Page 1

Fujitsu Microelectronics Europe

User Guide

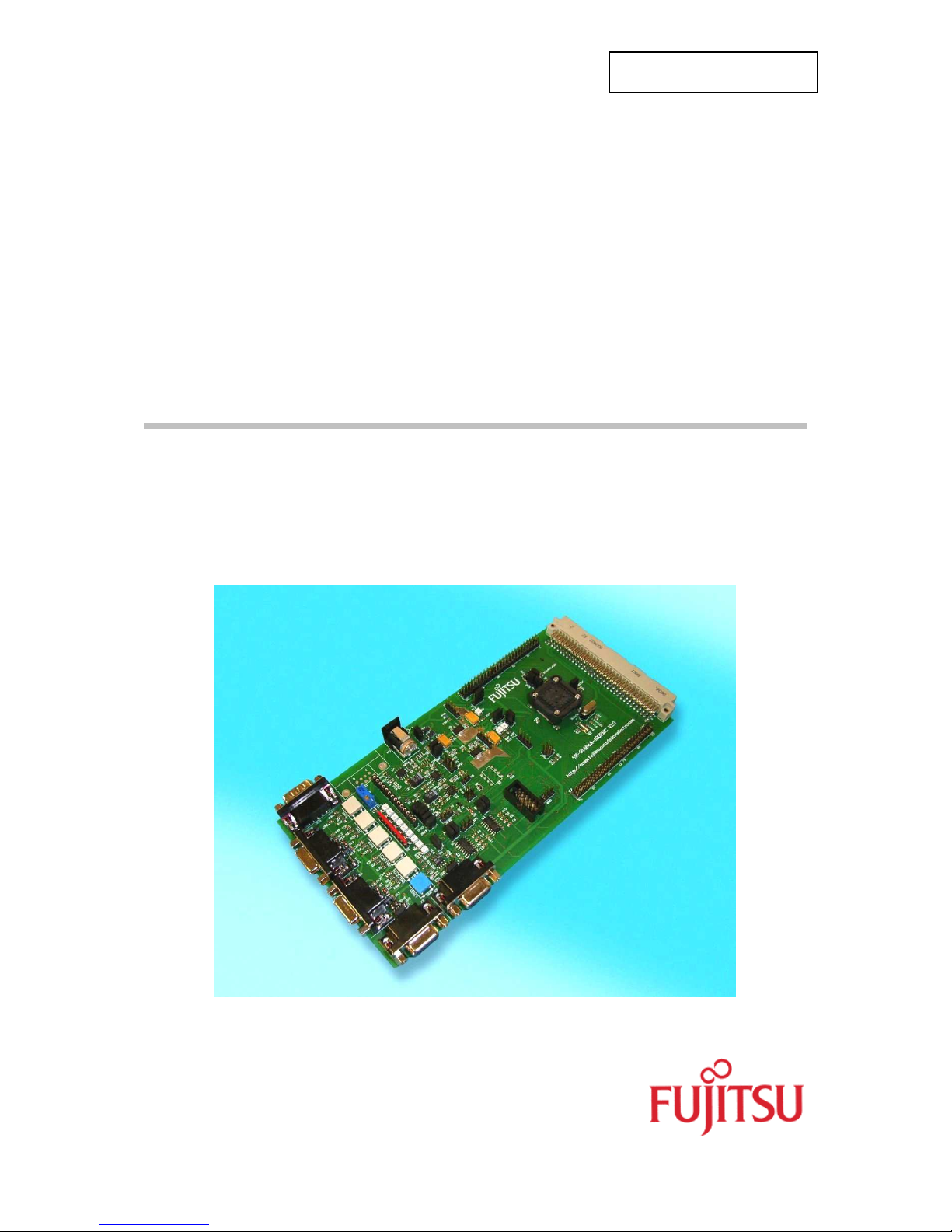

SK-91464A-100PMC

FMEMCU-UG-910025-15

MB91460 SERIES

EVALUATION BOARD

USER GUIDE

Page 2

SK-91464A-100PMC User Guide

Revision History

Revision History

Date Issue

2006/02/15 CHa First draft started

2006/05/11 V1.1, MH

2006/08/08 V1.2, MH smaller corrections jumper settings

2006/11/01 V1.2, MH correction FR-type

2006/11/27 V1.3, CSc, Socket Note added

2007/03/02 V1.4 Recycling Note added

2008/09/05 V1.5, MSc, China-RoHS regulation added

This document contains 28 pages.

FMEMCU-UG-910025-15 - 2 - © Fujitsu Microelectronics Europe GmbH

Page 3

SK-91464A-100PMC User Guide

Warranty and Disclaimer

Warranty and Disclaimer

To the maximum extent permitted by applicable law, Fujitsu Microelectronics Europe GmbH restricts

its warranties and its liability for the SK-91464A-100PMC Board and all its deliverables (eg.

software include or header files, application examples, target boards, evaluation boards, engineering

samples of IC’s etc.), its performance and any consequential damages, on the use of the Product in

accordance with (i) the terms of the License Agreement and the Sale and Purchase Agreement under

which agreements the Product has been delivered, (ii) the technical descriptions and (iii) all

accompanying written materials. In addition, to the maximum extent permitted by applicable law,

Fujitsu Microelectronics Europe GmbH disclaims all warranties and liabilities for the performance of

the Product and any consequential damages in cases of unauthorised decompiling and/or reverse

engineering and/or disassembling. Note, the SK-91464A-100PMC Board and all its deliverables

are intended and must only be used in an evaluation laboratory environment.

1. Fujitsu Microelectronics Europe GmbH warrants that the Product will perform substantially in

accordance with the accompanying written materials for a period of 90 days form the date of

receipt by the customer. Concerning the hardware components of the Product, Fujitsu

Microelectronics Europe GmbH warrants that the Product will be free from defects in material

and workmanship under use and service as specified in the accompanying written materials

for a duration of 1 year from the date of receipt by the customer.

2. Should a Product turn out to be defect, Fujitsu Microelectronics Europe GmbH´s entire liability

and the customer’s exclusive remedy shall be, at Fujitsu Microelectronics Europe GmbH´s

sole discretion, either return of the purchase price and the license fee, or replacement of the

Product or parts thereof, if the Product is returned to Fujitsu Microelectronics Europe GmbH in

original packing and without further defects resulting from the customer’s use or the transport.

However, this warranty is excluded if the defect has resulted from an accident not attributable

to Fujitsu Microelectronics Europe GmbH, or abuse or misapplication attributable to the

customer or any other third party not relating to Fujitsu Microelectronics Europe GmbH.

3. To the maximum extent permitted by applicable law Fujitsu Microelectronics Europe GmbH

disclaims all other warranties, whether expressed or implied, in particular, but not limited to,

warranties of merchantability and fitness for a particular purpose for which the Product is not

designated.

4. To the maximum extent permitted by applicable law, Fujitsu Microelectronics Europe GmbH´s

and its supplier’s liability are restricted to intention and gross negligence.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES

To the maximum extent permitted by applicable law, in no event shall Fujitsu

Microelectronics Europe GmbH and its suppliers be liable for any damages whatsoever

(including but without limitation, consequential and/or indirect damages for personal

injury, assets of substantial value, loss of profits, interruption of business operation,

loss of information, or any other monetary or pecuniary loss) arising from the use of

the Product.

Should one of the above stipulations be or become invalid and/or unenforceable, the remaining

stipulations shall stay in full effect

© Fujitsu Microelectronics Europe GmbH - 3 - FMEMCU-UG-910025-15

Page 4

0 Contents

SK-91464A-100PMC User Guide

Contents

REVISION HISTORY............................................................................................................ 2

WARRANTY AND DISCLAIMER ......................................................................................... 3

0 CONTENTS...................................................................................................................... 4

1 OVERVIEW...................................................................................................................... 6

1.1 Abstract................................................................................................................... 6

1.2 Features.................................................................................................................. 6

1.3 General Description................................................................................................. 7

2 INSTALLATION............................................................................................................... 8

Default Jumper settings for MB91464A............................................................................ 9

3 JUMPERS AND SWITCHES.......................................................................................... 11

3.1 Operating Mode (S2)............................................................................................. 11

3.2 Power Supply (JP: 29, 30, 37, 43, 44, 45)............................................................. 12

3.3 Analog Power Supply Voltage (JP: 11, 13, 15)......................................................13

3.4 UART”A” (JP: 1, 2, 31).......................................................................................... 14

3.5 UART”B” (JP: 6, 8, 32).......................................................................................... 14

3.6 LIN”A” (JP: 17, 18, 21, 22, 44)............................................................................... 15

3.7 LIN”B” (JP: 9, 10, 38, 39, 45)................................................................................. 15

3.8 CAN“A” (JP: 25, 26) ..............................................................................................16

3.9 Reset-Generation (JP: 3, 4, 5, 7, 24, 35)............................................................... 16

3.10 Buttons SW1, SW2, SW3, SW4, SW5, SW6 (JP: 12, 14, 16, 20, 23, 24) .............. 17

4 PROGRAMMING THE INTERNAL FLASH.................................................................... 18

4.1 Asynchronous Mode.............................................................................................. 18

4.2 Synchronous Mode ...............................................................................................19

5 CONNECTORS.............................................................................................................. 20

5.1 Power connector (X12).......................................................................................... 20

5.2 Edge connector (X1, X2)....................................................................................... 20

5.3 UART”A”, UART”B” connector (X3, X5).................................................................20

5.4 LIN”A”, LIN”B” Interface connector (X6, X8).......................................................... 21

5.5 CAN”A” Interface connector (X10)......................................................................... 21

5.6 USER-LEDs & optional LC-Display.......................................................................21

5.7 VG96 connector (X4)............................................................................................. 22

6 SILK-PLOT OF THE BOARD ........................................................................................23

7 RELATED PRODUCTS ................................................................................................. 24

FMEMCU-UG-910025-15 - 4 - © Fujitsu Microelectronics Europe GmbH

Page 5

SK-91464A-100PMC User Guide

Contents

8 INFORMATION IN THE WWW....................................................................................... 25

9 CHINA-ROHS REGULATION........................................................................................ 26

10 RECYCLING.................................................................................................................. 28

© Fujitsu Microelectronics Europe GmbH - 5 - FMEMCU-UG-910025-15

Page 6

SK-91464A-100PMC User Guide

Chapter 1 Overview

1 Overview

1.1 Abstract

The SK-91464A-100PMC is a multifunctional evaluation board for the Fujitsu 32-bit FR60

Flash microcontroller series MB91460.

It can be used stand-alone for software development and testing or as a simple target board

to work with the emulator system.

The board allows the designer immediately to start software development before his own

final target system is available.

1.2 Features

< Supports Fujitsu’s MB91F464AA MCU in LQFP100 package or the MB2198 Emulator

System with the Probe Cable MB91464A-NLS-100PMC

< 9-12V unregulated external DC power supply

< 5V and 3.3V onboard voltage regulators

< Power-LEDs for all supply voltages

< Onboard voltage supervisor monitors both supply voltages

< In-Circuit serial Flash programming (UART4)

< All resources available for evaluation

< All MCU pins routed to edge connectors

< 4 MHz main crystal

< 32 kHz crystal for sub clock operation

< Two RS232, two LIN and one CAN interface are usable simultaneously

< 3V capable CAN, LIN and RS232 transceivers

< 8 User LEDs, optional: alphanumeric standard LC-Display connectable instead of LEDs

< Reset button, Reset LED

< 5 User buttons

< 96-pin VG connector featuring most MCU signals

< 96-pin VG connector featuring supply voltage (VCC) for external circuits

(max. output current: 50 mA)

This board must only be used for test applications

in an evaluation laboratory environment.

FMEMCU-UG-910025-15 - 6 - © Fujitsu Microelectronics Europe GmbH

Page 7

SK-91464A-100PMC User Guide

Chapter 1 Overview

1.3 General Description

The SK-91464A-100PMC supports the 32-bit Flash microcontroller MB91F464AA.

It can be used as a stand-alone evaluation board or as a target board for the emulator

debugger.

The evaluation board supports the following package: FPT-100P-M20.

The board is supplied with a socketed 4 MHz crystal as main oscillation source. Using the

internal PLL of the µC, internal clock rates up to 80 MHz can be achieved.

Two separate RS232 transceivers are available to connect two on-chip UARTs to 9-pin D-

Sub connectors (X3, X5). The transceivers generate the adequate RS232 levels for the

receive (RXD) and transmit (TXD) lines. Either the DTR line or the RTS line can be selected

with jumpers (JP3, JP4, JP5) to generate a system reset. The RTS signal can be shortcut to

CTS using the jumpers JP31 and JP32.

In-circuit programming (asynchronous) can be done via UART”B” (X5).

Two single-wire LIN-transceivers (TLE7259) are available to connect two on-chip UARTs to

9-pin D-Sub connectors (X6, X8). The transceivers generate the adequate levels to drive the

bus line in LIN systems for automotive and industrial applications. The LIN Vs line can be

powered by the unregulated supply input of the board, so no additional supply is needed.

A high-speed CAN transceiver (TLE6250GV33) can be connected to the CAN interface of

the MCU to allow easy connection to CAN networks.

All transceivers are fully 3.3V IO compatible to enable low voltage applications.

All pins of the microcontroller except the oscillator pins X0/1(A) are connected to the edge

connectors X1 and X2 and are directly available to the user. Furthermore, most signals are

available on the VG96 connector X4.

The on-board voltage regulators allow the user to connect an unregulated DC input voltage

of +9V to +12V. In case of any modifications of the board, care should be taken that the total

power consumption will not overheat the voltage regulators. Max. output current for VCC on

connector X4 = 50 mA.

There are six push button switches on the board, which can be connected to input ports of

the microcontroller. This allows the user to evaluate external Interrupts, external ADC trigger

or Input Capture functions as well as simple input polling. One button is reserved as ‘Reset’button for the microcontroller, controlled by the supply monitor IC.

Eight user LEDs are connected to Port 27 and grounded by a 1K resistor network. If these

LEDs are not required, the resistor network can be removed to disconnect the LEDs and to

free the IO port.

Two additional pull-up resistors R42 and R43 can be connected to the I²C bus lines by

setting the according Jumpers (JP46, JP47).

1.3.1 Emulator System

If the board is used as an emulator target board, the microcontroller must be removed from

the socket and the corresponding probe cable has to be mounted:

Series V-Chip Probe cable NQ-Pack HQ-Pack

MB91464 MB91V460

© Fujitsu Microelectronics Europe GmbH - 7 - FMEMCU-UG-910025-15

MB91464A-NLS-

100PMC

NQPACK100SD HQPACK100SD

Page 8

SK-91464A-100PMC User Guide

Chapter 2 Installation

2 Installation

Carefully remove the board from the shipping carton.

First, check if there are any damages before powering up the evaluation board.

For the power supply a DC input voltage of 9V – 12V is recommended. The positive

voltage (+) must be connected to the shield, and ground (GND) must be connected to

the center pin of the connector X12!

Special care must be taken to the max. input voltage, if the LIN Vs lines are supplied

by the board (JP44/JP45), since the input supply voltage is directly applied to pin 1 of

X6 / X8 without a voltage regulator.

After power-on, the green power-on LEDs (D16, D17, D18) should be lit. If the LEDs do not

light up, switch off the power supply and check input polarity and the settings of JP43, JP29,

JP30 and JP37.

The in-circuit programming allows the user to program own applications into the Flash

memory. The procedures for Flash programming are described in chapter 4.

If the board shall be used as an emulator target board, switch off the power supply and

remove the microcontroller from the socket. Now the probe cable can be mounted on the

socket. Take care of the pin 1 marking on the socket and fasten the probe cable with the

provided screws.

Do not use any other probe cable than MB91464A-NLS-100PMC only!

Connect the probe cable to the MB2198-300 emulation Adapter Board. Check all jumper

settings of the evaluation board (especially JP29 and JP30), the Probe Cable and the

Adapter Board.

When turning on the system, be sure to use the following power-up sequence:

1. Power up the Emulator Main Unit (MB2198-01)

2. Power up the Adapter Board (MB2198-300)

3. Power up the target Board (SK-91464A-100PMC)

To turn off the system, switch off the components in reverse order, beginning with the target

Board.

Please refer to the corresponding user manuals and application notes for the emulator how

to set up the emulator system. After power on, the ‘Reset’-LED of the emulator must be off

and the ‘Vcc’-LED must be on.

If the Reset LED is still lit, check the DIP-switch settings of the emulator system and the

power supply of the evaluation board.

Note:

Some customers experience connectivity problems when connecting the MCU into

the socket adapter. Only the small red screwdriver available in your box should be

used to connect the cover (HQPACK) onto the socket (NQPACK).

If the four screws are not tightening equally, then it may cause a poor contact.

Do not screw the cover too tight (max 0.054 Nm). If you have connectivity problems

then please loosen the screws and tighten again the screws equally.

Do not clean NQPACK, YQPACK, and YQSOCKET with steam. Cleaning material will

contaminate inside of connector.

FMEMCU-UG-910025-15 - 8 - © Fujitsu Microelectronics Europe GmbH

Page 9

SK-91464A-100PMC User Guide

VDD5, VC

C 5V / 3.3V

*

VDD5R 5V / 3.3V

*

Chapter 2 Installation

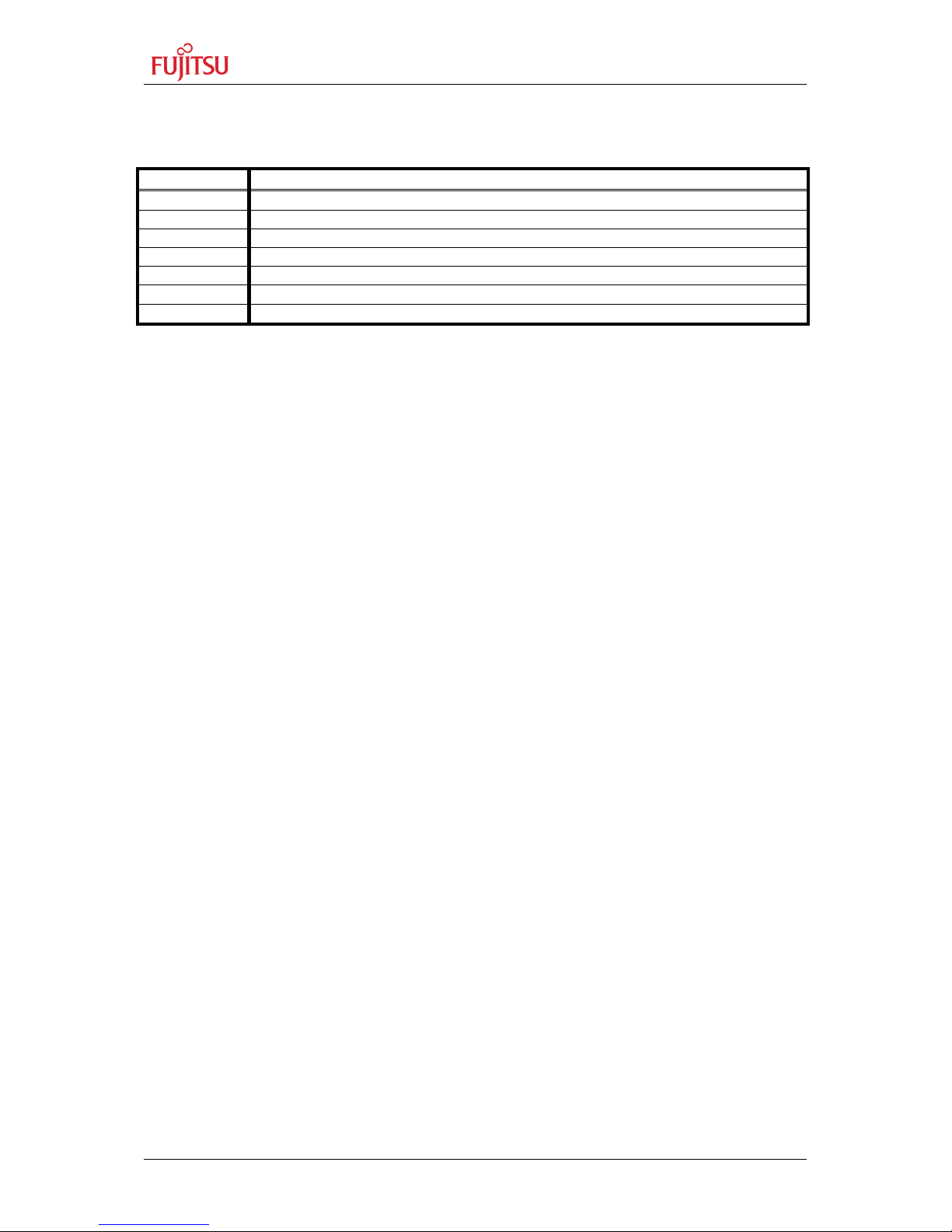

Default Jumper settings for MB91464A

Jumper Description / Function Type

JP1 UART A (TXD) / UART3 Jumper 2 pin Closed F 11

JP2 UART A (RXD) / UART3 Jumper 2 pin Closed F 11

JP3 DTR/RTS A Jumper 3 pin Open E 5

JP4 RESET UART A/B Jumper 3 pin Open F 12

JP5 DTR/RTS B Jumper 3 pin Open E 9

JP6 UART B (RXD) / UART4 Jumper 2 pin Closed F 14

JP7 Reset immediate / delayed Solder JP 3 pin

JP8 UART B (TXD) / UART4 Jumper 2 pin Closed F 13

JP9 LIN B enable Jumper 2 pin Open G 14

JP10 LIN B Master-Mode Jumper 2 pin Open F 5

JP11 AVcc Jumper 2 pin Closed J 23

JP12 SW1 (INT0) Jumper 2 pin Closed G 10

JP13 AVcc=AVRH Jumper 2 pin Closed J 23

JP14 SW2 (INT1) Jumper 2 pin Closed G 10

JP15 AVss Jumper 2 pin Closed J 23

JP16 SW3 (ATGX) Jumper 2 pin Closed G 10

JP17 LIN A enable Jumper 2 pin Open H 14

JP18 LIN A Master-Mode Jumper 2 pin Open H 5

JP19 VCC CAN-transceiver, CAN A Solder JP 3 pin

JP20 SW4 (ICU0/TIN0) Jumper 2 pin Closed G 10

JP21 LIN A (RXD) / LIN-UART0 Jumper 2 pin Open H 14

JP22 LIN A (TXD) / LIN-UART0 Jumper 2 pin Open H 14

JP23 SW5 (ICU2/TIN2) Jumper 2 pin Closed F 10

JP24 RESET Jumper 2 pin Closed F 9

JP25 CAN A TX Jumper 2 pin Closed J 14

JP26 CAN A RX Jumper 2 pin Closed J 14

JP29

JP30

JP31 RTS-CTS A Jumper 2 pin Closed E 5

JP32 RTS-CTS B Jumper 2 pin Closed E 9

JP33 VCC CAN-transceiver, CAN B Solder JP 3 pin

JP35 DTR / DTRx Jumper 3 pin Open G 11

JP36 “WAKE” LIN-transceiver, LIN A Solder JP 3 pin

JP37 VDD5 Jumper 2 pin Closed H 19

JP38 LIN B (RXD) / LIN-UART1 Jumper 2 pin Open G 13

JP39 LIN B (TXD) / LIN-UART1 Jumper 2 pin Open G 13

JP40 C-Pin Jumper 2 pin Closed G 24

JP42 “WAKE” LIN-transceiver, LIN B Solder JP 3 pin

JP43 Main Supply Jumper 2 pin Closed K 14

JP44 VBAT LIN A Jumper 2 pin Open H 5

JP45 VBAT LIN B Jumper 2 pin Open E 5

JP46 SDA0 Pullup Jumper 2 pin Open F 19

JP47 SCL0 Pullup Jumper 2 pin Open F 19

*)

for usage with MB2198 Emulator System and Probe Cable MB91464A-NLS-100PMC both jumpers

Jumper 3 pin 2-3 J 19

Jumper 3 pin 2-3 K 19

(JP29 and JP30) must either be set to position 1-2 or both must be set to position 2-3.

Default

Setting

1-2 E 8

1-2 J 11

1-2 J 15

1-2 H 13

1-2 G 13

Coordinates

© Fujitsu Microelectronics Europe GmbH - 9 - FMEMCU-UG-910025-15

Page 10

SK-91464A-100PMC User Guide

LIN“A“

LIN“B“

CAN

“A”

UART

“B”

UART

“A”

Chapter 2 Installation

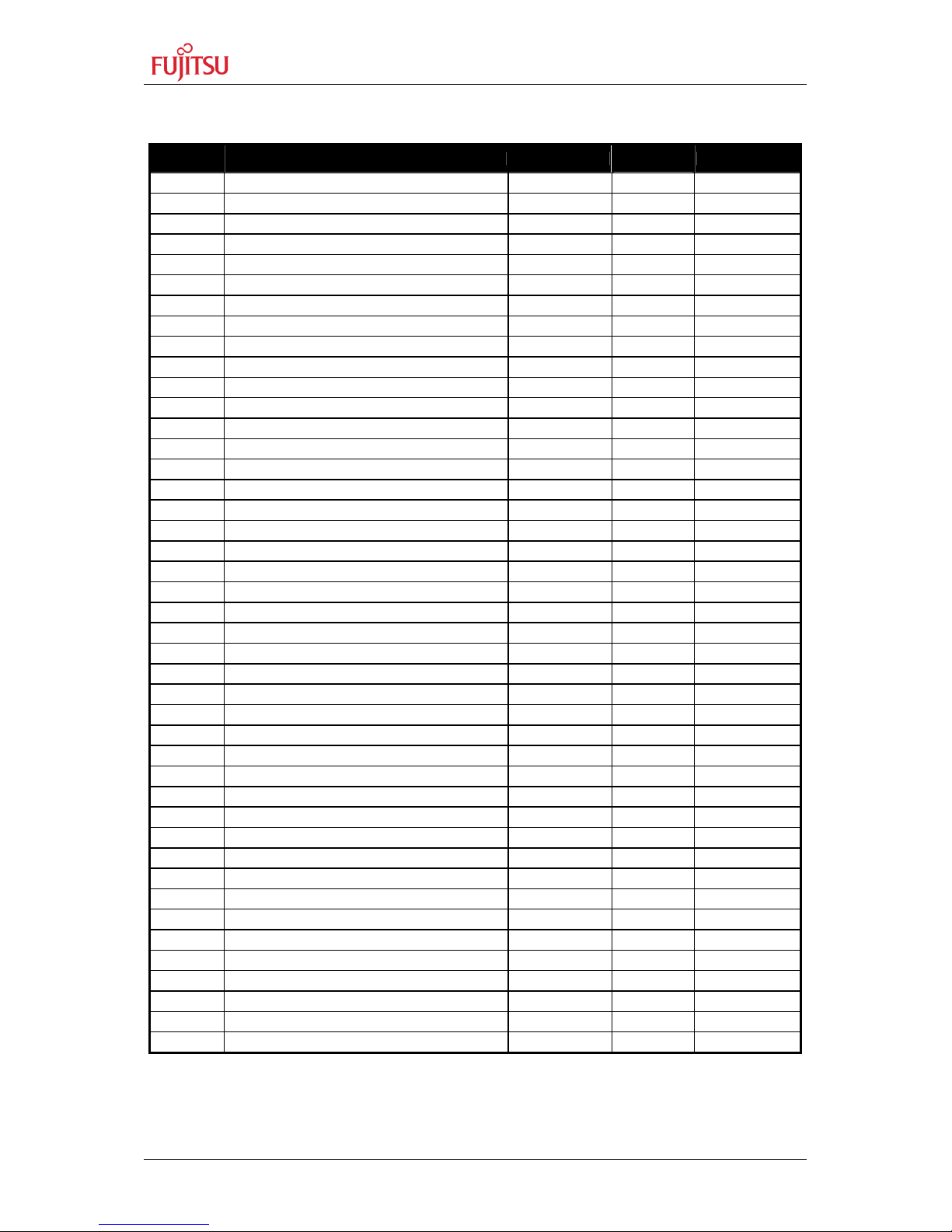

A B C D E F G H J K L M N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

UART1

UART0

3

4

5

UART3

CAN4

6

7

8

9

UART4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

17

18

19

20

21

22

23

24

25

26

27

A B C D E F G H J K L M N

FMEMCU-UG-910025-15 - 10 - © Fujitsu Microelectronics Europe GmbH

Page 11

SK-91464A-100PMC User Guide

1 2 3 4

MD0 MD1 MD2 nc

Chapter 3 Jumpers and Switches

3 Jumpers and Switches

This chapter describes all jumpers and switches that can be modified on the evaluation

board. The default setting (MB91F464AA Series) is shown with a grey shaded area.

3.1 Operating Mode (S2)

Since the MB91F464A MCU does not feature an external bus interface, the Mode switch

normally is obsolete and not mounted by default.

DIP switch Setting Logical value

S2/1 (MD0)

ON (closed) 1 (high)

OFF (open) 0 (low)

ON (closed) 1 (high)

S2/2 (MD1)

OFF (open) 0 (low)

ON (closed) 1 (high)

S2/3 (MD2)

OFF (open) 0 (low)

S2/4 not connected

Dip-Switch S2

(default setting)

ON

OFF

© Fujitsu Microelectronics Europe GmbH - 11 - FMEMCU-UG-910025-15

Page 12

SK-91464A-100PMC User Guide

Chapter 3 Jumpers and Switches

3.2 Power Supply (JP: 29, 30, 37, 43, 44, 45)

Two onboard voltage regulators provide stabilized 5V and 3.3V supplies to the MCU and

peripherals. Even though they are thermally protected against overload, care must be taken

when supplying current for additional circuitry.

The LIN Vs line can be connected directly to the input supply of the board by JP44 and

JP45. In this case, the input voltage to the board has to be suitable for the connected bus

devices (mostly around 12V). Since there is a protection diode between Vin and Vs, it is not

possible to power the board over the LIN bus.

JP29 Selects the MCU IO and peripherals Vcc voltage (3.3V or 5V)

JP30 Selects the MCU Core voltage regulator input voltage (3.3V / 5V)

JP37 Connects the MCU IO voltage to Vcc. Can be used for current measurement.

JP43 Main supply on / off

JP44 Connects Vs (Pin 1 of X8) to Vin

JP45 Connects Vs (Pin 1 of X6) to Vin

Jumper Setting Description

1 - 2 MCU / Peripherals @ 5V JP29

(VDD5 3V/5V)

(VDD5R 3V/5V)

(VDD5)

(Mains on/off)

(VBAT_A)

(VBAT_B)

2 - 3 MCU / Peripherals @ 3.3V

1 - 2 Supply to Core voltage regulator is 5V JP30

2 - 3 Supply to Core voltage regulator is 3.3V

Closed Power supply Vcc connected to VDD5 JP37

Open Power supply Vcc not connected to VDD5

Closed The board is switched on JP43

Open The board is switched off

Closed Vs of LIN A is powered by the board JP44

Open No voltage supply to Vs of LIN A

Closed Vs of LIN B is powered by the board JP45

Open No voltage supply to Vs of LIN B

FMEMCU-UG-910025-15 - 12 - © Fujitsu Microelectronics Europe GmbH

Page 13

SK-91464A-100PMC User Guide

Chapter 3 Jumpers and Switches

3.3 Analog Power Supply Voltage (JP: 11, 13, 15)

The power supply as well as the positive reference voltage for the A/D-converter can be

provided internally or externally.

JP11, JP15 connects analog power supply voltages (AVcc and AVss)

JP13 connects the analog reference voltage AVRH to AVcc

Jumper Setting Description

Closed AVcc is connected to Vcc

JP11 (AVcc)

Open AVcc is disconnected from Vcc

Closed AVRH is connected to AVcc

JP13 (AVRH)

Open AVRH defined by resistor network*1

Closed AVss is connected to GND

JP15 (AVss)

Open AVss is disconnected from GND

*1

By default the resistor network (R11, R23) is not mounted on the board

Default: JP11, JP13 and JP15 are closed

By default, the A/D-converter supply and reference voltage is same as the microcontroller

supply voltage.

Note:

If JP11 and JP15 are open, the user has to supply an adequate analog voltage supply (AVcc

and AVss) to the A/D-converter.

If JP13 is open, the resistors R11 and R23 define AVRH.

By default the resistor network (R11, R23) is not mounted on the board.

© Fujitsu Microelectronics Europe GmbH - 13 - FMEMCU-UG-910025-15

Page 14

SK-91464A-100PMC User Guide

Chapter 3 Jumpers and Switches

3.4 UART”A” (JP: 1, 2, 31)

One RS232-transceiver (U1, X3) can be connected to one of the microcontroller’s UART

interfaces.

JP1, JP2 connect UART 3 to the RS232-transceiver (U1, X3)

JP31 Some programs (e.g. Terminals) need a connection between CTS and RTS

Jumper Setting Description

JP2 (UART”A”RxD)

Closed SIN3 of the MCU is connected to UART”A”

Open SIN3 of the MCU is not connected to UART”A”

JP1 (UART”A”TxD)

Closed SOT3 of the MCU is connected to UART”A”

Open SOT3 of the MCU is not connected to UART”A”

Closed RTS and CTS of X3 are connected

JP31 (RTS-CTS)

Open RTS and CTS of X3 are not connected

By default, UART3 is connected to UART”A”.

3.5 UART”B” (JP: 6, 8, 32)

One RS232-transceiver (U3, X5) can be connected to one of the microcontroller’s UART

interfaces.

JP6, JP8 connect UART 4 to the RS232-transceiver (U3, X5)

JP32 Some programs (e.g. Terminals) need a connection between CTS and RTS

Jumper Setting Description

JP6 (UART”B”RxD)

Closed SIN4 of the MCU is connected to UART”B”

Open SIN4 of the MCU is not connected to UART”B”

JP8 (UART”B”TxD)

JP32 (RTS-CTS)

By default, UART4 is connected to UART”B”.

UART “B” can be used for serial asynchronous Flash programming.

FMEMCU-UG-910025-15 - 14 - © Fujitsu Microelectronics Europe GmbH

Closed SOT4 of the MCU is connected to UART”B”

Open SOT4 of the MCU is not connected to UART”B”

Closed RTS and CTS of X5 are connected

Open RTS and CTS of X5 are not connected

Page 15

SK-91464A-100PMC User Guide

Chapter 3 Jumpers and Switches

3.6 LIN”A” (JP: 17, 18, 21, 22, 44)

One LIN-transceiver (U5, X8) can be connected to one of the microcontroller’s UART

interfaces.

JP17 enable LIN-Transceiver

JP18 LIN Master-mode

JP21, JP22 connects UART 0 to the LIN-transceiver (U5, X8)

If the LIN interface is not used then the jumpers should be left open.

Jumper Setting Description

JP17 (LIN enable)

Closed LIN-transceiver is enabled

Open LIN-transceiver is disabled

JP18 (LIN Master)

Closed LIN Master-mode

Open LIN Slave-mode

JP21 (LIN”A”RXD)

Closed SIN0 of the MCU is connected to LIN”A”

Open SIN0 of the MCU is not connected to LIN”A”

JP22 (LIN”A”TXD)

Closed SOT0 of the MCU is connected to LIN”A”

Open SOT0 of the MCU is not connected to LIN”A”

JP44 (VBAT_A)

Closed Vs of LIN A is powered by the board

Open No voltage supply to Vs of LIN A

By default, the LIN”A”-interface is not connected to a UART.

3.7 LIN”B” (JP: 9, 10, 38, 39, 45)

One LIN-transceiver (U4, X6) can be connected to one of the microcontroller’s UART

interfaces.

JP9 enable LIN-Transceiver

JP10 LIN Master-mode

JP38, JP39 connects UART 1 to the LIN-transceiver (U4, X6)

If the LIN interface is not used then the jumpers should be left open.

Jumper Setting Description

JP9 (LIN enable)

JP10 (LIN Master)

JP38 (LIN”B”RXD)

JP39 (LIN”B”TXD)

(VBAT_B)

By default, the LIN”B”-interface is not connected to a UART.

© Fujitsu Microelectronics Europe GmbH - 15 - FMEMCU-UG-910025-15

Closed LIN-transceiver is enabled

Open LIN-transceiver is disabled

Closed LIN Master-mode

Open LIN Slave-mode

Closed SIN1 of the MCU is connected to LIN”B”

Open SIN1 of the MCU is not connected to LIN”B”

Closed SOT1 of the MCU is connected to LIN”B”

Open SOT1 of the MCU is not connected to LIN”B”

Closed Vs of LIN B is powered by the board JP45

Open No voltage supply to Vs of LIN B

Page 16

SK-91464A-100PMC User Guide

Chapter 3 Jumpers and Switches

3.8 CAN“A” (JP: 25, 26)

One high-speed CAN-transceiver can be connected to the microcontroller’s CAN interface.

JP25, JP26 connects a CAN-port to the CAN-transceiver (U7, X10).

If the CAN interface is not used then the jumpers should be left open.

Jumper Setting Description

JP25 (CAN”A”TX)

JP26 (CAN”A”RX)

closed TX4 of MCU is connected to CAN”A”

closed RX4 of MCU is connected to CAN”A”

3.9 Reset-Generation (JP: 3, 4, 5, 7, 24, 35)

In addition to the internal Power-On reset, the microcontroller can be reset by an external

reset circuit (Voltage Monitor) and also by a RS232 interface.

JP3, JP5 As well the DTR-line as the RTS-Line of UART”A” or UART”B” can be used

to generate a system reset.

JP4 This jumper selects whether the DTR/RTS line from UART”A” or UART”B”

will generate a system reset.

JP7 This solder jumper selects between normal (immediate) reset and delayed reset.

In delayed reset mode, the reset button has to be held down for 2 sec before a

reset is generated to avoid accidental resets.

JP24 Open this jumper if no external Reset shall be generated.

In this case only the internal reset is active (e.g.: power-on)

JP35 The signal on the DTR/RTS line can be negated with this jumper.

Remove the jumper in order to disable the RS232 reset circuit.

Jumper Setting Description

JP3 (DTR / RTS “A”)

JP4 (UART”A”/”B”)

JP5 (DTR / RTS “B”)

(Reset imm./delayed)

JP24 (Main Reset)

JP35 (Polarity)

FMEMCU-UG-910025-15 - 16 - © Fujitsu Microelectronics Europe GmbH

1-2 DTR of UART”A” is selected

2-3 RTS of UART”A” is selected

1-2 UART”A” is used to generate Reset

2-3 UART”B” is used to generate Reset

1-2 DTR of UART”B” is selected

2-3 RTS of UART”B” is selected

1-2 Reset is applied immediately when SW6 is pressed JP7

2-3 Reset is applied when SW6 is pressed >2sec

Closed External Reset generation is active

Open No external Reset generation

1-2 No negation for the DTR/RTS signal

2-3 DTR/RTS signal is negated

Page 17

SK-91464A-100PMC User Guide

Chapter 3 Jumpers and Switches

Default: JP24 is closed; JP3, JP4, JP5 and JP35 are open

By default, the external reset is enabled and set to immediate reset, the reset by UART is

disabled.

Note:

While a reset signal is asserted the red Reset-LED D14 is lit.

During normal operation, this LED should be off!

If JP35 (Polarity) is set, JP4 and either JP3 or JP5 have to be set, too.

If the reset LED is steadily on, check the power supply input voltage and the settings for the

reset-generation by UART.

3.10 Buttons SW1, SW2, SW3, SW4, SW5, SW6 (JP: 12, 14, 16, 20, 23, 24)

JP12, JP14, JP16, JP20, JP23

Five user push buttons SW1-SW5 can be connected to the microcontroller.

JP24 External reset circuit and button SW6 can be connected to the microcontroller.

Jumper Setting Description

Closed Pin 74 (INT0) of the MCU is connected to “SW1”

JP12 (SW1)

Open No connection to the microcontroller

Closed Pin 77 (INT1) of the MCU is connected to “SW2”

JP14 (SW2)

Open No connection to the microcontroller

Closed Pin 53 (ATGX) of the MCU is connected to “SW3”

JP16 (SW3)

Open No connection to the microcontroller

Closed Pin 2 (ICU0/TIN0) of the MCU is connected to “SW4”

JP20 (SW4)

Open No connection to the microcontroller

Closed Pin 4 (ICU2/TIN2) of the MCU is connected to “SW5”

JP23 (SW5)

Open No connection to the microcontroller

Closed INITX is connected to the reset IC and SW6

JP24 (Reset)

Open No connection to INITX

Default: JP12, JP14, JP16, JP20, JP23, JP24 = Closed

By default, all push-buttons as well as the reset circuit are connected to the microcontroller.

© Fujitsu Microelectronics Europe GmbH - 17 - FMEMCU-UG-910025-15

Page 18

SK-91464A-100PMC User Guide

Chapter 4 Programming the internal Flash

4 Programming the internal Flash

All Flash devices have an internal bootloader for asynchronous as well as synchronous

Flash-programming:

< asynchronous-serial Flash-programming via X5 (UART B)

< synchronous-serial Flash-programming via X17

4.1 Asynchronous Mode

To use the asynchronous Flash programming mode, follow these steps:

1. Install the FME FR Flash programmer.

2. Connect the Starterkit (UART B) to the PC using a 1:1 cable.

3. Start the Flash programmer by double-clicking on the flashprg.exe icon

4. Select appropriate MCU type, COM-Port, baudrate, and the path to your HEX-File

(.mhx)

5. Power-off the board or assert and hold RESET

FMEMCU-UG-910025-15 - 18 - © Fujitsu Microelectronics Europe GmbH

Page 19

SK-91464A-100PMC User Guide

SOT4 7

Chapter 4 Programming the internal Flash

6. Press the “Automatic” button to start programming and release the RESET button or

power up the board.

CAUTION : DO NOT INTERRUPT OR CUT OFF POWER DURING ERASE !!!

7. When download and programming is completed successfully, following screen

appears:

8. After successful programming, reset or Power off/on the board to start the application.

4.2 Synchronous Mode

In order to program the Flash-ROM synchronously special third-party soft- and hardware has

to be used, e.g. GALEP-4 from www.conitec.de. This tool is not available for free.

A dedicated Flash programming socket (X17) is provided on the evaluation-board for direct

connection to this programmer.

X17: Flash programming socket

n/c 1

MD0 3

RST 5

VCC 9

© Fujitsu Microelectronics Europe GmbH - 19 - FMEMCU-UG-910025-15

2 n/c

4 MD2

6 SIN4

8 SCK4

10 GND

Page 20

SK-91464A-100PMC User Guide

Chapter 5 Connectors

5 Connectors

5.1 Power connector (X12)

The following figure shows the power connection jack X12. This connector is used to

connect an external unregulated DC power supply voltage (9V-12V DC) to the evaluation

board.

Connector X12:

Shield is connected to positive voltage supply

Center is connected to ground (GND)

It is recommended to use 9V DC input to minimize the power dissipation of the voltage

regulators.

5.2 Edge connector (X1, X2)

All pins (except oscillator Pins) of the microcontroller are directly connected to X1 and X2 as

follows:

Connector MCU Pins

X1 (1 – 50) 1 – 50

X2 (51 – 100) 51 – 100

The odd pin numbers are located on the one side and the even pin numbers are located on

the other side of the connector.

5.3 UART”A”, UART”B” connector (X3, X5)

Two 9-pin D-Sub female connectors are used

for the serial interface UART”A” and UART”B”.

TXD is the transmit output, RXD is the receive input.

The DTR or RTS signal can be used to generate a reset.

Please use a 1:1 cable for PC-connection.

FMEMCU-UG-910025-15 - 20 - © Fujitsu Microelectronics Europe GmbH

Connectors X3, X5:

GND DTR RxD TxD

5

9

CTS RTS DSR

1

6

Page 21

SK-91464A-100PMC User Guide

Chapter 5 Connectors

5.4 LIN”A”, LIN”B” Interface connector (X6, X8)

Two 9-pin D-Sub female connectors are used

for the LIN communication.

Connectors X6, X8:

5.5 CAN”A” Interface connector (X10)

5

9

GND

BUS +Ubat

1

6

A 9-pin D-Sub male connector is used

for the CAN Bus interface.

CANL GND

Connector X10:

1

6

CANH

5.6 USER-LEDs & optional LC-Display

Eight LEDs are supplied for user applications. In order to disconnect the LEDs from the

related microcontroller port (Port 27), the resistor network N1 can be removed.

Instead of the user-LEDs an alphanumeric LC-Display (optional) can be connected.

The following control signals are provided:

5

9

14 13 12 11 10 9 8 7 6 5 4 3 2 1

LCD D7 D6 D5 D4 - - - - E R/W RS V0 VCC GND

LED D8 D7 D6 D5 D4 D3 D2 D1

MCU 23 22 21 20 19 18 17 16

Port 27_7 27_6 27_5 27_4 27_3 27_2 27_1 27_0

© Fujitsu Microelectronics Europe GmbH - 21 - FMEMCU-UG-910025-15

Page 22

5.7 VG96 connector (X4)

Connector-Pin cross-reference:

SK-91464A-100PMC User Guide

Chapter 5 Connectors

MCU X4 Function Evaboard MCU

1 - VDD5 VDD5

2 4A P14_0 JP20 (SW4)

3 4B P14_1 4 4C P14_2 JP23 (SW5)

5 5A P14_3 6 5B P14_4 7 5C P14_5 8 6A P14_6 -

9 6B P14_7 10 6C P15_4 11 7A P15_5 12 - VDD5R VDD5R

13 - VCC18C JP40 (C50, C29)

14 - VSS5 GND

15 - VDD5 VDD5

16 7B P27_0/AN16 LED D1

17 7C P27_1/AN17 LED D2

18 8A P27_2/AN18 LED D3

19 8B P27_3/AN19 LED D4

20 8C P27_4/AN20 LED D5

21 9A P27_5/AN21 LED D6

22 9B P27_6/AN22 LED D7

23 9C P27_7/AN23 LED D8 73 23A P22_1/TX4 JP 27 (CAN A)

24 10A P28_0/AN8 25 - VDD5 VDD5

26 3A,B,C VSS5 GND

27 10B P28_1/AN9 28 10C P28_2/AN10 29 11A P28_3/AN11 30 11B P28_4/AN12 31 - AVCC5 AVCC5

32 - AVRH5 AVRH5

33 - AVSS5 AVSS5

34 11C P29_0/AN0 35 12A P29_1/AN1 36 12B P29_2/AN2 37 12C P29_3/AN3 38 13A P29_4/AN4 39 13B P29_5/AN5 40 13C P29_6/AN6 41 14A P29_7/AN7 42 3A,B,C VSS5 GND

43 14B P22_4/SDA0 JP46 (Pullup 10k)

44 14C P22_5/SCL0 JP47 (Pullup 10k)

45 15A P19_0/SIN4 JP6 (UART B)

46 15B P19_1/SOT4 JP8 (UART B)

47 15C P19_2/SCK4 X17

48 16A P17_0/PPG0 49 16B P17_1/PPG1 50 - VDD5 GND

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

X4 Function Evaboard

3A,B,C VSS5 GND

16C INITX JP24 (Reset)

17A P16_7/ATGX JP16 (SW3)

17B P17_2/PPG2 17C P17_3/PPG3 18A P17_4/PPG4 18B P21_0/SIN0 JP21 (LIN A)

18C P21_1/SOT0 JP22 (LIN A)

19A P21_2/SCK0 19B P21_4/SIN1 JP38 (LIN B)

19C P21_5/SOT1 JP39 (LIN B)

20A P21_6/SCK1 -

- VDD5 VDD5

3A,B,C VSS5 GND

20B P17_5/PPG5 20C P17_6/PPG6 21A P17_7/PPG7 21B P15_0/OCU0/TOT0

21C P15_1/OCU1/TOT1

22A P15_2/OCU2/TOT2

22B P15_3/OCU3/TOT3

22C P22_0/RX4/INT12 JP 26 (CAN A)

23B P24_0/INT0 JP12 (SW1)

3A,B,C VSS5 GND

- VDD5 VDD5

23C P24_1/INT1 JP14 (SW2)

24A P24_2/INT2 24B P24_3/INT3 24C P24_4/INT4 25A P24_5/INT5 25B P24_6/INT6 25C P24_7/INT7 26A P20_0/SIN2 26B P20_1/SOT2 26C P20_2/SCK2 27A P20_4/SIN3 JP2 (UART A)

27B P20_5/SOT3 JP1 (UART A)

27C P20_6/SCK3 28A P16_0/PPG8 28B P16_1/PPG9 -

- MD0 Pulldown 1k

- X0A Crystal 32kHz

- X1A Crystal 32kHz

3A,B,C VSS5 GND

- X1 Crystal 4MHz

- X0 Crystal 4MHz

- MD1 Pulldown 1k

- MD2 Pulldown 1k

3A,B,C VSS5 GND

-

-

-

-

FMEMCU-UG-910025-15 - 22 - © Fujitsu Microelectronics Europe GmbH

Page 23

SK-91464A-100PMC User Guide

optional: LCD

SW1 SW2 SW3 SW4

Reset

Chapter 6 Silk-Plot of the Board

6 Silk-Plot of the Board

Pin 1

Pin 2

VG96-male

4MHz

Pin 99

Pin 100

X1 X2

MCU

91F464

Pin 50

Pin 49

X12

Power-

MAX232

MAX232

CAN”B”

Pin 52

Pin 51

FlashKit

X17

UART”B”

X11

CAN”A”

X10

© Fujitsu Microelectronics Europe GmbH - 23 - FMEMCU-UG-910025-15

LIN”A”

X8

X5

SW5

UART”A”

X3

LIN”B”

X6

Page 24

SK-91464A-100PMC User Guide

Chapter 7 Related Products

7 Related Products

< SK-91464A-100PMC Evaluation board for the MB91F464A MCU

in FPT-100P-M20 package

< MB2198-01 Emulator debugger main unit

< MB2198-10 DSU cable

< MB2198-300 Emulation Pod

< NQPack100SD-ND Socket for package FPT-100P-M20

(Tokyo Eletech Corp. www.tetc.co.jp/e_tet.htm)

< HQPack100SD Header for NQPACK100SD

< MB91464A-NLS-100PMC Emulator probe cable for MB91F464A MCU

< MB91460 Series

< MB91V460 MB91460 Series Evaluation chip

< MB91F464AAPMC Flash MCU

FMEMCU-UG-910025-15 - 24 - © Fujitsu Microelectronics Europe GmbH

Page 25

SK-91464A-100PMC User Guide

Chapter 8 Information in the WWW

8 Information in the WWW

Information about FUJITSU MICROELECTRONICS Products

can be found on the following Internet pages:

Microcontrollers (8-, 16- and 32bit), Graphics Controllers

Datasheets and Hardware Manuals, Support Tools (Hard- and Software)

http://www.fme.gsdc.de/gsdc.htm

Linear Products: Power Management, A/D and D/A Converters

http://www.fujitsu.com/emea/services/microelectronics/linears/

Media Products: SAW filters, acoustic resonators and VCOs

http://www.fujitsu.com/emea/services/microelectronics/saw/

For more information about FUJITSU MICROELECTRONICS

http://www.fujitsu.com/emea/services/microelectronics/

© Fujitsu Microelectronics Europe GmbH - 25 - FMEMCU-UG-910025-15

Page 26

SK-91464A-100PMC User Guide

Chapter 9 China-RoHS regulation

9 China-RoHS regulation

Evaluation Board

Emulation Board

根据SJ/T11364-2006

《电子信息产品污染控制标识要求》特提供如下有关污染控制方面的信息。

The following product pollution control information is provided according to SJ/T11364-2006

Marking for Control of Pollution caused by Electronic Information Products.

1.电子信息产品污染控制标志说明 Explanation of Pollution Control Label

评估板

仿真板

该标志表明本产品含有超过中国标准SJ/T11363-2006

《电子信息产品中有毒有害物质的限量要求》中限量的有毒有害物质。标志中的数字为本产品

的环保使用期,表明本产品在正常使用的条件下,有毒有害物质不会发生外泄或突变,用户使

用本产品不会对环境造成严重污染或对其人身、财产造成严重损害的期限,单位为年。

为保证所申明的环保使用期限,应按产品手册中所规定的环境条件和方法进行正常使用,并严

格遵守产品维修手册中规定的定期维修和保养要求。

产品中的消耗件和某些零部件可能有其单独的环保使用期限标志,并且其环保使用期限有可能

比整个产品本身的环保使用期限短。应到期按产品维修程序更换那些消耗件和零部件,以保证

所申明的整个产品的环保使用期限。

本产品在使用寿命结束时不可作为普通生活垃圾处理,应被单独收集妥善处理。

请注意:环保使用期限50年的指定不是与产品的耐久力,使用期限或任何担保要求等同的。

This symbol to be added to all EIO sold to China, indicates the product contains hazardous

materials in excess of the limits established by the Chinese standard SJ/T11363-2006

Requirements for Concentration Limits for Certain Hazardous Substances in Electronic

Information Products. The number in the symbol is the Environment-friendly Use Period

(EFUP), which indicates the period, starting from the manufacturing date, during which the

toxic or hazardous substances or elements contained in electronic information products will

not leak or mutate under normal operating conditions so that the use of such electronic

information products will not result in any severe environmental pollution, any bodily injury or

damage to any assets, the unit of the period is “Year”.

FMEMCU-UG-910025-15 - 26 - © Fujitsu Microelectronics Europe GmbH

Page 27

SK-91464A-100PMC User Guide

Chapter 9 China-RoHS regulation

In order to maintain the declared EFUP, the product shall be operated normally according to

the instructions and environmental conditions as defined in the product manual, and periodic

maintenance schedules specified in Product Maintenance Procedures shall be followed

strictly.

Consumables or certain parts may have their own label with an EFUP value less than the

product. Periodic replacement of those consumables or parts to maintain the declared EFUP

shall be done in accordance with the Product Maintenance Procedures.

This product must not be disposed of as unsorted municipal waste, and must be collected

separately and handled properly after decommissioning.

Please note: The designation of 10 years EFUP is not to be equated with the durability, useduration or any warranty-claims of the product.

产品中有毒有害物质或元素的名称及含量

Table of hazardous substances name and concentration

部件

部件

名称

名称

部件部件

名称名称

Component Name

有毒有害物质

有毒有害物质

有毒有害物质有毒有害物质

Hazardous substances name

或元素

或元素

或元素或元素

SK-91464A-100PMC

铅铅铅铅

(Pb)

x o o o o o

汞汞汞汞

(Hg)

镉镉镉镉

(Cd)

六价铬

六价铬

六价铬六价铬

(Cr(VI))

多溴联苯

多溴联苯

多溴联苯多溴联苯

(PBB)

多溴二苯醚

多溴二苯醚

多溴二苯醚多溴二苯醚

(PBDE)

O: 表示该有毒有害物质在该部件所有均质材料中的含量均在

表示该有毒有害物质在该部件所有均质材料中的含量均在SJ/T11363-2006 标准规定的限量要求以下

表示该有毒有害物质在该部件所有均质材料中的含量均在表示该有毒有害物质在该部件所有均质材料中的含量均在

X: 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出

表示该有毒有害物质至少在该部件的某一均质材料中的含量超出SJ/T11363-2006 标准规定的限量要求

表示该有毒有害物质至少在该部件的某一均质材料中的含量超出表示该有毒有害物质至少在该部件的某一均质材料中的含量超出

标准规定的限量要求以下

标准规定的限量要求以下标准规定的限量要求以下

标准规定的限量要求

标准规定的限量要求标准规定的限量要求

• 此表所列数据为发布时所能获得的最佳信息

•

由于缺少经济上或技术上合理可行的替代物质或方案,此医疗设备运用以上一些有毒有害物质来实现设备的预期

临床功能,或给人员或环境提供更好的保护效果

。

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous

materials for this part is below the limit requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in at least one of the

homogeneous materials used for this part is above the limit requirement in SJ/T11363-2006.

• Data listed in the table represents best information available at the time of publication

© Fujitsu Microelectronics Europe GmbH - 27 - FMEMCU-UG-910025-15

Page 28

SK-91464A-100PMC User Guide

Chapter 10 Recycling

10 Recycling

Gültig für EU-Länder:

Gemäß der Europäischen WEEE-Richtlinie und deren Umsetzung in landesspezifische

Gesetze nehmen wir dieses Gerät wieder zurück.

Zur Entsorgung schicken Sie das Gerät bitte an die folgende Adresse:

Fujitsu Microelectronics Europe GmbH

Warehouse/Disposal

Monzastraße 4a

63225 Langen

Valid for European Union Countries:

According to the European WEEE-Directive and its implementation into national laws we

take this device back.

For disposal please send the device to the following address:

Fujitsu Microelectronics Europe GmbH

Warehouse/Disposal

Monzastraße 4a

63225 Langen

FMEMCU-UG-910025-15 - 28 - © Fujitsu Microelectronics Europe GmbH

Loading...

Loading...