Page 1

FUJITSU SEMICONDUCTOR

CONTROLLER MANUAL

CM71-10126-2E

FR60

32-BIT MICROCONTROLLER

MB91319 Series

HARDWARE MANUAL

Page 2

Page 3

FR60

32-BIT MICROCONTROLLER

MB91319 Series

HARDWARE MANUAL

FUJITSU LIMITED

Page 4

Page 5

PREFACE

■ Objectives and Intended Reader

The MB91319 is a standard single-chip microcontroller that has a 32-bit high-performance RISC

CPU as well as built-in I/O resources for embedded controller that requires high-performance

and high-speed CPU processing.

The MB91319 is most suitable for embedded applications, such as TV and PDP controllers, that

require a high level of CPU processing power.

The MB91319 is one of the FR60 series of microcontrollers, which are based on the FR30/40

family of CPUs. It has enhanced bus access and is optimized for high-speed use.

This manual is intended for engineers who will develop products using the MB91319 and

describes the functions and operations of the MB91319. Read this manual thoroughly.

For more information on instructions, see the "Instructions Manual".

■ Trademarks

FR, which is an abbreviation of FUJITSU RISC controller, is a product of Fujitsu Limited.

REALOS (Real-time Operating System) is a trademark of FUJITSU LIMITED.

■ License

The names of other systems and products appearing in this manual are the trademarks of their

respective companies or organizations.

Purchase of Fujitsu I

use, these components in an I

Specification as defined by Philips.

2

C components conveys a license under the Philips I2C Patent Rights to

2

C system provided that the system conforms to the I2C Standard

i

Page 6

■ Organization of This Manual

This manual consists of the following 20 chapters and an appendix.

CHAPTER 1 "OVERVIEW"

This chapter provides basic information required to understand the MB91319 series, and

covers features, a block diagram, and functions.

CHAPTER 2 "HANDLING THE DEVICE"

This chapter provides precautions on handling the MB91319 series.

CHAPTER 3 "CPU AND CONTROL UNITS"

This chapter provides basic information required to understand the functions of the MB91319

series. It covers architecture, specifications, and instructions.

CHAPTER 4 "I/O PORT"

This chapter describes the I/O ports and the configuration and functions of registers.

CHAPTER 5 "16-BIT RELOAD TIMER"

This chapter describes the 16-bit reload timer, the configuration and functions of registers,

and 16-bit reload timer operation.

CHAPTER 6 "PROGRAMMABLE PULSE GENERATOR (PPG) TIMER"

This chapter gives an outline of the PPG (Programmable Pulse Generator) timer and

explains the register configuration and functions and the timer operations.

CHAPTER 7 "MULTIFUNCTION TIMER"

This chapter gives an overview of the multifunction timer and explains the register

configuration and functions and the timer operat ion.

CHAPTER 8 "16-BIT PULSE WIDTH COUNTER"

This chapter gives an overview of the 16-bit pulse width counter and explains the register

configuration and functions and the counter operation.

CHAPTER 9 "INTERRUPT CONTROLLER"

This chapter describes the interrupt controller, the configuration and functions of registers,

and interrupt controller operation. It also presents an example of using the hold request

cancellation request function.

CHAPTER 10 "EXTERNAL INTERRUPT AND NMI CONTROLLER"

This chapter describes the external interrupt and NMI controller, the configuration and

functions of registers, and operation of the external interrupt and NMI controller.

CHAPTER 11 "REALOS-RELATED HARDWARE"

This chapter explains the delayed interrupt module and bit search module that are REALOSrelated hardware. REALOS-related hardware is used by the real-time OS. When REALOS is

used, the hardware cannot be used with the user program.

CHAPTER 12 "10-BIT A/D CONVERTER"

This chapter gives an overview of the 10-bit A/D converter, register configuration and

functions, and 10-bit A/D converter oper at ion .

CHAPTER 13 "U-TIMER"

This chapter describes the U-TIMER, the configuration and functions of registers, and UTIMER operation.

ii

Page 7

CHAPTER 14 "UART"

This chapter describes the UART, the configuration and functions of registers, and UART

operation.

CHAPTER 15 "I

This chapter describes the I

2

C INTERFACE"

2

C interface, the configuration and functions of registers, and I2C

interface operation.

CHAPTER 16 "DMA CONTROLLER (DMAC)"

This chapter describes the DMA controller (DMAC), the configuration and functions of

registers, and DMAC operation.

CHAPTER 17 "USB FUNCTION"

This chapter gives an overview of the USB function, register configuration and functions,

operation of the USB function, and supplement ary notes on the USB function.

CHAPTER 18 "OSDC"

This chapter explains the features, block diagram, display function, control function, and

display control command of the on-screen display controller ( OSDC).

CHAPTER 19 "FLASH MEMORY"

This chapter provides an outline of flash memory and explains its register configuration,

register functions, and operations.

CHAPTER 20 "SERIAL PROGRAMMING CONNECTION"

The built-in FLASH product supports the serial onboard writing (Fujitsu standard) of the flash

ROM. The following explains its specification.

APPENDIX

This appendix consists of the following parts: the I/O map, interrupt vector, dot clock

generation PLL, USB clock, external bus interface setting, and instruction lists. The appendix

contains detailed information that could not be included in the main text and reference

material for programming.

iii

Page 8

• The contents of this document are subject to change without notice.

Customers are advised to consult with FUJITSU sales representatives before ordering.

• The information, such as descriptions of function and application circuit examples, in this document are

presented solely for the purpose of reference to show examples of operations and uses of FUJITSU

semiconductor device; FUJITSU does not warrant proper operation of the device with respect to use based

on such information. When you develop equipment incorporating the device based on such information, you

must assume any responsibility arising out of such use of the information. FUJITSU a ssumes no liability for

any damages whatsoever arising out of the use of the information.

• Any information in this document, including descriptions of function and schematic diagrams, shall not be

construed as license of the use or exercise of any intellectual property right, such as patent right or

copyright, or any other right of FUJITSU or any third party or does FUJITSU warrant non-in fringement of any

third-party's intellectual property right or other right by using such information. FUJITSU assumes no liability

for any infringement of the intellectual property rights or othe r rights of third parties which would result fro m

the use of information contained herein.

• The products described in this document are designed, developed and manufactured as contemplated fo r

general use, including without limitation, ordinary industrial use, general office use, personal use, and

household use, but are not designed, developed and manufactured as contemplated (1) for use

accompanying fatal risks or dangers that, unless extremely high safety is secured, could have a serious

effect to the public, and could lead directly to death, personal injury, severe physical damage or other loss

(i.e., nuclear reaction control in nuclear facility, aircraft flight control, air traffic control, mass transport control,

medical life support system, missile launch control in weapon system), or (2) for use requiring extremely high

reliability (i.e., submersible repeater and artificial satellite).

Please note that FUJITSU will not be liable against you and/or any third party for any claims or d amages

arising in connection with above-mentioned uses of the products.

• Any semiconductor devices have an inherent chance of failure. You must protect against injury, damage o r

loss from such failures by incorporating safety design measures into your facility and equipment such as

redundancy, fire protection, and prevention of over-current levels and other abnormal operating conditions.

• If any products described in this document represent goods or technolog ies subject to certain restrictions on

export under the Foreign Exchange and Foreign Trade Law of Japan, the prior authorization by Japa nese

government will be required for export of those products from Japan.

©2006 FUJITSU LIMITED Printed in Japan

iv

Page 9

READING THIS MANUAL

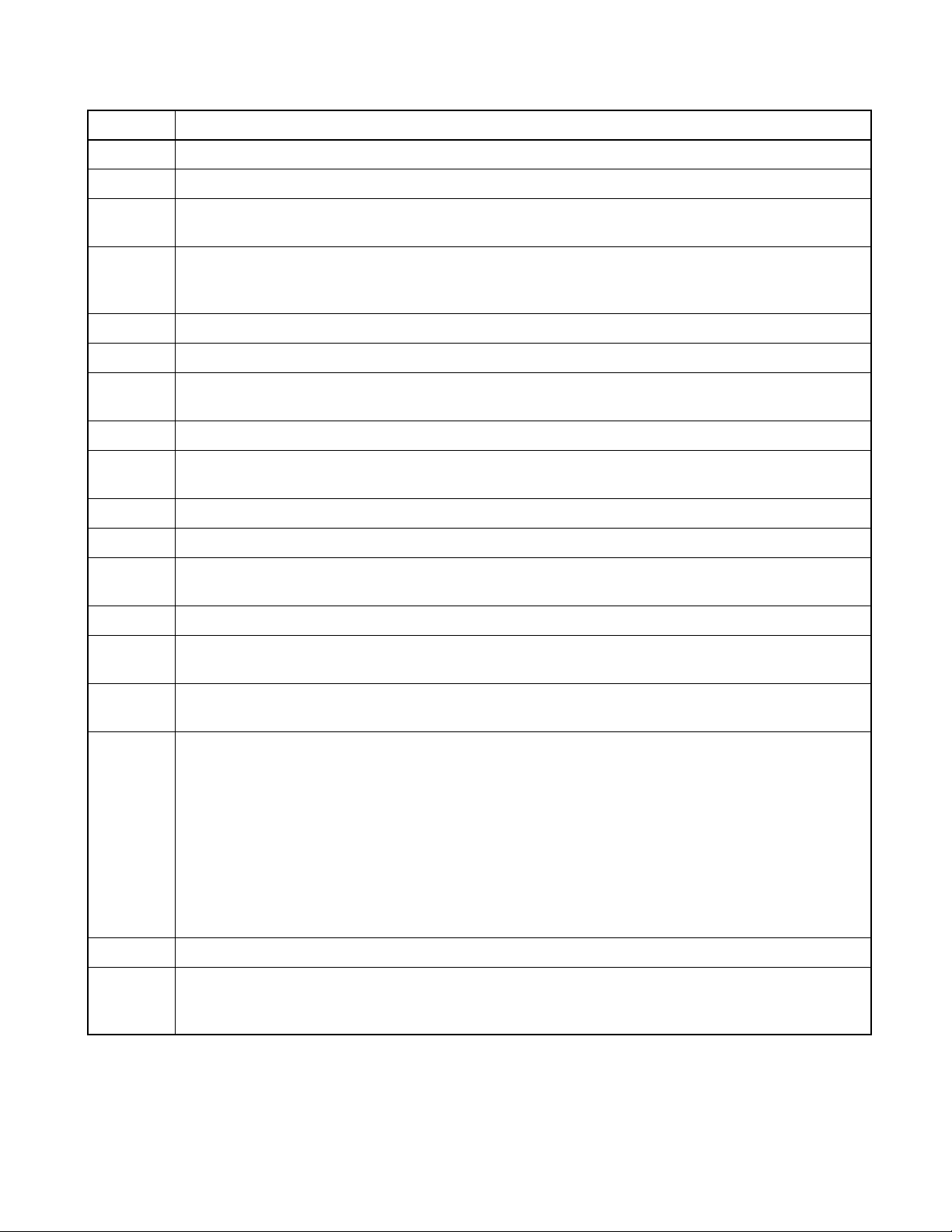

■ Terms Used in This Manual

The following defines principal terms used in this manual.

Term Meaning

32-bit bus for internal instructions. In the FR family, which is based on an

I-bus

D-bus Internal 32-bit data bus. An internal resource is conn ected to the D-bus.

F-bus

internal Harvard architecture, independent buses are used for instructions and

data. A bus converter is connected to the I-bus.

Princeton bus on which internal instructio ns and da ta are multiple xed. Th e F-bu s

is connected via a switch to the I-bus and D-bus. Built-in resources such as

ROM and RAM are connected to the F-bus.

X-bus

R-bus

E-unit Execution unit for operations.

CLKP

CLKB

CLKT

External interface bus. An external interface module is conn ected to the X-bus.

Data and instructions are multiplexed on the external data bus.

Internal 16-bit data bus. The R-bus is connected to the D-bus via an adapter. I/

O, a clock generator, and an interrupt controller are connected to the R-bus.

Since addresses and data are multiplexed on an R-bus that is only 16 bits wide,

more than one cycle is required for the CPU to access these resources.

System clock. Clock generated by the clock generator for each of the internal

resources connected to the R-bus. This clock has the same frequency as the

source oscillation at its maximum, but becomes a 1, 1/2, 1/3, 1/4, 1/5, 1/6, 1/7,...

or 1/16 (or 1/2, 1/4, 1/6, ... or 1/32) frequency clock as determined by the divideby rate specified by the B3 to B0 bits in the clock generator DIV0 register.

System clock. Operating clock for the CPU and each of the other resources

connected to a bus other than the R-bus and X-bus. This clock has the same

frequency as the source oscillation at its maximum, but becomes a 1, 1/2, 1/3, 1/

4, 1/5, 1/6, 1/7, ... or 1/16 (or 1/2, 1/4, 1/6, ... or 1/32) frequency clock as

determined by the divided-by rate specified by the P3 to P0 bits in the clock

generator DIV0 register.

System clock. Operating clock for the external bus interface connected to the Xbus. This clock has the same frequency as the source oscillation at its

maximum, but becomes a 1, 1/2, 1/3, 1/4, 1/5, 1/6, 1/7, ... or 1/16 (or 1/2, 1/4, 1/

6, ... or 1/32) frequency clock as determined by the divide-by rate specified by

the T3 to T0 bits in the clock generator DIV1 register.

v

Page 10

vi

Page 11

CONTENTS

CHAPTER 1 OVERVIEW ................................................................................................... 1

1.1 Featu res ..... ......... .......... .......... .......... ...... .......... ......... .......... .......... ......... .......... ....... ........................... 2

1.2 Block Diagram .................................................................................................................................... 7

1.3 External Dimensions ........................................................................................................................... 8

1.4 Pin Layout ........................................................................................................................................... 9

1.5 List of Pin Fun ctio ns .................. ... .... ... ... ... ....................................... ... ... .... ...................................... 10

1.6 Input-output Circuit Forms ................................................................................................................ 17

CHAPTER 2 HANDLING THE DEVICE .......................................................................... 23

2.1 Precautions on Handling the Device ................................................................................................. 24

CHAPTER 3 CPU AND CONTROL UNITS ..................................................................... 29

3.1 Memo ry Spa ce .............................. .... ... ....................................... ... ... ................................................ 30

3.2 Intern al Arc hite ct ur e ................................ ....................................... ... ... ... .......................................... 31

3.3 Programming Model ......................................................................................................................... 36

3.4 Data Configuration ............................................................................................................................ 43

3.5 Word Alignment ................................................................................................................................ 44

3.6 Memo ry Ma p . ... ... .... ...................................... .... ...................................... .... ... ................................... 45

3.7 Branch Instructions ........................................................................................................................... 46

3.8 EIT (Exception, Interrupt, and Trap) ................................................................................................. 49

3.8.1 EIT Interrupt Levels ..................................... ...................................... .... ... ... ................................ 50

3.8.2 Interrupt Control Unit (ICR) .......................................................................................................... 52

3.8.3 System Stack Pointer (SSP) .................................................................. ... ... ... ............................. 53

3.8.4 Table Base Register (TBR) ......................................................................................................... 54

3.8.5 Multiple EIT Processing ............................................................................................................... 58

3.8.6 EIT Operations ........................ .... ... ... ....................................... ... ................................................ 60

3.9 Opera tin g Mo d es ................................................. ... ... .... ... ... ....................................... ... . .................. 64

3.10 Reset (Device Initialization) .............................................................................................................. 67

3.10.1 Reset Levels ............ ....................................... ... ... .... ...................................... .... ... ...................... 68

3.10.2 Reset Sources ....................................................................... ... ... ... ............................................. 69

3.10.3 Reset Sequence ................................ ... ... ....................................... ... .... ... ................................... 71

3.10.4 Oscillation Stabilization Wait Time .............................................................................................. 72

3.10.5 Reset Operation Modes ........................... .... ... ....................................... ... ................................... 74

3.11 Clock Generation Control ................................. ... ... ... ....................................... ... .... ... ...................... 75

3.11.1 PLL Controls ................................................ ... ... ... ....................................... ... .... ... ...................... 76

3.11.2 Oscillation Stabilization Wait Time and PLL Lock Wait Time ...................................................... 78

3.11.3 Clock Distribution ......................................................................................................................... 80

3.11.4 Clock Division .............................................................................................................................. 82

3.11.5 Block Diagram of Clock Generation Controller ...................................... ... ... ................................ 83

3.11.6 Register of Clock Generation Controller ......................................... ... .... ... ................................... 84

3.11.7 Peripheral Circuits of Clock Controller ....................................................................................... 100

3.12 Device State Control ....................................................................................................................... 104

3.12.1 Device States and State Transitions ......................................................................................... 105

vii

Page 12

3.12.2 Low-power Modes ..................................................................................................................... 110

3.13 Watch Timer ................................................................................................................................... 114

3.14 Main Clock Oscillation Stabilization Wait Timer .............................................................................. 120

CHAPTER 4 I/O PORT .................................................................................................. 127

4.1 Overview of the I/O Port ................................................................................................................. 128

4.2 I/O Port Registers ........................................................................................................................... 130

CHAPTER 5 16-BIT RELOAD TIMER ........................................................................... 137

5.1 Overview of the 16-bit Reload Timer .............................................................................................. 138

5.2 16-bit Re loa d Timer Re gis ter s ...................... .... ... ... ... ....................................... ... .... ... .................... 139

5.2.1 Control Status Register (TMCSR) ............................................................................................. 140

5.2.2 16-bit Timer Register (TMR) ...................................................................................................... 143

5.2.3 16-bit Reload Register (TMRLR) ............................................................................................... 144

5.3 16-bit Re loa d Timer Op e ratio n ............... ... ... .... ... ... ....................................... ... ... .... ....................... 145

CHAPTER 6 PROGRAMMABLE PULSE GENERATOR (PPG) TIMER ...................... 151

6.1 Outline ............................................................................................................................................ 152

6.2 Block Diagram of the PPG Timer .................................................................................................... 153

6.3 Regis te rs of the PPG Timer .................................................... .... ...................................... .............. 155

6.3.1 Control Status Register (PCNH, PCNL) .................................................................................... 156

6.3.2 PPG Cycle Setting Register (PCSR) ......................................................................................... 159

6.3.3 PPG Duty Setting Register (PDUT) ........................................................................................... 160

6.3.4 PPG Timer Register (PTMR) ..................................................................................................... 161

6.4 PWM Mode ..................................................................................................................................... 162

6.5 One-shot Mode ............................................................................................................................... 164

6.6 Interr upts ....... ............. ............. ............. ............. ............. ......... ............. ............. .............................. 166

6.7 PPG Output of ALL-L and ALL-H .................................................................................................... 167

6.8 Precautions on Using the PPG Timer ............................................................................................. 168

CHAPTER 7 MULTIFUNCTION TIMER ........................................................................ 169

7.1 Overview of the Multifunction Timer ............................................................................................... 170

7.2 Regis te rs of the Multifunction Timer ............. .... ...................................... .... ... ... .............................. 172

7.2.1 Low-Pass Filter Control Register (TxLPCR) .............................................................................. 173

7.2.2 Capture Control Register (TxCCR) ............................................................................................ 174

7.2.3 Timer Setting Register (TxTCR) ................................................................................................ 176

7.2.4 Entire Timer Control Register (TxR) ............ ...................................... .... ... ... .............................. 178

7.2.5 Timer Compare Data Register (TxDRR) ................................................................................... 179

7.2.6 Capture Data Register (TxCRR) ................................................................................................ 180

7.2.7 Test Mode Register (TMODE) ................................................................................................... 181

7.2.8 Used Bit Description for Each Mode .......................................................................................... 182

7.3 Multifunction Timer Operation ......................................................................................................... 184

CHAPTER 8 16-BIT PULSE WIDTH COUNTER .......................................................... 189

8.1 Overview of the 16-Bit Pulse Width Counter .................................................................................. 190

8.2 Registers of the 16-Bit Pulse Width Counter .................................................................................. 191

8.2.1 PWC Control Register (PWCCL) ............................................................................................... 192

viii

Page 13

8.2.2 PWC Control Register (PWCCH) .............................................................................................. 194

8.2.3 PWC Data Register (PWCD) ..................................................................................................... 196

8.2.4 PWC Control Register 2 (PWCC2) ............................................................................................ 197

8.2.5 Upper Value Setting Register (PWCUD) ................................................................................... 198

8.3 Operation of the 16-Bit Pulse Width Counter .................................................................................. 199

CHAPTER 9 INTERRUPT CONTROLLER ................................................................... 203

9.1 Overview of the Interrupt Controller ................................................................................................ 204

9.2 Interr up t Con tr oller Re gisters ..................... ... .... ... ....................................... ... ... ... ........................... 206

9.2.1 Interrupt Control Register (ICR) ................................................................................................. 208

9.2.2 Hold Request Cancellation Request Level Setting Register (HRCL) ........................................ 210

9.3 Interr up t Con tr oller Op e ra tio n ....................... .... ... ... ....................................... ... ... .... ....................... 211

9.4 Example of Using the Hold Request Cancellation Request Function (HRCR) ............................... 214

CHAPTER 10 EXTERNAL INTERRUPT AND NMI CONTROLLER ............................... 217

10.1 Overview of the External Interrupt and NMI Controller ................................................................... 218

10.2 External Interrupt and NMI Controller Registers ............................................................................. 219

10.2.1 Interrupt Enable Register (ENIR) ............. .... ... ... ... .... ...................................... .... ....................... 220

10.2.2 External Interrupt Source Register (EIRR) ................................................................................ 221

10.2.3 External Interrupt Request Level Setting Register (ELVR) ........................................................ 222

10.3 Operation of the External Interrupt and NMI Con tr oller .................................................................. 223

CHAPTER 11 REALOS-RELATED HARDWARE .......................................................... 227

11.1 Delayed Interrupt Module ............................................................................................................... 228

11.2 Delayed Interrupt Module Registers ............................................................................................... 229

11.3 Operation of the Delayed Interrupt Module ............................. .... ... ... ....................................... ....... 230

11.4 Bit Search Module ............................................ ...................................... .... ... ... .............................. 231

11.5 Bit Search Module Registers ........ .... ... ... ....................................... ... ... ... ........................................ 232

11.6 Bit Search Module Operation ........ .... ...................................... .... ... ... ................................... ........... 235

CHAPTER 12 10-BIT A/D CONVERTER ........................................................................ 239

12.1 Overview of the 10-Bit A/D Converter ............................................................................................. 240

12.2 Registers of the 10-Bit A/D Converter ............................................................................................ 241

12.2.1 A/DC Control Register (ADCTH, ADCTL) ................................................................................. 242

12.2.2 Software Conversion Analog Input Select Register ................................................................... 244

12.2.3 A/D Conversion Result Register (Channels 0 to 9) ................................................................... 245

12.2.4 A/D Converter Test Register ..................................................................................................... 246

12.3 Operation of the 10-Bit A/D Converter ............................................................................................ 247

CHAPTER 13 U-TIMER ................................................................................................... 249

13.1 Overview .......................... ....................................... .......................................... .............................. 250

13.2 U-TIMER Registers ......................................................................................................................... 251

13.3 U-TIMER Operation ........................................................................................................................ 254

CHAPTER 14 UART ........................................................................................................ 255

14.1 Overview of the UART .................................................................................................................... 256

14.2 UART Registers ...................... ... ... .... ... ....................................... ... ... ... ........................................... 258

ix

Page 14

14.2.1 Serial Mode Register (SMR) ...................................................................................................... 259

14.2.2 Serial Control Register (SCR) ................................................................................................... 261

14.2.3 Serial Input Data Register (SIDR)/Serial Output Data Register (SODR) ................................... 264

14.2.4 Serial Status Register (SSR) ..................................................................................................... 265

14.2.5 UART Operation ........................................................................................................................ 269

14.2.6 Asynchronous (Start-stop Synchroniz at ion ) Mod e ................................................................... . 271

14.2.7 Clock Synchronous Mode .......................................................................................................... 272

14.2.8 Occurrence of Interrupts and Timing for Setting Flags .............................................................. 274

14.3 Example of Using the UART ........................................................................................................... 277

14.4 Example of Setting U-TIMER Baud Rates and Reload Values ...................................................... 279

CHAPTER 15 I2C INTERFACE ....................................................................................... 281

15.1 Overview of the I2C Interface .......................................................................................................... 282

15.2 I

15.3 I

15.4 Operation Flowcharts .... ... .... ... ... ... ....................................... ... ....................................... . ................ 315

2

C Interface Registers ................................................................................................................... 287

15.2.1 Bus Status Register (IBSR) ....................................................................................................... 289

15.2.2 Bus Control Register (IBCR) ..................................................................................................... 292

15.2.3 Clock Control Register (ICCR) .................................................................................................. 298

15.2.4 10-bit Slave Address Register (ITBA) ........................................................................................ 300

15.2.5 10-bit Slave Address Mask Register (ITMK) ............................................................................. 301

15.2.6 7-bit Slave Address Register (ISBA) ......................................................................................... 303

15.2.7 7-bit Slave Address Mask Register (ISMK) ............................................................................... 304

15.2.8 Data Register (IDAR) ................................................................................................................. 305

15.2.9 Clock Disable Register (IDBL) ................................................................................................... 306

2

C Interface Operation ................................................................................................................... 310

CHAPTER 16 DMA CONTROLLER (DMAC) .................................................................. 319

16.1 Overview of the DMA Controller (DMAC) ....................................................................................... 320

16.2 DMA Controller (DMAC) Registers ................................................................................................. 322

16.2.1 Control/Status Registers A (DMACA0 to DMACA4) .................................................................. 324

16.2.2 Control/Status Registers B (DMACB0 to DMACB4) .................................................................. 329

16.2.3 Transfer Source/Transfer Destination Address Setting Registers

(DMASA0 to 4/DMADA0 to 4) ................................................................................................... 336

16.2.4 All-Channel Control Register (DMACR) .................................................................................... 338

16.2.5 Other Functions ......................................................................................................................... 340

16.3 DMA Controller Operation .............................................................................................................. 341

16.3.1 Setting a Transfer Request ........................................................................................................ 344

16.3.2 Transfer Sequence ................................................................ ... ... .............................................. 346

16.3.3 General Aspects of DMA Transfer ............................................................................................. 351

16.3.4 Addressing Mode .. ... ....................................... ... ... .... ...................................... .... ... ... ... .............. 353

16.3.5 Data Types ................................................................................................................................ 354

16.3.6 Transfer Count Control ......................... ... .... ...................................... .... ... ... .............................. 355

16.3.7 CPU Control .............................................................................................................................. 356

16.3.8 Hold Arbitration .......................................................................................................................... 357

16.3.9 Operation from Starting to End/Stopping ................................................................................... 358

16.3.10 DMAC Interrupt Control ..................... ... ... ....................................... ... ........................................ 362

16.3.11 Channel Selection and Control .................................................................................................. 363

x

Page 15

16.3.12 Supplement on External Pin and Internal Operation Timing ..................................................... 365

16.4 Operation Flowcharts .... ... .... ... ... ... ....................................... ... ....................................... . ................ 370

16.5 Data Bus ......................................................................................................................................... 373

CHAPTER 17 USB FUNCTION ....................................................................................... 377

17.1 Overview of the USB Function ........................................................................................................ 378

17.2 USB Interface Registers ............ ....................................... ... ... .... .................................................... 381

17.2.1 Data Transmission Registers (for End Points) .......................................................................... 384

17.2.2 Status Registers ....................................................... ... ... ... ....................................... ................. 387

17.2.3 Control Registers ....................................................................................................................... 394

17.3 Operation of the USB Function ............... ....................................... ... ... ... ........................................ 409

17.3.1 Flow of Data Transfer ................................................................................................................ 410

17.3.2 CPU Access Operation .............................................................................................................. 416

17.3.3 Interrupt Sources ............................................................... .... .................................... ................ 423

17.3.4 Setting of End Point Buffer ........................................................................................................ 424

17.3.5 Examples of Software Control ..................... ...................................... .... ... ... .............................. 426

17.4 Supplementary Notes on the USB Function ................................................................................... 435

17.4.1 Double Buffer ............................................................................................................................. 436

17.4.2 Controlling the D+ Terminating Resistor on the Board .............................................................. 441

17.4.3 Automatic Response of Macro Program to USB Standard Requ e st Com m a nd s ...................... 442

17.4.4 USB Function Macro Program Operation in the Default Status ................................................ 444

17.4.5 USB Clock Control in the Suspended Status ........... ... ... ... .... ... ...................................... .... ... ... . 445

17.4.6 Detection of USB Connector Connection and Disconnection .................................................... 446

17.4.7 Accuracy of UCLK48 ................................................................................................................. 447

17.4.8 Setting of Transfer Enable bit (BFOK) during Control Transfer ................................................. 448

17.4.9 Precautions for Control Transfer ............................................................................................... 449

17.4.10 Macro Program Status after USB Bus Reset ............................................................................ 451

CHAPTER 18 OSDC ........................................................................................................ 453

18.1 ON-SCREEN DISPLAY CONTROLLER (OSDC) ................................... ........................................ 454

18.1.1 Features .................................................................................................................................... 455

18.1.2 Block Diagram ... ... ... ... .... ... ....................................... ... ... ... ....................................... ................. 457

18.2 Display Functions ........................................................................................................................... 458

18.2.1 Screen Configuration ................................................................................................................. 459

18.2.2 Screen Display Modes ............................................................................................................... 462

18.2.3 Screen Output Control ............................................................................................................... 464

18.2.4 Screen Display Position Control ................................................................................................ 465

18.2.5 Font Memory Configuration ......................................................... ... ... .... .................................... 475

18.2.6 Display Memory (VRAM) Configuration ..................................................................................... 476

18.2.7 Writing to Display Memory (VRAM) ........................................................................................... 477

18.2.8 Palette Configuration ................................................................................................................. 480

18.2.9 Character Display ........................... ... ... ....................................... ... ........................................... 481

18.2.10 Character Background Display ................................................................................. ... .............. 515

18.2.11 Line Background Display ........................................................................................................... 524

18.2.12 Screen Background Display ...................................................................................................... 533

18.2.13 Sprite Character Display .......................... ....................................... ... .... ... ................................. 538

18.3 Control Functions ............................................................................................................................ 542

xi

Page 16

18.3.1 Dot Clock Control ........................... ....................................... ... ... ... ........................................... 543

18.3.2 Sync Signal Input .. ... ....................................... ... ....................................... ... .............................. 548

18.3.3 Display Signal Output ................................................................................................................ 556

18.3.4 Display Period Control ............................................................................................................... 559

18.3.5 Synchronization Control ............................................................................................................ 561

18.3.6 Interrupt Control ................................. ... ....................................... ... ... ........................................ 564

18.3.7 OSDC Operation Control ....................................................... ...................................... ... ........... 567

18.4 Display Control Commands ............................................................................................................ 569

18.4.1 List of Display Control Commands ............................................................................................ 570

18.4.2 VRAM Write Address Set (Command 0) ................................................................................... 572

18.4.3 Character Data Set (Commands 1 and 2) ................................................................................. 573

18.4.4 Line Control Data Set (Commands 3 and 4) ............................................................................. 575

18.4.5 Screen Output Control (Commands 5-00 and 5-1) .................................................................... 577

18.4.6 Display Position Control (Commands 5-2 and 5-3) ................................................................... 579

18.4.7 Character Vertical Size Control (Command 6-0) ....................................................................... 580

18.4.8 Shaded Background Frame Color Control (Command 6-1) ...................................................... 581

18.4.9 Transparent/Translucent Color Control (Command 6-2) ........................................................... 582

18.4.10 Graphic Color Control (Command 6-3) ...................................................................................... 583

18.4.11 Screen Background Character Control (Commands 7-1 and 7-3) ............................................ 585

18.4.12 Sprite Character Control (Commands 8-1, 8-2, 9-0 and 9-1) .................................................... 587

18.4.13 Synchronization Control (Command 11-0 ) ..................................................................... .... ... ... . 590

18.4.14 I/O Pin Control (Commands 13-0 and 13-1) .............................................................................. 591

18.4.15 Display Period Control (Commands 14-0 to 14-3) ..................................................................... 593

18.4.16 Interrupt Control (Command 15-0) ............................................................................................ 596

18.4.17 Palette Control (Commands 16-0 to 16-15) ............................................................................... 597

18.4.18 OSDC Operation Control (Commands 17-0 an d 17 -1 ) ............. ... ... ....................................... ... . 599

18.4.19 PLLA Clock Control (Commands 18-0 to 18-3) ......................................................................... 601

18.4.20 PLLB Clock Control (Commands 18-4 to 18-7) ......................................................................... 603

18.4.21 PLLC Clock Control (Commands 18-8 to 18-11) ....................................................................... 605

18.4.22 Clock Selection Control (Commands 18-12 to 18-13) ............................................................... 607

18.5 Display Control Command (CC) ..................................................................................................... 609

18.5.1 CC Screen and Display Control Command List ........................................................................ 610

18.5.2 VRAM Write Address Setting (Command 0) .. ... ... .... ... ... ....................................... ... ... ... ........... 611

18.5.3 Character Data Setting (Command 1, Comman d 2) ...................................... .... ... ... ................. 612

18.5.4 Line Control Data Setting (Command 3, Command 4) .............................................................. 614

18.5.5 Display Output Control (Command 5-00, Command 5-1) ......................................................... 616

18.5.6 Display Position Control (Command 5-2, Command 5-3) ......................................................... 618

18.5.7 Character Vertical Size Control (Command 6-0) ....................................................................... 619

18.5.8 Transparent Color Control (Command 6-2) ............................................................................... 620

18.5.9 Display Period Control (Command 14-0, 14-1, 14-2, 14-3) ....................................................... 621

18.5.10 Interrupt Control (Command 15-0) ............................................................................................ 623

18.5.11 Palette Control (Command 16-0 to Command 16-15) ............................................................... 624

18.6 FONT RAM Interface ........................................... ... ... .... ...................................... .... ....................... 625

CHAPTER 19 FLASH MEMORY ..................................................................................... 629

19.1 Outline of Flash Memory ................................................................................................................. 630

19.2 Flash Memory Registers ................................................................................................................. 637

xii

Page 17

19.2.1 Flash Control/Status Register (FLCR) ....................................................................................... 638

19.2.2 Flash Memory Wait Register (FLWC) ................... ....................................... ... .... ... .................... 640

19.3 Flash Memory Access Modes ......................................................................................................... 642

19.4 Automatic Algorithm of Flash Memory ........................................... ... ... ... ........................................ 644

19.5 Execution Status of the Automatic Algorithm .................................................................................. 648

19.6 Writing to and Erasing from Flash Memory .................................................................................... 653

19.6.1 Read/Reset Status .................................................................................................................... 654

19.6.2 Data Writing ............................................................................................................................... 655

19.6.3 Data Erasure (Chip Erasure) ..................................................................................................... 657

19.6.4 Data Erasure (Sector Erasure) .................................................................................................. 658

19.6.5 Temporary Sector Erase Stop ..................... ... ... ... .... ... ....................................... ... ... ... .............. 660

19.6.6 Sector Erase Restart ................................................................................................................. 661

CHAPTER 20 SERIAL PROGRAMMING CONNECTION .............................................. 663

20.1 Serial Programming Connection ..................................................................................................... 664

APPENDIX ......................................................................................................................... 669

APPENDIX A I/O Map ................................................................................................................................ 670

APPENDIX B Interrupt Vector .................................................................................................................... 685

APPENDIX C Dot Clock Generation PLL ................................................................................................... 688

APPENDIX D USB Clock ........................................................................... ................................................. 690

APPENDIX E Macro Reset ......................................................................................................................... 691

APPENDIX F USB Low-power Consumption Mode ................................................................................... 692

APPENDIX G External Bus Interface Setting ............................................................................................. 693

APPENDIX H Pin State List ...................................................................................................... .................. 695

APPENDIX I Instruction Lists .................................................................................................................... 699

I.1 How to Read the Instruction Lists .................................................................................................. 700

I.2 FR Family Instruction Lists ............................................................................................................. 704

INDEX...................................................................................................................................721

xiii

Page 18

xiv xv

Page 19

Main changes in this edition

Page Changes (For details, refer to main body.)

Change pin names

-

(TO0 → TOUT0)

(TO1 → TOUT1)

(TO2 → TOUT2)

24

26

27

27

28

3

4

6

6

Change ■ Built-in RAM (MASK: Add 32KB RAM)

Change ■ A/D Converter (conversion time: about 10 µs → conversion ti me: about 8.5 µs)

Change CMOS technology of ■ Other Features

Change Supply voltage of ■ Other Features

Change the Figure 1.2-1 Block Diagram

(Add DSU)

7

(Add MASK 512KB to Flash 1MB)

(Add MASK 32KB to RAM)

(PWC 1ch → PWC 4ch)

(Add Font ROM product)

Change Figure 1.4-1 Pin Layout of the MB91319

9

(MB91F318A → MB91F318A/S)

(MB91FV319A

(Change the Note)

→ MB91FV319A/R)

Add a sentence to ■ Quartz Oscillation Circuit

Change Low Power Consumption Mode of ■ Lim itations

Change Note on using A/D

Add About Software Reset of Synchronous Mode

Change ❍ Unique characteristic of the evaluation chip MB91FV319A

(MB91FV319A → MB91FV319A/R)

30

70

70

74

81

83

85

87

90

Change Figure 3.1-1 Memory Map

(MB91F318 → MB91F318A/S and MB91FV319R)

(MB91F318, MB91316

→ MB91F318A/S, MB91316)

Add Reference: to ■ Software Reset (STCR: SRST Bit Writing)

Change ■ Watchdog Reset (watchdog reset postpone register (WPR) → time base counter clear

register (CTBR))

Add Reference: to ■ Synchronous Reset Operation

Add items to Notes: for ■ External Bus Clock (CLKT)

Change Figure 3.11-1 Block Diagram of Clock Generation Controller

(Delete WPR register)

Change [bit9, bit8] WT1, WT0 (Watchdog interval Time select) (WPR → CTBR)

Add Reference: to [bit4] SRST (Software ReSeT)

Add Note: to [bit9] SYNCR (SYNChronous Reset enable)

Page 20

Page Changes (For details, refer to main body.)

90

91

94

100

106

111

130

131

137 to 150

180

182

240

240

241

Add Note: to [bit8] SYNCS (SYNChronous Standby enable)

Change ■ Time Base Counter Clear Register (CTBR)

Delete ■ Watchdog Reset Post pone Register (WPR)

Change [P ostponing a watchdog reset] (watchdog reset postpone register (WPR)

→ time base counter clear register (CTBR))

Change Figure 3.12-1 Transition of Device States

Delete [Normal and synchronous standby operations]

Change Figure 4.2-1 Configuration of the Port Data Registers (PDR) (P75 → − )

Change Figure 4.2-2 Configuration of the Data Direction Registers (DDR) (P75 → − )

Replace the entire chapter CHAPTER 5 16-BIT RELOAD TIMER

Change ■ Capture Data Register (TxCRR)

Add 7.2.8 Used Bit Description for Each Mode

Change ■ Features of the 10-Bit A/D Converter

Change Figure 12.1-2 Block Diagram of the 10-Bit A/D Converter

(Add AN9)

(Add AN8)

Change Figure 12.2-1 Register Configuration of the 10-Bit A/D Converter

244

244

247

254

254

256

258

269

276

293

353

362

365

Change the bit9 and bit8 of Figure 12.2-3 Bit Configuration of the Software Conversion Analog

Input Select Register

("0" → i9)

(

"0" → i8)

Change the [bit9 to bit0] i9 to i0 (i7 to i0 → i9 to i0)

Change ■ A/D Conversion Started by External Trigger

Change ❍ Asynchronous (start-stop synchronization) mode

Change ❍ CLK synchronous mode

Change the ■ Features (Delete "The DMAC interrupt source is cleared if the DRCL register is

written to.")

Change Figure 14.2-1 UART Registers (Delete DMA req uest clear register (DRCL))

Delete DRCL Register description

Change ■ Precautions on Usage (Delete "Write to the DRCL register befor e starting DMA transfer

due to an interrupt for the first time.")

Add a sentence to Note:

Change the second bullet under the ■ Address Register Specifications

Change ■ DMA Transfer during Sleep

Change ■ Timing to Stop a Demand Transfer Request and Timing to Inv alidate the DREQ Pin Inpu t

366

Change Figure 16.3-6 Example of the Timing for Negating the DREQ Pin Input for 2-Cycle Transfer

from an External Circuit to an Internal Circuit

xvi

Page 21

Page Changes (For details, refer to main body.)

366

367

367

456

546

632

633

634

635

636

644

644

Change • For transfer from internal to external circuits:

Change ❍ For fly-by transfer

Change Figure 16.3-7 Example of the Timing for Negating the DREQ Pin Input for Fly-by (Timing to

IORD Pin) Transfer

Change ❍ Interrupt functions (MAIN is connected to the exter n al int er rupt ch5, cc is connected to

the external interrupt ch6) (Add "MAIN is connected to the external interrupt ch5, cc is connected to

the external interrupt ch6" )

Change Table 18.3-5 Oscillating VCO Selection Control

Change Figure 19.1-2 Memory Mapping for Access in Flash Memory Mode/CPU Mode

Change the title of Figure 19.1-3 Sect or Configuration in CPU Mode (MB91FV319A, MB91F318 A)

(add (MB91FV319A, MB91F318A))

Add Figure 19.1-4 Sector Configuration in CPU Mode (MB91F318S, MB91FV319R)

Change the title of Figure 19.1-5 Sector Configuration in FLASH Mode (MB91FV319A,

MB91F318A) (add (MB91FV319A, MB91F318A))

Add Figure 19.1-6 Sector Configuration in FLASH Mode (MB91F318S, MB91FV319R)

Change ■ Basic Configuration of Serial Programming Connection

Change the title of Table 19.4-1 Command Sequence (MB91FV319A, MB91F318A) (add

(MB91FV319A, MB91F318A))

644

665

666

671 to 679

688

689

Add Table 19.4-2 Command Sequence (MB91F318S, MB91FV319R)

Change Notes: (MB91FV319A Write control pin → MB91FV319A/R MB91F318A/S Write control

pin)

Change Figure 20.1-1 Example of Serial Programming Connection

(MB91FV319A → MB91FV319A/R, MB91F318A/S)

Change the Table A-1 I/O Map

(DRCL0 [W] -------- → DRCL0 --------*3)

(DRCL1 [W] -------- → DRCL1 --------*3)

(DRCL2 [W] -------- → DRCL2 --------*3)

(DRCL3 [W] -------- → DRCL3 --------*3)

(Change 000160

to 00017CH and 000180H to 00019CH to "Reserved")

H

(WPR [W] XXXXXXXX → WPR --------*3)

(Delete Address 007100

(Delete Address 007104

line)

H

line)

H

(Add *3: Reserved register. Access is disabled.)

Change Figure C-1 CP0 Pin Connection

Change the table and add a table

(Table C-2 0.25 µm: EVA, FLASH)

(Table C-3 0.18 µm: EVA, FLASH, MASK)

xvii

Page 22

xviii

Page 23

CHAPTER 1

OVERVIEW

This chapter provides basic inf ormation required to

understand the MB91319 series, and covers features, a

block diagram, and functions.

1.1 Features

1.2 Block Diagram

1.3 External Dimensions

1.4 Pin Layout

1.5 List of Pin Functions

1.6 Input-output Circuit Forms

1

Page 24

CHAPTER 1 OVERVIEW

1.1 Features

The FR family is a single-chip microcontroller that has a 32-bit high-performance RISC

CPU as well as built-in I/O resources for embedded controllers requiring highperformance and high-speed CPU processing.

The FR family is the most suitable for embedded applications, for example, TV and PDP

control, that require a high level of CPU processing performance.

This model is an FR60 series model that is based on the FR30/40-family of CPUs. It has

enhanced bus access and is optimized for high-speed use.

■ FR CPU

• 32-bit RISC, load/store architecture, five stages pipeline

• Operating frequency of 40 MHz [PLL used, original oscillation at 10 MHz]

• 16-bit fixed-length instructions (basic instructions), one instruction per cycle

• Memory-to-memory transfer, bit processing, instructions including barrel shift, etc.:

instructions appropriate for embedded applications

• Function entry and exit instructions, multi load/store instructions:

instructions compatible with high-level languages

• Register interlock function to facilitate assembly-language coding

• Built-in multiplier/instruction-level support

• Signed 32-bit multiplication: 5 cycles

• Signed 16-bit multiplication: 3 cycles

• Interrupts (saving of PC and PS): 6 cycles, 16 priority levels

• Harvard architecture enabling simultaneous execution of both program access and data

access

• 4-word queues in the CPU provided to add an instruction prefetch function

• Instructions compat ible with the FR family

■ Bus Interface

2

This bus interface is used for macro connections (USB and OSDC).

• Maximum operating fre quency of 20 MHz

• 16-bit data inpu t-output (interface with USB and OSDC)

• Totally independent 8-area chip select outputs that can be defined in the minimum units of

64K bytes

The CS1

•CS1

•CS2

•CS3

• Basic bus cycle (2 cycles)

, CS2, and CS3 areas are reserved as shown below.

area: Reserved

area: USB function

area: OSDC

Page 25

• Automatic wait cycle generator that can be programmed for each area and can insert waits

because CS1

■ Built-in RAM

• EVA: 64KB RAM, FLASH: 48KB RAM, MASK: 32KB RAM

• This RAM can be used as data RAM and instruction RAM if instruction codes are written to it.

■ DMAC (DMA Controller)

• 5 channels (channels 0 and 1 are connected to the USB function.)

• 3 transfer sources (internal peri pherals, software)

• Addressing mode with 32-b it full address specifications (increase, decrease, fixed)

• Transfer modes (deman d transfer, burst transfer, step transf er, block transfer)

• Transfer data size that can be selected from 8, 16, and 32 bits

■ Bit Search Module (Used by REALOS)

• Searches for the position of the first bit varying between 1 and 0 in the MSB of a word

, CS2, and CS3 are reserved, the setting is fixed.

CHAPTER 1 OVERVIEW

■ Reload Timer (Including One Channel for REALOS)

• 16-bit timer; 3 channels

• Internal clock that can be selected from those resulting from frequency divided by 2, 8, and 32

■ UART

• Full-duplex double buffer

• 5 channels

• Parity or no parity can be selected.

• Either asynchronous (start-stop synchronization) or CLK synchronous communication can be

selected.

• Built-in timer for dedicated baud rates

• An external clock can be used as the transfer clock.

• Plentiful error detection functions (parity, frame, overrun)

3

Page 26

CHAPTER 1 OVERVIEW

2

C Interface

■ I

• 4 channels (channel 3 can b e used for two ports.)

• Master/slave transmission and reception

• Clock synchronization function

• Transfer direction detection function

• Bus error detection function

• Supports standard mode (Max. 100 Kbps) and high-speed mode (Max, 400 Kbps).

• Arbitration function

• Slave address/general call address detection function

• Start condition repetitious occurrence and detection function

• 10-bit/7-bit slave address

• Built-in FIFO function: each 16-byte sending/receiving

■ Interrupt Controller

• Total of 5 external interrupts (one unmas kable pin (NMI

• Interrupts from internal peripherals

• Priority level can be defined as programmable (16 levels) except for the unmaskable pin

• Can be used for wake-up during stop.

■ A/D Converter

• 10-bit resolution, 10 channels

• Sequential comparison and conversion type (conversion time: about 8.5 µs)

• Conversion modes (single conversion mode and scan conversion mode)

• Causes of startup (software and external triggers)

■ PPG

• 4 channels

• 16-bit data register with 16-bit down counter and cycle setting buffer

• Internal clock: Frequency-divide-by number selectable from 1, 4, 16, and 64

■ PWC

• 1 channel (1 input)

) and four regular interrupt pins (INT3

to INT0))

• 16-bit up counter

• Simple LFP digital filter

4

Page 27

■ Multifunction Timer

• Low-pass filter that removes noise that is below the frequency of the set clock

• Pulse width measurement that can be performed by precise settings using seven types of

clock signals

• Event count for signals from pin input

• Interval timer using seven types of clocks and external input clocks

■ USB Function

• USB2.0 full-speed, double buffer

• CONTROL IN/OUT, BULK IN/OUT, and INTERRUPT IN

■ OSDC Function

• 3 bits per color - Red, Green and Blue (of 512 colors, 16 can be displayed)

• Analog RGB output maximum 50 MHz

• Digital RGB output maximum 90 MHz

• Display 24 × 32 dots font can be displayed as maximu m 80 × 32

CHAPTER 1 OVERVIEW

• MAIN/CC two-layer display (font is fixed at 18 dots wide for the CC layer)

• Maximum 4096 character types (font RAM: 16 characters)

■ Closed Caption Decoder Function

• 2 channels available

• CC decode function

• ID-1 (480i/4 80p) decode function

■ Video Clock PLL

• PLLs available to gene rate dot clock and VBI clock

■ Other Interval Timers

• 16-bit timer: 3 channels (U-TIMER)

• Watchdog timer

■ I/O Ports

• Maximum of 88 ports

5

Page 28

CHAPTER 1 OVERVIEW

■ Other Features

• Has a built-in oscillation circuit as a clock source.

•INIT

is provided as a reset pin.

• Additionally, a watchdog timer reset and software resets are provided.

• Stop mode and sleep mode supported as low-power modes

• Gear function

• Built-in time base timer

• Package: LQFP-176, 0. 5 mm pitch, and 24 mm × 24 mm

• CMOS technology: 0.25 µm (EVA(MB91FV319A), FLASH (MB91F318A))

0.18 µm (MASK(MB91316), EVA(MB91FV319R), FLASH (MB91F318S))

• Supply voltage: two sources of 3.3 V (-0.3 V to +0.3 V) and 2.5 V (-0.2 V to +0.2 V)

(0.25 µm : EVA(MB91FV319A), FLASH (MB91F318A))

two sources of 3.3 V (-0.3 V to +0.3 V) and 1.8 V (-0.15 V to +0.15 V)

(0.18 µm : MASK(MB91316), EVA(MB91FV319R), FLASH (MB91F318S))

2

THE I

C LICENSE:

2

Purchase of Fujitsu I

C components conveys a license under the Philips I2C Patent Rights to

use, these components in an I

2

C system provided that the system conforms to the I2C

Standard Specification as defined by Philips.

6

Page 29

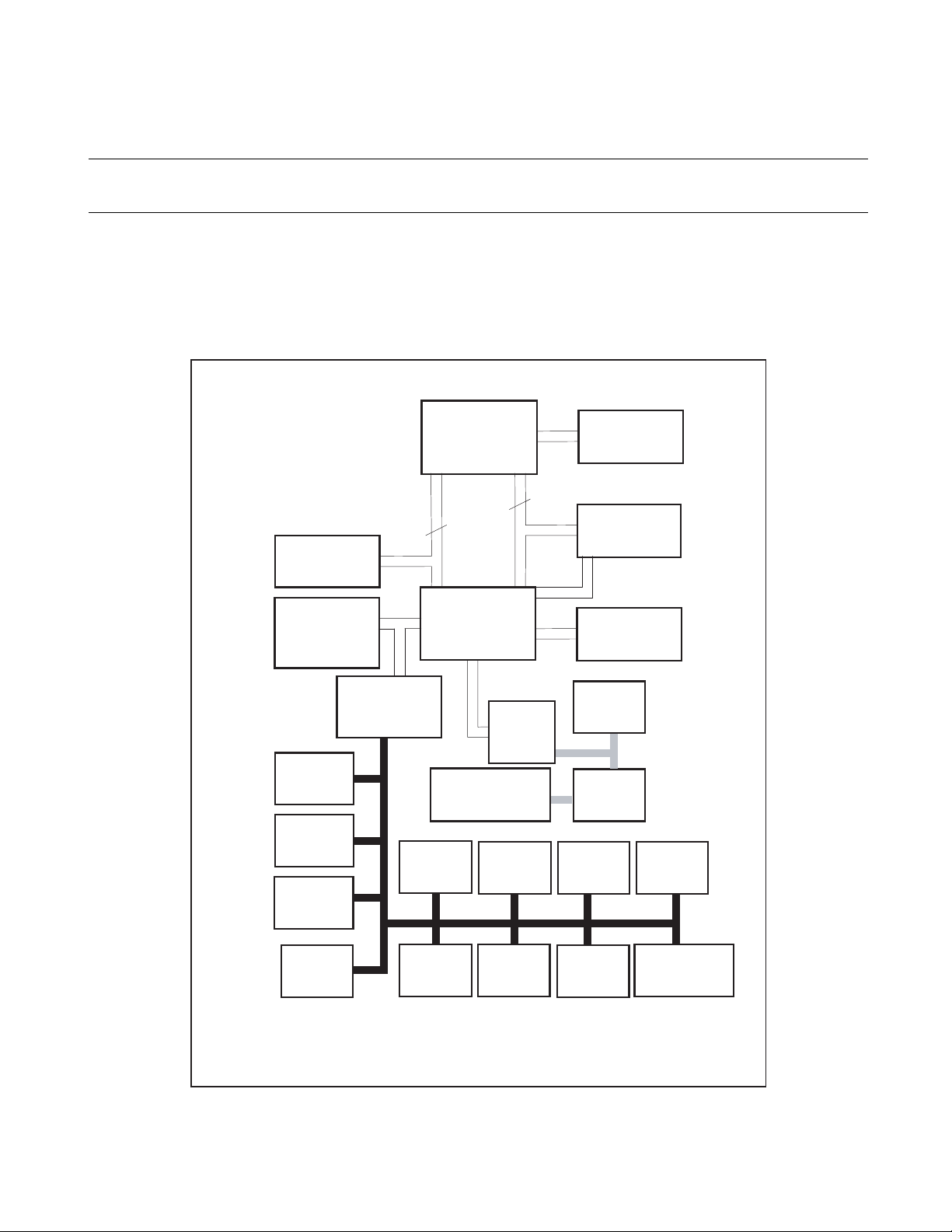

1.2 Block Diagram

Figure 1.2-1 is a block diagram of the MB91319.

■ Block Diagram

Figure 1.2-1 Block Diagram

CHAPTER 1 OVERVIEW

Bit search

RAM

EVA 64KB

FLASH 48KB

MASK 32KB

Clock

control

Interrupt

controller

External

interrupt

32

32 to 16

adapter

FR

CPU Core

Bus converter

Font ROM

FLASH 512 KB*

ROM 384 KB*

UART

5ch

32

External

memory

I/F

2

C

I

4ch

2

2

A/D

10ch

DSU*

Flash 1MB

MASK 512KB

DMAC5ch

USB

function

OSDC

CCD

2ch

1

Port

PWC

4ch

PPG

4ch

Reload

timer 3ch

Multifunction

timer 4ch

*1 : DSU is loaded only in MB91FV319A/R

*2 : Font ROM: MB91FV319A/R: FLASH 512 KB

: MB91F318A/S, MB91316 : MASK ROM 384 KB

7

Page 30

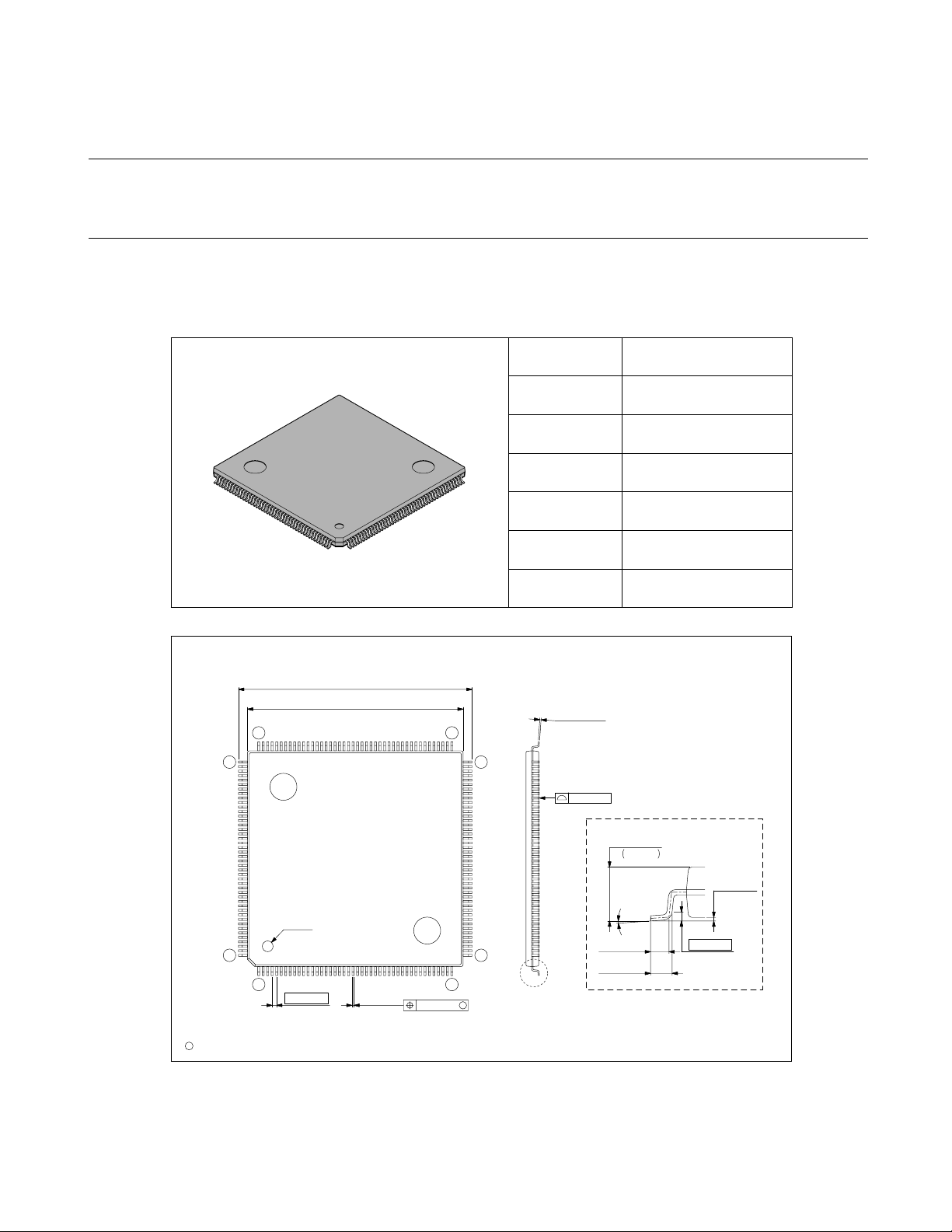

CHAPTER 1 OVERVIEW

176-pin plastic LQFP Lead pitch 0.50 mm

Package width ×

package length

24.0 × 24.0 mm

Lead shape Gullwing

Sealing method Plastic mold

Mounting height

1.70 mm MAX

Code

(Reference)

P-LQFP-0176-2424-0.50

176-pin plastic LQFP

(FPT-176P-M07)

(FPT-176P-M07)

C

2004 FUJITSU LIMITED F176013S-c-1-1

Details of "A" part

0˚~8˚

0.50±0.20

(.020±.008)

0.60±0.15

(.024±.006)

0.25(.010)

(Stand off)

(.004±.004)

0.10±0.10

1.50

+0.20

–0.10

+.008

–.004.059

(Mounting height)

0.08(.003)

(.006±.002)

0.145±0.055

"A"

INDEX

1

LEAD No.

44

45

88

89132

133

176

0.50(.020)

0.22±0.05

(.009±.002)

M

0.08(.003)

*24.00±0.10(.945±.004)SQ

26.00±0.20(1.024±.008)SQ

Dimensions in mm (inches).

Note: The values in parentheses are reference values.

Note 1)* : Values do not include resin protrusion.

Resin protrusion is +0.25(.010)Max(each side).

Note 2) Pins width and pins thickness include plating thickness

Note 3) Pins width do not include tie bar cutting remainder.

1.3 External Dimensions

The MB91319 is available in one type of package.

Figure 1.3-1 shows the dimensions of the MB91319.

■ Dimensions of the MB91319

Figure 1.3-1 External Dimensions of MB91319

8

Page 31

1.4 Pin Layout

This section shows the pin layout of the MB91319.

■ Pin Layout of the MB91 319

Figure 1.4-1 is a diagram of the pin layout of the MB91319 .

Figure 1.4-1 Pin Layout of the MB91319

VSYNC

DOCKI

DCKOFHVOB1

VOB2

176

175

174

VDDIR2R1R0G2G1G0B2B1B0UDP

173

172

171

170

169

168

167

166

165

164

163

162

161

160

UDM

159

VDDE

X0B

158

157

VSS

156

X1B

155

VDDI

154

PB7

153

PB6

152

PB5

151

PB4

150

PB3

149

PB2

148

PB1

147

PB0

146

P17

145

P16/ATRG

P15/PPG3

144

143

P14/PPG2

P13/PPG1

P12/PPG0

142

141

140

CHAPTER 1 OVERVIEW

P11/TMO3

P10/TMO2

P07/TMO1

P06/TMO0

P05/TOUT2

P04/TOUT1

P03/TOUT0

139

138

137

136

135

134

133

HSYNC1

HSYNC2

HSYNC3

VDDDE

VSS

VGS1/BCI1

CP01

VSSP1

VDDP1

VGS2/BCI2

CP02

VSSP2

VDDP2

VGS3/BCI3

CP03

VSSP3

VDDP3

VDDR

VRef(1.1V)

VR0(2.7kΩ)

ROUT

VSSR

VDDG

GOUT

VSSG

VDDB

BOUT

VSSB

VIN0

VIN1

VDDIS

VSSS

VDDI

AVCC

AVRH

AVSS/AVRL

PC0/AN0

PC1/AN1

PC2/AN2

PC3/AN3

PC4/AN4

PC5/AN5

PC6/AN6

PC7/AN7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

4546474849505152535455565758596061626364656667686970717273747576777879

X1

VSS

X0

VDDE

P32

P31

P30

P27

P26

P25

P24

P23

P22

P21/AN9

P20/AN8

TOP VIEW

LQFP-176

MB91FV319A/R

MB91F318A/S

MB91316

ICS1

ICS0

IBREAK

ICLK

TRSTX

VDDI

ICS2

ICD0

ICD1

ICD2

ICD3

MD0

MD1

MD2

MD3

P80/SCL0

INITX

P82/SCL1

P81/SDA0

80

81828384858687

P86/SCK0

P85/SO0

P84/SI0

P83/SDA1

P90/SO1

P87/SI1

P93/TMI0

P92/RIN

P91/SCK1

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

88

P94/TMI1

P02/SCK4/TIN2

P01/SO4/TIN1

P00/SI4/TIN0

P74

P73

P72

P71

P70

VDDE

VSS

VDDI

P57

P56

P55

P54

P53

P52/SCK3

P51/SO3

P50/SI3

P47/SCK2

P46/SO2

P45/SI2

P44/SDA4

P43/SDA3

P42/SCL4

P41/SCL3

P40/SDA2

P37/SCL2

P36/TRG3

P35/TRG2

P34/TRG1

P33/TRG0

NMIX

99

PA2/INT3

98

PA1/INT2

97

PA0/INT1

96

VDDI

95

X1A

94

VSS

93

X0A

92

VDDE

91

P97/INT0

90

P96/TMI3

89

P95/TMI2

Note: Do not be connected anything to TRST, ICS2 to ICS0, ICD3 to ICD0, ICLK and IBREAK pins on MB91FV319AR.

Because these pins are used as open pins on MB91F318A/S, and MB91316.

9

Page 32

CHAPTER 1 OVERVIEW

1.5 List of Pin Functions

This section describes the pin functions of the MB91319.

■ List of Pin Functions

Table 1.5-1 lists the pin functions.

Table 1.5-1 Pin Functions of the MB91319 (1 / 7)

Pin number Pin name I/O circuit type Function

1 HSYNC1 G Horizontal synchronous input 1

2 HSYNC2 G Horizontal synchronous input 2

3 HSYNC3 G Horizontal synchronous input 3

4 VDDE - I/O power supply

5 VSS - Ground

6 VGS1/VCI1 - Guard band ground

7 CPO1 K Charge pump output

8 VSSP1 - Dot clock PLL ground

9 VDDP1 - Dot clock PLL power supply (2.5 V)

10 VGS2/VCI2 - Guard band ground

11 CPO2 K Charge pump output

12 VSSP2 - Dot clock PLL ground

13 VDDP2 - Dot clock PLL power supply (2.5 V)

14 VGS3/VCI3 - Guard band ground

15 CPO3 K Charge pump output

16 VSSP3 - Dot clock PLL ground

17 VDDP3 - Dot clock PLL power supply (2.5 V)

18 VDDR - D/A power supply for Red

19 VREF(1.1V) K Voltage reference input

20 VRO(2.7kΩ) K Resistor connection pin

21 ROUT K Output for Red (analog)

22 VSSR - D/A ground for Red

23 VDDG - D/A power supply for Green

24 GOUT K Output for Green (analog)

25 VSSG - D/A ground for Green

26 VDDB - D/A power supply for Blue

27 BOUT K Output for Blue (analog)

28 VSSB - D/A ground for Blue

29 VIN0 K Data slicer input 0

30 VIN1 K Data slicer input 1

10

Page 33

Table 1.5-1 Pin Functions of the MB91319 (2 / 7)

Pin number Pin name I/O circuit type Function

31 VDDIS - Data slicer power supply (2.5 V)

32 VSSS - Data slicer ground

33 VDDI - Internal logic power supply (2.5 V)

34 AVCC - A/D power supply

35 AVRH - A/D reference power supply

36 AVSS/AVRL - A/D ground

37

38

39

40

41

42

43

44

45

46

47 P22 C Gene r al- pu rp o se po r t

48 P23 C Gene r al- pu rp o se po r t

49 P24 C Gene r al- pu rp o se po r t

50 P25 C Gene r al- pu rp o se po r t

51 P26 C Gene r al- pu rp o se po r t

52 P27 C Gene r al- pu rp o se po r t

53 P30 C Gene r al- pu rp o se po r t

54 P31 C Gene r al- pu rp o se po r t

55 P32 C Gene r al- pu rp o se po r t

56 VDDE - 3.3 V power supply

57 X0 A 10 MHz oscillation pin

58 VSS - Ground

59 X1 A 10 MHz oscillation pin

PC0

AN0 Analog input

PC1

AN1 Analog input

PC2

AN2 Analog input

PC3

AN3 Analog input

PC4

AN4 Analog input

PC5

AN5 Analog input

PC6

AN6 Analog input

PC7

AN7 Analog input

P20

AN8 Analog input

P21

AN9 Analog input

E

E

E

E

E

E

E

E

E

E

General-purpose port

General-purpose port

General-purpose port

General-purpose port

General-purpose port

General-purpose port

General-purpose port

General-purpose port

General-purpose port

General-purpose port

CHAPTER 1 OVERVIEW

11

Page 34

CHAPTER 1 OVERVIEW

Table 1.5-1 Pin Functions of the MB91319 (3 / 7)

Pin number Pin name I/O circuit type Function

60 VDDI - Internal logic power supply (2.5 V)

61

62

63

64

65

66

67

68

69

70

TRSTX

ICLK

IBREAK

ICS0

ICS1

ICS2

ICD0

ICD1

ICD2

ICD3

B

M

L

O

O

O

P

P

P

P

DSU tool reset (this pin is open in the MB91F31x model

series. DO NOT CONNECT)

DSU clock (this pin is open in the MB91F31x model series.

DO NOT CONNECT)

DSU break (this pin is open in the MB91F31x model series.

DO NOT CONNECT)

DSU status (this pin is open in the MB91F31x model series.

DO NOT CONNECT)

DSU status (this pin is open in the MB91F31x model series.

DO NOT CONNECT)

DSU status (this pin is open in the MB91F31x model series.

DO NOT CONNECT)

DSU data (this pin is open in the MB91F31x model series.