Page 1

ScanPartner 600C

Image Scanner

User’s Manual

Version 1.0

(Doc. No. 250-0062-0)

Page 2

2

Table of Contents

1.

INTRODUCTION …………………………………

3-4

2.

INSTALLATION AND CONNECTIONS ……….

5-13

2.1 Shipping Bracket ……………………………………………… 5

2.1.1 Removing the Shipping Bracket …………………………….. 5-6

2.1.2 Refitting the Shipping Bracket ………………………………. 7

2.2 SCSI Interface Device ID …………………………………….. 7-8

2.3 ADF Paper Chute ……………………………………………… 9

2.4 ADF Output Tray ……………………………………………… 10

2.5 Document Loading ……………………………………………. 11

2.6 ADF Scanning …………………………………………………. 12

2.7 Connecting the Cable …………………………………………. 13-14

3.

MAINTENANCE ………….……………………….

15-17

3.1 Cleaning the ADF ……………………….…………………….. 15-16

3.2 Cleaning the Glass ……………………………………………. 17

4.

TROUBLESHOOTING ……………….…………..

18-21

4.1 Question and Answer ………………………………………… 18-20

4.2 Paper Jam in the ADF ………………………………………… 20-21

5.

SPECIFICATIONS ………….……………………..

22

5.1 Model: ScanPartner 600C ………………………………….…. 23

Page 3

3

1. INTRODUCTION

Congratulations on your purchase of a Fujitsu ScanPartner 600C Image Scanner.

Before you install and operate the new Scanner, please take a few minutes to read through this manual. It provides you

with the proper instructions on how to unpack, install, operate and maintain the Scanner.

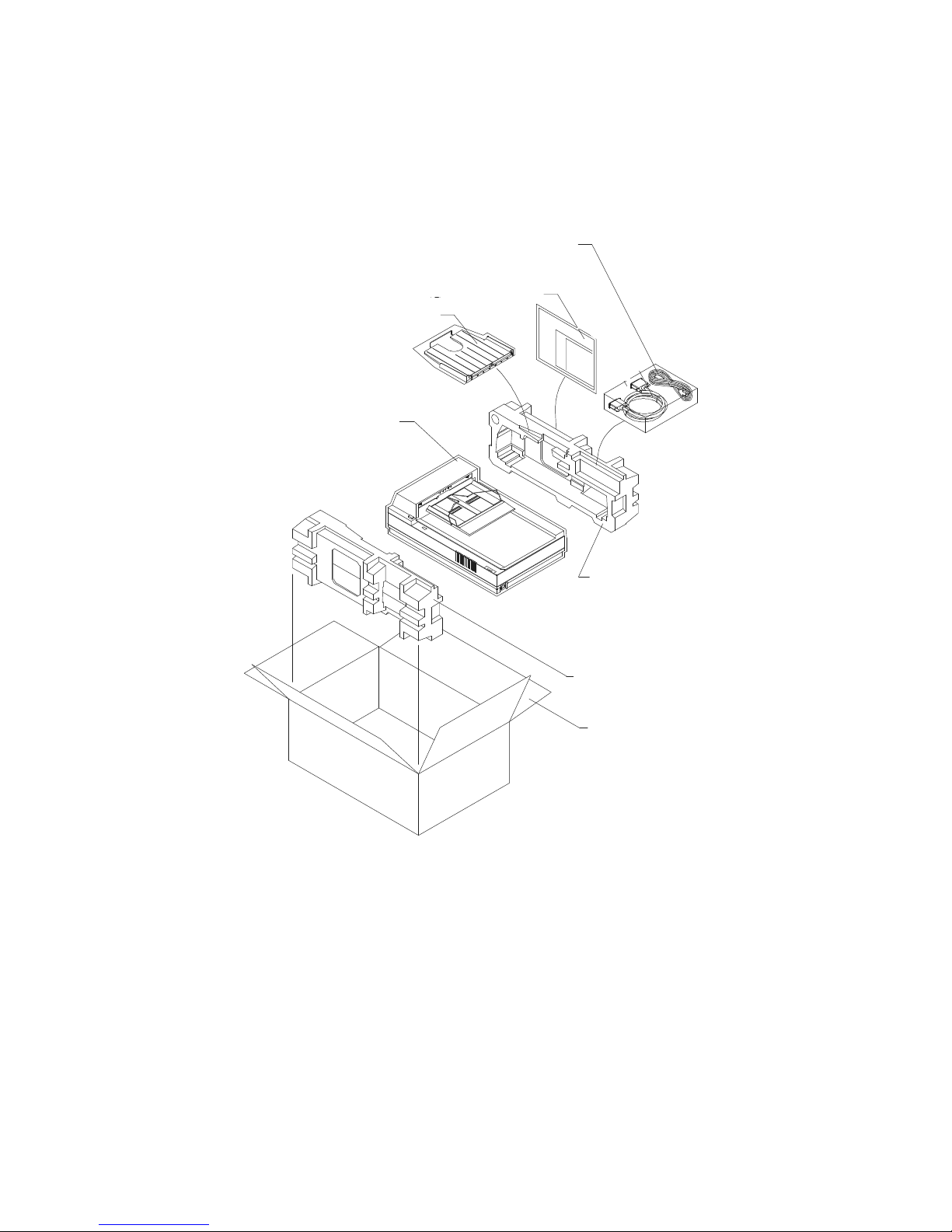

Figure 1-1 shows how the Scanner is packed. You can check all items against the “checklist”, included with your

Scanner.

Page 4

4

Figure 1-1 - Scanner Packing

User Manual

Output Paper Tray

Image Scanner

Power Cable

Foam

Foam

Carton

Page 5

5

2. Installation and Connections

Please unpack the Scanner carefully and check the contents against the “checklist”. If any items are missing or

damaged, please contact your authorised local dealer immediately.

Precautions:

v Keep the Scanner out of direct sunlight. Direct exposure to the sun or excessive heat may cause

damage to the unit.

v Do not install the Scanner in a humid or dusty place.

v Be sure to use the proper AC power source.

v Place the Scanner securely on an even, flat surface. Tilted or uneven surfaces may cause mechanical

or paper-feeding problems.

v Retain the Scanner box and packing materials for shipping purposes.

2.1 Shipping Bracket

The Scanner has a bracket that locks the carrier mechanism for transportation purposes. This bracket must be

put into the use position before using the Scanner.

Note:

If the power is turned on before the bracket has been removed the PAPER JAM light will

turn on. Before proceeding, turn the power off, disconnect all cables and follow the

instructions below to remove the shipping bracket.

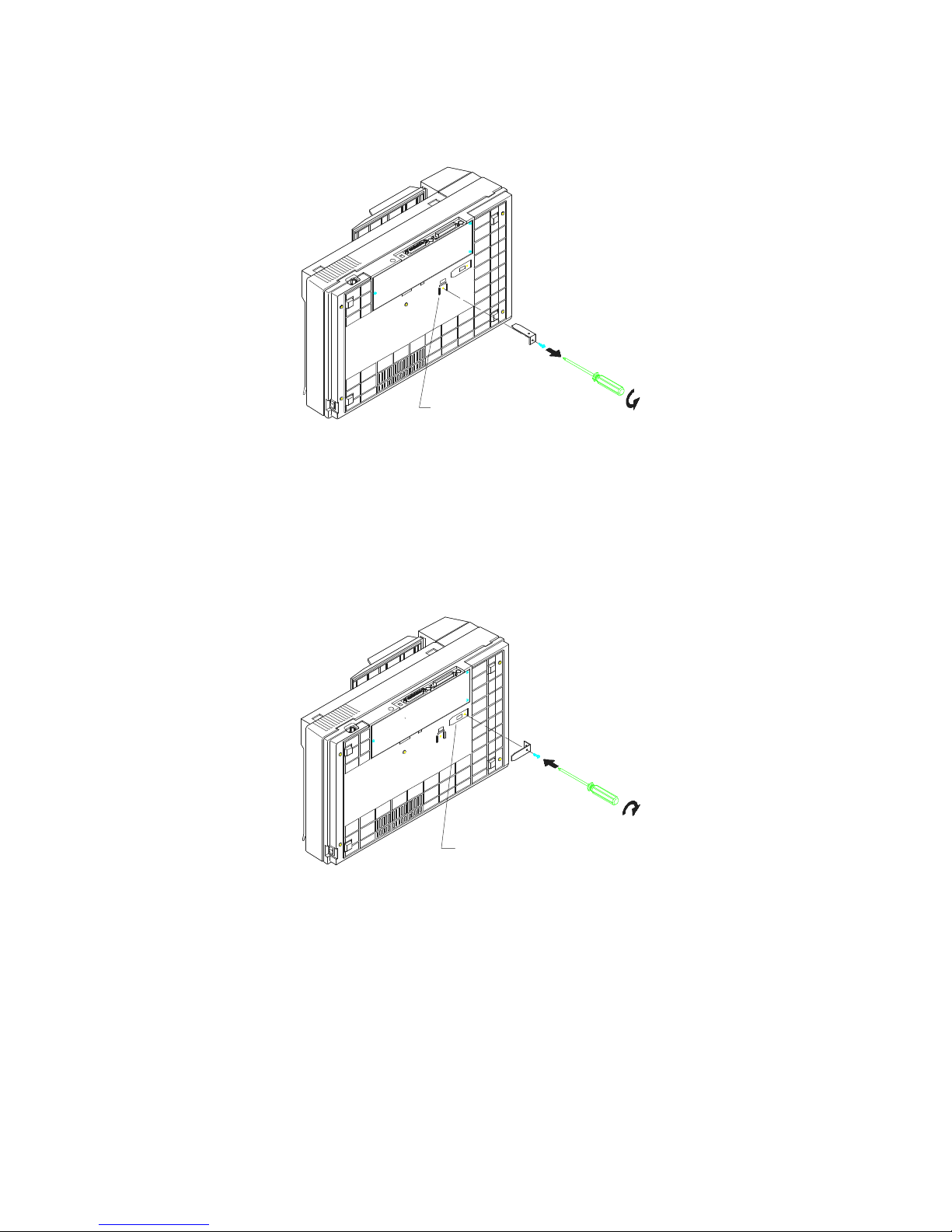

2.1.1 Removing the Shipping Bracket (refer to figures 2-1 and 2-2)

i) Carefully place the Scanner in an upright position on its front.

ii) Using a suitable screwdriver, remove the screw and pull out the shipping bracket.

iii) Put the shipping bracket into the use position with the short side extending into the scanner

base and secure it with the screw.

vi) Carefully place the Scanner back into its normal position.

Page 6

6

Figure 2-1 - Removing the Shipping Bracket

Figure 2-2 - Securing the Shipping Bracket

Shipping Position

Use Position

Page 7

7

2.1.2 Refitting the Shipping Bracket

Whenever you need to move the Scanner to a new location it is advisable to refit the shipping bracket

to avoid causing damage to the Scanners’ internal mechanism. Please follow the instructions below

to refit the shipping bracket.

i) Turn off the Scanner power at the power on/off switch.

ii) Disconnect all cables.

Note: For steps (iii) to (vi) please refer to figures 2-1 and 2-2

iii) Carefully place the Scanner in an upright position on its front side.

iv) Using a suitable screwdriver remove the screw holding the shipping bracket in the use

position.

v) Put the shipping bracket into the shipping position, with the long side extending into the

Scanner base. Secure it with the screw.

vi) Carefully place the Scanner back into its normal position.

2.2 SCSI Interface Device ID

When you have several devices on a SCSI chain, you may need to adjust the SCSI ID selector setting located

on the back of the Scanner. This setting assigns a specific “device ID” to the Scanner. If the assignment

conflicts with an existing SCSI device, please select a new ID (see Figure 2.3).

Note: The factory setting for the Scanner is ID 6. Usually, ID 0 is assigned to an internal hard disk drive,

and ID7, to SCSI adapter or host. ID 8 and 9 are not in actual use.

Using a suitable tool, turn the selector switch until the arrow points to the desired ID number.

Page 8

8

Figure 2-3 - Adjusting the SCSI ID Setting

SCSI ID Selector

Page 9

9

2.3 ADF Paper Chute (Figure 2-4)

i) Raise the right side of the paper chute to about 45 degrees.

ii) Pull down the wire leg from under the paper chute •.

iii) Insert the wire leg into the grips on the document cover ‚.

iv) Pull out the paper chute extension to the length you want.

Figure 2-4 - Setting the ADF Paper Chute

ADF Paper Chute

Document Cover

Page 10

10

2.4 ADF Output Tray (Figure 2-5)

i) Hold the output tray at an angle as shown in figure 2-5.

ii) Insert the three protrusions on the paper output tray to the three slots on the ADF •.

iii) Lower the paper tray gently ‚. Make sure the tray is firmly attached to the ADF.

iv) Pull out the output tray extension wire to the desired length.

Figure 2-5 - Install the ADF Output Paper Rack

Extensions

Page 11

11

2.5 Document Loading

For flatbed scanning.

Documents that cannot be scanned using the ADF can be placed on the flatbed for scanning. Refer to Figure

2-6).

i) Place the document to be scanned onto the document glass face down.

ii) Position the document so that the corner is aligned with the reference mark.

Figure 2-6 - Placing a Document on the Flatbed

Document Cover

Document Holding Pad

Reference Mark

Document

Document Board (Glass)

Reference Frame

Page 12

12

2.6 ADF Scanning

Standard paper sizes can be scanned automatically using the ADF. Refer to figure

2-7.

i) To prevent occasional paper jams when automatically feeding documents, fan the documents before

loading.

ii) Lift the balance wire and place the documents to be scanned onto the ADF paper chute face down,

with the leading edge in the auto feeder entrance. Let the balance wire rest on the top of the

documents.

iii) Adjust the left and right guides so that they are snug against the sides of the documents.

Figure 2-7 - Loading Paper into the ADF

Left Guide

Right Guide

Balance Wire

Document (blank side)

ADF Paper Chute

Document Size Scale

Page 13

13

2.7 Connecting the Cable

i) Turning the Power Off

The Power Switch is located on the right hand side of the Scanner.

Depress the side marked “O” to turn the power off.

ii) Turning the Power On

Depress the side marked “ ” to turn the power on. The POWER LED will light. If not, please check

the power source.

iii) Connecting the Power Cable and SCSI Signal Cables

Connect the power cable and SCSI signal cables as shown in Figure 2-8.

vi) SCSI Termination

The Fujitsu ScanPartner 600C comes complete with a built in SCSI terminator. If the Scanner is the

last device in a SCSI chain the terminator should be switched on. If the Scanner is not the last device

the terminator should be switched off. The terminator on/off switch is located on the back of the

Scanner, to the left of the SCSI cable connectors.

(TERMINATOR OFF)

OR

(TERMINATOR ON)

HOST

PC

SCANNER

SCSI DEVICE

TERM.

TERM.

HOST

PC

SCANNER

TERM.

Page 14

14

Figure 2-8 - ScanPartner 600C Scanner Cable Connections

Figure 2-9 ScanPartner 600C SCSI Scanner Cable Connections with Mac

SCSI Cable

Power

Cable

Power Switch PC SCSI Card

SCSI Cable

Power Cable

Power Switch

HOST COMPUTER

HOST COMPUTER

Page 15

15

3. Maintenance

3.1 Cleaning the ADF

Your Scanner is designed to be maintenance free. However, it still needs to be cleaned occasionally to ensure

optimum image quality and performance.

From time to time the pad assembly and feeding rollers may become contaminated with ink, toner particles or

paper dust. In this case the scanner may not feed documents smoothly or several documents may feed at once.

If this occurs please follow the cleaning procedures to return your Scanner to its original state.

The cleaning procedures (Figure 3-1):

i) Moisten a cotton swab with isoprophyl alcohol (95%). (Cleaner kits are available from Fujitsu).

ii) Open the ADF unit by depressing the button • in front of the ADF unit, carefully open the ADF to

the left ‚. Wipe the feeding rollers by moving the swab from side to side. Rotate the rollers forward

with your finger and repeat the above cleaning procedures until the rollers are clean. Be careful not to

snag or damage the pick springs.

iii) Wipe the pad in the direction from top to bottom. Be careful not to hook the pick springs.

iv) Close the ADF unit. Your Scanner is now ready for use.

Page 16

16

Figure 3-1 - Opening the ADF Unit and Document Cover

Feeding Roller

Pad Assembly

Page 17

17

3.2 Cleaning the Glass

The procedures:

i) Soak a cotton swab with some isoprophy alcohol (95%).

ii) Open the ADF unit and document cover as shown in Figure 3-2. Wipe the glass of flatbed area and

ADF area by moving the swab from side to side.

iii) Close the ADF unit and document cover. Your Scanner is now ready for use.

Figure 3-2 - The Cleaning Area

Glass

Page 18

18

4. Troubleshooting

The Scanner will automatically perform a simple self-test each time it is turned on. This will help spot major

system errors in the Scanner itself.

When the test is initiated, the ERROR LED will light on. When the test is completed, the ERROR LED light

will extinguish.

If you have problems with the operation of your Scanner please check the following troubleshooting hints.

4.1 Question and Answer

Question: The LED indicates that the Scanner is ready, but the Scanner does not respond to

the scan command from the host computer.

Answer: a) Please check the signal cable is firmly seated, and invoke the scan command again.

If there is still no response, please reset the Scanner by turning it off and then on

again, and reboot your host computer as well.

b) Check if the driver is correctly installed. You can use the DIAG.EXE file in

“Fujitsu Driver Kit” to check this out.

c) Try to select another port memory.

Question: Paper becomes jammed during scanning.

Answer: a) Open the ADF unit.

b) Pull out the jammed paper carefully

c) Close the ADF unit.

Question: More than one sheet of paper were fed into the Scanner.

Answer: a) Open ADF unit

b) Remove the multi-fed sheets of paper

c) Close the ADF unit

d) Flatten the corners and edges; loosen the paper before reloading it in the paper

guide.

e) Check the feeding roller condition and do the cleaning if necessary (see chapter 6).

Question: Paper becomes skewed in the Scanner.

Answer: a) Check the feeding roller condition; do the cleaning if necessary (See section 6.1).

b) Use the paper guide when feeding the paper.

Question: When I power on the Scanner, it makes noises and will not stand ready.

Answer: There are two possibilities:

a) You forgot to remove the shipping retainer from the Scanner. Please remove the

shipping retainer first.

b) You did not place the Scanner on a flat desktop surface. This may cause the

Scanner to function improperly.

Page 19

19

Question: When I power on the Scanner, the lamp does not light.

Answer: The possibilities are as follows:

a) The lamp is out of order. In that case, contact your authorised local dealer to change

the lamp. The life time of the lamp is about 15,000 hours.

b) The fuse on main board of the Scanner has blown. Check the main board of the

Scanner. If the fuse has blown, replace fuse with a 250V/2A fuse.

c) If the fuse blows again after changing, it means the invertor of the lamp has failed.

Contact your authorised local dealer to replace the invertor.

Question: Getting image from the Scanner is not a problem, but when scanning, the Scanner or

system will often crash.

Answer: Please check:

a) If the cable is firmly seated.

b) Only two SCSI terminators can be connected to your SCSI daisy chain. One is at

the end of the SCSI device, another is already in your host adapter.

Question: While scanning, the Scanner often makes noises, or it scans back and forth.

Answer: Please choose lower speed from the TWAIN user interface for low speed PC.

Question: The scanned image always comes out to be too dark.

Answer: a) Use your application to modify the Gamma setting to 2.2 and 1.8 for your printer

and monitor respectively.

b) Use Brightness setting from the TWAIN user interface to get a brighter image.

Question: The Scanner works well other wise, but for the line art, the lines of which seem

much thicker than those of the original.

Answer: Use the Brightness or Threshold setting to adjust the line art image.

4.2 Paper Jam in the ADF

In the event of paper jam, please follow the procedures below.

i) Press the button at the front left of the Scanner as shown in Figure 4-1, arrow A. The ADF

cover will be released.

iii) Open the ADF cover to the full open position, arrow B.

iv) Pull the paper out of the ADF unit carefully, as shown in Figure 4.2, arrow A.

Page 20

20

Figure 4.1 - ADF Paper Jam - Opening the ADF

B

A

Page 21

21

Figure 4-2 - ADF Paper Jam - Removing the Paper

Document (blank side)

Page 22

22

5. Specifications

All specifications are subject to change without notice.

The following cannot be properly fed by ADF:

v Paper with clip or staple attached

v Paper with ink not totally dry

v Paper with inconsistent thickness, such as envelopes

v paper with large wrinkles, curls, folds or tears

v Tracing paper

v Coating paper

v Carbon paper

v Paper narrower than 3.5” or wider than 8.5”

v Items other than papers, such as cloth, metal or OHP film

v Paper that has side perforations

v Paper with an odd (non-rectangular) shape

v Very thin paper

Please use the flatbed to scan documents that cannot be fed by the ADF.

Page 23

23

5.1 ScanPartner 600C Specifications

Scanner Type

v 1-pass colour

v Flatbed with ADF built-in

Scanning Mode

v 24-bit colour

v 8-bit Grey Scale (256 levels)

v Line Art

v Halftone (64 levels)

v Error Diffusion (single bit)

Optical Resolution

v 600 x 1200 dpi in 1 dpi increments

Light Source

v Cold Cathode fluorescent lamp

ADF Capacity

v 50 pages

ADF Scanning Speed

v 14 PPM (A4 200dpi, B/W mode, ADF)

Scanning Document Size Max.

v ADF mode 8.5” x 14”

v Flatbed mode 8.5” x 11.69”

Interface

v SCSI-2

Power Requirement

v 100 to 240 Vac, 47 to 63Hz

Power Consumption

v 35 watts

Humidity

v 20% to 80% RH

Operation Temperature

v 10 to 40

Storage Temperature

v -10 to 50

Dimension

v 570 x 350 x 165 mm (W x D x H)

Weight

v Appropriate 26.5 lbs (12 kg)

Loading...

Loading...