Page 1

MHL2300AT, MHM2200AT,

MHM2150AT, MHM2100AT

DISK DRIVES

C141-E104-02EN

PRODUCT MANUAL

Page 2

FOR SAFE OPERATION

Handling of This Manual

This manual contains important information for using this product. Read thoroughly before using

the product. Use this product only after thoroughly reading and understanding especially the

section “Important Alert Items” in this manual. Keep this manual handy, and keep it carefully.

FUJITSU makes every effort to prevent users and bystanders from being injured or from suffering

damage to their property. Use the product according to this manual.

IMPO R TANT NOTE TO USER S

READ THE ENTIRE MANUAL CAREFULLY BEFORE USING THI S PRODUCT.

INCORRECT USE OF THE PRO DUCT MAY RESULT IN INJURY OR DAMAGE TO

USERS, BYSTANDERS OR PROPERTY.

While FUJITSU has sought to ensure the accuracy of all information in this manual, FUJITSU

assumes no liability to any party for any damage caused by any error or omission contained in this

manual, its updates or supplements, whether such errors or omissions result from negligence,

accident, or any other cause. In addition, FUJITSU assumes no liability with respect to the

application or use of any product or system in accordance with the descriptions or instructions

contained herein; including any liability for incidental or consequential damages arising therefrom.

FUJITSU DISCLAIMS ALL WARRANTIES REGARDING THE INFORMATION CONTAINED

HEREIN, WHETHER EXPRESSED, IMPLIED, OR STATUTORY.

FUJITSU reserves the right to make changes to any products described herein without further

notice and without obligation.

The contents of this manual may be revised without prior notice.

The contents of this manual shall not be disclosed in any way or reproduced in any media without

the express written permission of Fujitsu Limited.

All Rights Reserved, Copyright FUJITSU LIMITED 2000

C141-E104-02EN

Page 3

This page is intentionally left blank.

Page 4

Revision History

(1/1)

Edition Date Revised section (*1)

(Added/Deleted/Altered)

01 2000-02-15 — —

02 2000-09-20 -Table 1.1

- Table 1.2

- (16) SET MAX in Section

5.3.2

- Table 5.17

- Specification (Number of Sections for

MHL2300AT) was altered.

- Order No. was changed.

- SET MAX commands are added.

- Values of host termination for DIOR-,

DIOW- and DMACK- signals are

changed.

Details

*1 Section(s) with asterisk (*) refer to the previous edition when those were deleted.

C141-E104-02EN

Page 5

This page is intentionally left blank.

Page 6

This manual describes the MHL Series and MHM Series, 2.5-inch hard disk drives.

These drives have a built-in controller that is compatible with the ATA interface.

This manual describes the specifications and functions of the drives and explains in

detail how to incorporate the drives into user systems. This manual assumes that

the reader has a basic knowledge of hard disk drives and their implementations in

computer systems.

This manual consists of seven chapters and sections explaining the special

terminology and abbreviations used in this manual:

Overview of Manual

CHAPTER 1 Device Overview

This chapter gives an overview of the MHL Series and MHM Series and describes

their features.

CHAPTER 2 Device Configuration

Preface

This chapter describes the internal configurations of the MHL Series and MHM

Series and the configuration of the systems in which they operate.

CHAPTER 3 Installation Condit ions

This chapter describes the external dimensions, installation conditions, and switch

settings of the MHL Series and MHM Series.

CHAPTER 4 Theory of Device Operation

This chapter describes the operation theory of the MHL Series and MHM Series.

CHAPTER 5 Interface

This chapter describes the interface specifications of the MHL Series and MHM

Series.

CHAPTER 6 Operations

This chapter describes the operations of the MHL Series and MHM Series.

Terminology

This section explains the special terminology used in this manual.

Abbreviation

This section gives the meanings of the definitions used in this manual.

C141-E104-02EN i

Page 7

Preface

Conventions for Alert Messages

This manual uses the following conventions to show the alert messages. An alert

message consists of an alert signal and alert statements. The alert signal consists of

an alert symbol and a signal word or just a signal word.

The following are the alert signals and their meanings:

CAUTION

IMPORTANT

In the text, the alert signal is centered, followed below by the indented message. A

wider line space precedes and follows the alert message to show where the alert

message begins and ends. The following is an example:

(Example)

Data corruption: Avoid mounting the disk drive near strong

magnetic sources such as loud speakers. Ensure that the disk drive is

not affected by external magnetic fields.

The main alert messages in the text are also listed in the “Important Alert Items.”

This indicates a hazardous situation could result in

minor or moderate personal injury if the user does

not perform the procedure correctly. This alert

signal also indicates that damages to the product or

other property may occur if the user does not perform

the procedure correctly.

This indicates information that could help the user

use the product more efficiently.

CAUTION

Operating Environment

This product is designed to be used in offices or computer rooms.

For details regarding the operating environment of use, refer to the

(Cnnn-Xnnn) and the

(Cnnn-Xnnn).

Attention

Please forward any comments you may have regarding this manual.

To make this manual easier for users to understand, opinions from readers are

needed. Please write your opinions or requests on the Comment at the back of this

manual and forward it to the address described in the sheet.

ii C141-E104-02EN

Page 8

Liability Exception

“Disk drive defects” refers to defects that involve adjustment, repair, or

replacement.

Fujitsu is not liable for any other disk drive defects, such as those caused by user

misoperation or mishandling, inappropriate operating environments, defects in the

power supply or cable, problems of the host system, or other causes outside the

disk drive.

Preface

C141-E104-02EN iii

Page 9

This page is intentionally left blank.

Page 10

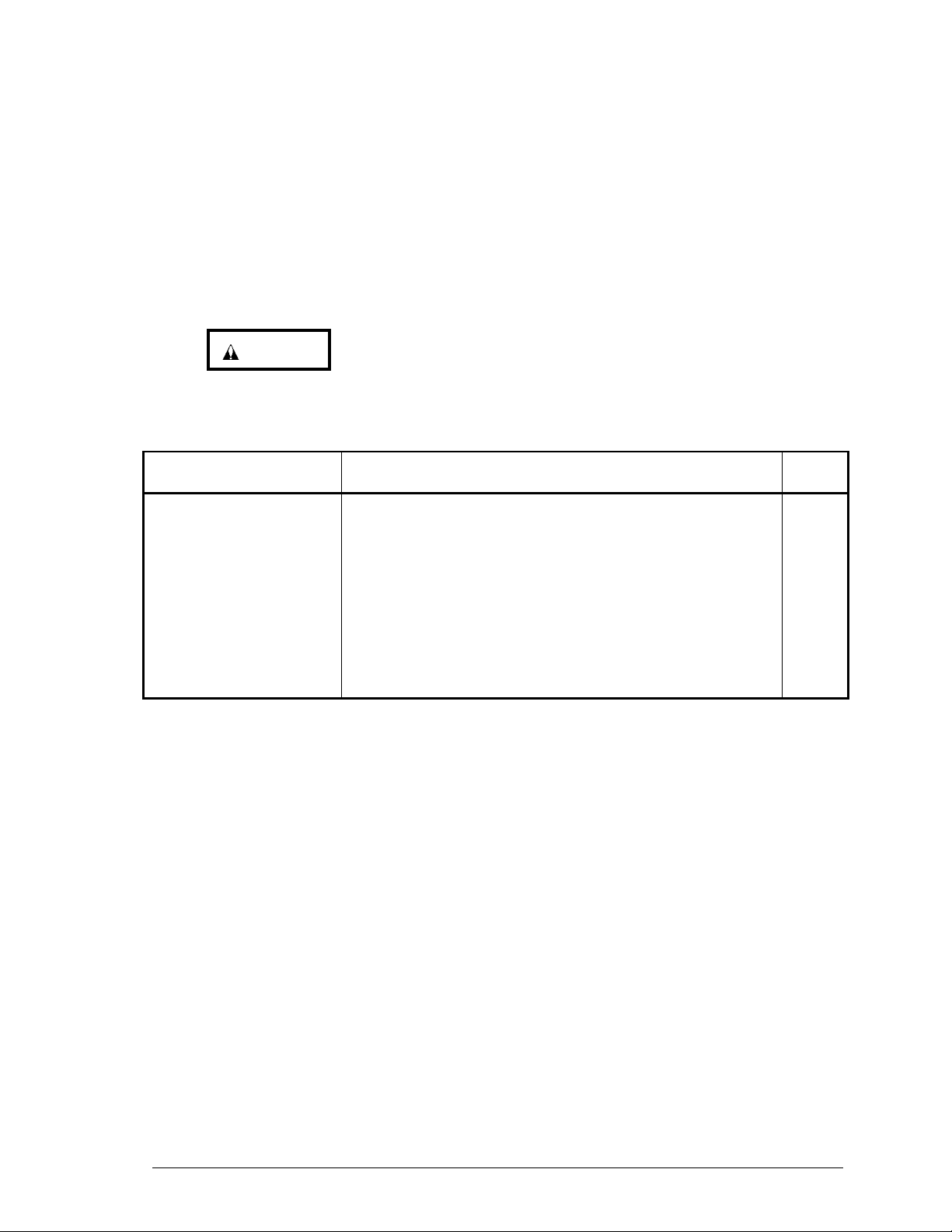

Important Alert Items

Important Alert Messages

The important alert messages in this manual are as follows:

CAUTION

Task Alert message Page

Normal Operation

A hazardous situation could result in minor or moderate personal

injury if the user does not perform the procedure correctly. Also,

damage to the predate or other property, may occur if the user does not

perform the procedure correctly.

Data corruption: Avoid mounting the disk near strong

magnetic sources such as loud speakers. Ensure that the disk

drive is not affected by external magnetic fields.

Damage: Do not press the cover of the disk drive. Pressing

it too hard, the cover and the spindle motor contact, which

may cause damage to the disk drive.

Static: When handling the device, disconnect the body

ground (500 kΩ or greater). Do not touch the printed circuit

board, but hold it by the edges.

3-8

C141-E104-02EN v

Page 11

This page is intentionally left blank.

Page 12

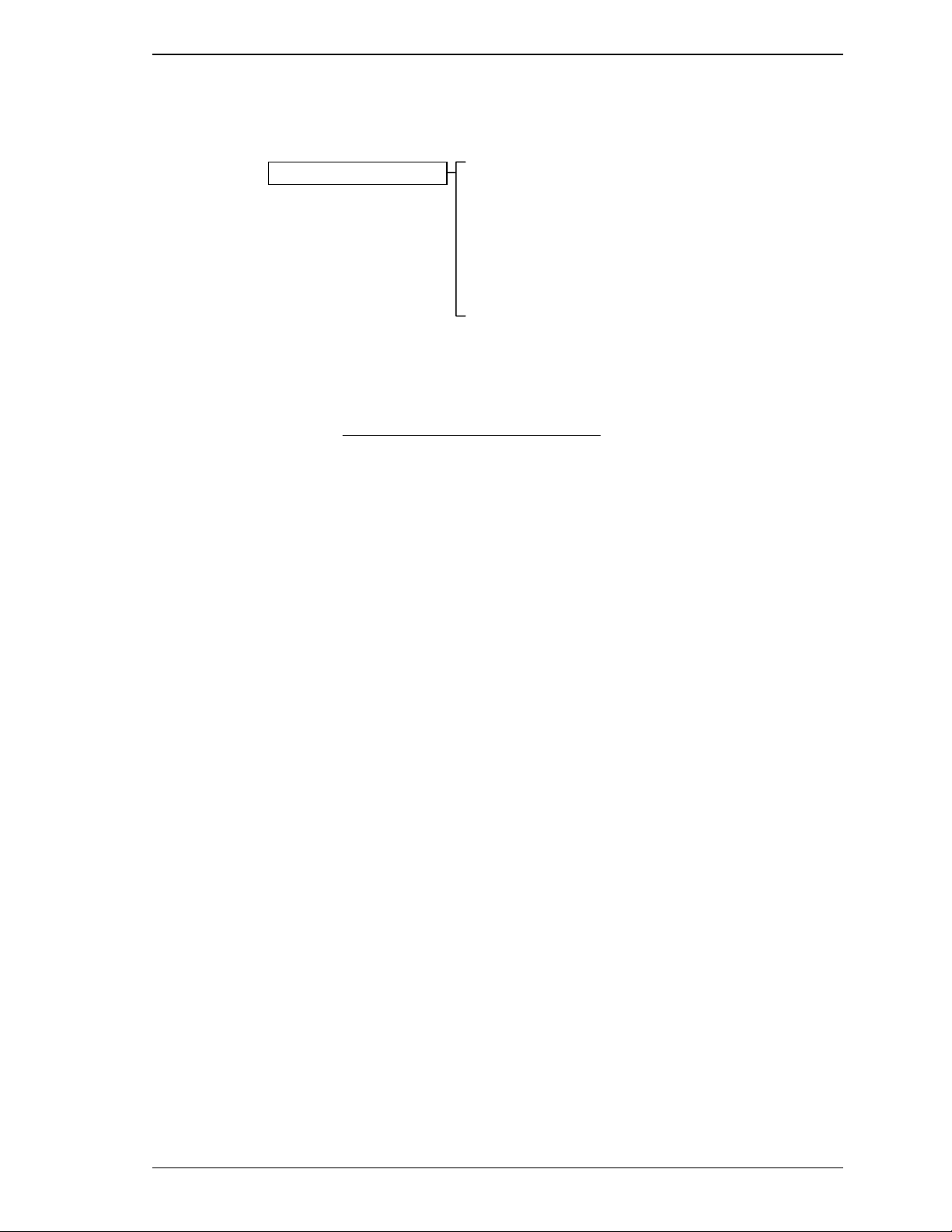

Manual Organization

MHL2300AT, MHM2200AT,

MHM2150AT, MHM2100AT

DISK DRIVES

PRODUCT MANUAL

(C141-E104)

<This manual>

MHL2300AT, MHM2200AT,

MHM2150AT, MHM2100AT

DISK DRIVES

MAINTENANCE MANUAL

(C141-F043)

• Device Overview

• Device Configuration

• Installation Conditions

• Theory of Device Operation

• Interface

• Operations

• Maintenance and Diagnosis

• Removal and Replacement Procedure

C141-E104-02EN vii

Page 13

This page is intentionally left blank.

Page 14

Contents

CHAPTER 1 Device Overview ....................................................................... 1-1

1.1 Features 1-2

1.1.1 Functions and performance 1-2

1.1.2 Adaptability 1-2

1.1.3 Interface 1-3

1.2 Device Specifications 1-4

1.2.1 Specifications summary 1-4

1.2.2 Model and product number 1-5

1.3 Power Requirements 1-5

1.4 Environmental Specifications 1-7

1.5 Acoustic Noise 1-8

1.6 Shock and Vibration 1-8

1.7 Reliability 1-9

1.8 Error Rate 1-10

1.9 Media Defects 1-10

CHAPTER 2 Device Configuration................................................................ 2-1

2.1 Device Configuration 2-2

2.2 System Configuration 2-4

2.2.1 ATA interface 2-4

2.2.2 1 drive connection 2-4

2.2.3 2 drives connection 2-4

C141-E104-02EN ix

Page 15

Contents

CHAPTER 3 Installation Conditions..............................................................3-1

3.1 Dimensions 3-2

3.2 Mounting 3-4

3.3 Cable Connections 3-10

3.3.1 Device connector 3-10

3.3.2 Cable connector specifications 3-11

3.3.3 Device connection 3-11

3.3.4 Power supply connector (CN1) 3-12

3.4 Jumper Settings 3-12

3.4.1 Location of setting jumpers 3-12

3.4.2 Factory default setting 3-13

3.4.3 Master drive-slave drive setting 3-13

3.4.4 CSEL setting 3-14

CHAPTER 4 Theory of Device Operation......................................................4-1

4.1 Outline 4-2

4.2 Subassemblies 4-2

4.2.1 Disk 4-2

4.2.2 Head 4-2

4.2.3 Spindle 4-3

4.2.4 Actuator 4-3

4.2.5 Air filter 4-3

4.3 Circuit Configuration 4-4

4.4 Power-on Sequence 4-7

4.5 Self-calibration 4-8

4.5.1 Self-calibration contents 4-8

4.5.2 Execution timing of self-calibration 4-9

4.5.3 Command processing during self-calibration 4-10

4.6 Read/write Circuit 4-10

4.6.1 Read/write preamplifier (HDIC) 4-10

x C141-E104-02EN

Page 16

Contents

4.6.2 Write circuit 4-11

4.6.3 Read circuit 4-13

4.6.4 Digital PLL circuit 4-14

4.7 Servo Control 4-15

4.7.1 Servo control circuit 4-15

4.7.2 Data-surface servo format 4-18

4.7.3 Servo frame format 4-20

4.7.4 Actuator motor control 4-21

4.7.5 Spindle motor control 4-22

CHAPTER 5 Interface..................................................................................... 5-1

5.1 Physical Interface 5-2

5.1.1 Interface signals 5-2

5.1.2 Signal assignment on the connector 5-3

5.2 Logical Interface 5-6

5.2.1 I/O registers 5-7

5.2.2 Command block registers 5-8

5.2.3 Control block registers 5-13

5.3 Host Commands 5-13

5.3.1 Command code and parameters 5-14

5.3.2 Command descriptions 5-16

5.3.3 Error posting 5-83

5.4 Command Protocol 5-85

5.4.1 Data transferring commands from device to host 5-85

5.4.2 Data transferring commands from host to device 5-87

5.4.3 Commands without data transfer 5-89

5.4.4 Other commands 5-90

5.4.5 DMA data transfer commands 5-90

5.5 Ultra DMA Feature Set 5-92

5.5.1 Overview 5-92

5.5.2 Phases of operation 5-93

C141-E104-02EN xi

Page 17

Contents

5.5.2.1 Ultra DMA burst initiation phase 5-93

5.5.2.2 Data transfer phase 5-94

5.5.2.3 Ultra DMA burst termination phase 5-94

5.5.3 Ultra DMA data in commands 5-95

5.5.3.1 Initiating an Ultra DMA data in burst 5-95

5.5.3.2 The data in transfer 5-96

5.5.3.3 Pausing an Ultra DMA data in burst 5-96

5.5.3.4 Terminating an Ultra DMA data in burst 5-97

5.5.4 Ultra DMA data out commands 5-100

5.5.4.1 Initiating an Ultra DMA data out burst 5-100

5.5.4.2 The data out transfer 5-100

5.5.4.3 Pausing an Ultra DMA data out burst 5-101

5.5.4.4 Terminating an Ultra DMA data out burst 5-102

5.5.5 Ultra DMA CRC rules 5-104

5.5.6 Series termination required for Ultra DMA 5-106

5.6 Timing 5-107

5.6.1 PIO data transfer 5-107

5.6.2 Multiword DMA data transfer 5-109

5.6.3 Transfer of Ultra DMA data 5-110

5.6.3.1 Starting of Ultra DMA data In Burst 5-110

5.6.3.2 Ultra DMA data burst timing requirements 5-111

5.6.3.3 Sustained Ultra DMA data in burst 5-113

5.6.3.4 Host pausing an Ultra DMA data in burst 5-114

5.6.3.5 Device terminating an Ultra DMA data in burst 5-115

5.6.3.6 Host terminating an Ultra DMA data in burst 5-116

5.6.3.7 Initiating an Ultra DMA data out burst 5-117

5.6.3.8 Sustained Ultra DMA data out burst 5-118

5.6.3.9 Device pausing an Ultra DMA data out burst 5-119

5.6.3.10 Host terminating an Ultra DMA data out burst 5-120

5.6.3.11 Device terminating an Ultra DMA data in burst 5-121

5.6.4 Power-on and reset 5-122

CHAPTER 6 Operations .................................................................................6-1

6.1 Device Response to the Reset 6-2

xii C141-E104-02EN

Page 18

6.1.1 Response to power-on 6-2

6.1.2 Response to hardware reset 6-4

6.1.3 Response to software reset 6-5

6.1.4 Response to diagnostic command 6-6

6.2 Address Translation 6-7

6.2.1 Default parameters 6-7

6.2.2 Logical address 6-8

6.3 Power Save 6-9

6.3.1 Power save mode 6-9

6.3.2 Power commands 6-11

6.4 Defect Management 6-11

6.4.1 Spare area 6-12

6.4.2 Alternating defective sectors 6-12

Contents

6.5 Read-Ahead Cache 6-14

6.5.1 Data buffer configuration 6-14

6.5.2 Caching operation 6-14

6.5.3 Usage of read segment 6-16

6.5.3.1 Mis-hit (no hit) 6-16

6.5.3.2 Sequential read 6-17

6.5.3.3 Full hit (hit all) 6-20

6.5.3.4 Partially hit 6-21

6.6 Write Cache 6-22

Glossary ..................................................................................................GL-1

Acronyms and Abbreviations......................................................................... AB-1

C141-E104-02EN xiii

Page 19

Contents

Figures

Illustrations

Figure 1.1 Current fluctuation (Typ.) at +5V when power is turned on 1-7

Figure 2.1 Disk drive outerview (the MHL Series and MHM Series) 2-2

Figure 2.2 Configuration of disk media heads 2-3

Figure 2.3 1 drive system configuration 2-4

Figure 2.4 2 drives configuration 2-4

Figure 3.1 Dimensions (MHL/MHM series) 3-2

Figure 3.2 Orientation (Sample: MHL2300AT) 3-4

Figure 3.3 Mounting frame structure 3-5

Figure 3.4 Location of breather 3-6

Figure 3.5 Surface temperature measurement points

(Sample: MHL2300AT) 3 -7

Figure 3.6 Service area (Sample: MHL2300AT) 3-8

Figure 3.7 Handling cautions 3-9

Figure 3.8 Connector locations (Sample: MHL2300AT) 3-10

Figure 3.9 Cable connections 3-11

Figure 3.10 Power supply connector pins (CN1) 3-12

Figure 3.11 Jumper location 3-12

Figure 3.12 Factory default setting 3-13

Figure 3.13 Jumper setting of master or slave device 3-13

Figure 3.14 CSEL setting 3-14

Figure 3.15 Example (1) of Cable Select 3-14

Figure 3.16 Example (2) of Cable Select 3-15

Figure 4.1 Head structure 4-3

Figure 4.2 Power Supply Configuration 4-5

Figure 4.3 Circuit Configuration 4-6

Figure 4.4 Power-on operation sequence 4-8

Figure 4.5 Read/write circuit block diagram 4-12

Figure 4.6 Frequency characteristic of programmable filter 4-13

Figure 4.7 Block diagram of servo control circuit 4-15

Figure 4.8 Physical sector servo configuration on disk surface 4-19

Figure 4.9 Servo frame format 4-20

Figure 5.1 Interface signals 5-2

Figure 5.2 Execution example of READ MULTIPLE command 5-20

xiv C141-E104-02EN

Page 20

Contents

Figure 5.3 Read Sector(s) command protocol 5-86

Figure 5.4 Protocol for command abort 5-87

Figure 5.5 WRITE SECTOR(S) command protocol 5-88

Figure 5.6 Protocol for the command execution without data transfer 5-90

Figure 5.7 Normal DMA data transfer 5-91

Figure 5.8 An example of generation of parallel CRC 5-105

Figure 5.9 Ultra DMA termination with pull-up or pull-down 5-106

Figure 5.10 Data transfer timing 5-108

Figure 5.11 Multiword DMA data transfer timing (mode 2) 5-109

Figure 5.12 Starting of Ultra DMA data In Burst transfer 5-110

Figure 5.13 Sustained Ultra DMA data in burst 5-113

Figure 5.14 Host pausing an Ultra DMA data in burst 5-114

Figure 5.15 Device terminating an Ultra DMA data in burst 5-115

Figure 5.16 Host terminating an Ultra DMA data in burst 5-116

Figure 5.17 Initiating an Ultra DMA data out burst 5-117

Figure 5.18 Sustained Ultra DMA data out burst 5-118

Figure 5.19 Device pausing an Ultra DMA data out burst 5-119

Figure 5.20 Host terminating an Ultra DMA data out burst 5-120

Figure 5.21 Device terminating an Ultra DMA data out burst 5-121

Figure 5.22 Power on Reset Timing 5-122

Tables

Figure 6.1 Response to power-on 6-3

Figure 6.2 Response to hardware reset 6-4

Figure 6.3 Response to software reset 6-5

Figure 6.4 Response to diagnostic command 6-6

Figure 6.5 Address translation (example in CHS mode) 6-8

Figure 6.6 Address translation (example in LBA mode) 6-9

Figure 6.7 Sector slip processing 6-12

Figure 6.8 Alternate cylinder assignment 6-13

Figure 6.9 Data buffer configuration 6-14

Table 1.1 Specifications 1-4

Table 1.2 Model names and product numbers 1-5

Table 1.3 Current and power dissipation 1-6

Table 1.4 Environmental specifications 1-7

Table 1.5 Acoustic noise specification 1-8

Table 1.6 Shock and vibration specification 1-8

Table 3.1 Surface temperature measurement points and standard values 3-7

Table 3.2 Cable connector specifications 3-11

C141-E104-02EN xv

Page 21

Contents

Table 4.1 Self-calibration execution timechart 4-10

Table 4.2 Write precompensation algorithm 4-11

Table 5.1 Signal assignment on the interface connector 5-3

Table 5.2 I/O registers 5-7

Table 5.3 Command code and parameters 5-14

Table 5.4 Information to be read by IDENTIFY DEVICE command 5-32

Table 5.5 Features register values and settable modes 5-41

Table 5.6 Diagnostic code 5-52

Table 5.7 Features Register values (subcommands) and functions 5-64

Table 5.8 Format of device attribute value data 5-68

Table 5.9 Format of insurance failure threshold value data 5-68

Table 5.10 SMART error log data format 5-72

Table 5.11 SMART self test log data format 5-74

Table 5.12 Contents of security password 5-76

Table 5.13 Contents of SECURITY SET PASSWORD data 5-80

Table 5.14 Relationship between combination of Identifier and Security level,

and operation of the lock function 5-80

Table 5.15 Command code and parameters 5-83

Table 5.16 Parallel generation equation of CRC polynomial 5-105

Table 5.17 Recommended series termination for Ultra DMA 5-106

Table 5.18 Ultra DMA data burst timing requirements 5-111

Table 6.1 Default parameters 6-7

xvi C141-E104-02EN

Page 22

CHAPTER 1 Device Overview

1.1 Features

1.2 Device Specifications

1.3 Power Requirements

1.4 Environmental Specifications

1.5 Acoustic Noise

1.6 Shock and Vibration

1.7 Reliability

1.8 Error Rate

1.9 Media Defects

Overview and features are described in this chapter, and specifications and power

requirement are described.

The MHL Series and MHM Series are 2.5-inch hard disk drives with built-in disk

controllers. These disk drives use the AT-bus hard disk interface protocol and are

compact and reliable.

C141-E104-02EN 1-1

Page 23

Device Overview

1.1 Features

1.1.1 Functions and performance

The following features of the MHL Series and MHM Series are described.

(1) Compact

The MHL2300AT has 3 built-in disks (the diameter is 65mm[2.5inch]), and its

height is 12.5 mm (0.492 inch). The MHM2200AT, MHM2150AT and

MHM2100AT have 1 disk or 2 disks of 65 mm (2.5 inches) diameter, and its

height is 9.5 mm (0.374 inch).

(2) Large capacity

The disk drive can record up to 10 GB (formatted) on one disk using the 16/17

MTR recording method and 15 recording zone technology. The MHL Series and

MHM Series have a formatted capacity of 30 GB (MHL2300AT), 20 GB

(MHM2200AT), 15 GB (MHM2150AT) and 10 GB (MHM2100AT) respectively.

(3) High-speed Transfer rate

The disk drives (the MHL Series and MHM Series) have an internal data rate up

to 28.7 MB/s. The disk drive supports an external data rate up to 66.6 MB/s (UDMA mode 4).

(4) Average positioning time

Use of a rotary voice coil motor in the head positioning mechanism greatly

increases the positioning speed. The average positioning time is 12 ms (at read).

1.1.2 Adaptability

(1) Power save mode

The power save mode feature for idle operation, stand by and sleep modes makes

The disk drives (the MHL Series and MHM Series) ideal for applications where

power consumption is a factor.

(2) Wide temperature range

The disk drives (the MHL Series and MHM Series) can be used over a wide

temperature range (5°C to 55°C).

(3) Low noise and vibration

In Ready status, the noise of the disk drives (the MHL Series and MHM Series) is

only about 30 dBA (measured at 1 m apart from the drive under the idle mode).

1-2 C141-E104-02EN

Page 24

1.1.3 Interface

(1) Connection to interface

With the built-in ATA interface controller, the disk drives (the MHL Series and

MHM Series) can be connected to an ATA interface of a personal computer.

(2) 2 MB data buffer

The disk drives (the MHL Series and MHM Series) uses a 2 MB data buffer to

transfer data between the host and the disk media.

In combination with the read-ahead cache system described in item (3) and the

write cache described in item (7), the buffer contributes to efficient I/O

processing.

(3) Read-ahead cache system

After the execution of a disk read command, the disk drive automatically reads the

subsequent data block and writes it to the data buffer (read ahead operation). This

cache system enables fast data access. The next disk read command would

normally cause another disk access. But, if the read ahead data corresponds to the

data requested by the next read command, the data in the buffer can be transferred

instead.

1.1 Features

(4) Master/slave

The disk drives (the MHL Series and MHM Series) can be connected to ATA

interface as daisy chain configuration. Drive 0 is a master device, drive 1 is a

slave device.

(5) Error correction and retry by ECC

If a recoverable error occurs, the disk drives (the MHL Series and MHM Series)

themselves attempt error recovery. The ECC has improved buffer error correction

for correctable data errors.

(6) Self-diagnosis

The disk drives (the MHL Series and MHM Series) have a diagnostic function to

check operation of the controller and disk drives. Executing the diagnostic

command invokes self-diagnosis.

(7) Write cache

When the disk drives (the MHL Series and MHM Series) receive a write

command, the disk drives post the command completion at completion of

transferring data to the data buffer completion of writing to the disk media. This

feature reduces the access time at writing.

C141-E104-02EN 1-3

Page 25

Device Overview

1.2 Device Specifications

1.2.1 Specifications summary

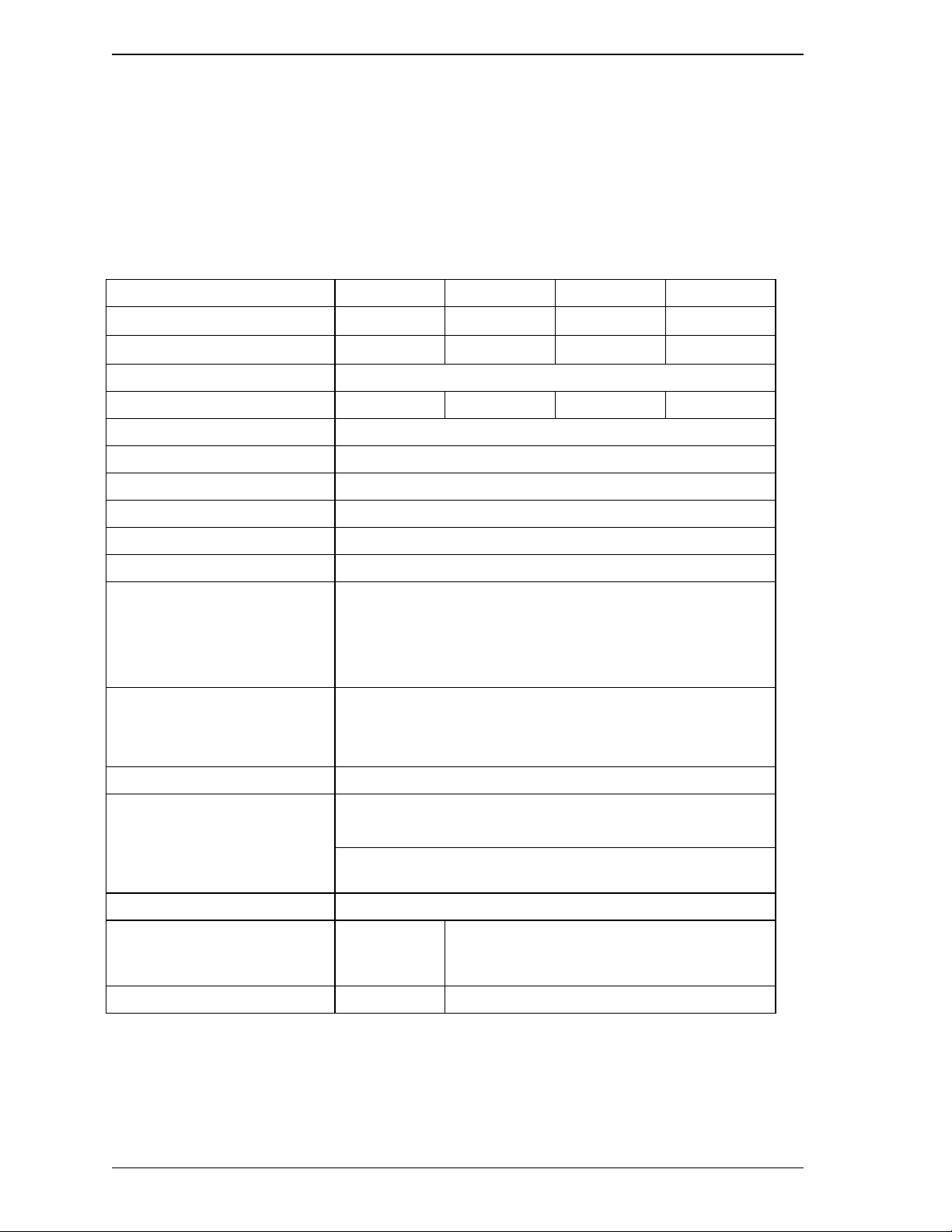

Table 1.1 shows the specifications of the disk drives (MHL Series and MHM Series).

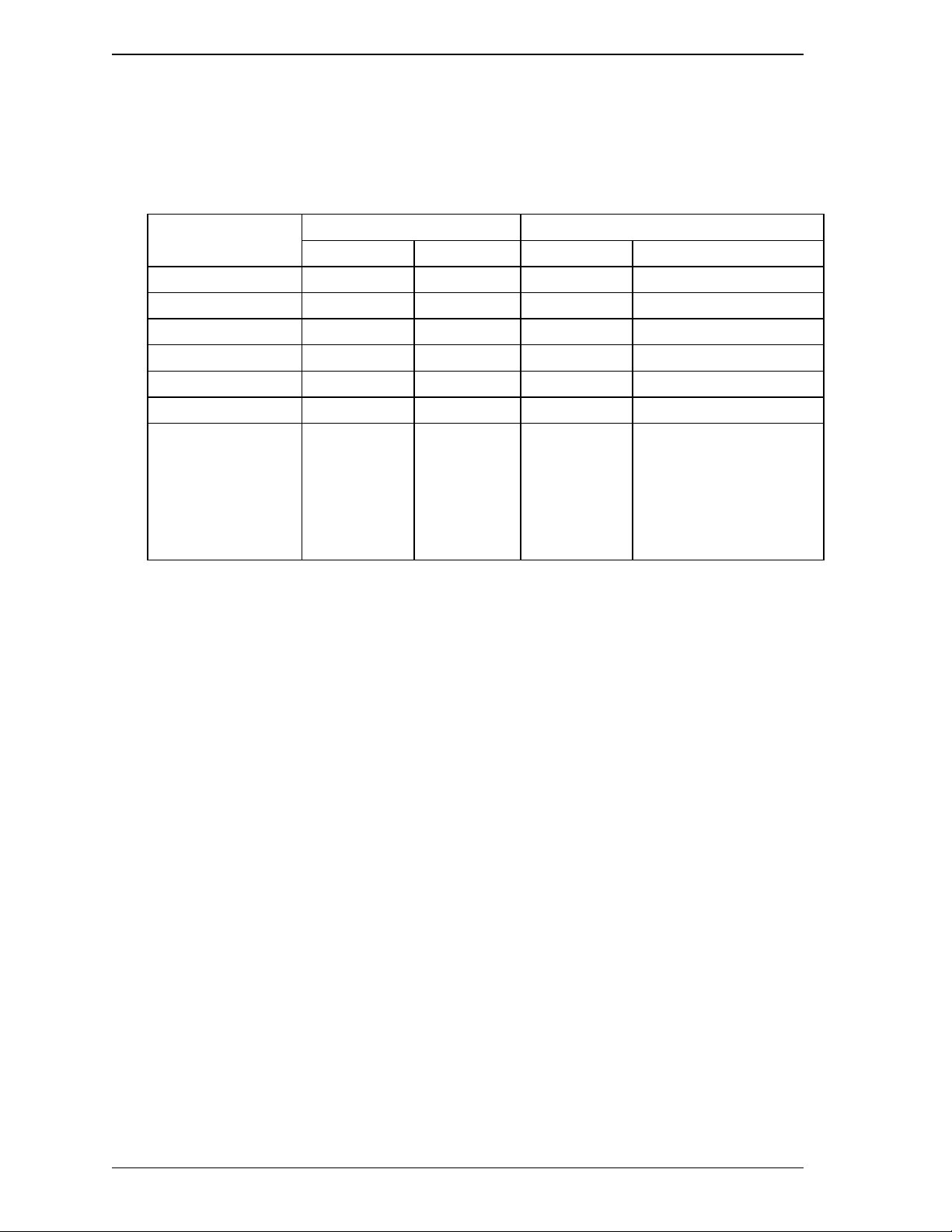

Table 1.1 Specifications ( 1/ 2)

MHL2300AT MHM2200AT MHM2150AT MHM2100AT

Format Capacity (*1) 30 GB 20 GB

Number of Heads 6 4

Number of Cylinders (User) 19,904

Number of Sectors (User) 58,605,120 39,070,080 29,498,112 19,640,880

Bytes per Sector 512

Recording Method 16/17 MTR

Track Density 32,300 TPI (1271 track/mm)

Bit Density 499.7 Kbpi (19.67 k bit/m m )

Rotational Speed 4,200 rpm ± 1%

Average Latency 7.14 ms

Positioning time (read and seek)

• Minimum (Track to Track)

• Average

• Maximum (Full)

Start/Stop time

• Start (0 rpm to Drive Read)

• Stop (at Power Down)

1.5 ms (typ.)

Read: 12 ms (typ.)

22 ms (typ.)

Typ.: 5 sec

Typ.: 5 sec

15 GB 10 GB

32

Interface ATA-5 (Max. Cable length: 0.46 m)

Data Transfer Rate

• To/From Media 16.4 to 28.7 MB/s

• To/From Host 66.6 MB/s Max.

(U-DMA mode 4)

Data Buffer Size 2 MB

Physical Dimensions

(Height × Width × Depth)

Weight 134 g 98 g

*1: Capacity under the LBA mode.

12.5 mm ×

100.0 mm ×

70.0 mm

9.5 mm × 100.0 mm ×70.0 mm

1-4 C141-E104-02EN

Page 26

1.3 Power Requirements

Under the CHS mode (normal BIOS specification), formatted capacity,

number of cylinders, number of heads, and number of sectors are as

follows.

Table 1.1 Specifications ( 2/ 2)

Model Capacity No. of Cylinder No. of Heads No. of Sectors

MHL2300AT 8.45 GB 16,383 16 63

MHM2200AT 8.45 GB 16,383 16 63

MHM2150AT 8.45 GB 16,383 16 63

MHM2100AT 8.45 GB 16,383 16 63

1.2.2 Model and product number

Table 1.2 lists the model names and product numbers of the MHL Series and

MHM Series.

Table 1.2 Model names and product numbers

Model Name Capacity

(user area)

MHL2300AT 30 GB M3, depth 3 CA05428-B061

MHM2200AT 20 GB M3, depth 3 CA05429-B041

MHM2150AT 15 GB M3, depth 3 CA05429-B031

MHM2100AT 10 GB M3, depth 3 CA05429-B021

Mounting screw Order No.

1.3 Power Requirements

(1) Input Voltage

• + 5 V ± 5 %

(2) Ripple

+5 V

Maximum 100 mV (peak to peak)

Frequency DC to 1 MHz

C141-E104-02EN 1-5

Page 27

Device Overview

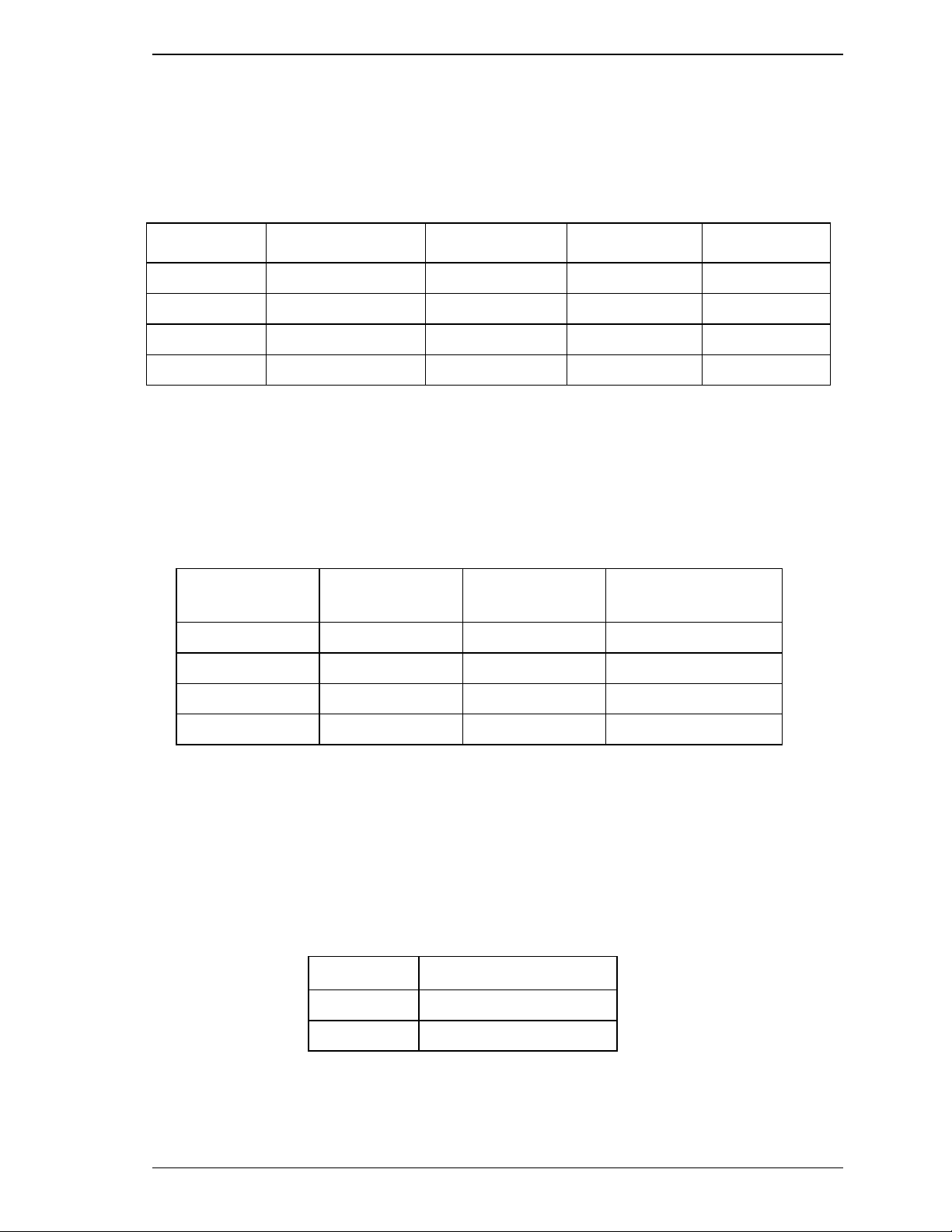

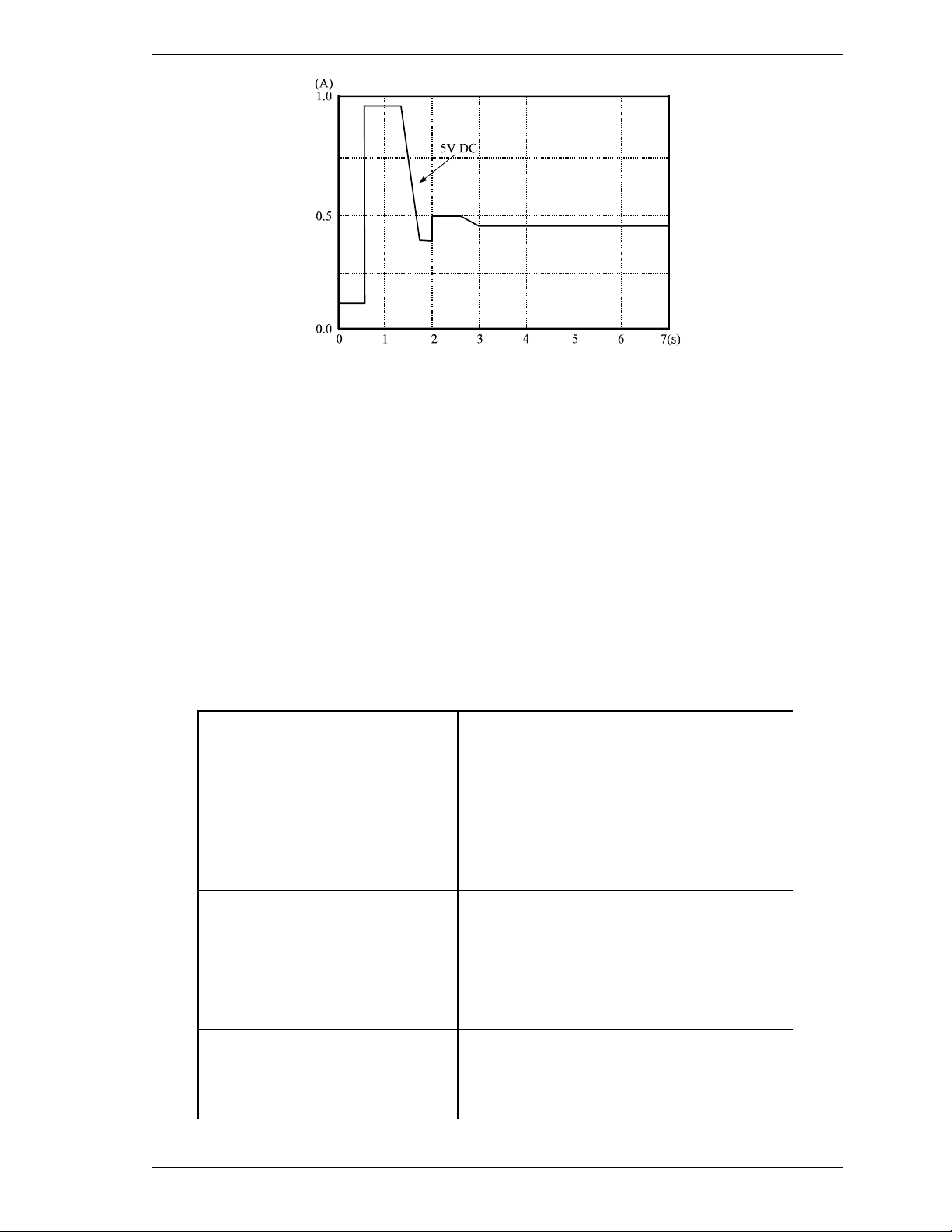

(3) Current Requirements and Power Dissipation

Table 1.3 lists the current and power dissipation.

Table 1.3 Current and power di ssi pat i on

Typical RMS Current Typical Power (*3)

MHL Series MHM Series MHL Series MHM Series

Spin up (*1) 0.9 A 0.9 A 4.5 W 4.5 W

Idle 190 mA 160 mA 0.95 W 0.8 W

R/W (on track) (*2) 520 mA 500 mA 2.6 W 2.5 W

Seek (*5) 490 mA 460 mA 2.45 W 2.3 W

Standby 50 mA 50 mA 0.25 W 0.25 W

Sleep 20 mA 20 mA 0.1 W 0.1 W

Energy

Efficiency (*4)

— — 0.032 W/GB

(rank E)

(rank E / MHM2200AT)

(rank E / MHM2150AT)

(rank D / MHM2100AT)

0.040 W/GB

0.040 W/GB

0.080 W/GB

*1 Current at starting spindle motor.

*2 At 30% disk accessing.

*3 Power requirements reflect nominal values for +5V power.

*4 Energy efficiency based on the Law concerning the Rational Use of Energy

indicates the value obtained by dividing power consumption by the storage

capacity. (Japan only)

*5 The seek average current is specified based on three operations per 100

msec.

(4) Current fluctuation (Typ.) at +5V when power is turned on

1-6 C141-E104-02EN

Page 28

Figure 1.1 Current fluctuation (Typ.) at +5V when power is turned on

(5) Power on/off sequence

The voltage detector circuits (the MHL Series and MHM Series) monitor +5 V.

The circuits do not allow a write signal if either voltage is abnormal. These

prevent data from being destroyed and eliminates the need to be concerned with

the power on/off sequence.

1.4 Environmental Specifications

1.4 Environmental Specifications

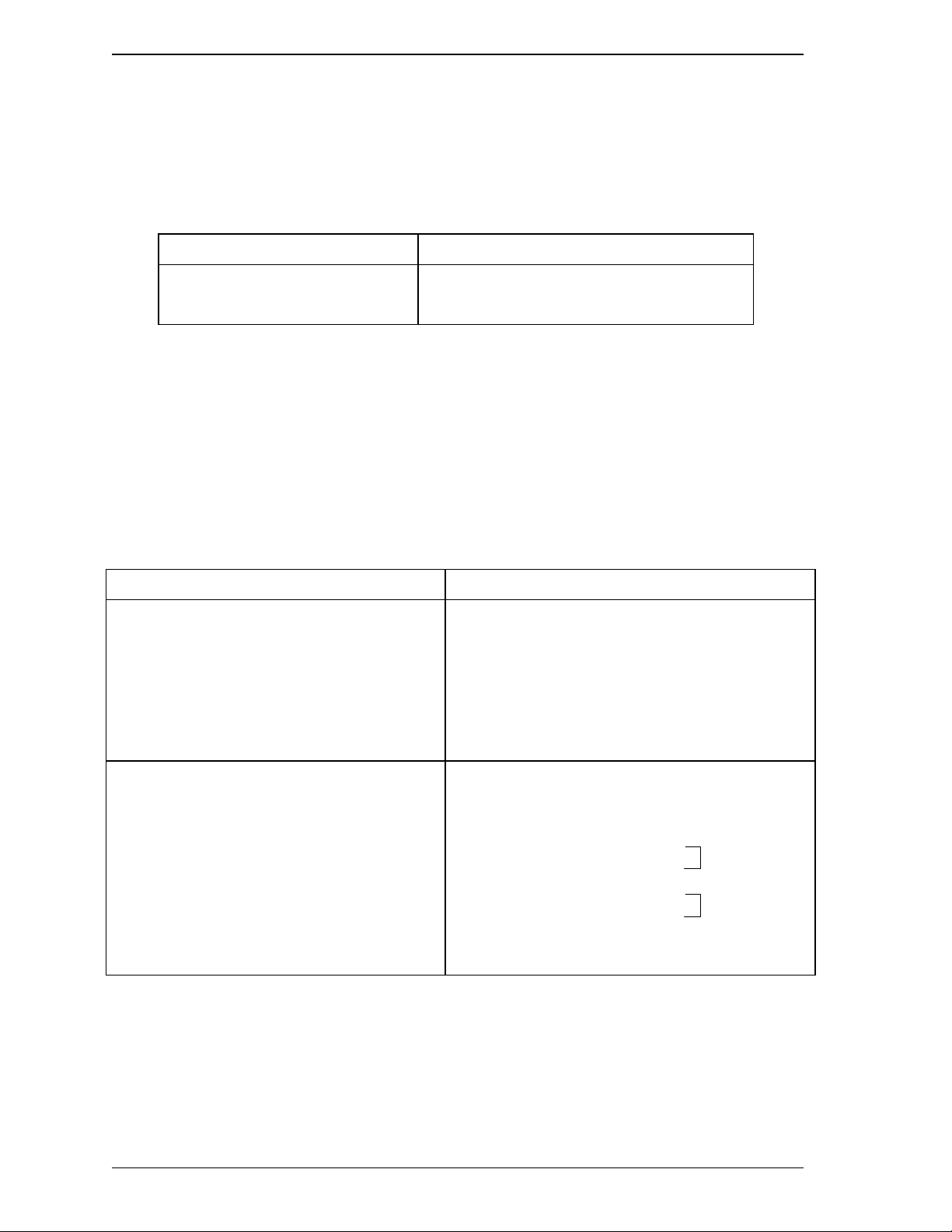

Table 1.4 lists the environmental specifications.

Table 1.4 Environmental specifications

Item Specification

Temperature

• Operating

• Non-operating

• Thermal Gradient

Humidity

• Operating

• Non-operating

• Maximum Wet Bulb

5°C to 55°C (ambient)

5°C to 60°C (disk enclosure surface)

–40°C to 65°C

20°C/h or less

8% to 90% RH (Non-condensing)

5% to 95% RH (Non-condensing)

29°C (Operating)

40°C (Non-operating)

Altitude (relative to sea level)

• Operating

• Non-operating

C141-E104-02EN 1-7

–300 to 3,000 m

–300 to 12,000 m

Page 29

Device Overview

1.5 Acoustic Noise

Table 1.5 lists the acoustic noise specification.

Table 1.5 Acoustic noise specification

Item Specification

Sound Pressure

• Idle mode (DRIVE READY) 30 dBA typical at 1 m

Note:

Measure the noise from the cover top surface.

1.6 Shock and Vibration

Table 1.6 lists the shock and vibration specification.

Table 1.6 Shock and vibration specificati on

Item Specification

Vibration (swept sine, one octave per minute)

• Operating

5 to 500 Hz, 1.0G 0-peak (MHL series)

5 to 400 Hz, 1.0G 0-peak (MHM series)

(without non-recovered errors) (9.8 m/s

• Non-operating

5 to 500 Hz, 5G 0-peak (MHL series)

5 to 400 Hz, 5G 0-peak (MHM series)

(no damage) (49 m/s

Shock (half-sine pulse)

• Operating

175G 0-peak (1,715 m/s

2 ms duration (without non-recovered errors)

• Non-operating

600G 0-peak (5,880 m/s

2 ms duration (no damage)

700G 0-peak (6,860 m/s

2 ms duration (no damage)

120G 0-peak (1,176 m/s

11 ms duration (no damage)

2

0-peak)

2

2

2

2

0-peak)

0-peak)

0-peak)

0-peak)

2

0-peak)

MHL series

MHM series

1-8 C141-E104-02EN

Page 30

1.7 Reliability

(1) Mean time between failures (MTBF)

Conditions of 300,000 h Power-on time 250H/month or less 3000H/years

MTBF is defined as follows:

Total operation time in all fields

MTBF= (H)

number of device failure in all fields (*1)

*1 “Disk drive defects” refers to defects that involve repair, readjustment, or

replacement. Disk drive defects do not include failures caused by external

factors, such as damage caused by handling, inappropriate operating

environments, defects in the power supply host system, or interface cable.

1.7 Reliability

or less

Operating time 20% or less of power-on time

CSS operations 50/day or less

Total 50,000 or less

Power on/off 1/day or more needed.

Environment 5 to 55°C/8 to 90%

But humidity bulb temperature

29°C or less

(2) Mean time to repair (MTTR)

The mean time to repair (MTTR) is 30 minutes or less, if repaired by a specialist

maintenance staff member.

(3) Service life

In situations where management and handling are correct, the disk drive requires

no overhaul for five years when the DE surface temperature is less than 48°C.

When the DE surface temperature exceeds 48°C, the disk drives requires no

overhaul for five years or 20,000 hours of operation, whichever occurs first.

Refer to item (3) in Subsection 3.2 for the measurement point of the DE surface

temperature. Also the operating conditions except the environment temperature

are based on the MTBF conditions.

(4) Data assurance in the event of power failure

Except for the data block being written to, the data on the disk media is assured in

the event of any power supply abnormalities. This does not include power supply

abnormalities during disk media initialization (formatting) or processing of

defects (alternative block assignment).

C141-E104-02EN 1-9

Page 31

Device Overview

1.8 Error Rate

Known defects, for which alternative blocks can be assigned, are not included in

the error rate count below. It is assumed that the data blocks to be accessed are

evenly distributed on the disk media.

(1) Unrecoverable read error

Read errors that cannot be recovered by maximum read retries of drive without

user’s retry and ECC corrections shall occur no more than 10 times when reading

data of 10

recovery procedure, and include read retries accompanying head offset operations.

(2) Positioning error

14

bits. Read retries are executed according to the disk drive’s error

Positioning (seek) errors that can be recovered by one retry shall occur no more

than 10 times in 10

1.9 Media Defects

Defective sectors are replaced with alternates when the disk (the MHL Series and

MHM Series) are formatted prior to shipment from the factory (low level format).

Thus, the hosts see a defect-free devices.

Alternate sectors are automatically accessed by the disk drive. The user need not

be concerned with access to alternate sectors.

7

seek operations.

1-10 C141-E104-02EN

Page 32

CHAPTER 2 Device Configuration

2.1 Device Configuration

2.2 System Configuration

This chapter describes the internal configurations of the hard disk drives and the

configuration of the systems in which they operate.

C141-E104-02EN 2-1

Page 33

Device Configuration

2.1 Device Configuration

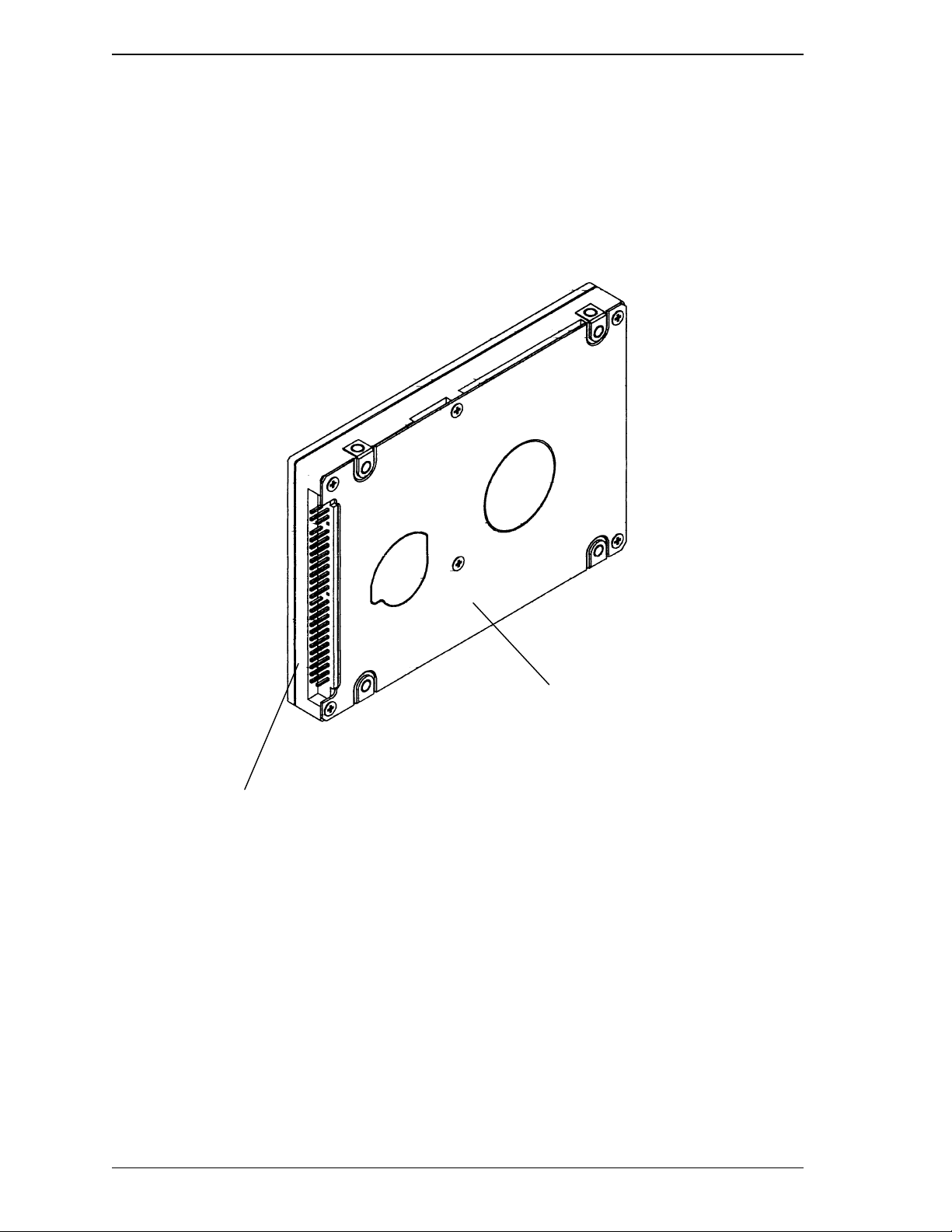

Figure 2.1 shows the disk drive. The disk drive consists of a disk enclosure (DE),

read/write preamplifier, and controller PCA. The disk enclosure contains the disk

media, heads, spindle motors, actuators, and a circulating air filter.

MHM SeriesMHL Series

(1) Disk

(2) Head

Figure 2.1 Disk drive outerview

The outer diameter of the disk is 65 mm. The inner diameter is 20 mm. The

number of disks used varies with the model, as described below. The disks are

rated at over 50,000 start/stop operations.

MHL2300AT: 3 disks

MHM2200AT: 2 disks MHM2150AT: 2 disks MHM2100AT: 1 disk

The heads are of the contact start/stop (CSS) type. The head touches the disk

surface while the disk is not rotating and automatically lifts when the disk starts.

Figure 2.2 illustrates the configuration of the disks and heads of each model. In

the disk surface, servo information necessary for controlling positioning and

read/write and user data are written. Numerals 0 to 5 indicate read/write heads.

2-2 C141-E104-02EN

Page 34

Head

5

4

3

Head

3

2.1 Device Configuration

Head

3

2

1

0

MHL2300AT

(3) Spindle motor

(4) Actuator

2

2

Head

1

0

MHM2200AT

1

0

MHM2150AT

1

0

MHM2100AT

(Either of head 0 or

head 3 is mounted.)

Figure 2.2 Configuration of disk media heads

The disks are rotated by a direct drive Hall-less DC motor.

The actuator uses a revolving voice coil motor (VCM) structure which consumes

low power and generates very little heat. The head assembly at the edge of the

actuator arm is controlled and positioned by feedback of the servo information

read by the read/write head. If the power is not on or if the spindle motor is

stopped, the head assembly stays in the specific CSS zone on the disk and is fixed

by a mechanical lock.

(5) Air circulation system

The disk enclosure (DE) is sealed to prevent dust and dirt from entering. The disk

enclosure features a closed loop air circulation system that relies on the blower

effect of the rotating disk. This system continuously circulates the air through the

circulation filter to maintain the cleanliness of the air within the disk enclosure.

(6) Read/write circuit

The read/write circuit uses a LSI chip for the read/write preamplifier. It improves

data reliability by preventing errors caused by external noise.

(7) Controller circuit

The controller circuit consists of an LSI chip to improve reliability. The highspeed microprocessor unit (MPU) achieves a high-performance AT controller.

C141-E104-02EN 2-3

Page 35

Device Configuration

2.2 System Configuration

2.2.1 ATA interface

Figures 2.3 and 2.4 show the ATA interface system configuration. The drive has a

44pin PC AT interface connector and supports PIO mode 4 transfer at 16.6 MB/s,

Multiword DMA mode 2 transfer at 16.6 MB/s and also U-DMA mode 4 transfer

at 66.6 MB/s.

2.2.2 1 drive connection

MHL2300AT

MHM2200AT

MHC2032AT

MHM2150AT

MHC2040AT

MHM2100AT

Figure 2.3 1 drive system configuration

2.2.3 2 drives connection

MHL2300AT

MHM2200AT

(Host adaptor)

Note:

When the drive that is not conformed to ATA is connected to the disk drive above

configuration, the operation is not guaranteed.

MHC2032AT

MHM2150AT

MHC2040AT

MHM2100AT

MHL2300AT

MHG2102AT

MHM2200AT

MHC2032AT

MHH2064AT

MHM2150AT

MHC2040AT

MHH2032AT

MHM2100AT

Figure 2.4 2 drives configuration

2-4 C141-E104-02EN

Page 36

2.2 System Configuration

IMPORTANT

HA (host adaptor) consists of address decoder, driver, and receiver.

ATA is an abbreviation of “AT attachment”. The disk drive is

conformed to the ATA-4 interface.

At high speed data transfer (PIO mode 3, mode 4, or DMA mode 2

U-DMA mode 4), occurrence of ringing or crosstalk of the signal

lines (AT bus) between the HA and the disk drive may be a great

cause of the obstruction of system reliability. Thus, it is necessary

that the capacitance of the signal lines including the HA and cable

does not exceed the ATA-5 standard, and the cable length between

the HA and the disk drive should be as short as possible.

No need to push the top cover of the disk drive. If the over-power

worked, the cover could be contacted with the spindle motor. Thus,

that could be made it the cause of failure.

C141-E104-02EN 2-5

Page 37

This page is intentionally left blank.

Page 38

CHAPTER 3 Installation Conditions

3.1 Dimensions

3.2 Mounting

3.3 Cable Connections

3.4 Jumper Settings

This chapter gives the external dimensions, installation conditions, surface

temperature conditions, cable connections, and switch settings of the hard disk

drives.

C141-E104-02EN 3-1

Page 39

Installation Conditions

3.1 Dimensions

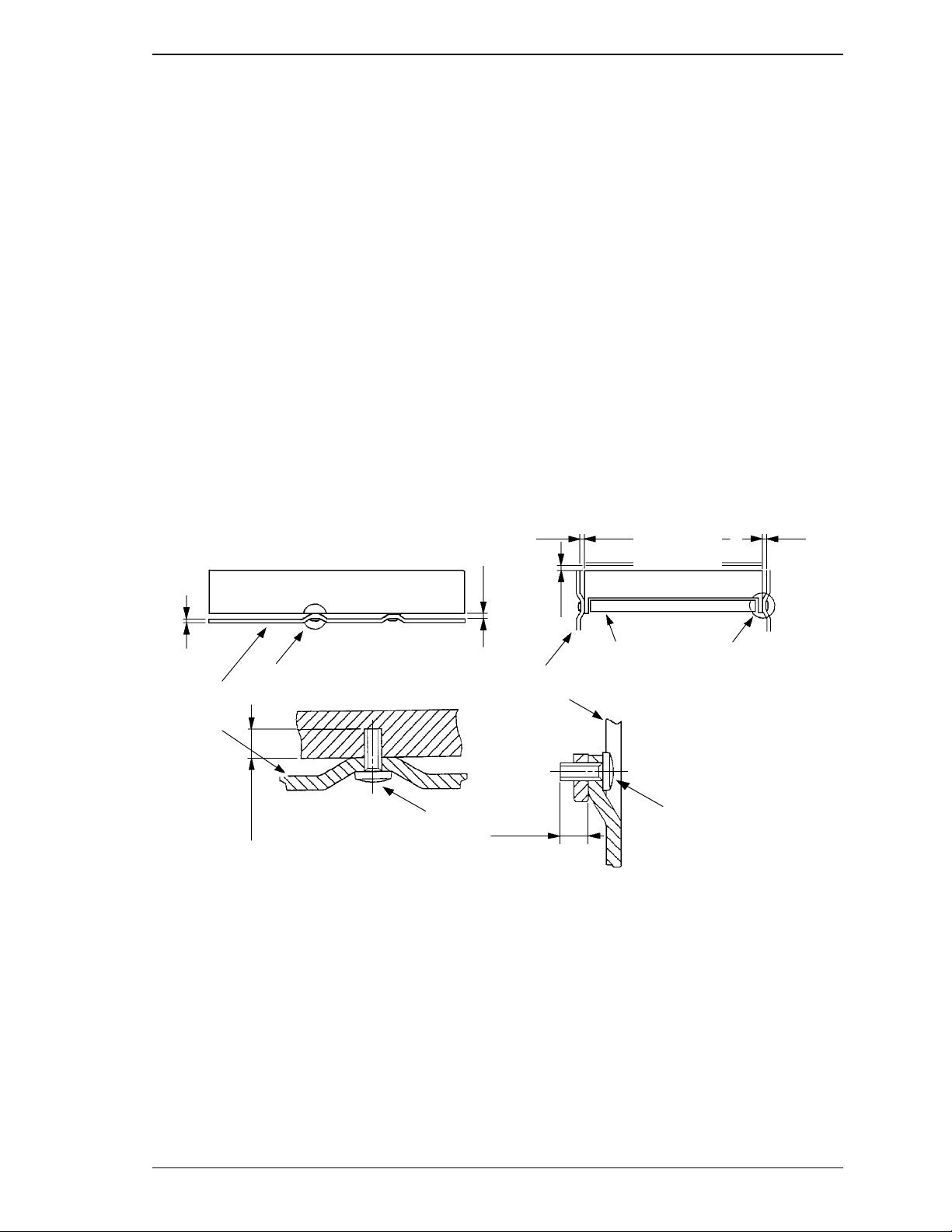

Figure 3.1 illustrates the dimensions of the disk drive and positions of the

mounting screw holes. All dimensions are in mm.

Figure 3.1 Dimensions (MHL series) (1/2)

3-2 C141-E104-02EN

Page 40

3.1 Dimensions

Figure 3.1 Dimensions (MHM series) (2/2)

C141-E104-02EN 3-3

Page 41

Installation Conditions

3.2 Mounting

(1) Orientation

Figure 3.2 illustrates the allowable orientations for the disk drive.

gravity

(a) Horizontal –1

(c) Vertical –1 (d) Vertical –2

(b) Horizontal –1

gravity

gravity

(e) Vertical –3 (f) Vertical –4

Figure 3.2 Orientation (Sample: MHL2300AT)

3-4 C141-E104-02EN

Page 42

(2) Frame

The MR head bias of the HDD disk enclosure (DE) is zero. The mounting frame

is connected to SG.

Use M3 screw for the mounting screw and the screw length should

satisfy the specification in Figure 3.3.

The tightening torque must be 0.49N·m(5kgf·cm).

When attaching the HDD to the system frame, do not allow the

system frame to touch parts (cover and base) other than parts to

which the HDD is attached.

(3) Limitation of mounting

Do not use the center hole. For screw length, see Figure 3.3.

Note) These dimensions are recommended values; if it is not possible to

3.2 Mounting

IMPORTANT

satisfy them, contact us.

Bottom surface mounting

2

A

Frame of system

cabinet

3.0 or less

DE

2.5

2.5

Frame of system

cabinet

Screw

3.0 or less

Details of A

Details of B

Figure 3.3 Mounting frame structure

Side surface

mounting

PCA

Screw

2.52.5

B

C141-E104-02EN 3-5

Page 43

Installation Conditions

IMPORTANT

Because of breather hole mounted to the HDD, do not allow this to

close during mounting.

Locating of breather hole is shown as Figure 3.4 in both MHL

series and MHM series.

For breather hole of Figure 3.4, at least, do not allow its around φ3

to block.

Figure 3.4 Location of breather

3-6 C141-E104-02EN

Page 44

(4) Ambient temperature

The temperature conditions for a disk drive mounted in a cabinet refer to the

ambient temperature at a point 3 cm from the disk drive. The ambient

temperature must satisfy the temperature conditions described in Section 1.4, and

the airflow must be considered to prevent the DE surface temperature from

exceeding 60°C.

Provide air circulation in the cabinet such that the PCA side, in particular,

receives sufficient cooling. To check the cooling efficiency, measure the surface

temperatures of the DE. Regardless of the ambient temperature, this surface

temperature must meet the standards listed in Table 3.1. Figure 3.5 shows the

temperature measurement point.

3.2 Mounting

1

Figure 3.5 Surface temperature measurement points (Sample: MHL2300AT)

Table 3.1 Surface temperature measurement points and standard values

No. Measurement point Temperature

1 DE cover 60°C max

C141-E104-02EN 3-7

Page 45

Installation Conditions

(5) Service area

Figure 3.6 shows how the drive must be accessed (service areas) during and after

installation.

Mounting screw hole

Cable connection

(6) Handling cautions

Mounting screw hole

Figure 3.6 Service area (Sample: MHL2300AT)

CAUTION

Data corruption: Avoid mounting the disk drive near strong

magnetic sources such as loud speakers. Ensure that the disk drive

is not affected by external magnetic fields.

Damage: Do not press the cover of the disk drive. Pressing it too

hard, the cover and the spindle motor contact, which may cause

damage to the disk drive.

Static: When handling the device, disconnect the body ground

(500 kΩ or greater). Do not touch the printed circuit board, but

hold it by the edges.

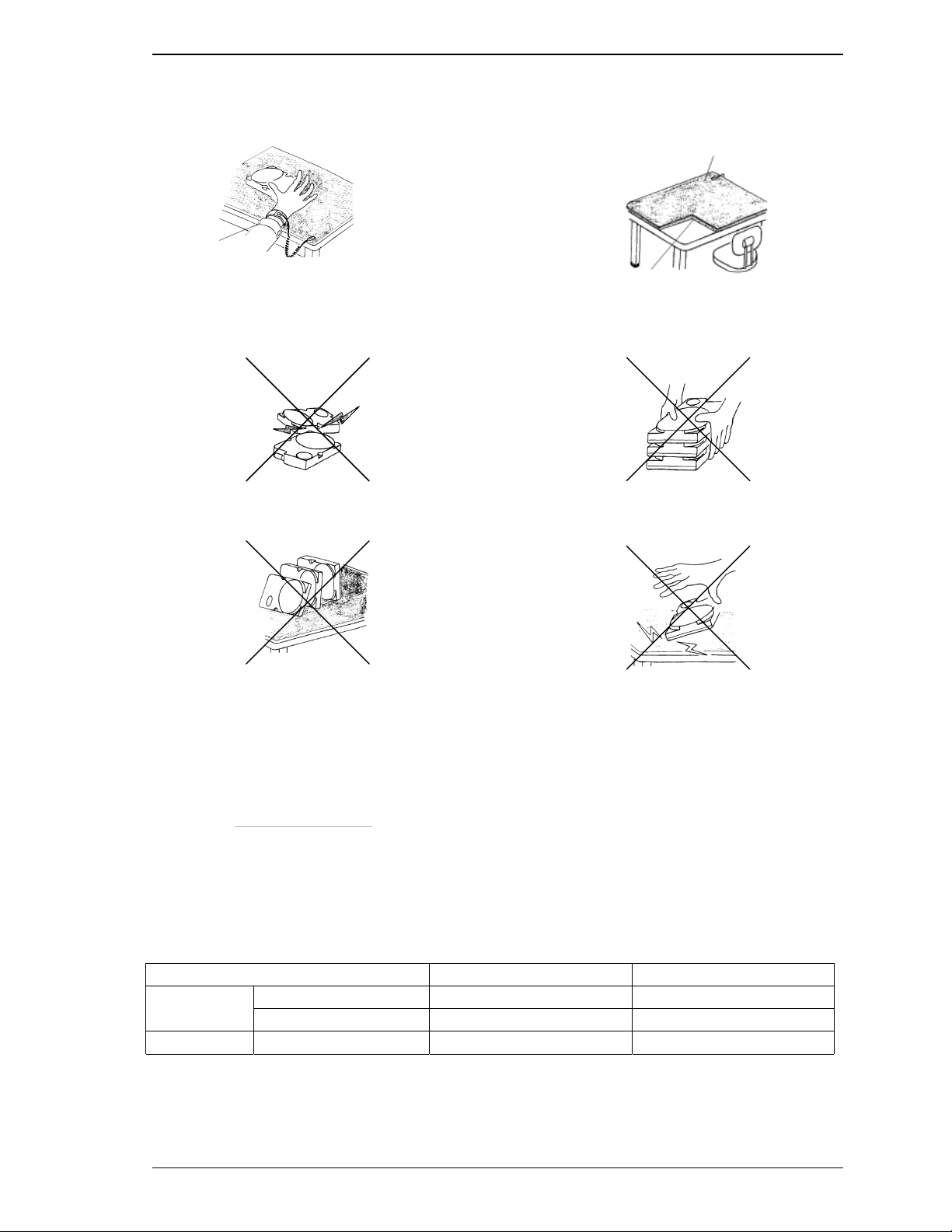

Please keep the following cautions, and handle the HDD under the safety

environment.

3-8 C141-E104-02EN

Page 46

- General notes

Wrist strap

Use the Wrist strap.

3.2 Mounting

ESD mat

Shock absorbing mat

Place the shock absorbing mat on the

operation table, and place ESD mat on it.

Do not hit HDD each other. Do not stack when carrying.

Do not place HDD vertically

to avoid falling down.

Figure 3.7 Handling cautions

- Installation

(1) Please use the driver of a low impact when you use an electric driver.

HDD is occasionally damaged by the impact of the driver.

(2) Please observe the tightening torque of the screw strictly.

M3 ······· 0.49 N·m (5 Kg·cm)

- Recommended equipments

Do not drop.

Contents Model Maker

Wrist strap JX-1200-3056-8 SUMITOMO 3MESD

ESD mat 76000DES (ASK7876) COMKYLE

Shock Low shock driver SS-3000 HIOS

C141-E104-02EN 3-9

Page 47

Installation Conditions

3.3 Cable Connections

3.3.1 Device connector

The disk drive has the connectors and terminals listed below for connecting

external devices. Figure 3.8 shows the locations of these connectors and

terminals.

PCA

Connector,

setting pins

Figure 3.8 Connector locations (Sample: MHL2300AT)

3-10 C141-E104-02EN

Page 48

3.3.2 Cable connector specifications

Table 3.2 lists the recommended specifications for the cable connectors.

Table 3.2 Cable connector specifications

Name Model Manufacturer

3.3 Cable Connections

ATA interface and power

supply cable (44-pin type)

For the host interface cable, use a ribbon cable. A twisted cable or

a cable with wires that have become separated from the ribbon may

cause crosstalk between signal lines. This is because the interface

is designed for ribbon cables and not for cables carrying differential

signals.

3.3.3 Device connection

Figure 3.9 shows how to connect the devices.

Cable socket

(44-pin type)

IMPORTANT

89361-144 BERG

Figure 3.9 Cable connections

C141-E104-02EN 3-11

Page 49

Installation Conditions

3.3.4 Power supply connector (CN1)

Figure 3.10 shows the pin assignment of the power supply connector (CN1).

Figure 3.10 Power supply connector pins (CN1)

3.4 Jumper Settings

3.4.1 Location of setting jumpers

Figure 3.11 shows the location of the jumpers to select drive configuration and

functions.

Figure 3.11 Jumper location

3-12 C141-E104-02EN

Page 50

3.4.2 Factory default setting

Figure 3.12 shows the default setting position at the factory.

3.4 Jumper Settings

Open

Figure 3.12 Factory default setting

3.4.3 Master drive-slave drive setting

Master drive (disk drive #0) or slave drive (disk drive #1) is selected.

Open

1C

2

A

BD

Open

Open

AC1

Short

BD2

(b) Slave drive(a) Master drive

Figure 3.13 Jumper setting of master or slave drive

Note:

Pins A and C should be open.

C141-E104-02EN 3-13

Page 51

Installation Conditions

3.4.4 CSEL setting

Figure 3.14 shows the cable select (CSEL) setting.

Open

AC1

BD2

Short

Note:

The CSEL setting is not depended on setting between pins Band D.

Figure 3.14 CSEL setting

Figure 3.15 and 3.16 show examples of cable selection using unique interface

cables.

By connecting the CSEL of the master drive to the CSEL Line (conducer) of the

cable and connecting it to ground further, the CSEL is set to low level. The drive

is identified as a master drive. At this time, the CSEL of the slave drive does not

have a conductor. Thus, since the slave drive is not connected to the CSEL

conductor, the CSEL is set to high level. The drive is identified as a slave drive.

drive drive

Figure 3.15 Example (1) of Cable Select

3-14 C141-E104-02EN

Page 52

drive drive

Figure 3.16 Example (2) of Cable Select

3.4 Jumper Settings

C141-E104-02EN 3-15

Page 53

This page is intentionally left blank.

Page 54

CHAPTER 4 Theory of Device Operation

4.1 Outline

4.2 Subassemblies

4.3 Circuit Configuration

4.4 Power-on Sequence

4.5 Self-calibration

4.6 Read/write Circuit

4.7 Servo Control

This chapter explains basic design concepts of the disk drive. Also, this chapter

explains subassemblies of the disk drive, each sequence, servo control, and

electrical circuit blocks.

C141-E104-02EN 4-1

Page 55

Theory of Device Operation

4.1 Outline

This chapter consists of two parts. First part (Section 4.2) explains mechanical

assemblies of the disk drive. Second part (Sections 4.3 through 4.7) explains a

servo information recorded in the disk drive and drive control method.

4.2 Subassemblies

The disk drive consists of a disk enclosure (DE) and printed circuit assembly

(PCA).

The DE contains all movable parts in the disk drive, including the disk, spindle,

actuator, read/write head, and air filter. For details, see Subsections 4.2.1 to 4.2.5.

The PCA contains the control circuits for the disk drive. The disk drive has one

PCA. For details, see Sections 4.3.

4.2.1 Disk

4.2.2 Head

The DE contains disks with an outer diameter of 65 mm and an inner diameter of

20 mm. The MHL2300AT have three disks and MHM2200AT and

MHM2150AT have two disks and MHM2100AT have one disk.

The head contacts the disk each time the disk rotation stops; the disk surface is

durable at least 50,000 CSS (Contact Start/Stop) or more.

Servo data is recorded on each cylinder (total 66). Servo data written at factory is

read out by the read head. For servo data, see Section 4.7.

Figure 4.1 shows the head structures. MHL2300AT has 6 heads and

MHM2200AT has 4 heads and MHM2150AT has 3 heads and MHM2100AT has

2 heads. These heads are raised from the disk surface as the spindle motor the

rated rotation speed.

4-2 C141-E104-02EN

Page 56

Head

5

4

3

Head

3

4.2 Subassemblies

Head

3

2

1

0

MHL2300AT

4.2.3 Spindle

4.2.4 Actuator

2

1

0

MHM2200AT

Figure 4.1 Head structure

The spindle consists of a disk stack assembly and spindle motor. The disk stack

assembly is activated by the direct drive sensor-less DC spindle motor, which has

a speed of 4,200 rpm ±1%. The spindle is controlled with detecting a PHASE

signal generated by counter electromotive voltage of the spindle motor at starting.

The actuator consists of a voice coil motor (VCM) and a head carriage. The

VCM moves the head carriage along the inner or outer edge of the disk. The head

carriage position is controlled by feeding back the difference of the target position

that is detected and reproduced from the servo information read by the read/write

head.

2

1

0

MHM2150AT

(Either of head 0 or

head 3 is mounted.)

Head

1

0

MHK2100AT

4.2.5 Air filter

There are two types of air filters: a breather filter and a circulation filter.

The breather filter makes an air in and out of the DE to prevent unnecessary

pressure around the spindle when the disk starts or stops rotating. When disk

drives are transported under conditions where the air pressure changes a lot,

filtered air is circulated in the DE.

The circulation filter cleans out dust and dirt from inside the DE. The disk drive

cycles air continuously through the circulation filter through an enclosed loop air

cycle system operated by a blower on the rotating disk.

C141-E104-02EN 4-3

Page 57

Theory of Device Operation

4.3 Circuit Configuration

Figure 4.2 shows the power supply configuration of the disk drive, and Figure 4.3

shows the disk drive circuit configuration.

(1) Read/write circuit

The read/write circuit consists of two LSIs; read/write preamplifier (PreAMP) and

read channel (RDC).

The PreAMP consists of the write current switch circuit, that flows the write

current to the head coil, and the voltage amplifier circuit, that amplitudes the read

output from the head.

The RDC is the read demodulation circuit using the Modified Extended Partial

Response (MEEPR), and contains the Viterbi detector, programmable filter,

adaptable transversal filter, times base generator, data separator circuits, 16/17

MTR (Maximum Transitions Limited) encoder Run Length and servo

demodulation circuit.

(2) Servo circuit

The position and speed of the voice coil motor are controlled by 2 closed-loop

servo using the servo information recorded on the data surface. The servo

information is an analog signal converted to digital for processing by a MPU and

then reconverted to an analog signal for control of the voice coil motor.

The MPU precisely sets each head on the track according on the servo

information on the media surface.

(3) Spindle motor driver circuit

The circuit measures the interval of a PHASE signal generated by counterelectromotive voltage of a motor at the MPU and controls the motor speed

comparing target speed.

(4) Controller circuit

Major functions are listed below.

• Data buffer (2 MB) management

• ATA interface control and data transfer control

• Sector format control

• Defect management

• ECC control

Error recovery and self-diagnosis

•

4-4 C141-E104-02EN

Page 58

4.3 Circuit Configuration

5V

HDC SVC HDIC MCU FROM

3.3V

- 3V

SDRAM

RDC

Figure 4.2 Power Supply Configuration

C141-E104-02EN 4-5

Page 59

Theory of Device Operation

Printed

Circuit

Board

FROM

Program

Memory

Host

ATA

Interface

Disk

Enclosure Head

HDC

(Hard Disk

Controller)

16 bit

SDRAM

Data

Buffer

RAM

Data

Buffer

Bus

16 bit

Read

and

Write

Data

Write Data

HDIC

RDC

Read

Channel

RDC

Control

Signal

Local Bus

Servo

Pulse

and

Position

Signal

Read Data

Read Data

MPU

(Micro

Processor

Unit)

SVC

Control

Signal

HDIC

Control

Signal

SVC

Motor

Controller

and

Driver

Read

Head

Write

Head

Read Data

Write Data

(Read/Write

Preamplifier)

Voice

Coil

Motor

Spindle

Motor

Figure 4.3 Circuit Configuration

4-6 C141-E104-02EN

Page 60

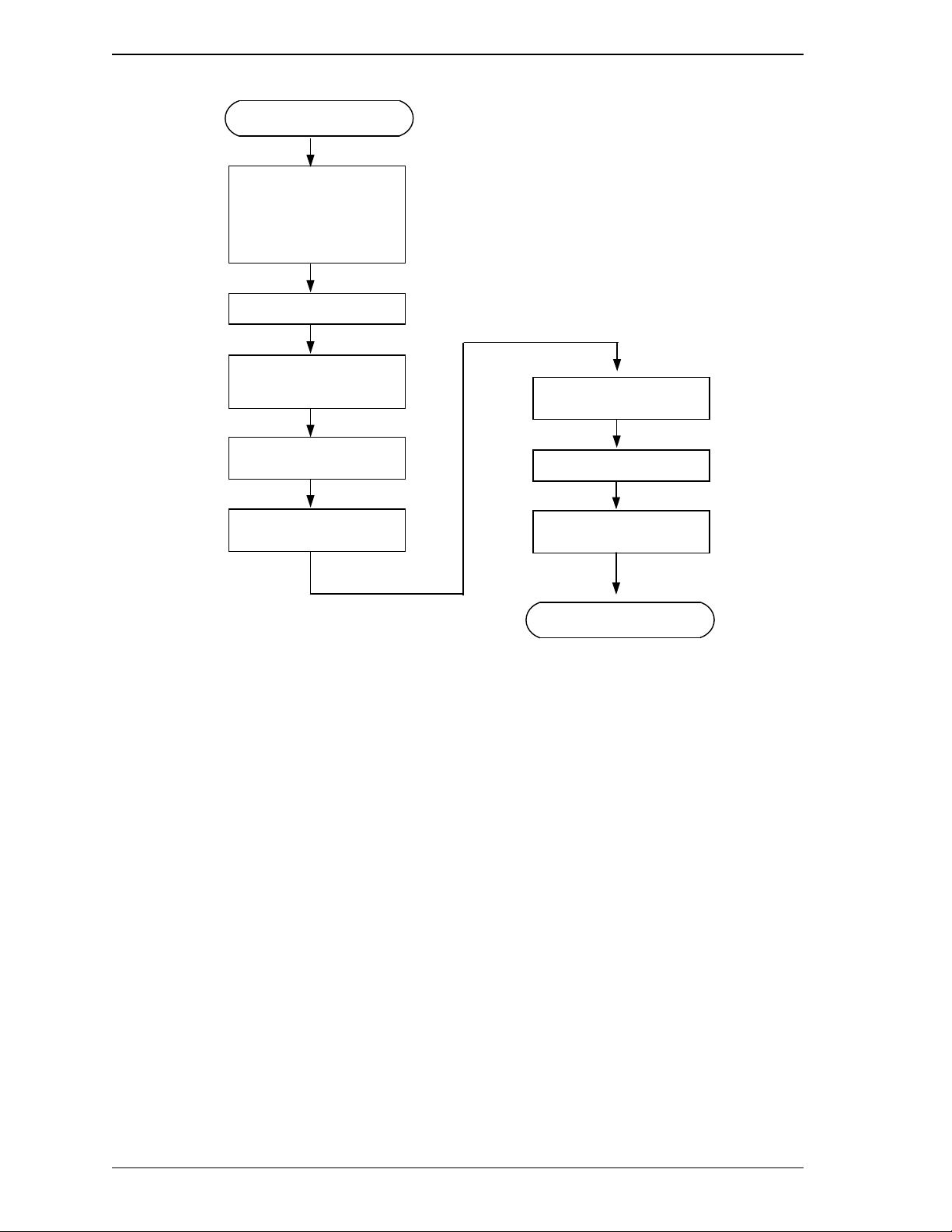

4.4 Power-on Sequence

Figure 4.4 describes the operation sequence of the disk drive at power-on. The

outline is described below.

a) After the power is turned on, the disk drive executes the MPU bus test,

internal register read/write test, and work RAM read/write test. When the

self-diagnosis terminates successfully, the disk drive starts the spindle motor.

b) The disk drive executes self-diagnosis (data buffer read/write test) after

enabling response to the ATA bus.

c) After confirming that the spindle motor has reached rated speed, the disk

drive releases the heads from the actuator magnet lock mechanism by

applying current to the VCM. This unlocks the heads which are parked at the

inner circumference of the disks.

d) The disk drive positions the heads onto the SA area and reads out the system

information.

4.3 Circuit Configuration

e) The disk drive executes self-seek-calibration. This collects data for VCM

torque and mechanical external forces applied to the actuator, and updates the

calibrating value.

f) The drive becomes ready. The host can issue commands.

C141-E104-02EN 4-7

Page 61

Theory of Device Operation

Power-on

a)

Self-diagnosis 1

- MPU bus test

- Internal register

write/read test

- Work RAM write/read

test

The spindle motor starts.

b)

Self-diagnosis 2

- Data buffer write/read

test

c)

Confirming spindle motor

speed

Releasing heads from

Actuator lock

Start

d)

Initial on-track and read

out of system information

e)

Execute self-calibration

f)

Drive ready state

(command waiting state)

Figure 4.4 Power-on operation sequence

4.5 Self-calibration

The disk drive occasionally performs self-calibration in order to sense and

calibrate mechanical external forces on the actuator, and VCM torque. This

enables precise seek and read/write operations.

4.5.1 Self-calibration contents

(1) Sensing and compensating for external forces

The actuator suffers from torque due to the FPC forces and winds accompanying

disk revolution. The torque vary with the disk drive and the cylinder where the

head is positioned. To execute stable fast seek operations, external forces are

occasionally sensed.

The firmware of the drive measures and stores the force (value of the actuator

motor drive current) that balances the torque for stopping head stably. This

includes the current offset in the power amplifier circuit and DAC system.

End

4-8 C141-E104-02EN

Page 62

The forces are compensated by adding the measured value to the specified current

value to the power amplifier. This makes the stable servo control.

To compensate torque varying by the cylinder, the disk is divided into 23 areas

from the innermost to the outermost circumference and the compensating value is

measured at the measuring cylinder on each area at factory calibration. The

measured values are stored in the SA cylinder. In the self-calibration, the

compensating value is updated using the value in the SA cylinder.

(2) Compensating open loop gain

Torque constant value of the VCM has a dispersion for each drive, and varies

depending on the cylinder that the head is positioned. To realize the high speed

seek operation, the value that compensates torque constant value change and loop

gain change of the whole servo system due to temperature change is measured and

stored.

For sensing, the firmware mixes the disturbance signal to the position signal at the

state that the head is positioned to any cylinder. The firmware calculates the loop

gain from the position signal and stores the compensation value against to the

target gain as ratio.

4.5 Self-calibration

For compensating, the direction current value to the power amplifier is multiplied

by the compensation value. By this compensation, loop gain becomes constant

value and the stable servo control is realized.

To compensate torque constant value change depending on cylinder, whole

cylinders from most inner to most outer cylinder are divided into 16 partitions at

calibration in the factory, and the compensation data is measured for

representative cylinder of each partition. This measured value is stored in the SA

area. The compensation value at self-calibration is calculated using the value in

the SA area.

4.5.2 Execution timing of self-calibration

Self-calibration is executed when:

• The power is turned on.

• The disk drive receives the RECALIBRATE command from the host.

• The self-calibration execution timechart of the disk drive specifies self-

calibration.

The disk drive performs self-calibration according to the timechart based on the

time elapsed from power-on. The timechart is shown in Table 4.1. After poweron, self-calibration is performed about every five or ten or fifteen minutes for the

first 60 minutes or six RECALIBRATE command executions, and about every 30

minutes after that.

C141-E104-02EN 4-9

Page 63

Theory of Device Operation

Table 4.1 Self-calibrati on execut i on t imechart

1 At power-on Initial calibration

2 About 5 minutes About 5 minutes

3 About 5 minutes About 10 minutes

4 About 10 minutes About 20 minutes

5 About 10 minutes About 30 minutes

6 About 15 minutes About 45 minutes

7 About 15 minutes About 60 minutes

8

.

.

.

.

Time elapsed Time elapsed

(accumulated)

Every about 30

minutes

4.5.3 Command processing during self-calibration

If the disk drive receives a command execution request from the host while

executing self-calibration according to the timechart, the disk drive terminates

self-calibration and starts executing the command precedingly. In other words, if

a disk read or write service is necessary, the disk drive positions the head to the

track requested by the host, reads or writes data, and restarts calibration.

This enables the host to execute the command without waiting for a long time,

even when the disk drive is performing self-calibration. The command execution

wait time is about maximum 40 ms.

4.6 Read/w rite Circuit

The read/write circuit consists of the read/write preamplifier (HDIC), the write

circuit, the read circuit, and the time base generator in the read channel (RDC).

Figure 4.4 is a block diagram of the read/write circuit.

4.6.1 Read/write preamplifier (HDIC)

HDIC equips a read preamplifier and a write current switch, that sets the bias

current to the MR device and the current in writing. Each channel is connected to

each data head, and HDIC switches channel by serial I/O. HDIC generates a write

unsafe signal (WUS) when a write error occurs due to head short-circuits or head

disconnection, that avoids error writing.

4-10 C141-E104-02EN

Page 64

4.6.2 Write circuit

The write data is output from the hard disk controller (HDC) with the NRZ data

format, and sent to the encoder circuit in the RDC. The NRZ write data is

converted from 16-bit data to 17-bit data by the encoder circuit then sent to the

HDIC, and the data is written onto the media.

(1) 16/17 MTR MEEPRML

This device converts data using the 16/17 MTR (Maximum Transitions Run

Length Limited) algorithm.

This code is converted so that a maximum of three 1’s are placed continuously

and so that there are two or fewer 1’s in a 17-bit border.

(2) Write precompensation

Write precompensation compensates, during a write process, for write nonlinearity generated at reading. Table 4.2 shows the write precompensation

algorithm.

4.6 Read/write Circuit

Table 4.2 Write precompensation algorithm

Bits Compensation

111001

111010

:

111111

000000

000001

:

010000

:

100000

–7

–6

–1

±0

+1

+16

+32

C141-E104-02EN 4-11

Page 65

Theory of Device Operation

HDIC

WDX/WDY RDX/RDY

RDC

SD

SC SE

Write

PreCompensation

Serial I/O

Registers

Digital

PLL

Flash

Digitizer

MEEPR

Viterbi

Detect

16/17

ENDEC

AGC

Amplifier

Programmable

Filter

ServoPulse

Detector

Position

A/B/C/D

(to reg)

WTGATE

REFCLK

RDGATE

DATA

RWCLK

SRV_CLK

SRV_OUT[1:0]

[7:0]

Figure 4.5 Read/write circuit bl ock di agram

4-12 C141-E104-02EN

Page 66

4.6.3 Read circuit

The head read signal from the PreAMP is regulated by the automatic gain control

(AGC) circuit. Then the output is converted into the sampled read data pulse by

the programmable filter circuit and the flash digitizer circuit. This clock signal is

converted into the NRZ data by the 16/17 GCR decoder circuit based on the read

data maximum-likelihood-detected by the Viterbi detection circuit, then is sent to

the HDC.

(1) AGC circuit

The AGC circuit automatically regulates the output amplitude to a constant value

even when the input amplitude level fluctuates. The AGC amplifier output is

maintained at a constant level even when the head output fluctuates due to the

head characteristics or outer/inner head positions.

(2) Programmable filter circuit

The programmable filter circuit has a low-pass filter function that eliminates

unnecessary high frequency noise component and a high frequency boost-up

function that equalizes the waveform of the read signal.

4.6 Read/write Circuit

-3 dB

Cut-off frequency of the low-pass filter and boost-up gain are controlled from the

register in read channel by an instruction of the serial data signal from MPU

(M5). The MPU optimizes the cut-off frequency and boost-up gain according to

the transfer frequency of each zone.

Figure 4.6 shows the frequency characteristic sample of the programmable filter.

Figure 4.6 Frequency characteristic of programmable filter

C141-E104-02EN 4-13

Page 67

Theory of Device Operation

(3) Flash digitizer circuit

This circuit is 10-tap sampled analog transversal filter circuit that cosine-equalizes

the head read signal to the Modified Extended Partial Response (MEEPR)

waveform.

(4) Viterbi detection circuit

The sample hold waveform output from the flash digitizer circuit is sent to the

Viterbi detection circuit. The Viterbi detection circuit demodulates data

according to the survivor path sequence.

(5) MEEPRM

This circuit converts the 17-bit read data into the 16-bit NRZ data.

4.6.4 Digital PLL circuit

The drive uses constant density recording to increase total capacity. This is

different from the conventional method of recording data with a fixed data

transfer rate at all data area. In the constant density recording method, data area is

divided into zones by radius and the data transfer rate is set so that the recording

density of the inner cylinder of each zone is nearly constant. The drive divides

data area into 15 zones to set the data transfer rate.

The MPU transfers the data transfer rate setup data (SD/SC) to the RDC that

includes the Digital PLL circuit to change the data transfer rate.

4-14 C141-E104-02EN

Page 68

4.7 Servo Control

The actuator motor and the spindle motor are submitted to servo control. The

actuator motor is controlled for moving and positioning the head to the track

containing the desired data. To turn the disk at a constant velocity, the actuator

motor is controlled according to the servo data that is written on the data side

beforehand.

4.7.1 Servo control circuit

Figure 4.7 is the block diagram of the servo control circuit. The following

describes the functions of the blocks:

(1)

4.6 Read/write Circuit

MPU

(2)

Head

Servo

burst

capture

Position Sense

CSR: Current Sense Resister

VCM: Voice Coil Motor

Figure 4.7 Block diagram of servo control circuit

DSP

unit

(3)

(5)

DAC

Spindle

motor

control

SVC

(4)

Power

Amp

(6)

Driver

(7)

VCM current

CSR

VCM

Spindle

motor

(1) Microprocessor unit (MPU)

The MPU includes the DSP unit, and the MPU starts the spindle motor, moves the

heads to the reference cylinders, seeks the specified cylinder, and executes

calibration according to the internal operations of the MPU. Main internal

operation of the MPU are shown below.

C141-E104-02EN 4-15

Page 69

Theory of Device Operation

The major internal operations are listed below.

a. Spindle motor start

Starts the spindle motor and accelerates it to normal speed when power is

applied.

b. Move head to reference cylinder

Drives the VCM to position the head at the any cylinder in the data area. The

logical initial cylinder is at the outermost circumference (cylinder 0).

c. Seek to specified cylinder

Drives the VCM to position the head to the specified cylinder.

d. Calibration

Senses and stores the thermal offset between heads and the mechanical forces

on the actuator, and stores the calibration value.

4-16 C141-E104-02EN

Page 70

(2) Servo burst capture circuit

The servo burst capture circuit reproduces signals (position signals) that indicate

the head position from the servo data on the data surface. SERVO A, SERVO B,

SERVO C and SERVO D burst signals shown in Figure 4.9 followed the servo

mark, cylinder gray and index information are output from the servo area on the

data surface via the data head. The servo signals do A/D-convert by Fourierdemodulator in the servo burst capture circuit. At that time the AGC circuit is in

hold mode. The A/D converted data is recognized by the MPU as position

information with A-B and C-D processed.

(3) D/A converter (DAC)

The D/A converter (DAC) converts the VCM drive current value (digital value)

calculated by the DSP unit into analog values and transfers them to the power

amplifier.

(4) Power amplifier

The power amplifier feeds currents, corresponding to the DAC output signal

voltage to the VCM.

4.7 Servo Control

(5) Spindle motor control circuit

The spindle motor control circuit controls the sensor-less spindle motor. This

circuit detects number of revolution of the motor by the interrupt generated

periodically, compares with the target revolution speed, then flows the current

into the motor coil according to the differentiation (aberration).

(6) Driver circuit

The driver circuit is a power amplitude circuit that receives signals from the

spindle motor control circuit and feeds currents to the spindle motor.

(7) VCM current sense resistor (CSR)

This resistor controls current at the power amplifier by converting the VCM

current into voltage and feeding back.

C141-E104-02EN 4-17

Page 71

Theory of Device Operation

4.7.2 Data-surface servo format

Figure 4.8 describes the physical layout of the servo frame. The three areas

indicated by (1) to (3) in Figure 4.8 are described below.

(1) Inner guard band

The head is in contact with the disk in this space when the spindle starts turning

or stops, and the rotational speed of the spindle can be controlled on this cylinder

area for head moving.

(2) Data area

This area is used as the user data area SA area.

(3) Outer guard band

This area is located at outer position of the user data area, and the rotational speed

of the spindle can be controlled on this cylinder area for head moving.

4-18 C141-E104-02EN

Page 72

4.7 Servo Control

!"

Servo frame

(66 servo frames per revolution)

CYLn + 1

W/R Recovery

Servo Mark

Gray Code

IGB

CYLn CYLn – 1 (n: even number)

W/R Recovery

Servo Mark

Gray Code

Data area

expand

W/R Recovery

Servo Mark

Gray Code

Erase Servo A Erase Servo A

Servo B Erase Servo B Erase

Servo C Erase Servo C

Erase Servo D Erase

PAD

Figure 4.8 Physical sector servo configuration on disk surface

OGB

Diameter

direction

#

#

Circumference

Direction

Erase: DC erase

area

C141-E104-02EN 4-19

Page 73

Theory of Device Operation

4.7.3 Servo frame format

As the servo information, the IDD uses the two-phase servo generated from the

gray code and servo A to D. This servo information is used for positioning

operation of radius direction and position detection of circumstance direction.

The servo frame consists of 6 blocks; write/read recovery, servo mark, gray code,

servo A to D, and PAD. Figure 4.9 shows the servo frame format.

Figure 4.9 Servo frame format

4-20 C141-E104-02EN

Page 74

(1) Write/read recovery

This area is used to absorb the write/read transient and to stabilize the AGC.

(2) Servo mark

This area generates a timing for demodulating the gray code and positiondemodulating the servo A to D by detecting the servo mark.

(3) Gray code (including index bit)

This area is used as cylinder address. The data in this area is converted into the

binary data by the gray code demodulation circuit

(4) Servo A, servo B, servo C, servo D

This area is used as position signals between tracks and the IDD control at ontrack so that servo A level equals to servo B level.

(5) PAD

4.7 Servo Control

This area is used as a gap between servo and data.

4.7.4 Actuator motor control

The voice coil motor (VCM) is controlled by feeding back the servo data recorded

on the data surface. The MPU fetches the position sense data on the servo frame

at a constant interval of sampling time, executes calculation, and updates the

VCM drive current.

The servo control of the actuator includes the operation to move the head to the

reference cylinder, the seek operation to move the head to the target cylinder to

read or write data, and the track-following operation to position the head onto the

target track.

(1) Operation to move the head to the reference cylinder

The MPU moves the head to the reference cylinder when the power is turned.

The reference cylinder is in the data area.

When power is applied the heads are moved from the inner circumference shunt

zone to the normal servo data zone in the following sequence:

a) Micro current is fed to the VCM to press the head against the inner

circumference.

b) Micro current is fed to the VCM to move the head toward the outer

circumference.

c) When the servo mark is detected the head is moved slowly toward the outer

circumference at a constant speed.

C141-E104-02EN 4-21

Page 75

Theory of Device Operation

d) If the head is stopped at the reference cylinder from there. Track following

control starts.

(2) Seek operation

Upon a data read/write request from the host, the MPU confirms the necessity of

access to the disk. If a read/write instruction is issued, the MPU seeks the desired

track.

The MPU feeds the VCM current via the D/A converter and power amplifier to

move the head. The MPU calculates the difference (speed error) between the

specified target position and the current position for each sampling timing during

head moving. The MPU then feeds the VCM drive current by setting the

calculated result into the D/A converter. The calculation is digitally executed by

the firmware. When the head arrives at the target cylinder, the track is followed.

(3) Track following operation

Except during head movement to the reference cylinder and seek operation under

the spindle rotates in steady speed, the MPU does track following control. To

position the head at the center of a track, the DSP drives the VCM by feeding

micro current. For each sampling time, the VCM drive current is determined by

filtering the position difference between the target position and the position

clarified by the detected position sense data. The filtering includes servo

compensation. These are digitally controlled by the firmware.

4.7.5 Spindle motor control

Hall-less three-phase twelve-pole motor is used for the spindle motor, and the 3phase full/half-wave analog current control circuit is used as the spindle motor

driver (called SVC hereafter). The firmware operates on the MPU manufactured

by Fujitsu. The spindle motor is controlled by sending several signals from the

MPU to the SVC. There are three modes for the spindle control; start mode,

acceleration mode, and stable rotation mode.

(1) Start mode

When power is supplied, the spindle motor is started in the following sequence:

a) After the power is turned on, the MPU sends a signal to the SVC to charge

the charge pump capacitor of the SVC. The charged amount defines the

current that flows in the spindle motor.

b) When the charge pump capacitor is charged enough, the MPU sets the SVC

to the motor start mode. Then, a current (approx. 0.7 A) flows into the

spindle motor.

c) The SVC generates a phase switching signal by itself, and changes the phase

of the current flowed in the motor in the order of (V-phase to U-phase), (Wphase to U-phase), (W-phase to V-phase), (U-phase to V-phase), (U-phase to

W-phase), and (V-phase to W-phase) (after that, repeating this order).

4-22 C141-E104-02EN

Page 76

d) During phase switching, the spindle motor starts rotating in low speed, and

generates a counter electromotive force. The SVC detects this counter

electromotive force and reports to the MPU using a PHASE signal for speed

detection.

e) The MPU is waiting for a PHASE signal. When no phase signal is sent for a

specific period, the MPU resets the SVC and starts from the beginning.

When a PHASE signal is sent, the SVC enters the acceleration mode.

(2) Acceleration mode

In this mode, the MPU stops to send the phase switching signal to the SVC. The

SVC starts a phase switching by itself based on the counter electromotive force.

Then, rotation of the spindle motor accelerates. The MPU calculates a rotational