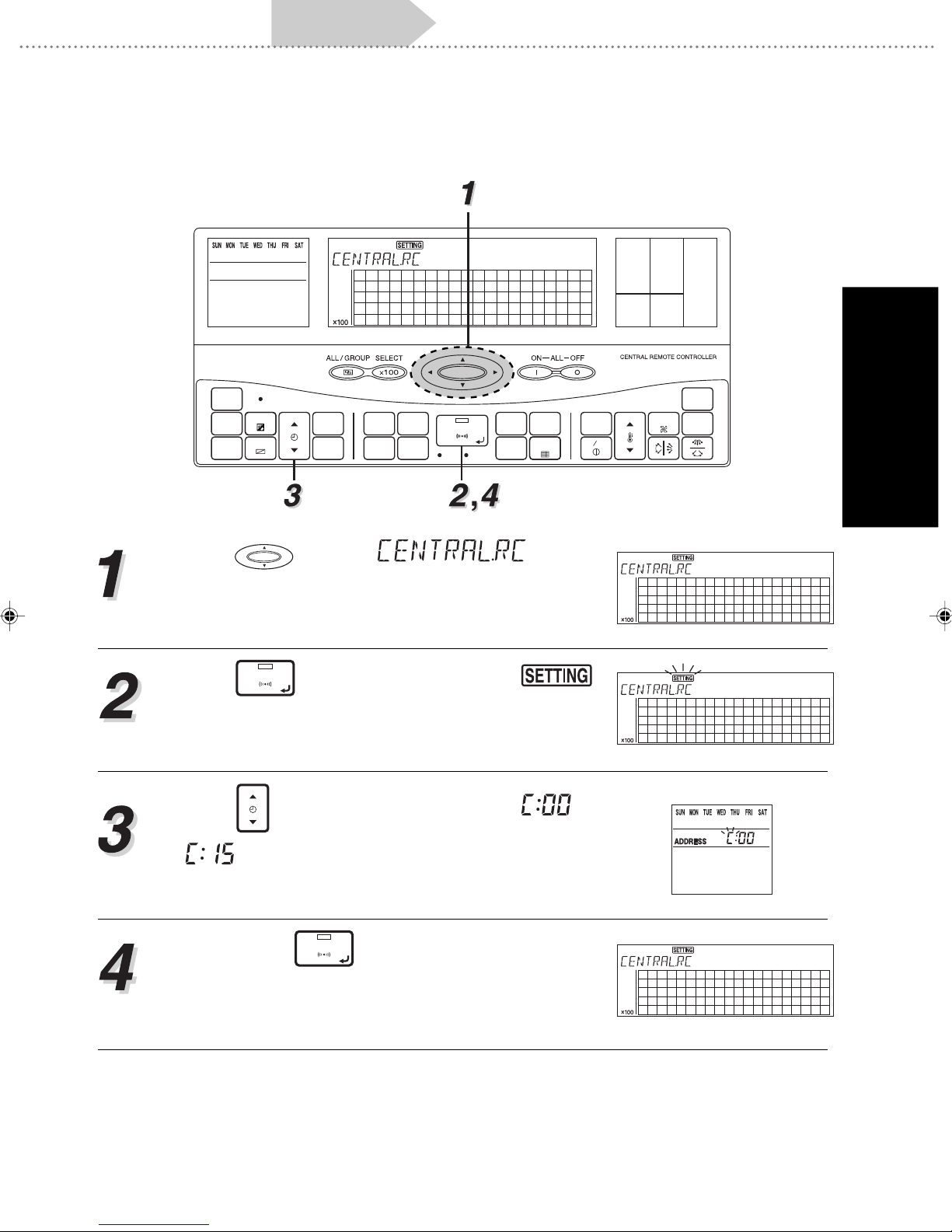

Turn on power Initial setting Clock setting

Group information store

(1)Central remote controller address setting

Use the following procedure to set the central remote controller address.

Test operation

ACL

CLOCK

ADJUST

DAY

TIMER

MODE

TIMER

COPY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

Press to display . Use the

initial setting menu to select central remote control-

ler address setting.

Press

SET

to enter the setting mode. (

will flash and address setting can be made.)

TIME

Press

and select a number between to

MASTER

CONTROL

FAN

TEMP.

ENERGY ANTI

SAVE

ON OFF

CONTROL

FREEZE

3. BASIC OPERATION

that does not duplicate the number of another

central remote controller.

Finally , press

SET

troller address.

to set the central remote con-

15

Page 18

3. BASIC OPERATION

Turn on power Initial setting Clock setting

Group information store

Test operation

(2) System information scanning

Searches all the indoor units connected by the communication cable and store them in the

central remote controller.

ACL

CLOCK

ADJUST

DAY

TIMER

MODE

TIMER

COPY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

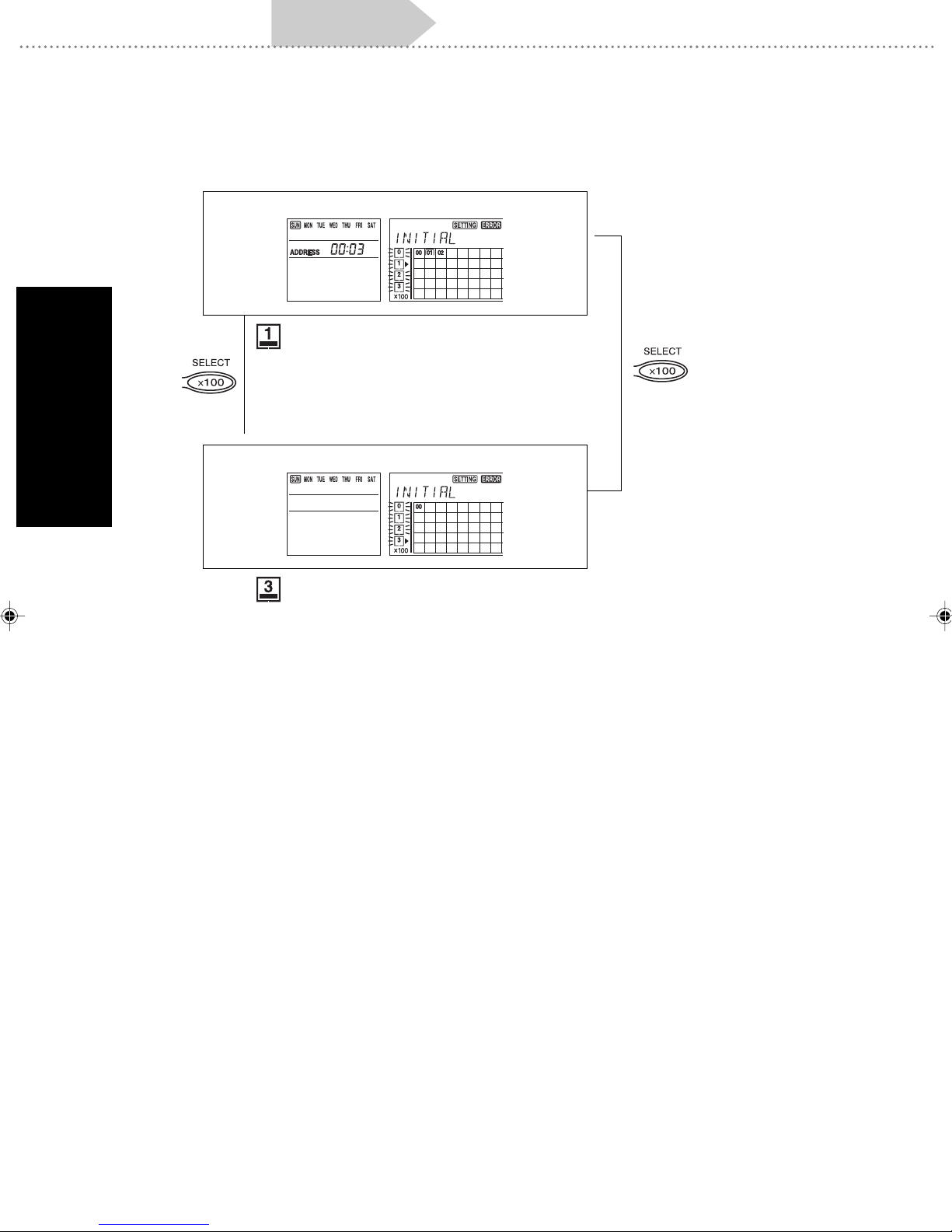

Press to display and select

system information scanning. Pre viously stored cen-

tral control numbers will light up.

Press

refrigerant system. The initial value is “99” so use

TIME

SET

and then perform scan to set the final

to select an optional scan final refrigerant sys-

tem number from 99 to 0.

• To delete an operation, press

BACK

to return to

1.

MASTER

CONTROL

FAN

TEMP.

ENERGY ANTI

SAVE

ON OFF

CONTROL

FREEZE

Press

SET

will flash and system information scanning will begin. Once the indoor scan has been completed, the

display in 1 will return.

16

again and and

Page 19

Turn on power Initial setting Clock setting

Group information store

Test operation

Notes • The system information scanning requires approximately 30 minutes to complete. (The time will depend

upon the number of indoor units connected.)

• Stop the operation of the indoor unit before performing system information scanning.

• The system information scanning can be interrupted and cancelled by pressing

• If system information scanning is performed, previously assigned central control numbers will be deleted.

• will light up if an error occurs during scanning. Error display is performed for each refrigerant

system.

• The system information scanning will be performed in the following manner when there are multiple

central remote controller.

When system information scanning and manual assignment 2 is performed, other central remote

controllers will show the following display and operations from them will be prohibited.

This display will continue until the system information scanning or the manual assignment 2 is cancelled.

Always perform the following when changing the address on the indoor unit.

• Turn on the power supply again.

(Refer to “3-2-1 Turn on power” for details about turning on the power.)

• Perform system information scanning once again.

DELETE

.

3. BASIC OPERATION

17

Page 20

3. BASIC OPERATION

Turn on power Initial setting Clock setting

Group information store

Test operation

• System information scanning error

An error during the system information scanning will be shown in following manner.

System setting error

▲

flashing: System setting error

Cause of error: System setting has not been

properly performed.

Always wait one minute or more after turning

on the power before starting the initial settings.

▼

Outside setting range error

flashing: Outside setting range error

Cause of error: The address of the indoor unit

has been set outside the range from 0 to 15.

18

Page 21

Turn on power Initial setting Clock setting

• Press to move among the errors.

Group information store

Test operation

• Press

BACK

to cancel the error display and return to the initial setting menu.

• When an error occurs, the number of units with errors will appear in .

• Use to check the address duplication errors and system setting errors for refrigerant

system address and / or indoor unit address for related indoor unit.

(3)Indoor unit storing

The following are the three methods f or storing the remote control group with the central remote

controller. Select any one of them. However, the these storing menus will not be displayed

unless the system information scanning has been completed.

• Automatic storing

This automatically stores the remote control group with the central remote controller . Storing of all

remote control groups connected by communication cab le is performed automatically in ascending order of the refrigerant system addresses and indoor unit addresses.

• Manual storing 1

A remote control group can be optionally stored to a central control number. Here , the refrigerant

system addresses and indoor unit addresses are specified and stored one at a time to selected

central control numbers.

• Manual storing 2

The remote control group is stored in sequence of the standard remote controllers as they are

operated. Sending the refrigerant system address and indoor unit address of the remote control

group actually operated to the central remote controller performs the storing.

3. BASIC OPERATION

Note After group information store has been performed, system information store is performed. All the

currently saved group information store data is deleted.

19

Page 22

3. BASIC OPERATION

Turn on power Initial setting Clock setting

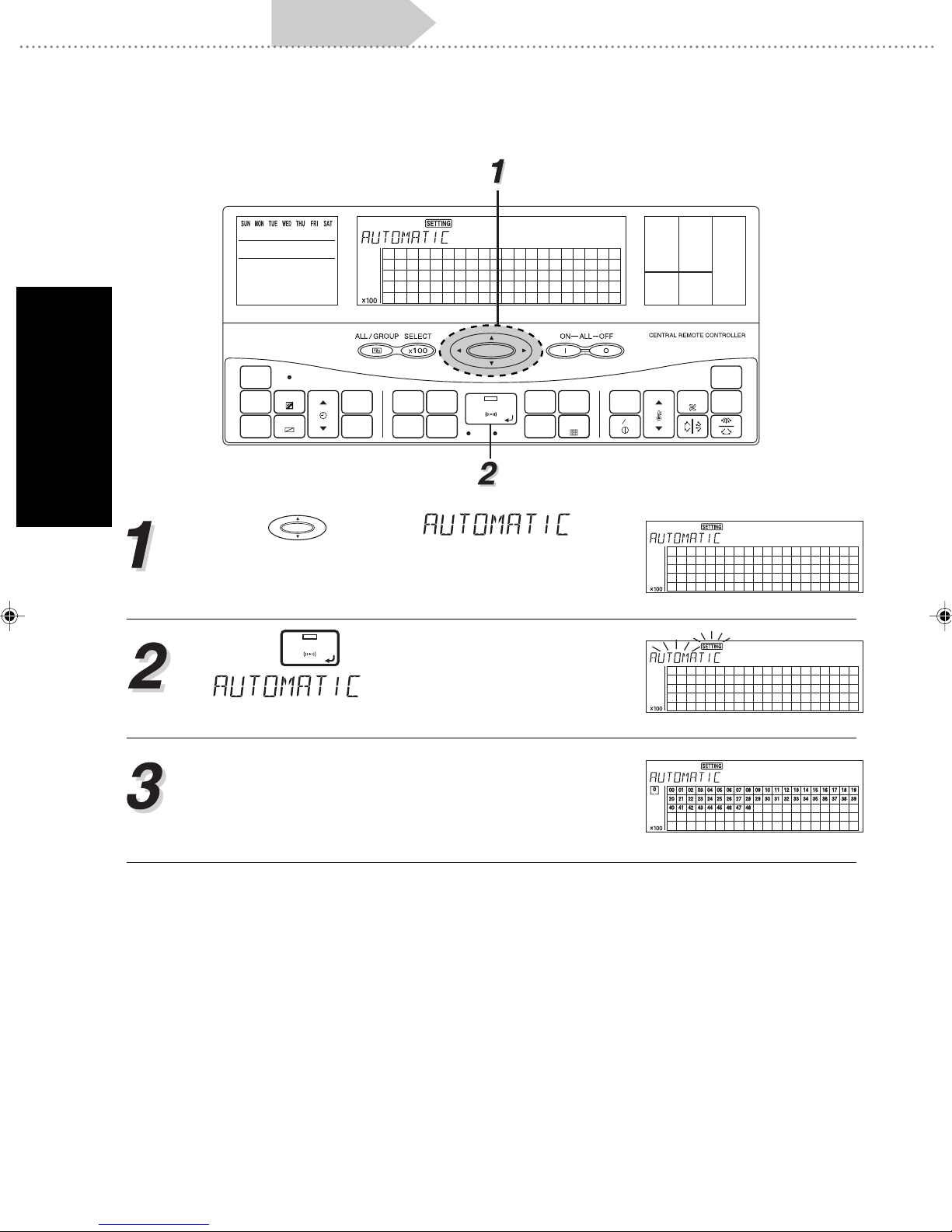

■Automatic storing

Group information store

Test operation

ACL

CLOCK

ADJUST

DAY

TIMER

MODE

TIMER

COPY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

Press to display . Use

the initial setting menu to select automatic storing.

Press

SET

to start automatic storing.

flashes and the automatic stor-

ing process begins.

The automatic storing process ends in approximately 10 minutes and then automatically returns

to the initial setting menu.

MASTER

CONTROL

FAN

TEMP.

ENERGY ANTI

SAVE

ON OFF

CONTROL

FREEZE

20

Page 23

Turn on power Initial setting Clock setting

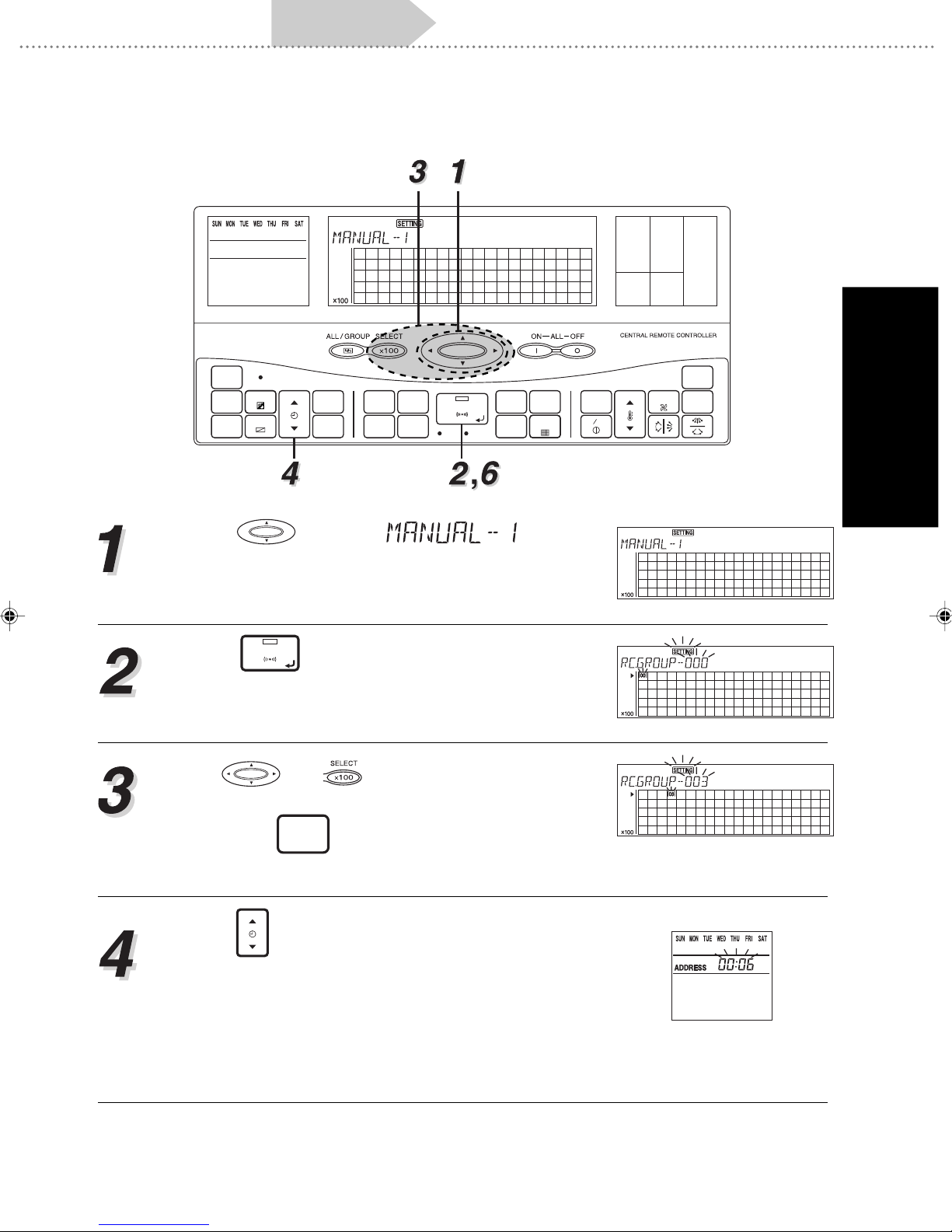

■Manual storing 1

Group information store

Test operation

ACL

CLOCK

ADJUST

DAY

TIME

TIMER

MODE

TIMER

COPY

DAY OFF

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

Press to display . Use the

initial setting menu to select manual storing 1.

Press

SET

to move to the storing execution

screen.

Use and to select the desired central

control number from the 100 segments.

MASTER

CONTROL

FAN

TEMP.

ENERGY ANTI

SAVE

ON OFF

CONTROL

FREEZE

3. BASIC OPERATION

• Pressing

DELETE

cel the storing of the central control number.

TIME

Press

and to select the address of the remote

control group to be stored in the central contr ol number selected in 3. (Of the indoor units making up the

remote control group, only the refrigerant system

addresses and indoor unit addresses of the indoor

unit with remote addresses of “0” will be displa yed.)

Storing is performed at the time of selection.

at the time of selection will can-

21

Page 24

3. BASIC OPERATION

Turn on power Initial setting Clock setting

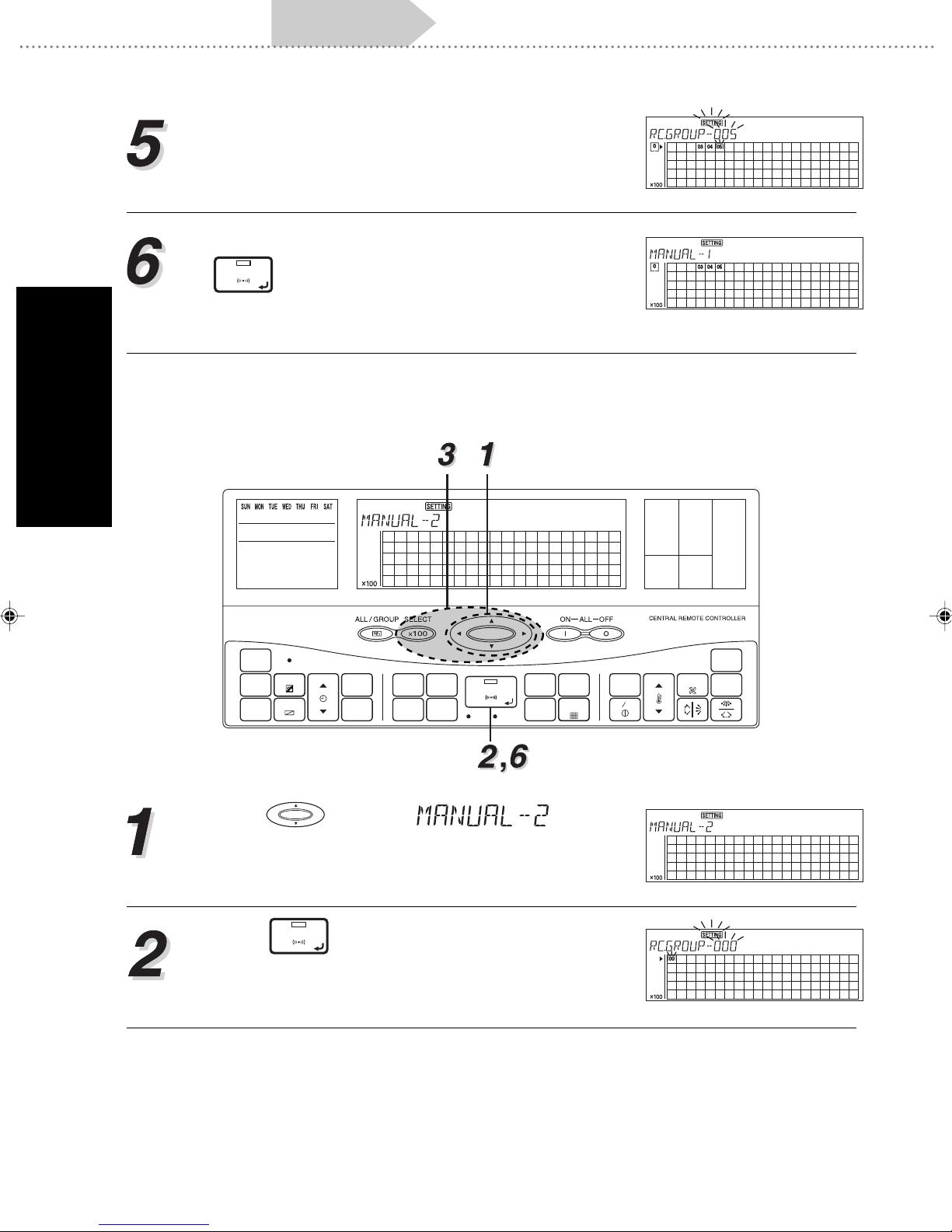

Repeat steps 3 and 4 to continue storing in sequence.

Once all the storing has been completed, press

SET

to return to the initial setting menu.

■Manual storing 2

Group information store

Test operation

ACL

CLOCK

ADJUST

DAY

TIMER

MODE

TIMER

COPY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

Press to display . Use the

initial setting menu to select manual storing 2.

Press

SET

to move to the storing execution

screen.

MASTER

CONTROL

FAN

TEMP.

ENERGY ANTI

SAVE

ON OFF

CONTROL

FREEZE

22

Page 25

Turn on power Initial setting Clock setting

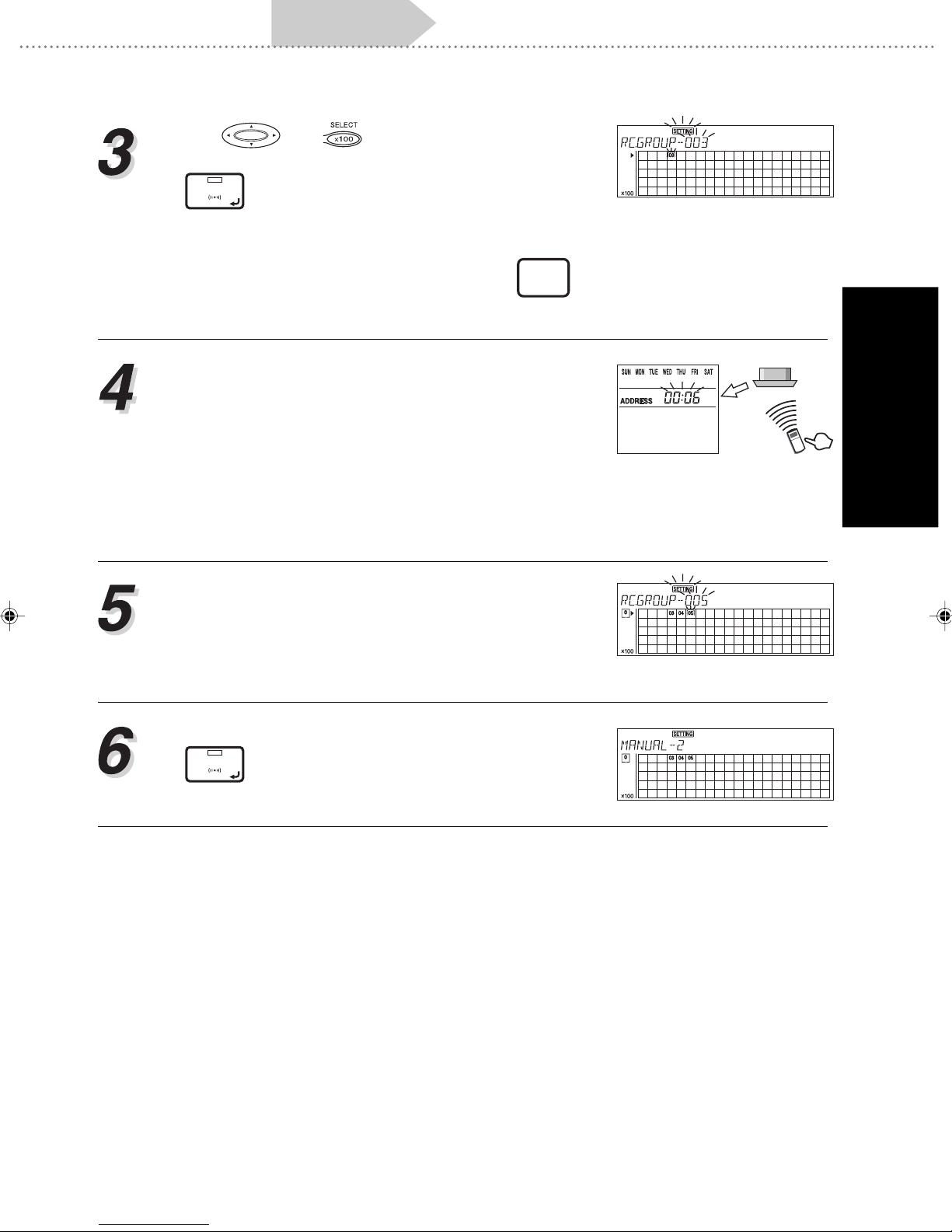

Use and to select the desired central

control number from the 100 segments, press

SET

. (The central remote controller will be in a

wait mode for a signal from the indoor unit.)

• If you wish to delete the operations for manual stor-

Group information store

Test operation

ing 2 using this storing screen, press

BACK

to

return to screen 1.

Operation is performed for the indoor units that are

to be stored to the central control number that was

selected in 3. (You must go to the actual location of

installation and perform the operation from the standard remote controller.) By performing the operation, the operating inf ormation is sent to the central

remote controller and is stored in the central control number that was selected on the central remote

controller .

Repeat the step 4. Use the standard remote controller to turn the indoor units on in sequence. Each

time the central control number is stored using the

operation in step 4, it will be automaticall y increased

by 1.

3. BASIC OPERATION

Once all the storing has been completed, press

SET

to return to the initial setting menu in 1.

23

Page 26

3. BASIC OPERATION

Turn on power Initial setting Clock setting

Group information store

Test operation

3-2-3. Clock setting

The clock setting can be used to set the current time or set various setting of the central remote

controller.

ACL

CLOCK

ADJUST

TIMER

MODE

TIMER

COPY

DAY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

TEMP.

ENERGY ANTI

SAVE

ON OFF

FAN

CONTROL

MASTER

CONTROL

FREEZE

Press

Press

CLOCK

to start the clock setting.

ADJUST

TIMER

to select 24-hour or 12-hour display.

MODE

The digits below the clock mean Clock Display settings.

: 24 Hour Clock Display

: 12 Hour Clock Display 1

: 12 Hour Clock Display 2

Year / Month / Day setting is performed. Use

to select the items to be changed and perform the

setting with .

Press

TIME

and set the current time.

24

Page 27

Turn on power Initial setting Clock setting

Group information store

Test operation

Press

Press

DAY

ON OFF

and set the current day.

and set the beep enable / disable set-

ting.

Finally, press

Note If there is an indoor unit that is operating based on the timer of the central remote controller. The

operations of the time setting mention above will be limited to items at 2 and 6.

CLOCK

to end the clock setting.

ADJUST

3. BASIC OPERATION

25

Page 28

3. BASIC OPERATION

Turn on power Initial setting Clock setting

Group information store

Test operation

3-2-4. Group information store

It is necessary to do group information store before group control is conducted with the central

remote controller.

The following shows the procedure of group information store.

ACL

CLOCK

ADJUST

TIMER

MODE

TIMER

COPY

DAY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

TEMP.

ENERGY ANTI

SAVE

ON OFF

FAN

CONTROL

MASTER

CONTROL

FREEZE

••

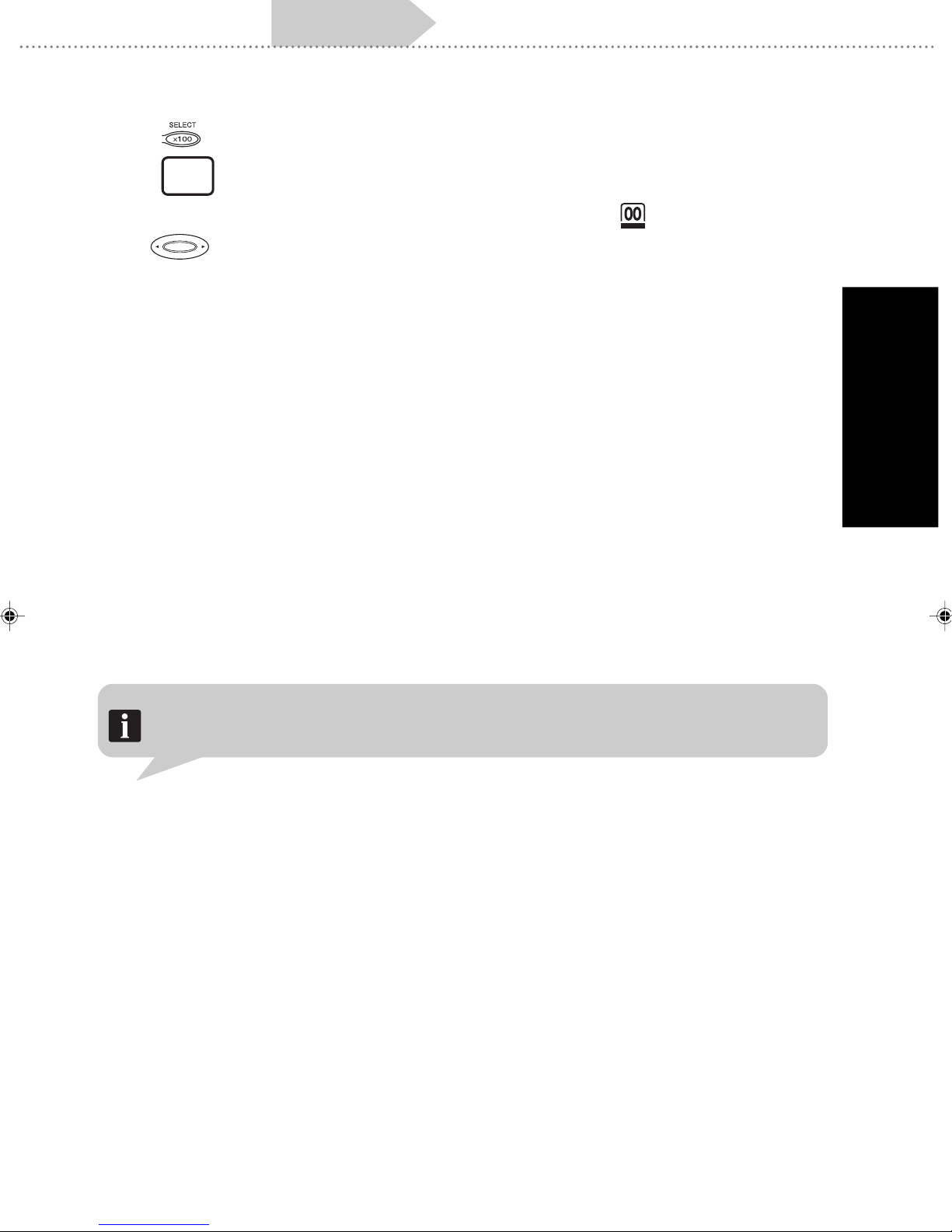

• To do group information store

••

Press

GROUP

to enter the group information store

SETTING

mode.

Select the group number whose group information

store need to be performed with and set by

pressing

SET

.

Press to select the central control number

to be stored in the selected group. Press

store.

To continue group information store, press

SET

to

BACK

to return to the group number selection screen of 1

and repeat steps 2 and 3. To complete the gr oup in-

formation store, press

tion screen shown in step 1.

26

GROUP

in the group selec-

SETTING

Page 29

Turn on power Initial setting Clock setting

••

• To delete the stored information in group

••

Group information store

Test operation

Press

GROUP

to enter the group information store.

SETTING

Use to select the group whose stored infor-

mation is to be deleted and then press

SET

to

set it.

DELETE

If

is pressed at this time, all the central con-

trol numbers registered in the selected group will

be deleted.

Use to select the central control number in

the group selected in step 2 and press

DELETE

to

delete it.

Repeat step 3 to continue deleting the stored central control number in the same group.

3. BASIC OPERATION

If you wish to delete the stored information in other

group, press

BACK

to return to screen of step 1.

Repeat steps 2 and 3.

T o end the deletion of the stored group inf ormation,

press

GROUP

SETTING

.

27

Page 30

3. BASIC OPERATION

Turn on power Initial setting Clock setting

3-2-5. Test operation

Group information store

Test operation

CLOCK

ADJUST

TIMER

MODE

TIMER

COPY

ACL

DAY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

TEMP.

ENERGY ANTI

SAVE

ON OFF

FAN

CONTROL

MASTER

CONTROL

FREEZE

Remote control group operation settings are performed in the control mode. The following procedure for the setting is the same for an y of the control modes: Individual control mode / Group control

mode / All control group.

Push to select control mode from among Individual control mode / Group contr ol mode / All con-

trol.

• When Individual control mode is selected, use

and to select the desired central con-

trol number, then go to step 3.

• When Group control mode is selected use

to select the desired group number , then go to step

3.

• When All control mode is selected, go directly to

step 3.

Press

and will light up. The operation

TEST

setting selected in 1 is applied to the selected control mode.

28

Page 31

Turn on power Initial setting Clock setting

Group information store

Test operation

Press

SET

to send the signal and test operation

setting is sent to the indoor unit. will flash as

the signal is being transmitted.

• 60 minute test operation starts.

• To interrupt the test operation, use the same operations as for stopping normal operation.

• It is possible is to change the settings for the operation mode (heating / cooling) and fan setting.

Once the signal has been transmitted, the seg-

ment will flash and LED

SET

will go out. The in-

door unit will start the test operation.

Note If the test operation is stopped midway, use the operation shown in 3 above and press

ON OFF

3. BASIC OPERATION

.

will come on and the operations in 4 will be sent to the indoor unit the same way. The test

operation will stop.

29

Page 32

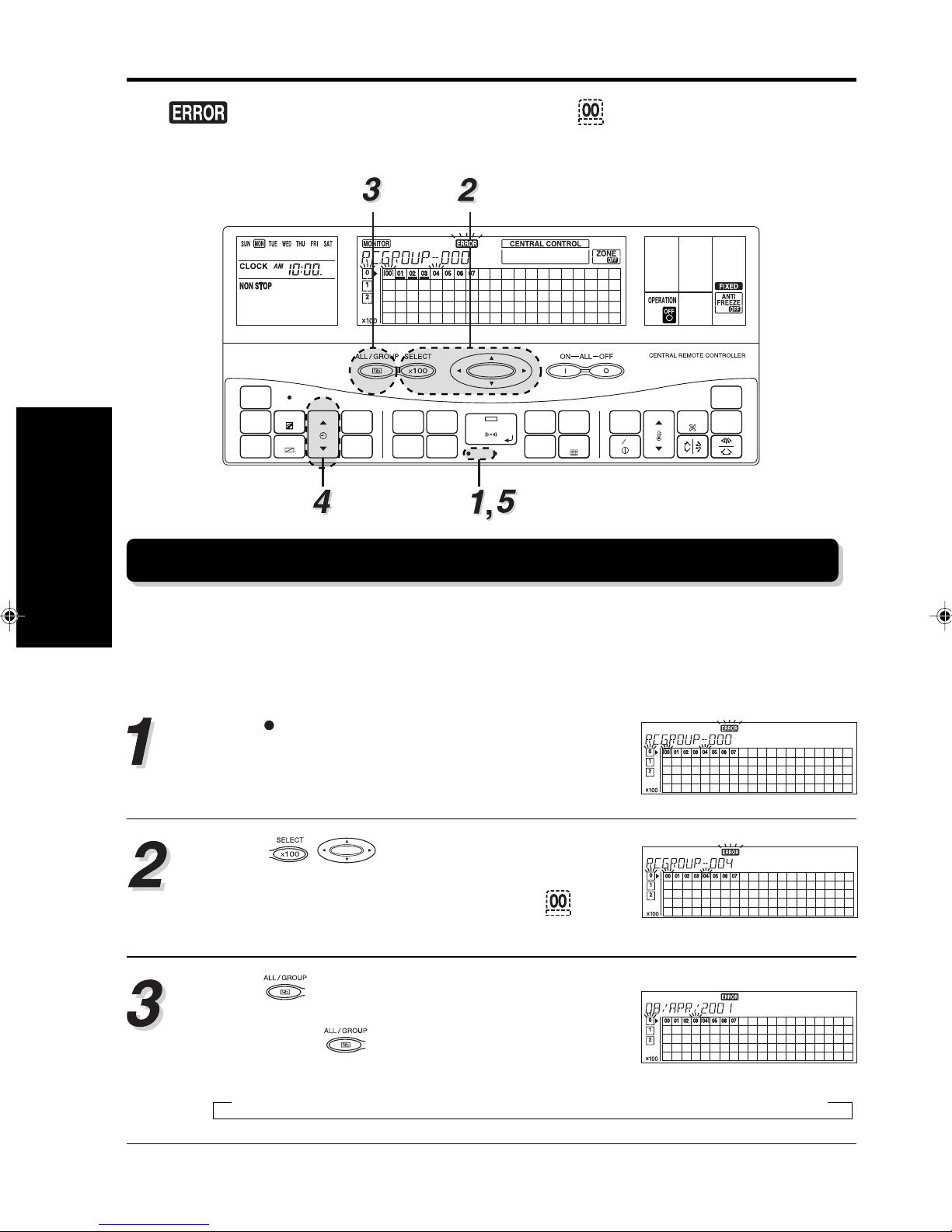

4. ERROR DISPLAY

4. ERROR DISPLAY

If the and the number for the central control number flash during operation, there is an

error at the relevant remote control g roup. Start the error monitor , identify the error and remove the

cause.

ACL

CLOCK

ADJUST

TIMER

MODE

TIMER

COPY

DAY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

CENTRAL

CONTROL

OPERATION

MEMORY

GROUP

SETTING SETTING

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

TEMP.

ENERGY ANTI

SAVE

ON OFF

FAN

CONTROL

MASTER

CONTROL

FREEZE

4-1. ERROR MONITOR

When the error monitor is started, the following can be performed.

• The error code for each remote control group (indoor units) is display ed.

• Up to two of the past error codes are displayed for each of the indoor units , the outdoor units and

the central remote controller group.

Press

The LCD changes to the error monitor screen.

Press to select the central control

number for which its details of the error contents

are to be confirmed. (The number of the causing the error is flashing.)

Press to select the display mode for the error

code.

to start the error monitor.

CHECK

Each press of will switch the display as shown

below.

▲

Current error code → First previous error code → Second previous error code

30

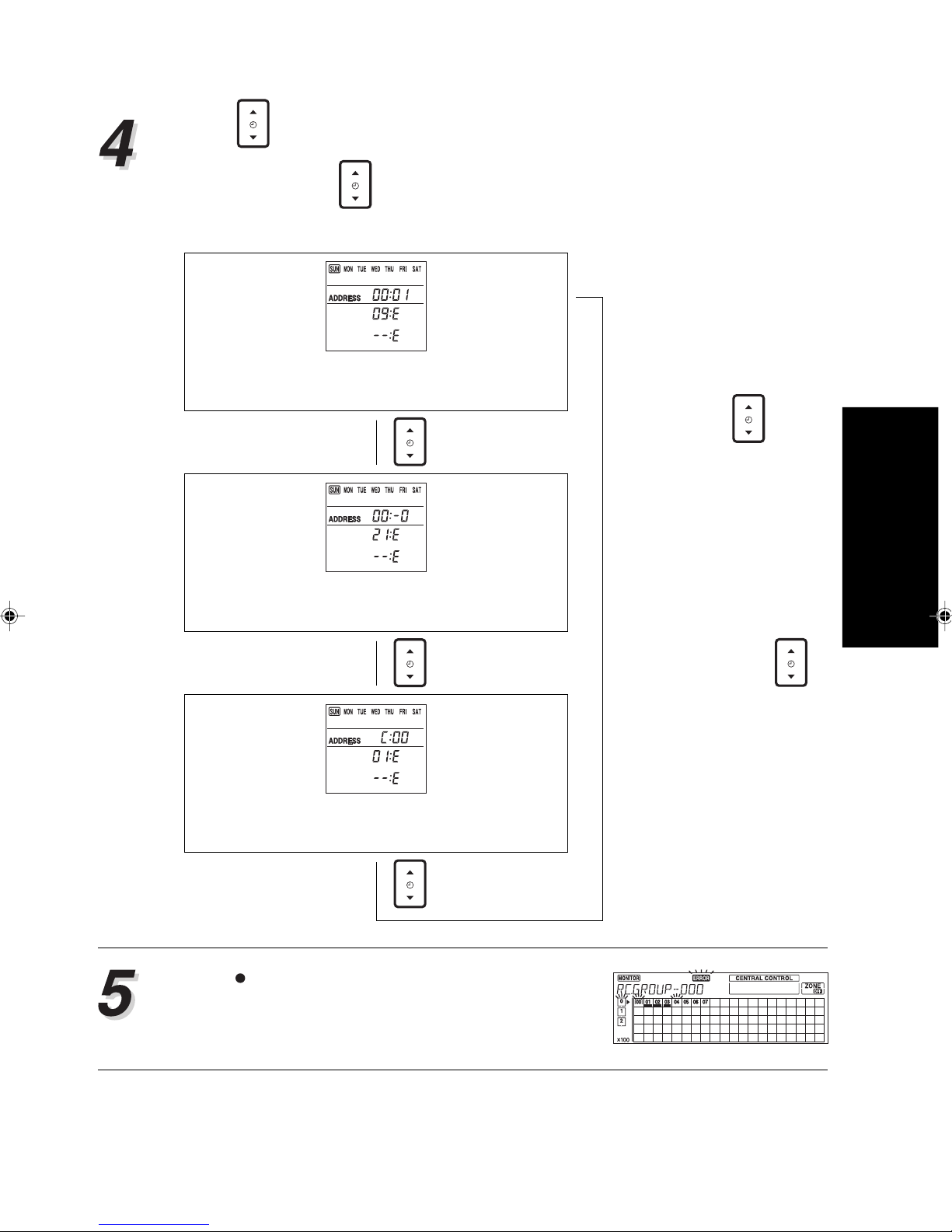

Page 33

TIME

Press

Continue pressing

to select the indoor units in the remote control group selected in 3.

TIME

, the error codes for the outdoor unit and the central re-

mote controller are displayed. Each of the displays is shown below.

Indoor unit

error display

▲

• If there have been multiple

“The refrigerant system address and indoor unit

errors for one unit, continu-

address are displayed.”

▲

TIME

ally pressing

TIME

will dis-

▼

Outdoor unit

error display

“Refrigerant system address” and “-0” are displayed.

▲

TIME

▼

Central remote

control error

display

The “C” code and the central remote controller

address are displayed.

▲

TIME

play the error codes in sequence. When all the error

codes have been displayed, the display will

switch to the next unit.

• If there is no error in the

central control number selected in 3, the display will

TIME

not change when

is

pressed. “00” displayed

means “no errors”.

4. ERROR DISPLAY

Press

CHECK

again to end the error monitor.

31

Page 34

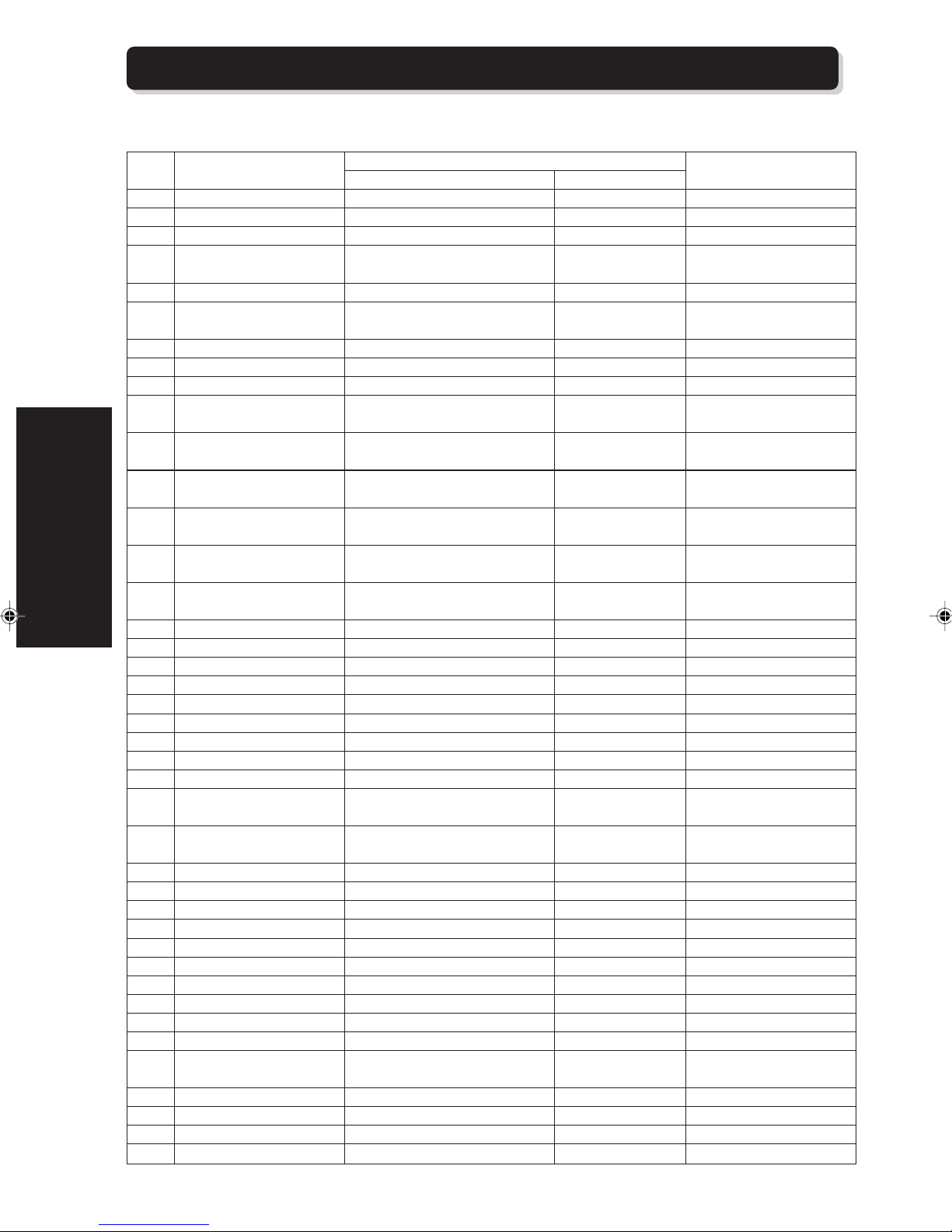

4-2. ERROR CODES

The following explains the meaning of each of the error codes.

4. ERROR DISPLAY

Error

Code

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

16

17

18

19

1A

1B

1C

1D

1E

1F

20

21

22

23

24

25

26

27

28

If indoor unit error

No error

–

Model information abnormal

Microcomputer error

Power supply frequency abnormal

–

EEPROM access error

EEPROM deletion error

–

Room temperature

thermistor error

Heat exchanger thermistor

(middle) error

Heat exchanger thermistor

(inlet) error

Heat exchanger thermistor

(outlet) error

Blower temperature thermistor

error

–

–

–

Drain abnormal

Room temperature abnormal

Fan error

–

–

–

–

Standard wired remote control

communication error

–

–

–

–

–

–

Transmission error

–

–

–

–

–

–

–

–

–

If outdoor unit error

S series V series

No error

–

Model information abnormal

Circuit board error 1

Power supply frequency error

Reverse phase blocker error

EEPROM access error

EEPROM deletion error

–

Compressor 1 error

Compressor 2 error

Compressor 3 error

–

Discharge temperature thermistor 1 error

Discharge temperature thermistor 2 error

Discharge temperature thermistor 3 error

Outdoor temperature thermistor error

Heat exchanger inlet thermistor 1 error

Heat exchanger inlet thermistor 2 error

Heat exchanger inlet thermistor 3 error

Heat exchanger outlet thermistor 1 error

Heat exchanger outlet thermistor 2 error

Heat exchanger outlet thermistor 3 error

Suction temperature thermistor error

–

Discharge pressure sensor error

Liquid pressure sensor error

Suction pressure sensor error

Oil sensor error

–

–

Transmission error

–

Discharge temperature 1 error

Discharge temperature 2 error

Discharge temperature 3 error

High-pressure error

Low-pressure error

–

Oil recovery error

Pump down error

No error

–

–

–

–

Reverse phase blocker

error

Outdoor PCB unit error

–

–

Compressor error

–

–

–

–

Outdoor unit thermistor

error

–

–

–

–

–

–

–

–

–

–

Sensor error

(except thermistor)

–

–

–

–

–

Transmission error

–

–

–

–

Operation error

(Pressure/temperature)

–

–

–

Pump down error

If central remote controller

error

No error

–

Circuit board error (Control panel)

Circuit board error

(Transmission adaptor)

Memory error

Node setting error

Parallel communication error

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Initial setting error

Connection error

Initial setting error

Manual store 2 error

Transmission error

–

Software error (Output)

Software error (Input)

–

–

–

–

–

–

32

Page 35

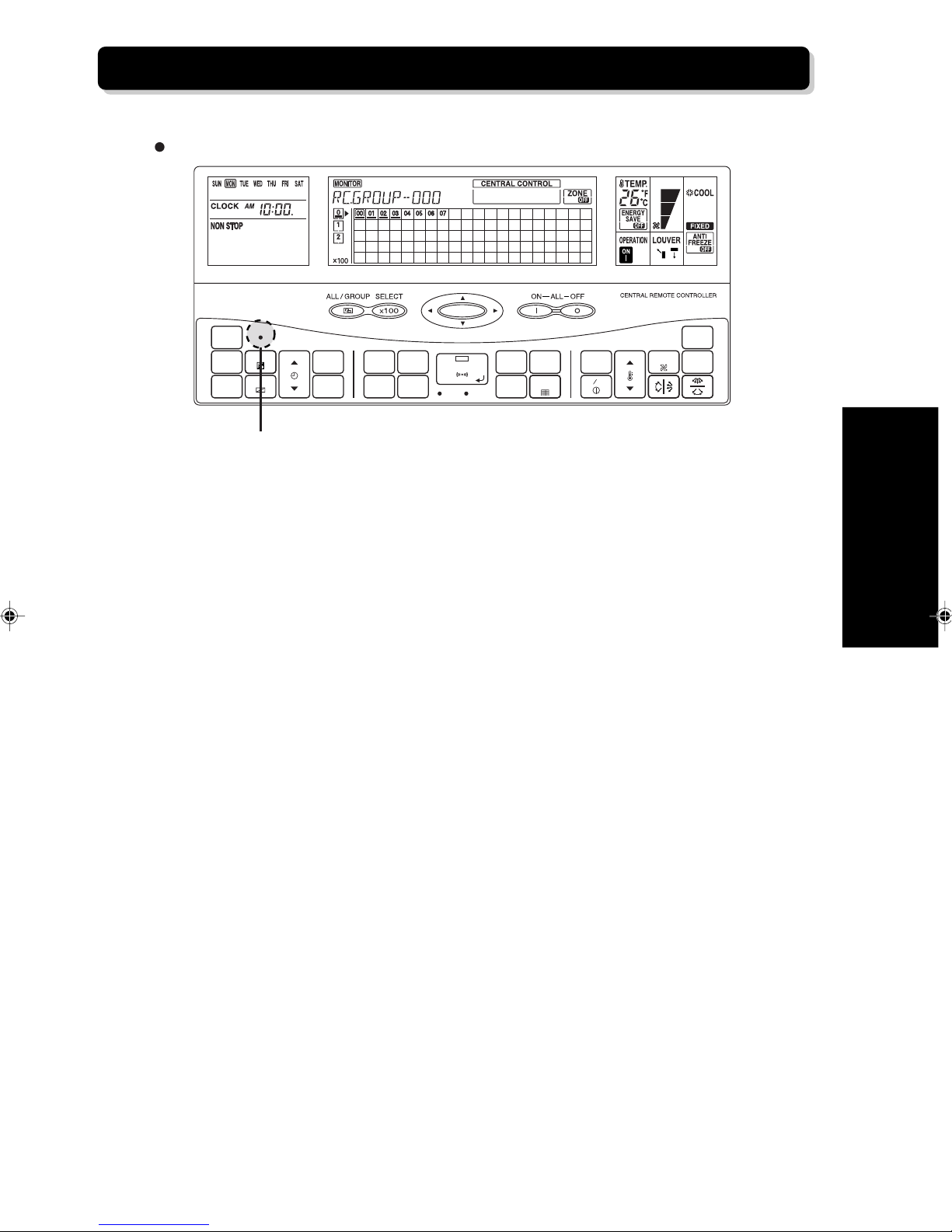

4-3. ALL CLEAR SWITCH

Press

ACL

to restart the central remote controller.

ACL

CLOCK

ADJUST

DAY

DAY OFF

TIME

TIMER

DELETE

TIMER

SET

MEMORY

OPERATION

MEMORY

SETTING SETTING

TIMER

MODE

TIMER

COPY

ACL Switch

CENTRAL

CONTROL

GROUP

CHECK

SET

TEST

BACK

DELETE

ZONE

FILTER

RESET

MASTER

CONTROL

FAN

TEMP.

ENERGY ANTI

SAVE

ON OFF

CONTROL

FREEZE

4. ERROR DISPLAY

33

Page 36

5. SPECIFICATIONS

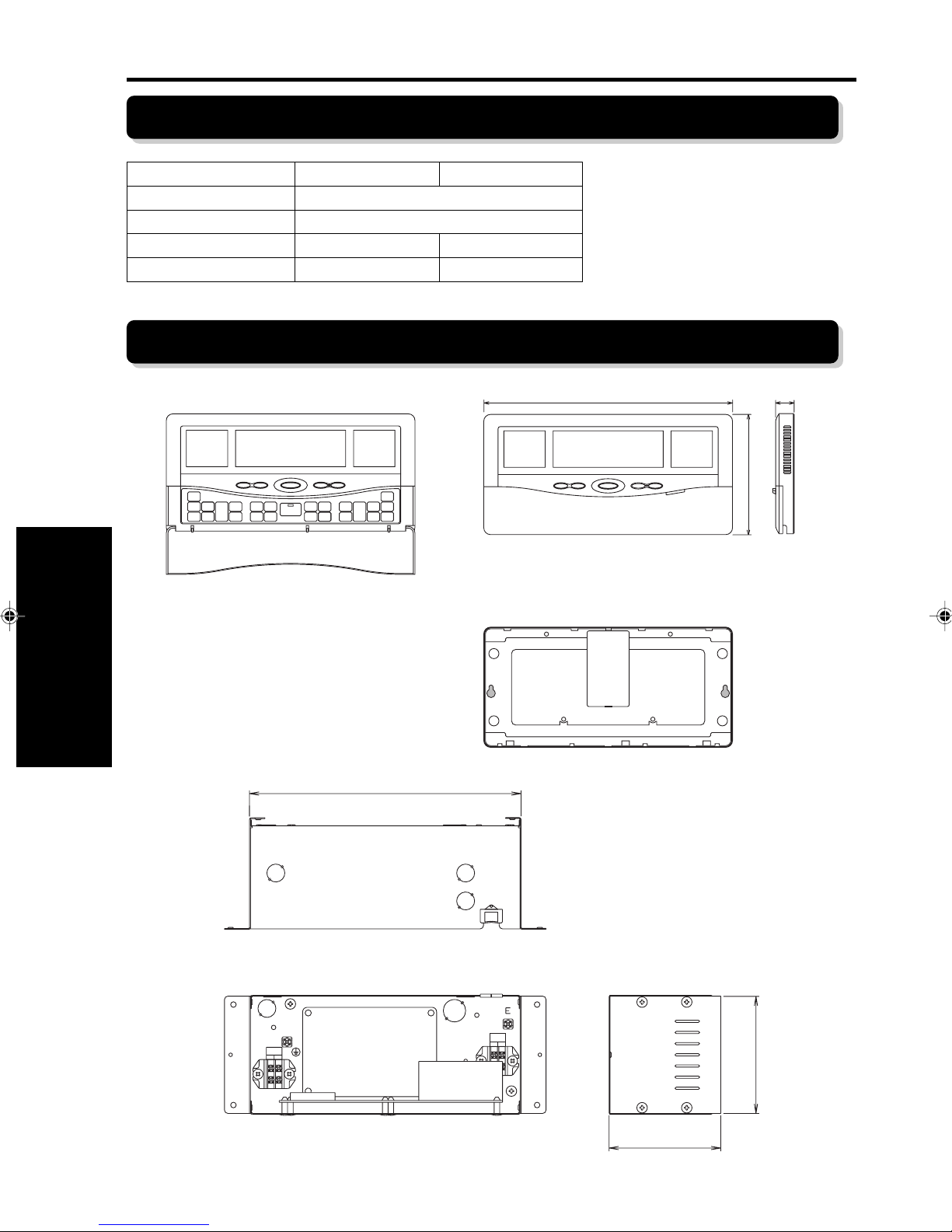

5-1. SPECIFICATIONS

5. SPECIFICATIONS

Operation panel

Supply power 50 — 60 Hz 220 — 240 V

Power consumption (W) 4.8 W

Size (H × W × D mm) 143 × 296 × 22 (107) × 288 × 100

Weight (g) 550 1300

Communication adapter

5-2. DIMENSIONS

296

Front View Side View

22

143

OPERATION PANEL

POWER

220-240V

12

243

TRANS

MISSION

12

Rear View

TRANSMISSION ADAPTOR

106.6

34

100

Page 37

Page 38

P/N9367842018-06

Loading...

Loading...