Page 1

P42HCA30WH

FUJITSU GENERAL Proprietary

Copy Prohibited

Page 2

CONTENTS

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SETTING SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PART NAMES AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

VIDEO MODE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RGB MODE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

TROUBLESHOOTING USING LED AND OSD . . . . . . . . . . . . . . . . . . . 12

TROUBLESHOOTING FLOWCHART . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

VOLTAGE OF EACH CONNECTOR

S AND VA ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

V

GENERAL CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DISASSEMBLY .

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TRANSPOR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

TATION AND HANDLING RESTRICTIONS . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 3

IMPORTANT INFORMATION

WARNING : TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, DO NOT EXPOSE THIS

PRODUCT TO RAIN OR MOISTURE.

Please use a screen saver to prevent burning of an after-image on the screen.

Electrical energy can perform many useful functions. This unit has been engineered and manufactured to assure your

personal safety. But IMPROPER USE CAN RESULT IN POTENTIAL ELECTRICAL SHOCK OR FIRE HAZARD.

In order not to defeat the safeguards incorporated into this unit, observe the following basic rules governing its installation,

use and service. Please read these "Important Safeguards" carefully before use.

Read all the safety and operating instructions before operating the unit.

Retain the safety and operating instructions for future reference.

Adhere to all warnings on the unit and in the operating instructions.

Follow all operating instructions.

Unplug the unit from the wall outlet before cleaning. Do not use liquid or aerosol cleaners. Use a damp cloth for cleaning.

Do not use attachments not recommended by the manufacturer as they may be hazardous.

Do not use the unit near water. Do not use the unit immediately after moving it from a low temperature to a high

temperature environment, as this causes condensation, which may result in fire, electric shock, or other hazards.

Do not place the unit on an unstable cart, stand, or table. The unit may fall, causing serious injury to a child or adult, and

serious damage to the unit. Mount the unit according to the manufacturer's instructions, using the mount recommended by

the manufacturer.

When the unit is used on a cart, avoid quick stops, excessive force, and uneven

surfaces which may cause the unit and cart to overturn, damaging the unit or

causing possible injury to the operator.

When transporting by car, place the unit as shown in the figure.

Slots and openings in the cabinet are provided for ventilation. These ensure reliable operation and protect the unit from

overheating. These openings must not be blocked or covered. (The openings should never be blocked by placing the unit

on a bed, sofa, rug, or similar surface. The unit should not be placed in a built - in installation such as a bookcase or rack

unless proper ventilation is provided and the manufacturer's instructions are adhered to.) For proper ventilation, separate

the unit from other equipment, which may obstruct ventilation. Keep the unit at least 10cm from other equipment.

Operate only with the type of power source indicated on the label. If you are not sure of the type of power supply to your

home, consult your dealer or local power company.

This unit is equipped with a three-wire plug. This plug will fit only into a grounded power outlet. If you cannot insert the plug

into the outlet, have an electrician install the proper outlet. Do not defeat the safety purpose of the grounded plug.

Route power cords so that they are not likely to be walked on or pinched by items placed on or against them. Pay

particular attention to cords at doors, plugs, receptacles, and where they exit from the unit.

For added protection during a lightning storm, or when the unit is left unattended and unused for long periods of time,

unplug it from the wall outlet and disconnect the cabling. This will prevent damage to the unit by lighting and power line

surges.

Do not overload wall outlets, extension cords, or convenience receptacles on other equipment as this can result in fire or

electric shock.

Never push objects of any kind into this unit through openings as they may touch dangerous voltage points or short-circuit

parts that could result in a fire or electric shock. Never spill liquid of any kind onto the unit.

- 2 -

Page 4

Do not attempt to service this unit yourself as opening or removing covers may expose you to dangerous voltages and

other hazards. Have all service done by qualified service personnel.

Unplug this unit from the wall outlet and have it serviced by qualified service personnel in the following cases:

a) If the power supply cord or plug is damaged.

b) If liquid has been spilled, or objects have fallen onto the unit.

c) If the unit has been exposed to rain or water.

d) If the unit does not operate normally by following the operating instructions. Adjust only those controls that are

covered by the Operation Manual, as improper adjustment of controls may result in damage and will often require

extensive work by a qualified technician to restore the unit to normal operation.

e) If the unit has been dropped or damaged in any way.

f) A distinct change in performance indicates that service is required.

When required, be sure the service technician uses replacement parts specified by the manufacturer or parts with the

same characteristics as the original parts. Unauthorized substitutions may result in fire, electric shock, or other hazards.

Upon completion of any service of repairs, ask the service technician to perform safety checks to determine that the

unit is in proper operating condition.

Place the unit more than one foot away from heat sources such as radiators, heat registers, stoves, and other devices

(including amplifiers) that produce heat.

When connecting other devices such as VCR's and personal computers, turn off the power to this unit to protect

against electric shock.

Do not place combustibles such as cloth, paper, matches, aerosol cans or gas lighters that prevent special hazards

when overheated behind the cooling fan.

Use only the accessory cord designed for this unit to prevent shock.

The power supply voltage rating of this unit is AC100-240V, but the attached power cord conforms to the following

power supply voltage. Use only the Power Cord designated by our dealer to ensure Safety and EMC.

When used with other power supply voltages, the power cable must be changed.

Consult your local dealer.

Power Cord

Power supply voltage : AC 100 - 125 V AC 200 - 240 V AC-240V

(SAA TYPE)

- 3 -

Page 5

SPECIFICATIONS

Power requirement

110-240V, 50/60Hz (W, E Type)

Current drain

3.7A-1.8A

Display panel

Screen size 92.2 (W) x 52.2 (H) [cm]

36.3 (W) x 20.5 (H) [inch]

Aspect ratio 16 : 9

Number of pixels 1,024 (H) x 1,024 (V) pixels

Pixel pitch 0.90mm x 0.51mm

Contrast ratio 1000 : 1

Luminance 1100 cd/m

2

Viewing angle Max. 160 degrees

Input Terminals

Analog RGB 1 input mD-sub:15pin (3 row type)

Video : 0.7V

P-P /75Ω

SYNC signal : TTL level

User set mode 8 memories (each RGB1,2,3)

Display frequency Horizontal :15.63 to 80.0MHz

Vertical : 50.0 to 120Hz

Dot clock:108MHz Max

UXGA 162MHz

RS-232C D-sub 9 pin terminal

Color system

NTSC/PAL/SECAM/N-PAL/M-PAL

/4.43NTSC/PAL60

Display colors

1.07 billion (1,024 each for R.G.B.)

Outer dimensions Width : 103.5cm (40.7 inch)

Height: 64.0cm (25.2 inch)

Depth : 8.5 cm ( 3.3 inch)

Net weight 29.5Kg (65.0 lbs)

Environment (Operating)

Temperature 0 to 40 C (32 to 104 F)

Relative humidity 20 to 80%

Pressure 850 to 1,114 hPa

Accessories 2 User's manual

Power cord

Ferrite core (2)

Remote controller

Batteries (Type AA x 2)

Options

Stand P-TT4200

P-WB4201Wall mounting unit

Hanging unit

P-CT4200

P-SP4200 (1 set of 2 speakers)Speaker

Speaker stand

Video board

P-ST4200 (1 set of 2 speakers

P-TE1100

P-TE1110

P-TE1120

P-TE1130

P-TE1140

Standards

P42HCA30WH

P42HCA30EH

UL,CSA

Safety: UL6500

C-UL

EMC: FCC Part15 Class A

ICES-003 Class A

CE

Safety: EN60065

EMC : EN55022 1998, Class A

EN61000-3-2 1995

EN61000-3-3 1995

EN55024 1998

EN61000-4-2 1995

EN61000-4-3 1996

EN61000-4-4 1995

EN61000-4-5 1995

EN61000-4-6 1996

EN61000-4-8 1993

EN61000-4-11 1994

AS

Safety : IEC60065

EMC : AS/NZS 3548

0 to 15 mounting angle

0 to 15 mounting angle

stands)

- 4 -

Page 6

SETTING SIGNALS

This display can store parameter settings for eight additional signals for RGB.

To do this, select the desired signal and follow "RGB MODE ADJUSTMENT" in the manual to adjust the parameters.

When you finish, the settings will be automatically stored.

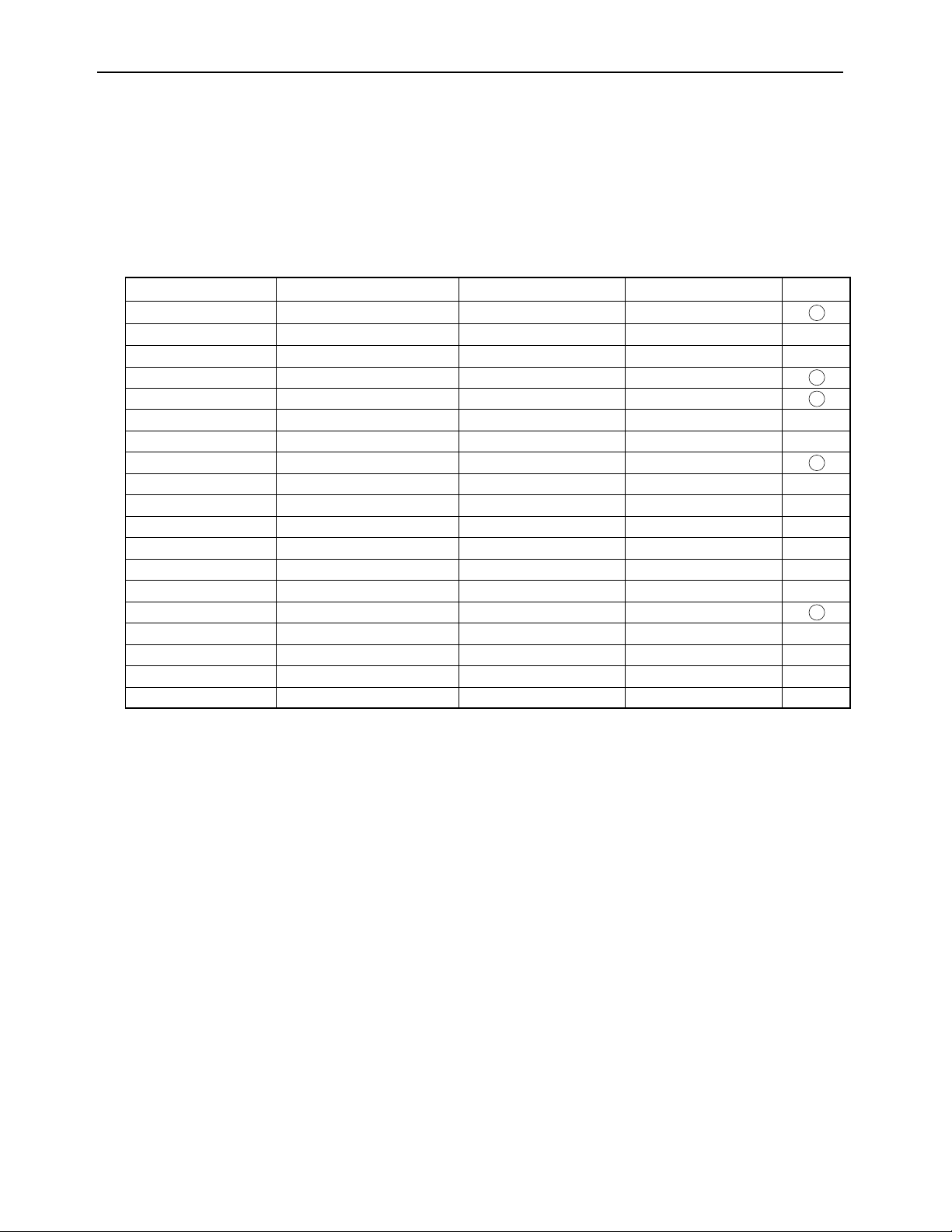

FACTORY SET SIGNALS (RGB MODE)

Main corresponding signals (RGB mode)

Display (dots x lines)

640 x 480 31.47 59.94 VGA

640 x 480

640 x 480

720 x 400

800 x 600

800 x 600

800 x 600

1024 x 768

1024 x 768

1024 x 768

1024 x 768

1280 x 1024 63.98 60.02 SXGA 60 Hz

1280 x 1024 79.98 75.03 SXGA 75 Hz

1600 x 1200 75.00 60.00

1600 x 1200

848 x 480 31.02 60.00

852 x 480 31.72

1360 x 768

720 x 485 15.73 59.94 60 fields

720 x 575 15.63 50.00 50 fields

* With some input signals, “Out of range” may appear even when the horizontal and vertical frequencies are within their permissible ranges. Make

sure that the vertical frequency of the input signal is 85 Hz or less for SVGA/XGA/UXGA, 75 Hz or less for SXGA.

Horizontal frequency (kHz) Vertical frequency (Hz)

37.50 75.00

43.27 85.01

31.47 70.09

37.88 60.32

46.88 75.00 SVGA 75 Hz

53.67 85.06 SVGA 85 Hz

48.36 60.00 XGA 60 Hz

60.02

68.68

106.25 85.00 UXGA 85 Hz

47.71

75.03

84.99

59.97

60.01

VGA 75 Hz

VGA 85 Hz

400 lines

SVGA 60 Hz

XGA 75 Hz

XGA 85 Hz

UXGA 60 Hz

Signal DVI-D

- 5 -

Page 7

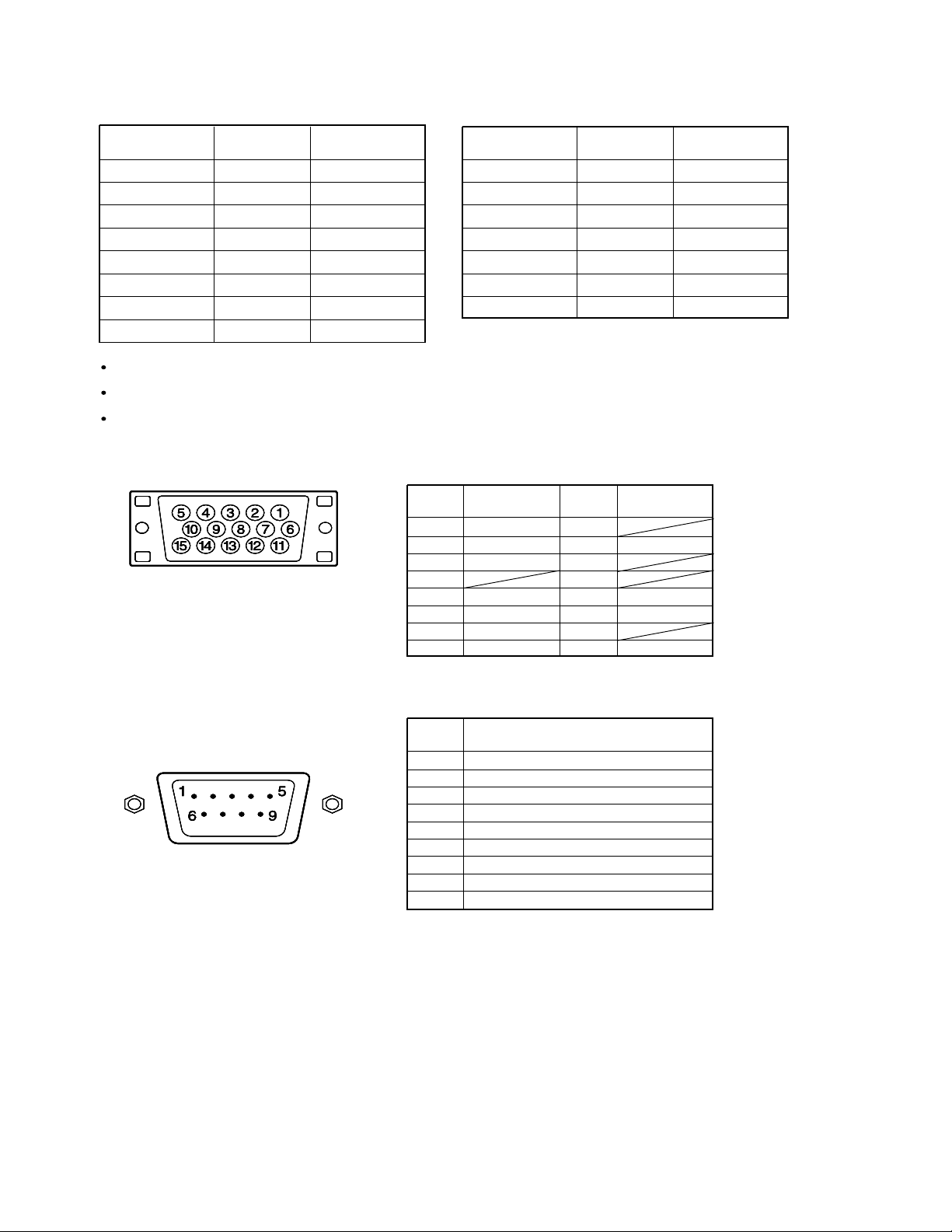

FACTORY SET SIGNALS (Component video mode)

Horizontal

frequency (kHz)

15.73 SDTV 480i

15.63 SDTV 576i

31.47 SDTV 480p

31.25 SDTV 576p

45.00 HDTV 720p

37.50 HDTV 720p

33.75 HDTV 1,080i

28.13 HDTV 1,080i

In the 800 x 600 and 1,024 x 768 modes, images of reduced size are displayed on the screen, using size reduction and

interpolation. Also note that on-screen information is also displayed in reduced size.

" Out of range" appears if the display receives a signal whose characteristic does not fall within the display's

permissible range.

You can check the input signals with "Information" on the OTHERS Menu screen.

Vertical

frequency (Hz)

59.94

50.00

59.94

50.00

60.00

50.00

60.00

50.00

Signal

FACTORY SET SIGNALS (Video, S-video mode)

Horizontal

frequency (kHz)

15.73 NTSC

15.63 PAL

15.63 SECAM

15.63 PAL 60

15.63 N-PAL

15.73 M-PAL

15.73 4.43 NTSC

Vertical

frequency (Hz)

59.94

50.00

50.00

59.52

50.00

59.95

59.94

RGB INPUT TERMINAL

Pin No. Input signal Pin No. Input signal

1 Red 9

2 Green 10 Ground

3 Blue 11

∗ The sync switch (TTL/ANALOG switch) is on

the rear of the 13-pin horizontal sync and

14-pin vertical sync terminals.

4

5 Ground 13 Horiz. sync

6 Ground 14 Vert. sync

7 Ground 15

8 Ground

12

Outer side

Ground

Signal

RS-232C INPUT TERMINAL

Pin No.

Pin No. No. signal

1 DCD (Data Carrier Detect)

2 RD (Receive Data)

3 TD (Transmit Data)

4 DTR (Data Terminal Ready)

5 GND (Ground)

6 DSR (Data Set Ready)

7 RTS (Request To Send)

8 CTS (Clear To Send)

9 RI (Ring Indication)

- 6 -

Page 8

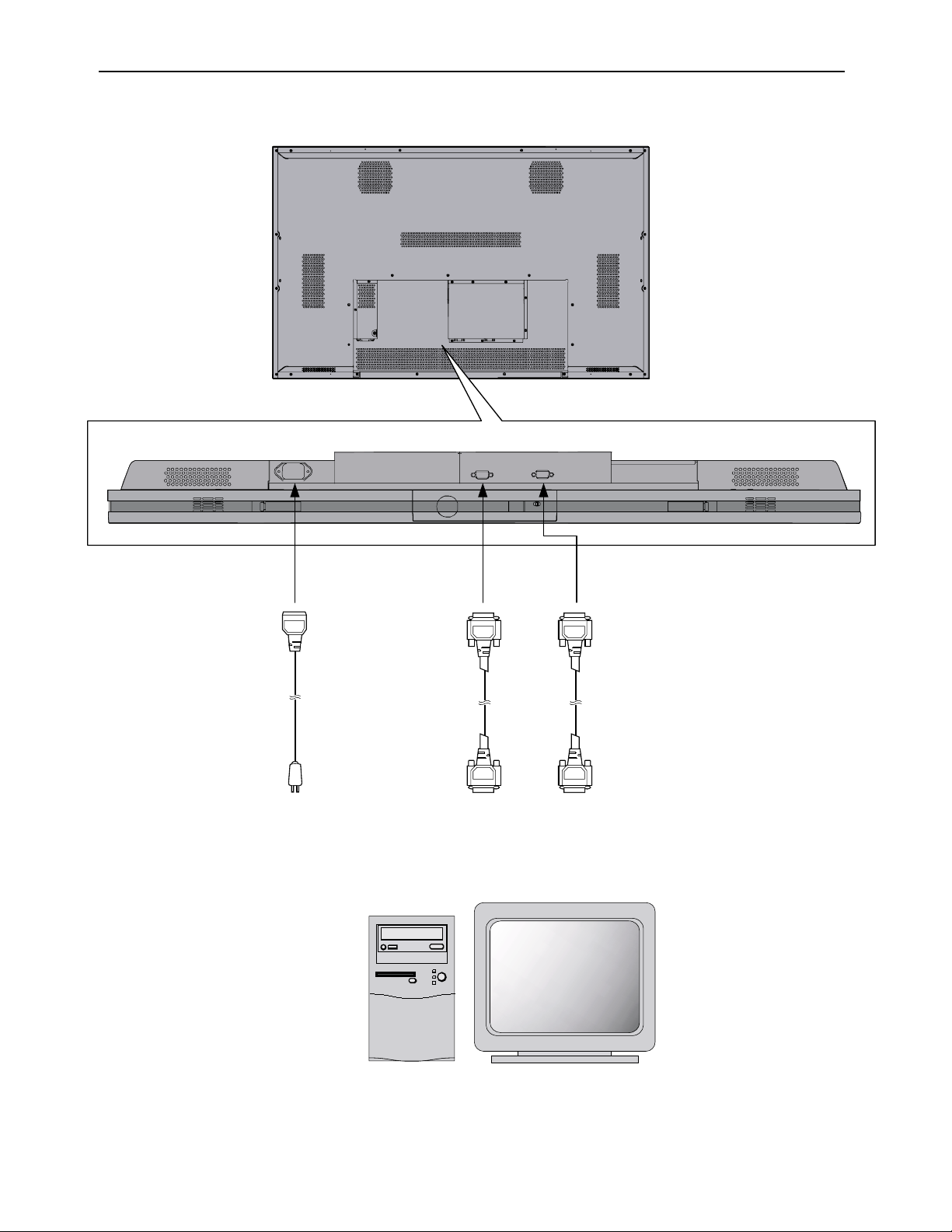

CONNECTION

POWER

INPUT

To receptacle

RGB1

INPUT

(mD-sub)

To display

(analog RGB)

output

terminal

RS-232C

To RS-232C

output

terminal

Connection to PC

- 7 -

Page 9

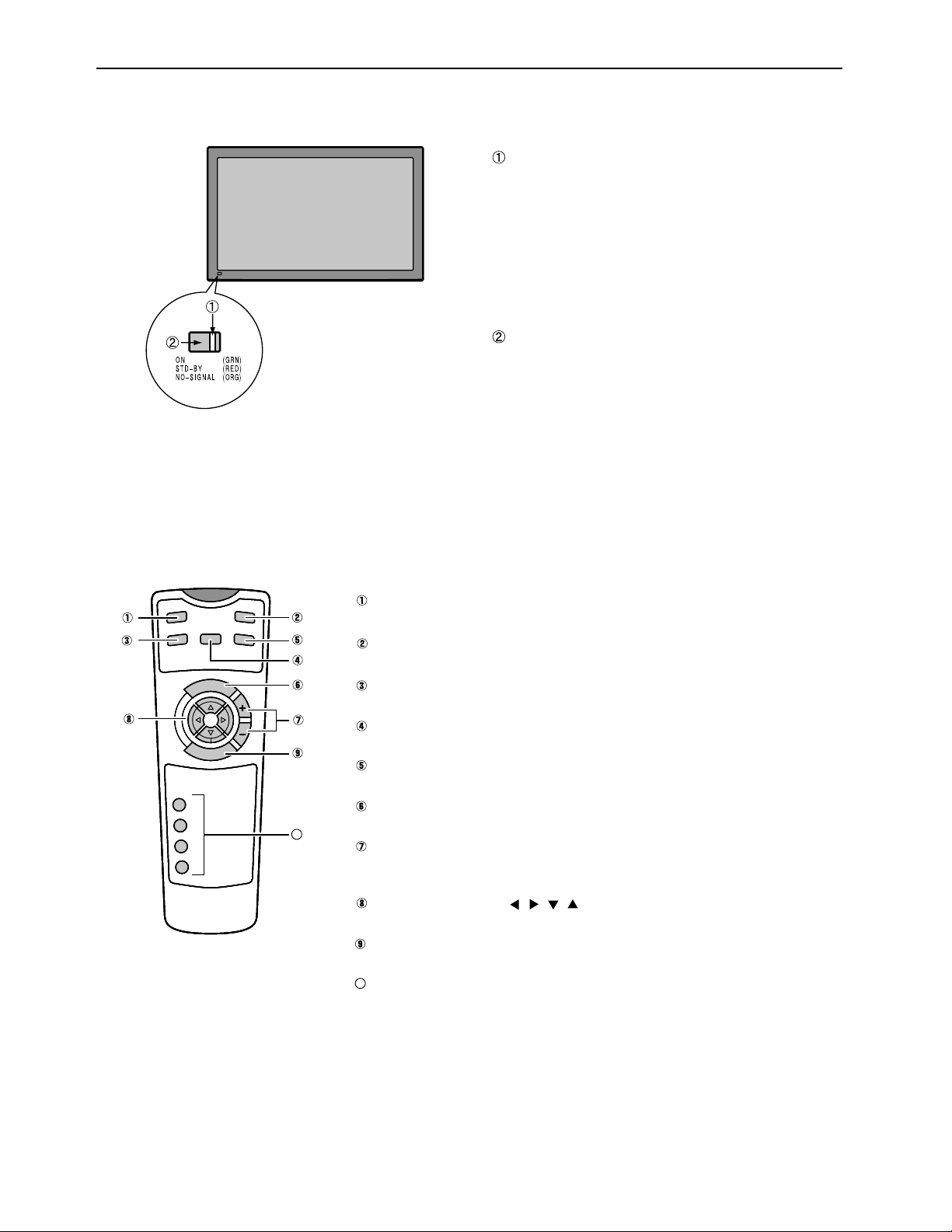

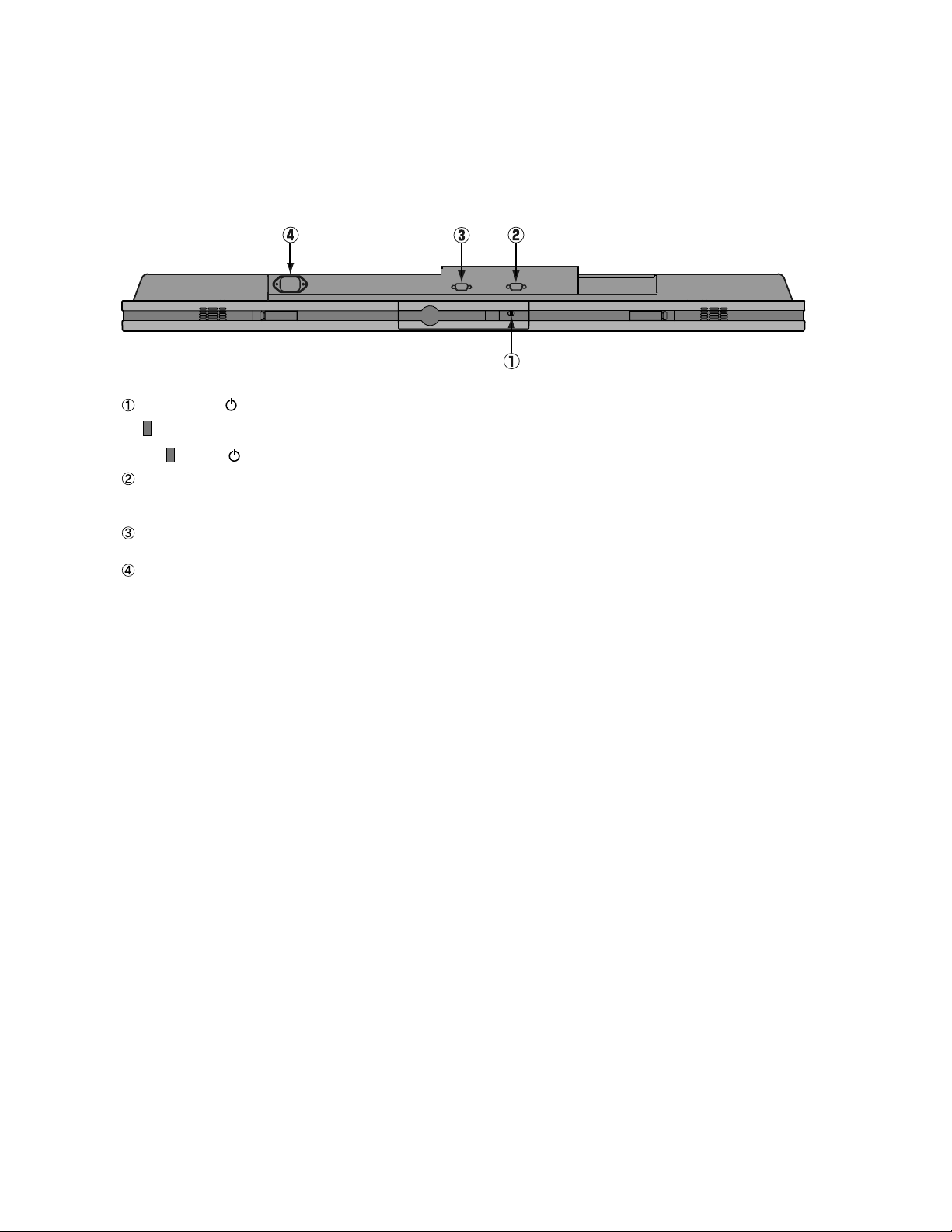

PART NAMES AND FUNCTIONS

Front

Power indicator lamp

This lamp shows the state of the power supply.

Remote control signal receiver

Receives signals from the remote control.

Lit (red): Stand-by

Lit (green): Power ON

Lit (orange): Power saving (DPMS: Power saving

function) mode ON

Flashing (red): Malfunction (Flashes differently depending

on the type of malfunction.)

REMOTE CONTROL

P

P

P

P

O

O

O

VIDEO

VIDEO

VIDEO

VIDEO

MENU

MENU

MENU

MENU

ENTER

ENTER

ENTER

ENTER

O

W

W

W

W

ER OFF

ER OFF

ER OFF

ER OFF

W

W

W

W

I

I

I

I

D

D

D

D

E

E

E

E

VOL

VOL

VOL

VOL

10

N

N

N

N

ER O

ER O

ER O

ER O

POW

POW

POW

POW

RGB

RGB

RGB

RGB

SHIFT

SHIFT

SHIFT

SHIFT

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

Power ON button [POWER ON]

Turns the power ON.

Power OFF button [POWER OFF]

Turns the power OFF.

RGB input mode selector button [RGB]

Switches between RGB input modes.

Video input mode selector button [VIDEO]

Switches between video input modes.

Wide screen selector button [WIDE]

Switches the screen over to a desired wide screen.

Menu button [MENU]

Use this button to display a desired menu for adjusting the picture.

Volume adjustment buttons [VOL +/-]

Adjust the volume. Press the + button to increase the volume.

Press the - button to reduce the volume.

Adjustment buttons [ / / / ]

Use these buttons to scroll through options in a menu and change values.

Enter button [ENTER]

Press this button to finalize the selection of a desired menu or option within a menu.

10

Display selector buttons [SHIFT 1-4]

When you use two or more displays, you can use these buttons to control up to four

displays by assigning an unique number to each display.

- 8 -

Page 10

DISPLAY SECTION – LOWER PART

Bottom (42" HCA30 type)

OFF/STD-BY switch

OFF :

STD-BY :The power indicator lamp lights red, and the power can be turned on or off by the power button.

RS-232C terminal (RS-232C)

This terminal is provided for you to control the display from the PC. Connect it to the RS-232C terminal on the PC.

When connecting a cable, attach a ferrite core to the cable.

RGB1 input terminal (RGB1 INPUT/mD-sub)

Connect this terminal to the PC's display (analog RGB) output terminal or decoder (digital broadcast tuner, etc.) output terminal.

Power input terminal

Connect this terminal to the power cable supplied with the display.

When connecting a cable, attach a ferrite core to the cable.

The power indicator lamp goes off, and the power can' t be turned on by the power button. The power is partly supplied.

- 9 -

Page 11

VIDEO MODE ADJUSTMENT

REMOTE CONTROLLER

POWER ON

POWER OFF

RGB

VIDEO

WIDE

VOL. +

VOL. -

Normal

Wide 1

Wide 2

Zoom 1

Zoom 2

RGB 1

RGB 2

Video

S-video

Normal

Wide 1

Wide 2

Zoom 1

Zoom 2

MENU

ENTER

PICTURE

POSITION/SIZE

AUDIO

FEATURES

FACTORY DEFAULT

Contrast

Brightness

Color

Tint

Sharpness

Picture Mode

Luminance*

Color Temp.

User Color Temp.*

Position

Size

Treble

Bass

Balance

Loudness

On Screen Menu

Input Terminal

Others

Execute

{-30 to +30}

{-60 to +60}

{-60 to +60}

{-30 to +30}

{-16 to +16}

Dynamic

Real

Static

{40 to 100%} *Can be set when Static is selected as the Picture Mode.

{-3500 to +3500}

Red

Green

Blue

Horizontal

Vertical

Width

Height

{-6 to +6}

{-6 to +6}

{-10 to +10}

On

Off

OSD

Language

Video Input

S-video Input

BNC Input

D-SUB Input

DPMS

Audio Input

Input Priority

Monitor No.

White Screen

Exhibition Mode

Installation

Information

Yes

No

*Can be set when User is selected as the Color Temp.

{0 to 255}

{0 to 255}

{0 to 255}

{-30 to +30}

{-7 to +7 (Zoom -15 to +15)}

{-7 to +16}

{-7 to +16}

On

Off

English

Deutsch

~

Espanol

Francais

~

Italiano

<

Portugues

K

Pycc * *Russian can only be set with the E-model.

NN

Auto

NTSC

PAL

SECAM

PAL60

4.43NTSC

RGB-Video

RGB-PC

Decoder

RGB-PC

Decoder

Time

Background

RGB 1

RGB 2

Video

S-video

Off

RGB 1

RGB 2

Video

S-video

0

1

2

3

4

On

Off

On

Off

-90 Deg.

Normal

+90 Deg.

Mode

Monitor No.

Freq. Scan Mode

Input Signal

Freq.

Mask

Mask

Mask

Off

1 min.

15 min.

45 min.

60 min.

Black

White

No Audio

Audio 1

Audio 2

Audio 3

Position Horizontal "-"

Off

5

10

15

Off

5

10

15

Off

5

10

15

Horizontal "+"

Vertical "-"

Vertical "+"

Size Width "-"

Width "+"

Height "-"

Height "+"

Mask Off

Mask 5

Mask 10

Mask 15

- 10 -

Page 12

RGB MODE ADJUSTMENT

REMOTE CONTROLLER

POWER ON

POWER OFF

RGB

VIDEO

WIDE

VOL. +

VOL. -

Normal

Wide 1

Wide 2

Zoom 1

Zoom 2

RGB 1

RGB 2

Video

S-video

Normal

Wide 1

Wide 2

Zoom 1

Zoom 2

MENU

ENTER

PICTURE

POSITION/SIZE

AUDIO

FEATURES

FACTORY DEFAULT

Contrast

Brightness

Color

Tint

Sharpness

Picture Mode

Luminance*

Color Temp.

User Color Temp.*

Position

Size

Treble

Bass

Balance

Loudness

Adjustment

On Screen Menu

Input Terminal

Others

Execute

{-30 to +30}

{-60 to +60}

{-60 to +60}

{-60 to +60}

{-4 to +4}

Dynamic

Real

Static

{40 to 100%} *Can be set when Static is selected as the Picture Mode.

{-3500 to +3500}

Red

Green

Blue

Horizontal

Vertical

Width

Height

{-6 to +6}

{-6 to +6}

{-10 to +10}

On

Off

Dot Clock

Clock Phase

Clamp Position

Auto Calibration

OSD

Language

Video Input

S-video Input

BNC Input

D-SUB Input

DPMS

Audio Input

Screen Orbiter

Input Priority

Monitor No.

Direct Setting

Code Setting

White Screen

Exhibition Mode

Installation

Information

Yes

No

{0 to 255}

*Can be set when User is selected as the Color Temp.

{0 to 255}

{0 to 255}

{-150 to +150}

{-150 to +150}

{-25 to +50}

{-25 to +50}

{-30 to +30}

Auto

Manual {1 to 32}

{-8 to +8}

Execute

On

Off

English

Deutsch

~

Espanol

Francais

~

Italiano

Portugues

K

Pycc

Auto

NTSC

PAL

SECAM

PAL60

4.43NTSC

RGB-Video

RGB-PC

Decoder

RGB-PC

Decoder

Time

Background

RGB 1

RGB 2

Video

S-video

Mode / Time

Moving Area

Off

RGB 1

RGB 2

Video

S-video

0

1

2

3

4

Auto

VGA

WVGA

480P

XGA

WXGA

SXGA

+

SXGA

Auto

Manual {00 to 34} *Hexadecimal

On

Off

On

Off

-90 Deg.

Normal

+90 Deg.

Mode

Monitor No.

Freq. Scan Mode

Input Sync

Freq.

Preset No.

Yes

No

<

*Russian can only be set with the E-model.

NN

Mask

Mask

Mask

Off

1 min.

15 min.

45 min.

60 min.

Black

White

No Audio

Audio 1

Audio 2

Audio 3

Off

Time

Mode

Min.

Std.

Max.

Position Horizontal "-"

Horizontal "+"

Vertical "-"

Vertical "+"

Size Width "-"

Width "+"

Off

5

10

15

Off

5

10

15

Off

5

10

15

Height "-"

Height "+"

Mask Off

Mask 5

Mask 10

Mask 15

- 11 -

Page 13

TROUBLESHOOTING USING LED AND OSD

1. Display

(1) OSD

Three kinds of error messages are displayed on the screen, and the power is turned off 10 sec later.

(2) LED

LED error is displayed continuously after the power is turned off.

2. Error types and check points

(1) OSD

On screen display Cause Check point

ERROR MESSAGE CONDITION 1

ERROR MESSAGE CONDITION 2 Temperature protector

(2) LED

Fan protector operated

operated

LED lamp display status Cause Check point

Steady light (Red)

1 time (Red) / 1 time (Green)

Flashes once Red LED and flashes

once Green LED every 3 sec.

1 time (Red) / 2 times (Green)

Flashes once Red LED and flashes

twice Green LED every 4 sec.

1 time (Red) / 3 times (Green)

Flashes once Red LED and flashes

three Green LED every 5 sec.

2 times (Red) / 1 time (Green)

Flashes twice Red LED and flashes

once Green LED every 4 sec.

2 times (Red) / 2 times (Green)

Flashes twice Red LED and flashes

twice Green LED every 5 sec.

3 times (Red) / 2 times (Green)

Flashes three Red LED and flashes

twice Green LED every 6 sec.

3 times (Red) / 3 times (Green)

Flashes three Red LED and flashes

three Green LED every 7 sec.

4 times (Red) / 1 time (Green)

Flashes four Red LED and flashes

once Green LED every 6 sec.

5 times (Red) / 1 time (Green)

Flashes five Red LED and flashes

once Green LED every 7 sec.

6 times (Red) / 1 time (Green)

Flashes six Red LED and flashes

once Green LED every 8 sec.

Stand-by status

No power

Power supply protector

operated

No power

Power supply protector

operated

No power

Power supply protector

operated

Temperature protector

operated

Temperature protector

operated

EEPROM device fault

EEPROM device Read /

Write fault

Main/Digital circuit fault

Video circuit fault

Fan protector operated

Fan

Main power PCB

Main/Digital PCB

Ambient temperature of unit

Main/Digital PCB

Temp. sensor IC6950

Main power PCB

PDP panel

Main/Digital PCB

Ambient temperature of unit

Main/Digital PCB

Temp. sensor IC6950

Main/Digital PCB

Main/Digital PCB

Main/Digital PCB

Video PCB

Fan 1

Main/Digital PCB

6 times (Red) / 2 time (Green)

Flashes six Red LED and flashes

twice Green LED every 10 sec.

Fan protector operated

- 12 -

Fan 2

Main/Digital PCB

Page 14

TROUBLESHOOTING FLOWCHART

LED lamp blinking

Turn power on and check

state of lamp.

LAMP STATE

Not lighted.

Blink LED

Blink LED

Blink LED

Blink LED

Blink LED

Blinks

1 time (Red)

continuously.

1 time (Green)

1 time (Red)

2 times (Green)

1 time (Red)

3 times (Green)

6 times (Red)

2 times (Red)

Note : 1. Since a voltage is applied to the Main Power

POWER SUPPLY STATE

Power supply

circuit faulty.

Power turned off

Power turned off

immediately.

immediately.

Power turned off

immediately.

Power turned off

immediately.

Power turned off

after 10 sec.

Power turned off

after 10 sec.

PCB heat sinks while the set is operating, do

not touch the heat sinks.

2. If the Main Power PCB insulation sheet is not

installed when assembling, the Main Power

PCB fuse will blow.

REMEDY

∗ Replace Main

Power PCB.

∗ Vs and V

Check 1

Check 1

Check PDP Panel.

Check Main/Digital

PCB

Check 2

Check 3

a must be adjusted.

Blink LED

Blink LED

Blink LED

GREEN

3 times (Red)

4 times (Red)

5 times (Red)

Lights steadily for

more than 10 sec.

Is on-screen display

normal?

YES

Power not turned

off, LED blinks only.

Power not turned

off, LED blinks only.

Power not turned

off, LED blinks only.

NO

All input image

faulty.

Video input image

faulty.

S-video input image

faulty.

Component video

input image faulty.

Check 4

Signal processing

PCB faulty.

Check 5

Check 5

Check 6

Replace Main/Digital

PCB.

Replace Main/Digital

PCB Assy.

Replace Video PCB

Assy.

Replace Main/Digital

PCB Assy.

RGB input image

faulty.

Check 7

- 13 -

Page 15

Check 1

Power supply protector operated

Power lamp : Flashing 1 time in Red.

Start

(1) Pull out Power Cord Plug and disconnect connectors CN6, CN23, CN33, CN42 and CN52

on Main Power PCB.

(2) Connect pin 1 and pin 13 of CN352 through a 1/4W, 1K

Connect pin 1 of CN352 and pin 5 of CN509 through a 1/4W, 1K

CN502 shorted.

(3)

Plug in Power Cord Plug and turn on power switch.

Flashing 1 time in Green.

Ω resistor.

Ω resistor.

Does

lamp change to

green?

No

(1) Pull out Power Cord Plug and disconnect connectors CN351 and CN352 on Main Power

PCB.

(2) Connect pin 1 and pin 13 of CN352 through a 1/4W, 1K

Connect pin 1 of CN352 and pin 5 of CN509 through a 1/4W, 1K

CN502 shorted.

(3)

Disconnect connectors on Main Power PCB. (CN6, CN23, CN33, CN42, CN52)

(4)

Plug in Power Cord Plug and turn on power switch.

Is voltage

at each connector on

Main Power PCB normal?

See page 26

Yes

(1) Pull out Power Cord Plug and connect connector CN351 and CN352 to Power Supply Unit.

(2) Remove Video PCB Assy.

Plug in Power Cord Plug and turn on power switch.(3)

(4) Check state of green lamp.

Yes

No

PDP faulty.

Power Supply

circuit faulty.

Ω resistor.

Replace PDP.

∗

∗ Vs and Vamust be adjusted.

Ω resistor.

Replace Main

∗

Power PCB.

∗ Vs and Vamust be adjusted.

Is green

lamp lit

continuously?

Yes

No

Main/Digital

circuit faulty.

Video circuit

faulty.

- 14 -

Replace Main

/Digital PCB Assy.

Replace Video PCB

Assy.

Page 16

Adjust PDP unit installation so that

peripheral temperature is 40.0 or

less.

(For 0.5 sec. at an interval of 5 sec.)

Replace

Main/Digital

PCB Assy.

Microcomputer

peripheral circuit

faulty.

Replace

temperature sensor

IC6950.

Temperature protector operated

No

Power lamp : Flashes intermittently twice in red.

Start

Is ambient temperature

Check 3

Yes

PCB less than 66 ?

of IC6950 on Sensor

Power Supply Unit

No

Does unit

operate normally

when temperature sensor

circuit faulty.

∗ Replace Main

Temperature

IC6950 changed ?

Power PCB.

Yes

Replace

adjusted.

∗ Vs and Va must be

sensor IC6950 faulty.

Main/Digital

PCB Assy.

Replace

Main/Digital

PCB Assy.

Fan1:Flashes six times Red LED and

flashes once Green LED every 8 sec.

flashes once Green LED every 10 sec.

Fan2:Flashes six times Red LED and

Fan protector operated

Power lamp: Flashes six times intermittently in Red

Start

No

Is voltage

at connectors

Main PCB 14V?

CN352 and on

Check 2

Yes

- 15 -

Microcomputer

peripheral circuit

faulty.

No

Yes

Is voltage at connectors CN951,

CN952 on Main/Digital PCB

+ and - of CN951 and 952

5V to 11V.

normal?

Microcomputer

Fan faulty Replace fan.

No

Is fan rotary signal of

Main/Digital PCB normal ?

Pin of CN951, CN952

16 to 90 Hz.

peripheral circuit

Yes

faulty.

Page 17

Check 4

OSD is not displayed

Power lamp : Lighted green.

(10 sec or more)

Start

Is picture

displayed on-screen

when signal input?

No

Is voltage at

each connector on

Main Power PCB

Normal?

Yes

Is picture displayed

normally when PDP

changed?

No

Yes

Signal processing

circuit faulty.

Signal processing

circuit faulty.

No

Power Supply

circuit faulty.

Yes

PDP panel faulty.

Replace Main/Digital

PCB Assy.

Replace Main

Power PCB.

Replace Main/Digital

PCB Assy.

- 16 -

Page 18

Check 5

Start

Video 1/ Video 2 input signal are abnormal.

Power lamp : Lighted green

(10 sec or more)

Can this unit

select only RGB mode?

No

Is picture

displayed on screen

normal when new video

PCB unit installed ?

No

Is signal input level

normal?

No

Yes

Yes

Yes

Microcomputer

peripheral circuit

faulty

Video PCB Assy

faulty.

Signal processing

circuit faulty.

Replace Main/Digital

PCB Assy.

Check input signal.

- 17 -

Page 19

Check 6

Start

Video 3 / Video 4 are abnormal.

Power lamp : Lighted green

(10 sec or more)

Can this unit select

only RGB mode ?

No

Is picture

displayed on screen

normal when new

Video PCB Unit

installed ?

No

Are brightness

and color difference

signals connected to

input terminals

correctly ?

Yes

Is signal

input level

normal?

Yes

Yes

Yes

No

Install Video PCB

Unit faulty.

Video PCB Unit

faulty.

Check connection

cable.

Signal processing

circuit faulty.

Replace Main/Digital

PCB Assy.

No

Check input signal

∗SYNC signals are added to the Y signal.

- 18 -

Page 20

No

No

Ye s

cable ?

Is composite sync.

signal input to pin 13 of RGB

Make sync. signal polarity output

from signal source negative, or make

output impedance TTL.

Check connection cable.

No

Check input signal.

Start

RGB input is abnormal.

Power lamp: Lighted green

k

Chec 7

Ye s

Is RGB

appropriate ?

cable pin arrangement

(10 sec or more)

Sync. on green signal

source ?

What kind of

Is composite sync.

signal is output from signal

Separate signal Composite signal

io

io

io

Is horizontal sync.

signal input to pin 2 of RGB

Check input signal.

No

.

le ?

RGB cable ?

signal input to pin 14 of

signal input to pin 13 and vertical sync

le ?

cable ?

Ye s

Note(∗): If the synchronizing signal cannot be identified by

TTL level, it in the 75Ω terminated state.

Check input signal.NoCheck input signal.

No

Ye s

Is Sync. signal

Connect RGB cable

to terminal.

Yes

negative ?

TTL and polarity

No

Ye s

∗

Is input level(∗) within specified

Is frequency of horizontal sync.

and vertical sync signals within

specified range ?

range ?

.

.

.

Ye s

Signal processing circuit faulty.

.

Replace Main/Digital PCB Assy.

- 19 -

Page 21

VOLTAGE OF EACH CONNECTOR

1. How to measure the voltages on the Main Power Supply PCB in protect mode.

Since a voltage is applied to the Main Power PCB heat sinks while the set is operating,

do not touch the heat sinks.

After the power cord plug was pulled out, do not pull out the connector on the Main Power PCB until

the Green LED (D531: Discharge check LED) turns off.

1) Disconnect CN6, CN23, CN33, CN42 and CN52

2)

Connect pin 1 and pin 13 of CN352 through a 1/4W, 1k resistor.

Connect pin 1 of CN352 and pin 5 of CN509 through a 1/4W, 1k resistor.

CN502 shorted.

3) Press the power button.

2. On the Main Power Supply PCB. (M03DJ)

CN352

No. NAME SPEC.

1 P5V 5.0V +/- 0.25V 5

3 +14V 14.0V +/- 0.7V 5

6 -8V -8.0V +/- 0.4V 7

CN33

No. NAME SPEC.

1 Vcc 1 5.1V +/- 0.25V 2

9 Vs 82.5V +/- 1.5V 5

CN6

No. NAME SPEC.

1 Vpri2 3.3V +/- 0.15V 3

Ground

Ground

Ground

CN351

No. NAME SPEC.

3 +2.5V 2.5V +/- 0.13V 2

7 +3.3V 3.3V +/- 0.17V 6

12 +6.5V 6.5V +/- 0.33V

CN23

No. NAME SPEC.

1 Va 60.0V +/- 1.3V 4

Ground

11

Ground

- 20 -

Page 22

VS AND VA ADJUSTMENT

When the Main Power Supply PCB and PDP panel are replaced, Vs and VA must be

adjusted.

Preparation : Within 3 minutes after power on.

Adjustment : Adjust the VSand VAin the no-signal state.

Check points : Refer to the drawing shown below.

Adjustment points : Refer to the drawing shown below.

Adjustment value : Within +/- 0.2V of voltage indicated on the label of the PDP panel.

- MAIN POWER SUPPLY PCB (M03DJ-PCB) -

CN1

CN2

CN352

CN507

CN351

T2

CN502

CN7

V

A

VR581

CN901

CN509

T3

ADJ

CN3

T4

ADJ.

VS

VR582

CN508

110

CN6

CN23

VS & VA

check point

CN23

1 pin V

4 pin GND

8 pin V

A

S

- 21 -

Page 23

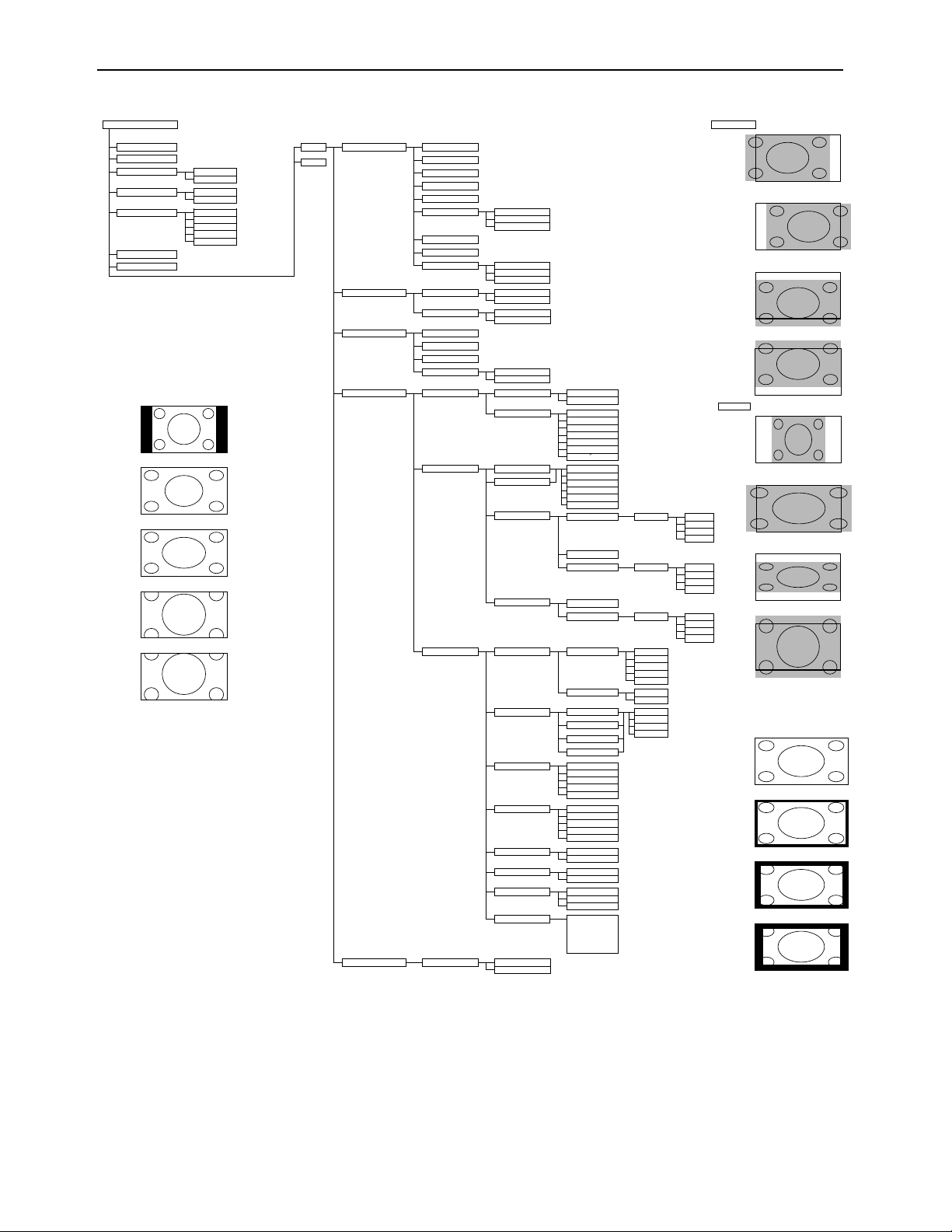

OPTICAL FILTER

FPF42C128128UC-56

PLASMA DISPLAY UNIT

M03EJ

SENSOR

92 FUN

92 FUN

M03CQ

MAIN/DIGITAL

M03DJ

MAIN POWER

INLET

GENERAL CONNECTION DIAGRAM

- 22 -

M033DD

(OPTIONAL)

M03CFA

LED/PHOTO

POWER

SWITCH

M03CFB

Page 24

DISASSEMBLY

1. Removing the Rear Case and layout of Main PCB

1. Remove the 25 screws and Rear Case.

A

* Layout of Main PCB.

B

A: Main Power PCB

B: Main/Digital PCB

- 23 -

Page 25

2. Removing the Main Power PCB

1. Remove the Rear Case.

2. Take away the insulator.

3. Disconnect the 8 circled connector.

4. Remove the 5 screws and Main Power

PCB.

* View after Main Power PCB removed.

- 24 -

Page 26

3. Removing the Main/Digital PCB

1. Remove the 13 sircled screws and shild main TOP.

2. Disconnect the 9 circled connector.

3. Remove the 4 circled screws and Main/Digital PCB.

* View after Main/Digital PCB removed.

- 25-

Page 27

4. Removing the PDP Unit (1 of 2 )

1. Remove the Rear Case, and Main/Digital Unit.

2. Disconnect the 1 circled connector.

3. Remove the 6 circled screws and shield main

bottom.

4. Disconnect the 1 circled connector.

5. Remove the 8 circled screws.

- 26 -

Page 28

4. Removing the PDP Unit (2 of 2)

6. Remove the Base Frame from the Front

Case together with the panel and PCBs.

* View after the Front Case Panel Unit and

PCBs were removed.

7. Remove the Main Power PCB.

8. Remove the 2 circled screws and sensor PCB.

9. Remove the 11 circled screws and Base Frame

together with Fans.

10. Remove the 6 circled screws and shield plate.

11. Disconnect the 1 circled connector.

* View after only the PDP Unit was removed.

* Replace the removed parts back in the correct

places when the PDP Unit is replaced.

- 27 -

Page 29

5. Removing the Bezel Front

1. Remove the 2 circled Cover Stands and

remove the screw in the holes.

2. Lift the bottom of the Bezel Front.

3. Lift the Bezel Front upward to

remove it.

(The top of the Bezel Front is

hooked.)

* View after Bezel Front was removed.

- 28 -

Page 30

6. Removing the Optical Filter

1. Remove the Bezel Front.

(To remove the Bezel Front, refer to

the Page 27)

2. Remove the 14 screws on the Filter

Holders at each side.

3. Remove by sliding the Filter Holder

in the arrow directions.

4. Remove the Optical Filter.

- 29 -

Page 31

PARTS LIST

Ref.no. Description

P42HCA30WH

Cabinet Bezel Front 8112000000

Case Rear 8117133000

Cover Stand 8108298008

Holder Filter L/R 8110619006

Holder Filter T/B 8110614001

Electric Fan Motor 8900298008

Optical Filter 8114891002

Sensor PCB

8117854004

LED/PHOTO PCB 8117833009

Main Digital PCB 8117830008

Main Power PCB 8117772001

PDP Unit S141014334

Power Cord UL.CSA 8111725003

VDE

----------------

Remote Control Unit 8108442005 ----------------

P42HCA30EH

8117831005

8111726000

Packing Carton Top 8115319000

Carton Bottom 8114547008

Carton Bottom W 8116485001

Packing Pad-Top 8114551005

Packing Pad-Bottom 8114550008

Packing Pad-Bottom W

8116486008

Packing Joint-D 8108655009

Carton Sheet 8116404002

Carton Accessory 8111799004

Sheet Protect

8111634008

: Same as left

- 30 -

Page 32

TRANSPOR

Transportation

Handling

TATION AND HANDLING RESTRICTIONS

Bad loading

Don't load the plasmavision on a truck

as shown in the drawing.

Never drop.Never topple.

Don't hold the

surface of the

optical filter.

Over 30 cm

Drop

Floor

- 31 -

Page 33

3333

4

Don't stack the

plasmavision over

three units high.

Example of good transportation and handling

Good loading

Load the plasmavision as shown above.

- 32 -

Page 34

FUJITSU GENERAL CUSTOMER SERVICE LIMITED

GLOBAL SUPPORT DIVISION

OCTOBER 2003

Loading...

Loading...