Page 1

FUJITSU SEMICONDUCTOR

DATA SHEET

ASSP For Power Supply Applications

(General Purpose DC/DC Converter)

1-ch DC/DC Converter IC

for low voltage

MB39A105

DESCRIPTION

■■■■

The MB39A105 is 1-channel DC/DC converter IC using pulse width modulation (PWM). This IC is ideal for up

conversion.

The minimum operating voltage is lo w (1.8 V) , and the MB39A105 is best for built-in power supply such as LCD

monitors. Also the short-circuit protection detection output function prevents input/output short on a chopper type

up-converter .

This product is covered by US Patent Number 6,147,477.

DS04-27233-2E

FEATURES

■■■■

• Power supply voltage range : 1.8 V to 6 V

• Reference voltage accuracy : ± 1 %

• High-frequency operation capability : 1 MHz (Max)

• Built-in standby function: 0 µA (Typ)

• Built-in timer-latch short-circuit protection circuit

• Built-in short-circuit protection detection output function

• Built-in soft-start circuit independent of loads

• Built-in totem-pole type output for Nch MOS FET

• Package : TSSOP-8P (Thickness 1.1 mm Max)

PACKAGE

■■■■

8-pin plastic TSSOP

(FPT-8P-M05)

Page 2

MB39A105

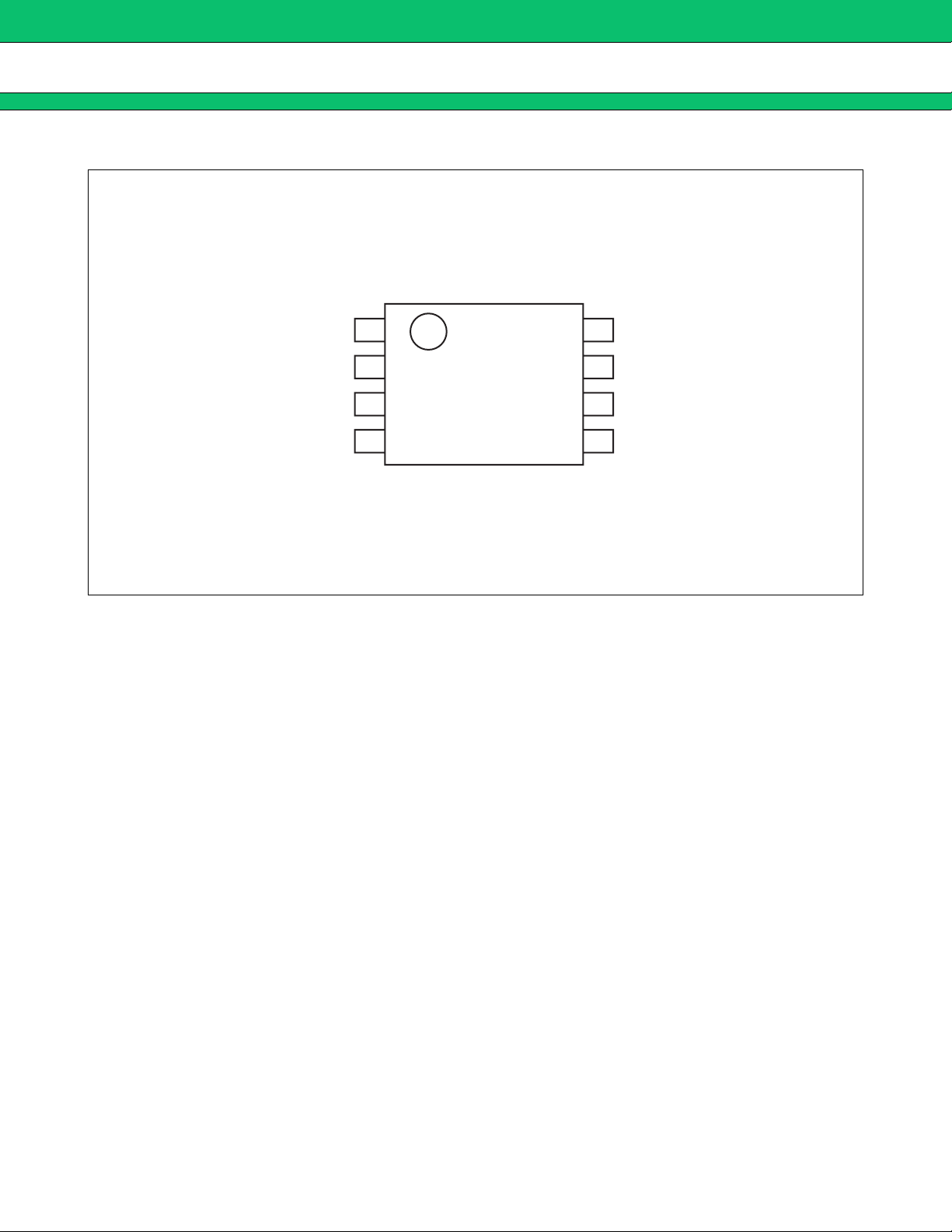

PIN ASSIGNMENT

■■■■

(TOP VIEW)

−INE

CSCP

VCC

SCPOD

1

2

3

4

(FPT-8P-M05)

8

7

6

5

FB

RT

GND

OUT

2

Page 3

MB39A105

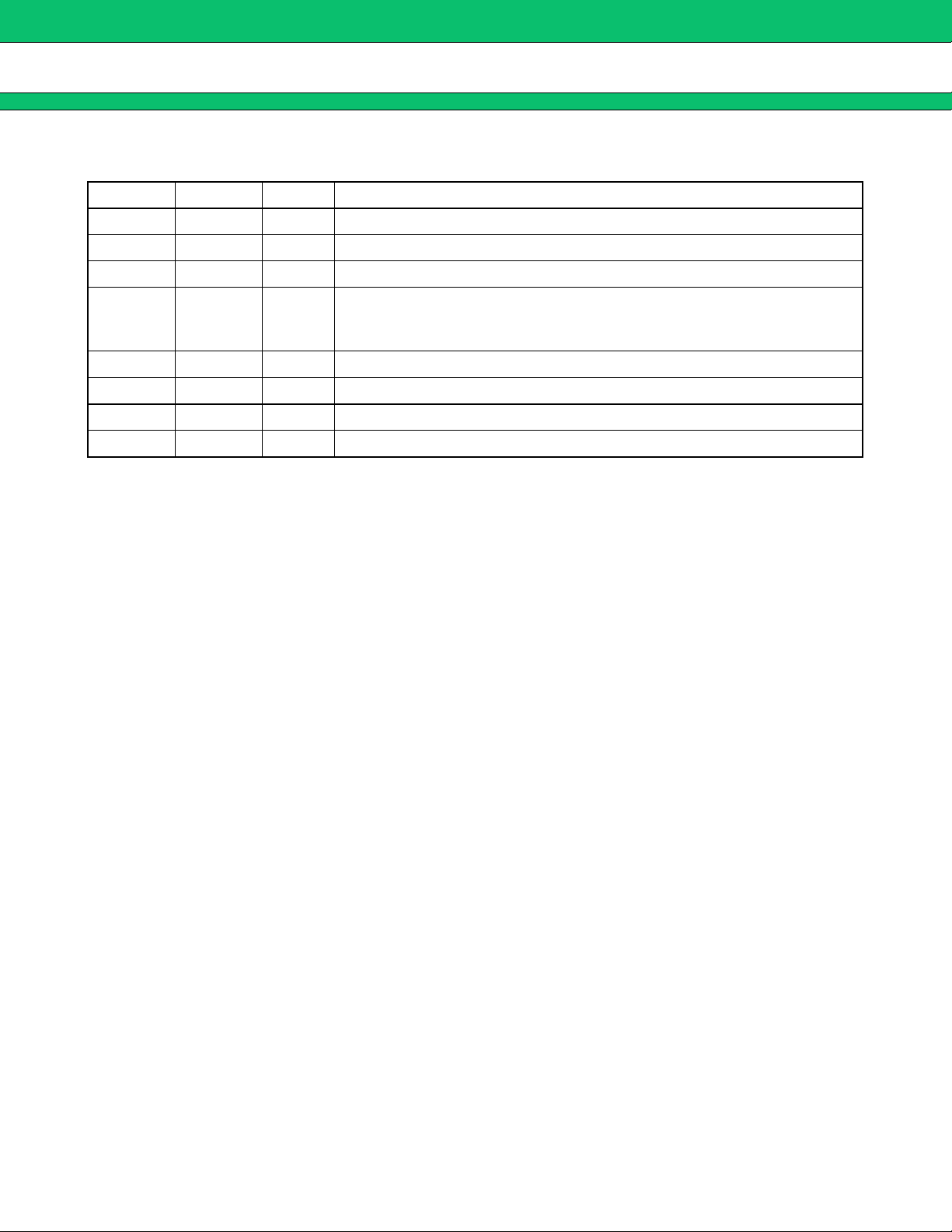

PIN DESCRIPTION

■■■■

Pin No. Symbol I/O Descriptions

1 −INE I Error amplifiers (Error Amp) inverted input terminal

2CSCP Timer-latch short-circuit protection capacitor connection terminal

3VCC Power supply terminal

Open drain output terminal for short-circuit protection detection

4SCPODO

5 OUT O External Nch FET gate drive terminal

6GND Ground terminal

7RT Triangular wave oscillation frequency setting resistor connection terminal

8 FB O Error Amplifier (Error Amp) output terminal

During timer-latch short-circuit protection operation : Output “High-Z”

During normal operation : Output “L”

3

Page 4

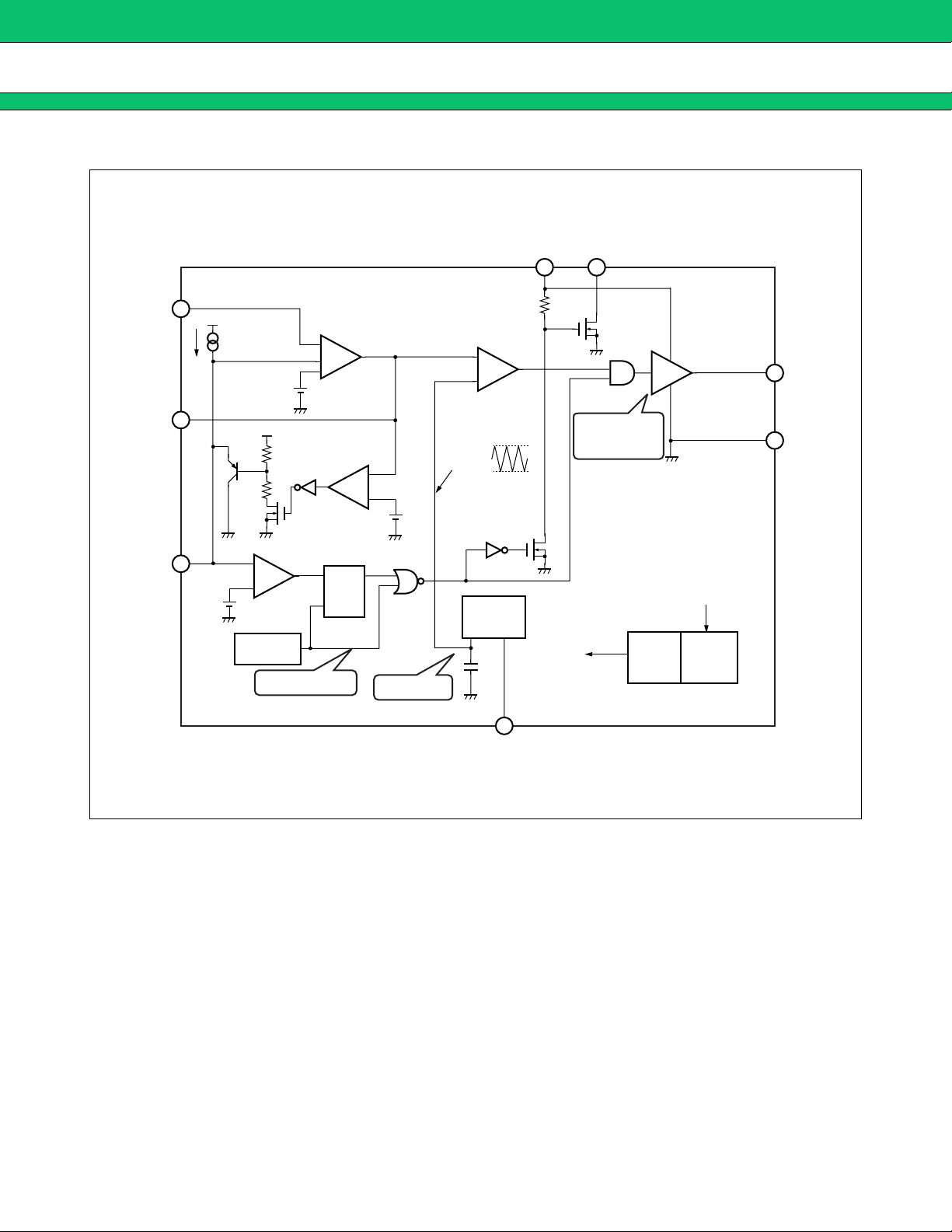

MB39A105

BLOCK DIAGRAM

■■■■

1

−INE

FB

VREF

8

VREF

Error Amp

−

+

+

(0.5 V ± 1%)

SCP

Comp.

+

−

(0.9 V)

+

−

(0.7 V)

(0.3 V)

PWM

Comp.

SCPODVCC

43

I

O = 400 mA

at VCC = 3.3 V

Nch

Drive

OUT

65GND

CSCP

2

(1.0 V)

+

−

UVLO

L : UVLO release

SQ

R

±10%

OSC

RT

RT Current

bias

VREF

(1.27 V)

7

VREF

Power

ON/OFF

CTL

4

Page 5

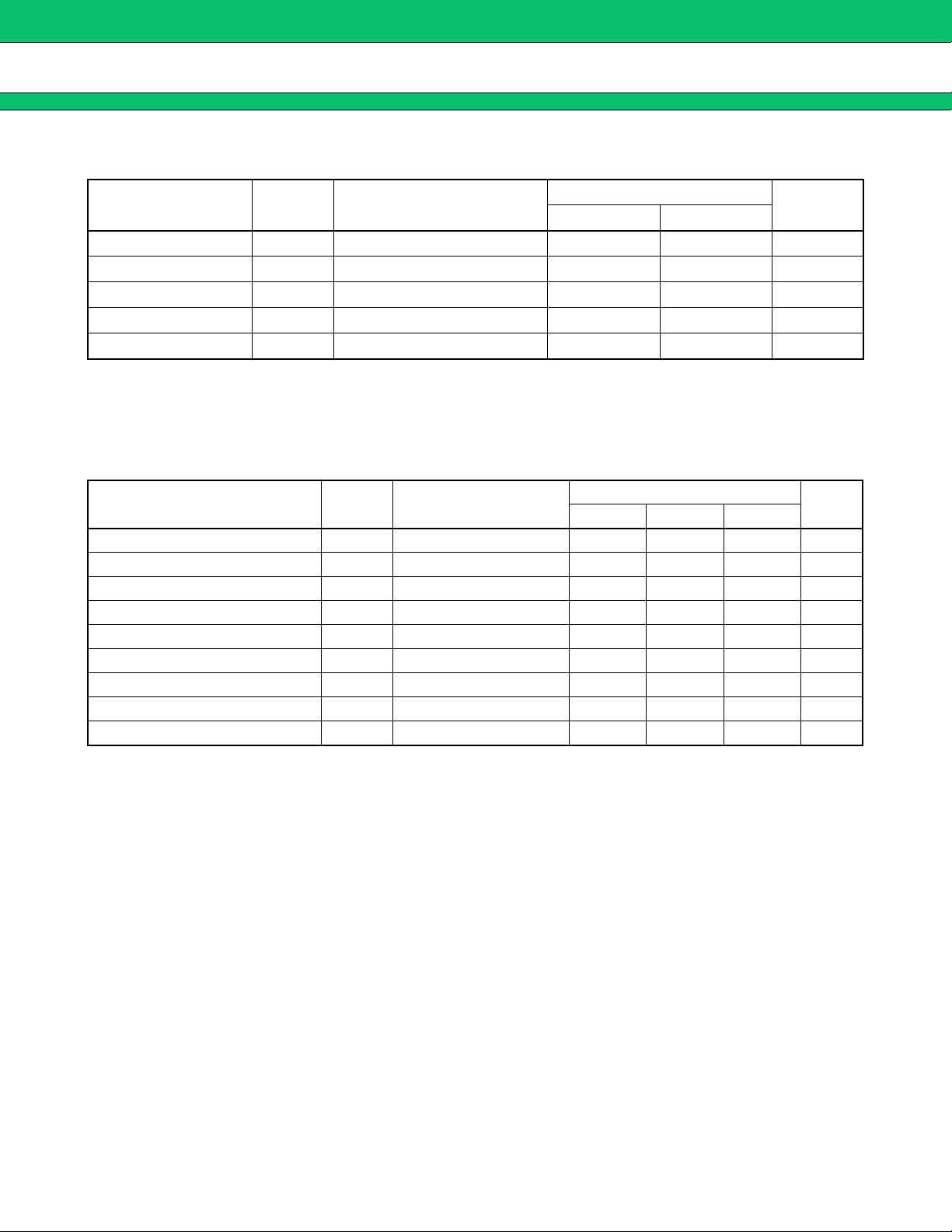

ABSOLUTE MAXIMUM RATINGS

■■■■

MB39A105

Parameter Symbol Condition

Unit

Min Max

Rating

Power supply voltage V

Output current I

Output peak current I

Power dissipation P

Storage temperature T

CC VCC terminal 7V

O OUT terminal 35 mA

OP Duty ≤ 5% (t = 1/fOSC×Duty) 700 mA

D Ta ≤ +25 °C 490* mW

STG −55 +125 °C

* : The packages are mounted on the epoxy board (10 cm × 10 cm).

WARNING: Semiconductor devices can be permanently damaged by application of stress (voltage, current,

temperature, etc.) in excess of absolute maximum ratings. Do not exceed these ratings.

RECOMMENDED OPERATING CONDITIONS

■■■■

Parameter Symbol Condition

Power supply voltage V

Input voltage V

SCPOD terminal output voltage V

SCPOD terminal output current I

Output current I

Min Typ Max

CC VCC terminal 1.8 6V

INE −INE terminal 0 VCC − 0.9 V

SCPOD SCPOD terminal 0 6V

SCPOT SCPOD terminal 0 2mA

O OUT terminal −30 +30 mA

Value

Unit

Oscillation frequency fosc 100 500 1000 kHz

Timing resistor R

Short-circuit detection capacitor C

T RT terminal 3.3 7.5 33 kΩ

SCP CSCP terminal 0.22 1.0 µF

Operating ambient temperature Ta −30 +25 +85 °C

WARNING: The recommended operating conditions are required in order to ensure the normal operation of the

semiconductor device. All of the device’s electrical characteristics are warranted when the device is

operated within these ranges.

Always use semiconductor devices within their recommended operating condition ranges. Operation

outside these ranges may adversely affect reliability and could result in device failure.

No warranty is made with respect to uses, operating conditions, or combinations not represented on

the data sheet. Users considering application outside the listed conditions are advised to contact their

FUJITSU representatives beforehand.

5

Page 6

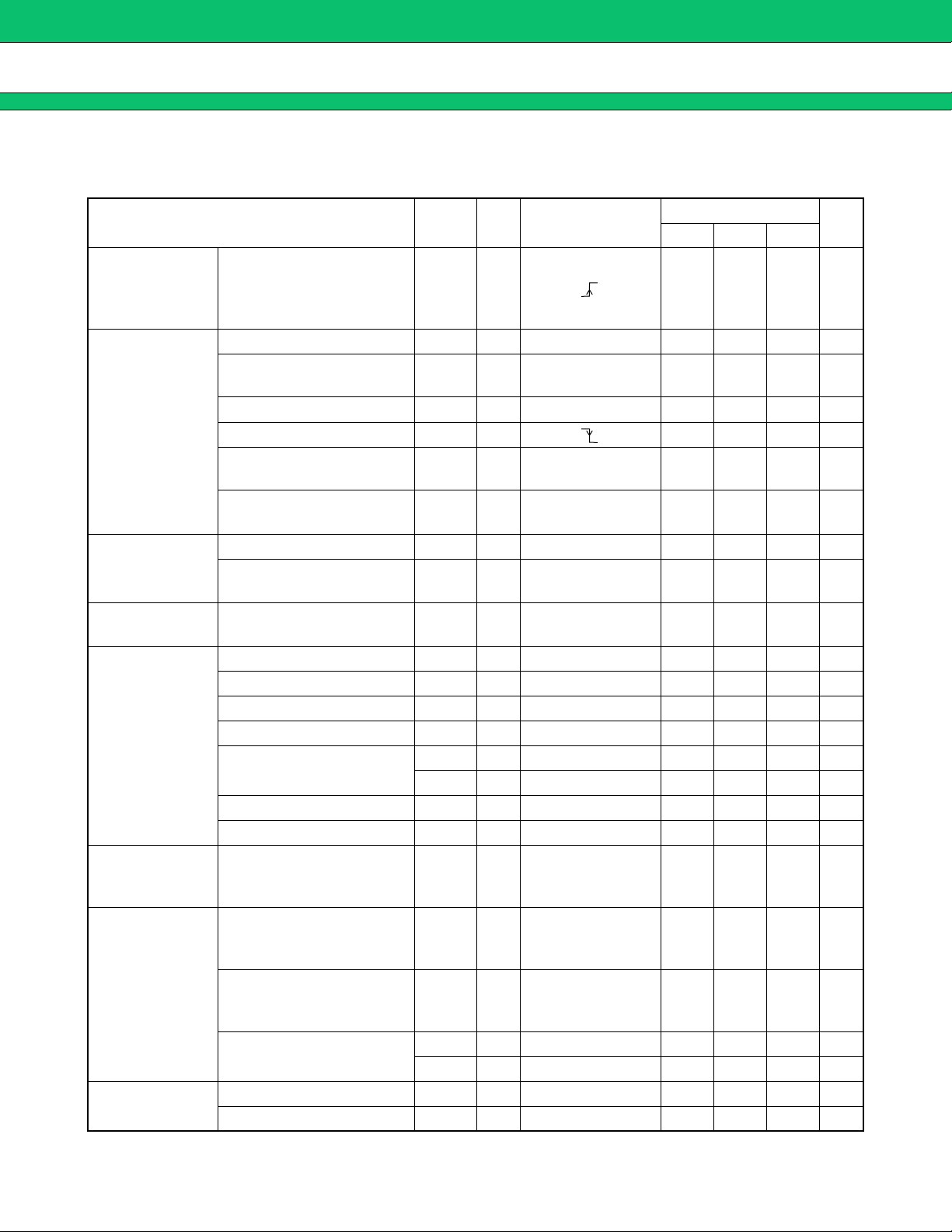

MB39A105

ELECTRICAL CHARACTERISTICS

■■■■

Parameter

1. Under voltage

lockout

protection circuit

block [UVLO]

2. Short-circuit

protection block

[SCP]

3. Triangular

wave oscillator

[OSC]

block

4. Soft-start block

[CS]

5. Error amplifier

block [Error Amp]

6. PWM comparator block

[PWM Comp.]

7.Output block

[Drive]

8. General block

Threshold voltage V

Threshold voltage V

Short-circuit detection time

setting difference voltage

Input source current I

Reset voltage VRST 3VCC = 1.1 1.3 1.5 V

SCPOD terminal output

leak current

SCPOD terminal output on

resistor

Oscillation frequency fosc 5 RT = 7.5 kΩ 450 500 550 kHz

Frequency temperature

variation

Charge current I

Threshold voltage V

Input bias current IB 1 −INE = 0 V −120 −30 nA

Voltage gain AV 8DC 70* dB

Frequency band width BW 8 A

Output voltage

Output source current I

Output sink current ISINK 8FB = 0.5 V 100 300 µA

Maximum duty cycle Dtr 5 RT = 7.5 kΩ 85 90 95 %

Output source current I

Output sink current I

Output ON resistor

Standby current ICCS 3RT = OPEN 010µA

Power supply current I

(VCC = 3.3 V, Ta = +25 °C)

Symbol

∆V

CSCP 2CSCP = 0.85 V −1.76 −0.88 −0.44 µA

I

LEAK 4SCPOD = 3.3 V 01.0µA

R

∆f

f

OSC

Pin

No

TLH 3VCC = 1.15 1.35 1.55 V

TH 2 0.95 1.00 1.05 V

CSCP 2 0.15 0.20 0.25 V

ON 4SCPOD = 1 mA 50 100 Ω

OSC/

CS 2CSCP = 0 V −16 −11 −6 µA

TH 1FB = 0.5 V 0.495 0.5 0.505 V

5Ta = 0 °C to +85 °C 1* %

Conditions

V = 0 dB 1.1* MHz

Min Typ Max

Value

VOH 8 1.17 1.27 1.37 V

VOL 8 40 200 mV

SOURCE 8FB = 0.5 V −80 −50 µA

OUT = 0 V,

SOURCE 5

Duty ≤ 5%

−400* mA

(t = 1/fosc×Duty)

OUT = 3.3 V,

SINK 5

Duty ≤ 5%

400* mA

(t = 1/fosc×Duty)

R

OH 5OUT = −15 mA 4.0* Ω

ROL 5OUT = 15 mA 3.0 6.0 Ω

CC 3RT = 7.5 kΩ1.2 1.8 mA

Unit

*: Standard design value.

6

Page 7

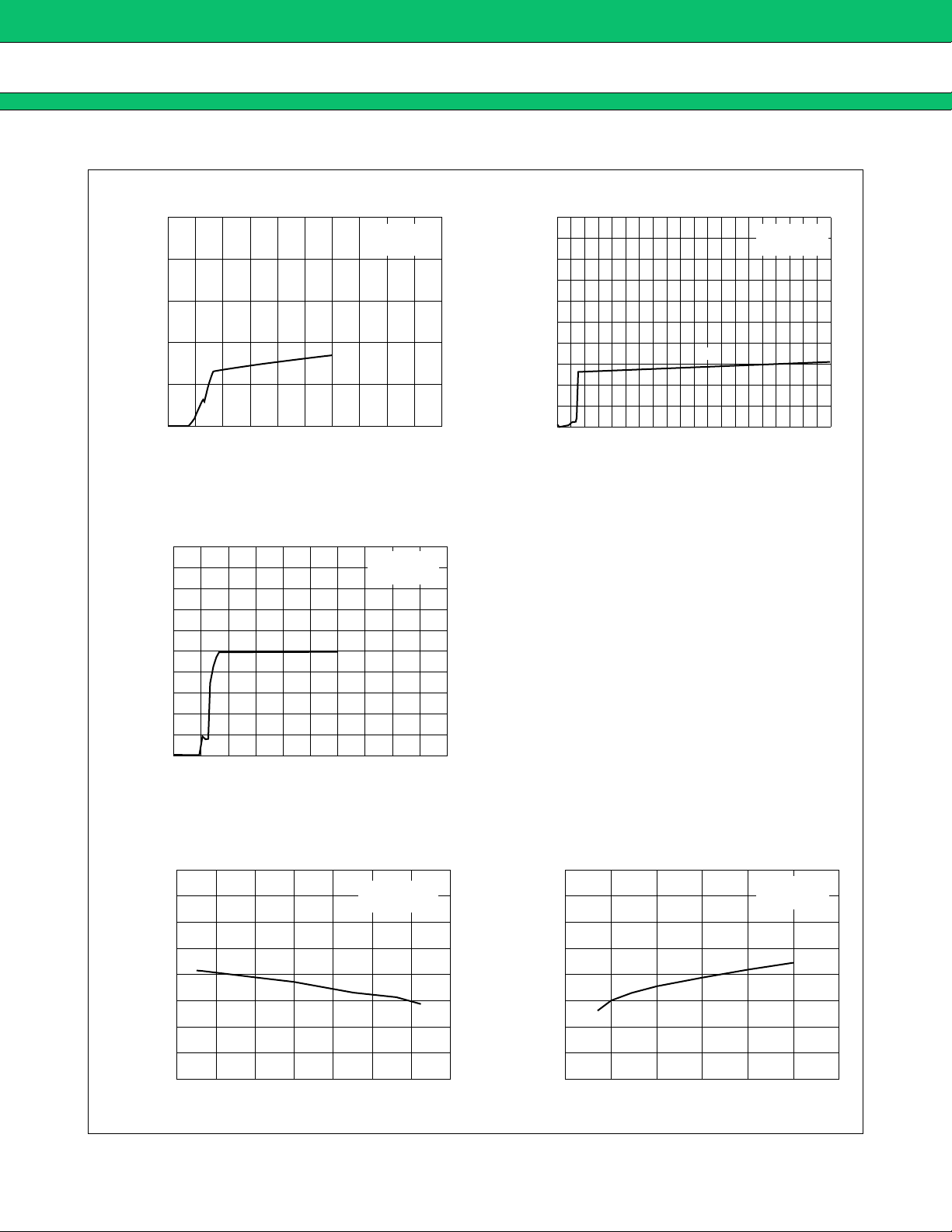

TYPICAL CHARACTERISTICS

■■■■

MB39A105

Power Supply Current vs. Power Supply Voltage

5

4

3

2

1

0

Power supply current ICC (mA)

0246810

Power supply voltage V

Ta = +25 °C

RT = 7.5 kΩ

CC (V)

Error Amplifier Threshold Voltage vs.

Power Supply Voltage

1.0

0.9

0.8

0.7

0.6

VTH (V)

0.5

0.4

0.3

Voltage

0.2

0.1

Error Amplifier Threshold

0.0

0246810

Ta = +25 °C

VCC = 3.3 V

Power supply voltage VCC (V)

Power Supply Current vs. RT Terminal Current

5.0

4.5

4.0

CC (mA)

3.5

3.0

2.5

2.0

1.5

1.0

0.5

Power supply current I

0.0

0 1020304050

I

CC

Ta = +25 °C

VCC = 3.3 V

RT terminal current IRT (µA)

Error Amplifier Threshold Voltage vs.

Ambient Temperature

0.52

0.51

VTH (V)

0.50

0.49

Voltage

Error Amplifier Threshold

0.48

−40 −20 0 20 40 60 80 100

Ambient temperature Ta (°C)

VCC = 3.3 V

RT = 7.5 kΩ

Triangular Wave Oscillation Frequency vs.

Power supply voltage

600

550

fOSC (kHz)

500

450

Frequency

Triangular Wave Oscillation

400

1234567

Power supply voltage V

Ta = +25 °C

RT = 7.5 kΩ

CC (V)

(Continued)

7

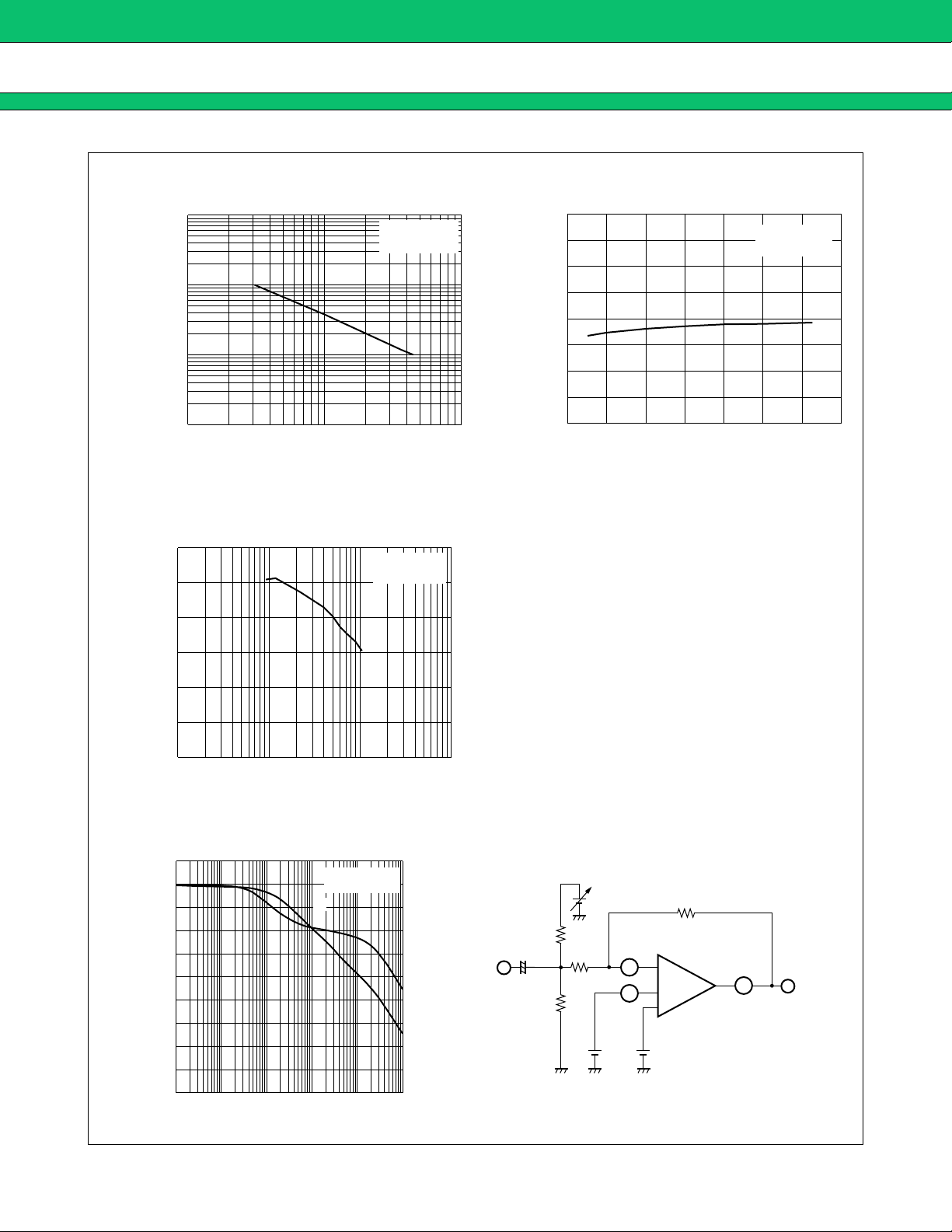

Page 8

MB39A105

Triangular Wave Oscillation Frequency

vs. Timing Resistor

10000

1000

OSC (kHz)

100

frequency f

Triangular wave oscillation

10

1 10 100

Timing resistor RT (kΩ)

Max On Duty vs.

Triangular Wave Oscillation Frequency

100

95

Ta = +25 °C

VCC = 3.3 V

Ta = +25 °C

VCC = 3.3 V

Triangular Wave Oscillation Frequency

vs. Ambient Temperature

600

550

OSC (kHz)

500

450

frequency f

Triangular wave oscillation

400

−40 −20 0 20 40 60 80 100

Ambient temperature Ta (°C)

VCC = 3.3 V

RT = 7.5 kΩ

90

85

80

Max On Duty (%)

75

70

10 100 1000 10000

Triangular wave oscillation frequency f

Error Amplifier Gain and Phase

vs. Frequency

40

30

20

10

V (dB)

−10

−20

Gain A

−30

−40

ϕ

0

Ta = +25 °C

VCC = 3.3 V

AV

OSC (kHz)

180

90

0

−90

Phase φ (deg)

−180

IN

10 kΩ

1 µF

+

10 kΩ

2.4 kΩ

10

11

240 kΩ

−

+

+

1.24 V

9

OUT

Error Amp

100 1 k 10 k 100 k 1 M 10 M

Frequency f (Hz)

(Continued)

8

Page 9

(Continued)

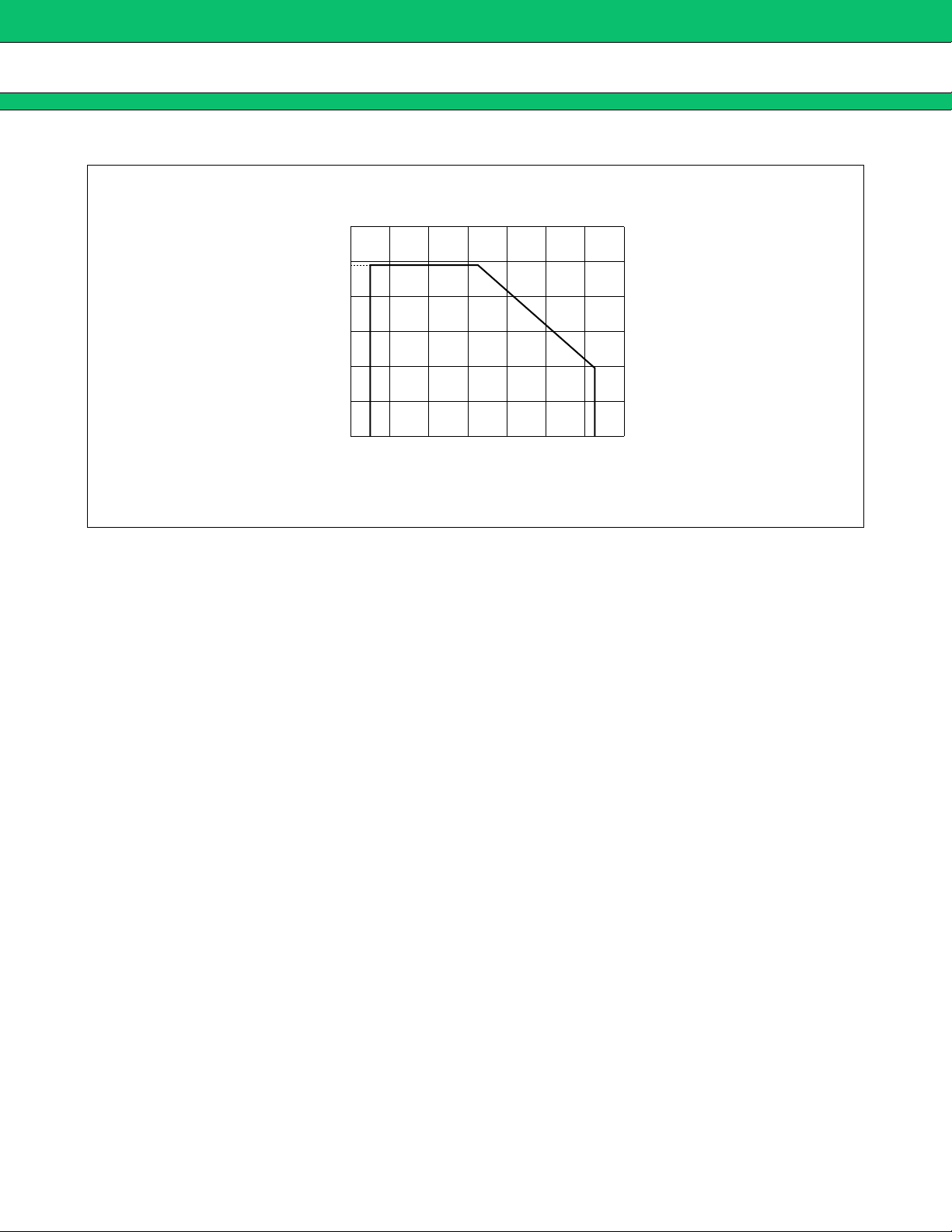

Power Dissipation vs. Ambient Temperature

600

500

490

400

300

200

100

Power dissipation PD (mW)

0

−40 −20 0 20 40 60 80 100

Ambient temperature Ta ( °C)

MB39A105

9

Page 10

MB39A105

FUNCTIONS

■■■■

1. DC/DC Converter Functions

(1) Triangular-wave oscillator block (OSC)

The triangular wave oscillator incorporates a timing resistor connected to RT terminal (pin 7) to generate

triangular oscillation waveform amplitude of 0.3 V to 0.7 V.

The triangular waveforms are input to the PWM comparator in the IC.

(2) Error amplifier block (Error Amp1, Error Amp2)

The error amplifier detects the DC/DC converter output voltage and outputs PWM control signals. In addition,

an arbitrary loop gain can be set by connecting a feedback resistor and capacitor from the output terminal to

inverted input terminal of the error amplifier, enabling stable phase compensation to the system.

Also, it is possib le to prevent rush current at power supply start-up by connecting a soft-start capacitor with the

CSCP terminal (pin 2) which is the non-inverted input terminal for Error Amp. The use of Error Amp for soft-start

detection makes it possible for a system to operate on a fixed soft-start time that is independent of the output

load on the DC/DC converter.

(3) PWM comparator block (PWM Comp.)

The PWM comparator is a voltage-to-pulse width modulator that controls the output duty depending on the input/

output voltage.

The comparator keeps output transistor on while the error amplifier output v oltage and the DTC voltage remain

higher than the triangular wave voltage.

(4) Output block (Drive)

The output block is in the totem pole configuration, capable of driving an external N-channel MOS FET.

10

Page 11

MB39A105

2. Power Control Function

A switch in series with a resistor connected with the RT terminal (pin 7) allows y ou to turn on or turn off the pow er.

On/off setting conditions of power supply

CTL Power

L OFF (standby)

H ON (operating)

ON/OFF CTL

(L : OFF, H : ON)

RT

3. Protective Functions

(1) Timer-latch short-circuit protection circuit (SCP)

Short-circuit detection comparator detects the error amplifier output voltage level. If the load conditions for the

DC/DC converter are stable, the short-circuit protection comparator is kept in equilibrium condition because the

error amplifier is free from output variation. At this time the CSCP terminal (pin 2) is held at the soft-start end

voltage (about 0.8 V) . If the DC/DC conver ter output voltage falls and error amplifier output is over 0.9 V, the

timer circuits are actuated to start charging the external capacitor C

When the capacitor voltage reaches about 1.0 V, the latch is set and the circuit is turned off the external FET

and sets the dead time to 100 %. At this time, latch input is closed and the CSCP terminal is held at the “L” level.

To reset the actuated protection circuit, turn off and on the power supply again and set VCC terminal voltage

(pin 3) to 1.1 V (Min) or less. (See ■SETTING TIME CONSTANT FOR TIMER-LATCH SHORT-CIRCUIT PR OTECTION CIRCUIT.)

(2) Under voltage lockout protection circuit (UVLO)

SCP.

The transient state or a momentary decrease in supply voltage, which occurs when the power supply is turned

on, may cause the IC to malfunction, resulting in breakdown or degradation of the system. To prevent such

malfunctions, under voltage loc kout protection circuit detects a decrease in internal reference voltage with respect

to the power supply voltage, turns off the output FET, and sets the dead time to 100% while holding the CSCP

terminal (pin 2) at the “L” level.

The circuit restores the output transistor to normal when the supply voltage reaches the threshold voltage of the

undervoltage lockout protection circuit.

(3) Short-circuit protection detection output function

Connecting the Pch MOS FET to SCPOD terminal (pin 4) turns off the Pch MOS FET when the shor t-circuit

protection is detected or under voltage lockout protection circuit operate. This allows you to prevent the shortcircuit between the input and output when the short-circuit protection is detected, thus preventing the input

voltage from occurring in the output region in the standby state.

(4) Protection circuit operating function table

This table refers to output condition when protection circuit is operating.

Operating circuit SCPOD OUT

Short-circuit protection circuit High-Z L

Under voltage lockout protection circuit High-Z L

11

Page 12

MB39A105

SETTING THE OUTPUT VOLTAGE

■■■■

• Output Voltage Setting Circuit

VO

R1

1

R2

SETTING THE TRIANGULAR OSCILLATION FREQUENCY

■■■■

−INE

CSCP

2

−

+

+

(0.5 V)

Error

Amp

V

O (V) = (R1 + R2)

0.5

R2

The triangular oscillation frequency is determined by the timing resistor (RT) connected to the RT terminal (pin 7) .

Triangular oscillation frequency : fosc

fosc (kHz) :=

3750

T (kΩ)

R

12

Page 13

MB39A105

SETTING THE SOFT-START TIMES

■■■■

To prevent r ush currents when the IC is tur ned on, you can set a soft-star t by connecting soft-star t capacitors

(C

SCP) to the CSCP terminal (pin 2). When IC star ts (VCC ≥ UVLO threshold voltage), the exter nal soft-start

capacitors (C

determined by comparison between the lower one of the potentials at two non-inverted input terminals (0.5 V

in an internal reference voltage, CSCP terminal voltages) and the inverted input terminal voltage (−INE (pin 1)

voltage).

The FB terminal voltage is decided for the soft-start period by the comparison between 0.5 V in an internal

reference voltage and the v oltages of the CSCP terminal. The DC/DC converter output voltage rises in proportion

to the CSCP terminal voltage as the soft-start capacitor connected to the CSCP terminal is charged.

The soft-start time is obtained from the following formula:

Soft-start time: ts (time to output 100%)

ts (s) := 0.045 × C

SCP) connected to CSCP terminal are charged at 11 µA. The error amplifier output (FB (pin 8) ) is

SCP (µF)

• Soft-Start Circuit

R1

R2

:= 0.8 V

:= 0.5 V

:= 0 V

VO

Soft-start time (ts)

−INE

1

CSCP

2

CSCP terminal voltage

Error Amp block −INE voltage

t

VREF

11 µA

L priority

Error Amp

−

+

+

(0.5 V)

C

SCP

FB

8

UVLO

13

Page 14

MB39A105

SETTING TIME CONST ANT FOR TIMER-LA TCH SHORT -CIRCUIT PRO TECTION CIRCUIT

■■■■

The error amplifier’s output level alaways does the comparison operation with the short-circuit protection comparator (SCP Comp.) to the reference voltage.

While DC/DC converter load conditions are stable, the short-circuit detection comparator output remains stable,

and the CSCP terminal (pin 2) is held at soft-start end voltage (about 0.8 V) .

If the load condition changes rapidly due to a short-circuit of the load and the DC/DC converter output voltage

drops, the output of the error amplifier usually goes over 0.9 V. In that case, the capacitor C

When the capacitor C

SCP is charged to about 1.0 V, the latch is set and the external FET is turned off (dead time

is set to 100%). At this time, the latch input is closed and the CSCP terminal (pin 2) is held at “L” level. When

CSCP terminal becomes “L” level, SCPOD terminal Nch MOS FET becomes OFF. SCPOD terminal (pin 4) is

held at “L” level and can be used as a short-circuit operating detection signal during normal operation.

To reset the actuated protection circuit, the power supply turn off and on again to lower the VCC terminal (pin

3) voltage to 1.1 V (Min) or less.

Short-circuit detection time (t

t

CSCP (s) := 0.23 × CSCP (µF)

•

Timer-latch short-circuit protection circuit

CSCP)

SCP is charged further.

R1

R2

O

V

8

FB

−INE

CSCP

1

(0.88 µA)(10.1 µA)

2

−

+

(1.0 V)

−

−

+

(0.5 V)

VREF

Error

Amp

SCP

Comp.

−

+

VREF

(0.9 V)

to Drive

14

SR

Latch UVLO

Page 15

•

Soft-start and short-circuit protection circuit timing chart

1.0 V

0.9 V

0.8 V

CSCP voltage

MB39A105

FB voltage

0.7 V

Soft-start time

t

S

Output

short

OSC

amplifier

Output short

Short-circuit detection time

t

CSCP

0.3 V

t

15

Page 16

MB39A105

I/O EQUIVALENT CIRCUIT

■■■■

〈〈Soft-start block (CS) 〉〉 〈〈Short-circuit protection circuit block (SCP) 〉〉

3

VCC

ESD

protection

element

6

GND

ESD

protection

element

CSCP

2

ESD

protection

element

VCC

CSCP

GND

1.0 V

+

−

4

SCPOD

〈〈Triangular wave oscillator block (RT) 〉〉

VCC

0.33 V

GND

+

−

RT

7

〈〈Output block〉〉

VCC

OUT

5

GND

VCC

(1.27 V)

−INE

GND

〈〈Error amplifier block〉〉

1

CS

0.5 V

FB

8

16

Page 17

APPLICATION EXAMPLE

■■■■

Q1

R8

100 kΩ

SCPOD

4

L1

O

V

A

6.8 µH

(9.0 V)

D1

OUT

Drive

Q2

5

Nch

C7

C6

C5

C4

MB39A105

0.1 µF

4.7 µF

4.7 µF

4.7 µF

GND

6

CTL

Power

RT Current

ON/OFF

VREF

C3

C2

C1

O = 400 mA

4.7 µF

4.7 µF

0.1 µF

3

VCC

R6

R5

−INE

330 kΩ

43 kΩ

PWM

Error Amp

VREF

1

R7

A

Comp.

+

+

−

22 kΩ

R4

I

at VCC = 3.3 V

−

(0.7 V)

(0.3 V)

+

−

(0.9 V)

+

51 kΩ

(0.5 V ± 1%)

C9

8

0.1 µF

SCP

VREF

FB

Comp.

SQ

+

2

CSCP

−

(1.0 V)

C8

0.22 µF

R

bias

OSC

VREF

(1.27 V)

±10%

UVLO

L : UVLO release

RT

R1

7.5 kΩ

7

Q3

R11

100 kΩ

ON/OFF CTL

(L : OFF, H : ON)

VIN

(1.8 V to

6.0 V)

17

Page 18

MB39A105

PARTS LIST

■■■■

COMPONENT ITEM SPECIFICATION VENDOR PARTS No.

Q1 Pch FET VDS = 20 V, ID = −2 A (Max) SANYO MCH3306

Q2, Q3 Nch FET VDS = 20 V, Qg = 4.5 nC (Typ) SANYO MCH3405

D1 Diode VF = 0.40 V (Max) , at IF = 1 A SANYO SBS004

L1 Inductor 6.8 µH 1.4 A, 144 mΩ SUMIDA CMD5D13-6R8

C1, C7, C9

C2 to C6

C8

Ceramics Condenser

NeoCapacitor

Ceramics Condenser

0.1 µF

4.7 µF

0.22 µF

50 V

10 V

10 V

TDK

NEC/TOKIN

TDK

C1608JB1H104K

TEPSLA21A475M8R

C1608JB1A224K

R1

R4

R5

R6

R7

R8, R11

Note : SANYO : SANYO Electric Co., Ltd.

SUMIDA : SUMIDA Electric Co., Ltd.

TDK : TDK Corporation

NEC/TOKIN : NEC TOKIN Corporation

ssm : SUSUMU Co., Ltd.

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

7.5 kΩ

51 kΩ

43 kΩ

330 kΩ

22 kΩ

100 kΩ

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

ssm

ssm

ssm

ssm

ssm

ssm

RR0816P-752-D

RR0816P-513-D

RR0816P-433-D

RR0816P-334-D

RR0816P-223-D

RR0816P-104-D

18

Page 19

MB39A105

SELECTION OF COMPONENTS

■■■■

• Nch MOS FET

The N-ch MOSFET for switching use should be rated for at least 20% more than the maximum output voltage.

To minimize continuity loss, use a FET with low R

and high frequency operation, on/off-cycle switching loss will be higher so that power dissipation must be

considered. In this application, the SANYO MCH3405 is used. Continuity loss, on/off switching loss, and total

loss are determined by the following f ormulas. The selection must ensure that peak drain current does not exceed

rated values.

DS(ON) between the drain and source. For high output voltage

Continuity loss : P

C

PC = ID 2 × RDS(ON) × Duty

On-cycle switching loss : PS (ON)

P

S (ON) =

VD (Max) × ID × tr × fOSC

6

Off-cycle switching loss : PS (OFF)

P

S (OFF) =

VD (Max) × ID (Max) × tf × fOSC

6

Total loss : PT

PT = PC + PS (ON) + PS (OFF)

Example: Using the SANYO MCH3405

Input voltage V

f

OSC = 500 kHz, L = 6.8 µH, drain-source on resistance RDS (ON) := 160 mΩ, tr = 18 ns, tf = 8 ns.

Drain current (Max) : I

I

D (Max) =

=

IN (Max) = 2.4 V, output voltage VO = 9 V, drain current ID = 0.94 A, Oscillation frequency

D (Max)

VO × IO

VIN(Min) 2L VO

9 × 0.25

2.4 2 × 6.8 × 10

+

+

VIN(Min)

ton ton =

2.4× (9−2.4)

−6

×

× 9500 × 10

1

VO − VIN(Min)

3

t

:= 1.20 (A)

Drain current (Min) : ID (Min)

ID (Min) =

VO × IO

VIN(Min) 2L

9 × 0.25

=

2.4 2 × 6.8 × 10

−

−

:= 0.68 (A)

VIN(Min)

ton

2.4× (9−2.4)

−6

×

× 9 500 × 10

1

3

19

Page 20

MB39A105

C = ID

P

2

× RDS (ON) × Duty

= 0.94

2

× 0.16 ×

9−2.4

:= 0.104 W

PS (ON) =

PS (OFF) =

VD (Max) × ID × tr × fOSC

6

9 × 0.94 × 18 × 10

=

:= 0.013

W

VD (Max) × ID (Max) × tf × fOSC

6

9 × 1.20 × 8 × 10−9 × 500 × 10

=

:=

0.007 W

PT = PC + PS (ON) + PS (OFF)

:= 0.104 + 0.013 + 0.007

:= 0.

124 W

9

−9

6

6

× 500 × 10

3

3

The above power dissipation figures for the MCH3405 is satisfied with ample margin at 0.8 W.

• Inductors

In selecting inductors, it is of course essential not to apply more current than the rated capacity of the inductor ,

but also to note that the lower limit for ripple current is a cr itical point that if reached will cause discontinuous

operation and a considerable drop in efficiency. This can be prevented by choosing a higher inductance value,

which will enable continuous operation under light loads. Note that if the inductance value is too high, however,

direct current resistance (DCR) is increased and this will also reduce efficiency. The inductance must be set at

the point where efficiency is greatest.

Note also that the DC superimposition characteristics become worse as the load current value approaches the

rated current value of the inductor , so that the inductance v alue is reduced and ripple current increases, causing

loss of efficiency. The selection of rated current value and inductance value will var y depending on where the

point of peak efficiency lies with respect to load current.

Inductance values are determined by the following formulas.

Inductance value : L

2

L ≥

VIN

2IOVO

ton

20

Page 21

Example:

MB39A105

IN (Max)

2IOVO

4

2

ton

2

×

9−4

×

1

3

L ≥

V

≥

2 × 0.25 × 9 9 500 × 10

≥ 3.95 µH

Inductance values derived from the above formulas are values that provide sufficient margin for continuous

operation at maximum load current, but at which continuous oper ation is not possible at light loads. It is theref ore

necessary to determine the load level at which continuous operation becomes possible. In this application, the

Sumida CMD5D13-6R8 is used. At 6.8 µH, the load current value under continuous operating conditions is

determined by the following formula.

Load current value under continuous operating conditions : I

IO ≥

≥

VIN (Max)

2 × 6.8 × 10

2LVO

2

ton

2

4

−6

× 9 9 500 × 10

×

9−4

×

1

3

O

≥ 145.2 mA

To determine whether the current through the inductor is within rated values, it is necessary to determine the

peak value of the ripple current as well as the peak-to-peak values of the ripple current that affect the output

ripple voltage. The peak value and peak-to-peak value of the ripple current can be determined by the following

formulas.

Peak value : I

IL ≥

L

VO × IO

VIN 2L VO

VIN

+

ton ton =

VO − VIN

t

Peak-to-peak value : ∆IL

∆IL =

VIN

L

ton

Example: Using the CMD5D13-6R8

6.8 µH (allowable tolerance ±20%) , rated current = 1.4 A

Peak value:

I

L ≥

≥

VO × IO

VIN 2L VO

9 × 0.25

2.4 2 × 6.8 × 10

VIN

+

+

ton

ton =

2.4 × (9 − 2.4)

−6

× 9 500 × 10

VO − VIN

×

t

1

3

≥ 1.20 A

21

Page 22

MB39A105

Peak-to-peak value:

L =

∆I

• Flyback diode

The flyback diode is generally used as a Shottky barrier diode (SBD) when the reverse voltage to the diode is

less than 40V. The SBD has the characteristics of higher speed in terms of faster reverse recovery time, and

lower forw ard v oltage , and is ideal f or achieving high efficiency . As long as the DC re v erse voltage is sufficiently

higher than the output voltage, the average current flowing through the diode is within the mean output current

level, and peak current is within peak surge current limits, there is no problem. In this application the SANYO

SBS004 is used. The diode mean current and diode peak current can be calculated by the following formulas.

VIN (Min)

L

4 × (9 − 4)

=

6.8 × 10

:= 0.654 A

ton

−6

×

× 9 500 × 10

1

3

Diode mean current : I

IDi ≥ IO × (1 −

VO−VIN (Min)

VO

Di

)

Diode peak current : IDip

IDip ≥

VO × IO

VIN (Min) 2L

+

VIN (Min)

ton

Example: Using the SANYO SBS004

VR (DC reverse voltage) = 15 V, mean output current = 1.0 A, peak surge current = 10 A,

VF (forward voltage) = 0.40 V, IF = 1.0 A

I

Di ≥ IO × (1 −

VO−VIN (Min)

VO

)

≥ 0.25 × (1 − 0.733)

≥ 66.8 mA

IDip ≥

VO × IO

VIN (Min) 2L

+

VIN (Min)

ton

≥ 1.20 A

22

Page 23

MB39A105

• Smoothing Capacitor

The smoothing capacitor is an indispensable element for reducing ripple v oltage in output. In selecting a smoothing capacitor it is essential to consider equivalent series resistance (ESR) and allowable ripple current. Higher

ESR means higher ripple voltage, so that to reduce ripple voltage it is necessary to select a capacitor with low

ESR. However, the use of a capacitor with low ESR can have substantial effects on loop phase characteristics,

and therefore requires attention to system stability. Care should also be taken to use a capacity with sufficient

margin for allowable ripple current. This application uses the TEPSLA21A475M8R (NEC/TOKIN) . The ESR,

capacitance value, and ripple current can be calculated from the following formulas.

Equivalent Series Resistance : ESR

ESR ≤

∆VO

∆IL 2πfCL

−

1

Capacitance value : C

CL ≥

2πf (∆VO − ∆IL × ESR)

∆IL

L

Ripple current : ∆ICL

V

∆IC

L ≥

IN

ton

L

Example: Using the TEPSLA21A475M8R (Three piecies are parallel.)

Rated voltage = 10 V, ESR = 500 mΩ, maximum allowable ripple current = 1 A

Equivalent series resistance

ESR ≤

≤

O

∆V

∆IL 2πfCL

0.18

0.654 2π × 500 × 10

−

−

1

1

3

× 14.1 × 10

−6

≤ 252.7 mΩ

Capacitance value : C

CL ≥

2πf (∆VO − ∆IL × ESR)

≥

2π × 500 × 10

L

∆IL

0.39

3

× (0.18 − 0.654 × 0.167)

p−p

≥ 2.94

µF

Ripple current : ∆ICL

V

4 × (9 − 4)

≥

6.8 × 10

IN

ton

L

∆ICL ≥

≥ 0.654 Ap−p

−6

×

× 9 500 × 10

1

3

23

Page 24

MB39A105

REFERENCE DATA

■■■■

100

Ta = +25 °C

9 V output

90

80

70

60

Conversion efficiency η (%)

50

Conversion Efficiency vs. Load current

Vin = 1.8 V

Vin = 3.3 V

Vin = 6.0 V

40

30

1 m 10 m 100 m 1

Load current IL (A)

Switching Wave Form

VG (V)

V

D (V)

10

5

0

15

10

5

0

Ta = +25 °C

VIN = 3.3 V

O = 9 V

V

I

O = 100 mA

24

012345678910

t (µs)

Page 25

MB39A105

USAGE PRECAUTION

■■■■

•

Printed circuit board ground lines should be set up with consideration for common impedance.

•

Take appropriate static electricity measures.

• Containers for semiconductor materials should hav e anti-static protection or be made of conductive material.

• After mounting, printed circuit boards should be stored and shipped in conductive bags or containers.

• Work platforms, tools, and instruments should be properly grounded.

• Working personnel should be grounded with resistance of 250 kΩ to 1 MΩ between body and ground.

•

Do not apply negative voltages.

The use of negative voltages below –0.3 V may create parasitic transistors on LSI lines, which can cause

abnormal operation.

ORDERING INFORMATION

■■■■

Part number Package Remarks

MB39A105PFT

8-pin plastic TSSOP

(FPT-8P-M05)

25

Page 26

MB39A105

PACKAGE DIMENSION

■■■■

8-pin plastic TSSOP

(FPT-8P-M05)

3.00±0.10(.118±.004)

INDEX

5

4

(.009

4.40

±0.10 6.40±0.20

0.22±0.10

±.004)

0.10(.004)

8

1

0.65(.026)

1.95(.077)

C

2002 FUJITSU LIMITED F08013Sc-1-1

(.252

0.127±0.03

±.001)

(.0050

±.008)(.173±.004)

Details of "A" part

1.10(.043)MAX

"A"

0~8˚

0.54(.021) 0.10±0.10

(.004

±.004)

Dimensions in mm (inches)

26

Page 27

MB39A105

FUJITSU LIMITED

All Rights Reserved.

The contents of this document are subject to change without notice.

Customers are advised to consult with FUJITSU sales

representatives before ordering.

The information and circuit diagrams in this document are

presented as examples of semiconductor device applications, and

are not intended to be incorporated in devices for actual use. Also,

FUJITSU is unable to assume responsibility for infringement of

any patent rights or other rights of third parties arising from the use

of this information or circuit diagrams.

The products described in this document are designed, developed

and manufactured as contemplated for general use, including

without limitation, ordinary industrial use, general office use,

personal use, and household use, but are not designed, developed

and manufactured as contemplated (1) for use accompanying fatal

risks or dangers that, unless extremely high safety is secured, could

have a serious effect to the public, and could lead directly to death,

personal injury, severe physical damage or other loss (i.e., nuclear

reaction control in nuclear facility, aircraft flight control, air traffic

control, mass transport control, medical life support system, missile

launch control in weapon system), or (2) for use requiring

extremely high reliability (i.e., submersible repeater and artificial

satellite).

Please note that Fujitsu will not be liable against you and/or any

third party for any claims or damages arising in connection with

above-mentioned uses of the products.

Any semiconductor devices have an inherent chance of failure. You

must protect against injury, damage or loss from such failures by

incorporating safety design measures into your facility and

equipment such as redundancy, fire protection, and prevention of

over-current levels and other abnormal operating conditions.

If any products described in this document represent goods or

technologies subject to certain restrictions on export under the

Foreign Exchange and Foreign Trade Law of Japan, the prior

authorization by Japanese government will be required for export

of those products from Japan.

F0209

FUJITSU LIMITED Printed in Japan

Loading...

Loading...